Page 1

Installation

& Operation Manual

Single Door Undercounter Refrigeration

HC Series / HB Series / HD Series

C

US

Form No. Z2363

Rev. 08.26.2014

Page 2

Single Door Undercounter Refrigeration Installation & Operation Manual

DANGER

INTRODUCTION/PREPARING THE CABINET - SINGLE DOOR UNDERCOUNTER CABINETS

Uncrating and Inspection

Table of Contents

Introduction ........................................... 2

Preparing the Cabinet for Use

Uncrating and Inspection ..................... 2

Plumbing/Electrical .............................. 2

Installing the Cabinet

Anti-Tip Brackets ................................. 3

Preparing the Space ............................ 3

Installing the Unit ................................. 4

Toe Plate/Shelving Installation ............. 5

Operation Instructions

Master Switch ...................................... 6

Interior Light......................................... 6

Controller Operation ............................ 6

Maintenance

Light Bulb Replacement ...................... 8

Stainless Steel Care Guide ................. 8

Cleaning Condenser ............................ 9

Troubleshooting ................................. 10

Contact Perlick ....................................11

Remove all crating material. Carefully inspect cabinet

for hidden damage. If damage is discovered, le your

claim immediately with the transport company. Perlick

is not responsible for damage in transit.

Plumbing

No plumbing connections are required. Condensate

from the cooling coil automatically evaporated through

a condensate pan located in the condensing section

of the unit.

Electrical

A 115 volt, 60 Hz, 15 amp circuit breaker and electrical supply are required. A separate circuit is required

for each Perlick unit installed.

Follow the National Electrical Code and any local

codes or ordinances when installing the receptacle.

All Perlick units come equipped with a NEMA 5-15P

90° plug with a 5’ cord extending beyond the rear of

the cabinet. The electrical outlet must be ush with,

or recessed into, the wall surface for all HC and HB.

HD models have a recess at the rear of the cabinet

to accomodate the plug and keep a true 18” depth.

Thank you for choosing Perlick

To register your product, visit our website at www.

perlick.com. Click on ‘Bar & Beverage Equipment’,

then ‘Service & Support’ and select the ‘Warranty

Registration Form’ option.You must complete and

submit this form or the installation date will revert

back to the ship date.

This manual has been prepared to assist you in the

installation of this cabinet and acquaint you with its

operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can

provide you with a list of qualied service agents.

For your own protection, never return merchandise

without our approval.

We thank you again for selecting a Perlick product

and assure you of our continuing interest in your

satisfaction.

Serious electrocution haz-

ard! Electrical grounding is

required. This appliance is equipped with a

3-prong (grounding) polarized plug for your protection against possible shock hazards. Failure

to comply with these electrical guidelines may

result in possible death or serious injury, re, or

loss of property.

► NEVER remove the round grounding prong from

the plug.

► NEVER use a 2-prong adapter.

► NEVER use an extension cord to connect power

to the unit.

Additional General Information

► All electrical instructions assume the outlet is

located 4” -10” above the oor surface.

► Floor must be level in the area of installation. Leg

levelers are used for ne-tune adjustment only

and should not be used to compensate for oor

differences exceeding 1/2”.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

2

Page 3

Single Door Undercounter Refrigeration Installation & Operation Manual

CAUTION

CAUTION

CAUTION

INSTALLING THE CABINET - SINGLE DOOR UNDERCOUNTER CABINETS

Preparing the Space

If the unit is to be installed

under a countertop, it is

recommended that the countertop be supported

by a structure other than the unit itself to prevent

damage to the unit.

Make sure the oor under the

unit is level with the surrounding

nished oor. Protect a nished oor with plywood,

cardboard, or some other suitable material before

moving the unit into place. Failure to do this may

result in damage to the oor.

1). Make sure the space opening is correctly sized for

the unit. See chart below for nished rough opening

requirements.

HC24 24” C-Series

Height Depth Width

34-3/8” minimum,

35-1/2” maximum

HB24 24” ADA-Compliant Series

Height Depth Width

32-1/2” 24” 24”

HD24 18” Shallow-Depth Series

Height Depth Width

32-1/2” 18” 24”

24” 24”

Installation

Unit may tip forward if loaded racks/shelves are all

pulled out at the same time. To prevent tipping, and to

provide stable installation, the unit must be secured in

place with the anti-tip brackets supplied with the unit.

The anti-tip brackets, when properly installed, should

secure the rear legs/glides to the mounting surface

and prevent the unit from tipping forward.

Please note:

► Anti-tip brackets are only used for stationary

cabinets and should not be installed on cabinets

with accessory casters. Caster kits are available

for HC and HB model cabinets. Refer to the

instructions supplied with the caster kit for proper

installation.

► If installing on a concrete oor, concrete fasteners

are required and not included with the anti-tip kit.

► Some installation sites may require modications

to provide a secure surface for attaching the

brackets.

A set of anti-tip brackets is supplied with the unit.

These brackets should be attached to the oor at

the rear of the unit. Each bracket must be located to

engage the rear glides when the cabinet is pushed

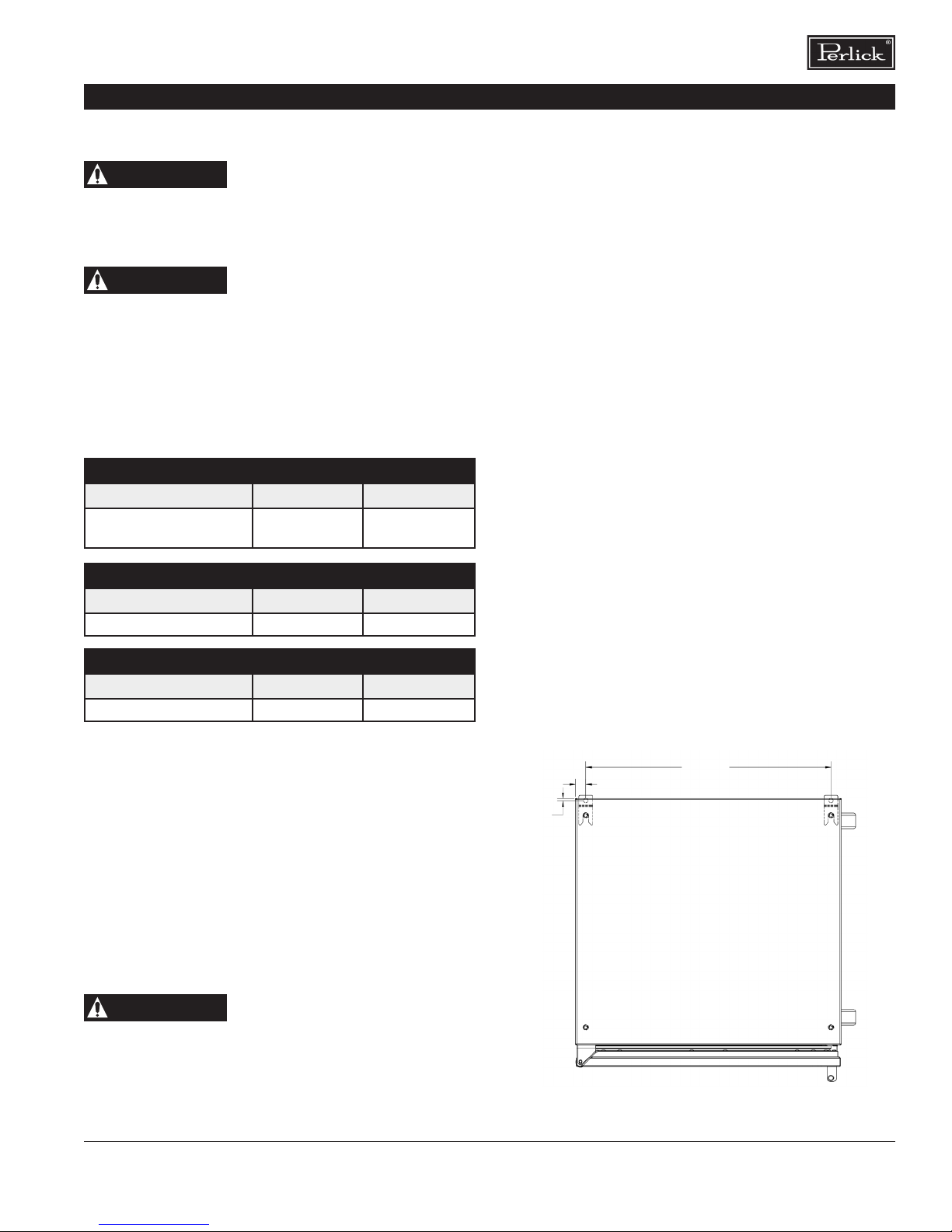

back into position. Refer to Figure 1 (shown below)

for anti-tip bracket mounting locations.

NOTE: For a cabinet door to open properly, the door

must open a minimum of 90°. Use a minimum 3” ller in corner installations to assure a full 90° opening.

Allow 25” clearance in front of unit for full door swing

and shelf/drawer pull out for all units

2). Check that the following are level and square:

► Front and interior opening

► Installation opening and oor surface

► Countertop bottom and front edge (if applicable)

NOTE: The oor under the unit

must be at the same level as

the surrounding nished oor. To prevent possible

damage to the countertop do not place heavy objects

on countertop directly over unit.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

22-⁄”

⁄”

⁄”

Figure 1. 24” Anti-Tip Bracket

3

Page 4

Single Door Undercounter Refrigeration Installation & Operation Manual

Installating the Unit

1). Plug the unit into the 15 amp grounded electrical

outlet located within the installation opening. With

power applied to the unit, check that the lighting and

cooling functions operate properly. Turn off the power

to the wall outlet at the circuit breaker.

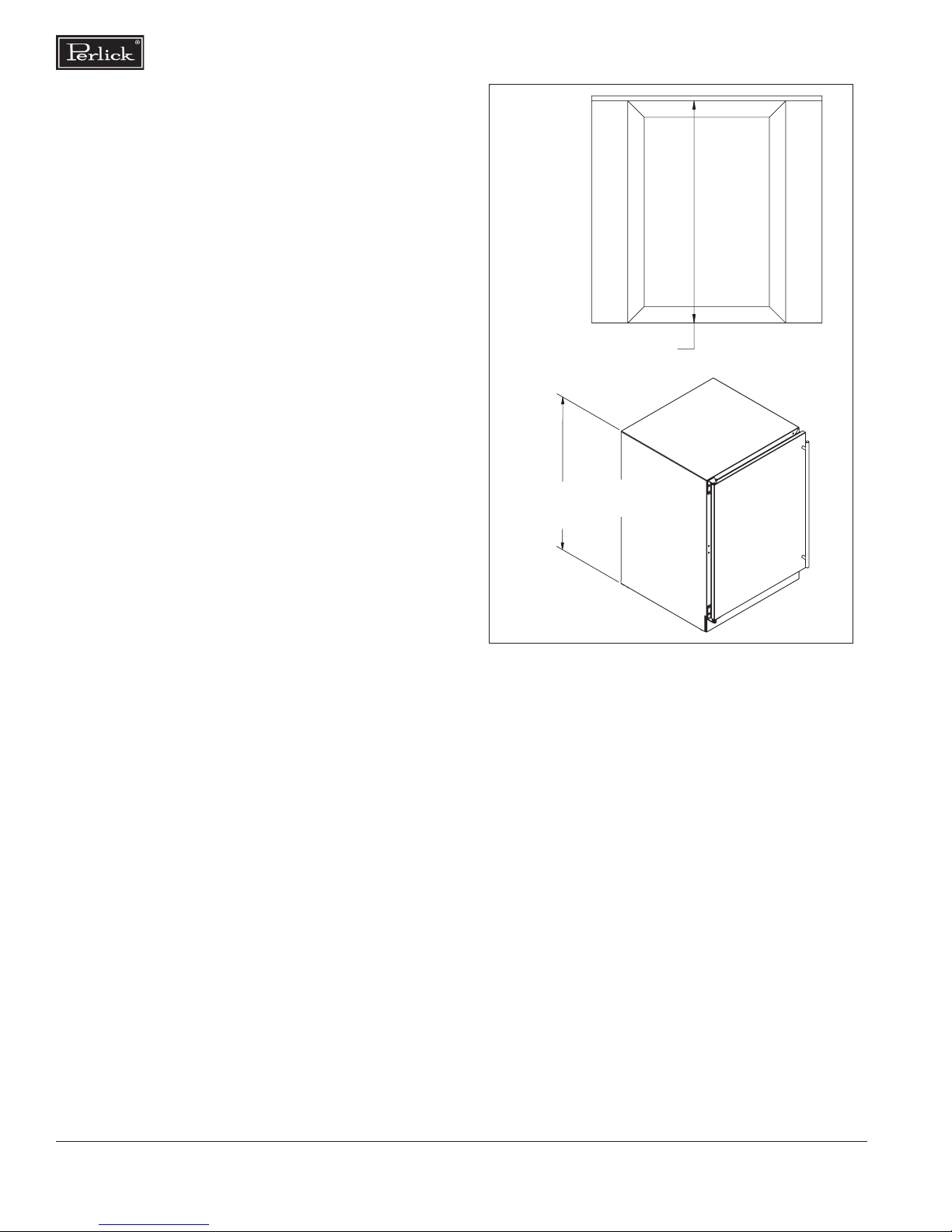

2). With all surfaces in the installation opening square

and level, refer to Figure 2 (shown right) and perform

the following steps:

► At the bottom of the opening, measure from

the oor to the bottom of the front edge of the

countertop.

► Measure from the oor surface to the top of the

unit at the rear corners.

► Adjust the unit legs so these two measurements

are equal. Using an adjustable wrench or pliers,

turn legs clockwise to lower the unit and clockwise

to raise it.

NOTE: Legs should not extend more than 3/4” from

the bottom of the unit.

Measure front of opening

from floor surface to bottom

edge of countertop

Measure at bot rear corners of

unit from floor surface to bottom

of countertop

3). Slide the unit into position in the opening. Make

sure the rear leveling legs slide under the antitip brackets. Push the unit into the opening until

the bottom front edge of the unit is ush with the

surrounding cabinetry, or until the rear legs are tight

against the anti-tip brackets.

NOTE: The rear leveling legs must be engaged under the anti-tip brackets.

4). Shim the front of the unit so the front face is ush

with surrounding cabinetry. Adjust the front legs to

support the countertop at the shimmed height. Using

an adjustable wrench of pliers, turn the legs clockwise

to lower the unit or counterclockwise to raise it.

Countertop should be resting on top of the unit.

NOTE: Countertop should be resting evenly on entire top of the unit. Shim if necessary to prevent damage to the countertop.

5). Check interior door openings to make sure the unit

is level and square. Install shelving and/or drawers.

Place the slide brackets squarely into the bracket

grooves. When installed properly, a “click: should be

heard from the slide bracket retaining tabs and the

brackets should slide smoothly. The retaining tabs will

stop the shelf/drawer when pulled out to full extension.

Figure 2. Leveling the Unit

6). Turn the power on to the circuit breaker.

NOTE: Improper shelf/drawer installation may not

actuate slide mechanism.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

4

Page 5

Single Door Undercounter Refrigeration Installation & Operation Manual

Toe Plate Installation

Once the unit is secured in place, install the louvered

toe plate. Secure the plate by snapping the latch

into the latch catch on the unit as shown in Figure 3

(shown below).

Latch

Strike

Latch

Figure 3. Toe Plate Installation

4). Repeat for other bracket(s).

5). Push extenders completely into the unit. Align the

shelf grooves with the extenders and slide completely

into the unit.

Lift one tab on extender UP while

hin tab on ooite extender

and ll ot to reoe

Shelving

Each cabinet comes with standard shelving (drawer

models excluded). All shelves are black vinyl-coated,

full-extension pullout shelves. Wine shelves have

stainless steel front.

Refrigerator - Two (2) refrigerator shelves

Freezer - Two (2) refrigerator shelves

Beverage Center - Two (2) wine shelves and one (1)

refrigerator shelf

Wine Reserve - Five (5) wine shelves

To adjust the shelving:

1). Pull the shelf out to its farthest position. Locate the

tabs in the middle of both extends, then press tabs

and pull shelf out of the unit. See Figure 4

2). Reposition each bracket separately. Grasp the

middle of the bracket, pull the front end up and out,

then forward to remove.

o reoe braet

reoe helf lift front

of braet to dienae

the front e lot then

ll forward to dienae

the rear e lot

Figure 4. Adjusting Shelf Position

3). Place bracket at the desired position. Push the

rear hook into the rear key slot. Set front bracket on

the wall hook.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

5

Page 6

Single Door Undercounter Refrigeration Installation & Operation Manual

OPERATION - SINGLE DOOR UNDERCOUNTER CABINETS

Master Switch

All cabinets come equipped with a master power

switch located behind the louvered toe kick. Remove

the toe kick to turn power on or off the the unit.

Interior Light

Door units are equipped with an interior light that

illuminate when the door is opened. The cabinet

also comes equipped with a manual light switch for

displaying the products through a glass door. For

C-Series (HC), ADA-Compliant (HB) and ShallowDepth (HD) models, this is located on the back wall

left of the light.

Always ensure that the manual light switch is in the

OFF position before closing a solid wood or stainless

steel door. If manual light switch is left on for an

extended period of time, it may increase the cabinet

temperature, and cause the refrigeration system to

run harder.

Loading Product

Before storing perishables, turn unit on and allow

it to operate for a minimum of 24 hours to allow

temperatures to stabilize.

When loading items into the unit, do not block internal

louvers and fan guard openings or performance will

be decreased.

Digital Temperature Control

The following are the programming button denitions:

SET button

DEFROST button (melting snowake)

UP arrow

DOWN arrow

ON/OFF button

Digital Controller Operating Instructions

To Set Target Temperature: Press and release the

SET button. Display will show the current temperature

set point.

To Change Setpoint Temperature

1. Press and hold the SET button until the display

shows the current setpoint temperature with the

“F” ashing.

2. Use the UP and DOWN arrow button to scroll to

the desired temperature.

To Start A Manual Defrost (Freezer Models Only)

Press the DEFROST button (melting snowake)

Perlick Single Door Freezer units come standard with

digital control (Figure 5).

Figure 5. Digital Controller

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

To Set Maximum Stored Temperature: Press the UP

arrow button to see the maximum stored temperature.

To reset the maximum stored temperature, while

displayed, press and hold the SET button until ‘rst’

ashes in the display.

To Set Minimum Stored Temperature: Press

the DOWN arrow button to see the minimum

stored temperature. To reset the minimum stored

temperature, while displayed, press and hold the SET

button until ‘rst’ ashes in the display.

On/Off: Press the ON/OFF button to turn the unit on

or off.

6

Page 7

Single Door Undercounter Refrigeration Installation & Operation Manual

The following are the programming button key

combinations:

+

Press the UP and DOWN arrow

buttons to lock and unlock the

keyboard

+

Press the SET and DOWN arrow

buttons simultaneously to enter

programming mode.

+

Press the SET and UP arrow

buttons simultaneously to return

to room temperature display.

NOTE: Dependent on the model and conguration,

the controllers have been programmed to only allow

a temperature adjustment within a specied range.

See the chart below for the specied range allowed

for your unit.

HC24 24” C-Series

Model Min Temp

Set

HC24FS -° F -° F -° F

Max Temp

Set

Factory Temp

Setpoint

HB24 24” ADA Compliant Series

Model Min Temp

Set

HB24FB -° F -° F -° F

Max Temp

Set

Factory Temp

Setpoint

Electromechanical Temperature Control

Perlick Single Door Refrigerator, Beverage Center

and Wine Reserve units come standard with an

electromechanical temperature control (Figure 6).

4

R

3

E

L

O

O

C

2

1

OFF

Figure 6. Electromechanical Temperature Control

5

6

COLD

Electromechanical Controller Operating

Instructions

Use a straight slot screwdriver to adjust the dial

temperature control. The control is located at the top

rear panel of the cabinet. Approximate temperature

ranges are as follows:

HC24 24” C-Series

Model Factory Temp Setpoint

HC24RS -° F

HC24WS -° F

The following table describes LED functions:

LED Mode Function

ON Compressor is on

Flashing Anti-short cycle

delay is on

ON Defrost is on

ON Alarm is on

Flashing You are in the process

of programming the unit

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

HB24 24” ADA Compliant Series

Model Factory Temp Setpoint

HB24RB -° F

HB24BB -° F

HB24WB -° F

HD24 18” Shallow-Depth Series

Model Factory Temp Setpoint

HD24RS -° F

HD24WS -° F

To Adjust to Colder Temperature: Turn the adjusting

screw clockwise (to the left)

To Adjust to Warmer Temperature: Turn the

adjusting screw counterclockwise (to the right)

To Turn Temperature Control OFF: Turn the

adjusting screw completelt counterclockwise to the

OFF position until a click is heard.

NOTE: Condenser fan motor turns o with compressor.

7

Page 8

Single Door Undercounter Refrigeration Installation & Operation Manual

DANGER

MAINTENANCE - SINGLE DOOR UNDERCOUNTER CABINETS

Checking Product Temperature

To accurately check the temperature of product

stored in the refrigerated compartment:

1. Insert an accurate thermometer into an

unbreakable plastic bottle, partially lled with

water. Tighten bottle cap securely.

2. Place bottle in the desired area for 24 hours.

Refrain from opening the unit during the testing

period. After 24 hours, check the temperature

of the water and adjust using the Controller

Operating Instructions on page 6.

Never attempt to repair or per-

form maintenance on the unit

until the main electrical power to the unit has

been disconnected.

Light Bulb Replacement

To replace a defective or burnt out bulb, remove the

glass light cover by pulling off the cover. Unscrew the

bulb and replace it with an identical or smaller bulb.

The Perlick replacement part number is 67026.

Stainless Steel Care

Stainless steel is a “passive” metal because it

contains other metals like chromium, nickel and

manganese that stabilize the atoms. Chromium

provides an invisible passive lm that covers the

steel surface, acting as a shield against corrosion.

As long as the lm is intact and not contaminated,

the metal is passive and stainless. If the passive

lm of stainless steel has been broken, equipment

can start to corrode and rust.

Three materials or processes can break down

stainless steel’s passive layer and allow corrosion

to occur:

► Mechanical abrasion

► Deposits and water

deposits from food preparation must be promptly

removed with an appropriate cleaning agent.

Chlorides are found nearly everywhere. They are in

water, food and table salt. Household and industrial

cleaners are the worst offenders.

Preventing Stainless Steel Rust

Use non-abrasive tools to clean stainless steel

products. Soft cloths and plastic scouring pads will

not harm the steel’s passive layer.

Clean with polish lines. Some stainless steels have

visible polishing lines or “grain”. When visible lines are

present, always scrub in a motion parallel to the lines.

When the grain cannot be seen, polish in a consistent

straight pattern and not in a circular motion.

Use alkaline, alkaline chlorinated or non-chloride

containing cleaners. While many traditional cleaners

are loaded with chlorides, the industry is providing an

ever-increasing choice of non-chloride cleaners. If you

are not sure of chloride content in the cleaner being

used, contact your cleaner supplier. If your present

cleaner contains chlorides, ask your supplier for an

alternative. Avoid cleaners containing quaternary salt;

it also can attack stainless steel and cause pitting

and rusting.

Keep food equipment clean. Use alkaline, alkaline

chlorinated or non-chloride cleaners at recommended

strength. Clean frequently to avoid build-up of hard,

stubborn stains. The single most likely cause of

damage is chlorides in the water. Remember, adding

heat to cleaners that contain chlorides dramatically

increases their effect on stainless steel.

If chlorinated cleaners are used, immediately rinse

and wipe equipment and supplies dry. The sooner

you wipe standing water, especially when it contains

cleaning agents, the better. After wiping equipment

down, allow it to air dry. Oxygen helps maintain the

stainless steel passive lm.

► Chlorides

Mechanical abrasion refers to items that will scratch

a steel surface. Steel pads, wire brushes and scrapers

are prime examples.

Water comes out of the faucet in varying degrees

of hardness. Hard water may leave spots. When

allowed to sit, these deposits will break down the

passive chromium layer and rust stainless steel. Other

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

8

Page 9

Single Door Undercounter Refrigeration Installation & Operation Manual

CAUTION

CAUTION

CAUTION

Cleaning the Cabinet Interior/Exterior

NEVER use hydrochloric

acid (muriatic acid) on

stainless steel. Do not use abrasive cleansers

Cleaning the Condenser

The condenser (located behind the front grille cover)

should be cleaned every three (3) months. Use a soft

bristle brush and vacuum to remove dust and lint.

on cloths on any interior or exterior surfaces,

including removable parts.

Glass panels may be cleaned using any standard

glass cleaner available on the market.

To clean interior and exterior non-metallic surfaces

and removable parts, wash with mild solution of soap

loss or mechanical failure.

Avoid damaging or crushing

the condenser ns or tubing.

Failure to clean the condenser

could result in temperature

and lukewarm water with a little baking soda. Rinse

and dry thoroughly. Avoid getting water on the lights,

controllers, fan motors and unnished wood wine

rack faces.

Recommended Cleaners for Specic Situations

Job Cleaning Agent Comments

Routine cleaning Soap, ammonia, detergent Apply with sponge or soft cloth

Fingerprints and smears Areal 20, Lac-O-Nu, Lumin Wash, O-Cedar

Cream Polish

Stubborn stains and discolorations AllChem Concentrated Cleaner, Samae,

Twinkle, Cameo Copper Cleaners, Grade

FFF Italian Pumice Whiting, Steel Bright,

Lumin Cleaner, Zud Restoro, Sta-Clean,

Highlite Cooper’s Stainless Steel Cleaner

or Revere Stainless Steel Cleaner

Old Dutch, Lighthouse Sunbrite, Wyandotte

Bab-O, Gold Dust, Sapollo, Bon Ami or

Comet

Liquid NuSteel or Dubois Temp For these products, rub the surface with

Heat tint or heavy discoloration Penny-Brite, Copper Brite, Paste Nu-Steel,

Dubois Temp or Tarnite

Bar Keepers Friend, Revere Stainless

Steel Cleaner, Allen Polish, Steel Bright

Wyandotte Bab-O or Zud

Tenacious deposits, rust, discoloration,

industrial atmospheric stains

Rust dicoloration or corrosion caused by

cleaning agents containing hydrochloric

(muriatic) acid or chlorine bleach

Use of property names is intended only to indicate a type of cleaner and does not constitute an endorsement. Omission of any

proprietary cleaner does not imply its inadequacy. All products should be used in strict accordance with instructions on the package.

Oakite No. 33 Dilac, Texo NY, Flash-Klenz

Caddy Cleaner, Turco Scale 4368 or

Permag 57

3M Scotch Pad, type A, grade “ne” Clean off the surface soil using cleaning

Provides barrier film to minimize

ngerprints. Can be used on all nishes.

Rub the surface with a cloth as directed

on the package.

Apply with a damp sponge or cloth, then

rinse with clear water and wipe dry.

For these household cleaners, rub with

a damp cloth. They may contain chlorine

bleaches so rinse thoroughly after use and

wipe dry.

a dry cloth using only a small amount of

cleanser. Rinse with water and dry.

Rub onto surface with a dry cloth

When using these cleaners, apply with a

damp sponge or cloth, rinse thoroughly

and wipe dry.

Swab and soak with a clean cloth. Let

stand for 15 minutes or more according

to directions on package, then rinse and

wipe dry.

methods above. Then rub discolored or

corroded areas lightly with a dry pad.

NOTE: Do NOT use steel wool or scouring pads to clean stainless steel.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

9

Page 10

Single Door Undercounter Refrigeration Installation & Operation Manual

DANGER

TROUBLESHOOTING - SINGLE DOOR UNDERCOUNTER CABINETS

If the unit appears to be malfunctioning, read through

the operation section rst, then check the guide below

to identify and resolve the problem.

Electrocution hazard! Never

attempt to repair or perform

maintenance on the unit until the main electrical

power has been disconnected.

No Interior Light

► Is the bulb loose?

► Is the bulb burnt out?

Light stays on when the door is closed

► Manual ON/OFF light switch is turned on.

► Is the door switch making contact with the

plunger?

Noisy during operation

► Certain sounds are normal. Soft sounds from the

compressor, fan motor and valves may be heard.

The refrigerated cabinet isn’t running

► Is there electrical power running to the unit?

► Is the door or drawer closing and sealing properly?

The refrigerated compartment is cooler

than usual

► Is the control set properly?

► Is the door or drawer closing and sealing properly?

The refrigeration system runs for long

periods of time

► Is the condenser area clean and free of obstruction?

► Has the door or drawer been open for long periods

of time or have more frequent door or drawer

openings occurred?

► Has warm product just been placed in the unit?

► On hot days and in warm room temperatures, the

system will run longer.

Condensation forms inside the refrigerated

compartments

► This is normal during high humidity and with

frequent door openings.

► Are the doors and drawers closing and sealing

properly?

► Is the building circuit breaker/fuse on?

► Is the control set properly?

► Is the condenser area clean?

The refrigerated compartment is warmer

than usual

► Is the control set properly?

► Is the light staying on?

► Is the condenser area clean and free of obstruction?

► Has the door or drawer been open for a long time

or have more frequent door or drawer openings

occurred?

► Are the internal louvres and fan guard openings

being obstructed?

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

Condensation forms on the outside of the

unit

► During periods of high humidity, some condensation

might appear on the outside surfaces. The

condensation will disappear when the humidity

drops. Meainwhile, be sure the doors and drawers

and closing and sealing properly. If condensation

persists, contact your Perlick Factory Authorized

Service Center.

10

Page 11

Single Door Undercounter Refrigeration Installation & Operation Manual

PRODUCT INFORMATION AND CONTACT INFORMATION

To obtain product information

► Contact your selling dealer

► Inquire on the web at www.perlick.com

► Call (800)558-5592 for factory assistance for

planning, installation or product information

► Write Perlick Corporation, Customer Service

Department, 8300 W. Good Hope Rd., Milwaukee,

WI 53223.

► Email us at warrantyserv@perlick.com

To obtain product service, replacement

parts or accessories

► Use only genuine Perlick replace parts and

accessories. Genuine Perlick parts and

accessories are designed to work correctly with

Perlick products and offer superior service life.

The use of non-Perlick parts can damage the unit

and may void the warranty.

► Check the model and serial number of the unit

located on the label attached to the ceiling inside

of the cabinet. Call a Perlick Factory Authorized

Service Center. For the location of the nearest

Service Center, use the contact information listed

above.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice.

11

Page 12

Additional product information and specifications are available for download

on perlick.com.

Contact Perlick Customer Service or Technical Service

toll-free at 800.558.5592.

Customer Service and Technical Service are available business days

Monday through Friday from 8 a.m. to 4:30 p.m. CST.

Perlick Corporation | 8300 W. Good Hope Rd., Milwaukee, WI 53223

(800)558-5592 • info@perlick.com

Form No. Z2363

Rev. 08.26.2014

Loading...

Loading...