Page 1

Luxury

Operation &

Installation Manual

Signature Series (HP24- and HP48-inch models)

Excludes Beer Dispenser Models

HP24FS

HP24RS

HP24BS

HP24WS

HP48RR

HP48RB

HP48WO

HP48WW

Form No. Z2340

Rev. 06/04/2012

Page 2

Page 3

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Table of Contents

Introduction ..........................................................................................................3

Warranty Registration ..................................................................................... 3

General Precautions .........................................................................................4

Installation Specications .............................................................................4

Overall Dimensions and Drawings ......................................................... 5

Preparing the Space ........................................................................................ 8

Preparing the Electrical Connections ...................................................8

Unpacking and Moving .................................................................................8

Anti-tip Brackets ................................................................................................. 9

Installation .............................................................................................................10

Shelving ...................................................................................................................11

Door Options .......................................................................................................13

Wood Overlay/Door Lock Installation .................................................. 13

INTRODUCTION

Congratulations on your purchase of a Perlick residential

refrigeration product. Perlick has taken its expertise and experience

into creating the highest quality and most innovative residential

products on the market. Perlick’s product oering gives you the

opportunity to enjoy the functionality and user friendliness in

just about any room of your home, including kitchens, bedrooms,

entertainment rooms, basements and even bathrooms. All Perlick

products are built with commercial-grade stainless steel – providing

you with the beauty and durability for a lifetime of use.

This Installation and Operation Manual will answer your questions

about the features, operation and maintenance of your Refrigerated

Cabinet model. If you have questions that are not addressed here,

call 800 558-5592.

IMPORTANT : PLEASE READ all instructions completely before

attempting to install or operate the unit. First, as you follow these

Installation and Operation instructions, take particular note of the

DANGER!, CAUTION! and WARNING! symbols when they appear.

This information is important for the safe and ecient installation,

operation and care of your Perlick unit.

Wooden Wine Rack Trim Finishing ......................................................... 20

Operation ............................................................................................................... 21

General .................................................................................................................21

Interior Light ..................................................................................................... 21

Loading Products ........................................................................................... 21

Light Bulb Replacement ............................................................................21

Temperature Control Panel ......................................................................22

Adjusting the Setpoint ...............................................................................22

Checking Product Temperature ...........................................................23

Maintenance ........................................................................................................24

Cleaning ..............................................................................................................24

Cleaning the Condenser ........................................................................... 24

Troubleshooting ................................................................................................. 24

Warranty .................................................................................................................. 26

Once the unit is completely installed, we suggest you keep this

manual and purchasing documentation in a safe place for future

reference. Should problems occur: refer to the troubleshooting

section of this manual. The information will help you quickly identify

a problem and get it remedied. In the event you require assistance,

please contact the dealer where you purchased your unit.

WARRANTY REGISTRATION CARD

To request information or service, the model number and serial

number must be provided. This information is located on the inside

ceiling of the unit and on the warranty registration card included

with information packet shipped with the unit.

IMPORTANT : Read through the included warranty statement

then complete and mail the Warranty Registration Card as

soon as possible to validate the registration date. Warranty

registration can also be done online at www.perlick.com. If

warranty registration is not completed, Perlick will use the date

of sale as the rst date of warranty for the unit. Please record the

purchase date of the unit and the dealer’s name, address and

telephone number below.

DANGER

Indicates a hazard that will result in serious injury or death if

precautions are not followed.

WARNING

Indicates a hazard may cause serious injury or death if

precautions are not followed.

CAUTION

Indicates a hazard where minor injury or product damage may

occur if you do not follow instructions.

MODEL NUMBER: ____________________________________

SERIAL NUMBER: ____________________________________

PURCHASE DATE: ___________________________________

DEALER NAME & ADDRESS:

__________________________________________________

__________________________________________________

__________________________________________________

DEALER PHONE: ____________________________________

3

Page 4

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

GENERAL PRECAUTIONS

DANGER

Risk of child entrapment, before you throw away your old

refrigerator or freezer, take o the doors and leave shelves in

place so that children may not easily climb inside.

DANGER

Altering, cutting of the power cord, or removal of the power

cord, removal of power plug, or direct wiring can cause serious

injury, re and/or loss of property and/or life and will void the

warranty.

WARNING

• Never attempt to repair or perform maintenance on the unit

until the electricity has been disconnected.

• The anti-tip kit must be installed on this unit before it is used.

Never use the drawers, shelves or door as steps or to support

more than they were designed to support.

INSTALLATION INSTRUCTIONS

CAUTION

• Do not lift unit by drawer or door handles.

• Failure to clean the condenser every three (3) months can

cause the unit to malfunction. This could void the warranty.

• Never install the unit behind closed doors. Be sure front

louvered toe plate is free of obstruction. Obstructing the

airow can cause unit to malfunction, and may void the

warranty.

CAUTION

Use only genuine Perlick replacement parts. Imitation parts can

damage the unit, and may void the warranty.

GENERAL

• All electrical instructions assume that outlet is located 4 to 10

inches from oor.

• Floor must be level in area of installation. Leg levelers are used

for ne-tune adjustment only and should not be used to compensate for oor dierences exceeding 1/2-inch.

• When moving unit into position, take care to protect oor surface with cardboard, rugs, etc.

• Never attempt to move unit without the aid of at least one

other person.

• Always secure door shut prior to moving the unit.

FINISHED OPENING REQUIREMENTS

24” Signature Series

Height Depth Width

34-3/8” minimum,

35-1/2” maximum

48” Signature Series

Height Depth Width

34-3/8” minimum,

35-1/2” maximum

24” 24”

24” 48”

4

Page 5

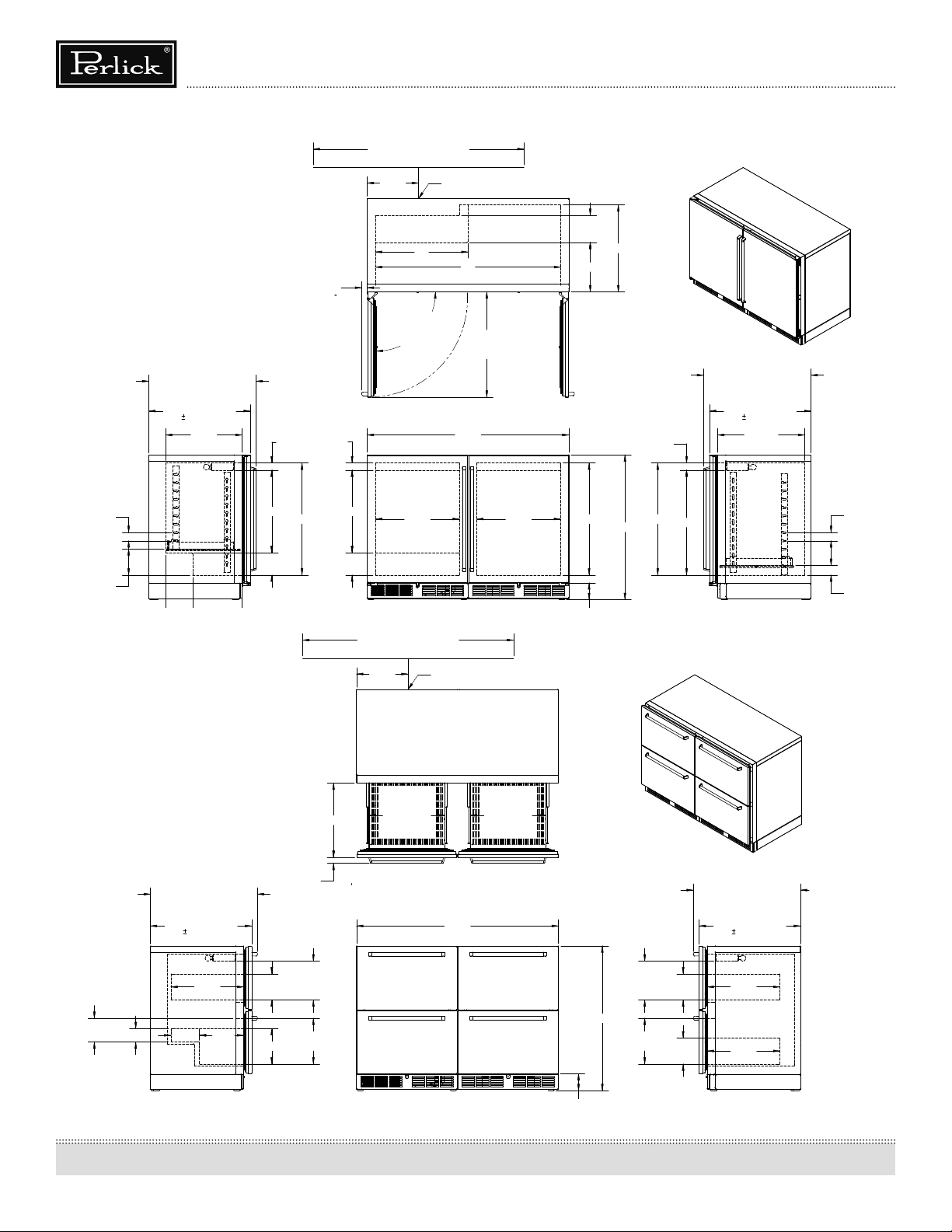

50" Area in which

electrical outlet must be located

7

9

16

"

when fully extended.

*

Leg levelers can add

3/4" to these dimensions

Signature Series HP24 Models

SCALE: 1:10

DAS

DR.:

DATE:

9/30/09

Power cord 65/8" off floor. *

17 "

16

11

17

13

16

"

Inside Drawer

(Top & Bottom)

25 7/16" Value may change

due to custom pull

with a wood overlay door.

when fully extended.

Leg levelers can add

3/4" to these dimensions

Signature Series HP24 Models

6

1

4

"

11

7

8

"

18

3

16

"

20"

50" Area in which

electrical outlet must be located

7

9

16

"

SCALE: 1:10

DR.:

DATE:

9/30/09DAS

when fully extended.

*

Leg levelers can add

3/4" to these dimensions

Signature Series HP24 Models

Power cord 65/8" off floor. *

90° Swing

when fully extended.

*

Leg levelers can add

3/4" to these dimensions

Signature Series HP24 Models

1/16" tolerance)(with

24"

25

7

16

" Values may change

due to custom pull

with a wood overlay door.

HP24 Models

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

7

1

1

" Min.

4

clearance from

a corner to

acheive 90

door swing.

50" Area in which

electrical outlet must be located

9

"

16

50" Area in which

electrical outlet must be located

9

7

"

16

Power cord 65/8" off floor. *

20"

90° Swing

required for

pullout shelf

clearance.

Power cord 65/8" off floor. *

1

6

"

4

7

11

"

8

15

24

"

16

Min clearance

for door swing.

required for

pullout shelf

clearance.

Door Models

(Figure 1)

7

"

23

5

1

"

8

3

18

"

16

3

21

"

8

1

3

"

2

8

20"

Drawer Models

(Figure 2)

23 "

8

15

24

"

16

Min clearance

for door swing.

15

1

9

26

"

16

34

*

7

*3

"

8

7

25

" Values may change

16

due to custom pull

with a wood overlay door.

24"

1/16" tolerance)(with

3

18

"

"

16

1

"

4

3

" 8 1

5

1

"

8

3

21

"

9

8

26

"

16

1

3

"

2

25 7/16" Value may change

16

7

11

" 6

8

due to custom pull

with a wood overlay door.

24"

1/16" tolerance)

(with

2" Shelf

adjustability.

1

4

" Lowest

1

"

4

4

shelf location.

*

13

17

"

16

Inside Drawer

(Top & Bottom)

* -Leg leveler can add 3/4” to these dimensions when fully extended

11

17 "

16

3

" 8 1

*3 7/8"

1

4

"7*34

9 3/16" Max.

product ht.

10 3/4" Max.

product ht.

3

6

16

3

8

"

8

" 17

1

10

2

1

"

4

" 6

5 9/16" Max.

3

"

4

3

product ht.

3

"

16

5

Page 6

Operation & Installation Manual

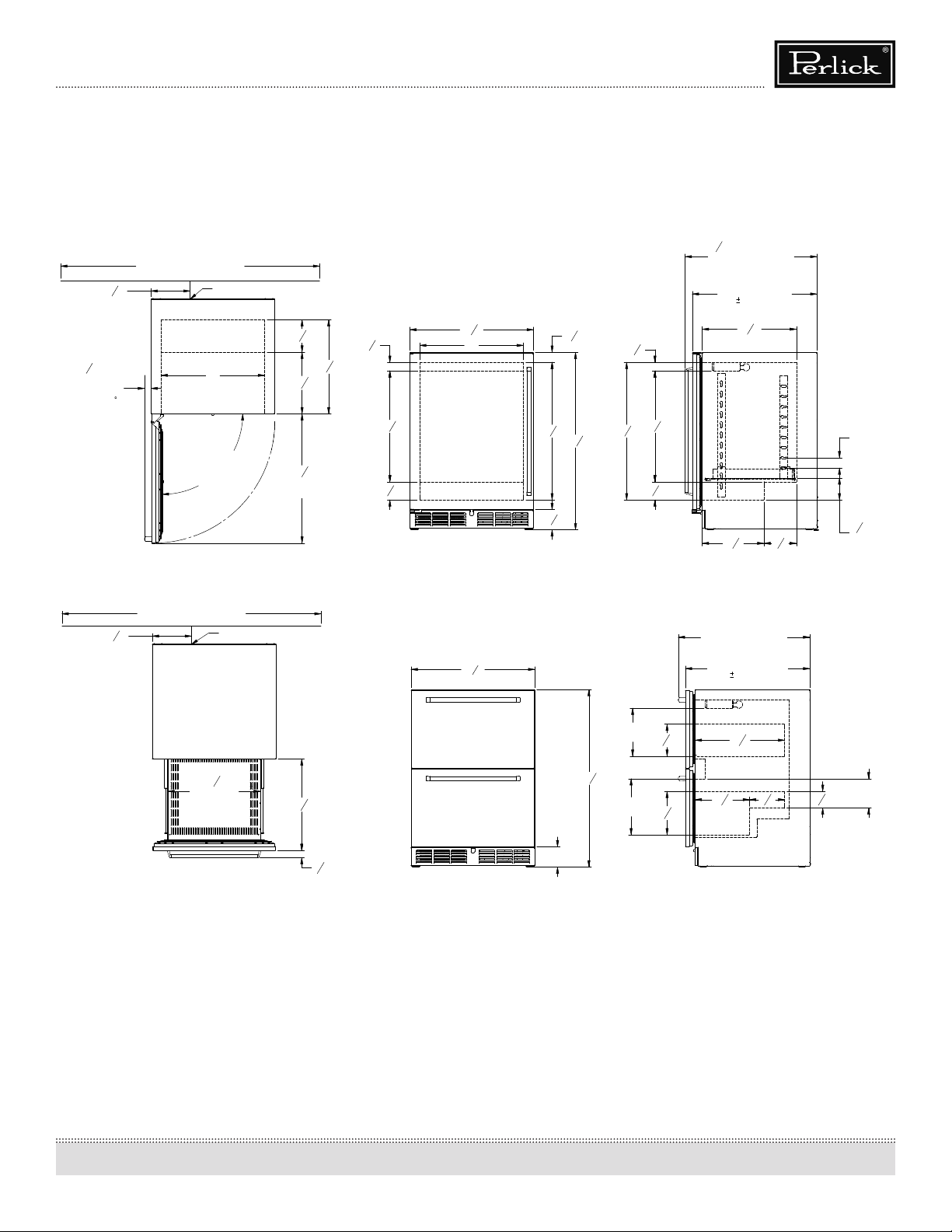

50" Area in which

Signature Series HP48 Models

50" Area in which

Signature Series HP48 Models

Signature Series (HP24 and HP48 models)

HP48 Models

All Door (Figure 3)/All Drawer

Models (Figure 4)

* Leg leveler can add

3/4" to these dimensions

when fully extended.

25 7/16" Values may change

due to custom pull

with a wood overlay door.

24"

(with 1/16" tolerance)

18 1/8"

1 11/16"

1 1/4" Min.

clearance from

a corner to

acheive 90

door swing.

1 11/16"

electrical outlet must be located.

12 1/4"

22"

90° Swing

required for

pullout shelf

clearance.

Power cord 81/4" off floor.*

47 7/8"

44"

24 15/16"

Min. clearance

for door swing.

6 3/8"

11 3/4"

20 5/8"

1 11/16"

25 7/16" Values may change

due to custom pull

with a wood overlay door.

24"

(with 1/16" tolerance)

20 11/16"

2" Shelf

adjustability.

6 3/16" Lowest

shelf location.

* Leg leveler can add

3/4" to these dimensions

when fully extended.

25 7/16" Values may change

due to custom pull

with a wood overlay door.

24"

(with

1/16" tolerance)

19 5/8"

5 1/4"

26 9/16"

1 3/8"

19 5/8"

5 1/4"

electrical outlet must be located.

17 11/16"

12 1/4"

Inside drawer

(Top & Bottom)

17 13/16"

Power cord 81/4" off floor.*

17 13/16"

Inside drawer

(Top & Bottom)

47 7/8"

*34 5/16"

26 9/16"

24 7/8"

25 7/16" Values may change

due to custom pull

with a wood overlay door.

(with

24"

1/16" tolerance)

26 9/16" 19 7/8" 19 7/8"

2" Shelf

adjustability.

2 1/4" Lowest

shelf location.

5 9/16" Max.

product ht.

6

17 1/4"

3 3/16" 6 3/4" 10 1/2"

6 3/16"

8 3/8"

9 3/16" Max.

product ht.

10 13/16" Max.

product ht.

*34 5/16"

9 3/16" Max.

product ht.

10 13/16" Max.

product ht.

6 3/16"

6 3/16"

17 1/4"

17 1/4"

Page 7

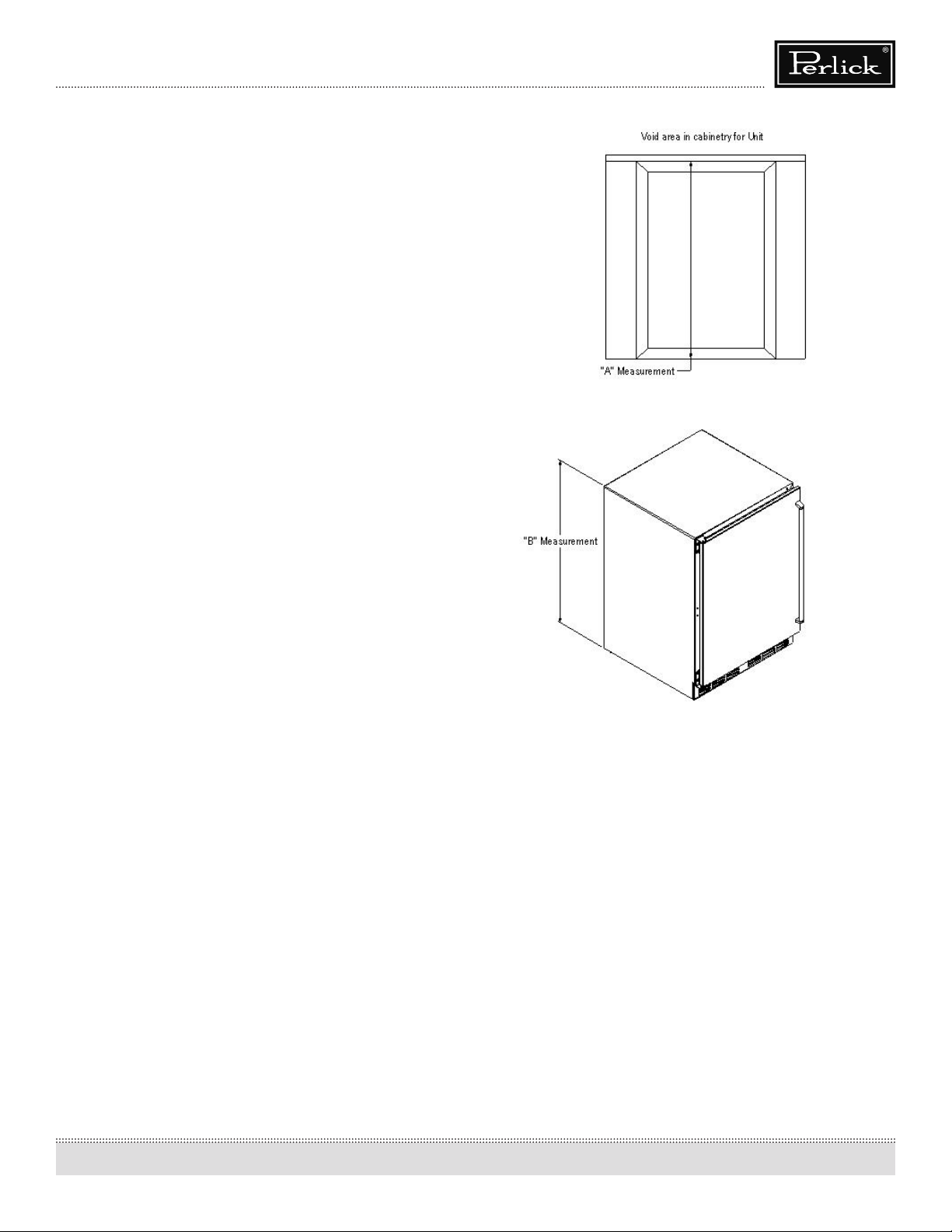

PREPARING THE SPACE

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Make sure that the space that the opening where the Perlick

cabinet(s) is/are to be installed is properly prepared. Refer to

Figures 1 and 2 (page 5) and Figures 3 and 4 (page 6) to ensure

proper space dimensions and electrical service are correct for the

model to be installed.

CAUTION

If cabinet is being installed under a countertop it is recommended

that the countertop be supported by structure other than the

refrigerated cabinet to prevent damage to the counter top.

IMPORTANT NOTE: For a cabinet door to operate properly, the

door must open a minimum of 90°. Use a minimum 3-inch ller

in corner installations to assure a 90° door opening. Allow 24”

clearance in front of the unit for full door swing, shelf pull-out or

drawer pull-out.

IMPORTANT NOTE: Make sure the oor under the unit is level

with the surrounding nished oor. Protect a nished oor with

plywood, cardboard or some other suitable material before moving

the unit into place. Failure to do this may result in damage to the

oor.

PREPARING ELECTRICAL CONNECTIONS

Where a two-prong wall receptacle is encountered or a longer

power cord is required, contact a qualied electrician to have it

replaced in accordance with applicable electrical cords.

DANGER

Failure to comply with the above electrical guidelines may result

in possible injury, death, re or loss of property.

UNPACKING AND MOVING

CAUTION

Do not cut cardboard sleeve covering the unit. Cutting may

result in damage to the exterior of the cabinet.

1. Uncrate the unit outside on a at surface. Remove the cardboard sleeve by removing the banding holding the sleeve to

the shipping base. Carefully lift the cardboard sleeve up over

the top of the unit.

2. Carefully lift unit o base and onto a hand truck or dolly (this

should be done with a minimum of two people; larger units

may require additional helpers!). Make sure the unit is balanced on transporting device using soft, exible strapping.

Protect unit surfaces with cloth material where strapping

contacts unit.

A 115 volt, 60Hz, 15 amp circuit breaker and electrical supply are

required. A separate circuit is required for each Perlick unit installed.

Follow the National Electrical Code and local codes and ordinances

when installing the receptacle.

All Perlick units come equipped with a NEMA 5-15P 90° plug with

a minimum of 5-feet of cord extending beyond the rear of the

cabinet. The electrical outlet must be ush with or recessed into

the back wall.

IMPORTANT NOTE: Never use an extension cord to extend the

power cord to the electrical receptacle.

DANGER

ELECTROCUTION HAZARD

Electrical grounding is required. This appliance is equipped with

a three prong (grounding) polarized plug for your protection

against possible shock hazards.

• Never remove the round grounding prong from the plug.

• Never use a two-prong grounding adapter.

• Never use extension cords to connect power to the unit.

3. Before moving unit, secure door to unit with tape to the door

closed.

4. Carefully move unit to installation site and place in front of

opening.

WARNING

A minimum of two people should lift the cabinet o the base to

prevent possible personal injury.

7

Page 8

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

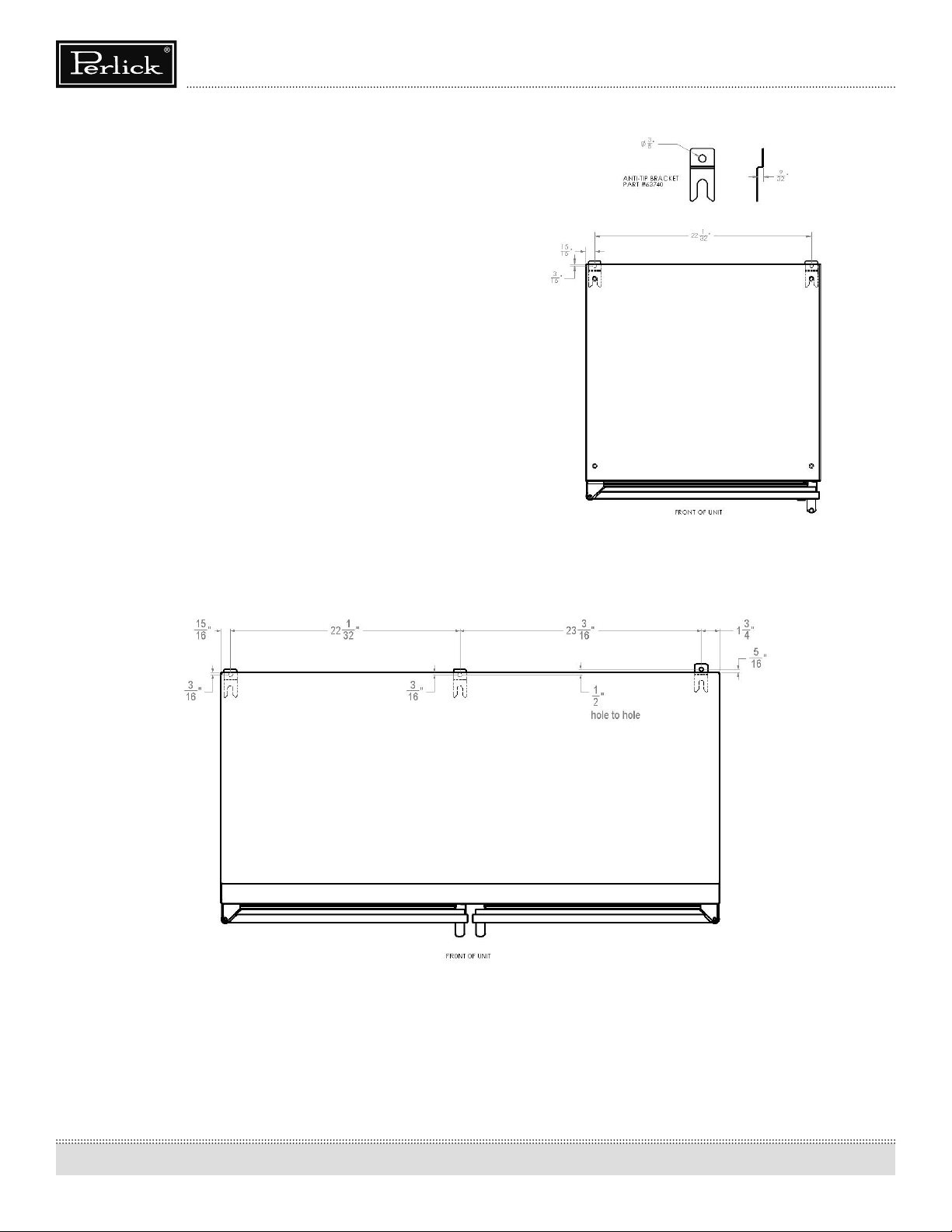

ANTI-TIP BRACKETS

WARNING

Unit may tip forward if loaded racks/shelves are all pulled

out at the same time. To prevent tipping and provide a stable

installation, the unit must be secured in place with the anti-tip

brackets provided with the unit.

A set of metal anti-tip brackets and necessary hardware is supplied

with the unit. The anti-tip brackets, when properly installed, should

secure the rear legs and prevent the unit from tipping forward.

Some installation sites may require modication to provide a secure

surface for attaching brackets. Refer to Figure 5 (right) and Figure

6 (below) for mounting bracket locations for 24” and 48” Signature

Series models.

IMPORTANT NOTE: If installing on a concrete oor, concrete

fasteners are required and are not included in the Anti-Tip Kit.

Figure 5 - 24” Anti-Tip Kit Drawing

Figure 6 - 48” Anti-Tip Kit Drawing

8

Page 9

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

INSTALLATION

CAUTION

Finished ooring should be protected with the appropriate

material to avoid damage from moving the unit.

If unit has been laid on its back or sides, place unit upright and

allow minimum of 24 hours before connecting power.

1. Plug in the unit into the 15 amp grounded outlet located

in the installation opening. With power applied to the unit,

check that the lighting and cooling function operate properly, then turn o power to the wall outlet at the circuit breaker.

WARNING

Shut o power to the wall outlet before installing unit into the

opening.

2. Check that the following are level and square:

• front face and interior opening

• installation opening and oor surface

• countertop bottom front edge

IMPORTANT NOTE: The oor under the unit must be at the same

level as the surrounding nished oor.

Figure 7 - Leveling

3. If all surfaces are level, refer to Figure 7 (right) and perform

the following:

a. Measure from the oor to the bottom of the front edge of

the countertop.

b. Mesure the rear of the unit cabinet from oor to top of

cabinet, at back corners.

c. Adjust rear legs so B measurement equals A measurement.

Usingt an adjustable wrench of pliers, turn legs counterclockwise to raise the unit or clockwise to lower the unit.

IMPORTANT NOTE: Leveling legs should not extend more than

3/4” from bottom of the unit.

4. Slide cabinet into position. Make sure the rear levelling legs

slide under the anti-tip brackets. Push the unit into the opening until the bottom front edge of the unit is ush with the

surrounding cabinetry, or until the rear legs are tight against

the anti-tip brackets.

IMPORTANT NOTE: Leveling legs should not extend more than

3/4” from bottom of the unit.

5. Shim the front of the unit so the front face is ush with the

surrounding cabinetry. Adjust the front legs to support the

countertop at the shimmed height. Using an adjustable

wrench or pliers, turn the legs counterclockwise to raise the

unit or clockwise to lower the unit. Countertop should be

resting on top of the unit.

IMPORTANT NOTE: If countertop is not resting entirely on unit top,

shim the countertop to prevent damage to the countertop.

CAUTION

To prevent damage to the countertop and unit underneath, do

not place heavy objects on countertop directly above the unit.

6. Check interior door openings inside the cabinet to ensure

the cabinet is level. Reinstall all shelving and sliding drawers

squarely into slide brackets and proper slide bracket grooves.

When sliding shelving and drawers are installed properly

a click should be heard from both slide bracket retaining

clips and should slide smoothly in the tracks. When sliding

shelving or drawers are pulled out to full extension a stop is

activated to prevent additional pull-out.

CAUTION

Improper shelving or drawer installation may not actuate slide

top mechanism.

9

Page 10

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

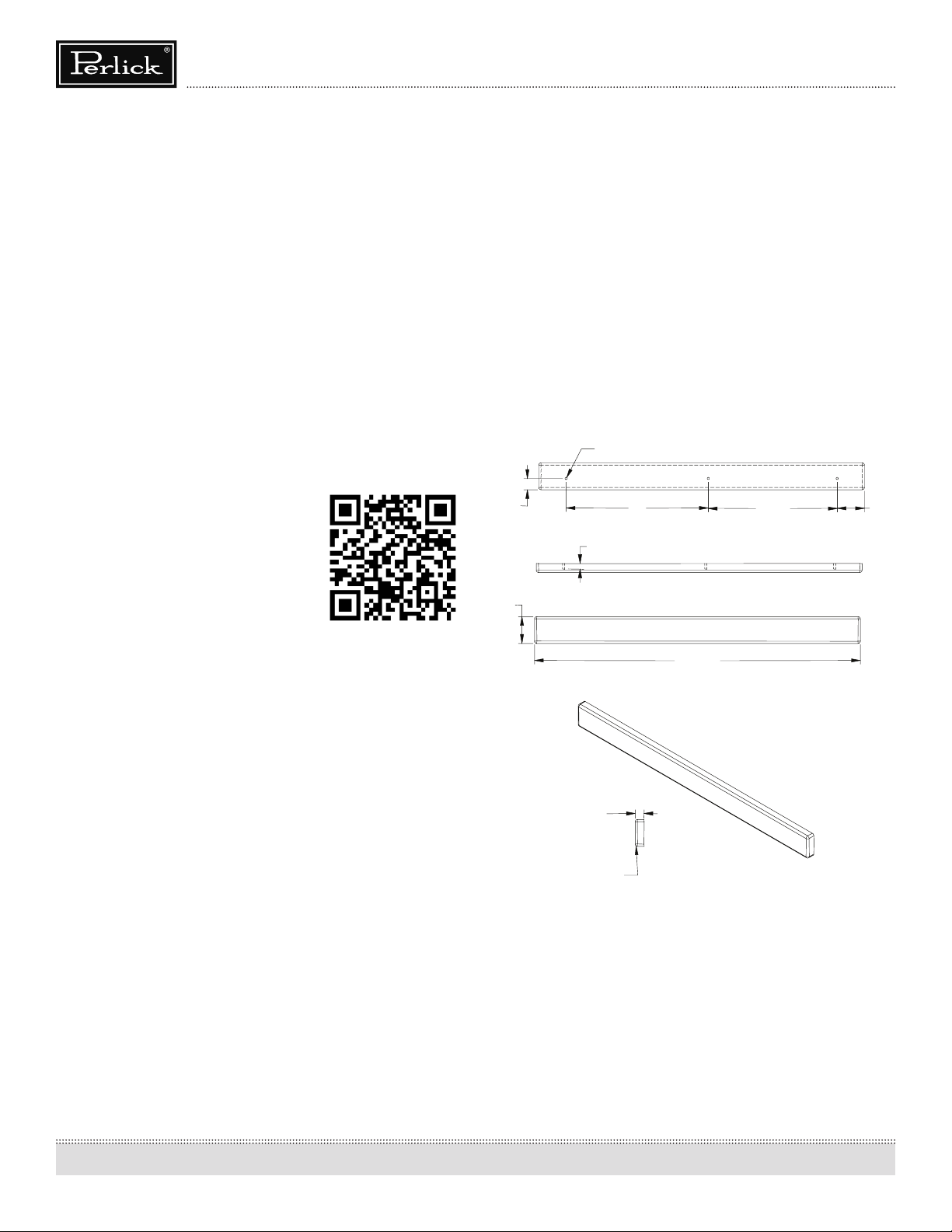

TOE PLATE INSTALLATION

When the unit is secured in place, install the louvered toe plate.

Secure louvered toe plate by snapping the latch into the latch

catch on the unit. Refer to Figure 8 (below) for Toe Plate Installation

Illustration and Figure 9 (page 11) for Toe Plate Wood Overlay

template.

CAUTION

The louvered toe plate must be removed to service the unit. The

oor cannot interfere with removal. The louvered sections must

not be covered or obstructed to prevent proper air circulation.

IMPORTANT NOTE: To achieve maximum performance, interior

louver openings and fan guard openings should never be

obstructed.

Figure 8- Toe Plate Installation

Single Door Beverage Center

The single door unit comes with two full-extension black vinylcoated wine racks and one Industry Exclusive full-extension black

vinyl-coated pullout shelf allowing for storage of both wine and

beverages. Shelving positions are adjustable.

Two Door All-Refrigerator

The two door all-refrigerator comes standard with four black

vinyl-coated pullout shelves and a bottome step shelf. Up to two

additional full-extension black vinyl-coated pullout shelves can be

used with these cabinets.

Two Door Refrigerator/Wine Reserve

The two door refrigerator/wine reserve (HP48RW) comes standard

with two full-extension black vinyl-coated pullout shelves and six

full-extension black vinyl-coated pullout wine racks capable or

storing 48 wine bottles.

Two Door Refrigerator/Beer Dispenser

The two door refrigerator/beer dispenser (HP48RT) comes standard

with two full-extension black vinyl-coated pullout shelves.

Two Door All-Wine Reserve

The two door all-wine reserve (HP48WW or HP48WO) comes

standard with ten full-extension black vinyl-coated pullout wine

racks capable of storing 88 total wine bottles. If the cabinet is a

multi-zone win reserve the rst door can hold 40 total wine bottles

while the second door can hold 48 total wine bottles.

SHELVING

Single Door Freezer/Refrigerator

The single door unit comes standard with two Industry Exclusive

full-extension black vinyl-coated pullout shelves.

Single Door Wine Reserve

The single door unit comes standard with ve full extension

black vinyl coated pullout wine racks capable of storing 40 total

wine bottles. Wine shelves are removable and adjustable to

accommodate oversized (magnum) bottles. Additional storage is

available on the lower step for an additional ve wine bottles.

10

Page 11

Operation & Installation Manual

2

3

B

A

1

C

THIS DOCUMENT / PUBLICATION / SOFTWARE / DRAWING CONTAINS PROPRIETARY INFORMATION WHICH IS THE PROPERTY OF THE PERLICK CORPORATION. IT MAY NOT BE REPRODUCED OR TRANSMITTED IN ANY FORM, ELECTRONIC OR MECHANICAL,

INCLUDING PHOTOCOPYING, RECORDING, OR USED IN ANYINFORMATION STORAGE, TRANSMISSION, OR RETRIEVAL SYSTEM, WITHOUT WRITTEN PERMISSION FROM THE PERLICK CORPORATION. COPYRIGHT 2001 PERLICK CORPORATION. ALL RIGHTS RESERVED.

SHEET 1 OF 4

Perlick Corporation

Milwaukee, Wisconsin

REVISIONS

GRILL, WOOD

STAND ALONE

WOOD GRILL

1:3

4/23/2008

J:\Dwg\_ Assembly\HHC GEN2\HHC GEN2 24IN RESIDENTIAL\Wood Grill.slddrw

Signature Series (HP24 and HP48 models)

Figure 9- Toe Plate Wood Overlay Template

SCALE =

DWG NO.

WOOD GRILL, STACKING

REFERENCE:

DATE

TITLE:

4/23/2008

4/23/2008

4/23/2008

PART NO.

PURCHASE REC.:

3/32"

5/32"

11/16"

DETAIL D

SCALE 1 : 1

7/32"

DETAIL C

1"

SCALE 1 : 2

TYPICAL

TYPICAL

3"

3/16"

TYPICAL

5/16"

3/8"

29/64"

1"

3/8"

43/64"

NAH

NAH

QTY.:

FINISH:

3/8"

TYPICAL

3/8"

1/32"

9/32"

SCALE 1 : 2

SECTION B-B

SIGNATURES

DRAWN

DESIGNED

CHECKED

NOTE: ALL INTERNAL RADII ARE 1/8IN UNLESS OTHERWISE SPECIFIED

BREAK SHARP EDGES - 015 X 45°.

RADIUS SHARP FILLETS - .015 TO .031

DIMENSIONS ARE IN INCHES

TOLERANCES:

.X= ,

.XX = ,

.XXX = ,

ANGULAR: ±1.0°, FRACTIONS: ±1/16

MATERIAL:

UNLESS OTHERWISE SPECIFIED:

WOOD

17/64"

3 27/64"

C

B

B

11 9/16"

1"

3/4"

1"

1/4"

R

23 7/8"

FRONT VIEW

11/16"

METAL CLIP REQUIRED FOR SNAP IN RETAINER THAT

ASSEMBLES GRILL TO THE UNIT. THIS CLIP MUST BE

SCREWED TO THE GRILL USING THE FEATURES SHOWN

IN DETAIL VIEW "D"

THICK (20GA)

RECOMMENDED

GALVANIZED OR

STAINLESS STEEL

1/32"

REAR VIEW

3/32"

9/32"

1/8"

1/2"

NOTE: GRILL SHOWN ON THIS PAGE IS FOR EITHER A SINGLE STAND ALONE UNIT OR

THE BOTTOM UNIT OF A STACKED CONFIGURATION

D

1 13/64" 1 13/64"

1/4"

7/8"

7/64" 7/64"

9/32"

11

Page 12

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Adjusting Full-extension Shelving

1. Pull the shelf out to its farthest position. Locate the tabs in the

middle of both extenders (Figure 10). Lift one tab up while

pushing the opposite tab down and pull shelf out.

2. Reposition each bracket separately. Grasp the middle of

the bracket, pull the front end up and out, then forward to

remove (Figure 11).

3. Place bracket at the desired position. Push the rear hook into

the rear key slot. Set front of the bracket on the wall hook.

4. Repeat for other bracket(s).

5. Push extenders completely into the unit. Align the shelf

grooves with the extenders and slide completely into the

unit.

Drawers

Drawer units (available in Refrigerator and Freezer units only) come

standard with two drawers for 24” units and four drawers for 48”

units (provided entire until is ordered with drawers). Like shelving,

drawers are full-extension.

Figure 10- Tab location

Lift one tab up while pushing the

opposite tab down and pull shelf out

Figure 11 - Bracket and extender location

To remove drawers:

1. Pull the drawer out to its farthest point.

2. Locate the tabs in the middle on both sides of the extenders.

Press left tab up and right tab down; pull shelf out.

3. Move each extender separately. Hold the middle of one extender, pull the front up then move extender 1/2-inch to the

inside of unit. Pull up, then out.

4. Place extender at desired height, place rear stando screw

into rear pilaster, slide back. Place front stand-o screw into

front pilaster, slide down.

5. To return drawer, rst push both extenders completely in

then line up the shelf grooves and slide easily into the unit.

CAUTION

Completely empty the drawer before removing.

To remove brackets,

remove shelf, lift front

of bracket to disengage

the front key slot, and

pull forward to disengage

the rear key slot.

12

Page 13

DOOR OPTIONS

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Perlick residential units oer a variety of door panel design

alternatives; solid stainless steel, solid wood overlay, glass with

stainless steel trim and glass with wood overlay trim.

Solid stainless steel and stainless steel glass doors are shipped from

the factory with decorative stainless steel panels and handles in

place on the appliance.

Solid wood overlay and glass wood overlay doors are designed to

accept a decorative front panel to match surrounding cabinetry

and door handles. The panel and door handles are supplied by the

customer.

All Perlick units accept any of the above door congurations and

are fully interchangable.

IMPORTANT NOTE: Units with a freezer only can utilize a solid

stainless steel door, solid wood overlay door, solid stainless drawers

or wood overlay drawers (stainless steel glass or wood overlay

glass doors will sweat if installed on a freezer section).

IMPORTANT NOTE: Glass with stainless trim and glass with wood

trim may sweat in conditions with relative humidity over 75%.

Panel drawings:

Refer to Figure 13 for solid wood overlay panel (page 14).

Refer to Figure 14 for glass wood overlay panel (page 15).

Refer to Figure 15 for drawer wood overlay panel (page 16).

Door Lock Installation (optional)

When installing to wood overlay, perform lock installation before

mounting wood overlay to door.

1. See Figure 12 (below), attaching mounting bracket to wood

overlay.

2. Insert lock body and attach with nut.

Lock installation drawings:

Refer to Figure 16 for Lock Installation on solid wood overlay panel

(page 17).

Refer to Figure 17 for Lock Installation on glass wood overlay panel

(page 18).

Refer to Figure 18 for Lock Installation on drawer wood overlay

panel (page 19).

Figure 12 - Lock installation

WOOD OVERLAY INSTALLATION

Before beginning installation, check all components for proper t

and nish.

WARNING

• All overlay doors require a trim panel of at least 3/4” thick.

• The solid wood overlay panel should not weight more than

20 pounds.

• The glass wood overlay panel should not weight more than

10 pounds.

The following instructions cover installing a solid wood overlay or

glass wood overlay panel and handle to a door or drawer.

IMPORTANT NOTE: Contact the factory or visit www.

bringperlickhome.com for full size wood overlay panel layouts.

Once on the site, select ‘Service and Support’ from the top menu

bar and click on ‘Wood Overlay Templates’. Take care in chosing the

correct template for your specic model.

IMPORTANT NOTE: You must install optional lock and handle

PRIOR to mounting the wood overlay onto the door frame.

Mounting bracket

Nut

Lock strike

Lockwasher

Lock body

Screw

Lock bracket

13

Page 14

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Figure 13 - Solid wood overlay panel template

14

Page 15

Figure 14 - Glass wood overlay panel template

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

15

Page 16

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Figure 15 - Wood overlay drawer panel template

16

Page 17

Figure 16 - Lock installation, solid wood overlay door panel

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

17

Page 18

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Figure 17 - Lock installation, wood overlay glass door panel

18

Page 19

Figure 18 - Lock installation, wood overlay drawer panel

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

19

Page 20

Operation & Installation Manual

1

/16” to 1/8”

radius all

outside edges

1

/2”

Signature Series (HP24 and HP48 models)

Handle Installation

CAUTION

Handle mounting on wood overlay door should be mounted on

overlay panel only (not the door) to avoid damage to the factory

door.

1. Handle must be attached to overlay before mounting overlay

onto door. Mark rear of wood overlay planel with handle

fastening locations.

2. Drill through wood overlay panel at marked locations taking

care not to damage the wood overlay panel.

3. Countersink screw heads so screw heads are ush with back-

side of panel. Attach handle to overlay panel.

CAUTION

Proper wood working materials and equipment should be used

to avoid damage or errors in workmanship.

Wood Overlay Panel Installation

Scan the QR code to the right with

your smart phone to watch a How-To

video on how to install Wood Overlay

panels onto Perlick doors, otherwise,

follow the instructions below.

WOODEN WINE RACK TRIM FINISHING (optional)

All wine racks come with sleek stainless steel fronts. Unnished solid

hardwood fronts are optional and can be removed and replaced

with other wood to match your cabinetry. See Figure 19 (below) for

wine rack face details..

IMPORTANT NOTE: The unnished faces should be nished and

sealed. In many cases, stains and/or nishes have odors that may

be objectionable in an enclosed area. Do not stain or nish wood

faces while in unit. To remove the front wood face from the wine

shelf, simply pull out the wine shelf and remove the fasteners.

Finish as desired, and when completely dry, reinstall with fasteners.

Figure 19 - Wood wine rack trim design

1

/8” x 0.312” deep

5

/8”

5

1

1

/2”

8”

/16”

1

7

/4”

17

/

1

32”

1. With the unit secured in position, open the door and make

sure panel’s pre-drilled holes align with door frame holes.

2. Loosely attach four corners of the overlay panel to the door

using #10 x 1” wood screws, installed through the door frame

from the rear.

3. Check for overall wood overlay panel t, position and func-

tion. Make minor adjustments as necessary. When panel is

properly aligned, tighten mounting screws securely. Install

the rest of the mounting screws and tighten securely.

CAUTION

Do not over-tighten wood overlay attachment screws as this

may damage the factory supplied door frame.

1

/2”

1

/16” to 1/8”

radius all

outside edges

18

5

/16”

20

Page 21

OPERATION

General

The unit is equipped with a state-of-the-art refrigeration system.

The variable speed compressor automatically changes speed

based on system conditions and load. The cabinet is equipped with

an adjustable digital temperature controller and LED display.

Freezer units are frost-free models, meaning the evaporator coil

automatically defrosts on demand at predetermined intervals.

The controller also has a manual defrost soft button on the

front panel signied by a melting snowake. If depressed it will

automatically put the system into a defrost cycle.

Interior Light

The unit is equipped with an interior light that illuminates when

the door is open. The cabinet also comes standard with a manual

light switch located next to the light for displaying your products

through a glass door.

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Always ensure that the manual switch is in the o position before

closing a solid wood or stainless door. If manual light switch is

left on for an extended period of time it may increase the cabinet

temperature, especially at the top and cause the refrigeration

system to run longer.

Loading Product

IMPORTANT NOTE: Before storing perishables, allow unit to run

for a minimum of 24 hours to allow temperature stabilization after

start-up.

When loading items into the unit, do not block internal louvers and

fan guard openings or performance will be decreased.

LIGHT BULB REPLACEMENT

To replace a defective or burnt out light bulb, unscrew the bulb

counterclockwise and replace with an identical 15-watt bulb or

smaller (Perlick replacement bulb number 67026).

21

Page 22

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

TEMPERATURE CONTROLLER

22

Page 23

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

IMPORTANT NOTE: Dependent on the mode and conguration, the controllers have been programmed to only allow a temperature

adjustment within a specied range. See chart below for the specied range allowed for your cabinet:

Single Door Units

Description Model No. Set Point Range

Freezer HP24 0°F -10 °F to 10°F

Refrigerator HP24R 38°F 30°F to 42°F

Beverage Center HP24B 42°F 30°F to 48°F

Wine Reserve HP24W 45°F 40°F to 68°F

Two Door Units

Description Model No. Set Point Range

All-Refrigerator HP48RR 38°F 30°F to 42°F

All-Wine HP48WO 45°F 40°F to 68°F

Refrigerator/Beverage Center HP48RB

Refrigerator Section 38°F 30°F to 42°F

Beverage Center Section 38°F 30°F to 42°F

Refrigerator/Wine Reserve HP48RW

Refrigerator Section 38°F 30°F to 42°F

Wine Reserve Section 55°F 40°F to 68°F

Wine Reserve/Wine Reserve HP48WW

Wine Reserve (Left) 45°F 40°F to 68°F

Wine Reserve (Right) 55°F 40°F to 68°F

IMPORTANT NOTE: All mutli-zone units must have a minimum of 8°F dierence between zones.

CHECKING PRODUCT TEMPERATURE

To accurately check the temperature of product stored in the

refrigerated compartment insert an accurate thermometer into a

plastic (non-breakable) bottle, partially lled with water. Tighten

the bottle cap securely.

Place the bottle in the desired area for 24 hours. Refrain from

opening the unit during testing period. After 24 hours, check the

temperature of the water. Adjust the control settings if necessary.

You Perlick unit is pre-set in order to achieve the recommended

temperature range when installed in a 70°F ambient room

temperature. Factors which aect the internal temperatures of the

refrigerated cabinet include:

• Temperature setting

• Room temperature where installed

• Number of times the door is opened and closed

• Length of times the door is left open

• Style of door installed

• Door gasket sealing and condition

• Amount of time the internal light is illuminated

• Installaion in direct sunlight or near a heart source

23

Page 24

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

CLEANING AND OTHER MAINTENANCE

CAUTION

Shut o electricity to the unit before cleaning the condenser

and other routine maintenance.

To clean stainless steel exterior or interior surfaces, use a soft, nonabrasive stainless steel cleaner to wipe down the surfaces. If you

have diculty nding a good cleaner, try Signature Polish from

Signature Limited Laboratory, P.O. Box 13436, Dayton, OH 454130436; or call toll-free at (877) 376-5474. Glass panels can be cleaned

using any standard glass cleaner available on the market today.

To clean interior and exterior non-metallic surfaces and removable

parts, wash with a mild solution of soap and lukewarm water with

a little baking soda. Rinse and dry thoroughly. Avoid getting water

on lights, controllers, fan motors and unnished wood wine rack

faces.

CAUTION

Do not use abrasive cleaners or cloths on any of the interior or

exterior surfaces or removable parts.

Cleaning the Condenser

The condenser should be cleaned every three (3) months. The

condenser is located behind the toe plate (Figure 6). Remove the

toe plate and use a soft bristle brush and vacuum to remove the

dust and lint. Avoid damaging or crushing the condenser ns or

tubing. Upon completion, reinstall the toe-plate.

CAUTION

Failure to clean the condenser could result in temperature loss

or mechanical failure. Clean this area every three months.

TROUBLESHOOTING

BEFORE CALLING FOR SERVICE:

If the unit appears to be malfunctioning, read through NORMAL OPERATION rst. If the problem persists, check the TROUBLESHOOTING

GUIDE. Locate the problem in the guide and refer to the cause and its remedy before calling for service. The problem could be

something which can be solved without a service call.

DANGER

NEVER ATTEMPT TO REPAIR OR PERFORM MAINTENANCE ON THE UNIT UNTIL THE MAIN ELECTRICAL POWER HAS BEEN

DISCONNECTED!

Problem: No interior light

• Is the bulb loose?

• Is the bulb burnt out?

Problem: Light stays on when door is closed

• Manual ON/OFF light switch is turned ON

• Is the door switch making contact with the door?

Problem: Noise during operation

• Certain sounds are normal. Soft sounds from the compressor, fan motor and valves will be heard

• During freezer defrost crackling is normal

Problem: Controller display is ashing “P1”

• There is a thermostat probe failure

Problem: Controller display is ashing “P2”

• There is an evaporator probe failure

24

Page 25

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

Problem: Controller display is ashing “HA”

• The internal compartment temperature has exceeded the high temperature alarm preset value for over 30 minutes.

• Check to ensure door is closed

• Check door gasket seal

• Has warm product been placed in the cabinet?

• Is the condenser clean?

• In the louvered toe plate obstructed?

• Has the surrounding ambient temperature changed dramatically?

• Is the interior light ON?

Problem: Controller display is ashing “LA”

• The internal compartment temperature has exceeded the low temperature alarm preset value for over 30 minutes

• Check to ensure door is closed

• Check for gasket seal

• Has the surrounding ambiant temperature changed dramatically?

Problem: Controller display is ashing “EE”

• The controller has a data or memory failure

Problem: The refrigerated cabinet isn’t running

• Is there electrical power to the unit?

• Is your home circuit breaker or fuse on?

• Is your ON/OFF key pad on?

• Is your condenser area clean?

Problem: The refrigerated compartment is warmer than usual

• Is your control set properly?

• Is the light staying on?

• Is your condenser area clean and free of obstructions?

• Has the door been open for a long time or more frequent door openings occured?

• Are the internal louvers and fan guard openings obstructed?

• Has warm product been placed in the cabinet?

Problem: The refrigeration system runs for long periods of time

• Is the condenser area clean and free of obstructions?

• Have the doors been open for a long time or more frequent door openings occured?

• Has warm product been placed in the cabinet?

• On hot days and in warm room temperatures the system will run long

Problem: Condensation forms inside the refrigerated compartments

• This is normal during high humidity and frequent door openings

• Are the doors closing and sealing properly?

Problem: Condensation forms on the outside of the unit

• During periods of high humidity some condensation might appear on outside surfaces. The condensation will disappear when the

humidity drops. Meanwhile, be sure doors are closing and sealing properly. If condensation persists, contact your Perlick Factory

Authorized Service Center.

You need product information:

• Contact your selling dealer

• Inquire via the web at www.perlick.com

• Call (800) 558-5592 for factory assistance on planning, installation or product information.

• Write to: Perlick Corporation, Customer Service Department, 8300 West Good Hope Road, Milwaukee, WI 53223

• E-mail us at warrantyserv@perlick.com

25

Page 26

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

You need product service:

• Check the model and serial number of your unit located on the label attached to the inside top of the cabinet. Then call your

Perlick FactoryAuthorized Service Center. For the location of the Service Center in your area, contact your dealer, inquire via the

web at www.perlick.com, call (800) 558-5592 for factory assistance on planning, installation or product information, write to: Perlick

Corporation, Customer Service Department, 8300 West Good Hope Road, Milwaukee, WI 53223, e-mail us at

warrantyserv@perlick.com.

You need replacement parts or accessories:

• Use only genuine Perlick replacement parts and accessories. Genuine Perlick parts and accessories are designed to work correctly

with Perlick products and oer superior service life. The use of non-Perlick parts can damage the unit and may void the warranty

• Check the model and serial number of your unit located on the label attached to the inside top of the cabinet. Then call your

Perlick Factory Authorized Service Center. For the location of the Service Center in your area, contact your dealer, inquire via the

WEB at www.perlick.com, or write to: Perlick Corporation, Customer Service Department, 8300 W. Good Hope Rd, Milwaukee, WI

53223, call 800/558-5592 or e-mail us at warrantyserv@perlick.com

RESIDENTIAL PRODUCTS WARRANTY

1A. PERLICK RESIDENTIAL REFRIGERATION PRODUCTS LIMITED WARRANTY

(excludes H50IM Clear Ice Makers; see warranty on page 31)

ENTIRE PRODUCT - Full Three Year Warranty*:

For three (3) years from date of original purchase, Perlick Corporation’s warranty covers all parts and labor to repair or replace any

part of the product, which proves to be defective in material and workmanship.

ADDITIONAL - Fourth through Sixth Year Limited Parts Only Warranty:

During the three (3) years following expiration of the Three Year Warranty*, Perlick will supply replacement parts only for the

hermetically sealed refrigeration system with consists of the compressor, condenser, drier, connecting tubing, evaporator and hot

gas bypass valve.

*You must register your product within 90 days of purchase to receive the Full Three Year Warranty. Without registration, you will receive the

standard Full Two Year Warranty with the additional Third through Sixth Year Limited Parts Only Warranty.

TERMS:

The Perlick Warranty applies to products installed in the fty United States, the District of Columbia or the ten provinces of

Canada.

All service provided by Perlick Corporation under the above warranty must be performed by authorized Perlick service

representatives, unless otherwise specied by Perlick.

Service will be provided in the home during normal business hours.

This warranty applies only to products installed for normal residential use, it does not include adjusting the controls, door reversal,

light bulb or cleaning the condenser.

This warranty is extended only to the original purchaser of the Perlick product.

26

Page 27

Operation & Installation Manual

Signature Series (HP24 and HP48 models)

The above warranty does not apply if:

• Failure of product was due to transportation

• Product was: improperly installed, misused, abused, operating with low voltage, wiring not conforming to electrical codes,

improperly maintained or modied.

• The original Bill of Sale, delivery date or serial number cannot be veried.

• Defective parts are not returned for inspection if so required by the Perlick Corporation.

To receive parts and or service and the name of the nearest Perlick authorized service representative, contact your Perlick dealer,

distributor or Perlick Corporation’s Customer Service Department; 8300 West Good Hope Road, Milwaukee Wisconsin, 53223; call

800 558-5592, E-mail us at warrantyserv@perlick.com , or visit our web: www.bringperlickhome.com.

This limited warranty is in lieu of any other warranty, expressed or implied, including, but not limited to any implied warranty of

merchantability or tness for a particular purpose; provided however, that to the extent required by law, implied warranties are

included but do not extend beyond the duration of the express warranty rst set above. Perlick’s sole liability and your exclusive

remedy under this warranty are set forth in the initial paragraph above. Perlick Corporation shall have no liability whatsoever for

any incidental, consequential or special damages arising from the sale, use or installation of the product or from any other causes

whatsoever, whether based on warranty(expressed or implied) or otherwise based on contract, tort or any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the above limitations may not apply to you. This warranty gives you specic legal rights, and you may

also have other rights, which vary, from state to state.

27

Page 28

1B. PERLICK H50IM CLEAR ICE MAKER LIMITED WARRANTY

ENTIRE PRODUCT - Full One Year Warranty:

For one (1) year from date of original purchase, Perlick Corporation’s warranty covers all parts and labor to repair or replace any

part of the product, which proves to be defective in material and workmanship.

TERMS:

The Perlick Warranty applies to products installed in the fty United States, the District of Columbia or the ten provinces of

Canada.

All service provided by Perlick Corporation under the above warranty must be performed by authorized Perlick service

representatives, unless otherwise specied by Perlick.

Service will be provided in the home during normal business hours.

This warranty applies only to products installed for normal residential use, it does not include adjusting the controls, door reversal,

light bulb or cleaning the condenser.

This warranty is extended only to the original purchaser of the Perlick product.

The above warranty does not apply if:

• Failure of product was due to transportation

• Product was: improperly installed, misused, abused, operating with low voltage, wiring not conforming

• electrical codes, improperly maintained or modied.

• The original Bill of Sale, delivery date or serial number cannot be veried.

• Defective parts are not returned for inspection if so required by the Perlick Corporation.

To receive parts and or service and the name of the nearest Perlick authorized service representative, contact your Perlick dealer,

distributor or Perlick Corporation’s Customer Service Department; 8300 West Good Hope Road, Milwaukee Wisconsin, 53223; call

800 558-5592, E-mail us at warrantyserv@perlick.com , or visit our web: www.bringperlickhome.com.

This limited warranty is in lieu of any other warranty, expressed or implied, including, but not limited to any implied warranty of

merchantability or tness for a particular purpose; provided however, that to the extent required by law, implied warranties are

included but do not extend beyond the duration of the express warranty rst set above. Perlick’s sole liability and your exclusive

remedy under this warranty are set forth in the initial paragraph above. Perlick Corporation shall have no liability whatsoever for

any incidental, consequential or special damages arising from the sale, use or installation of the product or from any other causes

whatsoever, whether based on warranty (expressed or implied) or otherwise based on contract, tort or any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the above limitations may not apply to you. This warranty gives you specic legal rights, and you may

also have other rights, which vary, from state to state.

8300 West Good Hope Road • Milwaukee, WI 53223 •

Toll Free 800.558.5592 • Fax 414.353.7069 • www.bringperlickhome.com

Form No. Z2340

Rev. 06/04/2012

Loading...

Loading...