Page 1

Installation

& Operation Manual

Commercial Back Bar

Sliding Door

SDB & SDP Series

Model SDBR48 Shown

Form No. 2722013

Rev. 04.24.2017

Page 2

Models SDB/SDP Installation & Operation Manual

DANGER

WARNING

CAUTION

TABLE OF CONTENTS

General Information ................................................................................................................................. 2

Safety ...................................................................................................................................................... 2

Prior To Installation .................................................................................................................................. 3

Installation ............................................................................................................................................... 4

Operation ................................................................................................................................................. 5

Adjustments ............................................................................................................................................. 6

Maintenance ............................................................................................................................................ 7

Troubleshooting ....................................................................................................................................... 9

Dimensions ............................................................................................................................................ 11

Wiring Diagrams .................................................................................................................................... 15

Warranty ................................................................................................................................................ 20

GENERAL INFORMATION

Introduction

Congratulations on your purchase of a Perlick

commercial back bar product. This manual has

been prepared to assist you in the installation of

your cabinet and to acquaint you with its operation

and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer

can provide you with a list of qualied service

agents. For your own protection, never return

merchandise for credit without our approval.

We thank you for selecting a Perlick product

and assure you of our continuing interest in your

satisfaction.

SAFETY

PLEASE READ all instructions completely

before attempting to install or operate the unit.

Take particular note of the DANGER, WARNING

an CAUTION information in the manual. The

information is important for the safe and efcient

installation, operation and care of your Perlick unit.

Indicates a hazard that WILL

result in serious injury or

death if precautions are not followed.

Warranty

To register your product, visit our web site at

www.perlick.com. Click on “Commercial”, then

“Service”. Click on the link “Warranty Registration

Form”. You must complete and submit this form

or the installation date will revert back to the ship

date.

Please record the purchase date and the dealer’s

name, address and telephone number below.

Model Number: ________________________

Serial Number: _________________________

Purchase Date: _______________________

Dealer Name & Address

______________________________________

______________________________________

______________________________________

Phone Number__________________________

Indicates a hazard MAY

cause serious injury or

death if precautions are not followed.

Indicates a hazard where

minor injury or product

damage may occur if precautions are not

followed.

IMPORTANT!

Read and understand all information in this manual before attempting the installation.

All plumbing and electrical work must be performed by a qualied technician and

conform to all applicable state and local codes.

Printed in USA 2 0213

Page 3

Models SDB/SDP Installation & Operation Manual

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

DANGER

DANGER

PRIOR TO INSTALLATION

Uncrating and Inspection

Remove all crating material. Carefully inspect

cabinet for hidden damage. If damage is

discovered, le your claim immediately with the

transport company. Perlick is not responsible for

damage in transit.

Do not cut cardboard

sleeve covering the unit.

Cutting may result in damage to the exterior

of the cabinet. Failure to follow this procedure

may damage the compressor and void

warranty.

1. Uncrate the unit on at, level surface. Remove

the cardboard sleeve by removing the banding

securing the sleeve to the shipping base.

Carefully lift the cardboard sleeve up over the

top of the unit.

2. Carefully lift unit off the base and onto a hand

truck or dolly. Make sure unit is balanced

on transporting device using soft, exible

strapping. Protect unit surfaces with cloth

material where strapping contacts unit.

Do not lift unit by drawer,

shelving or door handles

or damage to the unit could occur.

To prevent personal

injury, two people

minimum required to lift the unit. Larger units

may require additional personnel.

3. Before moving unit, secure door(s) to unit with

tape to prevent from opening.

4. Carefully move unit to installation site and

place in front of opening.

Finished ooring should

be protected with

appropriate material to avoid damage from

moving the unit.

Plumbing

Do not over-tighten drain

fitting or damage to the

threads could occur.

The condensate drain tube (furnished) must be

connected to the unit. One end is attached to the

barbed elbow on the evaporator condensate pan;

the other end is inserted through the evaporator

drain hole and exits the bottom of the cabinet.

The drain hole is located in the cabinet oor pan,

behind the vertical door mullion.

The drain tube must be placed over a oor drain

or into a condensate management system such

as a “Condensate Evapaway” pan and heater.

Electrical

The cabinet must be connected to a separately

fused power source (see Electrical Specication

Plate afxed to unit) in accordance with National

and Local electrical codes.

Self-contained Perlick units come equipped with

a NEMA 5-15P 90° plug with an 8’ cord extending

beyond the rear of the cabinet. The electrical

outlet must be ush with, or recessed into, the

wall surface.

NOTE: Never use an extension cord to extend the

power cord to the electrical receptacle.

If unit has been laid on its

back or sides, place unit

upright and allow minimum of 24 hours before

connecting power. Failure to follow this

procedure may damage the compressor and

void the warranty.

Do not attempt to operate

the equipment on any

other power source than that listed on the

Electrical Specication Plate attached to the

unit.

ELECTROCUTION HAZARD!

Electrical grounding is

required. Appliances furnished with a 3-prong

(grounding) polarized plug are equipped for

your protection against possible shock

hazards.

• Never remove the round grounding prong

from the plug.

• Never use a 2-prong adapter.

• Never use extension cord to connect

power to the unit.

• If a 2-prong receptacle is encountered, or

a longer power cord is required, contact

a qualied electrician to have it replaced

in accordance with applicable electrical

codes.

Failure to comply with these

electrical guidelines may

result in possible death or serious injury, re,

or loss of property.

Printed in USA 3 0213

Page 4

Models SDB/SDP Installation & Operation Manual

CAUTION

CAUTION

INSTALLATION

General Information

• For units equipped with a power cord, the

cord and plug may be aligned with a recess in

the back panel to allow the unit to be pushed

closer to the wall. For correct alignment, the

wall outlet must be located 4” - 10” above the

oor.

• Floor must be level in area of installation.

Preparing the Space

Make sure the oor under

the unit is level with the

surrounding nished oor. Protect a nished

oor with plywood, cardboard or some other

suitable material before moving the unit into

place. Failure to do this may result in damage

to the oor.

NOTE: If unit has been laid on its back or sides,

place unit upright and allow minimum of 24 hours

before connecting to a power source. Failure to

follow this procedure may damage the compressor

and void warranty.

Installing the Unit

If unit has been laid on its

back or sides, place unit

upright and allow minimum of 24 hours before

connecting power.

1. With power applied to the unit, check that

the lighting and cooling functions operate

properly, then turn off power to the wall outlet

and/or circuit breaker.

2. Position the cabinet into place using rollers

when necessary.

NOTE: Proper air ow around the condensing unit

is necessary for efcient operation. Never obstruct

the air ow in and out of the condensing unit.

3. When cabinet is in place, check installation

with carpenter’s level. When the unit is level

front-to-back and side-to-side, accumulated

water will drain out of cabinet to evaporator

drain.

4. Turn on power to the outlet and/or circuit

breaker.

1. Make sure the space opening is correctly

sized for the unit. See Dimension drawings at

the back of this manual for correct dimensions.

NOTE: For a cabinet door to open properly, the

door must open a minimum of 90°. Use a minimum

3” ller in corner installations to assure a 90°

opening. Allow 24” clearance in front of the unit

for full door swing and shelf/drawer pull-out.

2. Check that the following are level and square:

• Front and interior opening

• Installation opening and oor surface

NOTE: The oor under the unit must be at the

same level as the surrounding nished oor.

Casters or Legs

Refer to the instructions included with the Casters

or Legs Kit.

Electric Condensate Evapaway

(Optional)

For installation in areas of high humidity, a 115volt electric condensate pan can be installed

underneath the cabinet to collect and evaporate

the condensate from the cabinet evaporator. A 6’

3-prong plug is included. A separate circuit should

be provided for the heater. The kit can be used

only on cabinets equipped with 4” minimum legs;

it cannot be used on units equipped with platform

or base plate kits. Follow instructions supplied

with the kit.

Base Plate Installation (Optional)

Once the unit is secured in place, install the base

plate brackets to the cabinet bottom in the holes

provided. Attach base plate to brackets. Refer

to the installation instructions included with the

Base Plate Kit.

Printed in USA 4 0213

Page 5

Models SDB/SDP Installation & Operation Manual

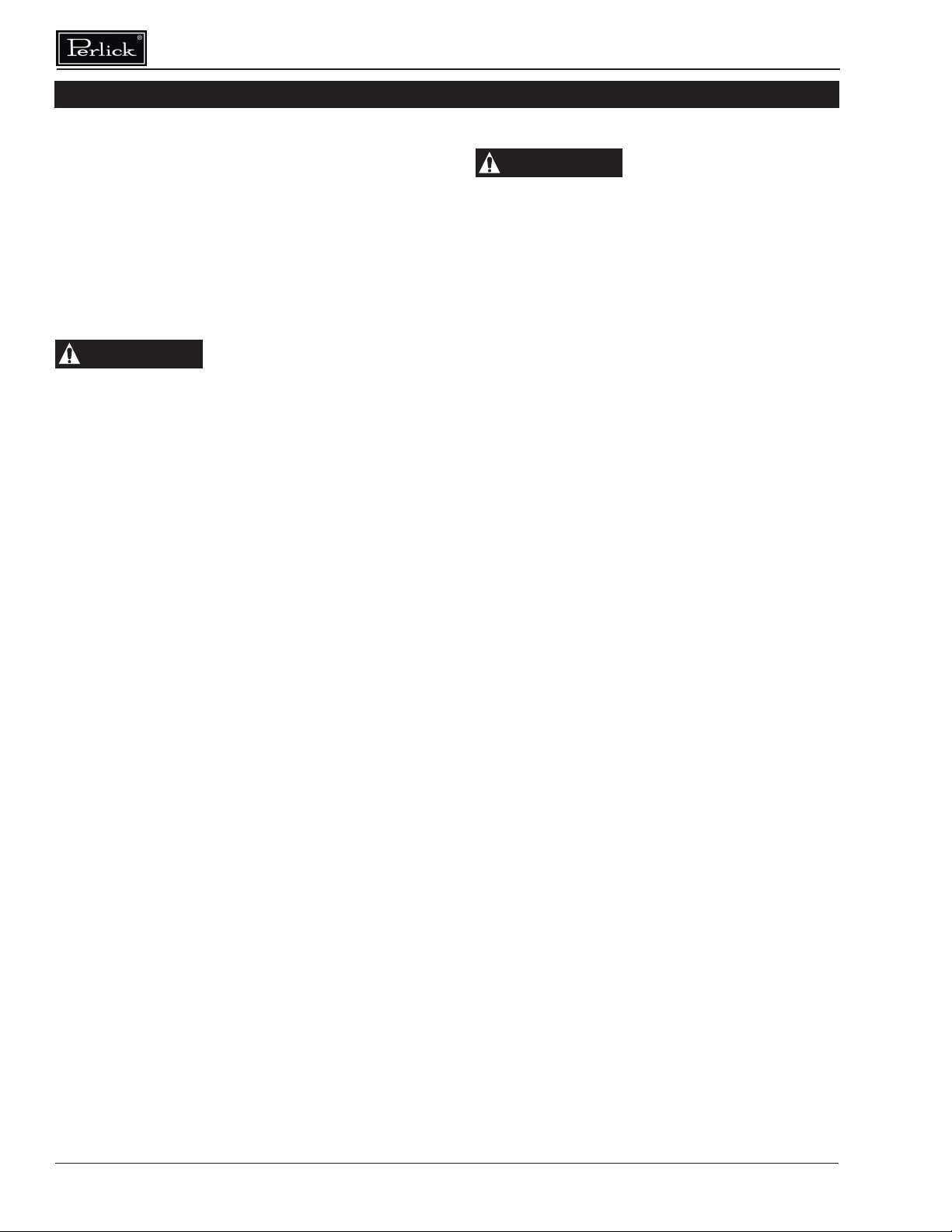

Sealing Cabinet to Floor

For units without casters or legs, it may be

necessary to seal the base of the cabinet to

the oor. This can be accomplished by laying a

bead of silicone sealant between the base of the

cabinet and the oor (Figure 1).

OPERATION

Refrigeration and Temperature Control

The cabinet is equipped with a heavy-duty

refrigeration system designed to automatically

maintain a storage temperature of approximately

36° F.

Allow a minimum of 24 hours for ambient

temperature product to reach storage temperature.

Draft beer should be stored at a temperature

between 32° – 38° F. The most common cause

of dispensing problems is improper temperature;

beer will foam at warmer temperatures.

Beer will freeze at temperatures lower than

30° F. When beer freezes, the alcohol in the beer

may separate and cause the beer to be cloudy

with an “off” taste.

The following chart shows how temperature

affects beer:

Cabinet

Bead Silicon

Sealer (RTV)

Floor

Figure 1. Sealing Cabinet to Floor

• Room temperature where installed

• Number of times the door is opened and

closed

• Length of time door is left open

• Style of door installed

• Door gasket seal and condition

• Amount of time the internal light is illuminated

• Installation in direct sunlight or near a heat

source

Interior Light

The unit is equipped with an interior LED light in

the upper front of the unit just inside the door or

drawer. The light illuminates when the manual

rocker light switch is turned on. The rocker light

switch is located behind the LED light on the inside

of the frame on either the right or left side (same

side as the compressor).

Digital Temperature Control

Checking Product Temperature

1. To accurately check the temperature of product

stored in the refrigerated compartment, insert

an accurate thermometer into a plastic

unbreakable bottle, partially lled with water.

Tighten bottle cap securely.

2. Place the bottle in the desired area for 24

hours. Refrain from opening the unit during

Setting the Set Point:

To display the Set point value press the key

the testing period. After 24 hours, check

the temperature of the water. Adjust the

temperature accordingly using the procedures

on this page.

The following factors affect the internal temperature

of the unit:

• Temperature setting

Printed in USA 5 0213

Figure 1. Digital Temperature Controller

when the ‘SET’ label is displayed. The Set point

value appears on the display. To change the Set

point value, press the and keys within 15

seconds. Press to conrm the modication.

Page 6

Models SDB/SDP Installation & Operation Manual

DANGER

CAUTION

ADJUSTMENTS

Never attempt to repair or

perform maintenance on

the unit until the main electrical power to the

unit has been disconnected!

Shelving Adjustment

Completely empty shelf or

drawer before removing.

1. Open the door. Tilt the shelf and remove it

from the unit

2. Reposition each bracket separately. Grasp the

middle of the bracket, pull the front end up and

out, then forward to remove it. See Figure 3.

3. Place brackets at desired location and reinstall

shelf(s).

5. Plug new LED into harness and secure to

housing using screws removed in step 2.

6. Snap LED cover into place.

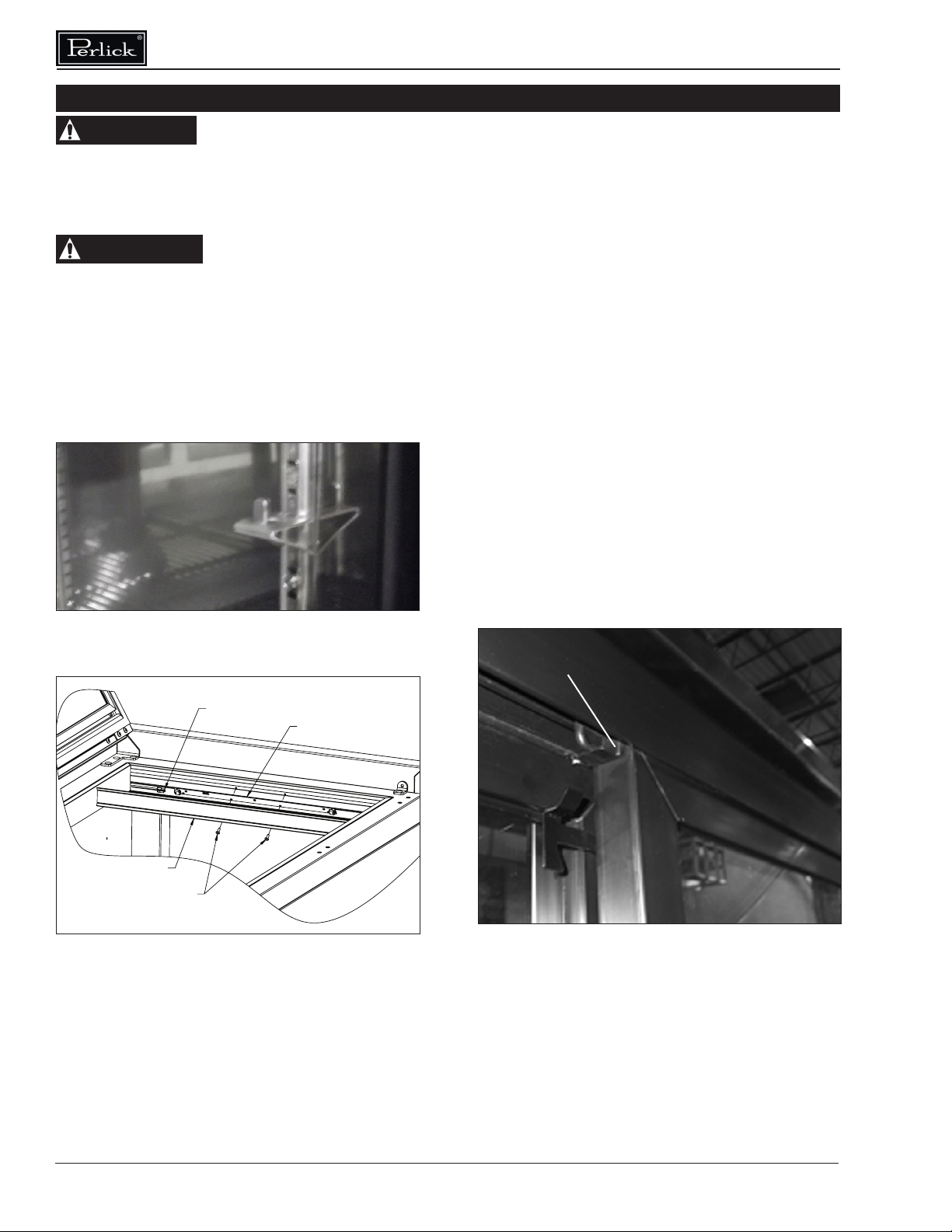

Sliding Doors

Removing / Installing

1. To remove the sliding door, simply grasp the

door on each side and lift up off the bottom

track, then tilt outwards and pull down to

remove from upper track.

2. To reinstall sliding door, place door in upper

track, making sure to engage the bracket

(Figure 5), lift door up into the track and place

into the bottom track.

Adjusting Door Spring Tension

A tension spring is located in the upper track of

each door. To increase or decrease spring tension,

remove the Phillips screw and position the bracket

in one of three detentes and reinstall screw. The

detente farthest to the left provides the least

amount of tension.

Figure 2. Shelf Bracket

LED Light Replacement

Unplug LED Light Strip

LED Light Strip

Lens Cover

#6-32 x 3/8”

machine screw (Qty. 2)

Figure 3. Interior LED Light

1. Open the door.

2. Using a at blade screwdriver, carefully pry

off the lens cover.

3. Remove the two screws securing LED light to

housing.

4. Unplug the LED from the wiring harness.

NOTE: Units are shipped from the factory with

springs set at the weakest setting.

Make sure door engages bracket

Figure 4. Removing/Installing Sliding Door

Sliding Door Lock

Each set of sliding doors is equipped with a keyed

lock located on the bottom of the right side door. To

lock the doors, place the lock lever in the DOWN

position and lock with the key. Unlock with the key

and place lever in the UP position to open.

Printed in USA 6 0213

Page 7

Models SDB/SDP Installation & Operation Manual

CAUTION

MAINTENANCE

Stainless Steel Care & Cleaning

General

Contrary to popular belief, stainless steel is

susceptible to rusting. Corrosion on metals is

everywhere. It is recognized quickly on iron

and steel as unsightly yellow/orange rust. Such

metals are called “active” because they actively

corrode in a natural environment when their atoms

combine with oxygen.

Stainless steel is a “passive” metal because it

contains other metals like chromium, nickel and

manganese that stabilize the atoms. Chromium

provides an invisible passive lm that covers the

steel surface acting as a shield against corrosion.

As long as the lm is intact and not contaminated,

the metal is passive and stainless. If the passive

lm of stainless steel has been broken, equipment

starts to corrode and rust.

There are three basic things which can break

down stainless steel’s passive layer and allow

corrosion to occur:

• Mechanical abrasion

• Deposits and water

• Chlorides

Mechanical abrasion refers to the things that will

scratch a steel surface. Steel pads, wire brushes

and scrapers are prime examples.

Water comes out of the faucet in varying degrees

of hardness. Depending on what part of the

country you live in, you may have hard or soft

water. Hard water may leave spots. When allowed

to sit, these deposits will break down the passive

layer and rust stainless steel. Other deposits from

food preparation must be promptly removed with

an appropriate cleaning agent.

Chlorides are found nearly everywhere. They

are in water, food and table salt. Household and

industrial cleaners are the worst offenders.

Preventing Stainless Steel Rust

Use the proper tools. Use non-abrasive tools to

clean stainless steel products. Soft cloths and

plastic scouring pads will not harm the steel’s

passive layer.

Clean with polish lines. Some stainless steels

come with visible polishing lines or “grain”. When

visible lines are present, always scrub in a motion

parallel to the lines. When the grain cannot be

seen, play it safe and do not use a circular motion.

Polish in a consistent straight pattern.

Use alkaline, alkaline chlorinated or non-chloride

containing cleaners. While many traditional

cleaners are loaded with chlorides, the industry

is providing an ever-increasing choice on nonchloride cleaners. If you are not sure of chloride

content in the cleaner being used, contact your

cleaner supplier. If your present cleaner contains

chlorides, ask your supplier if they have an

alternative. Avoid cleaners containing quaternary

salt; it also can attack stainless steel and cause

pitting and rusting.

Keep food equipment clean. Use alkaline

chlorinated or non-chloride cleaners at

recommended strength. Clean frequently to avoid

build-up of hard, stubborn stains. The single most

likely cause of damage is chlorides in the water.

Remember, adding heat to cleaners that contain

chlorides dramatically increases their effect on

stainless steel.

Rinse, rinse, rinse! If chlorinated cleaners are

used, immediately rinse and wipe equipment and

supplies dry. The sooner you wipe standing water,

especially when it contains cleaning agents, the

better. After wiping equipment down, allow it to

air dry. Oxygen helps maintain the stainless steel

passive lm.

Cleaning Cabinet Interior/Exterior

NEVER use hydrochloric

acid (muriatic acid) on

stainless steel. Do not use abrasive cleansers

or cloths on any interior or exterior surfaces

or removable parts.

Glass panels may be cleaned using any standard

glass cleaner available on the market.

To clean interior and exterior non-metallic surfaces

and removable parts, wash with a mild solution of

soap and lukewarm water with a little baking soda.

Rinse and dry thoroughly. Avoid getting water on

lights, controller and fan motors.

Cleaning the Door Tracks

Keep tracks clean of dirt and debris. Use a food

grade lubricant to periodically lube the tracks.

Printed in USA 7 0213

Page 8

Models SDB/SDP Installation & Operation Manual

CAUTION

Cleaning the Condenser

The condenser (located behind front grille cover)

should be cleaned every three (3) months. Use

a soft bristle brush and vacuum to remove the

dust and lint.

ns or tubing. Failure to follow this procedure

may damage the compressor and void the

warranty.

Avoid damaging or

crushing the condenser

Recommended Cleaners for Specic Situations

Job Cleaning Agent Comments

Routine cleaning. Soap, ammonia, detergent Apply with sponge or soft cloth.

Fingerprints and smears. Areal 20, Lac-O-Nu, Lumin Wash,

O’Ceder Cream Polish

Stubborn stains and discolorations. AllChem Concentrated Cleaner, Samae,

Twinkle, Cameo Copper Cleaners, Grade

FFF Italian Pumice Whiting, Steel Bright,

Lumin Cleaner, Zud Restoro, Sta-Clean,

Highlite Cooper’s Stainless Steel Cleaner

or Revere Stainless Steel Cleaner.

Old Dutch, Lighthouse Sunbrite,

Wyandotte Bab-O, gold Dust, Sapollo,

Bon Ami or Comet.

Liquid NuSteel or Dubois Temp For these products, rub the surface with

Heat tint or heavy discoloration. Penny-Brite, Copper Brite, Paste Nu-

Steel, Dubois Temp or Tarnite

Bar Keepers Friend, Revere Stainless

Steel Cleaner, Allen Polish, Steel Bright

Wyandotte Bab-O or Zud.

Tenacious deposits, rust, discoloration,

industrial atmospheric stains.

Rust discoloration or corrosion caused

by cleaning agents containing hydrochloric (muriatic) acid or chlorine bleach

Use of property names is intended only to indicate a type of cleaner and does not constitute an endorsement. Omission of any proprietary

cleaner does not imply its inadequacy. All products should be used in strict accordance with instructions on the package.

NOTE: Do not use steel wool or scouring pads to clean stainless steel.

Oakite No. 33 Dilac, Texo NY, Flash-

Klenz Caddy Cleaner, Turco Scale 4368

or Permag 57.

3M Scotch Brite pad, type A Grade “Fine” Clean off the surface soil using cleaning

Provides barrier lm to minimize ngerprints. Can be used on all nishes. Rub

the surface with a cloth as directed on

the package.

Apply with a damp sponge or cloth, then

rinse with clear water and wipe dry.

For these household cleaners, rub with

a damp cloth. They may contain chlorine

bleaches so rinse thoroughly after use

and wipe dry

a dry cloth using only a small amount of

cleanser. Rinse with water and dry.

Rinse and rub onto surface with a dry

cloth.

When using these cleaners, apply with a

damp sponge or cloth, rinse thoroughly

and wipe dry.

Use Swab and soak with a clean cloth. Let

stand for 15 minutes or more according

to directions on package then rinse and

wipe dry.

methods above. Then rub discolored or

corroded areas lightly with dry pad.

Printed in USA 8 0213

Page 9

Models SDB/SDP Installation & Operation Manual

DANGER

TROUBLESHOOTING

Before Calling For Service

If the unit appears to be malfunctioning, read through the Operation section in this manual rst. If the

problem persists, check through this troubleshooting section. Locate the problem and refer to the cause

and remedy before calling for service. The problem could be something that can be solved without a

service call.

Never attempt to repair or perform maintenance on the unit until the main electrical

power to the unit has been disconnected!

Problem Cause Solution

No interior light. Rocker switch in Off position. Turn switch on.

LED board inoperable. Contact your selling dealer.

Light stays on when door is

closed.

Noisy operation. Soft sounds from compressor, fan

LED Controller display is E1. Thermostat probe failure. Contact your selling dealer.

Unit is not running. No power to the unit.

Compartments are warmer than

usual.

System runs for long period of

time.

Condensation forms inside the

compartments.

Condensation forms on outside

of unit.

Manual switch on. Turn manual switch off.

Normal operation.

motor and valves heard.

Home circuit breaker tripped. Reset circuit

breaker.

ON/OFF keypad is off. Turn on.

Condenser dirty.

Control preset not set properly.

Light staying on.

Condenser dirty or obstructed.

Door is open or has been opened more

frequently lately.

Internal louvers and/or fan guard

obstructed.

Warm product placed in cabinet

recently.

Condenser dirty or obstructed.

Door kept open for long time or opened

more frequently.

Warm product place in cabinet recently.

Hot day and warm room temperature.

High humidity and/or frequent door

opening.

Door not closing and sealing properly.

High humidity and/or frequent door

opening.

Door not closing and sealing properly.

Clean the condenser.

Reset compartments presets.

Turn manual light switch off.

Clean condenser and clear obstruction.

Wait 24 hours and recheck temperature.

Reset preset temperature if necessary.

Make sure louvers and/or fan is not

obstructed.

Clean condenser and clear obstruction.

Wait 24 hours and recheck temperature.

Reset preset temperature if necessary.

Normal for system to run more frequently.

Normal operation.

Make sure door is closing properly. Check

door seals and replace if necessary.

Normal operation.

Make sure door is closing properly. Check

door seals and replace if necessary.

If condensation persists, contact your selling

dealer.

Printed in USA 9 0213

Page 10

Models SDB/SDP Installation & Operation Manual

For Product Information

• Contact your selling dealer.

• Inquire via the web at www.perlick.com

• Call (800) 558-5592 for factory assistance on

planning installation or product information.

• Write to Perlick Corporation, Customer

Service Department, 8300 West Good Hope

Road, Milwaukee, WI 53223.

• Email us at warrantyserv@perlick.com.

For Product Service

• Check the model and serial number of your

unit located on the label attached to the inside

top of the cabinet.

• Inquire via the web at www.perlick.com, or call

(800) 558-5592.

For Replacement Parts and Accessories

• Use only genuine Perlick replacement parts

and accessories. Genuine Perlick parts and

accessories are designed to work correctly

with Perlick products and offer superior

service life. The use of non-Perlick parts can

damage the unit and may void the warranty.

• Check the model and serial number of your

unit which is located on the right or left interior

panel. Call your Perlick Factory Authorized

Service Center.

• Inquire via the web at www.perlick.com, or call

(800) 558-5592.

Printed in USA 10 0213

Page 11

Models SDB/SDP Installation & Operation Manual

DIMENSIONS

Printed in USA 11 0213

Page 12

Models SDB/SDP Installation & Operation Manual

Printed in USA 12 0213

Page 13

Models SDB/SDP Installation & Operation Manual

Printed in USA 13 0213

Page 14

Models SDB/SDP Installation & Operation Manual

Printed in USA 14 0213

Page 15

Models SDB/SDP Installation & Operation Manual

WIRING DIAGRAMS

Printed in USA 15 0213

Page 16

Models SDB/SDP Installation & Operation Manual

Printed in USA 16 0213

Page 17

Models SDB/SDP Installation & Operation Manual

Printed in USA 17 0213

Page 18

Models SDB/SDP Installation & Operation Manual

Printed in USA 18 0213

Page 19

Models SDB/SDP Installation & Operation Manual

Printed in USA 19 0213

Page 20

Models SDB/SDP Installation & Operation Manual

WARRANTY

The terms and conditions set forth below

together with those appearing on the face of

the Acknowledgement (the “Order”) constitute

the complete and exclusive agreement between

Perlick Corporation and the Buyer pertaining to

the goods and/or services identied in the Order.

If there is a discrepancy or conict between any

exhibit or supplement to the Order and these

terms and conditions, these terms and conditions

shall control. The Order is intended by Seller and

Buyer to be the complete, exclusive, and nal

statement of their agreement. Any changes to an

Order must be in writing and signed by Perlick

and Buyer.

TERMS NET 30 DAYS

Payment by Visa, MasterCard, American Express

or Discover card accepted or cash in advance

unless prior accommodations have been made

with our Credit Department. Please direct inquiries

for detailed information to our Credit Manager.

All sales, excise, or similar taxes required by

law to be collected or paid by seller shall be in

addition to prices quoted unless an appropriate

Tax Exemption certicate is furnished. All goods

are sold F.O.B. factory. Except for otherwise

provided, Perlick will not be responsible for freight,

transportation, insurance, shipping, storage,

handling, demurrage or similar charges. Invoices

are payable in full in thirty (30) days following

the invoice‚s date of issuance. If by the terms

of sale credit is extended, Perlick reserves the

right to revoke such credit if buyer fails to pay

for any products when due and may demand

payment prior to the commencement of any

further shipment.

WAIVER

Any waiver of strict compliance with the provisions

of an Order must be in writing. No such waiver

shall be construed as a waiver of any other term

or condition except as provided in writing, nor as

a waiver of any subsequent breach of the same

term or condition.

METHOD OF SHIPMENT

All shipments are carefully packed and labeled.

Crates, boxes and cartons used are of approved

weight and strength. Freight rates are based upon

100 pound minimum.

LOST and DAMAGED MERCHANDISE

THE RESPONSIBILITY OF THE PERLICK

CORPORATION CEASES UPON ACCEPTANCE

OF ITS PRODUCTS BY THE CARRIER. Any

damage or loss sustained in shipment is the

carrier’s responsibility. Before giving the carrier

a clean receipt at time of delivery, make sure you

receive every item on the bill and inspect every

carton, crate and box for concealed damage,

i.e., broken boards, crushed or punctured

cartons, torn cardboard. IF ANY ITEMS ARE

SHORT OR DAMAGED, DO NOT ACCEPT THE

SHIPMENT UNLESS THE CARRIER MAKES A

NOTATION OF THIS ON YOUR FREIGHT BILL.

Then request an inspection. Do not destroy the

packing materials. If their agent does not make

an inspection within ve days, advise the carrier

via letter that you notied them regarding the

matter and they have failed to act. You will need

this letter to support your claim. Then le a claim

for your loss. When you give the carrier a clean

receipt, you accept the total responsibility for the

shipment. UPS shipments are insured individually

and UPS will replace all merchandise that is lost

or damaged.

RETURN OF MERCHANDISE

Do not return any merchandise without our

approval. Merchandise returned without a return

merchandise authorization number will not be

accepted at Perlick. Used, discontinued, and

certain custom made items cannot be returned for

credit. These custom items include non-catalog

products (specials) as well as custom assembled

catalog products. Catalog items are designated

as non-returnable on the price list page on which

they appear. Items returned must be in new

condition and packaged in their original carton

or crate. Freight charges must be prepaid on all

return shipments.

Printed in USA 20 0213

Page 21

Models SDB/SDP Installation & Operation Manual

When a return is authorized, a credit may be

allowed pending an examination of the returned

goods. The amount of the restocking charge will

depend on the condition of the equipment. The

minimum restocking charge for glass washers,

bottle coolers, frosters, direct draws, cooler

series back bars and accessory parts is 20%.

The minimum restocking charge for custom

series cabinets is 50%. The minimum restocking

charge for un-assembled, freestanding underbar

stainless steel modules is 20%. Assembled under

bar modules are considered custom products

and are not returnable for credit. The restocking

charge on the item returned is either a percentage

of the value of the item or $35.00, whichever is

greater.

ONE YEAR PARTS WARRANTY

Perlick products are guaranteed against defects

in both material and workmanship for a period of

one year from date of sale. Defective parts will be

replaced on a no-charge basis, F.O.B. our factory,

when adjudged defective upon inspection. We are

not responsible for parts damaged by alteration,

unauthorized service, accident or abuse. All costs

associated with replacement, including freight,

labor and/or loss of sales, are the responsibility

of the user.

ONE YEAR LABOR WARRANTY

In addition to Perlick’s one year parts warranty

and ve year compressor warranty, ALL PERLICK

REFRIGERATION SYSTEMS are offered with

a one year labor warranty at no extra charge.

Perlick’s one year labor warranty provides

that Perlick will pay for the cost of any labor to

replace any defective part for up to one year

after installation, subject to the following terms

and conditions:

(A) Parts returned to Perlick shall be returned

freight prepaid and shall be identied with

Perlick’s serial number and return authorization

number.

(B) Improper operation due to voltage variances,

inadequate wiring and physical damage is the

responsibility of the purchaser. They are not

manufacturing defects.

(C) Condenser coils shall be cleaned regularly.

Failure to provide an adequate ow of cooling

air will void this warranty.

(D) Factory-specied maintenance and installation

will be provided by the selling dealer who shall

also be responsible for the installation and setup of these products in accordance with local

plumbing, refrigeration and electrical codes.

Perlick’s one year labor policy applies to the

United States and Canada. IT DOES NOT

APPLY TO REFRIGERATION SYSTEMS

ADDED BY OTHERS (remote systems) or any

part which has been subject to misuse, neglect,

alteration, accident, or to any damage caused

by transportation, ood, re or other acts of God.

Printed in USA 21 0213

Page 22

Models SDB/SDP Installation & Operation Manual

Printed in USA 22 0213

Page 23

Models SDB/SDP Installation & Operation Manual

Printed in USA 23 0213

Page 24

Models SDB/SDP Installation & Operation Manual

8300 West Good Hope Road • Milwaukee, WI 53223 •

Toll Free 800.558.5592 • Fax 414.353.7069 • www.perlick.com

Printed in USA 24 0213

Loading...

Loading...