Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

PERLICK BATCH ROTARY GLASSWASHERS

PKBR24L

PKBR24

IMPORTANT INFORMATION

This manual has been prepared to assist you

in the operation of the Perlick Batch Rotary

Glasswasher.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can

provide you with a list of qualified service agents. For

your own protection, never return merchandise for

credit without our approval.

We thank you for selecting a Perlick product and

assure you of our continuing interest in your

satisfaction.

MODEL NOS.

■ PKBR24

■ PKBR24L

■ PKBR24R

Table of Contents

Warranty Information ........................................ 2

Specifications .................................................... 3

Chemical Specifications

Water Conditioning

Chemical Concentrations

Start-Up Procedures

Before Starting the Glasswasher

Starting the Glasswasher

Priming the Chemical System

Operational Testing

Installing Chemical Squeeze Tubes

Priming the Chemical Pumps

Setting the Chemical Controls

Owners Instructions

Component Identification

Instrument Panel

Operating the Glasswasher

Washing Glasses

Chemical Control Panel

Maintenance and Troubleshooting

End of Day Shutdown

Deliming .............................................................11

Troubleshooting .................................................11

Machine Operation & Cycle Sequence

Replacement Parts

Electrical Connection Diagram

Adjusting Chemical Concentrations

Calibrating the Chemical System

.............................................. 4

.................................... 4

........................5

.................................... 5

............................. 5

.............................................5

....................6

.............................. 7

............................ 7

.................................... 8

................................................. 9

................................. 9

.................................................9

....................................10

....................................... 11

.............12

............................................ 13

.......................... 14

.................. 15

...................... 15

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Page 2

Warranty Information

ONE YEAR LIMITED WARRANTY

The Perlick Corporation warrants its glasswasher to

be free from defects in material and workmanship,

under normal use and operation, for a period of one

(1) year from the date of initial start-up or eighteen

(18) months from the date of shipment from the

®

factory, whichever comes first. Perlick

replace, at our option, during the warranty period,

any part that may be defective in material and/or

factory workmanship. This warranty is conditioned

upon the customer's maintenance and care as

outlined in the service manual and the return of

the warranty registration card. Warranty repairs will

be performed, free of charge, during Perlick's®

authorized service agency's normal business hours.

Should the customer require after hours service,

it is the customer's responsibility for any overtime

premium. Machine is warranted only for the

initial place of installation. Removal of machine

automatically terminates this warranty.

Perlick® shall have no liability under this warranty

unless the customer promptly notifies Perlick® or

its factory authorized service agent of any alleged

defects. All defective parts become the property of

Perlick® and must be returned to Perlick®, or its agent,

®

at Perlick's

date of the part's replacement. Parts replaced within

the warranty carry only the unexpired portions of the

machine's warranty. Not covered by this warranty

are changes (parts and/or labor) necessitated by or

damage resulting from: water conditions, accident,

alteration, improper use, abuse, tampering, improp

er installation or failure to follow operating and

maintenance procedures. Examples of the foregoing, but without limitations are:

1) Damage to machine resulting from excessive

concentrations of chlorine or deliming acid solutions;

2) Use with utilities other than designated on the

glasswasher I.D. plate or owners manual;

expense, within thirty (30) days from the

will repair or

3) Improper connection of utility services;

4) Inadequate or excessive water pressure; 5) Leaks

caused by faulty installation; 6) Component failures

caused by water leaks due to faulty installation; 7)

Failure to comply to national and/or local codes; 8)

Failure due to deposits resulting from hard water,

detergents, chlorines, delimers, or improper main

taining, 9) Resetting breakers or fuse replacement;

10) Adjustments such as thermostats and chemical

pump system; 11) Improper opening of utility supply

valve; 12) Cleaning drain valves, line strainer, spray

nozzles, etc.; 13) Improper installation or malfunc

tion of chemical dispensing equipment supplied by

others; 14) Failure to provide regular and/or daily

maintenance and cleaning as outlined in this owners

manual.

THIS WARRANTY IS LIMITED TO GLASSWASHERS

INSTALLED WITHIN THE 48 CONTINENTAL

UNITED STATES AND CANADA. IN ALASKA,

HAWAII AND ELSEWHERE OUTSIDE THE

CONTINENTAL U.S. AND CANADA, THIS

WARRANTY IS LIMITED TO REPLACEMENT PARTS

ONLY.

THERE ARE NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, MADE BY THE

PERLICK CORPORATION FOR ITS GLASSWASHER,

INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE AND IN LIEU OF ALL

OTHER OBLIGATIONS OR LIABILITY ON THE

PART OF PERLICK

INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR FOR LOSS OF PROFITS OR GOODWILL.

NO OTHER WARRANTIES ARE AUTHORIZED ON

BEHALF OF PERLICK

®

, INCLUDING LIABILITY FOR

®

.

-

-

RECORD THIS INFORMATION

MODEL NO.__________________________________________________

SERIAL NO.._________________________________________________

INSTALLATION DATE:_________________________________________

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Page 3

HOT WATER

INLET 1/2” [13]

MALE N.P.T.

(R.H. & STD.

UNITS)

HOT WATER INLET

1/2” [13] MALE N.P.T.

(L.H. UNITS)

HOT WATER

INLET 1/2” [13]

MALE N.P.T.

(L.H. UNITS)

HOT WATER

INLET 1/2” [13]

MALE N.P.T.

(R.H. & STD.

UNITS)

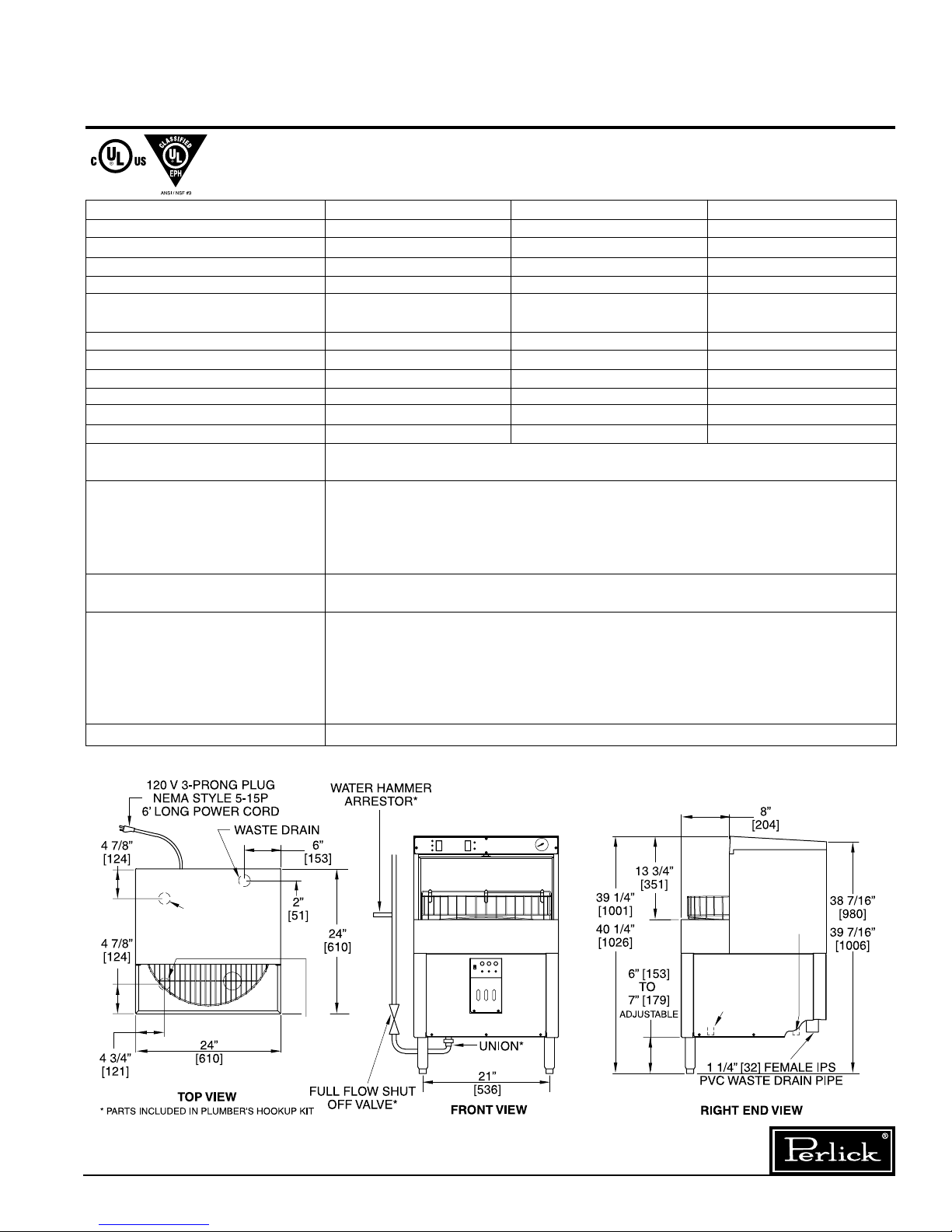

Sizes and Specifications

PKBR24 Glasswashers

MODEL NOS. PKBR24 PKBR24L PKBR24R

WASH TANK CAPACITY (gals.) 1 1 1

CYCLE TIME (sec.) 120 120 120

WASH TIME (sec.) 60 60 60

SANITIZER TIME (sec.) 35 35 35

GLASSES WASHED PER

1

HR. (2

/2” dia.)

TANK HEATER (watts) 650 650 650

WASH PUMP CAPACITY (gals./min.) 24 24 24

DRAIN FLOW (gals/cycle) 1.67 1.67 1.67

EXHAUST REQUIREMENT None None

MAXIMUM GLASS HEIGHT 10” 10” 10”

Ship wt lbs. (kg) 225 (103) 225 (103) 225 (103)

ELECTRICAL 120 Volt, 60 Hz., single phase AC. 5.4 amps, furnished with 6 foot power cord and standard

3 prong NEMA style 5-15P.

PLUMBING Hot Water Inlet Connection: 1/2 ” NPTM. Incoming Hot Water: 130–140° F, at 30-60 psi

with a flow rate of 4.0 gal/min. Drain: 11/4 IPS PVC socket connection to include an air gap.

Plumbers Hookup Kit: Includes water hammer arrestor, stop valve and union. Important:

Failure to install the Glasswasher with Plumbers Hookup Kit can damage the hot water

solenoid valve. Machine

WATER HARDNESS Water containing more than 15 GPG will require a water softener.

caused by hard water are not covered under

DETERGENT, SANITIZER and Detergent: A heavy-duty liquid warewashing detergent containing water conditioners.

RINSE AID

Chlorine Sanitizer: Any EPA registered chlorine can be used. The EPA marking can be found

on the container label.

conditioners.

the appropriate detergent and rinse aid for specific water conditions. These chemicals can be

purchased from a local chem

OPTIONAL ACCESSORIES • Low Sanitizer shut down kit - #61945 • Glass Rack - #50470-2

All plumbing and chemical lines must be routed so that the glasswasher can be pulled out for service.

720 720 720

None

failure due to improper installation is not covered by Perlick’s warranty.

Caution: Parts failure

Perlick’s warranty.

Rinse Aid: A low-foaming warewashing rinse aid containing water

Note: To ensure maximum glasswasher performance. It is important to select

ical supplier or food service distributor.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Page 4

Chemical Specifications

Water Conditioning

■ If the water you will use in the glasswasher is

too hard, the glasswasher will not clean and

sanitize glasses properly. Water contains

dissolved calcium/lime which makes water

"hard." Water can be conditioned mechanically

by using a water softener or chemically by

using a detergent and rinse aid which contains

water conditioners. If the water you will use in

the glasswasher is not properly conditioned,

the glasswasher will:

■ Require frequent deliming.

■ Cost more to operate (higher chemical usage).

■ Shorten machine life.

Water Hardness Type of Water

GPG (Grains Per Gallon) Treatment required

0 - 5 GPG Chemicals containing

Low water conditioners

6 - 10 GPG Chemicals containing

Medium water

conditioners

11 - 15 GPG Chemicals containing

High water conditioners

15 GPG Plus Water softener required

and chemicals

containing Low water

conditioners

Chemical Specifications

DETERGENT:

Heavy-duty, liquid warewashing detergent with

water conditioners.

SANITIZER (CHLORINE):

EPA registered, non-foaming liquid chlorine.

RINSE ADDITIVE:

Low-foaming, warewashing rinse additive.

Chemical Concentrations

DETERGENT

Start the glasswasher and wait for 30 seconds

into the wash cycle. Then stop the machine; take

a sample and test for active alkalinity. It should be

250 ppm. +10%.

SANITIZER

Run the glasswasher through a complete cycle.

Take a sample and test it for chlorine concentra

tion. It should be 50 ppm. minimum.

RINSE ADDITIVE

There is no minimum concentration. Visually check

the glassware for satisfactory wetting.

-

Water with more than 15 GPG will require a water

softener. It cannot be conditioned economically

with chemicals. Failure of parts caused by hard

water are not covered under the warranty.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

4

Page 5

START UP PROCEDURES

Important

When an indicated function does not occur, corrections MUST be made before proceeding. No steps

in a procedure should be ignored or omitted.

Before Starting The Glasswasher

CHECK TO DETERMINE IF...

■ Water and Power are ON to glasswasher.

■ Chemical System Power Switch is ON.

■ Chemicals (detergent, sanitizer, and rinse

aid) have been purchased and are on site

for use.

■ Chemical line drop tubes are in appropriate

containers:

■RED line into the detergent container.

■WHITE line into the sanitizer container.

■BLUE line into the rinse additive

container.

REMOVE...

■ All protective paper from the front of

machine.

■ Shipping block from under the lower spray

arm.

INSTALL...

■ Both glass racks onto the divider.

Priming The Chemical System

The chemical system prime buttons are located

in the chemical control panel. Each of the three

chemical systems must be primed separately.

■ Press the prime button until the chemical is

observed in the flow indicator window.

■ Continue to press the prime button for an

additional 15 seconds to complete the

priming.

■ Repeat procedure until all three systems

have been primed.

Operational Testing

PRESS

■ Wash switch to run the glasswasher

through a complete cycle.

CHECK

■ That only the power and washing lights are

illuminated while the machine is washing.

■ That only the power and cycle complete

lights are illuminated when cycle is fin

ished.

■ That the cycle complete light goes out

when divider is rotated.

-

Starting The Glasswasher

PLACE...

■ Power/drain (on-off drain) switch to ON.

CHECK...

■ Water level inside the tank (Level should be

at top of overflow tube.)

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

Page 6

DETERGENT (RED)

START UP PROCEDURES

Installing The Chemical Squeeze Tubes

When an indicated function does not occur, corrections MUST be made before proceeding. No steps

in a procedure should be ignored or omitted.

Important

The detergent, sanitizer, and rinse aid squeeze

tubes must be installed before operating the

glasswasher. Glassware will not be properly

washed or sanitized unless these tubes are

installed.

1. Remove the front panel and the chemical

control panel, exposing the three chemical

pumps.

2. Confirm water and power are on.

3. Place power switch to ON. Glasswasher

fills for 25 seconds.

4. IMPORTANT: Install squeeze tubes, one at

a time, to avoid possible mixing of

components during reassembly. Although

the components appear to be identical,

they are not. If the entire housing is

removed, it must be reinstalled in exactly

the same position to avoid stripping

the spider.

5. Remove 4 nylon nuts from pump

head. To remove the pump cover

without removing the entire

assembly, place a finger on the spider and

pull the cover straight off of the four

mounting studs.

Note: The roller has A & B engraved on its inte

rior. It has also been color coded on the spider.

Confirm the following:

Red .... A Position... Detergent .....................Left Pump

White ..A Position... Sanitizer (Chlorine) .....Middle Pump

Blue ....B Position .. Rinse Aid .....................Right Pump

6. Press the tube between the roller and

housing. Caution: Using tools to push the

squeeze tube in can result in damage to

the tube. To make squeeze tube installation

easier, use the prime button to rotate roller.

7. Replace the pump cover and nuts making

sure pump cover is locked in position.

8. Repeat procedure for the two remaining

pumps and replace the chemical control

panel and front panel.

-

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Page 7

START UP PROCEDURES

Priming The Chemical Pumps

Place the chemical, detergent, chlorine,

and rinse aid containers in a convenient

location. Place appropriate drop tube into

corresponding container as labeled on the drop

tube.

■ Red Line ........ Detergent Container

■ White Line ...... Sanitizer Container

■ Blue Line ........ Rinse Aid

Press and hold detergent prime button.

Window will illuminate so that chemical flow

can be observed. When chemical is observed,

hold for an additional 15 seconds. This will

allow the chemical to reach the wash tank

area. Repeat procedure for Sanitizer and

Rinse Aid.

Setting The Chemical Controls

2. DETERGENT CONTROL

Controls detergent concentration with

three pre-calibrated settings:

1 = Lowest Concentration

2 = Medium Concentration

3 = Highest Concentration

Your water hardness, detergent strength and

amount of water conditioners in the detergent will

determine the final setting of this control. Start

with the control on No. 1 and increase until the

best cleaning result is achieved.

3. SANITIZER CONTROL

Controls chlorine concentration with an

infinite adjustment. This control is set so

that a minimum of 50 ppm. of chlorine is

obtained. Use the chlorine test kit to set

this control provided with the glasswasher.

NOTE: This setting should be tested daily

and must be adjusted according to local

health standards.

1. CHEMICAL SWITCH

This switch turns the chemical pump system

on and off and will be used to delime the

machine. The switch should be in the

ON position.

4. RINSE AID

Controls rinse aid concentration with three

pre-calibrated settings:

1 = Lowest Concentration

2 = Medium Concentration

3 = Highest Concentration

Your water hardness and the strength of the rinse

aid used will determine the final setting of this

control. Start with the control in the No. 1 position.

If the water does not sheet on the glassware, and

droplets are present, increase the concentration.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

7

Page 8

OWNERS INSTRUCTIONS

Component Identification

1 - LOWER SPRAY ARM:

Oscillates 120° to enable the fan-shaped

spray to thoroughly clean and sanitize the

interior of the glasses.

2 - TANK COVER SCREEN:

Located at the bottom of the wash area.

Care should be taken to keep debris from

entering the tank when the screen has

been removed for cleaning.

3 - OVERFLOW TUBE:

Located in the wash tank. Drains overflow

water.

4 - TANK FILTER:

Located within the tank. Care should be

taken to keep debris from entering the

wash system when the filter is removed

for cleaning.

8 - CHEMICAL CONTROL PANEL:

Located on the front panel. This panel

contains all the user controls for the

chemical system.

■ Chemical control knobs control the

chemical concentrations in the wash

water

■ The prime buttons allow the chemical

lines to fill without having to run the

glass washer.

■ The chemical system power switch

should be kept on during normal

operation. This switch is turned off while

the glasswasher is cleaned.

9 - GLASS RACK(S)

10 - INSTRUMENT PANEL

5 - UPPER SPRAY ARM:

A stationary arm located at the top of the

wash compartment. The fan shaped

spray cleans and rinses the exterior of the

glasses.

6 - DIVIDER:

Holds two removable racks. The divider

can be manually rotated in either direction,

but must be parallel to the front of the

machine before a wash cycle can begin.

If the divider is rotated during a wash cycle,

the machine will stop.

7 - CHEMICAL FLOW INDICATORS:

Located just below the chemical control

panel. These windows illuminate while the

chemical pumps operate, providing a visual

indicator of the chemical flow.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

8

Page 9

START UP PROCEDURES

8

WASH

The Instrument Panel

ITEM NO. DESCRIPTION FUNCTION

1 POWER/DRAIN (On/Off Drain) The Power/drain (on/off drain) switch is a three-

* Note: Switch must be pressed for a Center position: Power is OFF; no lights are illuminated.

minimum of ten seconds to drain the Upper position: Power is ON and Power ON light is

tank. The drain is activated for only as illuminated. Opens hot water solenoid for 25 seconds.

long as the switch is pressed. Lower position: Machine is in the DRAIN* mode.

2 CHEMICALS OFF LIGHT Illuminated when the switch in the chemical control

panel is in the OFF position.

3 LOW WATER LIGHT

water in tank.

Flashing: Drain failure.

4 POWER ON LIGHT Illuminated when the power is ON.

5 WASH SWITCH Initiates a wash cycle when pressed.

6 CYCLE COMPLETE LIGHT Illuminated when the wash cycle is complete and divider is

ready to be rotated.

7 WASHING LIGHT Illuminated when the machine is in the wash cycle.

8 THERMOMETER Indicates water temperature inside tank. Operating

temperature should be 130-140° F.

Steady Illumination: Machine has stopped due to low

Operating The Glasswasher

1. Water temperature (No. 8) should be between

130-140° F. to assure proper glass washing.

Open a hot water faucet in the bar area to

ensure that adequate hot water is coming to the

glasswasher.

2. Press Power Switch (No.1.) Yellow Power On

Light (No. 4) comes on and wash tank fills with

water for 25 seconds. If the red Low Water Light

comes on, this indicates that incoming water

pressure or flow is not adequate. Contact Perlick

or your authorized service agency.

Washing Glasses

1. The glasswasher is provided with two vinyl-coat-

ed racks which hang on each side of the divider.

Racks are removable for easy loading and

unloading of glassware.

2. Place EMPTY glasses on glass rack, open end

down. (Maximum glass size is 10".) Solids which

are dumped into the glasswasher (i.e., napkins,

position rocker switch.

straws, sticks, fruit rinds, etc.) will significantly

affect the glasswasher's performance and time

needed for daily cleaning. Poor performance

due to poor cleaning is not covered by manufac turer's warranty.

3. Rotate loaded rack 180° into the wash area.

4. Depress Wash Switch (No. 5.) the yellow

Washing Light (No. 7) comes on initiating a two

minute wash cycle. Never rotate divider until

Cycle Complete light is illumnated. This action

terminates the wash cycle and then the glass ware will not have been properly washed and/or

sanitized.

5. When the yellow Cycle Complete light comes on,

this indicates that the glasses in the wash area

have been washed and sanitized. Rotate the

divider 180 degrees to gain access to clean

glasses. Yellow Cycle Complete light will go

off and the next load of dirty glasses is ready

to be washed.

6. Drain excess water from glass sumps by lifting

the front edge of the glass rack.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

9

Page 10

OWNERS INSTRUCTIONS

DETERGENT

CALIBRATING THE CHEMICAL SYSTEM

RINSE AID

Detergent and Rinse Additive:

Low Foaming Liquid

Position 1: Low soil and soft water

Position 2: Medium soil and soft water

Position 3: High soil and hard water

TO PRIME:

Depress buttons until chemicals appear in windows.

Sanitizer:

Adjust to min. 50 ppm chlorine

(see Test Kit Instructions)

EPA Registered

Non–Foaming Liquid

Alkaline

Non–Chlorinated

Low Foaming Liquid

CHLORINE

PRIME PRIME PRIME

ON

3 3

1

+

_

2 2

OFF

CHEMICAL

SWITCH

DETERGENT RINSE AIDSANITIZER

Chemical Control Panel

ITEM NO. DESCRIPTION FUNCTION

1 CHEMCIAL SYSTEM Should be kept in the ON position except during cleaning.

POWER SWITCH When switch is in the OFF position, the Chemical OFF

light on the instrument panel will be illuminated.

2 DETERGENT CONTROL KNOB Controls detergent concentration with three, pre-calibrated

settings:

1 = Lowest Concentration

2 = Medium Concentration

3 = Highest Concentration

3 SANITIZER CONTROL KNOB Controls sanitizer concentration with an infinite adjustment

to precisely dispense sanitizer to the required minimum of

50 ppm.

4 RINSE ADDITIVE CONTROL Controls rinse aid concentration with three, pre-calibrated

settings:

1 = Lowest Concentration

2 = Medium Concentration

3 = Highest Concentration

5 PRIME SWITCHES Fills chemical lines without running glasswasher. Power

ON light must be illuminated.

6 CHEMICAL FLOW INDICATORS These windows illuminate when a chemical is flowing

during a wash cycle or when chemical lines are being

primed, providing a visual indicator of chemical flow.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

10

Page 11

MAINTENANCE AND TROUBLESHOOTING

End of day Shutdown

Clear glassware from racks. Press lower portion of

Power/Drain (on-off drain) switch for ten (10) seconds to drain tank. Place Power/drain (on-off drain)

switch to off. We recommend that solid wastes be

removed from the load and unload area at least

once each day to ensure optimum performance.

Deliming

Prolonged hard water use may cause a white film

to appear on the inside surface of the wash area.

It is then necessary to delime the machine.

1. Remove all glassware from racks, and any

debris from the load and wash areas.

2. Chemically charged water must be drained

from the tank. Press the lower portion of

Power/drain (on-off drain) switch for 10

seconds.

3. Place the chemical system Power Switch

to OFF.

4. Refill the tank by placing the Power/drain

(on-off drain) switch to ON. (Power ON and

chemical OFF lights illuminate.)

5. Add delimer to wash area. Use amount

recommended on container.

6. Press Wash Switch. (Washing light does not

illuminate in cleaning mode.)

WARNING

Always protect skin, eyes, and mucous membranes when working with chemicals. Always

clean up chemical spills immediately. At full

strength the chemicals used in your glasswasher

can cause severe burns and metal corrosion. Do

not mix with anything but water. Never intermix

one with the other. Hazardous vapors may result.

Keep out of the reach of children. See manufac

turers label for complete instructions.

Troubleshooting

SYMPTOM PROBABLE CAUSE

Machine Does Circuit breaker tripped.

Not Operate Power/drain (on-off drain) switch off.

Divider not parallel with front of

glasswasher. Water supply turned off.

Electrical cord unplugged.

Glasses Not Incoming water temperature too low.

Clean (Required water temperature 130-

140° F.) Detergent setting too low.

Tank filter plugged.

Machine Shuts Water supply turned off.

Down (Low Water Light On) Incoming water

supply insufficient. (4 gallon per

minute flow rate required.)

Flashing Low This indicates a drain failure.

Water Light Call your service agency.

-

7. While the machine is running, clean the load

area and exterior of the machine with a damp

cloth and wipe dry. Replenish chemicals if

required. See warning!

8. Press the lower portion of Power/drain

(on-off drain) switch for 10 seconds to

drain tank.

9. To restore service, place chemical Power

Switch to ON.

10. Place Power/drain (on-off drain) switch to

ON. The glasswasher is now ready to use.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

11

Page 12

MAINTENANCE AND TROUBLESHOOTING

35 SECONDS

Maintenance Operation & Cycle

Sequence

At the beginning of the wash cycle, the water in the

tank is charged with detergent. After the cycle is

completed, the detergent water is dumped down

the drain. The sanitizing rinse cycle begins as the

tank is refilled with fresh water. Sanitizer and rinse

additive is pumped into the tank. The rinse water is

retained and will be used in the next wash cycle.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

12

Page 13

MAINTENANCE AND TROUBLESHOOTING

Replacement Parts

ITEM

NO. DESCRIPTION PART NO.

1 Glasswasher Control Kit 55042

2 Spray arm drive motor 52536

3 Wash pump 50445

4 Pump motor capacitor 52528

5 Water inlet valve 52652-1

6 Band heater 52669-1

7 Rinse aid pickup tube assembly 52626A-B

Detergent pickup tube assembly 52626A-R

Sanitizer pickup tube assembly 52626A-W

8 Divider side seal 52696

9 Wash water level switch R54978-1

10 Start/Wash switch 55003-1

11 Power/drain (on/off/drain) switch 55004-1

12 Red light 54809

13 Amber light 54810

14 Wash tank filter 52492

15 Safety switch - .250" quick connect 54995-1

16 Safety switch - .187" quick connect 54996-1

17 Roller bearing for divider lock C12698-1

ITEM

NO. DESCRIPTION PART NO.

18 Glass rack 50470-2

19 Top divider seal 52692

20 Top wash tank screen 50588

(For Serial Nos. to 443593 only)

20A Top wash tank screen R50614

21 Chemical system control board 50453

22 Drain valve 50451

23 Chemical system sight tube kit 52714A

24 Transformer 52566A

25 Temperature control 54153A

26 Fuse holder 54938-1

12 amp fuse 54939-1

27 Chemical pump gear motor 52537

PARTS NOT SHOWN

Chemical bulkhead fittings R54976

Amber chemical sight tube light 54790

Flat strainer 54965-1

Clean-out plugs for spray arms R54900-1

Seal kit R54965

1

⁄4" ID. chemical pump squeeze tube 52679-1

3

⁄16" ID chemical pump squeeze tube 52681-1

1

⁄8" ID chemical pump squeeze tube 52680-1

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

13

Page 14

MAINTENANCE AND TROUBLESHOOTING

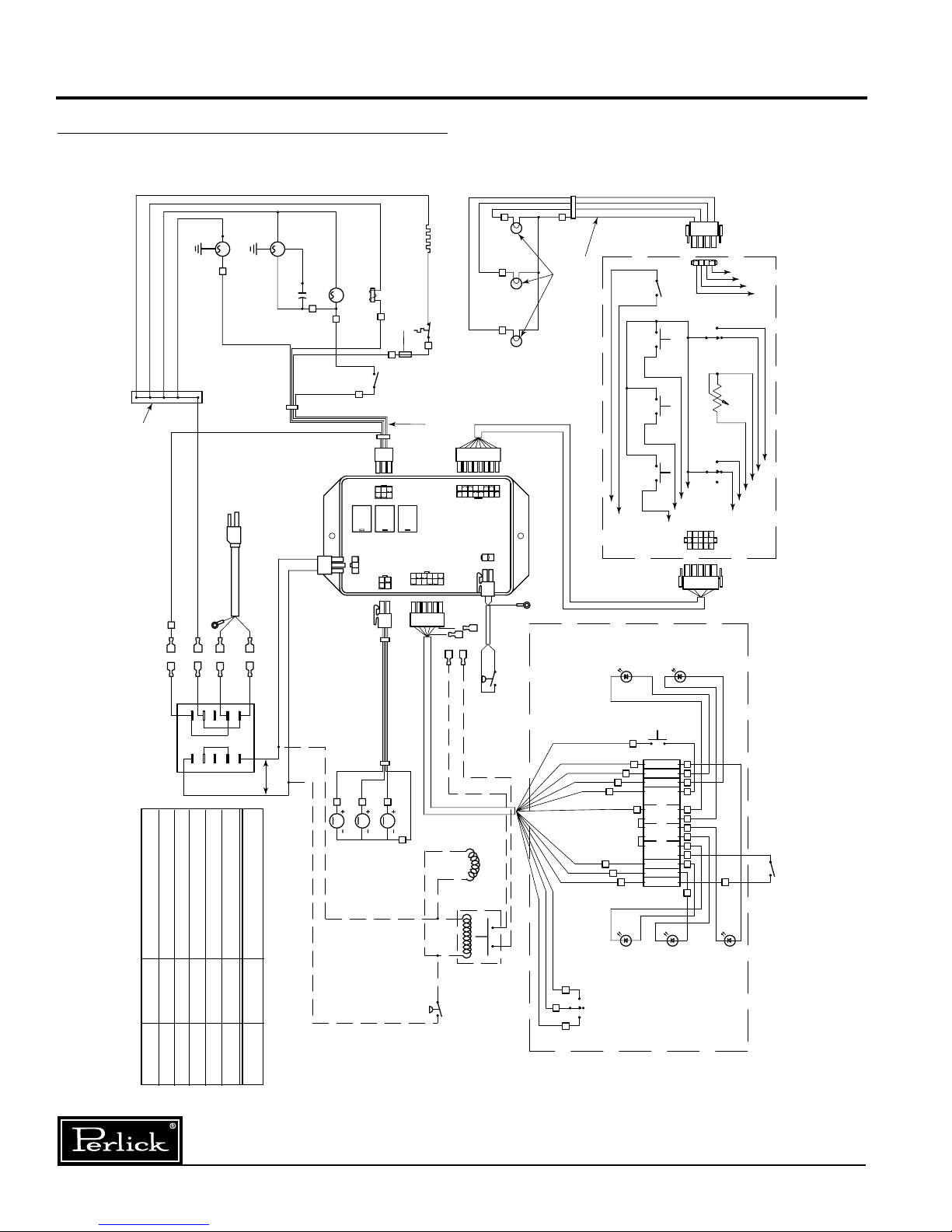

ELECTRICAL CONNECTION DIAGRAM

SANITIZER

PRIME

SWITCH

RINSE AID

PRIME

SWITCH

RINSE AID

24 VDC

HEATER

CONTROL

COMPONENT

WIRE HARNESS

120 VAC

SAFETY

SWITCH

12 AMP ABC FUSE

HOT WATER SOLINOID

SPRAY ARM MOTOR

CAPACITOR

WASH PUMP

DRAIN VALVE

TERMINAL BLOCK

120 VAC

POWER

SUPPLY

WASH TANK

HEATER

SANITIZER

24 VDC

DETERGENT

24 VDC

SANITIZER

SPEED

CONTROL

RINSE AID

SELECT

SWITCH

5 VDC

5 VDC

5 VDC

5 VDC

WASHING

LIGHT

GROUND

WHITE

WHITE

INSTRUMENT PANEL WIRE HARNESS

CHEMICAL PUMPS WIRE HARNESS

5 VDC

WASH WATER

LEVEL SWITCH

CYCLE

COMPLETE

LIGHT

5 VDC5 VDC24 VDC

DETERGENT

PRIME

SWITCH

CHEMICAL

SYSTEM

POWER

SWITCH

15

9

3

2

10

8

DETERGENT

SELECT

SWITCH

CHEMICAL SYSTEM CONTROL PANEL

SIGHT GLASS LIGHTS

WHITE

WHITE

WHITE

WHITE

24 VDC

24 VDC

1 7

8

11

12

6

5

2

1

4

3

2

24 VDC

24 VDC

28 VAC

1

POWER CORD

GROUND

TRANSFORMER

WHITE

WHITE

WHITE

GREEN

GREEN

WHITE

BLUE

BLUE

BLUE

BLUE

BLACK

BLACK

BLACK

BROWN

BLACK

BLACK

2

2

2

5

3

6

3

MOT

MOT

MOT

3

3 4

8

1

INSTRUMENT PANEL

GLASSWASHER

CONTROL

CHEMICAL SYSTEM

LIGHTS WIRE HARNESS

CHEMICAL SYSTEM

WIRE HARNESS

1

3

3

3

6

6

9

12

15

10

13

12

11

7

7

5

6

6

9

9

8 8 8 8 8 8

8

4

2

3

4

3

11

10

12

2

7

7

1

5

5

15

4

4

14

13

2

2

1

1

1

POWER

ON LIGHT

CHEMICALS

OFF LIGHT

START

SWITCH

5 VDC

ON / OFF / DRAIN SWITCH

24 VDC

TERMINAL BLOCK

OFF

DRAIN

ON

LOW WATER

LIGHT

5 VDC

SAFETY

SWITCH

16

1

9

1

17

6

6

12

1

1

1

3

3

3

24

4

2

MOT

MOT

MOT

WHITE

RELAY

OPTIONAL

LOW LEVEL

SWITCH KIT

PRESSURE

SWITCH

RINSE AID

PUMP

SANITIZER

PUMP

DETERGENT

PUMP

1

BLUE

LAMP

YELLOW

YELLOW

BLUE

ELECTRICAL SPECIFICATIONS

COMPONENT VOLTS AMPS

WASH PUMP 115 VAC 2.1 A

SPRAY ARM MOTOR 115 VAC 1.5 A

HEATER 120 VAC 5.4 A

DRAIN SOLINOID 115 VAC .43 A

HOT WATER SOLINOID 120 VAC .08 A

CHEMICAL PUMP MOTOR 24 VDC .22 FLA

Electrical Connection Diagram

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

14

Page 15

MAINTENANCE AND TROUBLESHOOTING

Adjusting Chemical Concentrations

IMPORTANT NOTE:

Damage resulting from excessive chemical con

centrations is not covered by warranty.

If adjustments are needed, the chemical control

panel has adjustment knobs for the chemical con

centrations in the wash water. The detergent and

rinse aid knobs are three position switches control

ling the run time of the chemical pump during a wash

cycle. The sanitizer knob is a potentiometer control

ling the speed of the sanitizer pump during a wash

cycle. Factory calibrated times for these controls are

as follows:

Detergent .........Position #1.......7 Seconds

Position #2.......10.5 Seconds

(11/2 X Position #1)

Position #3

(2 X Position #1)

Sanitizer .....................................12 Seconds regard-

less of the position

of the control

Rinse Additive

Position #2

(2 X Position #1)

Position #3.......8 Seconds

(4 X Position #1)

If more adjustment is required, the chemical sys

tem must be recalibrated. See Chemical System

Calibrating procedure.

.Position #1.......2 Seconds

.......14 Seconds

.......4 Seconds

-

-

-

-

-

Calibrating the Chemical System

IMPORTANT READ BEFORE BEGINNING

■ Remove power cord from outlet.

■ Remove lower front panel.

■ Remove screws and remove cover to the

electrical housing.

■ Place Dip Switch 1 to the ON position. LED

light will flash rapidly.

■ Plug the glasswasher in and place the Power/

drain (on-off drain) switch to On.

■ Place the detergent and rinse additive knob

to the #1 position. The sanitizer can be

calibrated with the sanitizer knob in any

position.

IMPORTANT NOTE:

CALIBRATE ONE PUMP AT A TIME.

Calibrating the pumps sets the time that the pumps

will run during a wash cycle. Twenty (20) seconds is

the maximum run time on any setting.

■ Depress and hold the prime button of the

pump being calibrated for the time

that is needed for the pump to run.

■ Place Dip Switch 1 back to the OFF position.

■ Confirm calibration of chemical system by

following the chemical concentration

test procedure.

■ Replace electrical housing cover and replace

lower front panel.

■ Repeat above procedures for each chemical.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

! WARNING !

Use extreme care, electrical box

contains live wires.

15

Page 16

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2121

Rev. 01.22.08

Loading...

Loading...