Page 1

INTRODUCTION

Congratulations on your purchase of a Perlick

residential refrigeration product. A pioneer in the

commercial refrigeration field for nearly 60

years, Perlick has decided to bring the ultimate

in beauty, high quality and innovative

commercial products to the residential market.

The vast product offering, available in both

indoor and outdoor models, gives you the

opportunity to enjoy the functionality and user

friendliness in just about any setting, including

home hospitality centers, kitchens, bedrooms

and summer rooms in either a built-in or

freestanding model. The all stainless interior and

front face will provide beauty and durability for a

lifetime of use.

This Installation and Use and Care Guide will

answer your questions about the features,

operation and maintenance of your Refrigerated

Cabinet model. If you have questions that are

not addressed here, call 800 558-5592.

IMPORTANT

PLEASE READ all instructions completely

before attempting to install or operate the unit.

First, as you follow these Installation and Use

and Care instructions, take particular note of the

CAUTION! and WARNING! symbols when they

appear. This information is important for the safe

and efficient installation, operation and care of

your Perlick Refrigerated Cabinet.

CAUTION

Signals a hazard where minor injury or

product damage may occur if you do not

follow instructions.

WARNING

States a hazard may cause serious injury or

death if precautions are not followed.

Once the unit is completely installed, we suggest

you keep this manual and purchasing

documentation in a safe place for future

reference. Should problems occur: refer to the

troubleshooting section of this manual. The

information will help you quickly identify a

problem and get it remedied. In the event you

require assistance, please contact the dealer

where you purchased your unit.

PLEASE RECORD YOUR MODEL’S

INFORMATION

Whenever you call to request information or

service, you will need to know your model

number and serial number. You can find this

information on the serial and identification plate

located on the inside ceiling of your unit and on

the warranty registration card.

WARRANTY REGISTRATION CARD

The package containing this manual also

includes your warranty registration information.

Warranty coverage begins on the date your

Perlick Refrigerated Cabinet was originally

purchased.

IMPORTANT NOTE: Take a moment to

read through the included warranty

statement and complete and mail the

Warranty Registration Card as soon as

possible to validate the registration date.

An alternative method of completing the

Warranty Registration can be

accomplished online at

www.bringperlickhome.com.

If you do not complete your Warranty

Registration Card on-line or return via U.S. mail,

Perlick will use the date of sale as the first date

of warranty for your new Refrigerated Cabinet.

Please record the purchase date of your Perlick

product and your dealer‟s name, address and

telephone number.

MODELNUMBER:_______________________

SERIAL NUMBER:_______________________

PURCHASE DATE:______________________

DEALER NAME & ADDRESS:

______________________________________

______________________________________

DEALER TELEPHONE:

______________________________________

www.bringperlickhome.com

1

Page 2

TABLE OF CONTENTS

INTRODUCTION…………………………………………………….. . 1

PLEASE RECORD YOUR MODEL‟S INFORMATION…….…..... . 1

WARRANTY REGISTRATION CARD……………………………... 1

TABLE OF CONTENTS……………………………………….… .. ….2

GENERAL PRECAUTIONS………………………………..... ......... 3

INSTALLATION INSTRUCTIONS………………………… ....... 4-15

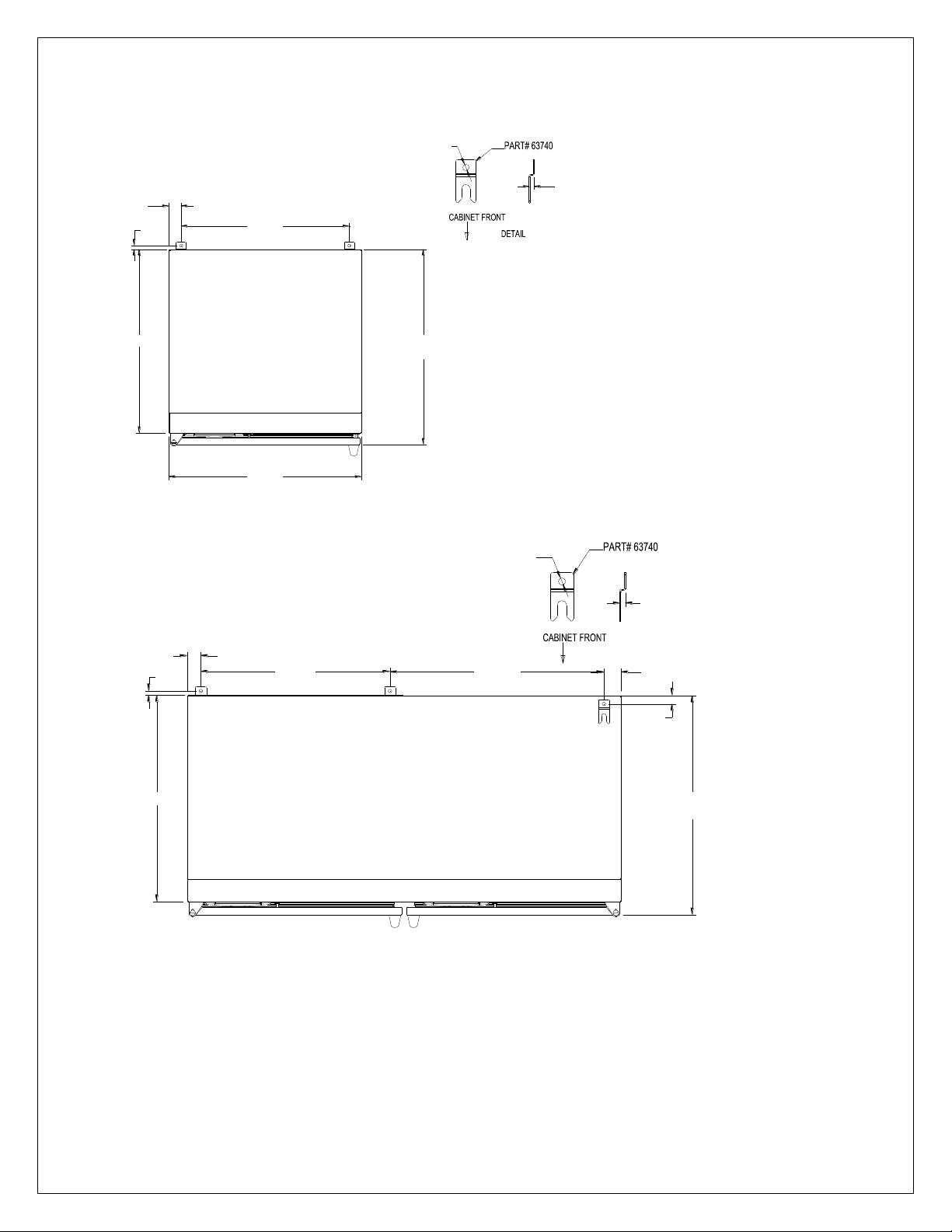

ILLUSTRATION 1. INSTALLATION SPECIFICATIONS……….... 4

PREPARING THE SPACE…………………………………….... ...... 5

PREPARING ELECTRICAL CONNECTIONS…………………… .. 5

UNPACKING AND MOVING…………………………...….…….. .... 6

ANTI-TIP-OVER INSTALLATION…………………….......... ........... 6

ILLUSTRATION 2. SINGLE DOOR ANTI-TIP LAYOUT……….. .. 7

ILLUSTRATION 3. TWO-DOOR ANTI-TIP LAYOUT..……. ......... 7

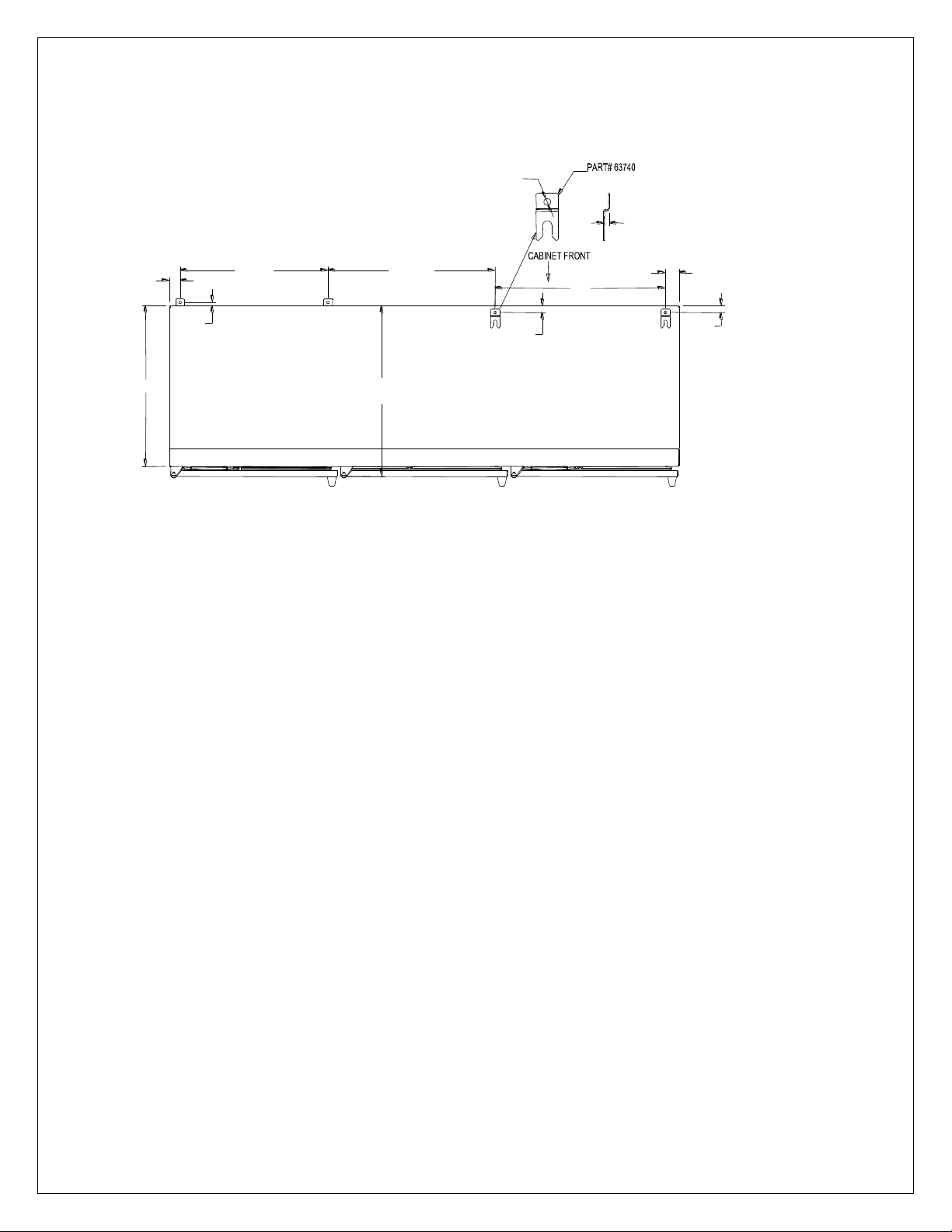

ILLUSTRATION 4. THREE-DOOR ANTI-TIP LAYOUT……….... . 8

INSTALLING……………………………………………………….... .. 9

TOE PLATE INSTALLATION………………….……….. ................. 9

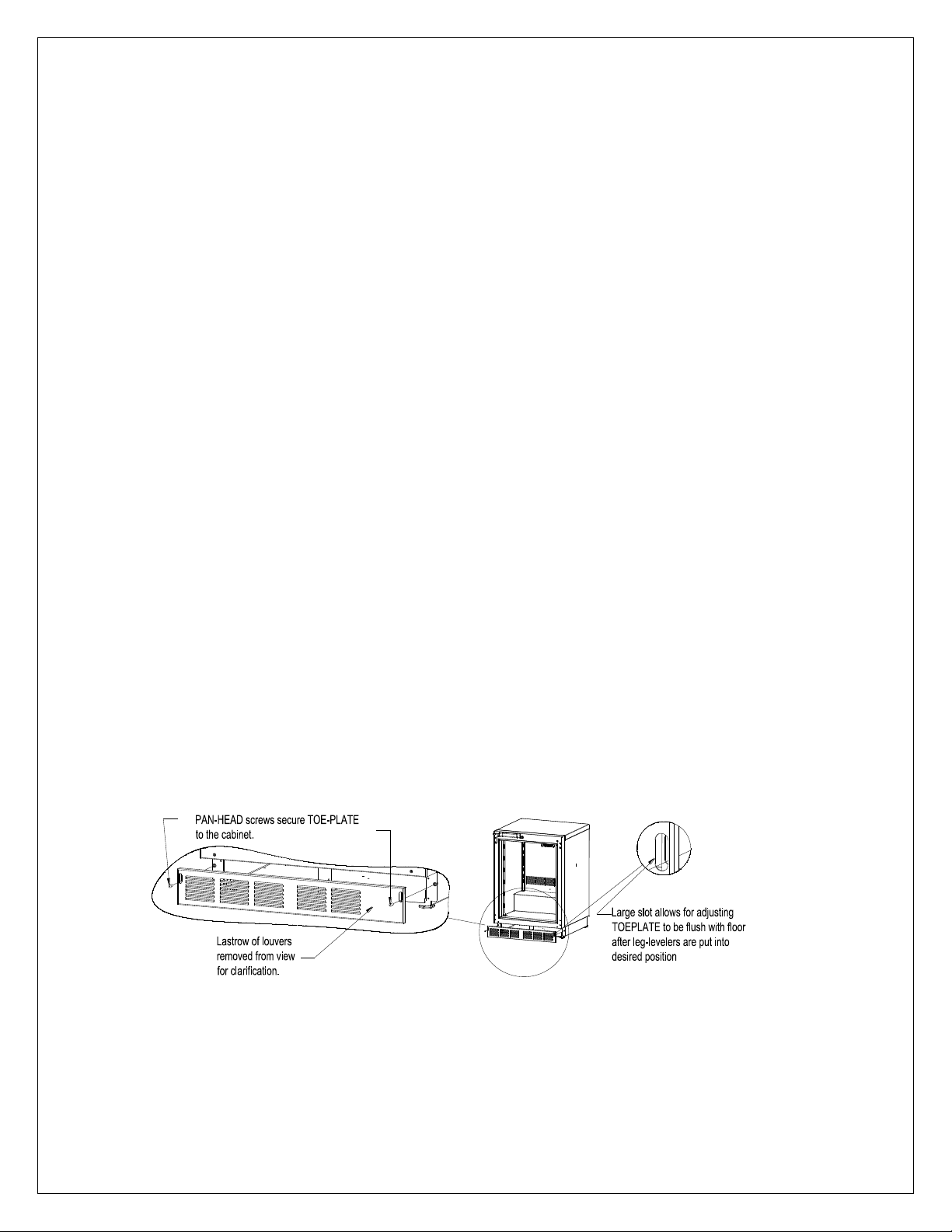

ILLUSTRATION 5. TOE PLATE INSTALLATION……………......10

DOOR REVERSING………………………………… …. ................12

ILLUSTRATION 6. DOOR SWING REVERSAL PROCEDURE.. 13

DOOR OPTIONS………………………………………….......... ......14

INSTALLATION OF WOOD OVERLAYS……………………........ 15

ILLUSTRATION 7. SOLID WOOD OVERLAY PANEL………… .16

ILLUSTRATION 8. GLASS WOOD OVERLAY PANEL……....... 16

ILLUSTRATION 9. WOOD DRAWER OVERLAY pANEL………. 17

STORAGE CAPABILITES………………………………. ...............16

All Units………………………………………. ............... 16-17

WOODEN WINE RACK TRIM FINISHING…………………..........18

ILLUSTRATION 10. WOODEN WINE RACK TRIM DESIGN.... .18

LOCK INSTALLATION…………………………………………. .......19

DRAWERS ABD SHELVING…………………………………… .....19

ILLUSTRATION 11. DOOR LOCK INSTALLATION……….... .....19

OPERATION……………………………………… ..........................20

SINGLE DOOR FREEZER OPERATION…………......... ............ 20

SINGLE DOOR REFRIGERATOR OPERATION…......... ........... 20

SINGLE DOOR WINE COOLER OPERATION……….. .............. 21

TWO DOOR FREEZER/REFRIGERATOR OPERATION… ....... 22

TWO DOOR ALL-REFRIGERATOR OPERATION…….............. 22

TWO DOOR ALL-WINE COOLER OPERATION……................. 23

TWO DOOR MULTI-ZONE WINE COOLER OPERATION. ....... 24

TWO DOOR REFRIGERATOR/WINE COOLER

OPERATION… .......................................................................... 25

THREE DOOR FREEZER/REFRIGERATOR/REFRIGERATOR

OPERATION………………….... ................................................. 26

THREE DOOR FREEZER/REFRIGERATOR/WINE COOLER

OPERATION…………….….... .................................................... 26

THREE DOOR ALL-REFRIGERATOR OPERATION……... ....... 27

THREE DOOR ALL-WINE COOLER OPERATION……... .......... 28

THREE DOOR THREE-ZONE WINE COOLER OPERATION. .. 29

THREE DOOR TWO-ZONE WINE COOLER OPERATION….... 30

THREE DOOR REFRIGERATOR/TWO-ZONE

WINE COOLER OPERATION…………………………….... ...... 31

TEMPERATURE CONTROLLER……………………………... ......32

TEMPERATURE CONTROLLER ADJUSTMENTS………….. .....32

CHART 1. PRODUCT TEMP. SET POINTS AND RANGES…... 34

CHECKING PRODUCT TEMPERATURE……………….…..........35

MAINTENANCE…………………………………………….……. .....35

CLEANING………………………………………….……. ....35

LIGHT BULB REPLACEMENT…………………….….... ...35

TROUBLESHOOTING…………………………………….……. .....36

GENERAL…… ………………………………….…... ............ 36

WIRING SCHEMATIC……………………….…….. ...........38

WARRANTY………………………………………………… 39

www.bringperlickhome.com

2

Page 3

GENERAL PRECAUTIONS

DANGER

RISK OF CHILD ENTRAPMENT, BEFORE

YOU THROW AWAY YOUR OLD

REFRIGERATOR OR FREEZER, TAKE OFF

THE DOORS AND LEAVE SHELVES IN

PLACE SO THAT CHILDREN MAY NOT

EASILY CLIMB INSIDE.

WARNING

NEVER ATTEMPT TO REPAIR OR

PERFORM MAINTENANCE ON THE UNIT

UNTIL THE ELECTRICITY HAS BEEN

DISCONNECTED.

ALTERING, CUTTING OF THE POWER

CORD, OR REMOVAL OF THE POWER

CORD, REMOVAL OF POWER PLUG, OR

DIRECT WIRING CAN CAUSE SERIOUS

INJURY, FIRE AND/OR LOSS OF

PROPERTY AND/OR LIFE AND WILL

VOID THE WARRANTY.

THE ANTI-TIP KIT MUST BE INSTALLED

ON THIS UNIT BEFORE IT IS USED.

NEVER USE THE DRAWERS, SHELVES

OR DOORS AS STEPS OR TO SUPPORT

MORE THAN THEY WERE DESIGNED TO

SUPPORT.

CAUTION

DO NOT LIFT UNIT BY DRAWER OR

DOOR HANDLES.

FAILURE TO CLEAN THE CONDENSER

EVERY THREE MONTHS CAN CAUSE

THE UNIT TO MALFUNCTION. THIS

COULD VOID THE WARRANTY.

NEVER INSTALL THE UNIT BEHIND

CLOSED DOORS. BE SURE FRONT

LOUVERED TOE PLATE IS FREE OF

OBSTRUCTION. OBSTRUCTING FREE

AIRFLOW CAN CAUSE UNIT TO

MALFUNCTION, AND MAY VOID THE

WARRANTY.

CAUTION

USE ONLY GENUINE PERLICK

REPLACEMENT PARTS. IMITATION PARTS

CAN DAMAGE THE UNIT, AND MAY VOID

THE WARRANTY.

INSTALLATION INSTRUCTIONS

IMPORTANT NOTE: The information in this

installation guide applies to all product models

unless noted.

www.bringperlickhome.com

3

Page 4

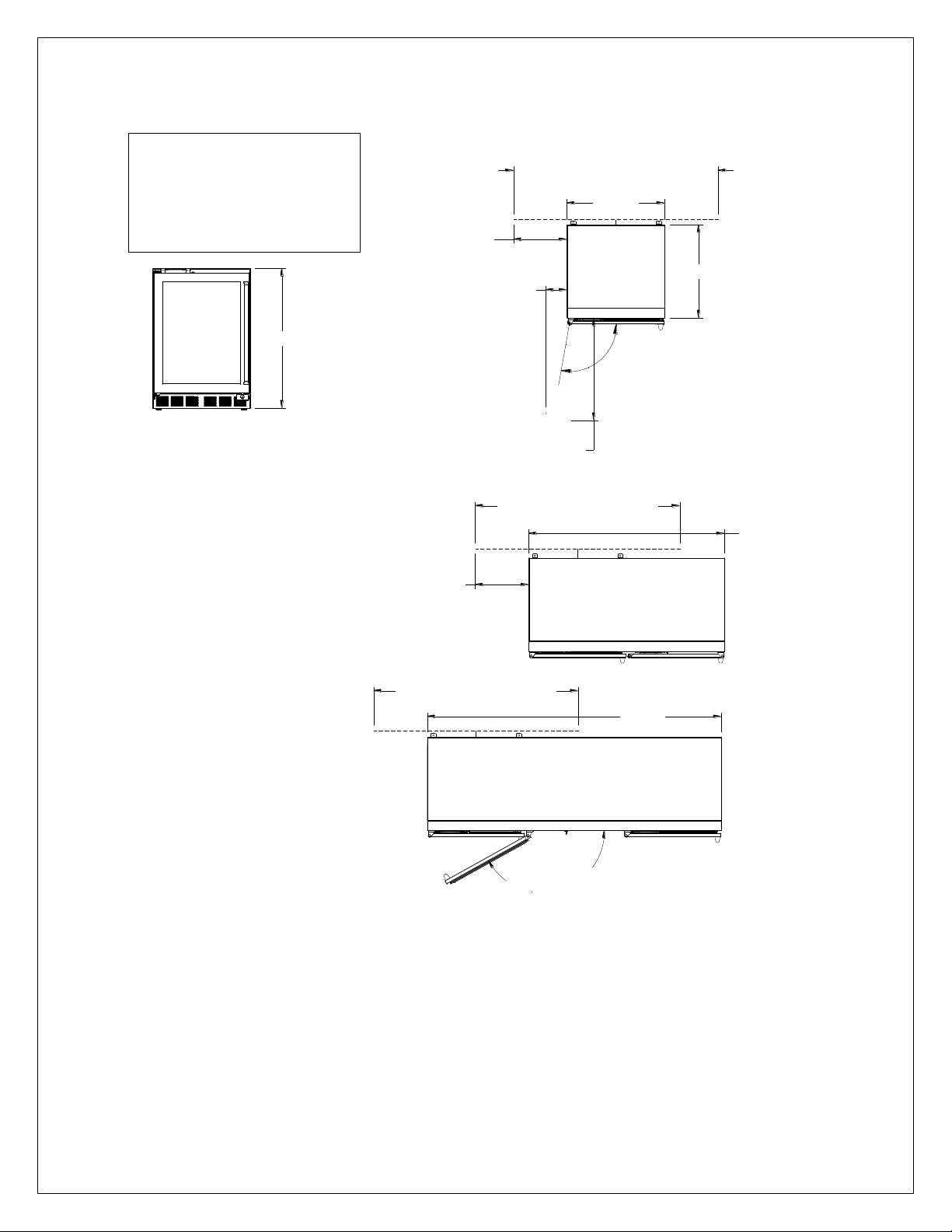

150° max swing

on inner doors of

a multi-door unit

71 7/8"

50" Area in which electrical

outlet must be located

13 3/32"

Same for Two and

Three door units

13 1/16" same on

both sides of unit

5 3/16" minimum clearance

required if installing in a corner

*5 3/4 for custom wood overlay

door

-All electrical instructions

assume that outlet is located

4-10 inches from floor

-Floor must be level in area of

installation, leg levelers are meant

as a means of fine tuning, not

recommended for making up

differences in the floor surpassing

1/2 inch

-When moving the units into place

take care to protect the floor as

necessary with cardboard, rugs, etc.

-Never attempt to move unit without

at least one other person present

-Always secure doors shut prior to

moving the unit

Finished rough opening requirements

*Height-----------------34 1/2 inches

*Depth------------------24 inches

*same across all units

One door width------24 inches

Two door width------48 inches

Three door width----72 inches

NOTE:

34 3/32"

105° max swing

for custom wood overlay

doors

47 7/8"

50" Area in which electrical

outlet must be located

Top View

Three Door

Top View

Two Door

recommended minimum swing.

Max swing is 175° on single door

and end cabinets on multi-door units

22 3/4"

50" Area in which electrical outlet

must be located

23 7/8"

100°

25" Min Clearance

for door swing

Top View

Single Door

ILLUSTRATION 1. INSTALLATION SPECIFICATIONS

www.bringperlickhome.com

4

Page 5

PREPARING THE SPACE

Make sure that the opening where the Perlick

cabinet(s) is/are to be installed is properly

prepared. Refer to Illustration 1 to ensure the

space dimensions and electrical service are

correct for the models to be installed.

CAUTION

IF CABINET IS BEING INSTALLED UNDER A

COUNTER TOP IT IS RECOMMENDED THAT

THE COUNTER TOP BE SUPPORTED BY

STRUCTURE OTHER THAN THE

REFRIGERATED CABINET TO PREVENT

DAMAGE TO THE COUNTER TOP.

IMPORTANT NOTE: For a cabinet door to

operate properly, the door must open a

minimum of 100 . Use a minimum 5-3/4-inch

filler in corner installations to assure a 100 door

opening. Allow enough clearance in front of the

unit for full door swing, shelf pull-out or drawer

pull-out.

IMPORTANT NOTE: Make sure the floor under

the unit is level with the surrounding finished

floor. Protect a finished floor with plywood,

cardboard or some other suitable material

before moving the cabinet across it. Failure to

do this may result in damage to your flooring.

PREPARING ELECTRICAL

CONNECTIONS

A 115 volt, 60Hz, 15 amp circuit breaker and

electrical supply are required. A separate circuit

is required for each Perlick Refrigerated Cabinet

installed. Follow the National Electrical Code

and local codes and ordinances when installing

the receptacle. All Perlick Refrigerated Cabinets

come equipped with a NEMA 5-15P 90 plug

with a minimum of 5-feet of cord extending

beyond the rear of the cabinet. (Refer to

Illustration 1 for exact power cord exit location of

your particular model). The electrical outlet

must be flush with or recessed into the back

wall.

IMPORTANT NOTE: Never use an extension

cord to extend the power cord to the electrical

receptacle.

DANGER

ELECTROCUTION HAZARD!!

ELECTRICAL GROUNDING REQUIRED. THIS

APPLIANCE IS EQUIPPED WITH A THREE

PRONG (GROUNDING) POLARIZED PLUG

FOR YOUR PROTECTION AGAINST

POSSIBLE SHOCK HAZARDS.

NEVER REMOVE THE ROUND

GROUNDING PRONG FROM THE PLUG.

NEVER USE A TWO-PRONG

GROUNDING ADAPTER.

NEVER USE EXTENSION CORD TO

CONNECT POWER TO THE UNIT.

WHERE A TWO-PRONG WALL RECEPTACLE

IS ENCOUNTERED OR A LONGER POWER

CORD IS REQUIRED, CONTACT A

QUALIFIED ELECTRICIAN TO HAVE IT

REPLACED IN ACCORDANCE WITH

APPLICABLE ELECTRICAL CODES.

WARNING

FAILURE TO COMPLY WITH THE ABOVE

ELECTRICAL GUIDELINES MAY RESULT IN

POSSIBLE INJURY/DEATH/FIRE OR LOSS

OF PROPERTY.

www.bringperlickhome.com

5

Page 6

UNPACKING AND MOVING

CAUTION

DO NOT CUT CARDBOARD SLEEVE

COVERING THE UNIT. CUTTING MAY

RESULT IN DAMAGE TO THE EXTERIOR OF

THE CABINET.

Uncrate the unit outside on a flat level surface.

Remove the cardboard sleeve by removing the

staples holding the sleeve to the wood-shipping

base. Carefully lift the cardboard sleeve up over

the top of the cabinet (this should be done with a

minimum of two people, larger cabinets may

require additional helpers). Carefully cut the

banding holding the cabinet to the woodshipping base. Remove all packing materials

from the interior of the cabinet and discard.

Remove door(s), drawers and all cantilever,

sliding or unfastened shelving from the cabinet.

To remove the door(s), remove the upper pivot

pin using a standard straight blade screwdriver

and turning the fastener counterclockwise

(always support the door when unfastening the

upper pivot pin). Once the upper pivot pin is

loose pull the pin up and tip the door slightly

away from the upper cabinet hinge. Gently lift

up on the door to remove the door from the

lower pivot pin. Set door aside in safe location

to prevent damage. Re-install the upper pivot

pin for safekeeping. Refer to PROCEDURE

FOR SWITCHING DIRECTION OF DOOR

SWING pages 13-15, STEP 1 for Removal and

Step 6 for Re-hanging.

To remove cantilever shelving, lift shelf upward

and pull forward. Set cantilever shelving aside

for safekeeping.

To remove sliding shelving or sliding drawers,

pull shelf or drawer forward until completely

extended. Press on both release points on

outside edge of shelf or drawer brackets and pull

shelf or drawer completely out. Continue until all

shelving has been removed from the cabinet.

Set all drawers and shelving aside for

safekeeping.

WARNING

PULL ONLY ONE DRAWER OR SHELF OUT

AT A TIME TO PREVENT POSSIBLE TIPOVER.

CAUTION

SUPPORT SLIDING DRAWERS AND SLIDING

SHELVING HORIZONTALLY AND PULL

STRAIGHT OUT TO AVOID DAMAGE TO

SLIDES.

Carefully lift cabinet off wood base and onto a

hand truck(s) or dolly. Ensure cabinet is

balanced on transporting device. Multi-door

cabinets have an offset center of gravity towards

the left-most door when facing the front of the

cabinet due to the refrigeration system in and

under the first door. Secure the cabinet to the

transporting device(s) using soft flexible

strapping (to prevent damage to exterior cabinet

finish cover and protect cabinet with cloth

material where banding touches the cabinet).

WARNING

A MINIMUM OF TWO PEOPLE SHOULD LIFT

THE CABINET OFF THE WOOD BASE.

LARGER CABINETS MAY REQUIRE

ADDITIONAL HELPERS TO REMOVE FROM

THE WOOD SHIPPING BASE.

Carefully move cabinet to installation opening.

Place in front of opening.

ANTI-TIP-OVER INSTALLATION

WARNING

TO PREVENT THE UNIT FROM TIPPING

FORWARD IF LOADED BOTTLE RACKS,

LOADED PULLOUT SHELVES OR DRAWERS

ARE PULLED OUT AT ONE TIME, AND TO

PROVIDE A STABLE INSTALLATION, THE

UNIT MUST BE SECURED IN PLACE WITH

AN ANTI-TIP DEVICE.

A set of metal anti-tip brackets and installation

screws (#10 X ¾” wood screw) are supplied with

the unit. This device should be attached to the

floor, towards the back of the appliance; each

bracket located to catch each rear leveling leg

when inserted into the opening. The anti-tip

brackets must catch each of the feet to have a

stable and safe installation. Some installation

sites might need to be modified to provide a

secure surface for attaching the bracket. Refer

to Illustration 2, 3 or 4 below for anti-tip

mounting bracket locations.

www.bringperlickhome.com

6

Page 7

20 7/8"

7/16"

1 1/2"

22 3/4"

23 7/8"

24 3/16" SS DOOR

24 5/8" WOOD DOOR

DIA. 0.375"

1/4" REF

23 9/16"

1 15/16"

15/16"

22 3/16" SS DOOR

24 5/8" WOOD DOOR

20 7/8"

1 1/2"

22 3/4"

7/16"

Ø.375

1/4" REF

ILLUSTRATION 2. SINGLE DOOR ANTI-TIP LAYOUT.

ILLUSTRATION 3. TWO-DOOR ANTI-TIP LAYOUT.

www.bringperlickhome.com

7

Page 8

24"

1 15/16"

23 9/16"

15/16"

15/16"

24 3/16" SS DOOR

24 5/8" WOOD DOOR

22 3/4"

20 7/8"

1 1/2"

7/16"

Ø.375

1/4" REF

ILLUSTRATION 4. THREE-DOOR ANTI-TIP LAYOUT.

INSTALLING

IMPORTANT NOTE: If installing on a concrete

floor, concrete fasteners are required and not

included with the anti-tip kit.

CAUTION

ANY FINISHED FLOORING SHOULD BE

PROTECTED WITH APPROPRIATE

MATERIAL TO AVOID DAMAGE FROM

MOVING THE UNIT. IF FOR ANY REASON

THE UNIT HAS BEEN LAID ON ITS BACK OR

SIDES, YOU MUST ALLOW THE UNIT TO

STAND UPRIGHT FOR A MINIMUM OF 24

HOURS BEFORE CONNECTING POWER.

Re-install the doors by removing the upper pivot

pin completely, sliding the door onto the lower

pivot pin and re-installing the upper pivot pin and

fastening tightly. Before moving the unit, make

sure the door is secured to the cabinet (tape

may be required to hold the doors closed).

Plug the unit into the 15 amp grounded outlet

located in the cabinet installation opening. With

power applied to the appliance, check for

lighting and cooling before going any further.

Once you are satisfied the unit is operating

properly, turn off the power to the wall outlet at

the circuit breaker and proceed.

WARNING

SHUT OFF POWER TO THE WALL OUTLET

BEFORE INSTALLING INTO THE OPENING.

Check the surrounding cabinetry to ensure that

the front face and interior opening is level and

square. Check to ensure the entire floor where

the cabinet is to be installed is level. Check that

the countertop bottom front edge is level. If all

surfaces are level, measure from the floor to the

bottom of the front edge of the countertop.

Measure the rear of refrigerated cabinet from

floor to top of cabinet at back corners. Adjust

rear corner leveling legs to achieve identical

measurements as previously measured from

floor to bottom edge of countertop. Adjust legs

by turning counterclockwise to raise the unit and

clockwise to lower the unit, using an adjustable

wrench or pliers. Once measurements are

identical, and if the cabinet has additional

leveling legs on rear of cabinet, adjust to proper

height to support center of cabinet.

IMPORTANT NOTE: Leveling legs should not

be extend more than ¾” from bottom of the

cabinet.

IMPORTANT NOTE: The floor under the Perlick

cabinet must be at the same level as the

surrounding finished floor.

www.bringperlickhome.com

8

Page 9

Slide the cabinet into position, making sure the

rear cabinet leveling legs slide under the anti-tip

devices. Push the cabinet into the opening until

the bottom front edge of the cabinet is flush with

the surrounding cabinetry or the leveling legs

are tight with the anti-tip devices (Refer to ANTITIP ILLUSTRATIONS on pages 8-9 for details).

The rear cabinet leveling legs should be held

between the anti-tip device and the floor.

To finish the leveling of the cabinet, shim the

front of the cabinet so the front face of the

cabinet is flush with the surrounding cabinetry.

Adjust the front leveling legs to support the

cabinet at the shimmed height. Adjust legs by

turning counterclockwise to raise the unit and

clockwise to lower the unit, using an adjustable

wrench or pliers. Countertop should be resting

on top of cabinet.

IMPORTANT NOTE: If countertop is not resting

on entire cabinet top, shimming of the

countertop should be performed to prevent

damage to the countertop.

CAUTION

CARE SHOULD BE TAKEN TO PREVENT

DAMAGE TO THE REFRIGERATED CABINET

AND COUNTERTOP BY NEVER PLACING

HEAVY OBJECTS ON TOP OF THE

COUNTERTOP DIRECTLY ABOVE THE

APPLIANCE.

ILLUSTRATION 5. TOE PLATE INSTALLATION.

Check interior door openings inside the cabinet

to ensure the cabinet is level. Re-install all

shelving and drawers. Take extreme care to

insert sliding shelving and sliding drawers

squarely into slide brackets and proper slide

bracket grooves. When sliding shelving and

drawers are installed properly a click should be

heard from both slide bracket retaining clips and

should slide smoothly in the tracks. When

sliding shelving or drawers are pulled out to full

extension a stop is activated to prevent

additional pull-out.

CAUTION

IMPROPER SHELVING OR DRAWER

INSTALLATION MAY NOT ACTUATE SLIDE

STOP MECHANISM.

TOE PLATE INSTALLATION

When the unit is secured in place, install the

louvered toe plate. Using included fasteners,

secure the louvered toe plate to the cabinet flush

with the floor. Refer to TOE-PLATE

INSTALLATION ILLUSTRATION below.

CAUTION

THE LOUVERED TOE PLATE MUST BE

REMOVABLE FOR SERVICING. THE FLOOR

CANNOT INTERFERE WITH REMOVAL. THE

LOUVERED

www.bringperlickhome.com

SECTIONS OF THE TOE PLATE MUST NOT

BE COVERED OR OBSTRUCTED SO AS TO

PREVENT PROPER AIR CIRCULATION.

9

Page 10

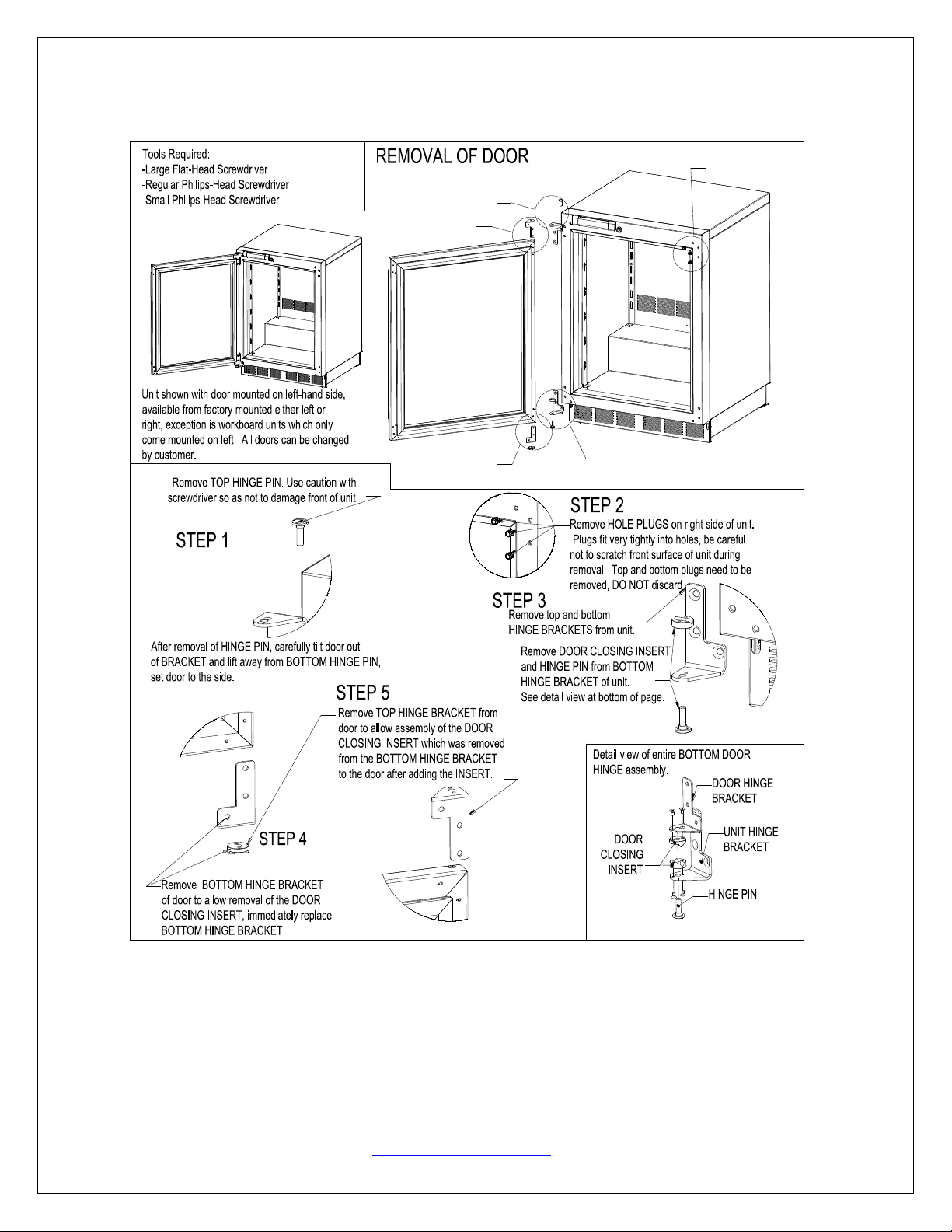

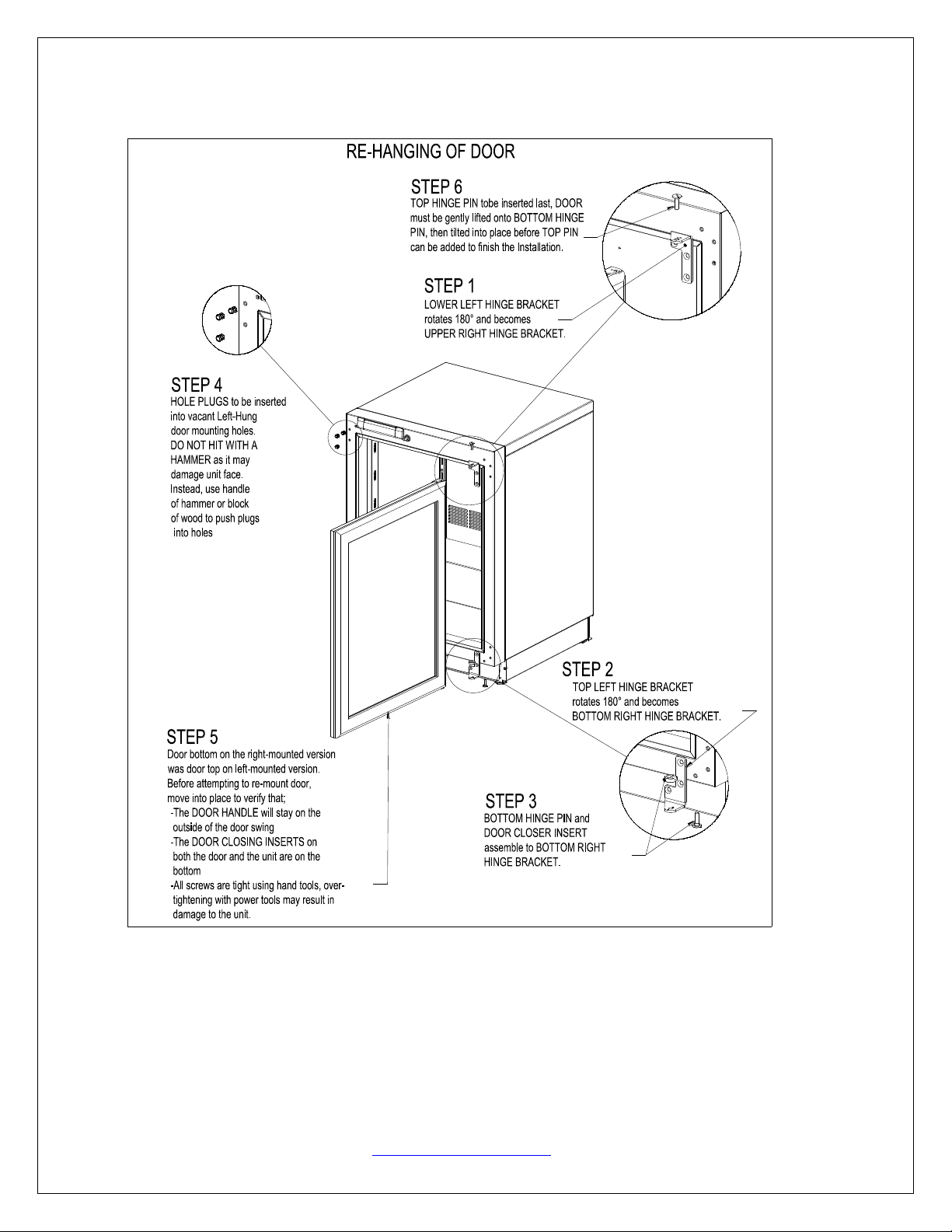

DOOR REVERSING

All Perlick Residential Refrigerated Cabinets

come equipped with field reversible left or right

hand opening door capabilities. Refer to DOOR

REVERSING ILLUSTRATIONS on pages 13-14.

To reverse the opening of the door remove the

top pivot pin from the upper cabinet hinge

bracket. Pull the top pivot pin out of door hinge

bracket and remove the door by tilting forward

and lifting off bottom hinge pin. Re-install pivot

pin in top hinge. Remove cabinet hinge screw

hole plugs (3 each, top and bottom) from new

hinge location. Do not discard. Remove the

bottom cabinet hinge bracket (3 screws).

Remove lower cabinet hinge bracket (3 screws).

Remove door closer insert from the lower

cabinet hinge bracket and install on new bottom

hinge bracket (old top hinge bracket). Install

new bottom cabinet hinge bracket at new bottom

hinge location. Install new top cabinet hinge

bracket at new top hinge location. Remove

upper and lower door hinge brackets from door

(3 screws each). Remove door closer insert

from lower door hinge bracket and install on new

lower door hinge bracket (old top door hinge

bracket). Rotate the door 180 so handle is on

new opening side (Old bottom of door is new top

of door). Install new lower door hinge bracket to

bottom of door (3 screws). Install new upper

door hinge bracket to top of door (3 screws).

Remove top pivot pin from the upper cabinet

hinge bracket. To re-install the door, slide lower

door hinge bracket onto lower pivot pin. Tilt top

of door into position aligned with top cabinet

hinge bracket and install top pivot pin (tighten

securely). Install cabinet hinge screw hole plugs

removed earlier in open hinge holes (3 each, top

and bottom)

www.bringperlickhome.com

11

Page 11

STEP 4

STEP 5

STEP 1

STEP 3

STEP 2

ILLUSTRATION 6. DOOR SWING REVERSAL PROCEDURE.

www.bringperlickhome.com

12

Page 12

www.bringperlickhome.com

13

Page 13

DOOR OPTIONS

Perlick Residential Refrigerated cabinets offer a

variety of door panel design alternatives; solid

stainless steel, solid wood overlay, stainless

steel glass and wood overlay glass. This,

together with door swing choices, result in a

variety of possible combinations.

Solid stainless steel and stainless steel glass

doors are shipped from the factory with

decorative stainless steel panels and handles in

place on the appliance, ready for use.

Solid wood overlay and glass wood overlay

doors are designed to accept a decorative front

panel to match surrounding cabinetry and door

handles. This panel and door handle will be

provided by the customer.

All Perlick Refrigerated cabinets accept any of

the above door configurations and are fully

hinge reversible and interchangeable.

IMPORTANT NOTE: DRAWERS CAN REPLACE

ANY SECOND OR THIRD DOOR ON A MULTIDOOR CABINET WITH THE ADDITION OF A

FACTORY INSTALLED MULLION.

IMPORTANT NOTE: CABINETS WITH A FIRST

DOOR FREEZER CAN ONLY UTILIZE A SOLID

STAINLESS STEEL DOOR OR A SOLID WOOD

OVERLAY DOOR (STAINLESS STEEL GLASS OR

WOOD OVERLAY GLASS DOORS WILL SWEAT IF

INSTALLED ON A FREEZER SECTION).

IMPORTANT NOTE: STAINLESS STEEL GLASS

OR WOOD OVERLAY GLASS DOORS MAY

SWEAT IN CONDITIONS WITH RELATIVE

HUMIDITY OVER 75%.

INSTALLATION OF WOOD OVERLAYS

Before beginning installation, check for the

correct components for the fit and finish desired.

All overlay doors require a trim panel at least

3/4” thick. The solid wood overlay panel should

not weigh more than 20 pounds. The glass

wood overlay panel should not weigh more than

10 pounds. The solid wood drawer overlay

panels should not weigh more than 10 pounds

each.

This section gives detailed instructions of how to

install a solid wood overlay or glass wood

overlay panel and handle to a Perlick

Customizable door or drawer.

NOTE: CONTACT THE FACTORY FOR FULLSIZED WOOD OVERLAY PANEL LAYOUTS.

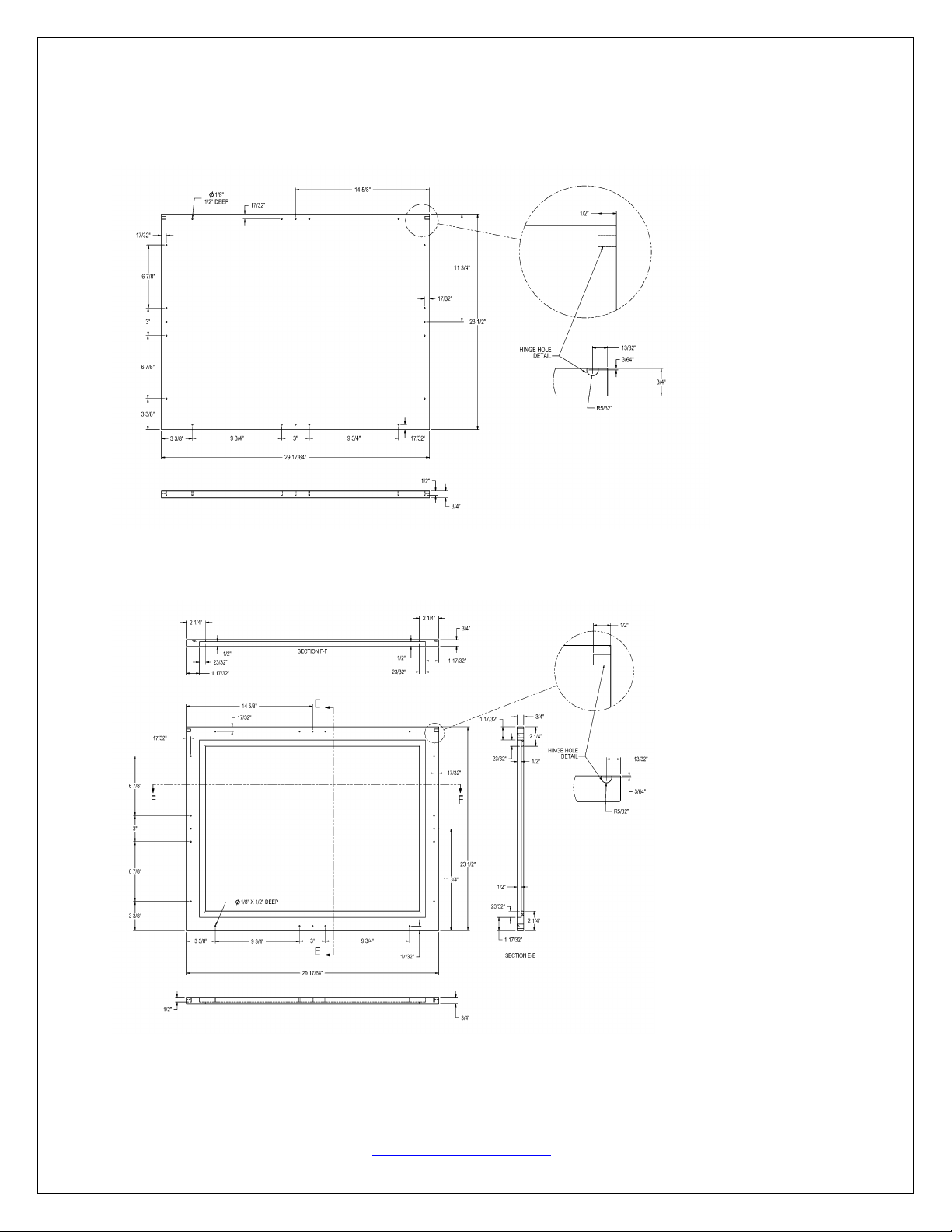

See Illustration 7 for details for the design of a

solid wood overlay panel.

See Illustration 8 for details for the design of a

glass wood overlay panel.

See Illustration 9 for details for the design of a

solid wood drawer overlay panel.

Inspect the wood door panel for the proper

design specified in the previous illustrations.

The handle must be attached to the wood panel.

The handle must be attached to that first.

IMPORTANT NOTE: HANDLE MOUNTING ON

WOOD OVERLAY DOOR SHOULD ALWAYS BE

MOUNTED ON WOOD OVERLAY ONLY TO AVOID

DAMAGE TO FACTORY DOOR. SEE PREVIOUS

DESIGN ILLUSTRATIONS FOR ACCEPTABLE

HANDLE MOUNTING HARDWARE PASSAGE

THROUGH WOOD OVERLAY PORTION OF THE

DOOR SO FASTENERS DO NOT INTERFERE.

To attach the door handle to wood overlay

panel, first decide which direction the door will

be hinged. Once decided, mark rear of wood

overlay panel with handle fastener location(s).

Drill through wood overlay panel at marked

handle fastening location(s) taking proper care

to not damage the wood overlay panel.

Countersink screw head(s) so when installed in

the wood overlay panel the screw head(s) is/are

flush with the backside of the wood overlay

panel.

CAUTION

PROPER WOOD WORKING MATERIALS AND

EQUIPMENT SHOULD BE USED TO AVOID

DAMAGE OR ERRORS IN WORKMANSHIP.

Decorative wood panels should be attached to

the factory supplied overlay doors using #10 X

1” wood screws passing through the doorframe

from the rear, into the overlay panel. The

factory supplied overlay doorframe is predrilled

for ease of overlay panel installation.

IMPORTANT NOTE: DO NOT OVER-TIGHTEN

WOOD OVERLAY ATTACHMENT SCREWS AS

THIS MAY DAMAGE FACTORY SUPPLIED

DOORFRAME.

With the cabinet secured in position, open

cabinet door and ensure wood overlay panel

predrilled pilot fastening holes align with factory

www.bringperlickhome.com

14

Page 14

door frame predrilled holes. Start inserting

fasteners in four corners of the doorframe and

fasten loosely. Before proceeding with

additional mounting fasteners, check for overall

wood overlay fit, position and function. Make

minor adjustments as needed. Upon

satisfaction with appearance, securely tighten

existing screws. Complete installation of wood

overlay panel by installing the rest of the

fasteners and completely tightening. Check all

screws for tightness.

www.bringperlickhome.com

15

Page 15

ILLUSTRATION 7. SOLID WOOD OVERLAY PANEL.

WARNING: SOLID WOOD OVERLAY PANEL MUST NOT EXCEED 20 POUNDS IN WEIGHT.

ILLUSTRATION 8. GLASS WOOD OVERLAY PANEL.

WARNING: GLASS WOOD OVERLAY PANEL MUST NOT EXCEED 10 POUNDS IN WEIGHT.

www.bringperlickhome.com

16

Page 16

ILLUSTRATION 9. SOLID WOOD DRAWER OVERLAY PANEL.

WARNING: THE SOLID WOOD DRAWER OVERLAY PANEL MUST NOT EXCEED 10 POUNDS IN

WEIGHT.

STORAGE CAPABILITES

IMPORTANT NOTE: INTERIOR LOUVER

OPENINGS AND FAN GUARD OPENINGS

SHOULD NEVER BE OBSTRUCTED TO

ACHIEVE MAXIMUM PERFORMANCE.

Two types of shelving are available for freezer

and refrigerator compartments, cantilever and

full extension pullout shelves. The cantilever or

full extension pullout wire-formed shelving

comes with a durable black vinyl coated finish

impermeable to rust and corrosion with side rails

to prevent container tip-over. The full extension

allows for easy product loading, removal as well

as visual inspection. One fixed storage bottom

step wire-formed shelf with the same durable

finish comes standard with each cabinet.

One type of shelving is available for wine cooler

compartments, full extension wine racks. The

full extension wire-formed wine racks come with

the same durable black vinyl coated finish and

allow for full extension for easy bottle loading,

removal and visual inspection. The fixed

storage wire-formed wine rack is coated with the

same durable black vinyl coated finish and is

sized to hold any size of wine bottle. All wine

rack spacing has been designed to optimize

flexibility in storage of various sized wine bottles.

SINGLE DOOR FREEZER & SINGLE DOOR

REFRIGERATOR

The single door freezer (H1F) and the single

door refrigerator (H1R) come standard with

either a single black vinyl coated cantilever or

full extension pullout shelf and a bottom step

shelf. One additional black vinyl coated

cantilever or pullout shelf can be used in these

cabinets.

SINGLE DOOR WINE COOLER

The single door wine cooler (H1W) comes

standard with four full extension black vinyl

coated wine racks capable of storing 32 total

wine bottles (standard, magnum, or half size

bottles). An additional fixed storage rack is

nestled into the lower step for storage of an

additional 10 wine bottles (standard, magnum,

or half size bottles).

www.bringperlickhome.com

17

Page 17

TWO DOOR FREEZER/REFRIGERATOR &

TWO DOOR ALL-REFRIGERATOR

The two-door freezer/refrigerator (H2FR) and

the two-door all-refrigerator (H2RO) come

standard with three black vinyl coated cantilever

or pullout shelves and a bottom step shelf. Up

to two additional black vinyl coated cantilever or

pullout shelves can be used in these cabinets.

TWO DOOR REFRIGERATOR/WINE COOLER

The two door refrigerator/wine cooler (H2RW)

comes standard with one black vinyl coated

cantilever or pull-out shelf, a bottom step shelf

and six full extension black vinyl coated wine

racks capable of storing 48 total wine bottles

(standard, magnum, or half size bottles). One

additional black vinyl coated cantilever or pullout

shelf can be used in this cabinet.

TWO DOOR ALL WINE COOLER

The two door all-wine cooler (H2WW or H2WO)

comes standard with ten full extension black

vinyl coated wine racks capable of storing 80

total wine bottles (standard, magnum, or half

size bottles). An additional fixed storage rack is

nestled into the lower step of the first door for

storage of an additional 10 wine bottles

(standard, magnum, or half size bottles). If the

cabinet is a multi-zone wine cooler the first door

can hold 42 total wine bottles while the second

door can hold 48 total wine bottles.

THREE DOOR

FREEZER/REFRIGERATOR/REFRIGERATOR & THREE DOOR ALLREFRIGERATOR

The three-door freezer/refrigerator/refrigerator

(H3FRO) and the three-door all-refrigerator

(H3ROO) come standard with five black vinyl

coated cantilever or pullout shelves and a

bottom step shelf. Up to three additional black

vinyl coated cantilever or pullout shelves can be

used in these cabinets.

THREE DOOR REFRIGERATOR/REFRIGERATOR/WINE COOLER

The three door refrigerator/refrigerator/wine

cooler (H3ROW) comes standard with three

black vinyl coated cantilever or pull-out shelves,

a bottom step shelf and six full extension black

vinyl coated wine racks capable of storing 48

total wine bottles (standard, magnum, or half

size bottles). Up to two additional black vinyl

coated cantilever or pullout shelves can be used

in this cabinet.

THREE DOOR REFRIGERATOR/WINE

COOLER/WINE COOLER

The three door refrigerator/wine cooler/wine

cooler (H3RWO or H3RWW) comes standard

with one black vinyl coated cantilever or pull-out

shelf, a bottom step shelf and twelve full

extension black vinyl coated wine racks capable

of storing 96 total wine bottles (standard,

magnum, or half size bottles). Up to one

additional black vinyl coated cantilever or pullout

shelf can be used in this cabinet. The second

and third door wine cooler compartments each

can hold 48 wine bottles.

THREE DOOR ALL WINE COOLER

The three door all wine cooler (H3WOO,

H3WOW, H3WWO, or H3WWW) comes

standard with sixteen full extension black vinyl

coated wine racks capable of storing 128 total

wine bottles (standard, magnum, or half size

bottles). An additional fixed storage rack is

nestled into the lower step of the first door for

storage of an additional 10 wine bottles

(standard, magnum, or half size bottles). If the

cabinet is a multi-zone wine cooler the first door

can hold 42 total wine bottles while the second

door and third doors can each hold 48 total wine

bottles.

www.bringperlickhome.com

18

Page 18

ILLUSTRATION 10. WOODEN WINE RACK TRIM DESIGN.

WOODEN WINE RACK TRIM

FINISHING

All wine racks come with an unfinished solid

hardwood face, which can be removed and

replaced with other wood to match your

cabinetry. See design illustration 10 below for

wine rack face details.

The included unfinished faces can be finished

and sealed. In many cases stains and/or

finishes have odors that may be objectionable in

an enclosed area. To remove the front woodface from the wine shelf, simply pull out the wine

shelf and remove the fasteners, finish as desired

and re-install with fasteners.

www.bringperlickhome.com

19

Page 19

LOCK INSTALLATION &

REVERSING

A Door Lock Kit can be ordered as an

accessory. Two kits are available a right hand

opening and a left hand

ILLUSTRATION 11. DOOR LOCK INSTALLATION

opening kit. To install or remove the lock,

remove the three fasteners holding the Lock

Mechanism to the cabinet and the three

fasteners holding the Lock Bracket to the door.

SHELVING AND DRAWERS

Shelving

Perlick has three different types of shelving. All

designed to easily be moved and adjusted.

Cantilever

moved up and down for desired heights. Pick

up the shelving by pulling up and unhooking the

back hooks from the railing. Move to desired

height, then place the hooks in the railing and

set down.

Full extension Shelving

its

farthest point. Locate the tabs in the middle on

both sides of the extenders. Press tabs and pull

shelf out.

Move each extender separately. Hold the

Middle of one extender, pull the front up then

rotate to the inside of unit. Once at a 45 degree

angle, pull up then pull out. Place extender at

is stationary shelving. It can be

- Pull the shelf out to

desired height, at the 45 degree angle push in

the hook to the back rail, rotate toward wall and

set front section on the wall hook.

To return shelf, first push both extenders

completely in then line up the shelf grooves and

slide easily into the unit.

Wine Shelving

See Full Extension shelving.

Note: All shelving is inter-changeable with all

products.

Drawers

To remove, fully extend the drawers. Hold on to

both side and pull straight up and out.

To return drawers, fully extend the extenders.

Line up the back slots first, keep the extender

completely out, then set the back slots down into

place. Next, easily set down the front.

Caution: COMPLETELY EMPTY THE DRAWER

BEFORE REMOVING

www.bringperlickhome.com

20

Page 20

OPERATION – SINGLE

DOOR

SINGLE DOOR FREEZER

The Perlick Single Door Freezer (H1F) comes

equipped with a state of the art refrigeration

system. The compressor is of a variable speed

variety, which automatically changes speeds

based on system conditions and load. The

cabinet is equipped with an adjustable digital

temperature controller and LED display. The

controller can be adjusted through a range of 10 F to +10 F. The controller has been factory

set to modulate from -3 F to +5 F. To properly

determine product temperature see “CHECKING

PRODUCT TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

on demand at predetermined intervals. The

controller also has a manual defrost soft button

on the front panel signified by a melting

snowflake. If depressed it will automatically put

the system into a defrost cycle.

PROPER PRODUCT STORAGE

Install items as desired. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controller turned

ON. To turn the cabinet OFF or ON press the

blue soft button on the front face of the controller

(if the controller is turned off with power applied

to the cabinet the LED display will read OFF,

when turned on it will read a temperature). The

controller is located on the top front face of the

cabinet and is equipped with a tinted seethrough lens, which opens by pulling out on the

bottom of the lens and rotating upwards. Always

ensure lens cover is closed before closing door

to avoid damage to the controller or lens.

The electronic control comes preset for a

product temperature of approximately 0 F with a

product temperature adjustability range of -10 F

OPERATION

to +5 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, AN 8 F AIR TEMPERATURE

SWING DOES NOT CHANGE THE ACTUAL

PRODUCT TEMPERATURE. PRODUCT

TEMPERATURE REMAINS AT A VERY

STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Single Door Freezer has an interior light

that is illuminated when the door is opened. The

cabinet also comes standard with a manual light

switch located next to the light. Always ensure

that the manual switch is in the off position

before closing the door. If manual light switch is

left on for an extended period of time it may

increase the cabinet temperature, especially at

the top and cause the refrigeration system to run

longer.

SINGLE DOOR

REFRIGERATOR

OPERATION

The Perlick Single Door Refrigerator (H1R)

comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with an

adjustable digital temperature controller and

LED display. The controller can be adjusted

through a range of 30 F to 42 F. The controller

has been factory set to modulate from 34 F to

40 F. To properly determine product

temperature see “CHECKING PRODUCT

TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

during off cycles. The controller also has a

manual defrost soft button on the front panel

signified by a melting snowflake, which is

www.bringperlickhome.com

21

Page 21

disabled for this model.

PROPER PRODUCT STORAGE

Install items as desired. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controller turned

ON. To turn the cabinet OFF or ON press the

blue soft button on the front face of the controller

(if the controller is turned off with power applied

to the cabinet the LED display will read OFF,

when turned on it will read a temperature). The

controller is located on the top front face of the

cabinet and is equipped with a tinted seethrough lens, which opens by pulling out on the

bottom of the lens and rotating upwards. Always

ensure lens cover is closed before closing door

to avoid damage to the controller or lens.

The electronic control comes preset for a

product temperature of approximately 38 F with

a product temperature adjustability range of

33 F to 45 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, A 6 F AIR TEMPERATURE

SWING DOES NOT CHANGE THE ACTUAL

PRODUCT TEMPERATURE. PRODUCT

TEMPERATURE REMAINS AT A VERY

STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Single Door Refrigerator has an interior

light that is illuminated when the door is opened.

The cabinet also comes standard with a manual

light switch located next to the light for

displaying your products through a glass door.

Always ensure that the manual switch is in the

off position before closing a solid wood or

stainless steel door. If manual light switch is left

on for an extended period of time it may

increase the cabinet temperature, especially at

the top and cause the refrigeration system to run

longer.

SINGLE DOOR WINE

COOLER OPERATION

The Perlick Single Door Wine Cooler (H1W)

comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with an

adjustable digital temperature controller and

LED display. The controller can be adjusted

through a range of 40 F to 68 F. The controller

has been factory set to modulate from 53 F to

57 F. To properly determine product

temperature see “CHECKING PRODUCT

TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

during off cycles. The controller also has a

manual defrost soft button on the front panel

signified by a melting snowflake, which has been

disabled for this model.

PROPER PRODUCT STORAGE

This wine cooler will accommodate 42 bottles of

wine. Specially designed full extension wine

racks allow for proper horizontal storage of the

wine. The cork remains moist, which keeps air

from entering the bottle. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controller turned

ON. To turn the cabinet OFF or ON press the

blue soft button on the front face of the controller

(if the controller is turned off with power applied

to the cabinet the LED display will read OFF,

when turned on it will read a temperature). The

controller is located on the top front face of the

cabinet and is equipped with a tinted seethrough lens, which opens by pulling out on the

bottom of the lens and rotating upwards. Always

ensure lens cover is closed before closing door

to avoid damage to the controller or lens.

The electronic control comes preset for a

product temperature of approximately 55 F with

www.bringperlickhome.com

22

Page 22

a product temperature adjustability range of

42 F to 70 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, A 4 F AIR TEMPERATURE

SWING DOES NOT CHANGE THE ACTUAL

PRODUCT TEMPERATURE. PRODUCT

TEMPERATURE REMAINS AT A VERY

STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Single Door Wine Cooler has an interior

light that is illuminated when the door is opened.

The cabinet also comes standard with a manual

light switch located next to the light for

displaying your products through a glass door. If

manual light switch is left on for an extended

period of time it may increase the cabinet

temperature and in turn product temperature,

especially in close proximity to the light at the

top and cause the refrigeration system to run

longer.

OPERATION – TWO

DOOR

TWO DOOR

FREEZER/REFRIGERATOR

OPERATION

The Perlick Two Door Freezer/Refrigerator

(H2FR) comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with two

adjustable digital temperature controllers and

LED displays. The freezer controller can be

adjusted through a range of -10 F to +10 F.

The freezer controller has been factory set to

modulate from -3 F to +5 F. The refrigerator

controller can be adjusted through a range of

30 F to 42 F. The refrigerator controller has

been factory set to modulate from 37 F to 39 F.

To properly determine product temperature see

“CHECKING PRODUCT TEMPERATURE” on

page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

IMPORTANT NOTE: PERLCK’S MULTI-ZONE

UNITS ARE NOT DESIGNED FOR OUTDOOR

APPLICATIONS. INSTALLING MULTI-ZONE

UNITS OUTDOORS WILL VOID THE

WARRANTY.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

on demand at predetermined intervals. The

controller also has a manual defrost soft button

on the front panel signified by a melting

snowflake. If depressed it will automatically put

the system into a defrost cycle.

PROPER PRODUCT STORAGE

Store product as desired. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controllers

turned ON. To turn the refrigeration system OFF

or ON press the blue soft button on the front

face of the freezer controller (if the controller is

turned off with power applied to the cabinet the

LED display will read OFF, when turned on it will

read a temperature). The controller is located on

the top front face of the cabinet above the left

door and is equipped with a tinted see-through

lens which opens by pulling out on the bottom of

the lens and rotating upwards. Always ensure

lens cover is closed before closing door to avoid

damage to the controller or lens. The refrigerator

control looks and responds identical to the

freezer control with the exception that it only

controls the cooling system for the refrigerator

zone and is located above the right door.

The freezer electronic control comes preset for a

product temperature of approximately 0 F with a

product temperature adjustability range of -10 F

to +5 F. The refrigerator electronic control

comes preset for a product temperature of

approximately 38 F with a product temperature

adjustability range of 33 F to 42 F. To change

temperature controller settings see section

“TEMPERATURE CONTROLLER

ADJUSTMENTS” on page 42.

www.bringperlickhome.com

23

Page 23

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, AN 8 F AIR TEMPERATURE

SWING IN THE FREEZER COMPARTMENT

AND A 2 F AIR TEMPERATURE SWING IN

THE REFRIGERATOR COMPARTMENT DOES

NOT CHANGE THE ACTUAL PRODUCT

TEMPERATURE. PRODUCT TEMPERATURE

REMAINS AT A VERY STABLE

TEMPERATURE.

LIGHT SWITCH AND BULB

Your Two-Door Freezer/Refrigerator has two

interior lights that are illuminated when the

corresponding door is opened. The cabinet also

comes standard with manual light switches

located next to each light for displaying your

products through a glass door. If manual light

switch is left on for an extended period of time it

may increase the cabinet temperature,

especially in close proximity to the light at the

top and cause the refrigeration system to run

longer.

TWO DOOR ALL-

REFRIGERATOR

OPERATION

The Perlick Two Door All-Refrigerator (H2RO)

comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with an

adjustable digital temperature controller and

LED display. The controller can be adjusted

through a range of 30 F to 42 F. The

refrigerator controller has been factory set to

modulate from 34 F to 40 F. To properly

determine product temperature see “CHECKING

PRODUCT TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

during off cycles. The controller also has a

manual defrost soft button on the front panel

signified by a melting snowflake, which has been

disabled on this model.

PROPER PRODUCT STORAGE

Store product as desired. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controllers

turned ON. To turn the refrigeration system

OFF or ON press the blue soft button on the

front face of the controller (if the controller is

turned off with power applied to the cabinet the

LED display will read OFF, when turned on it will

read a temperature). The controller is located

on the top front face of the cabinet above the left

door and is equipped with a tinted see-through

lens which opens by pulling out on the bottom of

the lens and rotating upwards. Always ensure

lens cover is closed before closing door to avoid

damage to the controller or lens.

The refrigerator electronic control comes preset

for a product temperature of approximately 38 F

with a product temperature adjustability range of

33 F to 45 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, A 6 F AIR TEMPERATURE

SWING IN THE REFRIGERATOR

COMPARTMENT DOES NOT CHANGE THE

ACTUAL PRODUCT TEMPERATURE.

PRODUCT TEMPERATURE REMAINS AT A

VERY STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Two-Door All-Refrigerator has two interior

lights that are illuminated when each

corresponding door is opened. The cabinet also

comes standard with manual light switches

located next to each light for displaying your

products through a glass door. If manual light

switch is left on for an extended period of time it

may increase the cabinet temperature,

especially in close proximity to the light at the

top and cause the refrigeration system to run

longer.

www.bringperlickhome.com

24

Page 24

TWO DOOR ALL-WINE

COOLER OPERATION

The Perlick Two Door All-Wine Cooler (H2WO)

comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with an

adjustable digital temperature controller and

LED display. The controller can be adjusted

through a range of 40 F to 65 F. The

refrigerator controller has been factory set to

modulate from 53 F to 57 F. To properly

determine product temperature see “CHECKING

PRODUCT TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

during off cycles. The controller also has a

manual defrost soft button on the front panel

signified by a melting snowflake, which has been

disabled on this model.

PROPER PRODUCT STORAGE

This wine cooler will accommodate 90 bottles of

wine. Specially designed full extension wine

racks allow for proper horizontal storage of the

wine. The cork remains moist, which keeps air

from entering the bottle. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controller turned

ON. To turn the refrigeration system OFF or ON

press the blue soft button on the front face of the

controller (if the controller is turned off with

power applied to the cabinet the LED display will

read OFF, when turned on it will read a

temperature). The controller is located on the

top front face of the cabinet above the left door

and is equipped with a tinted see-through lens

which opens by pulling out on the bottom of the

lens and rotating upwards. Always ensure lens

cover is closed before closing door to avoid

damage to the controller or lens.

The wine cooler electronic control comes preset

for a product temperature of approximately 55 F

with a product temperature adjustability range of

40 F to 70 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, A 4 F AIR TEMPERATURE

SWING IN THE WINE COOLER

COMPARTMENT DOES NOT CHANGE THE

ACTUAL PRODUCT TEMPERATURE.

PRODUCT TEMPERATURE REMAINS AT A

VERY STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Two-Door All-Wine Cooler model has two

interior lights that are illuminated when each

door is opened. The cabinet also comes

standard with manual light switches located next

to each light for displaying your products through

a glass door. If manual light switch is left on for

an extended period of time it may increase the

cabinet temperature and in turn product

temperature, especially in close proximity to the

light at the top and cause the refrigeration

system to run longer.

TWO DOOR MULTI-ZONE

WINE COOLER

OPERATION

The Perlick Two Door Multi-Zone Wine Cooler

(H2WW) comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with two

adjustable digital temperature controllers and

LED displays. The low temperature wine zone

controller located above the left door can be

adjusted through a range of 40 F to 56 F. The

low temperature wine zone controller has been

factory set to modulate from 53 F to 57 F. The

high temperature wine zone controller located

above the right door can be adjusted through a

range of 52 F to 65 F. The high temperature

wine zone controller has been factory set to

modulate from 64 F to 66 F. To properly

determine product temperature see “CHECKING

PRODUCT TEMPERATURE” on page 44.

www.bringperlickhome.com

25

Page 25

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

IMPORTANT NOTE: PERLCK’S MULTI-ZONE

UNITS ARE NOT DESIGNED FOR OUTDOOR

APPLICATIONS. INSTALLING MULTI-ZONE

UNITS OUTDOORS WILL VOID THE

WARRANTY.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

during off cycles. The controller also has a

manual defrost soft button on the front panel

signified by a melting snowflake, which has been

disabled on this model.

PROPER PRODUCT STORAGE

The low temperature wine zone will

accommodate 42 bottles of wine. The high

temperature wine zone will accommodate 48

bottles of wine. Specially designed full extension

wine racks allow for proper horizontal storage of

the wine. The cork remains moist, which keeps

air from entering the bottle. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controllers

turned ON. To turn the refrigeration system OFF

or ON press the blue soft button on the front

face of the low temperature wine zone controller

(if the controller is turned off with power applied

to the cabinet the LED display will read OFF,

when turned on it will read a temperature). The

low temperature wine zone controller is located

on the top front face of the cabinet above the left

door and is equipped with a tinted see-through

lens which opens by pulling out on the bottom of

the lens and rotating upwards. Always ensure

lens cover is closed before closing door to avoid

damage to the controller or lens. The warm

temperature wine zone controller appears

identical except it controls this zones cooling

system and is located above the right door.

The low temperature wine zone electronic

control comes preset for a product temperature

of approximately 55 F with a product

temperature adjustability range of 40 F to 56 F.

The warm temperature wine zone electronic

control comes preset for a product temperature

of approximately 65 F with a product

temperature adjustability range of 54 F to 68 F.

To change temperature controller settings see

section “TEMPERATURE CONTROLLER

ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, A 4 F AIR TEMPERATURE

SWING IN THE WINE COOLER

COMPARTMENT DOES NOT CHANGE THE

ACTUAL PRODUCT TEMPERATURE.

PRODUCT TEMPERATURE REMAINS AT A

VERY STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Two Door Multi-Zone Wine Cooler has two

interior lights that are illuminated when each

respective door is opened. The cabinet also

comes standard with manual light switches

located next to each light for displaying your

products through a glass door. If manual light

switch is left on for an extended period of time it

may increase the cabinet temperature and in

turn product temperature, especially in close

proximity to the light at the top and cause the

refrigeration system to run longer.

TWO DOOR

REFRIGERATOR / WINE

COOLER OPERATION

The Perlick Two Door Refrigerator/ Wine Cooler

(H2RW) comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with two

adjustable digital temperature controllers and

LED displays. The refrigerator zone controller

located above the left door can be adjusted

through a range of 33 F to 43 F. The refrigerator

zone controller has been factory set to modulate

from 34 F to 40 F. The wine cooler zone

controller located above the right door can be

adjusted through a range of 50 F to 60 F. The

wine cooler zone controller has been factory set

to modulate from 54 F to 56 F. To properly

determine product temperature see “CHECKING

PRODUCT TEMPERATURE” on page 44.

www.bringperlickhome.com

26

Page 26

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

IMPORTANT NOTE: PERLCK’S MULTI-ZONE

UNITS ARE NOT DESIGNED FOR OUTDOOR

APPLICATIONS. INSTALLING MULTI-ZONE

UNITS OUTDOORS WILL VOID THE

WARRANTY.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

during off cycles. The controller also has a

manual defrost soft button on the front panel

signified by a melting snowflake, which has been

disabled on this model.

PROPER PRODUCT STORAGE

The refrigerator can be filled as desired. The

wine cooler zone will accommodate 48 bottles of

wine. Specially designed full extension wine

racks allow for proper horizontal storage of the

wine. The cork remains moist, which keeps air

from entering the bottle. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controllers

turned ON. To turn the refrigeration system

OFF or ON press the blue soft button on the

front face of the low temperature wine zone

controller (if the controller is turned off with

power applied to the cabinet the LED display will

read OFF, when turned on it will read a

temperature). The low temperature wine zone

controller is located on the top front face of the

cabinet above the left door and is equipped with

a tinted see-through lens which opens by pulling

out on the bottom of the lens and rotating

upwards. Always ensure lens cover is closed

before closing door to avoid damage to the

controller or lens. The warm temperature wine

zone controller appears identical except it

controls this zones cooling system and is

located above the right door.

The refrigerator zone electronic control comes

preset for a product temperature of

approximately 38 F with a product temperature

adjustability range of 33 F to 43 F. The wine

cooler zone electronic control comes preset for a

product temperature of approximately 55 F with

a product temperature adjustability range of

50 F to 60 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, A 6 F OR 2 F AIR

TEMPERATURE SWING IN THE

REFRIGERATOR/ WINE COOLER

COMPARTMENTS DOES NOT CHANGE THE

ACTUAL PRODUCT TEMPERATURE.

PRODUCT TEMPERATURE REMAINS AT A

VERY STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Two-Door Refrigerator/Wine Cooler has

two interior lights that are illuminated when each

respective door is opened. The cabinet also

comes standard with manual light switches

located next to each light for displaying your

products through a glass door. If manual light

switch is left on for an extended period of time it

may increase the cabinet temperature and in

turn product temperature, especially in close

proximity to the light at the top and cause the

refrigeration system to run longer.

OPERATION – THREE

DOOR

THREE DOOR

FREEZER/REFRIGERATOR

/ REFRIGERATOR

OPERATION

The Perlick Three Door

Freezer/Refrigerator/Refrigerator (H3FRO)

comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with two

adjustable digital temperature controllers and

LED displays. The freezer controller can be

adjusted through a range of -10 F to +10 F.

The freezer controller has been factory set to

www.bringperlickhome.com

27

Page 27

modulate from -3 F to +5 F. The refrigerator

controller can be adjusted through a range of

30 F to 42 F with an adjustable differential to

optimize storage conditions. The refrigerator

controller has been factory set to modulate from

37 F to 39 F. To properly determine product

temperature see “CHECKING PRODUCT

TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

IMPORTANT NOTE: PERLCK’S MULTI-ZONE

UNITS ARE NOT DESIGNED FOR OUTDOOR

APPLICATIONS. INSTALLING MULTI-ZONE

UNITS OUTDOORS WILL VOID THE

WARRANTY.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

on demand at predetermined intervals. The

controller also has a manual defrost soft button

on the front panel signified by a melting

snowflake. If depressed it will automatically put

the system into a defrost cycle.

PROPER PRODUCT STORAGE

Store product as desired. Do not block internal

louvers or fan guard openings, as this will

decrease operating performance.

CONTROL SETTINGS

The cabinet is shipped with the controllers

turned ON. To turn the refrigeration system OFF

or ON press the blue soft button on the front

face of the freezer controller (if the controller is

turned off with power applied to the cabinet the

LED display will read OFF, when turned on it will

read a temperature). The freezer controller is on

the top front face of the cabinet above the left

door and is equipped with a tinted see-through

lens which opens by pulling out on the bottom of

the lens and rotating upwards. Always ensure

lens cover is closed before closing door to avoid

damage to the controller or lens. The refrigerator

control looks and responds identical to the

freezer control with the exception that it only

controls the cooling system for the refrigerator

zone and is located above the center door.

The freezer electronic control comes preset for a

product temperature of approximately 0 F with a

product temperature adjustability range of -5 F

to +5 F. The refrigerator electronic control

comes preset for a product temperature of

approximately 38 F with a product temperature

adjustability range of 33 F to 42 F. To change

temperature controller settings see section

“TEMPERATURE CONTROLLER

ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, AN 8 F AIR TEMPERATURE

SWING IN THE FREEZER COMPARTMENT

AND A 2 F AIR TEMPERATURE SWING IN

THE REFRIGERATOR COMPARTMENT DOES

NOT CHANGE THE ACTUAL PRODUCT

TEMPERATURE. PRODUCT TEMPERATURE

REMAINS AT A VERY STABLE

TEMPERATURE.

LIGHT SWITCH AND BULB

Your Three-Door

Freezer/Refrigerator/Refrigerator has three

interior lights that are illuminated when each

respective door is opened. The cabinet also

comes standard with a manual light switches

located next to each light for displaying your

products through a glass door. If manual light

switch is left on for an extended period of time it

may increase the cabinet temperature,

especially in close proximity to the light at the

top and cause the refrigeration system to run

longer.

THREE DOOR

FREEZER/REFRIGERATOR/ WINE

COOLER OPERATION

The Perlick Three Door

Freezer/Refrigerator/Wine Cooler (H3FRW)

comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically

changes speeds based on system conditions

and load. The cabinet is equipped with three

adjustable digital temperature controllers and

LED displays. The freezer controller can be

adjusted through a range of -10 F to +10 F.

The freezer controller has been factory set to

modulate from -3 F to +5 F. The refrigerator

controller can be adjusted through a range of

30 F to 42 F. The refrigerator controller has

www.bringperlickhome.com

28

Page 28

been factory set to modulate from 37 F to 39 F.

The wine cooler controller can be adjusted

through a range of 50 F to 60 F. The refrigerator

controller has been factory set to modulate from

54 F to 56 F. To properly determine product

temperature see “CHECKING PRODUCT

TEMPERATURE” on page 44.

IMPORTANT NOTE: ALWAYS ALLOW

CABINET TO RUN FOR A MINIMUM OF 24

HOURS TO ALLOW TEMPERATURE

STABILIZATION AFTER START-UP BEFORE

STORING PERISHABLE ITEMS.

IMPORTANT NOTE: PERLCK’S MULTI-ZONE

UNITS ARE NOT DESIGNED FOR OUTDOOR

APPLICATIONS. INSTALLING MULTI-ZONE

UNITS OUTDOORS WILL VOID THE

WARRANTY.

This cabinet is a frost-free model meaning the

evaporator (cooling coil) automatically defrosts

on demand at predetermined intervals. The

controller also has a manual defrost soft button

on the front panel signified by a melting

snowflake. If depressed it will automatically put

the system into a defrost cycle.

PROPER PRODUCT STORAGE

Store product as desired in the freezer and

refrigerator. The wine cooler zone will

accommodate 48 bottles of wine. Specially

designed full extension wine racks allow for

proper horizontal storage of the wine. The cork

remains moist, which keeps air from entering the

bottle. Do not block internal louvers or fan guard

openings, as this will decrease operating

performance.

CONTROL SETTINGS

The cabinet is shipped with the controllers

turned ON. To turn the refrigeration system OFF

or ON press the blue soft button on the front

face of the freezer controller (if the controller is

turned off with power applied to the cabinet the

LED display will read OFF, when turned on it will

read a temperature). The freezer controller is on

the top front face of the cabinet above the left

door and is equipped with a tinted see-through

lens which opens by pulling out on the bottom of

the lens and rotating upwards. Always ensure

lens cover is closed before closing door to avoid

damage to the controller or lens. The refrigerator

control looks and responds identical to the

freezer control with the exception that it only

controls the cooling system for the refrigerator

zone and is located above the center door.

The freezer electronic control comes preset for a

product temperature of approximately 0 F with a

product temperature adjustability range of -5 F

to +5 F. The refrigerator electronic control

comes preset for a product temperature of

approximately 38 F with a product temperature

adjustability range of 33 F to 42 F. The wine

cooler electronic control comes preset for a

product temperature of approximately 55 F with

a product temperature adjustability range of

50 F to 60 F. To change temperature controller

settings see section “TEMPERATURE

CONTROLLER ADJUSTMENTS” on page 42.

IMPORTANT NOTE: THE LED DISPLAY IS

READING ACTUAL AIR TEMPERATURE NOT

PRODUCT TEMPERATURE. UNDER THESE

CONDITIONS, AN 8 F AIR TEMPERATURE

SWING IN THE FREEZER COMPARTMENT

AND A 2 F AIR TEMPERATURE SWING IN

THE REFRIGERATOR OR WINE COOLER

COMPARTMENT DOES NOT CHANGE THE

ACTUAL PRODUCT TEMPERATURE.

PRODUCT TEMPERATURE REMAINS AT A

VERY STABLE TEMPERATURE.

LIGHT SWITCH AND BULB

Your Three-Door Freezer/Refrigerator/Wine

Cooler has three interior lights that are

illuminated when each respective door is

opened. The cabinet also comes standard with

a manual light switches located next to each

light for displaying your products through a glass

door. If manual light switch is left on for an

extended period of time it may increase the

cabinet temperature, especially in close

proximity to the light at the top and cause the

refrigeration system to run longer.

THREE DOOR ALL-

REFRIGERATOR

OPERATION

The Perlick Three Door All-Refrigerator

(H3ROO) comes equipped with a state of the art

refrigeration system. The compressor is of a

variable speed variety, which automatically