Page 1

HOW TO ASSEMBLE AND INSTALLATION

THE PERLICK MODULAR BAR DIE SYSTEM

MODEL NOS.

MBS

IMPORTANT INSTALLATION INFORMATION

The Perlick Modular Bar Die System makes building

a bar quick and easy. The bar die arrives on the job

site in sections up to eight feet long with stainless

steel underbar equipment already installed, saving

time and labor costs.

FLOOR PREPARATION

We suggest the bar die be installed on an unfinished

floor. Tile can then belaid, abutted to the bar die, to form

a watertight seal.

These illustrated, easy to follow instructions help to

ensure a professional, trouble-free installation.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Table of Contents

General Information ............................................... 2

Utility Specs ..........................................................2

Floor Sink Location ...............................................3

Uncrating ............................................................... 4

Placing ...................................................................4

Joining ................................................................... 4

Leveling ................................................................. 5

Attaching Bar Die to the Floor ..............................5

Installing Beer Lines .............................................. 5

Installing Utility Lines ............................................ 6

Sealing the Bar to the Floor ..................................6

Front Finishing Panels ........................................... 7

Bar Top ..................................................................8

Soda Guns ............................................................ 8

Form No. Z2162

Rev. 06.12.10

Page 2

General Information

Tools and Equipment Required

Phillips screwdriver Level

Power drill with various bits Marking pencil

Clamps (optional) Tape measure

Chalk Line

Fasteners

#10-16 x 3⁄4" Phillips Round Head

Thread Cutting Screw

Use to assemble Modular Bar

sections.

Actual Size

Not Shown

#10-16 x 1⁄2" Phillips Pan Head

Use to attach front panel clips;

secure to bar top.

#7055-45 Connector Kit used to

assemble workboard equipment

sections.

Arrival at the Job Site

Remove crate top, sides, ends and exposed lag bolts

holding structure to the crate skid. Note: Whenever

possible, the underbar equipment has been attached

to the bar structure. Free-standing equipment such as

bottle coolers, frosters, etc, are to be set into the open

sections which have been programmed into the bar

structure.

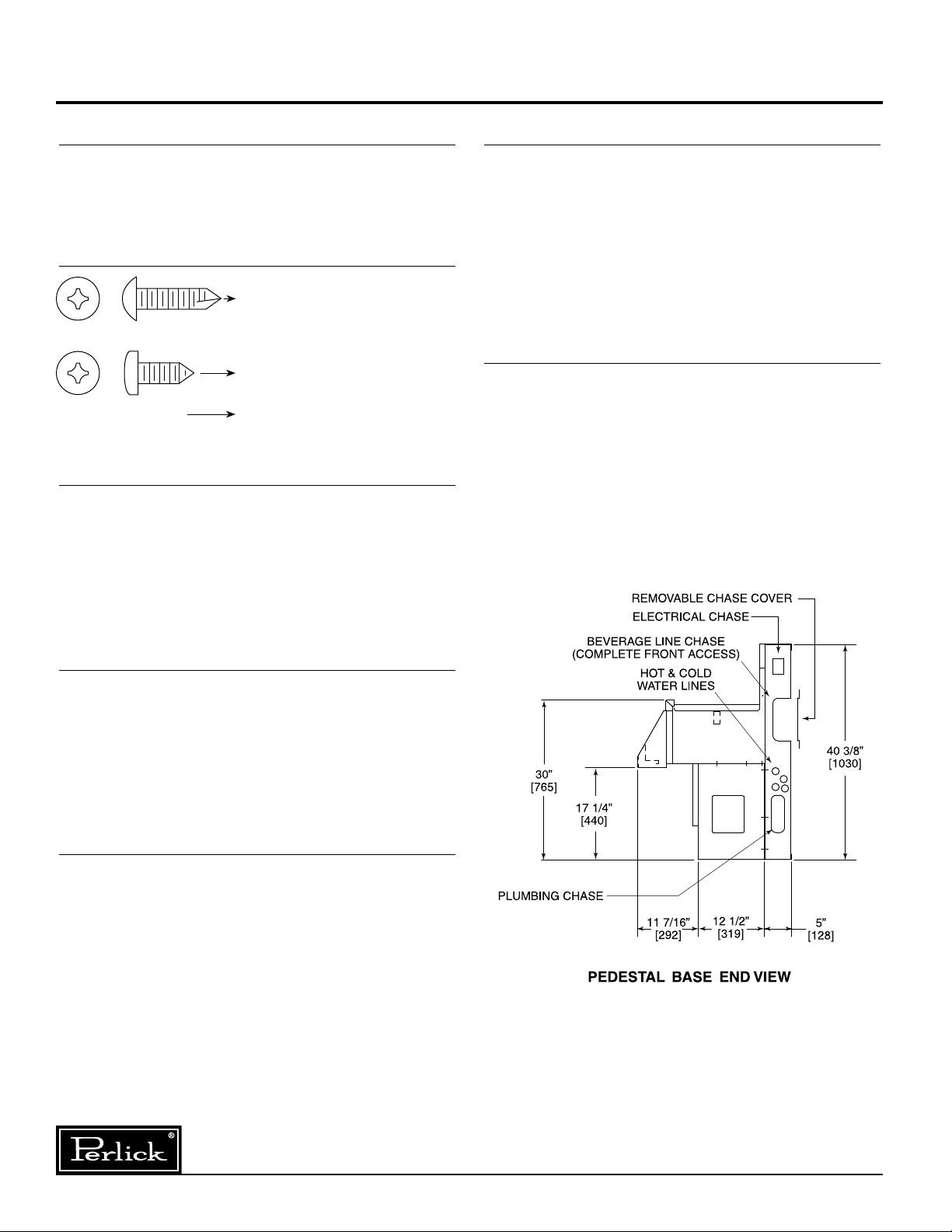

Utility Specifications

A 5" open zone is furnished behind the equipment

to provide room for trunk lines, soda lines, plumbing,

electrical, etc. to travel vertically or horizontally within

the bar structure.

Connections can be made from the front of the bar

with panels removed.

Plumbing and Electrical

(Installed According to Local Codes)

All water service and waste connections can be

made from the front of the bar (decorative front panel

removed). Local codes dictate installation (by others).

All electrical requirements such as receptacle to

blenders, washers, coolers, soda guns, lights, etc. (by

others).

Plug-in flourescent lighting is available in conjunction

with 8020-51 backsplash electrical outlets.

General Specifications

Structure: Configured to the exact size and shape

of underbar equipment, freestanding cabinets and

openings, as specified.

Chase: Interior chase runs the entire length of

structure to include corners.

Millwork

: By others.

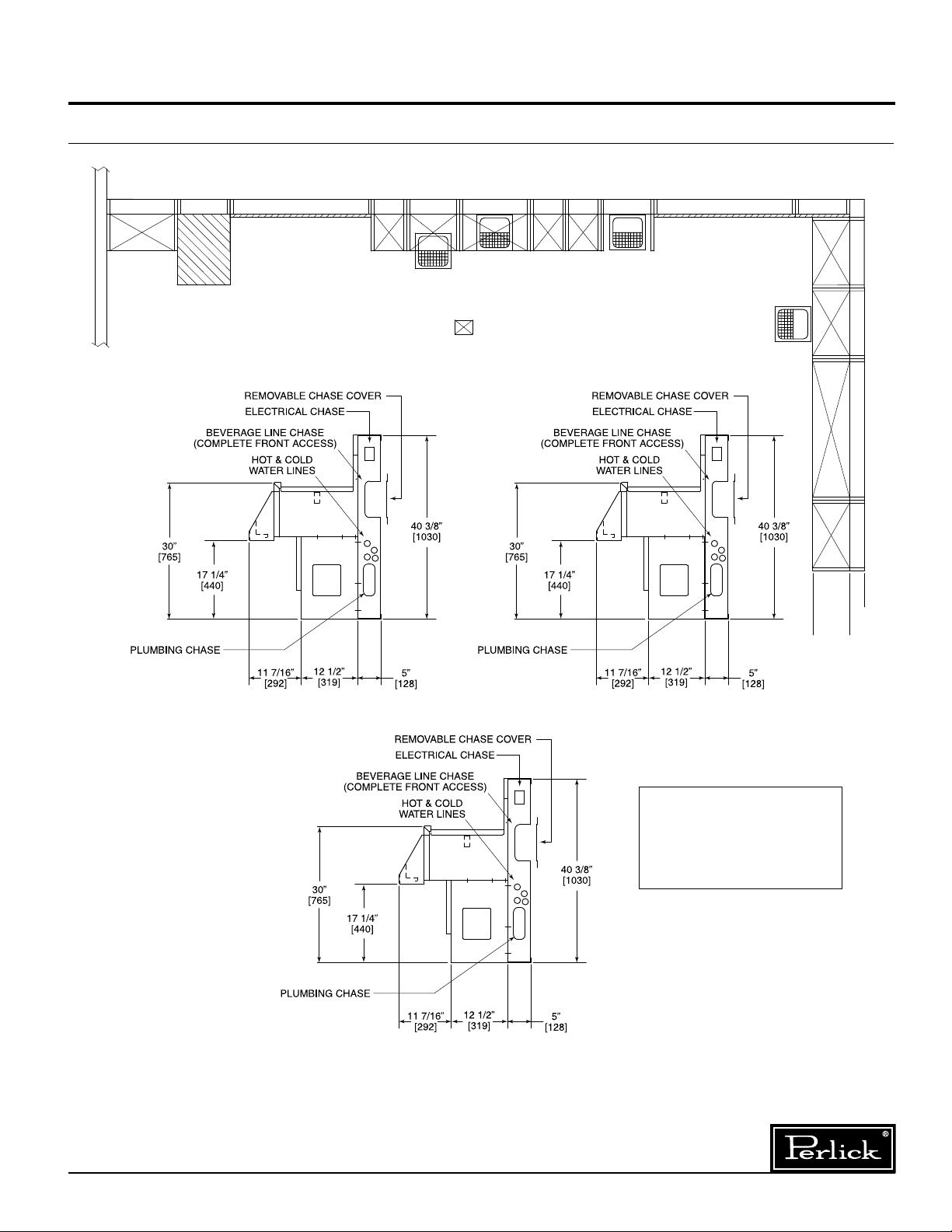

Mechanical Specifications

Utility Lines: Dedicated chase locations for hot/cold

water supply lines, beverage line conduits, and electrical conduit (behind the underbar equipment.) See

drawing. This chase is accessible from the floor and

runs the entire length of the bar.

Floor Drains

workboard equipment. The number of floor drains will

vary depending on the bar layout and local codes.

: Locate floor drains directly below

Form No. Z22162

Rev. 06.12.10

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Page 3

Option 1

Option 2

Option 4

Option 2

Available Soon

Options 2 & 3

Option 4

Option 1

Locating Floor Sinks

Choose yo u r o p ti o n

depending upon local

codes.

“FOOT PRINT”

(LIMITED ACCESS BELOW)

5”

12 1/2”

DENOTES OPEN AREA

FOR UTILITY STUB-UPS

General Information

Before You Begin: Floor Sink Location

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Form No. Z22162

Rev. 06.12.10

Page 4

General Information

Uncrating

Uncrate and remove skids from underneath

Modular Bar.

Placing

Joining

a) Screws are installed from the outside of

the bar structure from right to left.

b) Loosely attach sections through holes in

vertical studs. Do not tighten completely

until bar is completely leveled.

Use #10-16 x

provided. (Typ. 6 places).

3

⁄4" thread cutting s.m.s.

Move sections to desired location, over previouslyplaced beverage line conduits, plumbing and electrical rough-in stub ups.

Form No. Z22162

Rev. 06.12.10

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

4

Page 5

General Information

Leveling

a) Use wood or steel shims to level bar sections.

Note: The bar structure must be level so that the

equipment fits properly.

b) Any gaps created from leveling will be

hidden when the finish flooring is installed.

c) Join stainless steel equipment modules

together (use 7055-45 or 7055-55

Connector Kit).

d) Seal Modular Bar sections using NSF approved caulk.

Attaching Structure to the Floor

a) Temporarily insert freestanding equipment to

ensure proper fit.

b) Bar die can be attached to the floor using holes

in the bottom plate.

c) Several different methods can be used to

fasten bar to the floor. The installing contractor

will select the best method for your individual

installation.

Installing Beer Lines

a) Remove chase cover plate prior to installation.

b) An open utility chase is provided for easy beer

trunk housing installation.

c) Replace chase plate when installation is

complete.

With chase plate removed.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

With chase plate in place.

Form No. Z22162

Rev. 06.12.10

Page 6

General Information

Installing Utility Lines

Ample space is provided for electrical and plumbing lines.

See Utility Specifications on page 2.

Sealing Structure to the Floor

a) Loosen lower finish panel screws until lower

panel drops to the floor (1" adjustment).

b) Tighten finish panel screws.

c) Tile floor.

d) For sanitary purposes, the bar can then be

sealed to the floor using your choice of methods.

Form No. Z22162

Rev. 06.12.10

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Page 7

General Information

Front Panels (Shown for Reference Only)

Front Panels

Removable customer-side front panels are

meant to provide access for installation and

future servicing.

Method A

In this method panels hang on the front lower

structure rail.

a) Panel clips (not included) are attached to the

inside of the bar front panel.

b) Place clip over lower finish panel.

c) Use screws to attach panel to the

upper part of the structure.

Method B

In this method panels slide into a channel created

by two pieces of wood.

a) No screws or fasteners

required.

b) Panels lift up and swing

out for service.

End Panels

End panels to conceal the structure at gate

openings or bar end, etc. are not supplied by

Perlick. They should be fabricated by the

millworker.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

7

Form No. Z22162

Rev. 06.12.10

Page 8

General Information

Bar Top and Bar Rail by Others

(Shown for Reference Only)

The underside of the bar top should have a flat

single plane.

a) After all other steps have been completed, place

the assembled bar top in position.

Note: If bar layout includes a Model 8000 ice

cream unit, place into module before

installing top.

b) Fasten top to bar structure using #10 x 1/2" long

round head screws.

Soda Guns

Soda gun locations should be predetermined so the

factory can provide an opening for soda hoses.

a) Wunderbar brand soda hose manifolds can be

attached to the underside of the bar top

in front of filler strip, taking into consideration any

underbar lighting which may be present.

b) Six inch stainless steel Manifold Housing for

Concealing Soda Manifold. Installs on TS6CO.

Accessory Part #7055-66SG.

Form No. Z22162

Rev. 06.12.10

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

8

Loading...

Loading...