Page 1

SERVICE MANUAL

Residenal and Commercial

Front Venng Refrigeraon

Product Series Covered in this Manual:

Residenal

HA24BB, HA24RB, HA24WB

HA24FB

HC24BB, HC24RB, HC24RO,

HC24TB, HC24TO, HC24WB

HP15, HK15

HH24

HP24, HK24, HM24 (Med Temp)

HP24, HK24 (Low Temp)

HP24, HK24, HM24 (Dual Zone FRZ/REF)

HP24, HK24, HM24 (Dual Zone, Med Temp)

HP48

HHA24, HPA24

Front Venng Commercial

HC48

HB24BS, HB24RS, HB24WS

HB24FS

HC24FS, HC24RS, HC24WS

HD24RS, HD24WS

Scan here to

download a pdf copy

of this manual.

Form No. Z2506

Page 2

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

Table of Contents

1.0 GENERAL INFORMATION ................................................................................ 1-1

Use of Service Manual .................................................................................... 1-1

Model Families .............................................................................................. 1-1

2.0 SAFETY INFORMATION ................................................................................... 2-1

Refrigerant HFC-134a ..................................................................................... 2-1

Potential Problems with HFC-134a ................................................................... 2-1

Service Manual Safety Labels ...........................................................................2-1

3.0 TROUBLESHOOTING GUIDE ............................................................................ 3-1

Refrigeration System ...................................................................................... 3-1

Electrical System ............................................................................................ 3-4

Doors, Drawers, and Shelving ......................................................................... 3-9

Beverage Dispensing ...................................................................................... 3-10

4.0 VARIABLE SPEED COMPRESSOR SPECIFICATION .......................................... 4-1

5.0 COMPRESSOR INVERTER OPERATION ........................................................... 5-1

5.1 Compressor Start-Up ........................................................................................ 5-1

5.2 Normal Operation ............................................................................................. 5-1

6.0 TROUBLESHOOTING COMPRESSOR INVERTER .............................................. 7-1

7.0 REFRIGERATION SYSTEM REPAIR INSTRUCTIONS ........................................ 7-1

Air Inltration ............................................................................................... 7-1

System Operating Pressures .......................................................................... 7-3

7.2.1 Process Tubes and Access Valve ...................................................................... 7-4

Remove Evaporator Fan Panel ....................................................................... 7-4

De-Ice Blocked Evaporator Coil .................................................................... 7-5

Evaporator Airow by Model ......................................................................... 7-6

Air Flow Obstructions ................................................................................... 7-7

Clean Condenser Coil ................................................................................... 7-7

Ambient Temperature .................................................................................. 7-7

Compressors ............................................................................................... 7-8

Replace Condenser. Fan Motor ...................................................................... 7-9

Replace Evaporator Fan Motor ...................................................................... 7-9

Replace Compressor .................................................................................... 7-10

Leak Detection ............................................................................................ 7-10

Recharge Procedure .................................................................................... 7-10

Replace compressor starting device ............................................................. 7-11

Beverage Dispensing ................................................................................... 7-12

C0

2 gauge pressure, temperature and carbonation level reference chart .......... 7-12

Calculate ideal gague pressure of straight CO

............................................... 7-13

2

Beer Dispensing Cleaning ............................................................................ 7-13

7.20 Refrigeration System Diagrams ..................................................................... 7-15

Table of Contents Page 1

Page 3

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

8.0 ELECTRICAL SYSTEM REPAIR INSTRUCTONS................................................. 8-1

Electrical Specications ................................................................................... 8-1

Wiring Diagrams ............................................................................................ 8-2

Load Operation Modes .................................................................................... 8-18

Electronic Controller ....................................................................................... 8-26

Factory Set Point ............................................................................................ 8-27

8.6.1 Dixell Controller: Reset Factory Parameter Settings ........................................... 8-30

8.6.2 Eliwell Controller: Reset Factory Parameter Settings .......................................... 8-30

8.6.3 Replacing Control Module ................................................................................ 8-30

8.6.3.1 Replacing Electro-mechanical Controller .............................................. 8-30

8.6.3.2 Replacing Digital Controller – Dixell & Eliwell ....................................... 8-30

8.6.4 Temperature Probe ......................................................................................... 8-32

LED Lighting .................................................................................................. 8-33

8.7.1 Replace LED Light Strip ................................................................................... 8-33

Replace DC Driver/Inverter ............................................................................. 8-33

8.10 Mullion Heater Hook Up .............................................................................. 8-34

9.0 SERVICE INSTRUCTIONS - DOORS, DRAWERS, AND SHELVING .................... 9-1

Proper Door and Drawer Usage ........................................................................ 9-1

Reverse Door Swing ....................................................................................... 9-1

Replace Door Hinge ........................................................................................ 9-4

Drawer & Shelf Slides ..................................................................................... 9-4

9.4.1 Shelving Adjustment ....................................................................................... 9-3

9.4.2 Cleaning/Lubricating Drawer shelf Extenders .................................................... 9-4

Replace Door & Drawer Gasket ........................................................................ 9-5

Residential Drawer Mullion Repair .................................................................... 9-5

Replace Door Handle ...................................................................................... 9-7

Lock Troubleshooting ...................................................................................... 9-7

9.9 Custom Overlay Panels

10.0 REPLACEMENT PARTS ............................................................................... 10-1

HP24 Medium Temperature Cabinets - Evaporator Compartment Service Parts .. 10-1

HP24 Low Temperature Cabinets - Evaporator Compartment Service Parts ....... 10-2

HP24 Medium Temperature Cabinets - Condenser Compartment Service Parts .. 10-3

HP24 Low Temperature Cabinets - Condenser Compartment Service Parts ........ 10-4

HP24 Cabinets – Door Service Parts ............................................................... 10-6

HP24 Cabinets - Shelving Service Parts .......................................................... 10-7

HP24 Cabinets - Drawer Service Parts ............................................................ 10-8

HP15 Cabinets – Evaporator Compartment Service Parts ................................. 10-9

HP15 Cabinets - Condenser Compartment Service Parts .................................. 10-10

HP15 Cabinets - Door Service Parts ............................................................. 10-12

HP15 Cabinets - Shelving Service Parts ........................................................ 10-13

HP15 Cabinets - Drawer Service Parts .......................................................... 10-14

HA24 Medium Temperature Cabinets - Evaporator Compartment Service Parts 10-15

Table of Contents Page 2

Page 4

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

HA24 Low Temperature Cabinets - Evaporator Compartment Service Parts ....... 10-16

HA24 Medium Temperature Cabinets - Condenser Compartment Service Parts .. 10-17

HA24 Low Temperature Cabinets - Condenser Compartment Service Parts ........ 10-19

HA24 Cabinets - Door Service Parts ................................................................ 10-21

HA24 Cabinets - Shelves Service Parts ............................................................ 10-22

HA24 Cabinets - Drawers Service Parts ........................................................... 10-23

HH24 Cabinets - Evaporator Compartment Service Parts .................................. 10-24

HH24 Cabinets - Condenser Compartment Service Parts .................................. 10-25

HH24 Cabinets - Door Service Parts ............................................................... 10-27

HH24 Cabinets - Shelving Service Parts .......................................................... 10-28

HC24BB, HC24RB, HC24WB, HC24RO, HC24TB & HC24TO Cabinets - Evaporator

Compartment Service Parts ..................................................................................... 10-29

HC24BB, HC24RB, HC24WB, HC24RO, HC24TB & HC24TO Cabinets - Condenser

Compartment Service Parts ..................................................................................... 10-30

HC24 Cabinets - Door Service Parts ............................................................... 10-32

HC24 Cabinets - Shelving Service Parts........................................................... 10-33

HC24 Cabinets - Drawer Service Parts ............................................................ 10-34

HC24RS & HC24WS Cabinets - Evaporator Compartment Service Parts ............. 10-35

HC24FS Cabinets - Evaporator Compartment Service Parts .............................. 10-36

HC24RS &HC24WS Cabinets - Condenser Compartment Service Parts .............. 10-37

HC24FS Cabinets - Condenser Compartment Service Parts .............................. 10-38

HC24 Commercial Cabinets - Door Service Parts ............................................. 10-39

HC24 Commercial Cabinets - Shelving Service Parts ........................................ 10-40

Table of Contents Page 3

Page 5

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

Table of Figures

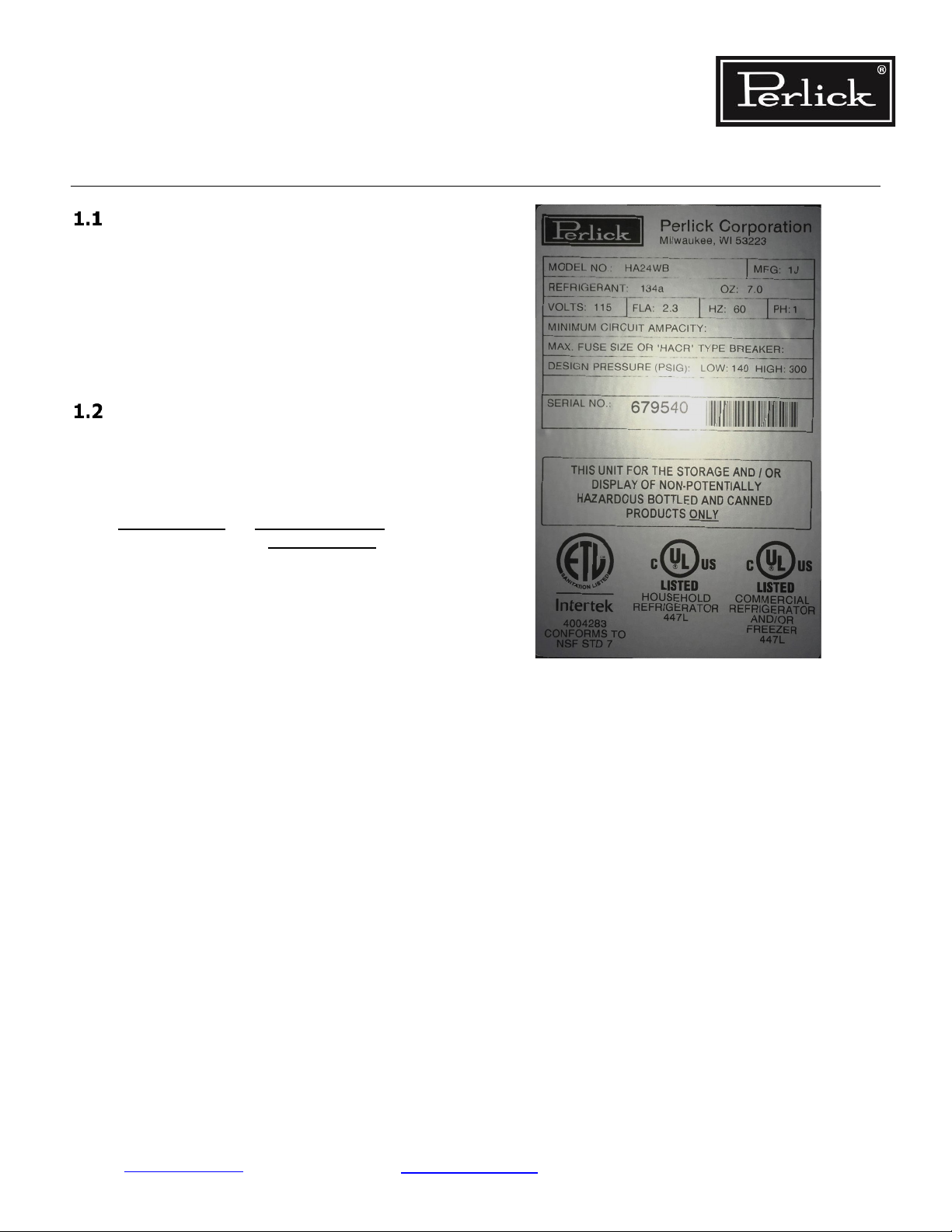

Figure 1-1. Information Plate ........................................................................................... 1-1

Figure 7-1. Sealing Compound at Wiring Pass-through – Back ............................................ 7-1

Figure 7-2. Sealing Compound at Wiring Pass-through – Inside .......................................... 7-2

Figure 7-3. Evaporator Condensate Drain .......................................................................... 7-2

Figure 7-4. Process Tubes ................................................................................................ 7-4

Figure 7-5. Remove Shelves ............................................................................................. 7-4

Figure 7-6. Remove Shelf Slide ......................................................................................... 7-4

Figure 7-7. Remove Pilaster ............................................................................................. 7-4

Figure 7-8. Evaporator Fan Panel Screw Locations ............................................................. 7-5

Figure 7-9. Remove Evaporator Fan Panel ......................................................................... 7-5

Figure 7-10. Deicing Evaporator ....................................................................................... 7-5

Figure 7-11. Check for Obstructions ................................................................................. 7-7

Figure 7-12. Remove Front Grille ...................................................................................... 7-7

Figure 7-13. Clean Condenser Coils .................................................................................. 7-7

Figure 7-14. Condenser Fan Mounting Hardware ............................................................... 7-9

Figure 7-15. Dual Zone F-R Gen 3 Refrigeration System Diagram ....................................... 7-15

Figure 7-16. Dual Zone Med Temp Gen 3 Refrigeration System Diagram ............................. 7-16

Figure 7-17. Freezer Refrigeration System Diagram............................................................ 7-17

Figure 7-18. Med Temp Refrigeration System Diagram ...................................................... 7-18

Figure 8-1. HC24RS & HC24WS Wiring Diagram ................................................................ 8-2

Figure 8-2. HC24FS Wiring Diagram ................................................................................. 8-3

Figure 8-3. HP48 Signature Series Wiring Diagram ............................................................ 8-4

Figure 8-4. HP24 Signature Series Wiring Diagram ............................................................ 8-5

Figure 8-5. HP Freezers Wiring Diagram ........................................................................... 8-6

Figure 8-6. HA Freezers Wiring Diagram ........................................................................... 8-7

Figure 8-7. HP15 Signature Series Wiring Diagram ............................................................ 8-8

Figure 8-8. HC & HH Wiring Diagram ................................................................................ 8-9

Figure 8-9. HA Wiring Diagram ........................................................................................ 8-10

Figure 8-10. HB24BS, HB24RS & HB24WS Wiring Diagram ................................................. 8-11

Figure 8-11. HB24FB & HB24FS ADA Series Wiring Diagram ............................................... 8-12

Figure 8-12. HPA & HHA Wiring Diagram .......................................................................... 8-13

Figure 8-13. HC Wiring Diagram ....................................................................................... 8-14

Figure 8-14. HC48RS, HC48WS, HC48RW & HC48WW Wiring Diagram ................................ 8-15

Figure 8-15. HP24ZS/ZO Wiring Diagram .......................................................................... 8-16

Figure 8-16. HP24CS/CO/DS/DO Wiring Diagram ............................................................... 8-17

Figure 8-17. Temperature Probe ....................................................................................... 8-31

Figure 8-18. Interior LED Light ......................................................................................... 8-32

Figure 9-1. Door Removal ................................................................................................ 9-1

Figure 9-2. Hinge Removal ............................................................................................... 9-2

Table of Figures Page 4

Page 6

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

Figure 9-3. Hinge Installation ........................................................................................... 9-2

Figure 9-4. Door Brackets ................................................................................................ 9-2

Figure 9-5. Removing Front Panel ..................................................................................... 9-3

Figure 9-6. Bearing and V-Block ....................................................................................... 9-3

Figure 9-7. Door Hinges ................................................................................................... 9-3

Figure 9-8. Installing V-Block ........................................................................................... 9-4

Figure 9-9. Installing Door ............................................................................................... 9-4

Figure 9-10. Shelf Locking Mechanism .............................................................................. 9-4

Figure 9-11. Removing/Installing Shelf ............................................................................. 9-5

Table of Contents Page 5

Page 7

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

Table of Tables

Table 7-1. System Operating Pressures ............................................................................. 7-1

Table 7-2. Compressor Data............................................................................................. 7-2

Table 7-3. C0

Table 8-1. Electrical Specications .................................................................................... 8-1

Table 8-2. HA24BB, RB, WB Load Operation Modes .......................................................... 8-18

Table 8-3. HA24FB Load Operation Modes........................................................................ 8-18

Table 8-4. HB24BS, RS, WS Load Operation Modes ........................................................... 8-18

Table 8-5. HB24FS Load Operation Modes ........................................................................ 8-19

Table 8-6. HC24BB, RB, RO, TB, TO WB Load Operation Modes ......................................... 8-19

Table 8-7. HC24FS Load Operation Modes ........................................................................ 8-19

Table 8-8. HC24RS, WS Load Operation Modes ................................................................ 8-20

Table 8-9. HD24RS, WS Load Operation Modes ................................................................ 8-20

Table 8-10. HH24BO, BS, RO, RS, WO, WS Load Operation Modes ..................................... 8-20

Table 8-11. HP15BO, BS, RO, RS, TO, TS, HK15BO, RO, TO Load Operation Modes ............. 8-21

Table 8-12. HP15WO, WS, HK15WO Load Operation Modes .............................................. 8-21

Table 8-13. HP24BO, BS, RO, RS, TO, TS, HK24BO, RO, TO, HM24RO, TO Load Operation

Modes ........................................................................................................................... 8-22

Table 8-14. HP24WO, WS, HK24WO Load Operation Modes .............................................. 8-22

Table 8-15. HP24FO, FS, HK24FO Load Operation Modes .................................................. 8-22

Table 8-16. HP24CO, CS, DO, DS, HK24CO, DO, HM24CO Load Operation Modes ................ 8-23

Table 8-17. HP24ZO, ZS, HK24ZO, HM24ZO Load Operation Modes ................................... 8-24

Table 8-18. HC48RS, RW, WS, WW Load Operation Modes ................................................ 8-25

Table 8-19. HP48WO-S, WW-S Load Operation Modes ...................................................... 8-25

Table 8-20. Factory Temperature Settings ........................................................................ 8-27

Table 8-21. Temperature Resistance Values ...................................................................... 8-32

Table 9-1. Door Hinges .................................................................................................... 9-1

2 equilibrium pressure given volumes of C02 and temperature ......................... 7-1

Table of Tables Page 6

Page 8

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

1.0 General Information

Use of Service Manual

This service manual is intended for use by a quali-

ed service technician. It is provided as a guide to

diagnose and repair service issues for the product

models listed on the cover.

If you have any questions or require additional

assistance, contact Perlick Customer Service during

regular hours of operation.

Model Families

This manual contains specic instructions for

servicing the Perlick Residential and Front Venting

Commercial Series refrigeration products, which

include the following families:

RESIDENTIAL FRONT VENTING

COMMERCIAL

HA

HC

HH

HC

HB

HD

HK

HM

HP

HHA

HPA

The model and serial numbers can be found on the

Ceiling of the refrigerated space. See Figure 1-1.

Figure 1-1. Information Plate

Return to Table of Contents

General Information Page 1-1

Page 9

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

2.0 Safety Information

Refrigerant HFC-134a

All self-contained models covered in this service

manual are manufactured using refrigerant HFC134a.

Potential Problems with HFC-134a

HFC-134a compressors are manufactured with a

synthetic based ester oil charge.

• The hygroscopic (water attraction) property of

ester oil is many times greater than that of the

mineral oils previously used with CFC-12.

• High system moisture causes the formation

of acids and alcohol, which can damage the

compressor.

• Systems or components of the refrigeration

system should not be left open to atmosphere

for more than (15) minutes at any time as

humidity from the air will enter the system and

be absorbed by the oil.

To ensure system dehydration:

• System should be evacuated to a level less than

250 microns

• Flux must not be used on any brazed joints.

Anytime a Perlick Refrigeration System is being

serviced:

• It is recommended that the drier be changed

using the exact same style and size within the

system to avoid possible charge problems or

contaminant issues.

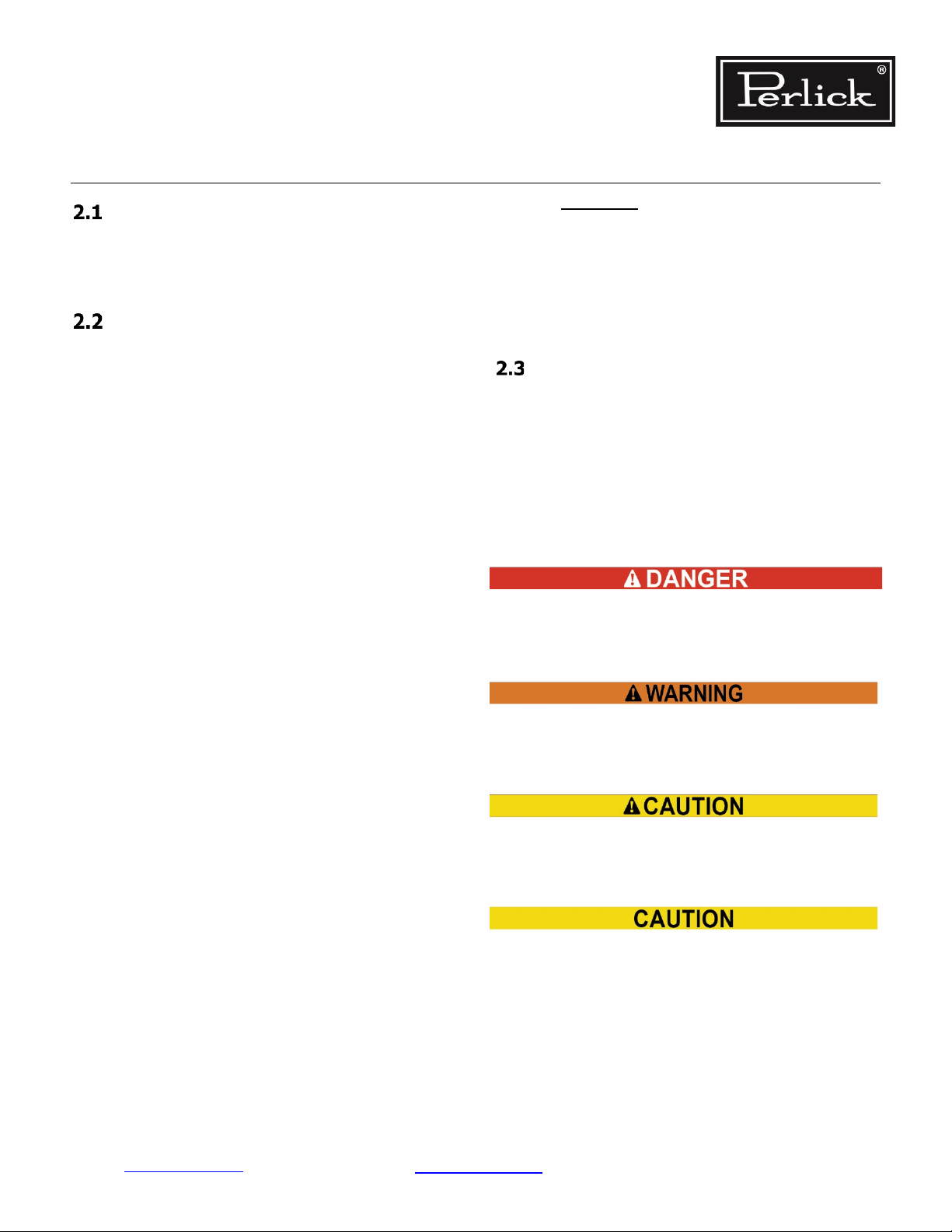

Service Manual Safety Labels

PLEASE READ all instructions completely before attempting to service the unit. Take particular note of

the DANGER, WARNING and CAUTION information

in this manual. The information is important for the

safe and efcient service, operation and care of the

Perlick unit.

HAZARD!!

Indicates hazardous situation that will result

in death or serious injury if not avoided.

• When isolated, shall not exceed 500 microns for

a minimum of 10 minutes.

• Vacuum pump oil must never be allowed to

enter the refrigeration system.

• No leak detection dyes are authorized for use

within any Perlick Refrigeration Products.

• Use of these materials will void complete sys

tem warranty and place the burden on the

service company for down-line service issues.

Cleanliness of the system is extremely important.

• The presence of residue (Chlorinated or greasy

residues, mineral oil, or impurities) can lead

to capillary tube restrictions, oil return prob

lems and compressor damage.

• A nitrogen purge should be utilized when

brazing.

Indicates hazardous situation that may

result in death or serious injury if not

avoided.

-

Caution indicates hazardous situation that

could result in minor or moderate injury and

property damage.

Caution without symbol indicates unsafe practice

situation that could result in property damage only.

Return to Table of Contents

Safety Information Page 2-1

Page 10

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

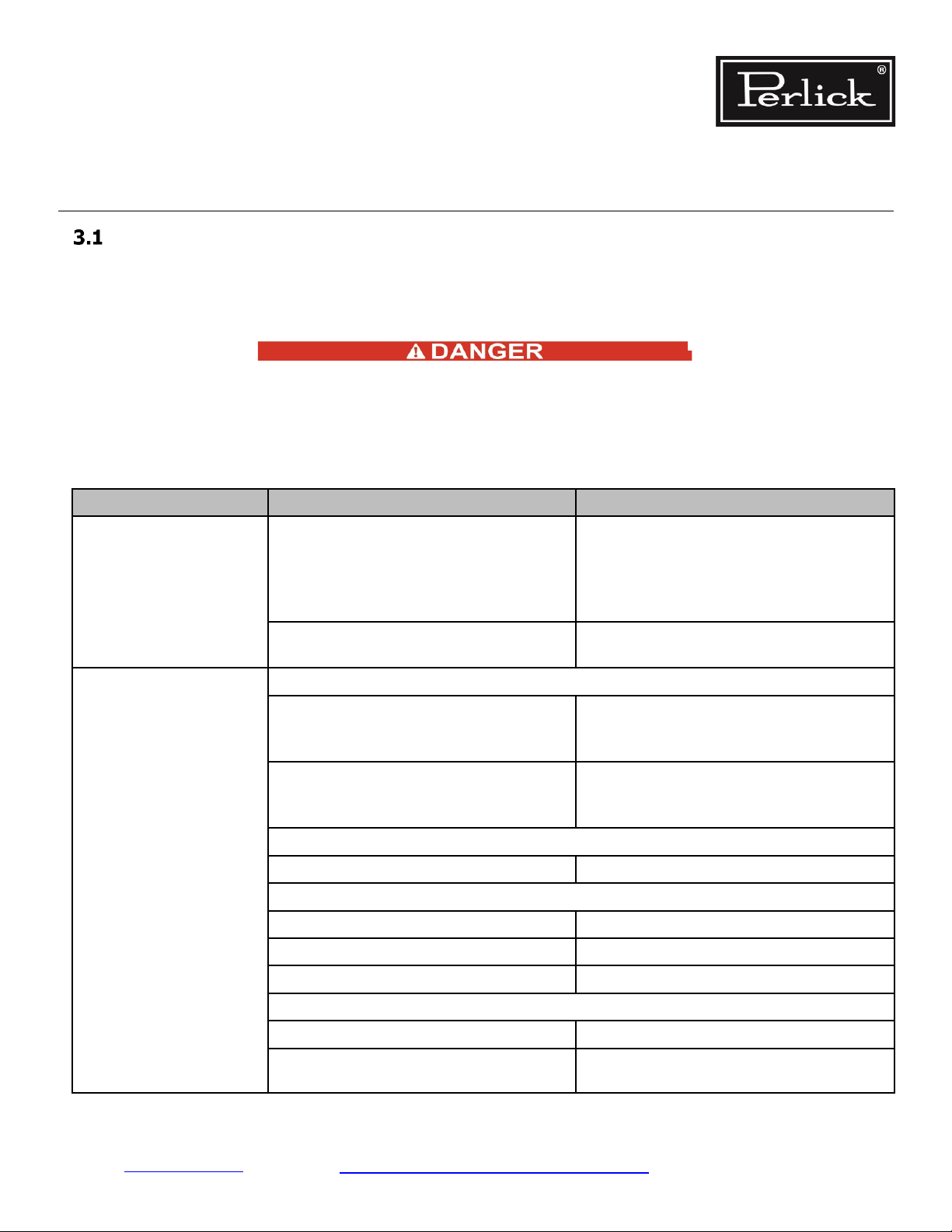

3.0 Trouble Shooting Guide

Refrigeration System

Use this diagnostic guide to identify issues and to locate applicable instructions within this service manual.

This diagnostic guide can be used for any of Perlick’s Residential and Front Venting Commercial Series Re

frigeration Products.

ELECTROCUTION HAZARD!!

Never attempt to repair or perform maintenance

on the unit until the Main electrical power has

been disconnected.

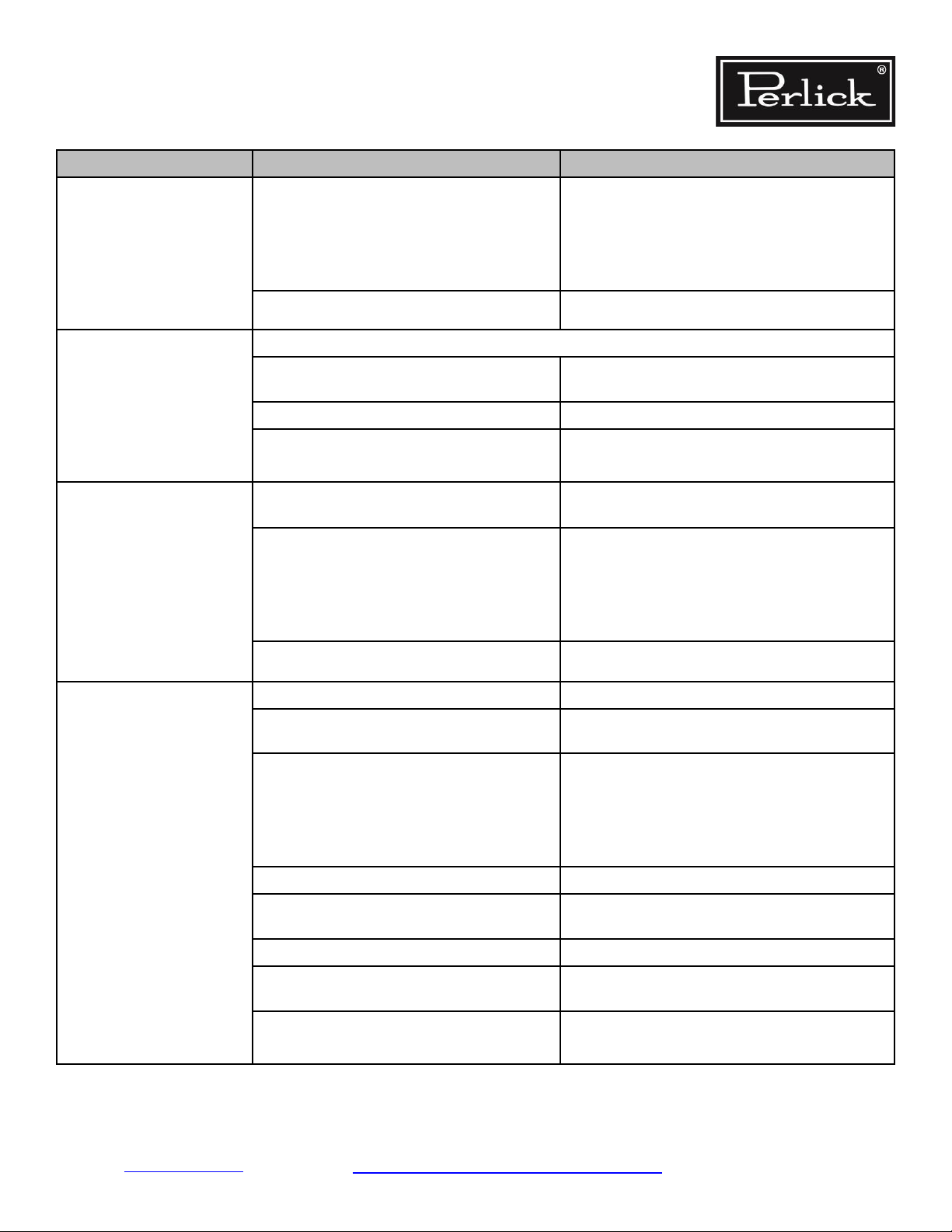

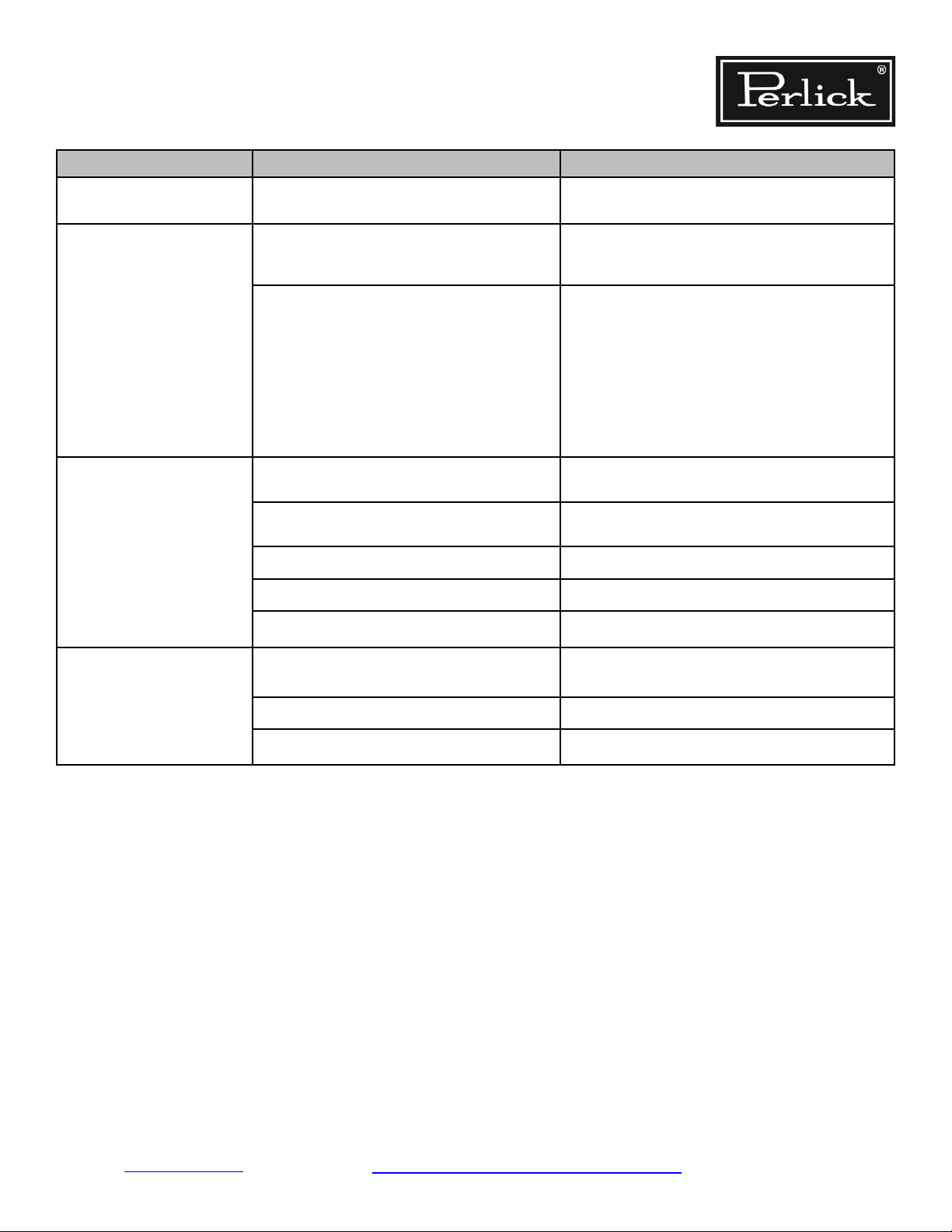

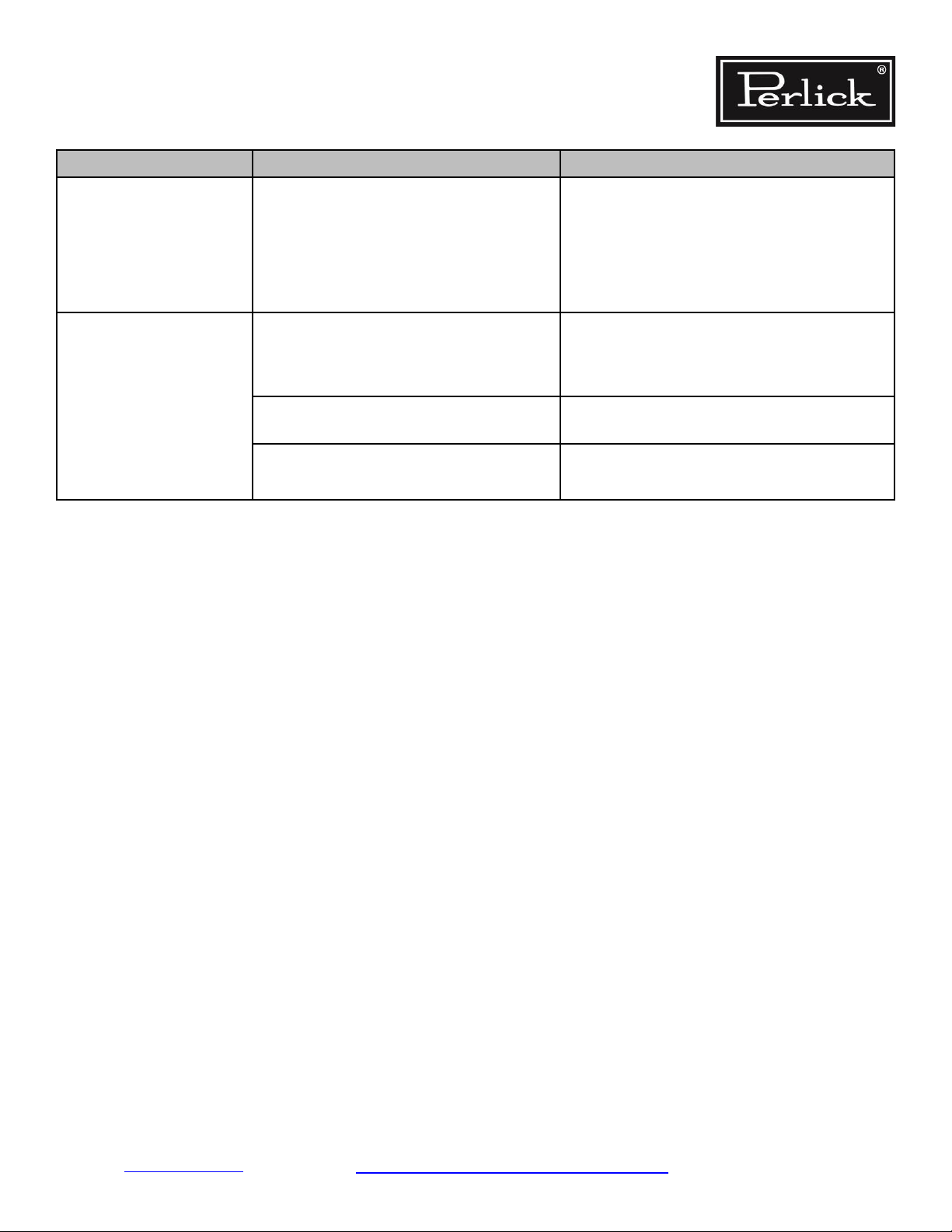

PROBLEM CAUSE SOLUTION

Refrigerator does not run. No power to the unit. Check circuit protection devices. Fuses,

breakers, GFI).

Restore power to unit.

Refer to information plate. See

and

Table 8-1.

Section 1.2

-

Incorrect control settings or faulty control.

Refrigerator is too warm. Power

No power to unit.

Incorrectly wired internal wiring connec

tions.

Fans

Evaporator fan is not running. Refer to Evaporator fan is not running

Coils

Evaporator coil has iced over.

Condensing coil is not clean. Clean with soft brush and vacuum.

Fins are bent or damaged. Straighten ns.

Control

No power to control. Refer to Control not functioning

Control is not calling for cooling. Refer to Control not functioning

Return to factory settings (see

Check outlet for voltage.

Check power cord connection to machine

compartment harness.

Verify wiring per wiring diagram. See

-

Section 8.2.

Reconnect wires if needed.

Remove ice. See

Section 7.4

Section 8.6).

Return to Table of Contents

Troubleshooting Guide - Refrigeration System Page 3-1

Page 11

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

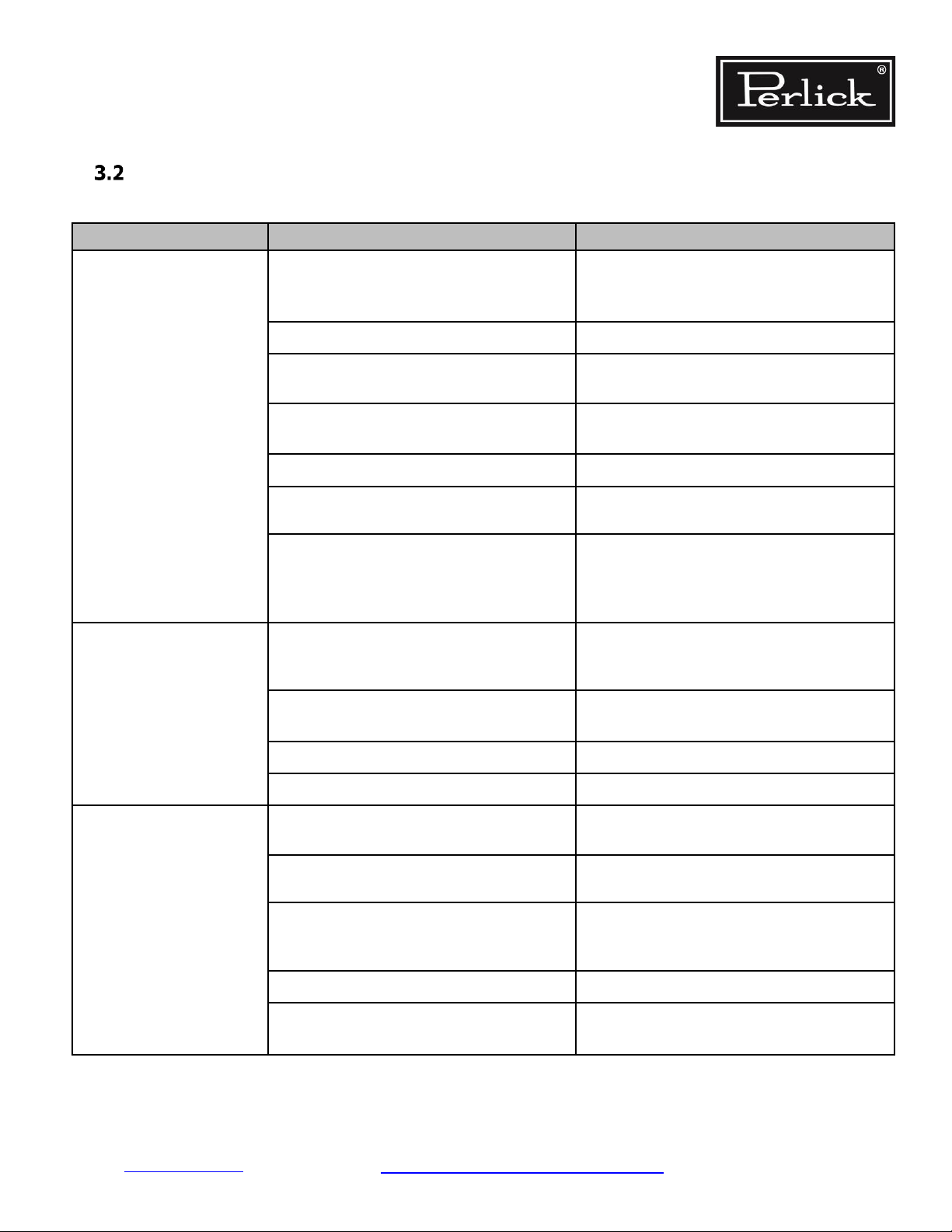

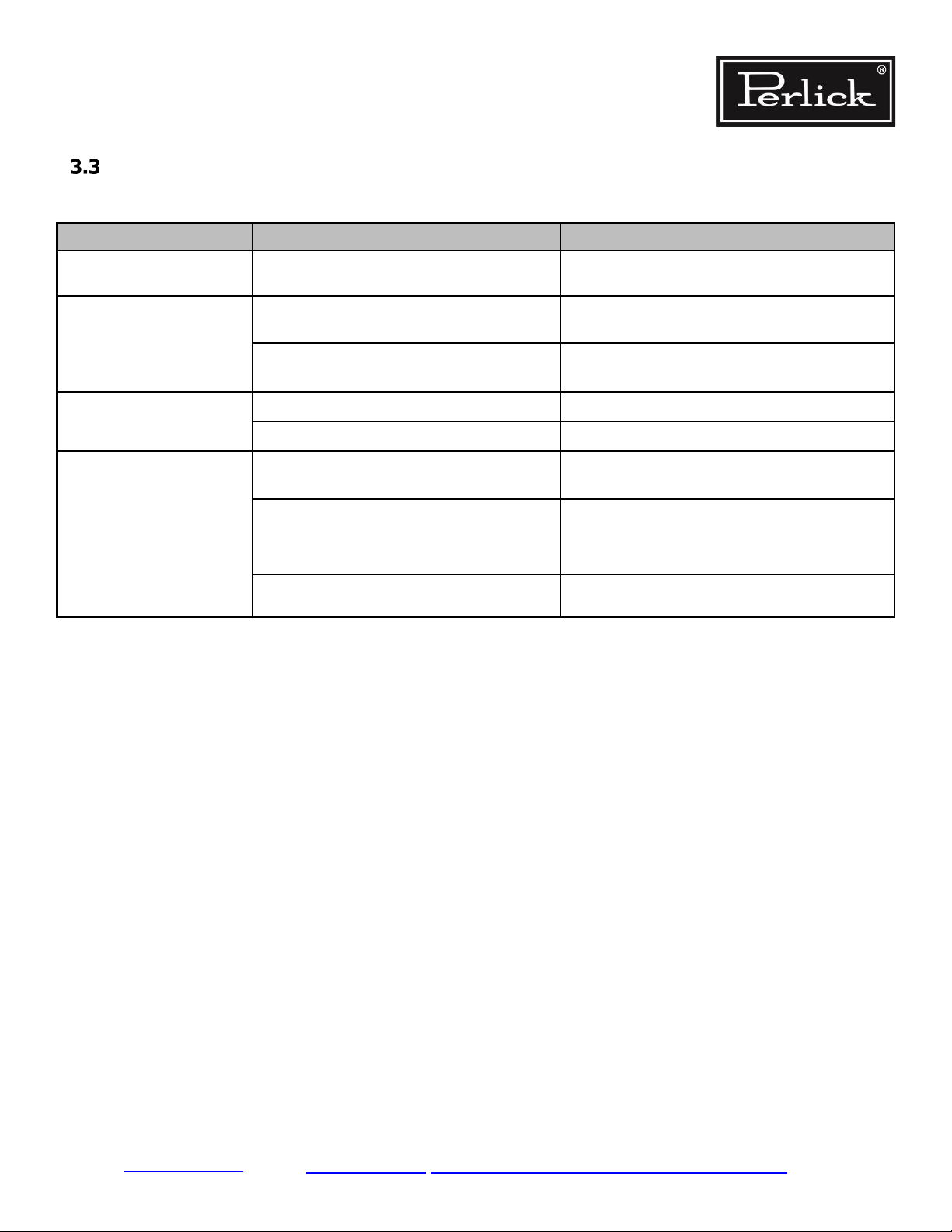

PROBLEM CAUSE SOLUTION

Probe failure.

Refrigerator is too warm.

(continued)

Refrigerator is too cold.

Probe is not connected to the control.

Air Inltration

Sealing compound does not form a com

plete seal.

Door gasket is damaged or out of place.

Condensate drain line/air trap is not

positioned properly.

Incorrect control settings.

Probe failure.

Refer to

place probe if needed. See Section 8.6.4.

Reconnect probe. See

-

Refer to

Refer to

Reposition in loop. See

Return to factory settings.

See

Table 8-21 for resistance values. Re-

Section 8.6.4.

Section 7.1.

Sections 7.1 and 9.5.

Figure 7-3.

Section 8.6.

Table 8-21 for resistance values. Replace

probe if needed. See Section 8.6.4.

Control failure. Refer to Electrical System

Refrigerator runs continu

ously.

-

Condensing coil is dirty. Clean with soft brush and vacuum.

Incorrect control settings.

Probe failure.

Return to factory settings.

Section 8.6.

See

Table 8-21 for resistance values. Replace

Evaporator coil has iced over.

Sealing compound does not form a com

plete seal.

Door gasket is damaged or out of place.

Condensate drain line/air trap is not posi

tioned properly.

Extreme ambient conditions.

probe if needed. See

Remove ice per

-

Refer to

Refer to

-

Reposition in loop. See

Refer to

Section 7.1.

Section 7.1 and 9.5.

Section 7.8.

Section 8.6.4.

Section 7.4.

Figure 7-3.

Return to Table of Contents

Troubleshooting Guide - Refrigeration System Page 3-2

Page 12

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

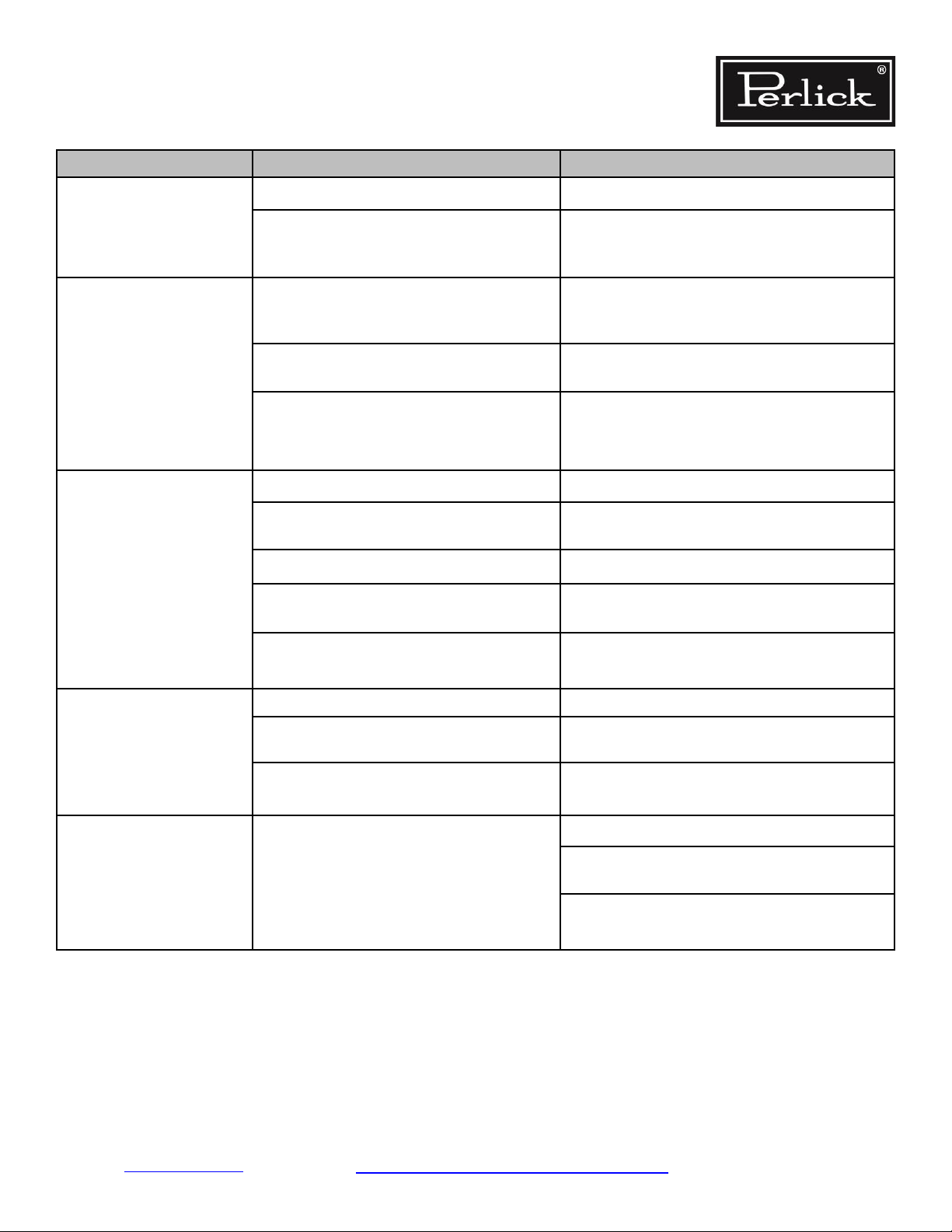

PROBLEM CAUSE SOLUTION

Water on the oor outside

of unit.

Water on the oor outside

of unit.

(continued)

Refrigeration/Charge level is too low.

High ambient temperature and high am

bient humidity conditions coupled with

frequent door opening.

Condensate pan overowing.

Unit is not level.

Sealing compound does not form a com

plete seal.

Door gasket is damaged.

Evaporator coil has iced over.

Evaporator pan and/or drain line restricted. Remove restriction.

Check for leaks, repair, and recharge per

Section 7.13 and 7.14.

Ensure doors close completely.

-

Remove excess water.

Check for the following:

• Air inltration. See

• Doors close completely and seals are

intact. See

• Ice buildup. See

Unit must be level front-to-back and side-toside for water to drain properly.

-

Refer to

Refer to

Remove ice. Refer to

Section 9.0.

Section 7.1.

Sections 7.1 and 9.5.

Section 7.1.

Section 7.4.

Section 7.4

Water on the oor inside

of unit.

Unit is not level.

Evaporator coil has iced over.

Unit must be level front-to-back and side-toside for water to drain properly.

Remove ice. Refer to

Section 7.4

Return to Table of Contents

Troubleshooting Guide - Refrigeration System Page 3-3

Page 13

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Electrical System

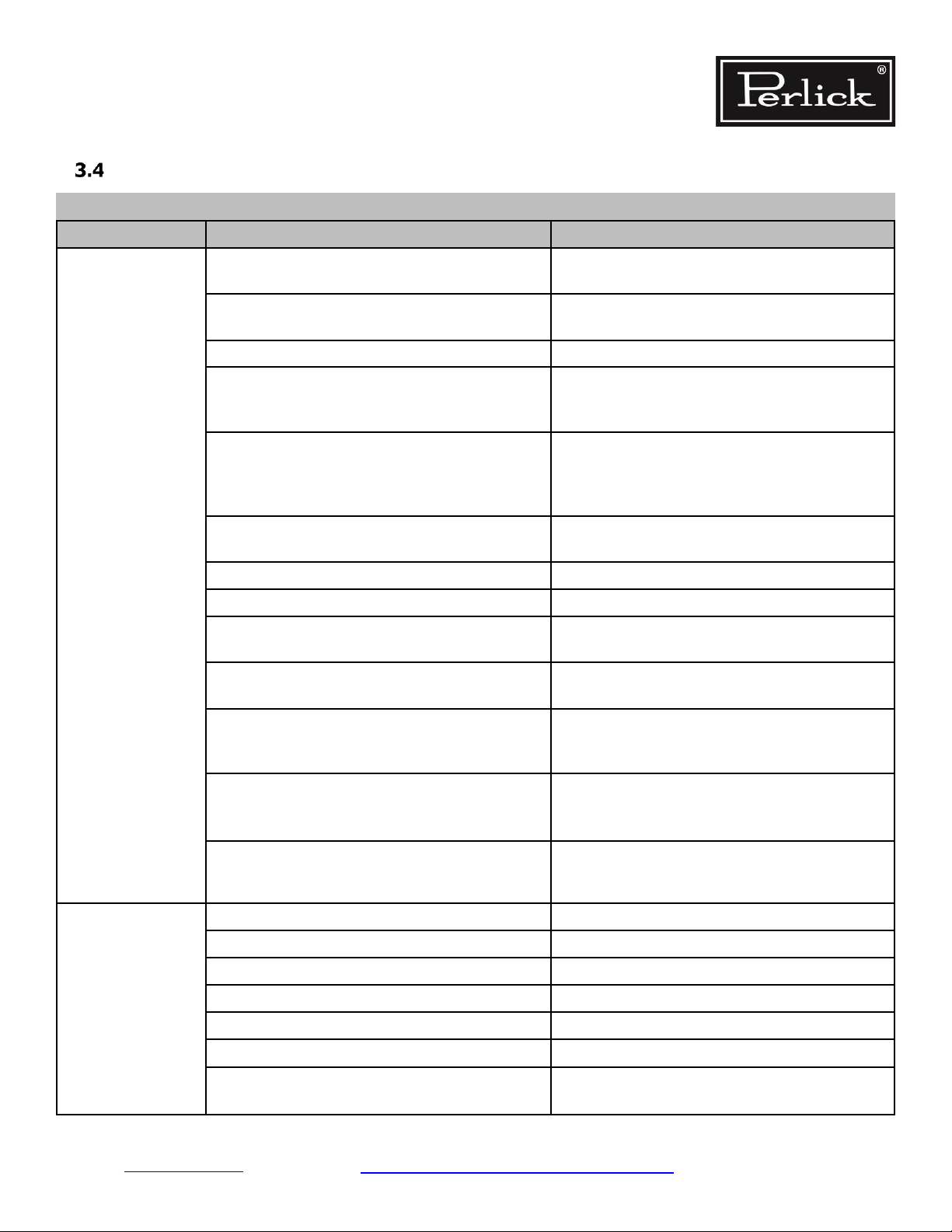

PROBLEM CAUSE SOLUTION

Compressor is not running.

Condenser fan is not running.

No power to compressor.

No call for cooling from control.

Incorrectly wired connections in machine

compartment.

Incorrect control settings.

Faulty control.

Starting device is not operational (start

relay/capacitor).

Faulty compressor.

No power to fan

Incorrectly wired.

Check wiring to compressor.

Check where power is interrupted between

controller and compressor.

Check control settings or for bad control.

Verify wiring per wiring diagram,

Section 8.2.

Return to factory settings.

Section 8.6.

See

Refer to Control not functioning.

Replace compressor electrical components.

Check compressor, see

Restore power to unit.

Refer to information plate. See

Section 7.9

Section 1.0 and Table 8-1

Verify wiring per wiring diagram,

Section 8.2.

Remove obstructions.

Replace condenser fan per

Check wiring and continuity of switch con

tacts. Replace switch if defective.

Install bracket and/or align.

Restore power to unit.

Refer to information plate. See

Section 7.0.

Evaporator fan is not run

ning.

Fan is obstructed.

Fan still does not run.

-

Faulty/defective door switch or wiring to

door switch.

Missing or misaligned door switch plunger

bracket.

No power to evaporator fan motor.

Section 1.0 and Table 8-1

Fan is obstructed.

Incorrectly wired.

Remove obstruction.

Verify wiring per wiring diagram,

Section 8.2.

Return to Table of Contents

Troubleshooting Guide - Electrical System Page 3-4

-

Page 14

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

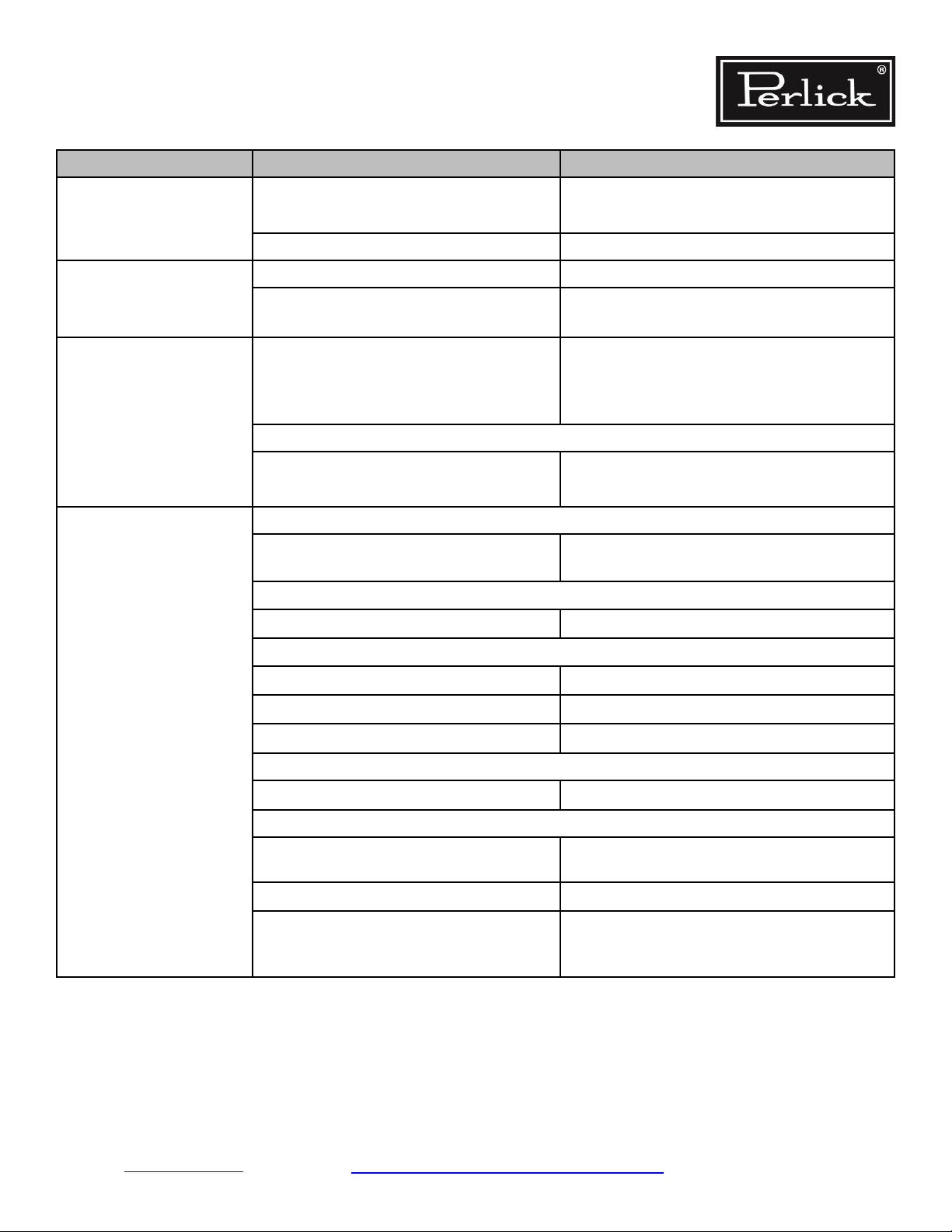

PROBLEM CAUSE SOLUTION

Control not functioning

Lights not functioning

If Evaporator fan is still not running

No power to/from DC inverter/driver

(12V).

No power to unit.

Incorrectly wired harness.

No call for cooling.

Light switch in off position.

No power to light.

Faulty LED strip

Faulty/defective door switch or wiring to

door switch.

Replace evaporator fan per

If no power: restore power, replace. Refer to

Section 7.11.

Section 1.1.

Restore power to unit.

Refer to information plate. See

and

Table 8-1

Verify wiring per wiring diagram,

Reconnect wires if needed.

Check probe connections and verify resistance

readings.

Check control settings.

Replace control.

Turn on light switch.

Verify wiring per wiring diagram,

Replace LED strip.

Check wiring for continuity of switch contacts.

Replace switch if faulty.

Section 1.0

Section 8.2.

Section 8.2.

Light stays on when door is

closed.

Eliwell Control: LED

Controller display is ash

ing “E1”

-

Door switch plunger bracket missing or

misaligned.

Manual switch is on. Turn off manual switch.

Faulty/defective door switch or wiring to

door switch.

Door switch plunger bracket missing or

misaligned.

Probe 1 error. Reading out-of-range of

operating values.

Install bracket and/or align properly.

Check wiring and continuity of switch contacts.

Replace switch if faulty.

Install bracket and/or align properly.

Check probe connections to control.

Check probe resistance readings per

Table 8-21.

Check probe wiring.

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 3-5

Page 15

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

PROBLEM CAUSE SOLUTION

Eliwell Control: LED

Controller display is ash

ing “AH1”

Eliwell Control: LED

Controller display is ash

ing “AH1”

(continued)

-

-

Probe 1 HIGH temperature alarm.

Control

Incorrect control settings.

Power

Incorrectly wired.

Fans

Evaporator fan is not running.

Coils

Evaporator coil has iced over.

Coils

(continued)

Condensing coil is not clean.

Fins are bent or damaged.

Replace probe per Section 8.6.3.

Return to factory settings. See

Verify wiring per wiring diagram,

Section 8.2.

Refer to Evaporator fan is not running.

Remove ice. See

Clean with soft brush and vacuum.

Straighten ns.

Section 7.4

Section 8.6.

Eliwell Control: LED

Controller display is ash

ing “AL1”

Probe

Probe is not connected to control.

Air Inltration

Sealing compound does not form a

complete seal.

Door gasket is damaged or not seated

properly.

Condensate drain line/air trap is not

positioned properly.

Refrigeration/Charge level is too low.

Probe 1 LOW temperature alarm.

Incorrect control settings.

Reconnect probe.

See Section 8.6.4.

Refer to

Refer to

Reposition in loop.

Check for leaks, repair, and recharge.

See

This is a critically charged system, re

charging should only be done when all

other options have been thoroughly

checked.

Section 7.1.

Section 7.1 and 9.5.

Section 7.13 and 7.14.

Return to factory settings.

See

Sections 8.6.

-

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 3-6

Page 16

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

PROBLEM CAUSE SOLUTION

Dixell Control: LED

Controller display is ash

ing “P1”.

Dixell Control: LED

Controller display is ash

ing “HA”. Maximum temperature alarm.

Dixell Control: LED

Controller display is ash

ing “HA”. Maximum temperature alarm.

(continued)

Probe failure.

Control failure. Refer to Control not functioning

Probe failure.

Probe disconnected from control. Plug in probe connector.

Internal compartment has exceeded the

high temperature alarm preset value for

over 30 minutes.

Control

Incorrect control settings.

Power

-

Incorrectly wired.

Fans

Evaporator fan is not running.

Coils

Table 8-21 for resistance values.

Refer to

Table 8-21 for resistance values

Return to factory settings.

See

Section 8.6.

Verify wiring per wiring diagram,

Section 8.2.

Refer to Evaporator fan is not running

Evaporator coil has iced over.

Condensing coil is not clean.

Fins are bent or damaged.

Probe

Probe is not connected to the control.

Air Inltration

Sealing compound does not form a com

plete seal.

Door gasket is damaged or out of place.

Condensate drain line/air trap is not

positioned properly.

Remove ice per

Clean with soft brush and vacuum.

Straighten ns.

Reconnect probe per

-

Refer to

Refer to

Reposition in loop. See

Section 7.1.

Section 7.1 and 9.5.

Section 7.4.

Section 8.6.4.

Figure 7-3.

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 3-7

Page 17

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

PROBLEM CAUSE SOLUTION

Check for leaks, repair, and recharge per

Refrigeration/Charge level is too low.

Section 7.13 and 7.14.

Dixell Control: LED

Controller display is ash

ing “LA”. Minimum temperature alarm.

Internal compartment has exceeded the

low temperature alarm preset value for over

30 minutes.

Incorrect control settings.

Probe failure.

This is a critically charged system,

recharging should only be done when

all other options have been thoroughly

checked.

Return to factory settings.

See

Section 8.6.

Table 8-21 for resistance values.

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 3-8

Page 18

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Doors, Drawers and Shelving

PROBLEM CAUSE SOLUTION

Key won’t come out after

door is locked.

Hinge problems, door

misaligned.

Door handles loose

Condensation on glass

doors.

Key not in proper position.

Improper door mounting

Excessive wear

Improper handle mounting

Excessive wear

High ambient temperature, high humidity

and environmental conditions.

Frequent door opening.

Cabinet temperature too low.

Rotate key to the proper position and remove.

Verify proper mounting. Refer to

Section 9.2.

Replace worn parts.

Refer to

Verify proper mounting. Refer to

Replace worn parts. Refer to

Refer to

Condensation may build up on interior of glass

from frequent door openings as the cabinet

comes back down in temperature condensation

will evaporate.

Adjust temperature. Refer to

Factory Temperature Settings.

Section 9.2.

Section 9.7.

Section 9.7.

Section 7.8.

Table 8-20.

Return to Table of Contents

Table of Contents Troubleshooting Guide - Doors, Draws and Shelving Page 3-9

Page 19

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Beverage Dispensing

DIRECT DRAW SYSTEMS

PROBLEM CAUSE SOLUTION

Beer Foaming

Temperature too warm

(should be 36° F)

Temperature too cold/frozen beer in lines

(should be 36° F)

Adjust temperature control or call qualied

service person

Adjust temperature control or call qualied

service person

Kinked beer line Change beer line

Wrong diameter or length beer line (should be

Change beer line

6.5 ft. of 3/16” vinyl tubing or possibly even

longer)

2 regulator to brewer’s specication

Applied pressure too high

(should be 12 to 14 psi for most beers)

Adjust C0

(If CO2 pressure has been too high, kegged

product may be over-carbonated and be bad

and not correctable).

Applied pressure too low

(should be 12 to 14 psi for most beers)

Adjust C0

2 regulator to brewer’s specication

Coupler washers bad Replace coupler washers

Faucet washer bad Replace faucet washers

System dirty Clean system or call customer’s line cleaning

service

2 leaks or out of C02 Check ttings, clamps, shut-offs and regulators,

C0

replace as necessary

Beer foaming in jumper - keg valve seal torn or

ripped

If seal is ripped/torn, gas enters the liquid ow

stream causing foaming. Replace keg and report

defective keg to distributor

Beer foaming in jumper - physical obstructions at

coupler-valve junction

Remove any physical obstructions or debris

(e.g. a piece of a dust cover) that could allow

gas to enter the liquid ow

Beer foaming at faucet - clogged vent hole(s)

(If applicable to the faucet being used)

No Beer at Faucet Empty C0

2 bottle Replace with full C02 bottle

Disassemble and clean faucet, or call line

cleaning service

Regulator shutoff closed Open shutoff

2 bottle main valve turned off Tum on C02 bottle main valve

C0

Keg empty Replace with full keg

Coupler not engaged Tap keg properly and engage coupler

Check ball in coupler stuck (If applicable) Free check ball

Line/faucet dirty Clean line/faucet

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 3-10

Page 20

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

4.0 Variable Speed Compressor Specication

Never connect compressor directly to AC power!

Always use specied inverter when testing

compressor!

• The compressors employed within many of Perlick’s cabinets are on the cutting edge of technology for

reciprocating hermetic compressors. The compressors are variable speed models developed and man

ufactured by Embraco. Depending on the model of the cabinet, either a VEMY3H, VEMY6H or VEGY7H

will be found powering the refrigeration system. The compressor itself looks like a standard fractional

horsepower hermetic reciprocating compressor. The electrical, overload, relay and capacitor, which

are normally found connected to the compressor pins has been replaced by an electronic box which is

called the inverter.

-

• The inverter is an electronic board, which controls the compressor and has to have power to it at all

times for it to function properly. It controls the starting of the compressor and the speed at which it is

running at from 1600 rpm to 4500 rpm. A normal hermetic reciprocating compressor runs at a con

stant 3600 rpm. The Digital Temperature Control controls a separate power circuit used as the power

to the inverter driver circuit, which turns the compressor on and off.

• The inverter is powered by 115-127V 50-60Hz 1 Ph AC. The inverter driver circuit power is also 115-

127V 50-60Hz 1Ph AC power. The inverter converts this to 230V 53-150Hz 3 Ph power to drive the

compressor. The resistance between any combination of the three compressor pins for the HP24”

Series is 16.07 ohms, and the HP48 & HP72” series is 6.4 ohms. The inverter has a plastic 3-pin recep

tacle which gets plugged onto the compressor pins (can only be installed one way for proper orientation). The inverter also comes with a ground wire, which gets plugged onto the compressor ground

lug. The inverter is then mounted to the compressor fence by sliding it down and tipping to the vertical

position. A single fastener is then used to mount it to the fence (do not over tighten as it is fastening

into the plastic inverter housing).

-

-

Return to Table of Contents

Refrigeration System Repair Instructions Page 4-1

Page 21

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

5.0 Compressor Inverter Operation

• Upon initial power to the inverter, the electronic board is checked for problems or malfunctioning

components. If a problem is detected, the inverter will not allow power to the compressor and will

wait 8 minutes until it will repeat the process to see if it has been corrected.

• If the inverter power circuit is interrupted or reduced to a level below operation level, the inverter will

not allow continued operation of the power circuit to the compressor.

Compressor Start-Up

• Upon the temperature control calling for cooling, the inverter will wait 1-3 seconds before applying

current to the compressor motor for the rst time. In case of any abnormality in trying to start the

compressor (unequal pressures, locked rotor condition or open winding, etc.), the inverter will wait

6 seconds before establishing a new start-up trial.

• The maximum number of start-up trials is 12. If the compressor does not start after 12 trials, a

start-up error is set, and the system will wait for 8 minutes to repeat the starting procedure.

• During start-up of the compressor, the current is limited in accordance with the type of motor

connected to the inverter. The compressor always starts in its minimum rpm condition (1600 rpm)

to conserve energy and alleviate noise associated with a standard compressor start-up.

• During initial power being applied to the refrigerated cabinet, the compressor will always start in its

minimum rpm condition (1600 rpm) and remain at this speed for 7 minutes. After this time has

passed the program will move the compressor to its maximum rpm level until the initial controller

cut-out temperature has been achieved.

Normal Operation

During running condition, the speed is measured each shaft turn and the result is compared with

the desired speed. If the actual speed is lower than desired, the inverter will increase the power applied

to the motor, which in turn will increase the shaft speed until the equilibrium is achieved. The opposite can

happen likewise, in that if the actual speed is higher than the desired speed, the inverter will decrease the

power applied to the motor, which in turn will decrease the shaft speed until the equilibrium is achieved.

The compressor will generally run at its slowest speed (1600 rpm) during normal cycling conditions with

out added load to the cabinet or door openings. This is done to conserve energy and reduce noise. A typical refrigeration system is designed for high load, high ambient conditions, meaning the compressor is

typically oversized for normal daily operation. It has been shown in residential equipment that a refriger

ator or freezer or combination of the two with standard reciprocating compressor is typically designed for

conditions it sees less than 25% of the time (high load/high ambient). While employing the variable speed

compressor the equipment has been designed for the conditions it sees 75% of the time while still having

the capacity to cover the conditions it sees 25% of the time.

-

-

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 5-1

Page 22

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

6.0 Troubleshooting Compressor Inverter

• Ensure the inverter has 120V applied to the two pin connector on the inverter. If no power,

check where power is interrupted.

• If temperature control is calling for cooling, check inverter signal circuit for 120V, typically

the red lead. If no power, check where power is interrupted. If there is power, disconnect

power to the entire unit and wait 5 minutes to ensure internal system pressures are

equalized. Plug in unit and feel top of compressor to see if it is trying to start (see in-

formation from section Compressor Start-Up above). If compressor is trying to start, but

unable to, the system could have a restriction, the inverter may not be applying the correct

power to the compressor pins (check pins to see if getting 120V to each pin).

• Resistance between all pins should be the same. Dependent upon temperature of the com-

pressor, resistance could be different than the resistance specied at the standard temperature.

7.0 Refrigeration System Repair Instructions

Air Inltration

Air inltration can occur in several locations.

Note: Unit may manifest longer than normal run

times caused by the additional loads that

air inltration presents.

Signs of air inltration include:

• Presence of water, moisture or ice

• Condensation on glass or metal surfaces

STEP 1. Door Gaskets

• Check door gaskets for rips, cracks, or oth

er damage.

• The door gasket should be pushed in rmly

and lay at.

• Ensure gasket forms a complete seal

around door.

-

STEP 2. Sealing Compound

• Sealing compound is used to seal wiring and

line set pass-through between the con

denser and the evaporator compartments.

See Figure 7-1 and Figure 7-2.

• Check for voids and ensure sealing

compound completely lls the space.

Figure 7-1. Sealing Compound at Wiring Pass-through –

-

Back

Return to Table of Contents

Troubleshooting Guide – Beverage Dispensing Page 7-1

Page 23

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Figure 7-2. Sealing Compound at Wiring Pass-through –

Inside

STEP 3. Drain

Check that the evaporator condensate drain is

secure and connected. Figure 7-3.

Figure 7-3. Evaporator Condensate Drain

Note: Drain tube should be routed through metal

bracket and end of tube should be retained by metal

insert to create a trap. This trap should be lled with

water to prevent air from moving through the tube

and into the cabinet. Sometimes, gurgling sounds

will be heard upon the door closing as the internal

cabinet pressure changes requiring air to be pushed

out which happens through the drain tube trap.

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-2

Page 24

Residential Refrigeration

and Front Venting Commercial Refrigeration Service Manual

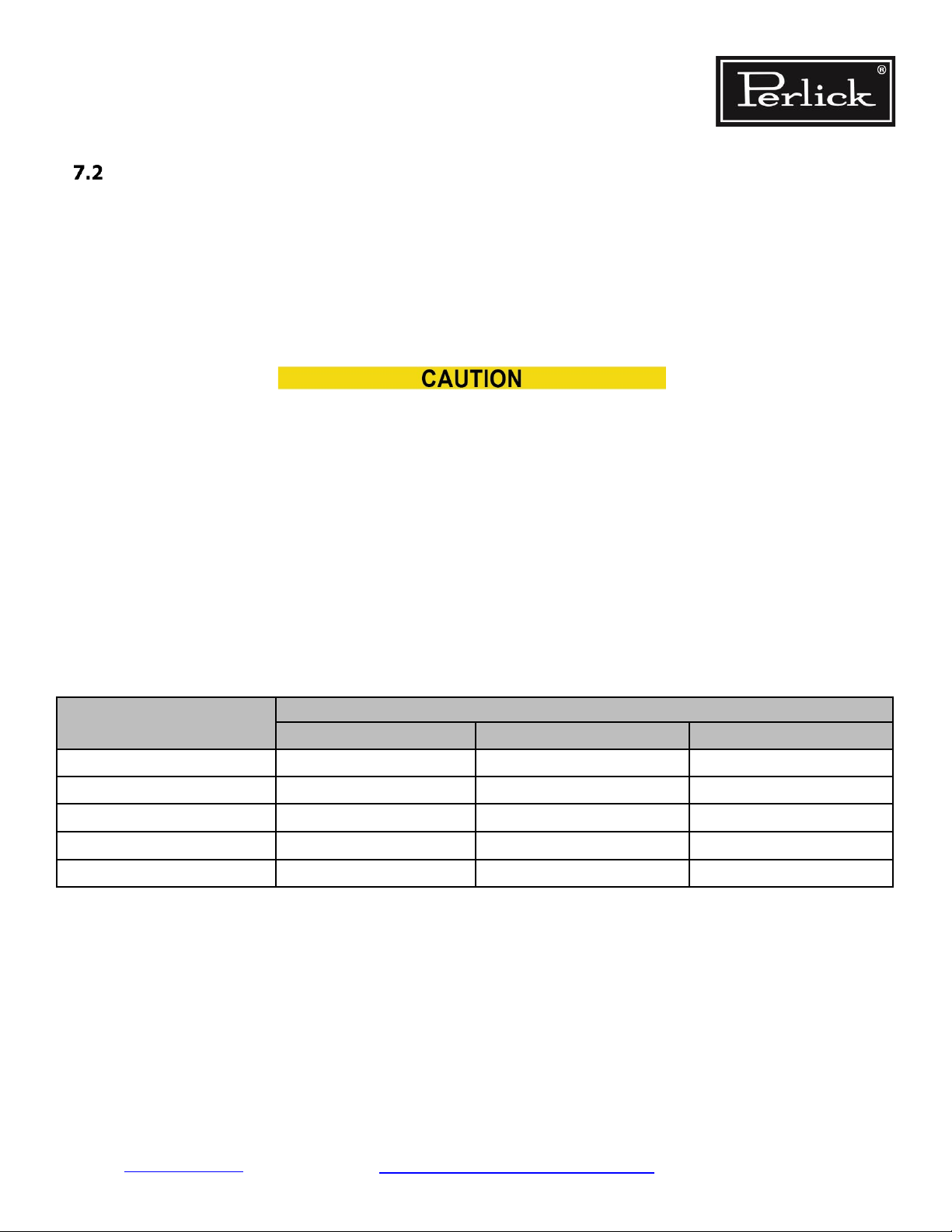

System Operating Pressures

Note: To check operating pressures, you must install access valves onto the process tubes. See Section

7.2.1.

Values in

Table 7-1

represent a range of normal pressures. The measured pressure can vary depending on

ambient conditions and at the point at which unit is in the refrigeration cycle.

Operating pressures shown in

Table 7-1 are nominal and dependent on

many factors (box temperature, position in the

refrigeration cycle, cleanliness of the condenser,

etc.), should only be used as reference.

Never add or remove charge based on the

operating pressures in Table 7-1. These prod

ucts are critically charged and must have the

refrigerant charge weighed into the system with

accurate equipment to plus/minus 2 grams.

Table 7-1. System Operating Pressures

70° F

Ambient

90° F 105° F

Models Low/High Low/High Low/High

Freezer 4” Hg/105 PSIG 3” Hg/145 PSIG 2” Hg/185 PSIG

Medium Temp* 15 PSIG /110 PSIG 16 PSIG /150 PSIG 17 PSIG /190 PSIG

Dual Zone Frz/Ref 5” Hg/105 PSIG 4” Hg/145 PSIG 3” Hg/185 PSIG

Dual Zone Medium Temp** 12 PSIG /110 PSIG 13 PSIG /150 PSIG 14 PSIG /190 PSIG

*Medium Temp = Refrigerator, Beverage Center, Wine Reserve, Beer Dispenser

**Dual Zone Medium Temp = Ref/Wine and Wine/Wine

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-3

Page 25

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

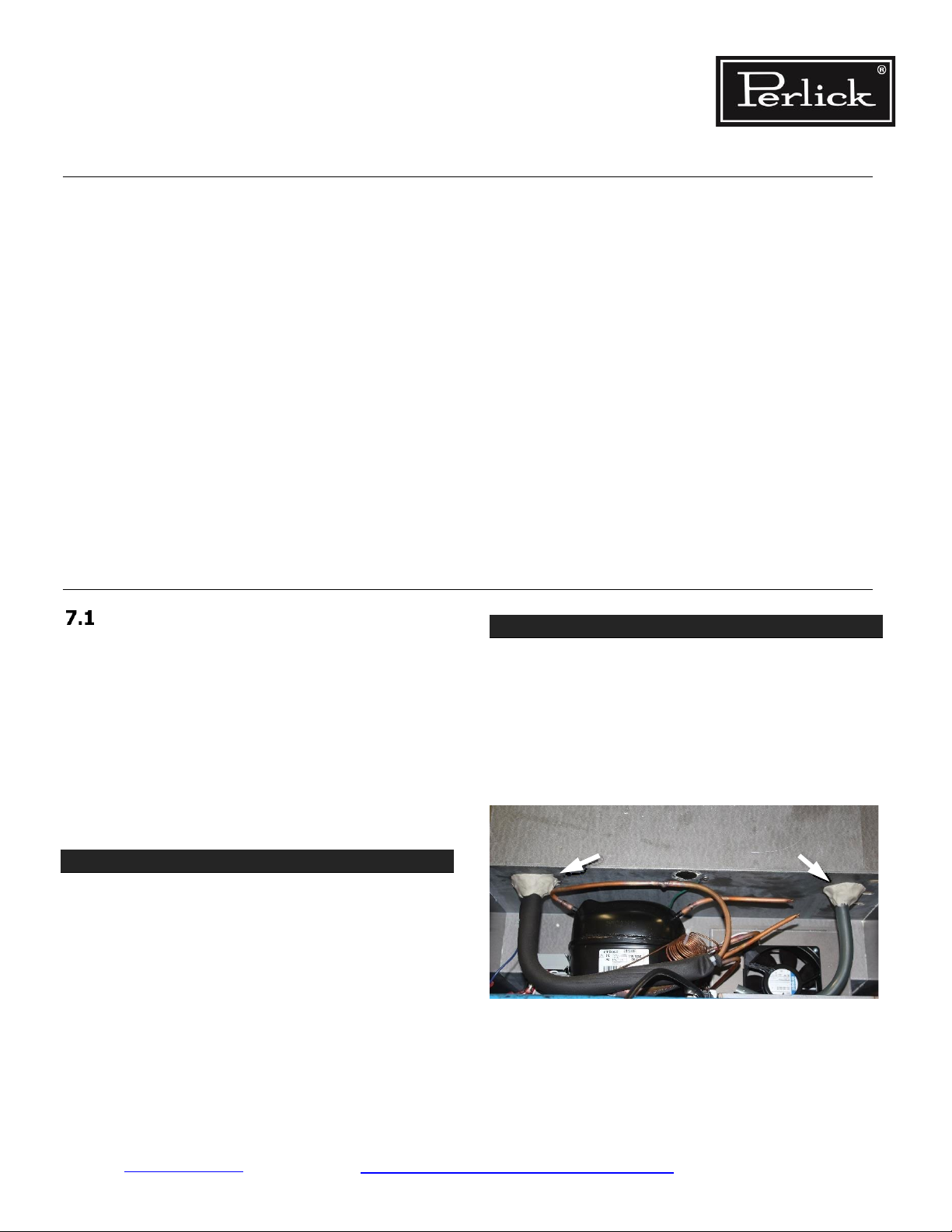

7.2.1 Process Tubes and Access Valve

Refrigerant system is hermetically sealed. Use

access tubes to charge unit and check pressure.

Note: Access valves (saddle valves) are not

provided and may vary.

Access valves should never be left on the

equipment permanently as they tend to

leak over time. Install Schrader valves any

time the system has been accessed.

Shelf

Lock

Figure 7-5. Remove Shelves

Saddle

Valve

Figure 7-4. Process Tubes

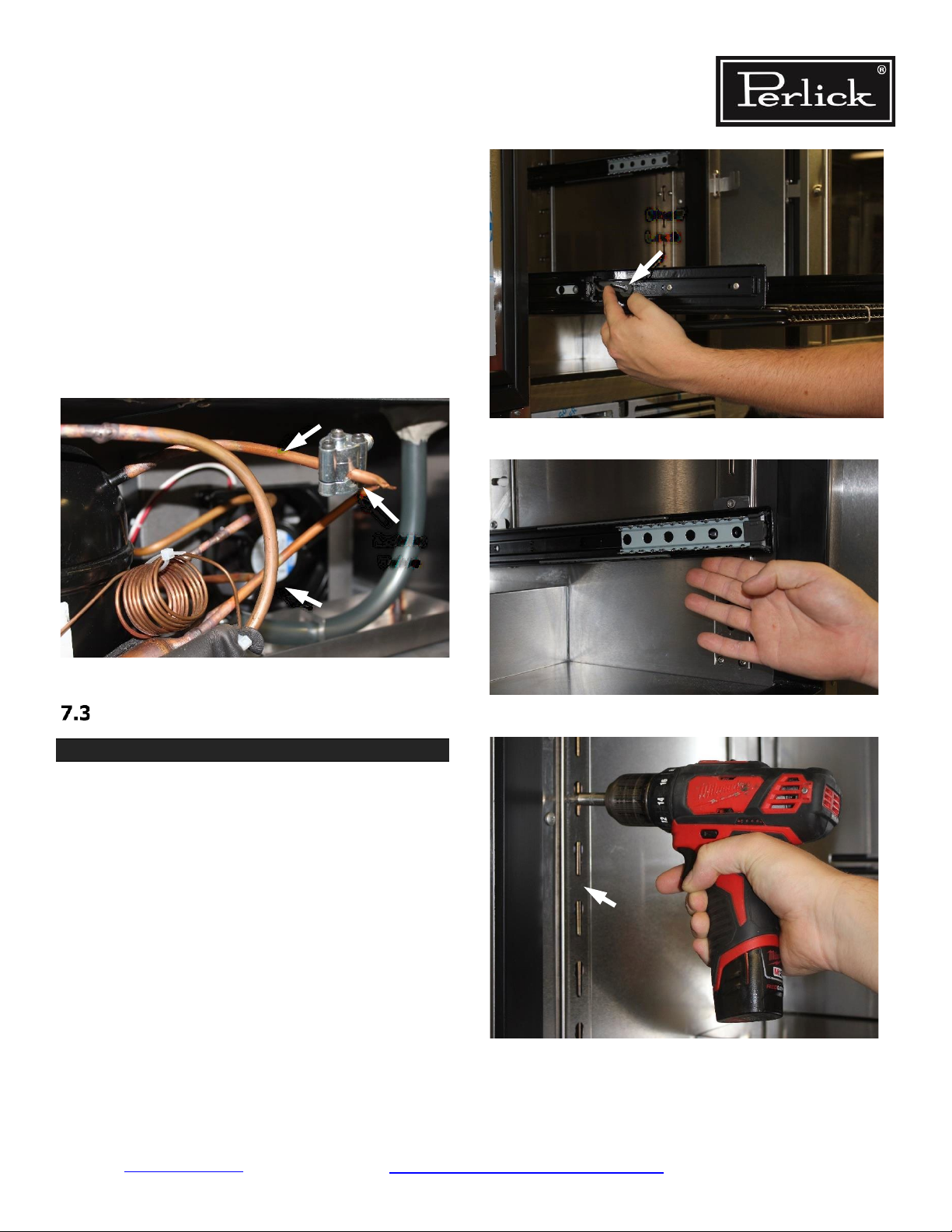

Remove Evaporator Fan Panel STEP

STEP 1.

Remove shelves, shelf slides and pilasters from

refrigerator section nearest the evaporator coil.

To remove a full extension shelf, pull shelf out so it

is fully extended, release lock mechanism on each

slide and pull out shelf. See Figure 7-5.

To remove the slides, lift up on front of slide and

pivot slightly inward to remove from the front

pilaster key slot. Pull slide forward to remove slide

from rear pilaster key slot. See Figure 7-6.

Remove screws from pilasters and remove. See

Figure 7-7.

Figure 7-6. Remove Shelf Slide

Figure 7-7. Remove Pilaster

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-4

Page 26

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

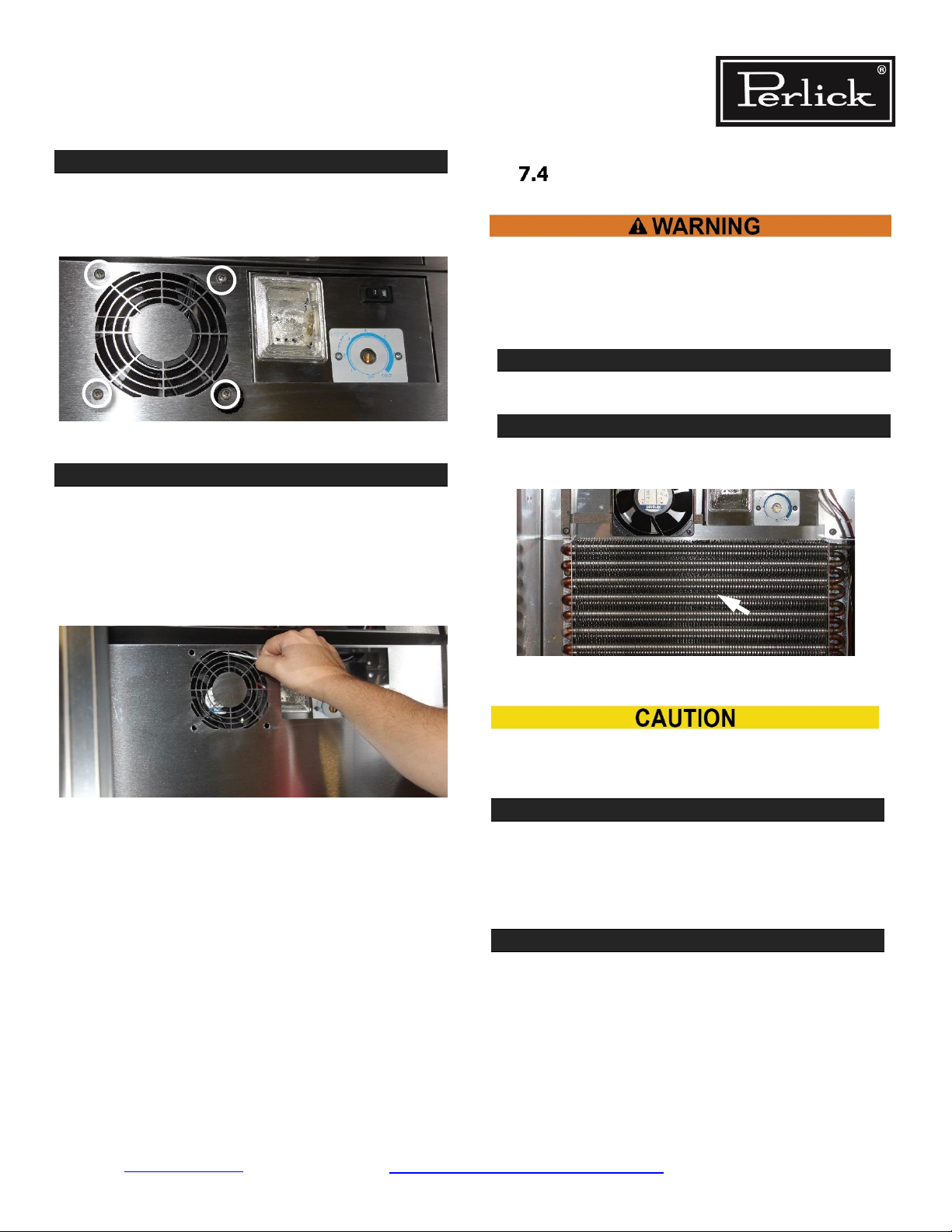

STEP 2.

Remove Evaporator Fan panel by removing 2 (or

4) Phillips head screws from around the evaporator

fan. See Figure 7-8.

Figure 7-8. Evaporator Fan Panel Screw Locations

STEP 3.

Pull outward from fan cutouts using a small

screwdriver, tilt panel top out towards you.

Pull up on panel to release anges from the

bottom inner liner of cabinet.

Carefully remove panel from cabinet.

De-Ice Blocked Evaporator Coil

Use towels to absorb water to avoid damage to ma-

chine compartment or surrounding ooring. Machine

compartment condensate pan may overow if manu-

ally defrosted without use of towels.

STEP 1.

Remove evaporator fan panel. See Section 7.3.

STEP 2.

Using a fan or heat gun to gently direct warm air

over ice to remove. See Figure 7-10.

Figure 7-9. Remove Evaporator Fan Panel

Figure 7-10. Deicing Evaporator

DO NOT use any tools to chip at or physically

remove ice!

STEP 3. When ice has been removed:

Check sealing compound. Re-forming, if necessary,

to close any gaps around wire harness and piping.

Check for other potential sources of air inltration.

See Section 7.1.

STEP 4.

Reverse steps in Section 7.3 to close the

evaporator fan panel.

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-5

Page 27

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

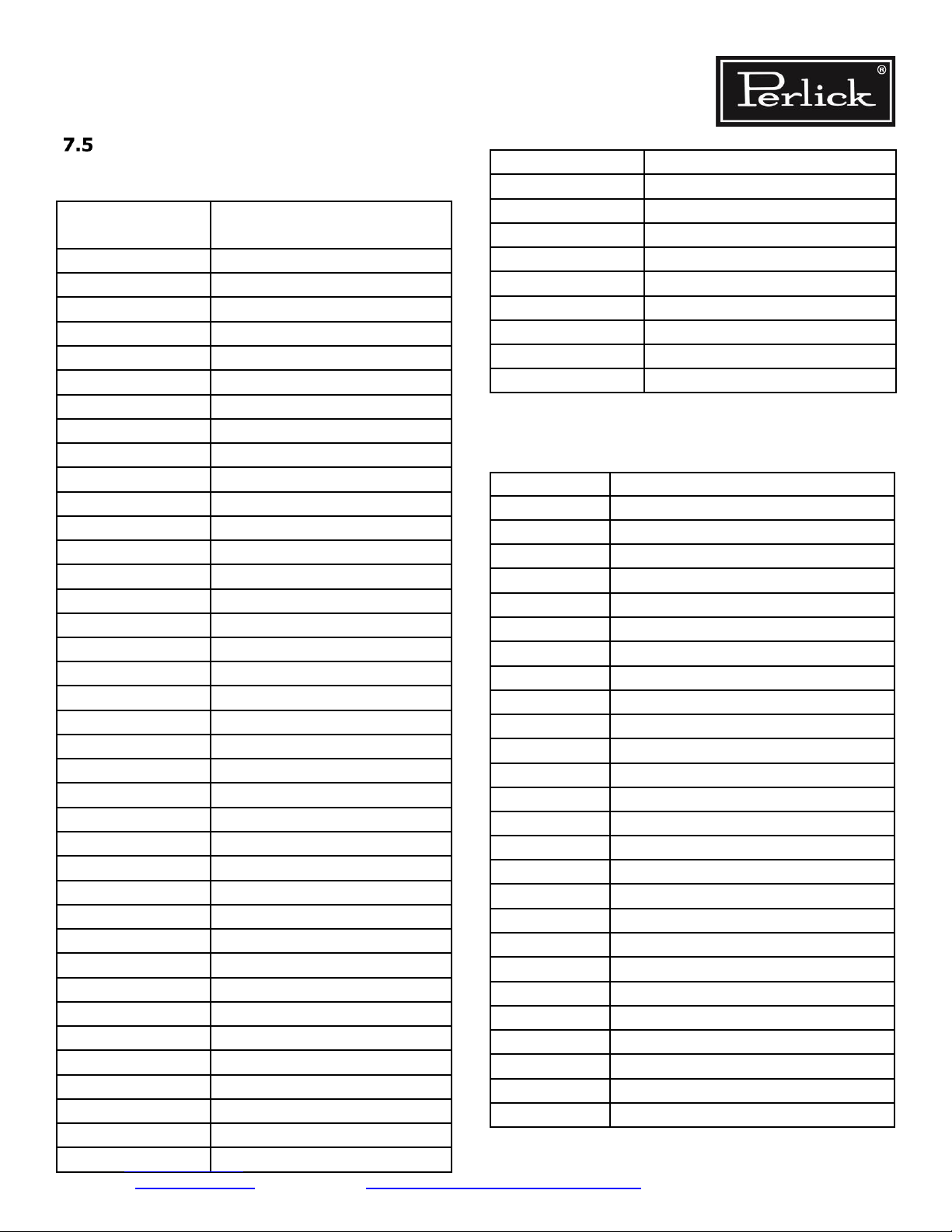

Evaporator Airow by Model

Standard-In at the bottom through louvers, out at

the top through fan.

Model

Evaporator Airow

Direction

HA24BB Standard

HA24FB Standard

HA24RB Standard

HA24WB Standard

HB24BS Standard

HB24FS Standard

HB24RS Standard

HB24WS Standard

HC24FS Standard

HC24RS Standard

HC24WS Standard

HC48RS Standard

HC48RW Standard

RC48WS Standard

HC48WW Standard

HD24RS Standard

HD24WS Standard

HH24BO Standard

HH24BS Standard

HH24RO Standard

HH24RS Standard

HH24WO Standard

HH24WS Standard

HHA24BO Standard

HHA24RO Standard

HHA24WO Standard

HK24BO Standard

HK24FO Standard

HK24RO Standard

HK24TO Standard

HK24WO Standard

HM24RO Standard

HM24TO Standard

HP24BO Standard

HP24BS Standard

HP24FO Standard

HP24FS Standard

HP24RO Standard

Return to Table of Contents

Return to Table of Contents Refrigeration System Repair Instructions Page 7-6

HP24RS Standard

HP24TO Standard

HP24TS Standard

HP24WO Standard

HP24WS Standard

HPA24BO Standard

HPA24RO Standard

HPA24WO Standard

HP48WO-S Standard

HP48WW-S Standard

Reverse-In at the top through fan, out at the

bottom through louvers

Model Evaporator Airow Direction

HC24BB Reverse

HC24RB Reverse

HC24RO Reverse

HC24TB Reverse

HC24TO Reverse

HC24WB Reverse

HK15BO Reverse

HK15RO Reverse

HK15TO Reverse

HK15WO Reverse

HK24CO Reverse

HK24DO Reverse

HK24ZO Reverse

HM24CO Reverse

HP15BO Reverse

HP15BS Reverse

HP15RO Reverse

HP15RS Reverse

HP15TO Reverse

HP15TS Reverse

HP15WO Reverse

HP15WS Reverse

HP24CO Reverse

HP24CS Reverse

HP24ZO Reverse

HP24ZS Reverse

Page 28

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

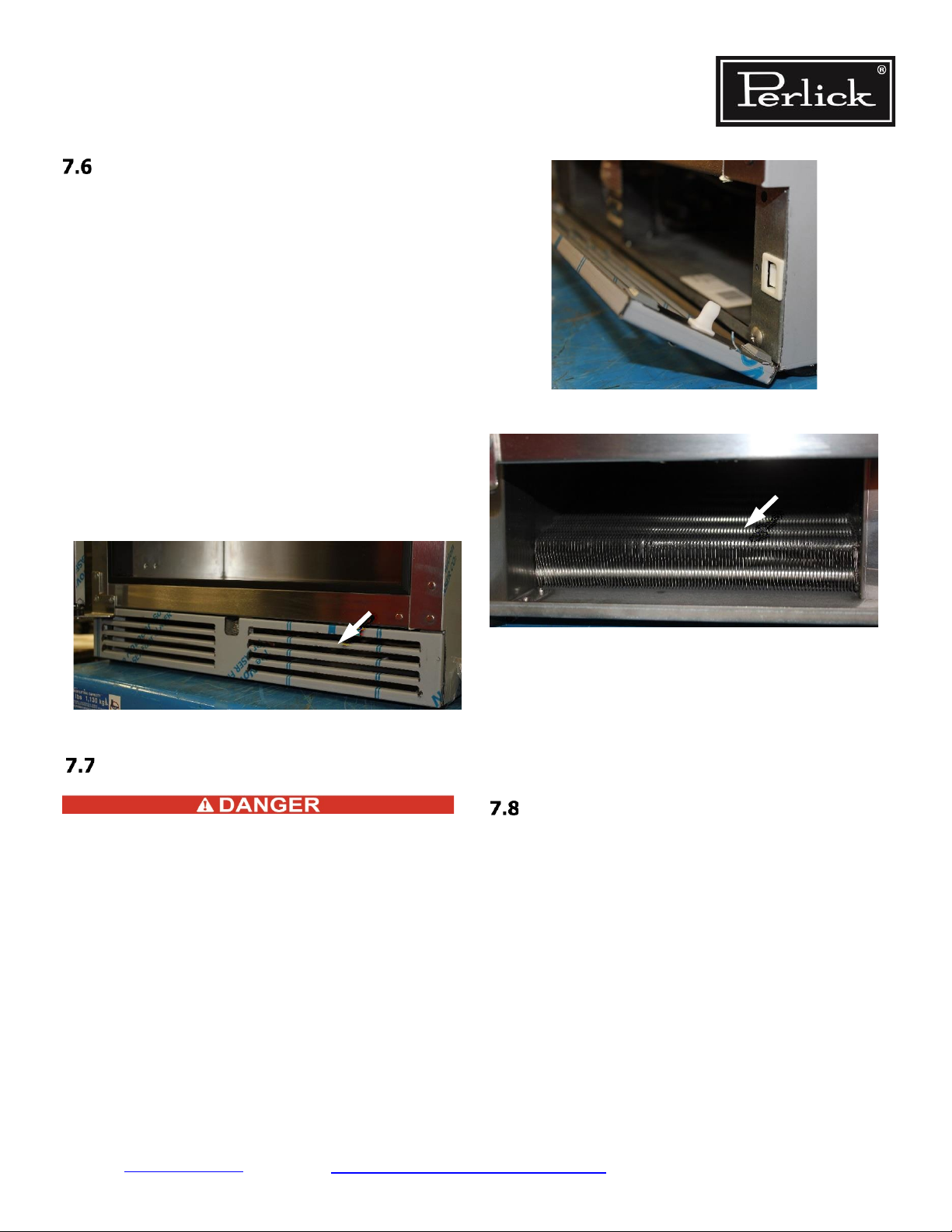

Air Flow Obstructions

The unit must have free air ow to front grille to

operate properly.

Restricted air ow results in high head pressures

and reduction in efciency due to longer run times.

Proper air ow through condenser and evaporator is

necessary for efcient operation.

• Never obstruct air ow in and out of the

machine compartment.

• The front grille must be free from

obstructions, dust, and debris.

• Never obstruct air ow to Evaporator Fan.

• Make sure higher temperature ambient air from

another unit is not directed to condenser coil

(i.e. another heat source directly across from

the unit).

Figure 7-12. Remove Front Grille

Figure 7-11. Check for Obstructions

Clean Condenser Coil

ELECTROCUTION HAZARD!! Never attempt

to repair or perform maintenance on the unit

until the Main electrical power has been dis

connected.

Perlick’s warranty does not cover cleaning of con

denser.

The condenser is located directly behind the front

grille. See Figure 7-11 through Figure 7-13.

-

-

Figure 7-13. Clean Condenser Coils

Condenser coils that are covered with dust and de-

bris restrict air ow. This results in high head pressures and lower efciency due to longer run times.

Use soft brush and vacuum to clean coil every 90

days, or more often if conditions require.

Ambient Temperature

High ambient temperature and high humidity conditions may result in performance issues and/or refrigeration system failure.

The unit must be protected from precipitation.

Do not subject to direct solar load.

Under extreme temperature and/or relative humidity

conditions the front face, gasket and/or glass door

may show signs of condensation. When temperature

and/or relative humidity conditions return to normal

condensation will disappear.

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-7

Page 29

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Compressors

Table 7-2. Compressor Data

START

WINDING

COMPRESSOR

MODEL HP

EM30HHR 1/10 RSIR 20.9 5.5 14.5

EM65HHC 1/6+ RSCR 3.7 3.2 15.0 PTC

EM20HSC 1/10 RSCR 13.2 9.3 5.2 TSD2-115V

EM3D50HLT 1/5 RSCR 5.9 5.4 8.0

VEGY3H 1/10 BPM 16.1 16.1 2.1 Inverter Inverter N/A

VEGY7H 1/4 BPM 6.4 6.4 3.3 Inverter Inverter N/A

MOTOR

TYPE

RESISTANCE

Ω AT 77°F

(+/-8%)

RUN

WINDING

RESISTANCE

Ω AT 77°F

(+/-8%)

LOCKED

ROTOR

AMPERAGE

(LRA)

STARTING

DEVICE

Current

Relay

TSD2-

115V0.6

MOTOR

PROTECTION

4TM575MFBYY-

53

4TM427NFBYY-

53

4TM189KFBYY-

53

4TM302KFBYY-

53

CAPACITOR

(Run/Start)

(uF/VAC Minimum)

Run (20/170)

Run (5/175)

Run (15/200 or

N/A

12/200)

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-8

Page 30

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

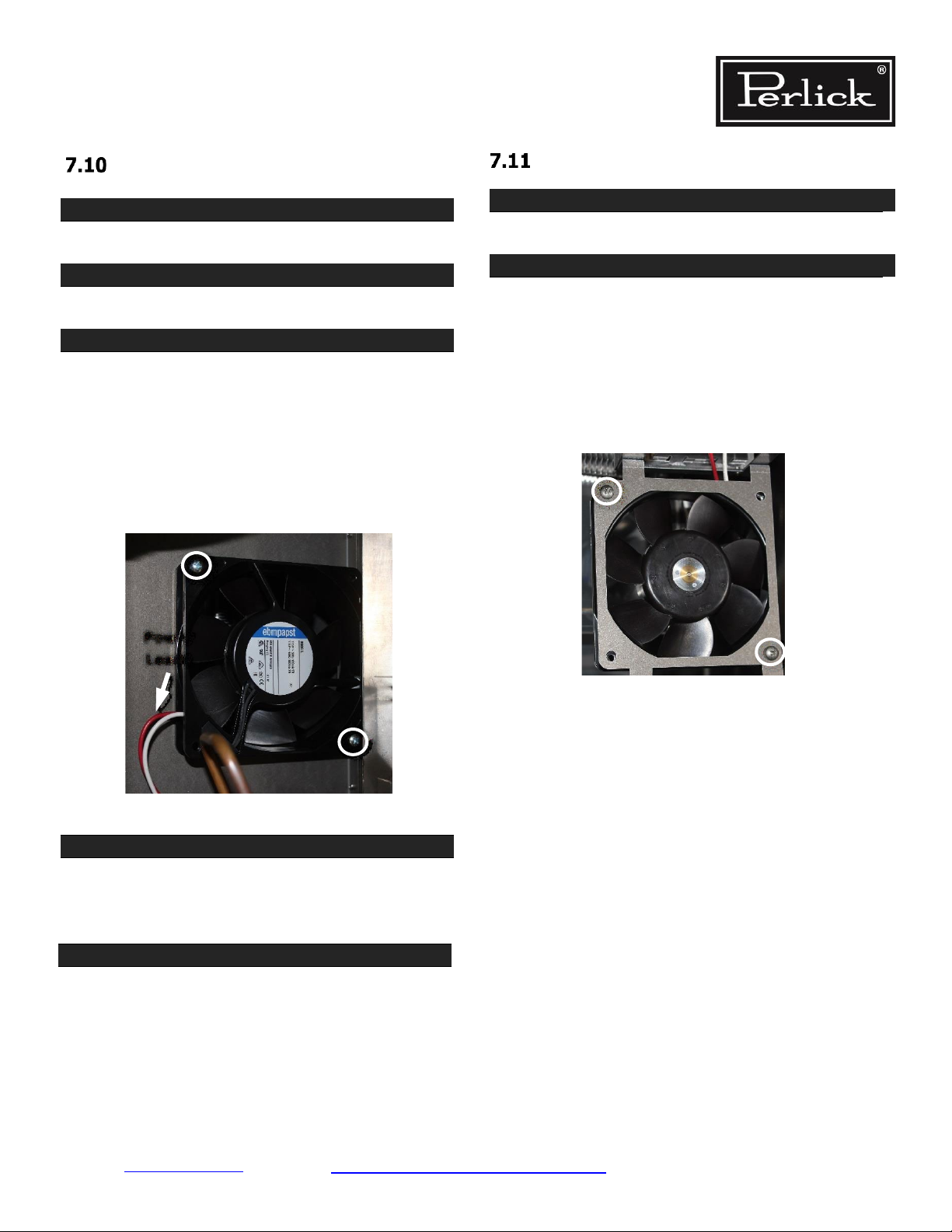

Replace Condenser Fan Motor

STEP 1.

Remove equipment compartment rear cover.

STEP 2.

Unplug the fan power leads. See Figure 7-14.

STEP 3.

Note orientation of fan motor (air should be pulled

through the condenser). Remove fan motor by

removing 2 Phillips head screws that hold the

fan bracket. The condensate pan may need to be

removed to access the screws (condensate pan is

installed using double sided tape). If the conden

sate pan is removed, reinstall properly to prevent

vibration/noise issues.

-

Replace Evaporator Fan Motor

STEP 1.

Remove evaporator fan panel. See Section 7.3.

STEP 2.

Note orientation of the fan motor so when re-in

stalled, the unit has the correct direction of airow.

Remove 2 Phillips head screws that hold fan to

bracket.

NOTE: The evaporator fan bracket may need to

be removed from the rear wall of the cabinet (4

screws) to access the fasteners holding the fan in

place.

-

Power

Leads

Figure 7-14. Condenser Fan Mounting Hardware

STEP 4.

Install new fan motor using 2 Phillips head screws

and connect power leads. Use only original Perlick

OEM parts.

STEP 5.

Install equipment compartment rear cover.

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-9

Page 31

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

STEP 3.

Disconnect evaporator fan wire leads from main

wiring harness.

STEP 4.

Evaporator fan motor can now be replaced. Evapo

rator fan motor should only be replaced with Perlick

OEM parts.

mining where original refrigerant charge

exited the sealed system!

• Placing a system that has lost refrigerant

under a vacuum without rst repairing the

leak will draw contaminants into the system

through the point of leak. Find source of the

leak and correct it!

• The use of an electronic leak detector is

highly encouraged.

• If the entire charge has leaked out of the unit,

the sealed system should be pressurized with

200 lbs. of dry nitrogen and tracer refriger

ant. Then use an electronic leak detector or

a soap and water solution to pinpoint the

location of the leak. Never use soap and water

solution on a system that is in a vacuum.

• Be certain to check all brazed connections

thoroughly for leaks. Look for spots where

the sealed system components might have

-

been worn through by structural or cabinet

components. Additionally, look for oil that

has leaked from the system to determine the

location of a leak.

-

STEP 5.

Reverse steps in Section 7.3 to close the

evaporator fan panel.

NOTE: Ensure airow is in the correct direc

tion (see section 7.5).

Replace Compressor

-

• Note: Never try and add or remove refrigerant

from the system. These products are critically

charged and must have an ID plate quantity

charge injected to run properly.

Recharge Procedure

STEP 1.

Check that the system been properly installed,

To gain access to compressor, remove the rear

pressure tested, and evacuated.

equipment compartment cover from the back of the

cabinet.

Compressor should only be replaced with Perlick

OEM parts.

Always replace drier when replacing compressor.

STEP 2.

Condenser and evaporator must be clean. Evapo

rator fan and condenser fan blades must be able to

move the correct amount of air.

STEP 3.

Compressor and drier connections should never be

de-soldered as this can cause contamination issues

to move in the system. Always cut tubing using nor

mal refrigeration servicing practices.

Leak Detection

If during a check of operating system pressures, it

is determined that refrigerant level is low, you must

Before installing gauges, vent hoses and manifold

with refrigerant type used in unit. This avoids in

troduction of air into system.

STEP 4.

Use process tubes and Schrader valves. See

Section 7.2.1.

perform a leak test.

STEP 5.

• Do not recharge a system without rst deter

Charge weightl is listed on unit information plate.

See Figure 1-1.

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-10

-

-

Page 32

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Once charge level has been set, avoid installing

gauges as part of regular service. System should

be kept sealed.

Do not “top off” or add refrigerant to an unknown

existing charge.

Completely recover existing refrigerant in accor

dance with EPA regulations and thoroughly evacuate the system.

After evacuating the system:

1. Close high side valve and weigh in correct

total charge amount per the I.D. plate.

2. During charging, plug in the unit so the sys

-

tem operates to reduce low side pressure.

3. Upon complete charge being weighed in,

remove charging line set with minimal pres

-

sure remaining in the line set.

4. Note: Never remove line set when in a vac

uum as containments can be sucked into the

system.

Replace compressor starting

device

STEP 1.

Remove equipment compartment rear cover panel

(6 Phillips head screws).

STEP 3.

Use screw driver to pry off overload relay and

starting device.

STEP 4.

Starting device and overload device are now

accessible. Remove leads and replace.

STEP 2.

On side of compressor, lift tab to remove gray

cover.

Starting

device

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-11

Overload

device

Page 33

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Beverage Dispensing

Perfectly poured draught beer is the result of

proper temperature, gas pressure, mixture, and

a well-maintained draught beer system. It’s easy

to take all the variables for granted when beer

is pouring well. But improperly pouring beer

can be very frustrating, and can result in loss of

sales- This chapter is intended to provide useful

troubleshooting steps anyone can follow to solve

draught beer dispense problems.

The single most common cause of problems

encountered in draught beer dispense systems

is temperature control. The rst step in solving

any dispensing problem is to conrm that the

temperature of the keg and the cooler are where

they are supposed to be. In air-cooled and

glycol-cooled systems, the next step is to check

the temperature of the beer being delivered to

the faucet, conrming that the air and glycol

systems

used to maintain proper beer line temperature are

working properly.

The troubleshooting steps that follow are

organized by the type of draught beer system and

how the systems are cooled, using air. Direct-draw

systems cooled by air or glycol each have unique

features that are addressed in the troubleshooting

steps

Other steps including gas pressure and supply,

beer supply, and mechanical issues are also

discussed.

Perfect

Carbonation

Under

Carbonation

Over

Carbonation

C02 gauge pressure, temperature and carbonation level reference chart

Table 7-3. C02 equilibrium pressure given volumes of C02 and temperature

Vol. CO2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 3.0 3.1

Temp. °F psi psi psi psi psi psi psi psi psi psi psi

33 5.0 6.0 6.9 7.9 8.8 9.8 10.7 11.7 12.6 13.6 14.5

34 5.2 6.2 7.2 8.1 9.1 10.1 11.1 12.0 13.0 14.0 15.0

35 5.6 6.6 7.6 8.6 9.7 10.7 11.7 12.7 13.7 14.8 15.8

36 6.1 7.1 8.2 9.2 10.2 11.3 12.3 13.4 14.4 15.5 16.5

37 6.6 7.6 8.7 9.8 10.8 11.9 12.9 14.0 15.1 16.1 17.2

38 7.0 8.1 9.2 10.3 11.3 12.4 13.5 14.5 15.6 16.7 17.8

39 7.6 8.7 9.8 10.8 11.9 13.0 14.1 15.2 16.3 17.4 18.5

40 8.0 9.1 10.2 11.3 12.4 13.5 14.6 15.7 16.8 17.9 19.0

41 8.3 9.4 10.6 11.7 12.8 13.9 15.1 16.2 17.3 18.4 19.5

42 8.8 9.9 11.0 12.2 13.3 14.4 15.6 16.7 17.8 19.0 20.1

Based on Data from “Methods of Analysis,’ American Society of Brewing Chemists, 5th Edion – 1949

• The values in this table assume sea-level altitude, beer specic gravity of 1015, and beer alcohol

content at 3.8% abw or 4.8% abv. Values shown are in psig or gauge pressure.

• It’s important to remember that carbonation is proportional to absolute pressure, not gauge pres

sure. Atmospheric pressure drops as elevation goes up. Therefore, the gauge pressure needed to

achieve proper carbonation at elevations above sea level must be increased. Add 1 psi for every

2,000 feet above sea level. For example, a retailer at sea level would use 11.3 psi gauge pressure to

-

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-12

Page 34

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

maintain 2.5 volumes of C02 in beer served at F. That same retailer would need 13.3 psi gauge

pressure at 4,000 feet elevation to maintain 5 volumes of C0

2.

Calculate ideal gauge pressure of

straight C02

Carbonation level not known.

STEP 5.

Set the regulator pressure to 5 psi.

STEP 6.

Tap a fresh keg. Make sure the keg has been in

the cooler long enough to be at the cooler tem

perature.

STEP 7.

Pour a small amount of beer through the faucet.

STEP 8.

Observe the beer in the draught line directly

above the keg coupler (with a ashlight if nec

essary), inspecting for bubbles rising up from the

beer in the keg.

STEP 9.

If bubbles are present, raise the regulator

pressure 1 psi.

-

-

in the system. Below, you’ll nd instructions on

how to properly and thoroughly clean your beer

dispenser.

Tools required

Perlick Cleaning Kit

(Part No. 63797):

check ball lifter

cleaning pump jar

cleaning brush

coupling washer

STEP 10.

spanner wrench

Repeat steps 3 - 5 until no bubbles are present.

STEP 11.

Check the keg temperature 24 hours after setting

4 oz. BLC line cleaning

chemical

the initial gauge pressure to assure temperature

stability, and to reset the gauge pressure as need

-

ed due to a change in keg temperature.

This is the lowest pressure at which the gas in

Buckets

Water

the beer is not escaping. This is your ideal gauge

pressure.

Beer Dispenser Cleaning

To ensure brewery-fresh avor, it is recommended

that the beer system be cleaned after every barrel

or every two weeks to eliminate bacteria, yeast

The chemicals used to clean beer lines are

hazardous. Please follow all recommended

safety instructions on the chemical’s

container.

and beer stone build-up

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-13

Page 35

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

STEP 1.

Turn off the CO2, either at the CO2 cylinder or at

the air distributor.

STEP 2.

Remove tapping device (keg coupler) from the

barrel.

STEP 3.

If tapping device contains a check ball, insert check

ball lifter into the bottom of the coupler (Perlick

Low Prole Coupler does not contain a check ball).

STEP 4.

Place tapping device into a small bucket.

STEP 5.

Using a spanner wrench, remove the beer faucet

from the dispensing head.

STEP 6.

Fill cleaning pump with warm water.

STEP 7.

Attach cleaning pump jar connector with washer

to where faucet was removed from dispensing

head.

STEP 8.

Pump the warm water through the system to re

move all remaining beer from the system. Empty

tapping device bucket and rinse out. Place tapping

device back into the bucket.

STEP 9.

Fill cleaning pump jar with water and cleaning

chemical per the recommendations on the cleaning

chemical container.

STEP 10.

Pump cleaning solution into system, leaving about

a 1/2 the solution in the cleaning pump jar.

STEP 11.

Let stand 15 minutes, then pump remaining

solution through the system.

STEP 12.

Using a cleaning brush, clean the exterior

surfaces of the tapping device and rinse with

clean fresh water

STEP 13.

Rinse out cleaning pump jar with fresh water

STEP 14.

Fill cleaning pump jar with clean warm water and

pump entire jar through the system

STEP 15.

Repeat STEP 13 using clean cold water

STEP 16.

During the 15 minutes that the solution is in

the system, mix a small container with water

and cleaning chemical per the instructions on the

cleaning chemical container and disassemble the

faucet per faucet manufacturers recommenda

-

tions and let soak in solution

STEP 17.

Using cleaning brush, clean the components of

the faucet

STEP 18.

Rinse all components of the faucet in clean fresh

water. Check all seals on the faucet for wear and

replace if necessary

STEP 19.

Reassemble faucet

STEP 20.

Remove cleaning pump jar from dispensing

tower connection and reinstall faucet using

spanner wrench to tighten properly

STEP 21.

Turn on CO

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-14

2 and tap new keg

Page 36

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Refrigeration System Diagrams

Figure 7-15. Dual Zone F-R Gen 3 Refrigeration System Diagram

Dual Zone: Freezer/Refrigerator

ITEM

NUMBER

DESCRIPTION

ITEM

NUMBER

DESCRIPTION

1 Compressor 9 Evaporator Fan (Lower)

2 Condenser 10 Temperature Control

3 Condenser Fan 11 Liquid Line Solenoid (Upper)

4 Drier 12 Capillary Tube (Upper)

5 Hot – Gas Bypass Valve 13 Heat Exchanger (Upper)

6 Capillary Tube (Lower) 14 Evaporator (Upper)

7 Heat Exchanger (Lower) 15 Evaporator Fan (Upper)

8 Evaporator (Lower)

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-15

Page 37

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Figure 7-16. Dual Zone Med Temp Gen 3 Refrigeration System Diagram

Dual Zone: Refrigerator/Wine, Wine/Wine

ITEM

NUMBER

DESCRIPTION

ITEM

NUMBER

DESCRIPTION

1 Compressor 9 Evaporator Fan (Lower)

2 Condenser 10 Temperature Control

3 Condenser Fan 11 Liquid Line Solenoid (Upper)

4 Drier 12 Capillary Tube (Upper)

5 N/A 13 Heat Exchanger (Upper)

6 Capillary Tube (Lower) 14 Evaporator (Upper)

7 Heat Exchanger (Lower) 15 Evaporator Fan (Upper)

8 Evaporator (Lower)

Return to Table of Contents

Refrigeration System Repair Instructions Page 7-16

Page 38

Residential Refrigeration

and Front Venting Commercial Refrigeration

Service Manual

Figure 7-17. Freezer/Commercial Chiller Refrigeration System Diagram

Freezer/Commercial Chiller

ITEM

NUMBER

DESCRIPTION

ITEM

NUMBER

DESCRIPTION