Page 1

PKD24A

INSTALLATION & OPERATION

Rev. 11.09

800- 5 5 8 - 5592

F A X 4 1 4 - 353- 7069

P e r l i c k C o r p o r a t i o n

8 3 0 0 W G o o d H o p e R d

Owner’s Manual

Keep with machine for reference

perlick.com

Page 2

TABLE OF CONTENTS

PERLICK PKD24A

1. SPECIFICATIONS ................................................................................................... 2

1.1. PKD24A .............................................................................................. ERROR! BOOKMARK NOT DEFINED.

1.2. PKD24A OPERATIONAL CYCLE .............................................................................................................. 3

2. GETTING STARTED ............................................................................................... 5

2.1. INTRODUCTION TO THE PKD24A ............................................................................................................ 5

2.2. RECEIVING AND INSTALLATION ............................................................................................................... 6

2.2.1. Electrical ................................................................................................................................. 6

2.2.2. Plumbing ................................................................................................................................. 6

2.2.3. Post Instructions ..................................................................................................................... 6

2.2.4. Installers Checklist .................................................................................................................. 7

3. OPERATION ......................................................................................................... 8

3.1. INITIAL SETUP ..................................................................................................................................... 8

3.1.1. Check… .................................................................................................................................... 8

3.1.2. Chemicals ................................................................................................................................ 8

3.1.3. Filling the Machine ................................................................................................................. 8

3.2. GENERAL ........................................................................................................................................... 8

3.2.1. Pre-Scrapping .......................................................................................................................... 8

3.2.2. Proper Chemical Dosage ......................................................................................................... 8

3.2.3. Proper Filling ........................................................................................................................... 9

3.2.4. Water Pump ............................................................................................................................ 9

3.2.5. Pump Cavitation ..................................................................................................................... 9

4. MAINTENANCE .................................................................................................. 10

4.1. TIMER ASSEMBLY ............................................................................................................................... 10

4.1.1. Cam Adjustment ................................................................................................................... 10

4.2. QUICK SERVICE GUIDE ......................................................................................................................... 11

4.3. TROUBLESHOOTING............................................................................................................................ 11

5. ADDENDUM FOR MACHINES INSTALLED IN THE CITY OF CHICAGO ...................... 15

APPENDIX A: OPERATOR & CLEANING INSTRUCTIONS ............................................... 16

6. ELECTRICAL DIAGRAM ........................................................................................ 17

Page 3

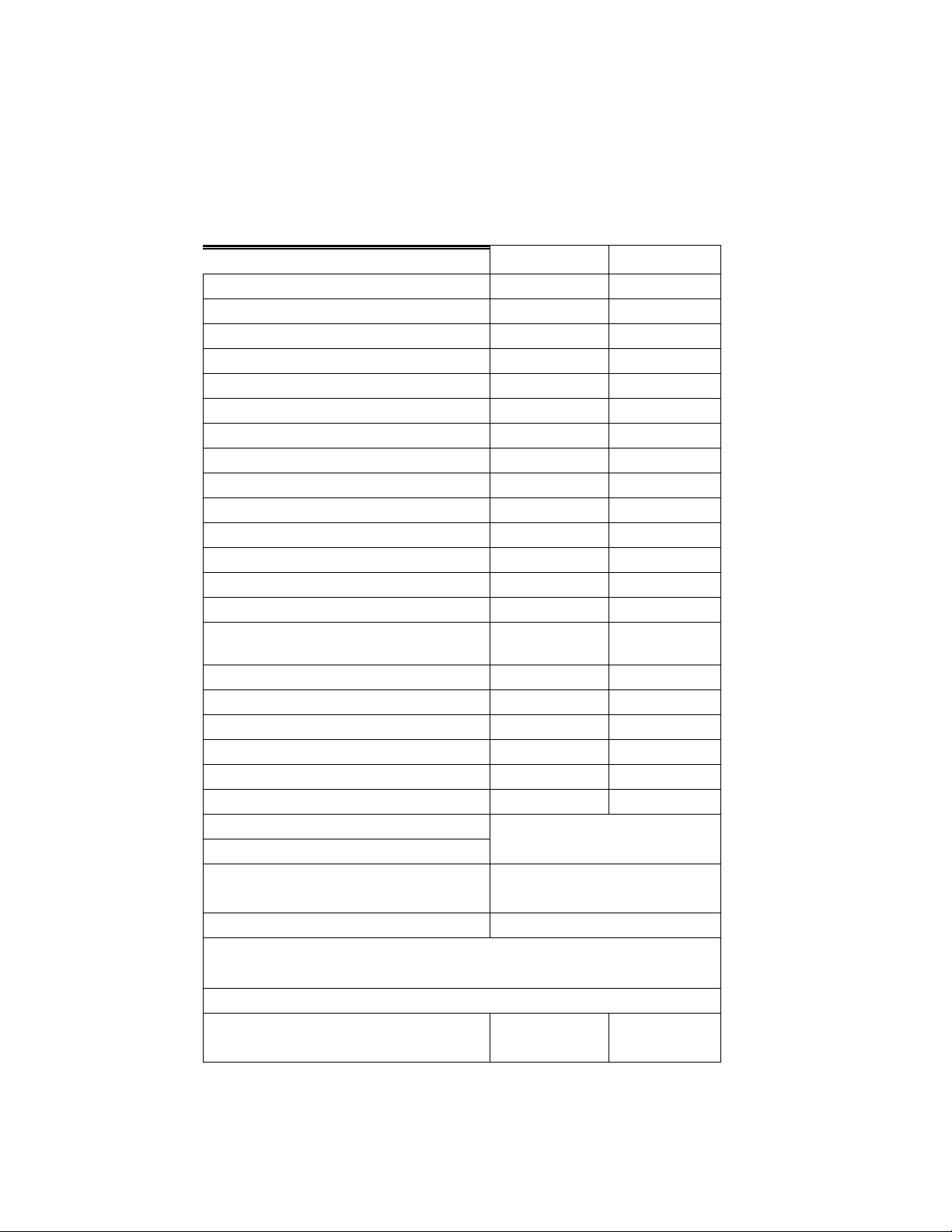

2

WATER CONSUMPTION

PER RACK

1.7 GAL.

6.44 L

PER HOUR

40.8 GAL.

154.4 L

OPERATING CYCLE

WASH TIME-SEC

57

57

RINSE TIME-SEC

48

48

DWELL TIME-SEC

15

15

TOTAL CYCLE

2 MIN.

2 MIN.

OPERATING CAPACITY

RACKS PER HOUR

30

30

WASH TANK CAPACITY

1.7 GAL.

6.44 L

PUMP CAPACITY

35 GPM

132.5 LPM

WATER REQUIREMENTS

140°F

60°C

WATER INLET

½”

1.27 cm

DRAIN CONNECTION

1”

2.54 cm

CYCLE

TEMPERATURES(recommended)

140°F

60°C

WASH-°F (Min)

120°F

52°C

FRAME DIMENSIONS

DEPTH

24 3/4”

63 cm

WIDTH

24”

61 cm

HEIGHT (34 ¾”), with legs adjusted

39”-40 1/8”

99-102 cm

MAX CLEARANCE FOR GLASSES

11 ¼”

28.57cm

ELECTRICAL*

115 VAC

16 AMPS

SUSTAINER HEATER

(Not Booster Heater)

1.25 kW

WASH PUMP MOTOR

13.4 AMPS

*MUST CONNECT TO DEDICATED 20 AMP SUPPLY CIRCUIT.

COMPLIANCE WITH LOCAL ELECTRICAL CODES MUST BE FOLLOWED.

SHIPPING WEIGHT

PKD24A (Approximate)

244#

110.6 kg

METRIC

EQUIVALENT

1. Specifications

1.1. PDK24A

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 Page

Page 4

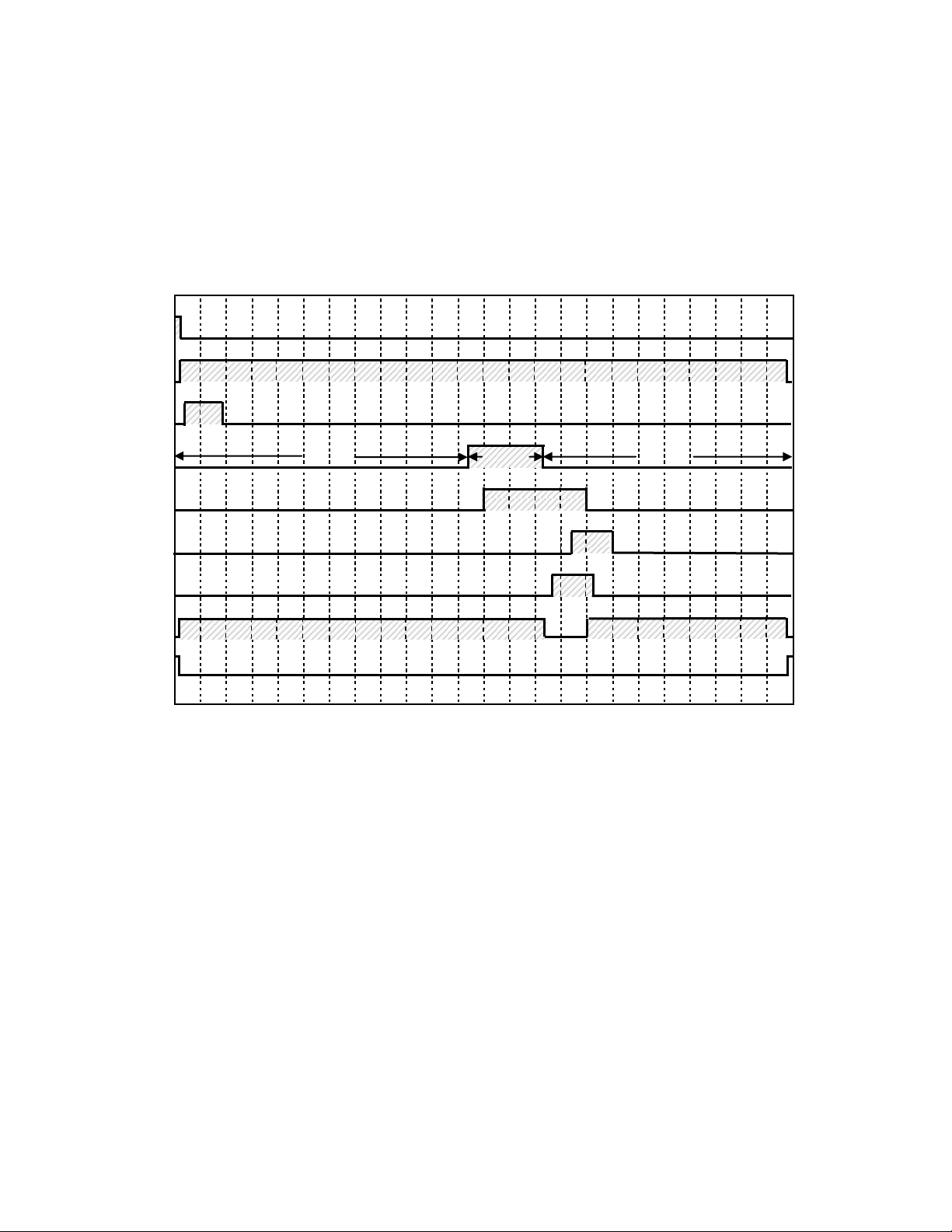

3

Start/Stop

Detergent

Drain/Rack

Counter

Flush/Fill

Sanitizer

Rinse

Pump Motor

Heater*

WASH

RINSE

DRAIN

Instant

Start Relay

Cam 1

Cam 2

Cam 3

Cam 4

Cam 5

Cam 6

Cam 7

Cam 8

1.2. PKD24A Operational Cycle

The PDK24A Operational Cycle has a total cycle time of 2 minutes (120 seconds). The

Timing Diagram and the steps listed below detail the individual functions that are

executed during each Operational Cycle.

Seconds: 0 10 20 30 40 50 60 70 80 90 100 110 120

1. With the machine powered on, toggling the START switch begins a cycle.

a) Toggling the START switch energizes both the cam timer motor and the instant

start relay. The instant start relay latches ON the power to the cam timer motor so

that the START switch can be released a moment after it has been toggled without

the cam timer motor losing power.

b) After about 2 seconds, Cam 1—the Start cam—latches ON the power to the cam

timer motor and drops out the instant start relay. The cam timer motor continues to

run for a total of 2 minutes, at which time it switches OFF—resetting the cam

timer—and waits for the next start command.

2. Cam switch 7 controls the pump motor. The pump motor comes ON at the beginning

of the operational cycle and continues to run until the end of the drain function

(controlled by cam switch 3), at which time it turns off for about eight seconds

allowing time for the machine to refill enough to avoid running the pump dry before

the pump motor restarts and runs to the completion of the operational cycle.

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 5

4

The pump motor runs the pump for the 57-second wash cycle, then pumps the water

out through the drain, turns off for about 8 seconds (allowing the machine to refill with

clean rinse water) and then runs the pump for the 48-second rinse cycle.

3. Cam switch 3 controls the drain function. At the end of the 57-second wash cycle, cam

switch 3 energizes the drain valve solenoid allowing the pump motor to drain the wash

water out of the machine. Cam switch 3 also increments the rack counter by one each

cycle.

4. Cam switch 4 controls the water valve solenoid on the water supply to flush and fill

the machine. At the end of the wash cycle the drain valve is opened, the pump motor

continues to run (to pump the wash water out through the drain), and the Flush

function begins. At first, flushing the machine because the drain valve is still open,

then—with the drain valve closed and the pump motor stopped— the machine begins

to fill for the rinse cycle. Once the machine has refilled sufficiently, the pump motor

restarts carrying out the rinse portion of the cycle as the filling of the wash tank

completes.

5. Cam switch 2 controls the detergent pump and turns ON about 5 seconds after the

operational cycle is started and runs for a few seconds to provide sufficient detergent

for the wash cycle. This cam can be adjusted as necessary for proper detergent dosage.

See section 4.1.1 Cam Adjustment

6. Cam switches 5 and 6 control the sanitizer and rinse pumps respectively. They turn

ON at the beginning of the rinse cycle and run for a few seconds to provide sufficient

sanitizer and rinse aid for the rinse cycle. These cams can be adjusted as necessary for

proper chemical dosage. See section 4.1.1 Cam Adjustment

7. Cam switch 8 operates the sustainer heater. This cam assures that the sustainer heater

only turns on when the dishmachine is not in a cycle. This prevents the machine from

drawing too much electrical current at any one time.

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 6

Getting Started

5

2. Getting Started

2.1. Introduction to the PKD24A

The PKD24A Glasswasher is unique in its field; it has all the features of a standard commercial

size machine packed into an under-counter, standalone glasswasher.

Operation of the PKD24A is extremely easy. After initially filling the machine (see section 3.1.3

Filling the Machine), pressing the rocker Fill/Start switch to the “START” position begins the

operation cycle, which runs automatically.

To reduce service time, all electrical components are mounted in a sliding drawer for easy access.

This “Works-In-A-Drawer” can be removed by disconnecting wires on power block.

The only external connections necessary are the power source, water supply and drainpipe.

The optional sustainer heater with thermostat is extremely practical for maintaining wash tank

temperature between cycles. The 1250-watt heater will hold the wash tank temperature between

130°F and 140°F when machine is not in operation.

The supply water to the PKD24A must be a minimum of 140°F. The pipe supplying the water must

be ½” minimum. The plumbing connection is located at the back of the machine. The drain is a 1"

NPT fitting located at the back of the machine for easy attachment of your drain hose. See section

2.2.2 Plumbing.

This manual is structured to provide a complete reference guide to the PKD24A. It is presented in

a manner that all users will be able to comprehend and use as an effective tool in supporting the

installation, operation and maintenance of the glasswasher. The first section provides the

specifications and details of the operational cycle. The next section explains how the machine is

packaged and what to look for when receiving the machine. After unpacking the machine, this

manual explains how to install and set up the machine for use. Requirements are given for

plumbing, wiring, and space considerations. Our well-trained sales representatives prior to the

order being placed always take these attributes of the machine into consideration. In the manual,

guidance is also given for operation to ensure that the machine will be able to run optimally.

The Operation section of the manual may be used for instruction and procedures when required.

We make this portion of the manual easy to understand so that all levels of operators may be able

to read and comprehend the operation of the machine. The function of the machine itself is mostly

automatic and takes little training to put into full operation. The Operation section also includes

diagnostic considerations for the machine if problems occur.

The Maintenance section of the manual is for qualified personnel and provides trouble shooting

procedures and specific maintenance instructions.

The final section of the manual is the Parts Manual. This section has the parts lists and wiring

diagram for the machine.

Perlick warranties the workmanship of the machine.

At Perlick we are committed to providing the best machines and customer service in the food and

beverage industry and your feedback is welcome. The Q.C. form found in each machine has a

section, which we encourage you to fill out for feed back regarding the equipment.

MODEL PDK24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 7

Getting Started

6

2.2. Receiving and Installation

The glasswasher is shipped from the factory in a corrugated box on a wooden pallet. The

installation guidelines give a systematic procedure for setting up the machine.

1. Start by removing the box and packaging material. Check for the following component parts:

A. Drain Screen:

The Wash Tank Scrap Screen is shipped inside the wash cavity of the machine. This

screen must be in place during operation. It has been designed to perform two basic

functions:

Strain water that is circulating through the spray arms and pump assembly.

A basket to catch heavy solids or broken glass that could plug the pump.

B. Spray Arms

The end caps on the spray arms have been caped to protect them in shipping. Remove

the cap from the spray arms.

C. Tube Stiffeners:

The tube stiffeners must be used to prevent the feed tubes from curling up inside the

chemical pail allowing the tip to rise out of the chemical. Remove the tie-wraps securing

the tube stiffeners to the dishmachine to free them up for use.

2. Set the machine in place and, using the leg adjusters, level from side-to-side and front-to-back

(VERY IMPORTANT).

2.2.1. Electrical*

A 20-amp, 115 volt, 60 Hz dedicated circuit must be used to supply electrical power to the

PKD24A machine (see specification sheet page 2). The power connection must be such that there

is sufficient length of flexible conduit to permit the machine to be moved for cleaning.

2.2.2. Plumbing*

The machine is equipped with a gate valve with a ½” female NPT connection located at the lower

left-hand corner (facing the back) of the machine. A 140°F water line should be plumbed to this

point. The water line used must be of sufficient length and flexibility to permit the machine to be

moved for cleaning.

A 1” male NPT fitting is provided for the drain connection on the discharge port of the diverter

valve (lower, right-hand corner of machine). This fitting may be removed and user provided

hardware might be used if necessary to facilitate compliance with local plumbing codes. Code

requires that the drain discharge provide an air gap no less than 1” or two pipe diameters;

whichever is greater, above the flood level rim of an approved floor drain.

2.2.3. Post Instructions

Mount the wall chart provided where it can be easily viewed and instruct the operators on proper

cleaning and operation of the PKD24A. The instruction chart is also provided as an appendix to

this manual (see appendix 1).

*

Electrical and plumbing connections must be made by a qualified person who will comply with all

available Federal, State, and Local Health, Electrical, Plumbing and Safety codes

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 8

Getting Started

7

2.2.4. Installers Checklist

Glasswasher checked for concealed damage

Hot water supply is recommended 140° F (60 C)

Incoming water supply line is ½” minimum

Supply circuit breaker for machine is properly sized (20 amp)

Service voltage and phase type are correct to machine data plate

Drain hose is installed with adequate air gap

Glasswasher is properly grounded

Glasswasher is properly leveled

Machine circuit breaker is labeled “GLASSWASHER”

Machine has been connected with correctly sized wire (To handle 20

amp)

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 9

8

3. Operation

3.1. Initial Setup

3.1.1. Check…

Drain screen is in place

Spay arms and end plugs are secure

3.1.2. Chemicals

Assure there is a sufficient supply of chemicals before beginning a shift.

3.1.3. Filling the Machine

With the power ON, press and hold the Fill/Start switch in the “FILL” position

until the water level in the wash tank is about 1” deep, for best results use

water level indicator located at the back of the wash tank.

3.2. General

Caution: Do not operate the dishmachine without the drain screen in place. Debris

getting into the pump impeller can damage the pump.

1. Load a rack of glass into the machine and close the door.

2. With the machine filled to the proper level, press rocker Fill/Start switch to the

“START” position – the machine will automatically begin its cycle. The green running

light on the switch will illuminate while an operational cycle is in process.

3. At the end of the shift, drain the machine by holding the Drain rocker switch in the

“DRAIN” position until the machine is completely drained. To avoid running the pump

dry, do not hold the Drain rocker switch in the “DRAIN” position any longer than

necessary.

4. Remove and clean the drain screen. Remove and clean the spray arms. (See wall

chart instructions).

5. Replace the drain screen and spray arms.

3.2.1. Pre-Scrapping

It is essential that the operator thoroughly understand the importance of pre-scrapping the

glasses before loading them. The PKD24A is equipped with a removable drain screen.

The drain screen can be easily removed for cleaning between Operational Cycles of the

dishmachine. Properly pre-scrapping the glasses should permit the glasswasher to

operate for an entire shift before needing to remove and clean the drain screen.

3.2.2. Proper Chemical Dosage

The amount of chemical delivered, whether it is detergent, sanitizer or rinse aid, is

determined by its respective cam on the cam timer.

Cam number 2 runs the detergent pump

Cam number 5 runs the sanitizer pump

Cam number 6 runs the rinse aid pump

These cams were set at the factory but must be adjusted after final installation to

maximize efficiency of chemical use (see section 4.1.1 Cam Adjustment.)

Operation

MODEL PDK24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 10

Operation

9

3.2.3. Proper Filling

The number 4 cam determines the amount the machine is automatically filled each cycle.

When the number 4-cam switch actuator rides down into the cam groove, the solenoid

valve on the fill line is energized causing the machine to fill. Since the cam only controls

the duration of the fill, varying water pressure can vary the amount the machine fills. If the

water pressure at the facility where the machine is installed is higher or lower than the

water pressure was at the factory, the number 4 cam may need to be adjusted to correct

the difference (see section 4.1.1 Cam Adjustment). The machine should be filling to a

level about 1” deep over the entire bottom of the wash tank, or just below the lower wash

arm. If the water pressure at the facility varies throughout the day, a pressure regulator

may have to be installed on the water supply line to the machine to maintain constant

pressure.

Note: The tank must be properly filled, and the machine properly leveled, or the float

switch, which prevents the heater from turning on if the level is too low, will not permit the

heater to turn on.

3.2.4. Water Pump

The water pump takes in water from the drain sump and pumps it to the spray nozzles at a

rate of 35 gallons per minute and a pressure at the nozzles of approximately 7 to 10 PSI.

After being released through the spray arms and washing or rinsing the dishes, the water

runs down the pan to the sump, through drain screen, and back to the pump.

A 115-volt, 1 HP motor operating at 3450 RPM, drives the pump. The impeller is mounted

with a right-hand thread onto a 5/8” stainless steel shaft, which is coupled to the motor

armature shaft.

3.2.5. Pump Cavitation

By listening to the normal pumping sound of the motor it can be determined if there is

insufficient water in the machine, as you will hear a hesitation in the normal pumping

rhythm, which is created by the air getting into the pump. Cam 4 can be adjusted to

increase the amount of water that is automatically fed into the machine during a cycle (see

section 4.1.1 Cam Adjustment).

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 11

10

HEATER

MOTOR

PAUSE

RINSESANI.FLUSHDRAINDET.START

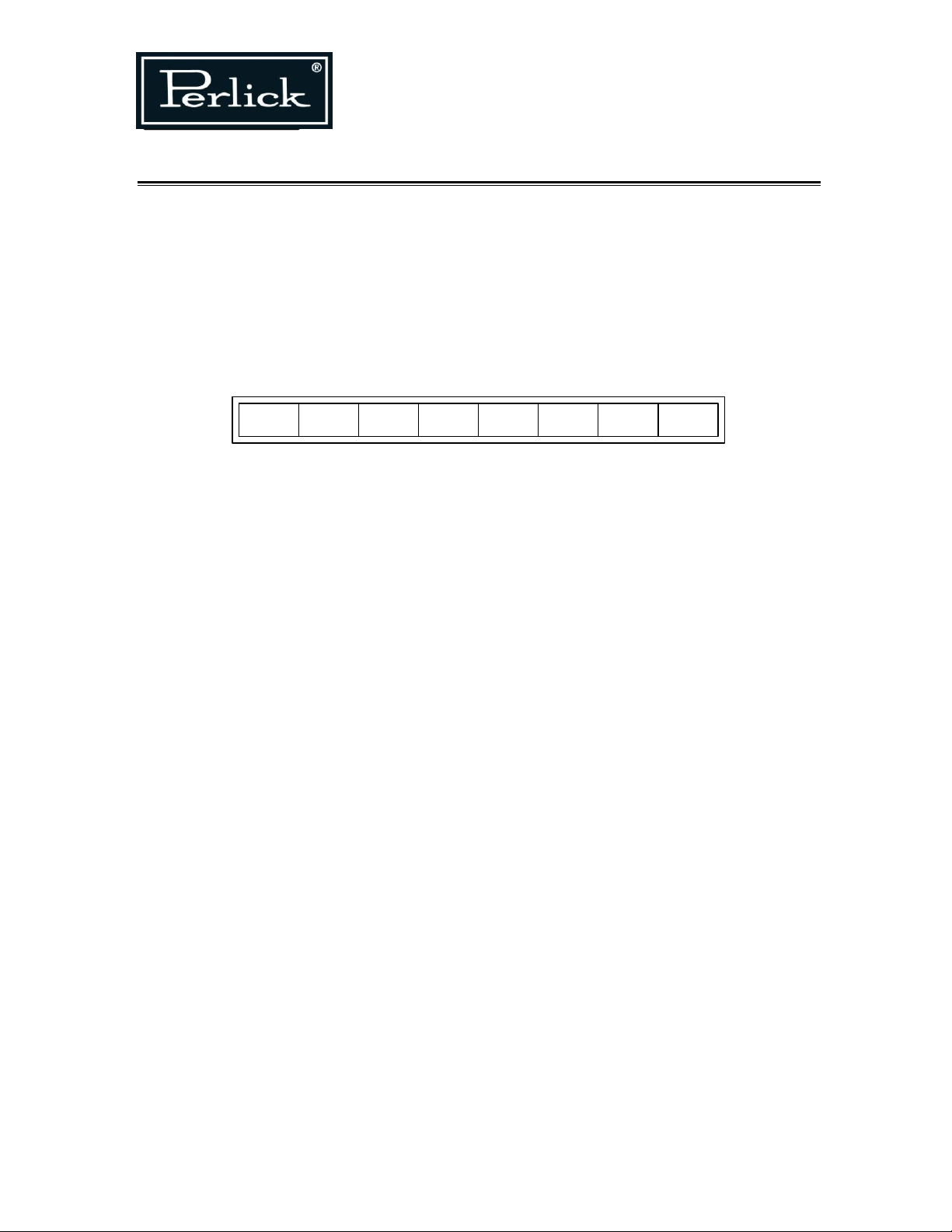

Maintenance

4. Maintenance

The maintenance procedures detailed in this section are to be performed by qualified personnel.

4.1. Timer assembly

The standard timer assembly consists of a (2 minutes per revolution) motor turning a common

shaft, which, in turn, rotates eight cams. As the cams rotate, they control various functions and the

sequence of the operational cycle.

A label on the timer assembly identifies the individual function of each of the 8 cams. Cams 1

through 8 are positioned from left to right beginning with the “START” cam (cam 1).

Timer Assembly Label

Except for cams 1, and 3, all other cams can be user adjusted. The cam positions are all set at the

factory and only the cams controlling the chemical pumps (cams 2, 5 & 6) should ever need

adjusting. Each micro switch on the timer assembly is turned on and off by the cam its actuator

rides on. For all of the cams, except cams 1, 7 and 8, its corresponding switch is ON when its

actuator is down in the cam groove. (Cams 1, 7 and 8 are reverse acting and are turned ON when

the micro switch actuator is up out of the groove.) Opening the groove of any cam other than cams

1, 7 or 8 will increase the amount of time that the micro switch is held ON. The cams are slip-fit

and a cam adjustment wrench is provided (a small screw driver or the edge of a table knife can

also work to adjust the cams).

4.1.1. Cam Adjustment

The two sides of each cam connect to the shaft with a slip-fit so all cam adjustments are

made by rotating one side of the cam on the shaft to either increase or decrease the size

of the cam groove.

1. Turn off the circuit breaker providing power to the machine before accessing the timer

assembly.

Caution: One of the terminals on the main power switch remains “hot” even when the

machine’s main power switch is turned off—so turn the power off at the circuit

breaker.

2. Remove the two screws securing the front lower panel.

3. Using the timer assembly label, determine which cam is to be adjusted. Double check

by counting over from cam 1 to the cam to be adjusted.

4. Determine which edge of the cam groove to be adjusted is the leading edge (contacts

the limit switch actuator first when the shaft is rotating) and which edge of the groove

is the trailing edge. The leading edge of the cam groove determines when in the cycle

the control action begins and should not be changed.

5. Adjust the trailing edge of the cam groove by rotating the appropriate side of the cam

in the proper direction to either increase or decrease the cam’s groove; resulting in

increasing or decreasing the total time that switch will be held ON.

MODEL PDK24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 12

11

4.2. Quick service guide

PROBLEM

LIKELY CAUSE

SOLUTION

MODELS: GLX

TECHNICAL ISSUE

CAUSE

SOLUTION

Delimer switch in delime position

Flip to

NORMAL

position

Wash Pump motor will not shut off

Faulty delimer switch

Replace switch, P/N 00475.30

Faulty manual drain switch

Replace switch, P/N 03406.62

Faulty contactor

Replace contactor, P/N 00404.82

Continues cycles

Faulty #1 micro switch (start/stop)

Replace switch, P/N 00411.00

Faulty start/fill switch

Replace switch, P/N 03470.01

Faulty #1 micro switch

Replace switch, P/N 00411.00

Low water level inside machine

Add water to tank to activate float switch, adjust

water cam on timer

Sustainer heater not working

Faulty float switch

Replace switch, P/N 13463.10

Machine not level

Level machine

Faulty ice cube relay

Replace relay, P/N 00631.00

Machine does not drain

Faulty #3 micro switch (drain)

Replace switch, P/N 00411.00

Faulty drain valve

Replace drain valve, P/N 04103.00

Does not hold water

Faulty #3 micro switch (drain)

Replace switch, P/N 00411.00

Clogged or defective drain valve

Clean and/ or replace drain valve, P/N 04103.00

Tank overflows overnight

Debris in water Solenoid Valve

Clean and replace valve diaphragm, P/N

00707.00

Water leaks out of Vacuum Breaker

Dirty or defective vacuum breaker kit

assy

Clean or replace internal parts, P/N 03623.00

Faulty check valve

Replace check valve, P/N 00715.00

Male/ female plug on the back of control

drawer is loose

Secure plug

Wash Pump motor not running

Faulty door reed switch

Replace reed switch, P/N 00557.55

Faulty 7th micro switch

Replace switch, P/N 00411.00

Faulty motor contactor

Replace contactor, P/N 00404.82

Faulty Start/Fill Switch

Replace switch, P/N 03470.01

Timer does not rotate

Faulty #1 micro switch

Replace switch, P/N 00411.00

Faulty timer motor

Replace motor assembly, P/N 00501.00

Faulty #4 Micro switch

Replace switch, P/N 00411.00

Machine does not fill

Debris inside water solenoid valve or

Faulty valve

Clean and replace valve diaphragm, P/N

00707.00

Faulty water solenoid coil

Replace solenoid coil, P/N 00738.10

Delimer switch in wrong position

Switch to

NORMAL

position

Sanitizer pump does not run

Faulty 5th micro switch

Replace switch, P/N 00411.00

Faulty sanitizer pump motor

Replace motor, P/N 00416.00

0204

4.3. Troubleshooting

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Maintenance

Page 13

Maintenance

12

PROBLEM

LIKELY CAUSE

SOLUTION

Machine inoperative

Power off at circuit breaker

Reset circuit breaker

Defective power switch

Replace power switch

P/N: 00433.10

Defective timer assembly motor

Replace timer assembly motor

P/N: 00501.00

Pump Motor inoperative

Door is open

Close door

Control drawer is pulled out

Secure control drawer

Defective reed (door) switch

Replace reed (door) switch

P/N: 00557.55

Defective timer assembly

(Cam 7)

Replace timer assembly*

P/N: 00408.80

Defective pump motor contactor

Replace contactor

P/N: 00404.82

Defective pump motor

Replace pump motor

P/N: 00201.00

Pump Motor runs with door

open

Defective reed (door) switch

Replace reed (door) switch

P/N: 00557.55

Defective pump motor contactor

Replace contactor

P/N: 00404.82

Delime switch is on

Turn off delime switch

Motor runs continuously

Delime switch is on

Turn off delime switch

Sustainer Heater

Defective thermostat on heater

Replace heater

P/N: 04109.10

Defective heater relay

Replace heater relay

P/N: 00631.00

Defective timer assembly

(Cam 8)

Replace timer assembly *

P/N: 00408.80

Defective heater

Replace heater

P/N: 04109.10

Defective float switch

Replace float switch

P/N: 13463.00

Float switch not actuated

Fill wash tank completely

Level machine

Sustainer Heater

Defective thermostat on heater

Replace heater

P/N: 04109.10

Defective timer assembly

(Cam 8)

Replace timer assembly *

P/N: 00408.80

Defective heater relay

Replace heater relay

P/N: 00631.00

*The timer assembly motor (P/N: 00501.00) or micro switches (P/N: 00411.00) can be replaced

independently if that is the only component that has failed.

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 14

Maintenance

13

PROBLEM

LIKELY CAUSE

SOLUTION

Low heat during operation

Low incoming water temperature

(below 140° F)

Turn up supply water heater

Insulate supply water pipe

Thermostat out of adjustment

Adjust thermostat

Defective sustainer heater

Replace heater

P/N: 04109.10

Low spray arm water flow

Limed up spray arm nozzles

De-lime spray arm nozzles

With power on, activating

start switch does not begin

cycle

Defective fill/start switch (cycle

light will not light either)

Replace fill/start switch

P/N: 03470.01

Defective timer assembly

(Cam 1)

Replace timer assembly*

P/N: 00408.80

Start switch requires more

than 1-second activation to

run cycle

Defective (Instant Start) ice cube

relay

Replace ice cube relay

P/N: 00631.00

Activating fill switch does

not fill machine

Defective fill/start switch

Replace fill/start switch

P/N: 03470.01

Defective water solenoid valve

Replace water solenoid valve

P/N: 03603.10

Fill water won’t shut off

Defective water solenoid valve

Replace water solenoid valve

P/N: 03603.10

Defective fill/start switch

Replace fill/start switch

P/N: 03470.01

Defective timer assembly

(Cam 4)

Replace timer assembly*

P/N: 00408.80

Activating drain switch

does not drain machine

Drain hose is kinked

Un-kink drain hose

Defective drain switch

Replace drain switch

P/N: 03406.64

Defective drain valve motor

(Pump will still run)

Replace drain valve motor

P/N: 04103.21

Detergent pump does not

run

Defective detergent pump motor

Replace pump motor

P/N: 00416.00

Defective timer assembly

(Cam 2)

Replace timer assembly*

P/N: 00408.80

Sani pump does not run

Defective sani pump motor

Replace pump motor

P/N: 00416.00

Defective timer assembly

(Cam 5)

Replace timer assembly*

P/N: 00408.80

*The timer assembly motor (P/N: 00501.00) or micro switches (P/N: 00411.00) can be replaced

independently if that is the only component that has failed.

Rinse pump does not run

Defective rinse pump motor

Replace pump motor

P/N: 00416.00

Defective timer assembly

(Cam 6)

Replace timer assembly*

P/N: 00408.80

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 15

Maintenance

14

PROBLEM

LIKELY CAUSE

SOLUTION

Activating detergent primer

switch does not run pump

Defective sani/detergent primer

switch

Replace primer switch

P/N: 03470.00

Defective detergent pump motor

Replace pump motor

P/N: 00416.00

Activating sani primer

switch does not run pump

Defective sani/detergent primer

switch

Replace primer switch

P/N: 03470.00

Defective sani pump motor

Replace pump motor

P/N: 00416.00

Activating rinse primer

switch does not run pump

Defective rinse primer switch

Replace primer switch

P/N: 03470.00

Defective rinse pump motor

Replace pump motor

P/N: 00416.00

Counter does not

increment

Defective counter

Replace counter

P/N: 03408.50

Defective timer assembly

(Cam 3)

Replace timer assembly*

P/N: 00408.80

Running light does not

light while cycle runs

Defective cycle light

Replace running light (green)

P/N: 00476.00

Power light does not light

but machine runs

Defective power light

Replace power light (red)

P/N: 00406.00

Wash tank temperature

gauge displays wrong

temperature

Defective temperature gauge

Replace temperature gauge

P/N: 03202.00

Delime switch does not

activate pump motor

Defective delime switch

Replace delime switch

P/N: 00475.30

Defective pump motor

Replace pump motor

P/N: 00201.00

*The timer assembly motor (P/N: 00501.00) or micro switches (P/N: 00411.00) can be replaced

independently if that is the only component that has failed.

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 16

Addendum

15

5. Addendum for Machines Installed in the City of Chicago

“All food dispensing establishments using chlorine or other approved chemical sanitizers shall, at all

times, maintain an adequate testing device.”

“Dishes and other eating and drinking utensils to be washed in a dishwashing machine shall be

properly scraped and pre-rinsed and shall be stacked in racks or trays so as to avoid overcrowding,

and so as to permit the wash and rinse waters to reach all surfaces of each utensil.”

“In machine washing, multi-use eating and drinking utensils shall be washed in water containing a

suitable detergent at a temperature of 120 F to 140 F or other method approved by the Department

of Health.”

“The water in the wash tank shall be changed during operation as often as is necessary to keep it

reasonably clean. An effective concentration of detergent in the wash water shall be maintained at

all times.”

“Bactericidal treatment shall consist of exposure of all surfaces of dishes and utensils being washed

to a rinse of clean water, at a temperature of not less than 180 F or other method approved by the

Department of Health.”

“All dishwashing machines shall maintain a flow pressure not less than 15 or more than 25

pounds per square inch on the fresh water line at the machine and not less than 10 pounds per

square inch at the rinse nozzles. A suitable gauge cock shall be provided immediately upstream

from the final rinse sprays to permit checking the flow of the final rinse water. An easily readable

thermometer accurate to a 2 F. shall be provided on both the wash and rinse water lines of the

dishwashing machine which will indicate the temperature of the water solution there in.”

“Dishwashing machines shall be thoroughly cleaned at least once each day. The pumps and the

wash and rinse sprays or jets shall be so designed that a forceful stream of water will reach all

surfaces of the utensils when they are properly racked. These parts shall be thoroughly cleaned at

least once each day. The pumps and the wash and rinse sprays or jets shall be designed that a

forceful stream of water will reach all surfaces of the utensils when they are properly racked. These

pars shall be readily accessible for inspection and cleaning.

“After bactericidal treatment, utensils and containers shall be stored at a sufficient height above the

floor in a clean, dry place, protected from flies, splash, dust, overhead leakage and condensation,

and other contamination. Containers and utensils shall be inverted, covered, or otherwise protected

from contamination until used for serving.”

Drain racks, trays and shelves shall be made of non-corrodible material and shall be kept clean. In

handling containers and utensils the surfaces thereof which come in contact with food or drink shall

not be touched by the hands, except during the process of washing. Tables for clean and dirty

dishes and food shall be so arranged that the dirty dishes will be as far removed from the food and

clean dishes as may be possible.

All single service articles and utensils shall be purchased in sanitary cartons and stored in a clean,

dry place until used, and after removal from the cartons, these articles shall be handled in such a

manner as to prevent contamination.

Please note the following procedures must be followed for City of Chicago Approval:

1. All low energy models must have low-level sani-alarms, both visual and audio.

2. All models must have a City of Chicago approval data label affixed to the machine.

3. Chlorine sanitizer must be a minimum of 100 PPM.

MODEL PDK24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 17

16

Appendix A: Operator & Cleaning Instructions

MODEL PDK24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 18

Electrical Diagram

17

6. Electrical Diagram

MODEL PDK24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Page 19

Electrical Diagram

18

PKD24A INSTALLATION & OPERATION MANUAL Rev. 11.09 PAGE

Loading...

Loading...