Perlick FR24 Series, FR36 Series, FR48 Series, FR60 Series Installation And Operation Instructions Manual

Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

c

U

L

®�

C

L

A

S

S

I

F

I

E

D

SANITATION

GLASS FROSTERS

MODEL NOS.

FR24 Series

FR36 Series

FR48 Series

FR60 Series

IMPORTANT INFORMATION

This manual has been prepared to assist you in the

installation of your Glass Froster and to acquaint you

with its operation and maintenance.

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If, however service is required, call

Perlick at 1-800-777-7267 or your dealer who can

provide you with a list of qualified service agents.

For your own protection, never return merchandise

for credit without our approval.

We thank you for selecting a Perlick product

and assure you of our continuing interest in

your satisfaction.

IMPORTANT WARRANTY INFORMATION

To register your product, visit our web site at

(www.perlick.com). Click on “Commercial”, then

“Service”. You will see the link to “Warranty

Registration Form”. You must complete and submit

this form or the installation date will revert back to

the ship Date.

Table of Contents

Cabinet Specifications .........................................2

Installing

Uncrating and Inspection ...............................

Plumbing ........................................................

Electrical .........................................................

Installing Shelves ............................................

Installing Casters or LegsCasters ..................

Placing The Cabinet .......................................

Sealing the Floor ............................................

Defrost System ..................................................... 4

Temperature Control .............................................4

Cleaning ............................................................... 5

Cleaning Stainless Steel/Avoiding Corrosion ....... 5

Replacement Parts ............................................ 6/7

Wiring Diagram ..................................................... 8

3

3

3

3

3

3

3

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Form No. Z2296

Rev. 12.05.09

Page 2

Job ___________________________

24” [610]

9 5/8” [244]

8 7/8” [225]

OPTIONAL

FIELD

INSTALLED

SHELF

LOCATION

FACTORY

INSTALLED

SHELF

LOCATION

24” [610]

11 5/8”

[296]

2”

[51]

2”

[51]

19 1/4”

[489]

INSIDE

34 1/8”

[867]

5 3/4”

[146]

5 3/4”

[146]

6 5/8”

[169]

2”

[51]2”[51]

FRONT VIEW

24” CABINET

END VIEW

24” CABINET

c

U

L

®�

C

L

A

S

S

I

F

I

E

D

SANITATION

11 5/8”

[295]

2” [50]

34”

[864]

6 7/8”

[175]

7”

[178]

2” [50]

2” [50] 2” [50]

24” [610]

OPTIONAL

SHELF

FRONT VIEW

36”, 48”, 60” CABINET

END VIEW

36”, 48”, 60” CABINET

17 3/16”

[437]

HOUSING

STEP

27 7/8”

[708]

INSIDE

36” [914]

48” [1219]

60” [1524]

13 7/8” [352]

TOP SHELF

7” [178]

CENTER SHELF

7” [178]

BOTTOM SHELF

Installation and Operating Instructions

Area __________________________

Item No. _______________________

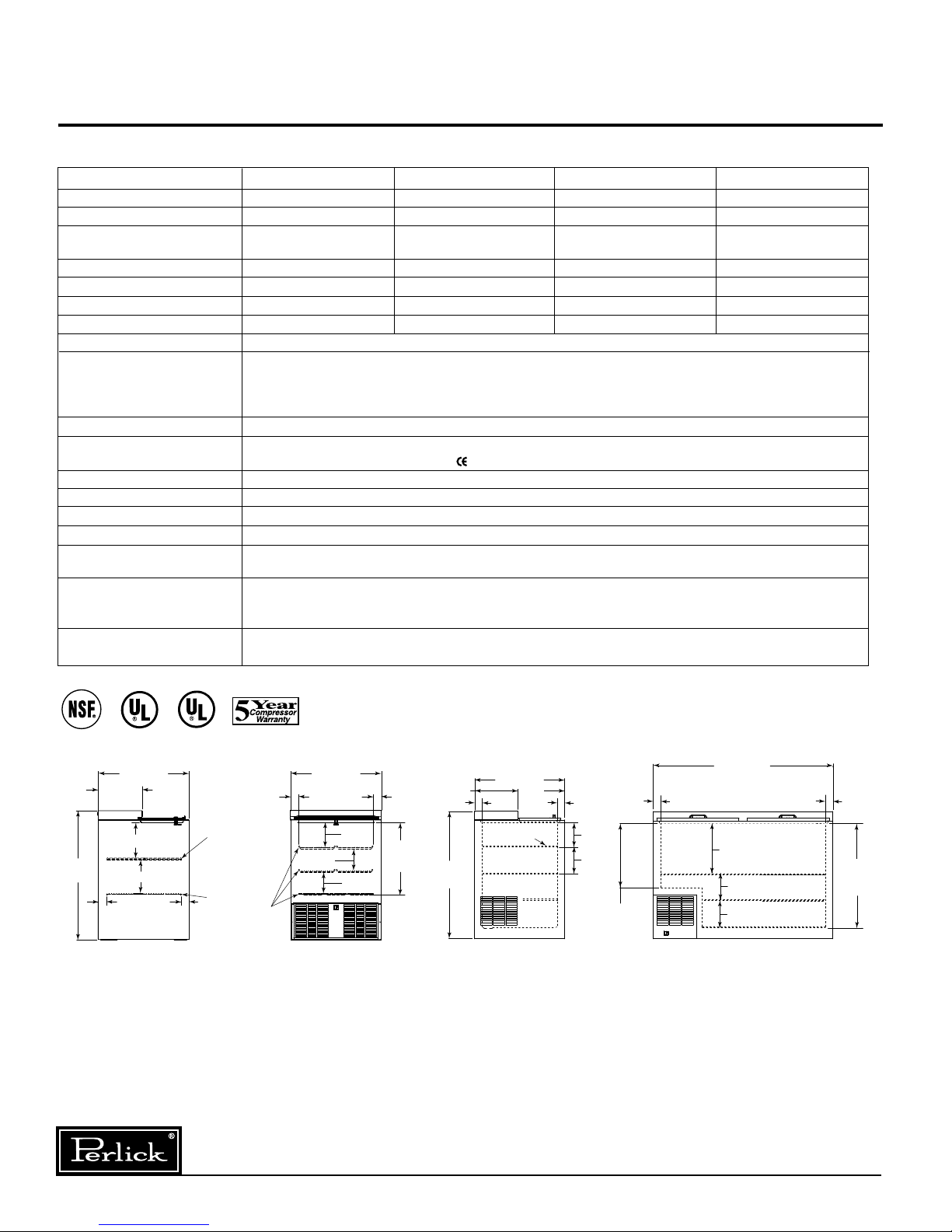

Sizes and Specifications, Glass Frosters

MODELS FR24 FR36 FR48 FR60

LENGTH (mm) 24” (610) 36” (915) 48” (1219) 60” (1524)

INTERIOR CU. FT.

PLATE CAPACITY† 135 Plates 215 Plates 300 Plates 400 Plates

GLASS CAPACITY†

(w/2 Optional Shelves)

WITH OPTIONAL THIRD SHELF N/A 172 Glasses 273 Glasses 363 Glasses

CONDENSING UNIT H.P.

AMPS 5.8 6.8 6.2 7.1

SHIP WT lbs. (kg) 190 (86) 245 (111) 265 (120) 300 (136)

INTERIOR All models have stainless steel walls and floor.

EXTERIOR

Black Option: Front and ends are black vinyl coated steel, back and bottom are galvanized.

Stainless Steel Option: Front and ends are stainless steel, back and bottom are galvanized.

All Stainless Option: Front, ends, back and bottom are all stainless steel.

DOORS (Sliding) Stainless steel top and bottom pans. Die cast handle.

ELECTRICAL 115V, 60 Hz., 1 Phase. Furnished with 6 foot rubber plug-in cord (115V model only). Also available in

230V, 50Hz., 1 Phase AC. carries marking of conformity.

PLUMBING None required. Moisture drains to self-evaporating condensing pan in machinery compartment.

INSULATION 2 inch foamed-in-place polyurethane insulation.

TEMPERATURE RANGE Adjustable from -10° to +10° F.

REFRIGERATION R134a expansion valve system with hermetic condensing unit. Pulls out for service and cleaning.

VENTILATION 2’ model is front vented, all other models require 2” clearance from wall either on left end or back of

cabinet for proper air flow.

DEFROST SYSTEM Solid-state, push-button defrost system, manually initiated at end of each day, automatically termi-

nates after six hours. Evaporator automatically defrosts every 4 hours for approximately 20 minutes

(time/temperature terminated).

OPTIONAL ACCESSORIES • Additional set of nesting shelves w/ brackets • Set of 4 casters w/ brakes • Interior light

• Set of 4 adjustable legs • 2’, 3’, 4’ and 5’ Bottle rail (field installed) • Roller basket shelving

† Capacity calculations based on use of 3” dia. glass and 91⁄2” dia. x 1⁄2” thick plate.

(m3) 3.75 (0.10) 7.83 (0.22) 11.68 (0.33) 15.53 (0.44)

90 Glasses 142 Glasses 214 Glasses 286 Glasses

1

/3

1

/3

Choice of black, stainless steel and all stainless.

Model No. _____________________

1

/3

1

/3

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

2

Form No. Z2296

Rev. 12.05.09

Page 3

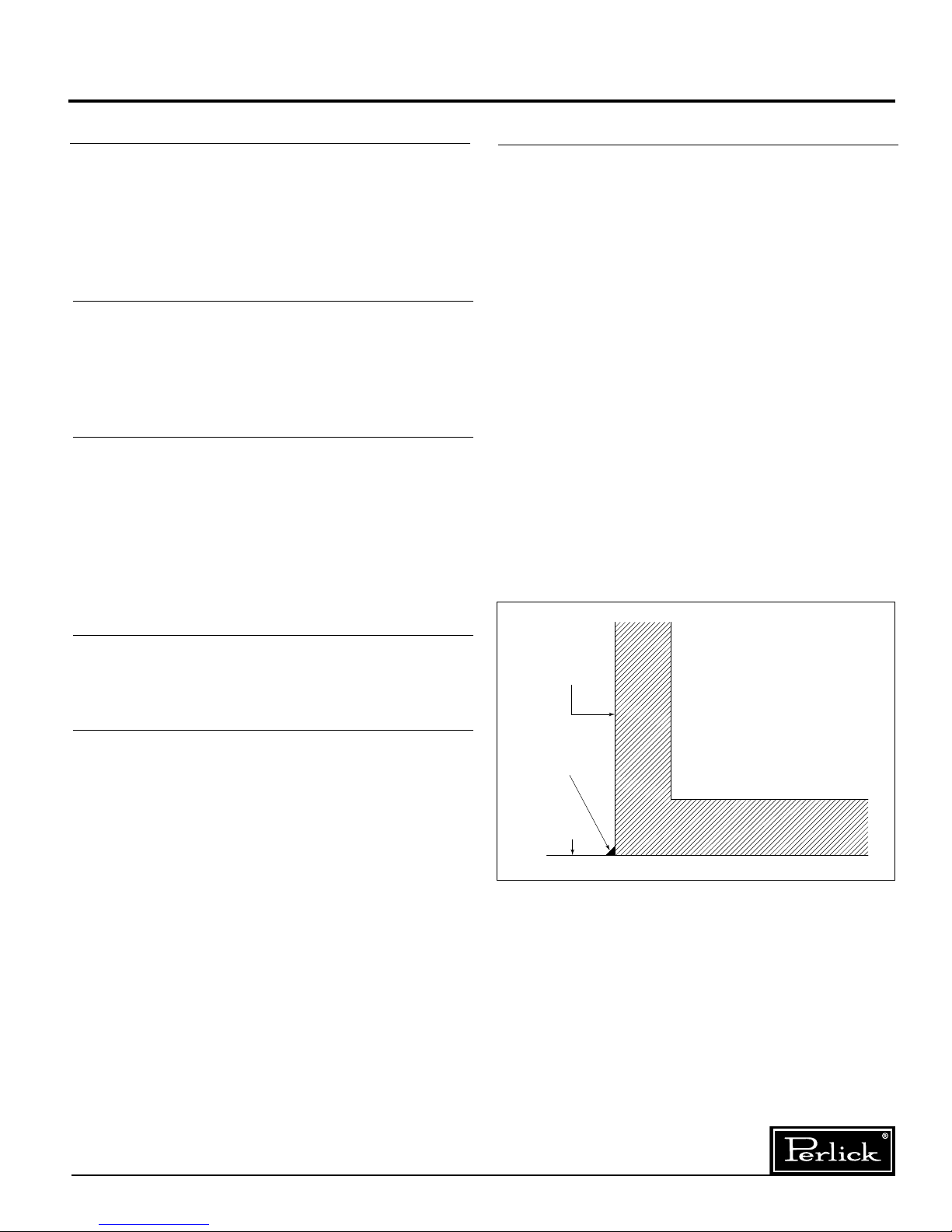

Preparing the Cabinet – Glass Frosters

BEAD SILICON

SEALER (RTV)

FLOOR

CABINET

Uncrating and Inspection

Remove all crating material before operating.

Carefully inspect cabinet for hidden damage.

If damage is discovered, file your claim immediately

with the transport company. Perlick is not

responsible for damage in transit.

Plumbing

No plumbing connections are required. Condensate

from the cooling coil is automatically evaporated

through a condensate pan located in the

condensing unit section.

Electrical

The cabinet must be connected to a separately

fused power source (see Electrical Specification

Plate) and grounded in accordance with National

and Local Electrical Codes.

CAUTION:

ment on any other power source than that listed

on the Electrical Specification Plate.

Do not attempt to operate the equip-

Placing the Cabinet

To assure maximum performance, fresh air must

be allowed to circulate through the machinery

compartment. It is important to allow at least two

inches of clearance at the back or left end of the

cabinet. Do not place anything in front of the

cabinet that would obstruct air flow at these grilles.

Do not place the unit in an unventillated small

room.

CAUTION:

Removing the factory installed back clearance

spacers without providing proper left side grill

clearance for compressor air flow will void the

warranty.

Cabinet should be leveled.

For sanitation purposes, it may be necessary to

seal the base of the cabinet to the floor. This

can be accomplished by laying a bead of silicone

sealant along the base of the cabinet as shown

by the figure below.

Installing Shelves (when provided)

The front and rear horizontal shelf brackets have

been factory installed for a 2 shelf kit glass froster.

Installing Casters or Legs (optional)

Attach casters or legs to the cabinet bottom in

holes provided. Use the supplied 1⁄4”–20 hex head

self-tapping machine screws. If unit is tipped on its

back for an extended period of time, wait 24 hours

after the unit is uprighted to plug the unit in.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

3

Form No. Z2296

Rev. 12.05.09

Page 4

Operation Instructions – Glass Frosters

NORMAL

05

4

6

1

9

2

8

3

7

WARMER

COOLER

CONDENSING UNIT

Defrost System

This system consists of a six-hour, as well as a four

hour defrost cycle. The six hour defrost cycle is

manually activated and automatically terminated,

while the four hour cycle is completely automatic.

The Six Hour Solid-State Defrost Timer

This timer shuts off the power to the condensing

unit, door frame heater, evaporator heater, and the

automatic four hour defrost timer, while it supplies

power to the evaporator fan.

To activate the six hour defrost system, depress

the defrost switch located on the front grill of the

cabinet. An amber light will illuminate and the

defrost cycle will begin. When the defrost cycle

ends, the light goes off and the cabinet resumes

normal operation. To manually cancel the defrost

cycle, momentarily turn off the electricity to the

machine.

The Four Hour Defrost Timer

This timer ensures that frost will not buildup on the

evaporator coil. Every four hours it shuts down the

condensing unit and evaporator fan and supplies

power to the defrost element clamped to the bottom of the evaporator. The defrost cycle lasts for

approximately 20.

During normal operation it is recommended that

the doors are not left open to prevent excessive

frost buildup on the coil.

Temperature Control

An adjustable temperature control is located inside

the froster on the evaporator fan panel assembly.

Approximate temperature operating range: minus

15° F. minimum and plus 10° F. maximum. Make

adjustments as shown to attain the desired

temperature.

■ Colder Temperatures: Turn the adjusting

screw clockwise (to the right).

■ Warmer Temperatures: Turn the adjusting

screw counterclockwise (to the left).

■ Temperature Control “OFF”: Turn the

adjusting screw completely counterclock wise to the “O” position until a click is

noted.

The condenser fan motor turns off and on with

the compressor. The evaporator fan motor runs

continuously, except during the 20 minute

period of the four-hour defrost.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

4

Form No. Z2296

Rev. 12.05.09

Page 5

Cleaning Instructions – Glass Frosters

Cleaning the Condenser:

■ The condenser (located behind the front

grille) should be inspected every 30 days,

and cleaned, if necessary. Failure to keep

the condenser clean will cause a loss in

condensing unit efficiency, or compressor

failure.

Cleaning the Doors:

■ Doors should be periodically removed from the

cabinet and inspected for a buildup of foreign

materials, such as syrups, beer, etc. Buildups

on the underside of the doors, along with the

cabinet breaker strips on which they ride, will

cause them to bind, and therefore, not function

as designed. If dirty, these surfaces should be

cleaned with a mild detergent and water then

coated with a silicone lubricating material.

Aerosol silicone sprays can be obtained locally

at most department or automotive stores.

To remove doors:

■ With door closed, lift it upward by its handle and

slide forward until door clears the cabinet top.

Use the reverse procedure to reinstall the doors.

Cleaning the Cabinet:

■ Use a damp cloth with a mild detergent and

water to clean the inside and outside of the

cabinet. Dry thoroughly. Do not allow cleaning

agents or large amounts of water to go down

the drain. Use an acceptable stainless steel

polish to clean all stainless steel surfaces.

Never use steel wool or scouring pads to clean

stainless steel.

Avoiding Stainless Steel Corrosion

Corrosion can be prevented by following product cautions, cleaning instructions and avoiding use of certain chemicals or objects which will cause stainless steel corrosion.

STAINLESS STEEL ENEMY

■ Steel wool or steel scouring pads

■ Cherry/Orange/Olive juice

■ Chlorine Bleach

■ Sharp Objects

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

5

Form No. Z2296

Rev. 12.05.09

Page 6

Replacement Parts – Glass Frosters

19

13

4

18

9

20

5

7

30

29

8

28

6

10

15

12

3

23

22

17

26

25

27

1

11

2

16

14

21

24

CAUTION

■ Service should be done by a qualified

refrigeration technician.

■ Disconnect all power before servicing

the cabinet.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

6

Form No. Z2296

Rev. 12.05.09

Page 7

Replacement Parts – Glass Frosters

MODEL NOS. FR24 FR36 FR48 FR60

Item Description Part Numbers

1 Complete condensing unit C22646A C22646A C22646A C22646A

2 Replacement compressor, R134a 513200003 513200003 513200003 513200003

Condensing unit fan motor assy. 515315009 515315009 515315009 515315009

Terminal Board 519100088 519100088 519100088 519100088

Overload Protector US-PB12HBX1 US-PB12HBX1 US-PB12HBX1 US-PB12HBX1

Relay US-PB12HBX1 US-PB12HBX1 US-PB12HBX1 US-PB12HBX1

Start capacitor US-PB12HBX1 US-PB12HBX1 US-PB12HBX1 US-PB12HBX1

3 Condensate pan 64537 64626-1 64626-1 64626-1

4 Expansion valve 63549 63549 63549 63549

5 Evaporator fan motor(s) C15239A C15239A C15239A C15239A

6 Evaporator fan motor bracket 65671-1 65671-1 60988-1 60988-1

7 Evaporator fan motor blade 63461 63461 63461 63461

8 Evaporator fan guard 65666 65666 65666 65666

9 Evaporator coil 64785-1EP C17511-1EP C17511-1EP C17511-2EP

10 Evaporator defrost heater C25655-1 65045-1 65045-1 61900

11 Temperature control 61282 61282 65290 65290

12 Solid state defrost timer 57466 57466 57466 57466

13 Defrost limit switch 57676 57676 57676 57676

14 Rocker switch with pilot C31659 C31659 C31659 C31659

15 Compressor side shelf N/A 64810-1 64810-1 64810-1

16 Front grille 66498-2A 65662-2A 65662-2A 65662-2A

17 Rear grille/panel 66498-1 65662-3 65662-3 65662-3

18 Top assemby RT-SL2 RT-SL2 RT-SL2 RT-SL2

19 Top wiper gasket 63671-24 63671-36 63671-48 63671-60

20 Door assembly RD-SL2 RD-SL2 RD-SL2 RD-SL2

21 Vertical partition 66503 66441 66441 66441

22 Roller basket N/A 66442-1 66442-1 66442-1

23 Wide shelf N/A N/A 64811-1 64811-1

24 Narrow shelf 64809-1 64809-1 64809-1 64809-1

25 Bottom floor rack (wide) 64814-1 64814-1 64814-1 64814-1

26 Bottom floor rack (narrow) N/A N/A 64815-1 64815-1

27 Shelf bracket 65653-24 65653-36 65653-48 65653-60

28 Door handle 63931 63931 63931 63931

29 Light bulb C15046 C15046 C15046 C15046

30 Light socket 63484 63484 63484 63484

Items Not Shown

Wire harness, main 65039-1 65039-1 65038-1 65038-1

Wire harness, defrost timer

to switch

Suction/liquid line with drier 65089 65089 65089 65089

Mullion assembly N/A N/A 66551 66551

Refrigerant charge (oz. R134a) 8.0 10.3 12.5 12.5

61959 61959 61959 61959

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

7

Form No. Z2296

Rev. 12.05.09

Page 8

PLUG-IN-CORD

TO CONDENSING UNIT

WHITE

BLACK

WHITE

BLACK

TEMPERATURE

CONTROL

A2

DOOR FRAME

HEATER

WHITE

A (BLACK)

A2 (BLACK)

B1 (BLACK)

RED

(2’ MODEL)

RED

2ND FAN ON

4’ & 5’ MODELS

EVAP

FAN.

EVAP

FAN.

EVAPORATOR HEATER

NOTE:

SWITCHES SHOW COOLING POSITION

BLACK

B (POWER)

WHITE

INTERNAL

CONNECTIONS

WHITE

(3’, 4’ & 5’ MODELS)

3

2

1

6 5 4

4

3

3

A1

A2

A

B2

B1

T11

T12

T13

DEFROST TEMP.

LIMIT SWITCH

T14T15

WB

RELAY

RELAY

S.S. TIMER

INSIDE OF

CABINET

INSIDE OF

CABINET

INSIDE OF

CONDENSING

UNIT HOUSING

INSIDE OF

CONDENSING

UNIT HOUSING

S.P.S.T. MOMENTARY

CONTACT DEFROST SWITCH

W/ INDICATOR LIGHT

2

Wiring Diagram – Glass Frosters

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414-353-7060 • Fax 414-353-7069

Toll Free 800-558-5592 • E-Mail: Perlick@Perlick.com • www.Perlick.com

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specifications without prior notice.

Form No. Z2296

Rev. 12.05.09

Loading...

Loading...