Page 1

Installation and Operation Instructions

48” Commercial Two Door and Dual-Zone Refrigerator/Wine Reserve

MODEL NO.

HC48RS

HC48WS

HC48RW

HC48WW

Refrigerator

HC48WS

IMPORTANT INFORMATION

This manual has been prepared to assist in the installation of

your Two Door Refrigerator and to acquaint you with its operation and maintenance.

We dedicate considerable time to ensure that our products

provide the highest level of customer satisfaction. If, however service is required, call Perlick at 1-800-777-7267 or your

dealer who can provide you with a list of qualied service

agents. For your own protection, never return merchandise for

credit without our approval.

We thank you for selecting a Perlick product and assure you of

our continuing interest in your satisfaction.

IMPORT WARRANTY INFORMATION

To register your product, visit our web site at

(www.perlick.com). Click on “Bar & Beverage Equipment”,

then “Service & Support”. You will see the link to

Warranty Registration Form”. You must complete and submit

this form or the installation date will revert back to the

ship date.

Dual Zone Wine Reserve

HC48WW

C

US

Table of Contents

Cabinet Specications .......................................2

Cabinet Drawings ..................................................3

Preparing the Cabinet

Uncrating and Inspection ................................4

Plumbing ..........................................................4

Electrical ...........................................................4

Installing Casters or Legs ......................................4

Placing the Cabinet ...............................................4

Anti-Tip Setup ...................................................4

Sealing the Cabinet ..........................................5

Shelving ............................................................6

Adjusting Full Extension Shelving ..................6

Safety ......................................................................7

Operation ...............................................................7

Checking Product Temperature ............................7

Programming Button Denitions.........................7

HC48 Control Instructions ....................................8

LED Functions ........................................................8

Maintenance ..........................................................9

Troubleshooting ................................................. 10

Wiring Diagram ................................................... 11

Page 2

PRODUCT CUTSHEETS Refrigerated Cabinets

48” TWO DOOR AND DUALZONE

REFRIGERATOR/WINE RESERVE

JOB

AREA

ITEM NO.

MODEL NO.

*

MODEL NO.

HC48RS

HC48WS

HC48RW

Refrigerator

HC48WS

MODEL NO. HC48RS HC48WS HC48RW HC48WW

CABINET

DIMENSIONS

SHIP WEIGHT LBS. (KG) 375 (170) 375 (170) 375 (170) 375 (170)

CAPACITY CU. FT. (L.) 11.7 (331) 11.7 (331) 11.1 (314) 11.1 (314)

SHELVING 2 black vinyl-coated full-exten-

TEMPERATURE SETTINGS F°(C) Range 32°F (0°) - 42°F (5.6°)

TAPPING Centered over door

CABINET CONSTRUCTION (INT.) Interior Stainless Steel

CABINET CONSTRUCTION (EXT.) Exterior Sides, Exterior Top and Grill Stainless Steel Exterior Back and Exterior Bottom Stainless Steel

CABINET INSULATION Polyurethane-Ecomate. Wall Thickness-2” Door Thickness-2”

DOORS, HINGING & HARDWARE

CONDENSING UNIT H.P. 1/6 Condenser Access Front

REFRIGERATION Refrigerant 9.0 oz. - R134a Expansion Device Capillary Tube Type w/Hermetic Compressor

PLUMBING None required. Moisture drains to self evaporating condensate pan

ELECTRICAL Electrical Supply 115V/60 Hz/1 Phase Running Load Amps 2.8 Cord Connection Cord Connected (3-prong

VENTILATION

Length Ins. (mm) 47-7/8” (1216) 47-7/8” (1216) 47-7/8” (1216) 47-7/8” (1216)

Depth Ins. (mm) 24” (610) 24” (610) 24” (610) 24” (610)

Height Ins. (mm) 34-3/8” (873) 34-3/8” (873) 34-3/8” (873) 34-3/8” (873)

sion shelves (adjustable) per

door & oor racks

Factory Set Point

36°F (2.2°)

compartment 2 only.

Door Exterior Customer Choice (see below under ‘Customer Options’)

Number of Doors 2 Opening Style Hinged (Left or Right) Door Style Solid or Glass

Door Swing Clearance 25” (635) Locks Available (factory installed)

6’ NEMA 5-15P) Thermostat Digital Lighting Type LED blue/white

Front-vented

Dual Zone Wine Reserve

HC48WW

4 full-extension wine

shelves & 6 full-extension wine shelves.

Magnum oor rack 1st

compartment.

40°F (4.4°) - 68°F (20°)

Factory Set Point

43°F (6.1°)

Wine tapping not

available.

2 black vinyl-coated

full-extension shelves

(adjustable) & 6 full

extension wine shelves

32°F (0°) - 42°F (5.6°)

40°F (4.4°) - 68°F (20°)

Factory Set Point

36°F (2.2°)

43°F (6.1°)

Wine tapping not

available.

C

US

HC48WW

4 full-extension wine

shelves & 6 full-extension

wine shelves. Magnum

oor rack 1st compartment.

43°F (6.1°)

54°F (12.2°)

Factory Set Point

40°F (4.4°) - 68°F (20°)

40°F (4.4°) - 68°F (20°)

Wine tapping not

available.

*NOTE: This equipment is intended for the storage and display of

non-potentially hazardous bottled or canned products only!

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

2

Form No. Z2426

03.22.16

Page 3

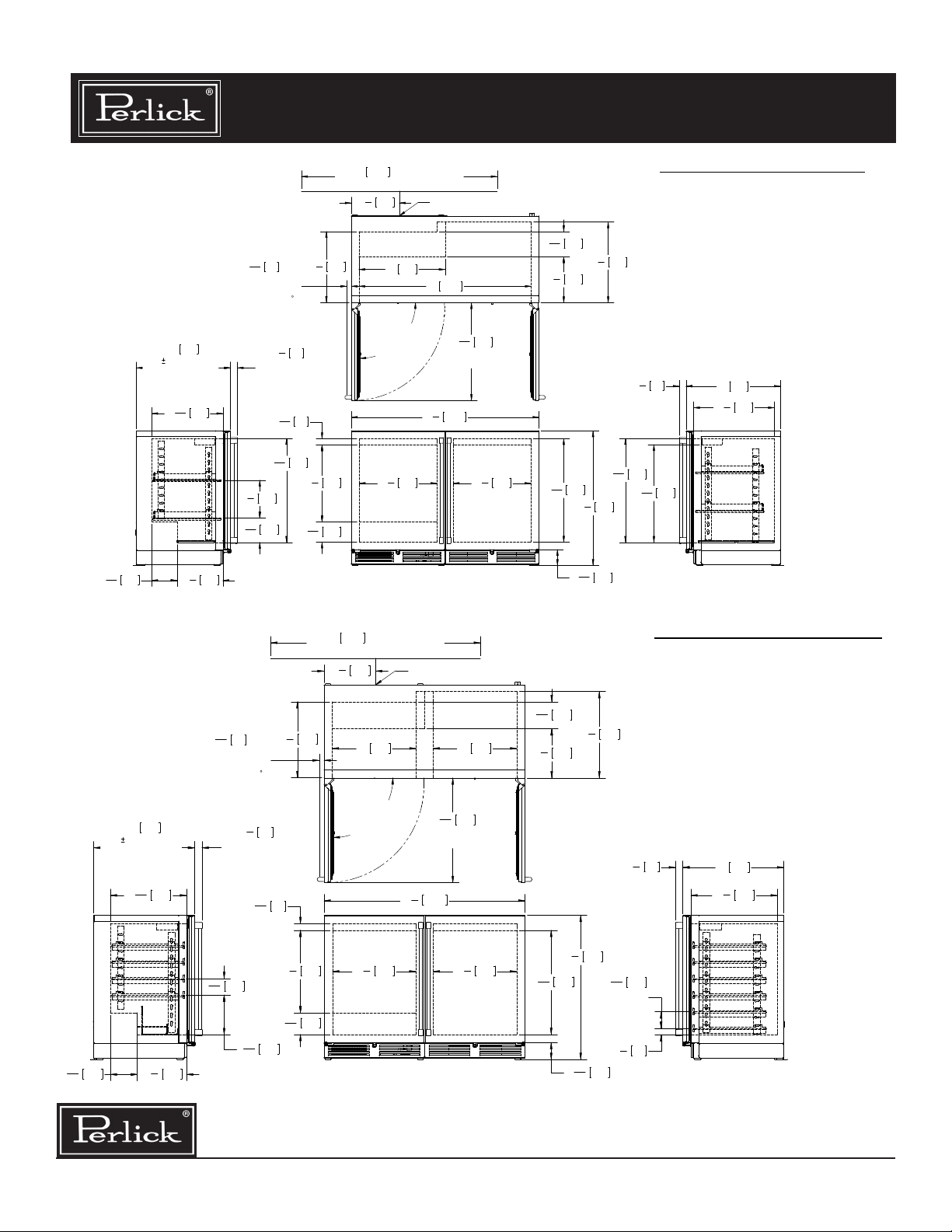

PRODUCT CUTSHEETS Refrigerated Cabinets

when fully extended

HC48RW& HC48WW MODELS

when fully extended

48” TWO DOOR AND DUALZONE

REFRIGERATOR/WINE RESERVE

(with 1/16" tolerance)

wood overlay door.

7

"

164

16

24" 611

Value may

change with a

3

18

" 462

16

3

"

11

4

2986

3

"

1

30 Min.

16

clearance from

a corner to

acheive 90

door swing.

3

1

" 44

4

Value may

change due to a

custom pull.

9

1

16

9

26

"

16

5

9

245

"

8

3

6

" 158

16

50" 1270 Area in which

electrical outlet must be located.

12

1

18

" 460

8

" 40

674

5

19

" 498

8

3

5

" 132

16

1

" 311

4

90° Swing

required for

pull-out shelf

clearance.

19

Power cord 8-1/4" [210] off floor.*

22" 559

44" 1118

7

7

" 504 19

8

* - Leg leveler can add

3/4" [19] to these dimensions

15

24

" 634

16

Min. clearance

for door swing.

"4781216

7

8

" 504

HC48RS & HC48WS MODELS

7

6

" 164

16

11

26

3

4

7

16

" 298

" 671

*34 " 873

*4

5

20

523

"

8

3

1

" 44

4

9

26

674

"

16

15

24

" 634

3

8

1

" 103

16

16

24" 611

5

20

" 523

8

Shelves adjustable by 2" [51].

RELEASE FOR PRODUCTION

A

1/28/2016

REVISIONS

SCALE: 1:12

JMP

(with 1/16" tolerance)

wood overlay door.

7

6

" 164 11

16

24" 611

Value may

change with a

3

18

" 462

16

3

" 298

4

3

1

" 30 Min.

16

clearance from

a corner to

acheive 90

door swing.

3

1

4

Value may

change due to a

custom pull.

1

15

3

" 100

16

7

9

16

" 44

9

16

" 240

50" 1270 Area in which

electrical outlet must be located.

1

12

" 311

4

1

18

" 460

8

pull-out shelf

" 40

5

19

" 498

8

3

5

" 132

16

Power cord 8-1/4" [210] off floor.*

20" 50820"

508

90° Swing

required for

clearance.

7

19

" 504 19

8

* - Leg leveler can add

3/4" [19] to these dimensions

15

24

16

Min. clearance

for door swing.

7

"4781216

" 634

7

8

" 504

67"16164

3

11

" 298

4

13

24

16

*34 " 873

" 630

*4

5

" 52320

8

3

1

" 44

4

3

8

15

3

" 100

16

Typical

Wine Shelf

Spacing

1

1

" 39

2

1

" 103

16

24" 611

5

20

" 523

8

Shelves adjustable by 2" [51].

RELEASE FOR PRODUCTION

A

1/28/2016

REVISIONS

SCALE: 1:12

JMP

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

Form No. Z2426

3

03.22.16

Page 4

Preparing the Cabinet

Uncrating and Inspection

Remove all crating material before operating. Carefully

inspect cabinet for hidden damage. If damage is discovered,

le your claim immediately with the transport company.

Perlick is not responsible for damage in transit.

Plumbing

No plumbing connections are required. Condensate from

the cooling coil is automatically evaporated through a condensate pan located in the condensing unit section.

Electrical

The cabinet must be connected to a separately fused power

source (see Electrical Specication Plate) and grounded in

accordance with National and Local Electrical Codes.

CAUTION: Do not attempt to operate the equipment on

any other power source than that listed on the Electrical

Specication Plate.

Installing Casters or Legs (optional)

Remove existing cabinet glides. Attach bracket assembly

to the bottom of the cabinet base using the 1/4”-20 Phillips head machine screws provided. Attach casters or legs

to the mounting bracket with 1/4” - 20 Phillips head screws

provided.

NOTE: To comply with NSF requirements, cabinet must be

sealed to oor or on legs, casters or rollers.

Placing the Cabinet

To assure maximum performance, fresh air must be allowed

to circulate through the machinery compartment. Do not

place anything in front of the cabinet that would obstruct air

ow at these grilles. Do not place the unit in an unventilated

small room.

Cabinet should be leveled front to back and side to side.

Anti-tip (without Legs, Casters or Rollers)

To prevent the cabinet from tipping forward and to provide

a stable installation, the cabinet must be secured in place

with an anti-tip device.

A set of metal anti-tip brackets are supplied. These brackets

should be attached to the oor, at the back of the cabinet;

each bracket located to catch each rear glide when the cabinet is pushed back into position.

THE ANTITIP BRACKETS MUST CATCH EACH OF THE

GLIDES TO HAVE A STABLE AND SAFE INSTALLATION.

Some installation sites might need to be modied to provide

a secure surface for attaching the bracket. Refer to the illustration below for anti-tip mounting bracket locations.

⁄”

⁄”

22-⁄” 23-⁄”

⁄”

Figure 3. 48” Anti-tip Kit

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

½“ to hole

4

1-¾”

⁄”

Form No. Z2426

03.22.16

Page 5

Preparing the Cabinet

Sealing the Cabinet

For sanitation purposes, it may be necessary to seal the

base of the cabinet to the oor. This can be accomplished

by laying a bead of silicone sealant between the base of the

cabinet and the oor as shown by the gure below.

When sealing the cabinet to the oor, make sure that the

louvered front grille plate can still be removed for condenser

maintenance and cleaning.

CAUTION: Finished ooring should be protected with

appropriate material to avoid damage from moving

the unit.

If unit has laid on its back or sides, place unit upright and

allow minimum of 24 hours before connecting power.

Plug the unit into the 15 amp grounded outlet located in the

installation opening. With power applied to the unit, check

that lighting and cooling function operate properly, then

turn o power to wall outlet at the circuit breaker.

CAUTION: To prevent damage to the counter top and

unit underneath, do not place heavy objects on the

counter top directly above the unit.

Check interior door openings inside unit and ensure unit

is level.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

5

Form No. Z2426

03.22.16

Page 6

Preparing the Cabinet

Shelving

IMPORTANT: To achieve maximum performance, interior

louver openings and fan guard openings should never be

obstructed.

Refrigerator:

The refrigerator compartments come standard with black

vinyl coated adjustable full extension pullout shelves.

Wine Reserve:

The two door unit comes standard with 4 full extension

wine shelves and six full extension black vinyl coated wine

shelves. The shelves are removable and adjustable to accomodate oversized (magnum) bottles.

Adjusting Full Extension Shelving

• Pull the shelf out to its furthest position. Locate the tabs

in the middle of both extenders (See Extender Tabs Below).

Press tabs and pull out.

• Reposition each bracket separately. Grasp the middle of

the bracket, pull the front end up and out, then forward to

remove (See Mounting Brackets Below).

• Place bracket at desired position. Push the rear hook into

the rear key slot. Set front of bracket on the wall hook.

• Repeat for other bracket(s).

• Push extenders completely into the unit. Align the shelf

grooves with the extenders and slide completely into

the unit.

Sliding Shelf Extender Tabs

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Sliding Shelf Mounting Brackets

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

6

Form No. Z2426

03.22.16

Page 7

SAFETY

DANGER

WARNING

CAUTION

PLEASE READ all instructions completely before attempting to install or operate the unit. Take particular

note of the DANGER, WARNING and CAUTION information in the manual. The information is important for

the safe and ecient installation, operation and care of

your Perlick unit.

Indicates a hazard that WILL result in serious injury

or death if precautions are not followed.

Indicates a hazard MAY cause serious injury or death

if precautions are not followed.

When loading items into the unit, do not block internal

louvers and fan guard openings or performance will be

decreased.

CHECKING PRODUCT TEMPERATURE

1). To accurately check the temperature of product

stored in the refrigerated compartment, insert an

accurate thermometer into a plastic unbreakable

bottle, partially lled with water. Tighten bottle cap

securely.

2). Place the bottle in the desired area for 24 hours.

Refrain from opening the unit during the testing

period. After 24 hours, check the temperature of the

water. Adjust the temperature accordingly using the

following procedures:

Indicates a hazard where minor injury or product

damage may occur if precautions are not followed.

OPERATION

MASTER SWITCH

These products come equipped with a master power

switch located behind the louvered toe kick. Remove

the toe kick to turn power on or o to the unit.

INTERIOR LIGHT

Units are equipped with an interior light that illuminate

when the door is opened. All HC48 models come

standard with adjustable blue and white LED lighting.

The cabinet also comes equipped with a manual light

switch for displaying the products through a glass

door.

Always ensure that the manual light switch is in the

OFF position before closing a solid wood or stainless

steel door. If manual light switch is left on for an

extended period of time, it may increase the cabinet

temperature, and cause the refrigeration system to run

harder.

DIGITAL TEMPERATURE CONTROL

HC48 Models

Figure 1. Digital Temperature Controller

Programming Button Denitions:

SET button

DEFROST button (melting snowake)

UP arrow

DOWN arrow

ON/OFF button

LOADING PRODUCT

Before storing perishables, turn unit on and allow

it to operate for a minimum of 24 hours to allow

temperatures to stabilize.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

7

Form No. Z2426

03.22.16

Page 8

HC48 Control Instructions

HC48 Control Instructions

To Set Target Temperature

Press and release the SET button. Display will show the

current temperature setpoint.

To Change Setpoint Temperature

1. Press and hold the SET button until the display

shows the current setpoint temperature with the “F”

ashing.

2. Use the UP and DOWN arrow button to scroll to the

desired temperature.

To Set Maximum Stored Temperature

Press the UP arrow button to see the maximum stored

temperature. To reset the maximum stored temperature, while displayed, press and hold the SET button

until ‘rst’ ashes in the display.

To Set Minimum Stored Temperature

Press the DOWN arrow button to see the minimum

stored temperature. To reset the minimum stored

temperature, while displayed, press and hold the SET

button until ‘rst’ ashes in the display.

Signature Series – HC48RS Models

Model Min Temp Set Max Temp Set

HC48RS 36° F (2.2°) 42°F (5.6°)

Signature Series – HC48WS Models

Model Min Temp Set Max Temp Set

HC48WS 40° F (4.4°) 68° F (20°)

Signature Series – HC48RW Models

Model Min Temp Set Max Temp Set

HC48RW Left 32° F (0°)

Right 40° F (4.4°)

Signature Series - HC48WW

Model Min Temp Set Max Temp Set

HC48WW 43° F (6.1°) 54° F (12.2°)

NOTE: The colder temperature setting must always be

applied to the compartment on the left. A minimum

temperature dierence of 6° between the left and right

compartments is required.

Example: 42° Left compartment and 48° right compartment

is achievable. 40° Left compartment and 44° right

compartment is not achievable.

Left 42° F (5.6°)

Right 68° F (20°)

On/O

Press the ON/OFF button to turn the unit on or o.

Key Combinations:

+

Press the UP and DOWN arrow

buttons to lock and unlock the

keyboard

+

Press the SET and DOWN arrow

buttons simultaneously to enter

programming mode.

+

Press the SET and UP arrow buttons simultaneously to return to

room temperature display.

NOTE: Dependent on the model and conguration, the

controllers have been programmed to only allow a temperature

adjustment within a specied range. See the chart top right for

the specied range allowed for your unit.

LED Functions

The following table describes LED functions

LED Mode Function

ON Compressor is on

Flashing Anti-short cycle

delay is on

ON Defrost is on

ON Alarm is on

Flashing You are in the process of

programming the unit

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

8

Form No. Z2426

03.22.16

Page 9

Maintenance

WARNING:

Shut o the electricity to the unit before cleaning the condenser and other routine maintenance.

Cleaning:

To clean stainless steel exterior or interior surfaces, use a

soft, non-abrasive stainless steel cleaner to wipe down the

surfaces.

Glass doors can be cleaned using any standard glass cleaner

available on the market.

To clean interior non-metallic surfaces and removable

parts, wash with a mild solution of soap and lukewarm water

with a little baking soda. Rinse and dry thoroughly. Avoid

getting water on lights, control panel, fan motor and unnished wood wine rack faces.

CAUTION:

Do not use abrasive cleaners or cloths on any of the interior

or exterior surfaces or removable parts.

Cleaning the Condenser:

The condenser should be cleaned every 3 months. The condenser is located behind the toe plate. Remove the toe plate

and use a soft bristle brush and vacuum to remove dust and

lint. Avoid damaging or crushing the condenser ns or tubing. Upon completion, re-install the toe plate.

CAUTION:

Failure to clean the condenser could result in temperature loss or mechanical failure. Clean this area every three

months.

Avoiding Stainless Steel Corrosion:

Corrosion can be prevented by following product cautions,

cleaning instructions and avoiding use of certain chemicals

or objects which will cause stainless steel corrosion.

Stainless Steel Enemy:

• Steelwool or steel scouring pads

• Cherry, Orange or Olive Juice

• Chlorine bleach

• Sharp objects

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

9

Form No. Z2426

03.22.16

Page 10

Troubleshooting

If the unit appears to be malfunctioning, read through the

OPERATION section rst, then check the guide below to

identify and resolve the problem.

PROBLEM RESOLUTION

No interior light

Light stays on when the

door is closed

Noisy during operation

The refrigerated cabinet

isn’t running

The refrigeration compartment is warmer than usual

The refrigerated compartment is cooler than usual

The refrigerations runs for

long periods of time

Condensation forms

inside the refrigerated

Is the bulb loose?

Is the bulb burned out?

Manual ON/OFF light switch is turned on.

Is the door switch making contact with the plunger?

Certain sounds are normal. Soft sounds from the compressor, fan motor and valves will be heard.

Is there electrical power to the unit?

Is the building circuit breaker or fuse on?

Is the control set properly?

Is the condenser area clean?

Is the control set properly?

Is the light staying on?

Is the condenser area clean and free of obstruction?

Has the door been open for a long time or more frequently door opening occurred?

Are internal louvers and fan guard openings obstructed?

Is the control set properly?

Is the door closing and sealing properly?

Is the condenser area clean and free of obstruction?

Has the door been open for a long time or more frequently door opening occurred?

Has warm product just been placed in the unit?

On hot days and in warm room temperatures, the system will

run longer.

This is normal during high humidity and frequent door openings.

Are the doors closing and sealing properly?

compartments

Condensation forms on

the outside of the unit

During periods of high humidity, some condensation might appear on the outside surface. The

condensation will disappear when the humidity drops. Meanwhile, be sure doors are closing and

sealing properly. If condensation persists, contact your Perlick Factory Authorized service center.

DANGER: Electrocution hazard! Never attempt to repair

or perform maintenance on the unit until the main elec-

trical power has been disconnected.

To Obtain Product Information

• Contact your selling dealer.

• Inquire on the web at www.perlick.com.

• Call 800-558-5529 for factory assistance for information,

planning, installation or product information.

• Write Perlick Corporation, Customer Service Department,

8300 W. Good Hope Road, Milwaukee, Wisconsin 53223.

• E-mail us at warrantyserv@perlick.com.

To Obtain Product Service, Replacement Parts

or Accessories:

Use only genuine Perlick replacement parts and accessories.

Genuine Perlick parts and accessories are designed to work

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

correctly with Perlick products and oer superior service life.

The use of non-Perlick parts can damage the unit and may

void the warranty.

Check the model and serial number of the unit located

on the label attached to the inside top of the cabinet.

Call a Perlick Factory Authorized service center. For the location of the nearest Service Center, contact your dealer, or

inquire via the web at www.perlick.com, or write to:

Perlick Corporation, Customer Service Department,

8300 W. Good Hope Road, Milwaukee, Wisconsin 53223,

call 800-558-5592, or e-mail us at:

warrantyserv@perlick.com.

10

Form No. Z2426

03.22.16

Page 11

HOT KEY

CSP-1

6

COMMON

DEFROST PROBE

ROOM PROBE

XR60CX-D1

101211 78 4 35 12

G

L

N

EFM-1

21

DSW-1

232220

CFM-1

XR60CX-D1--REFRIGERATION SYSTEM CONTROLLER

DSW-1--LIGHT AND EVAP FAN MOTOR DOOR SWITCH

SW-1--MASTER POWER SWITCH

LIGHT BOARD--BLUE&WHITE LED

EFM-1--EVAPORATOR FAN MOTOR

CSP-1--REFRIGERATED COMPARTMENT 1 SENSOR PROBE

COMP-1--COMPRESSOR

BLACK

BLACK

BLACK

BLACK

WHITE

RED

BLUE

WHITE

BLUE

WHITE

WHITE

RED

WHITE

WHITE

BLACK

BLACK

HGS

COMP-1

INV-1

MH-1

INV-1--INVERTER

MH-1--MULLION HEATER (DRAWERS ONLY)

HGS-1--HOT GAS SOLENOID (FRZ ONLY)

SW-2

WHITE-BLUE

BLACK-BROWN

LED DRIVER

RED

RED

BLACK

BLUE

LIGHT BOARD

WHITE

120VAC

12VDC

-

+

SW-1

SW-2--3-WAY LIGHT SWITCH

WHITE

BLACK

NOTE: DRAWER UNITS DO NOT HAVE LIGHTS

HOT KEY

CSP-1

6

COMMON

DEFROST PROBE

ROOM PROBE

XR20CX-D1

101211 78 4 35 12

EFM-2

21

DSW-2

232220

XR20CX-D1--REFRIGERATION SYSTEM CONTROLLER

DSW-2--LIGHT DOOR SWITCH

LIGHT BOARD--BLUE&WHITE LED

EFM-2--COMPARTMENT #2 FAN MOTOR

CSP-2--REFRIGERATED COMPARTMENT 2 SENSOR PROBE

BLACK

BLACK

WHITE

BLUE

BLUE

WHITE

BLACK

SW-3

RED

RED

BLACK

BLUE

LIGHT BOARD

WHITE

12VDC

-

+

SW-3--3-WAY LIGHT SWITCH

WHITE

BLACK

NOTE: DRAWER UNITS DO NOT HAVE LIGHTS

AFM-1

AFM-1--AUX. FAN MOTOR (IF ONE TEMPERATURE ZONE)

NOTE: NO CONTROL OR EFM-2 ON SINGLE ZONE

NOTE: IF 1ST COMPARTMENT DRAWERS (DRIVER IS

LOCATED IN SECOND COMPARTMENT)

DIMENSIONS ARE IN INCHES

Wiring Diagram

TOLERANCES UNLESS OTHERWISE SPECIFIED

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

11

Form No. Z2426

03.22.16

Page 12

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-mail: Perlick@Perlick.com • Perlick.com

12

Form No. Z2426

03.22.16

Loading...

Loading...