Page 1

INSTALLATION AND OPERATION INSTRUCTIONS

4400 SERIES POWER PAKS

MODELS

4400 Series

4404 4404W

4410 4410W

4414 4414W

4414-230 4420W

4420

IMPORTANT INFORMATION

To register your product, visit our web site at www.

perlick.com. Click on Commercial, then Service.

You will see the link to Warranty Registration Form.

You must complete and submit this form or the

installation date will revert back to the ship date.

Permanently mount the enclosed Warning/Safety

Instruction label in a visible location near the CO2

regulator.

This manual has been prepared to assist you in the

installation of your Century Remote Beer System and

to acquaint you with its operation and maintenance.

C

Table of Contents

Sizes & Specications ............................................ 2-3

Air-Cooled Models ................................................. 2

Water-Cooled Models ............................................ 3

General Information .......................................... 4

Installation ........................................................ 5

Connecting Power Pak to Trunk Housing .............. 6

Connecting to Trunk Housing ................................ 7

Power Pak Start-Up ................................................... 8

LEDS ......................................................................... 9

Preventative Maintenance ......................................... 9

Replacement Parts .................................................. 10

Wiring Diagrams ...................................................... 11

US

We dedicate considerable time to ensure that our

products provide the highest level of customer

satisfaction. If service is required, your dealer can

provide you with a list of qualified service agents. For

your own protection, never return merchandise for

credit without our approval.

We thank you for selecting a Perlick product and assure

you of our continuing interest in your satisfaction.

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414.353.7060 • Fax 414.353.7069

Toll Free 800.558.5592 • E-Mail perlick@perlick.com • www.perlick.com

Form No. Z2020

Rev. 04.15.2015

Page 2

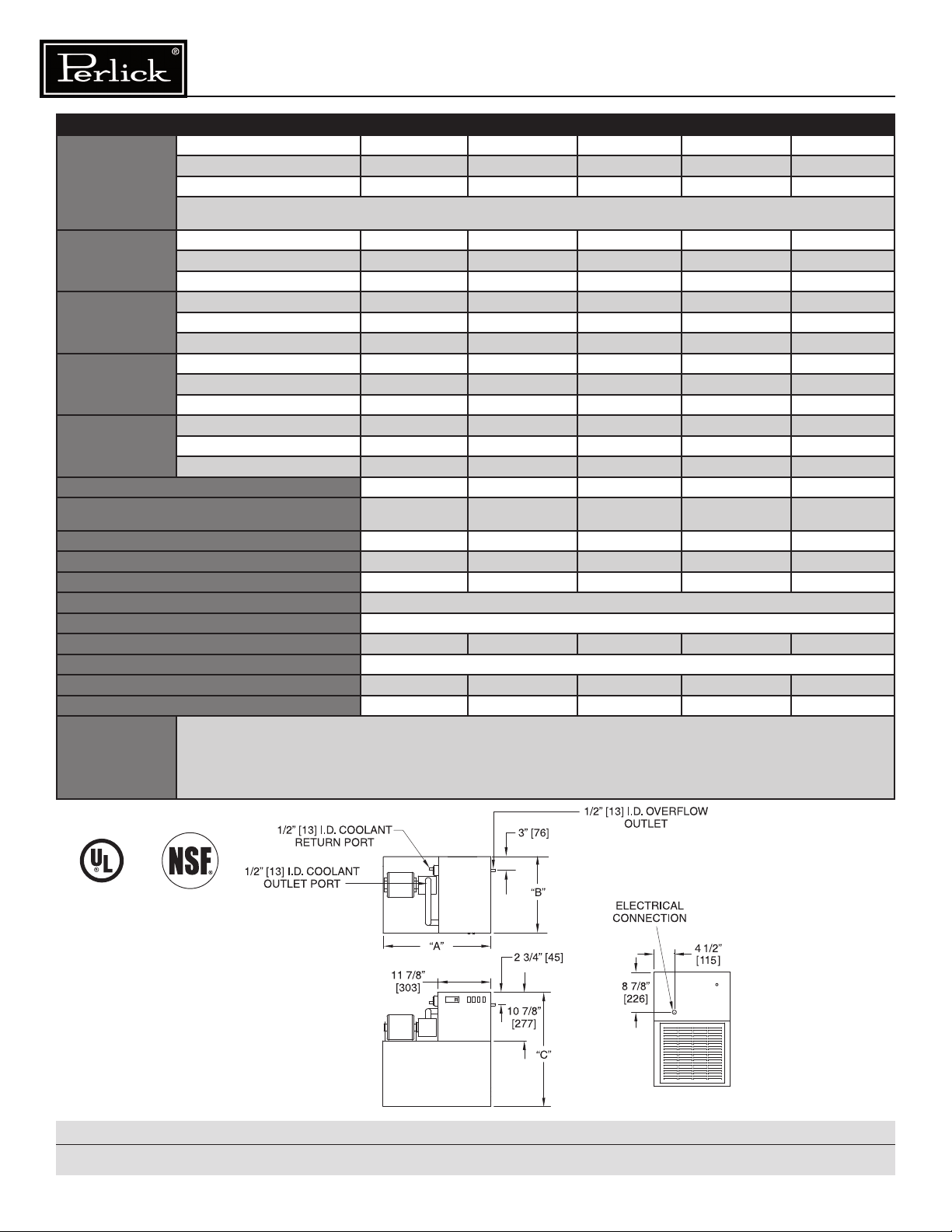

4400 SERIES POWER PAKS AIR COOLED

Operation/Installation Manual

MODEL NOS. 4404 4410 4414 4414-230 4420

DIMENSIONS:

EXTERIOR (mm)

Length “A” 24

Width “B” 17

Height “C” 25

1/4

” (616) 24

1/4

” (438) 17

1/2

” (648) 25

A minimum of six inches of clearance should be allowed around the entire unit for proper performance.

Additional clearance should be considered for above the unit and in front of the unit for servicability.

ELECTRICAL Voltage 120 V 120 V 120 V 208/230 V** 208/230 V**

Frequency 60 Hz 60 Hz 60 Hz 60 Hz 60 Hz

Phase 1 Ø 1 Ø 1 Ø 1 Ø 1 Ø

SINGLE PUMP RLA (Rated Load Amps) 15.1 15.7 17.1 10.5 21.9

MCA (Min. Circuit Ampacity) 17.2 18.0 19.6 12.2 26.4

MOCP (Max. over Current Protection) 25 25 25 15 40.0

DUAL PUMPS

(add -2 to model #)

RLA (Rated Load Amps) N/A 21.8 22.7 13.3 24.7

MCA (Min. Circuit Ampacity) N/A 24.1 25.2 15.0 29.2

MOCP (Max. over Current Protection) N/A 30.0 35.0 20.0 45.0

TRIPLE PUMPS

(add -3 to model #)

RLA (Rated Load Amps) N/A N/A N/A 16.1 27.5

MCA (Min. Circuit Ampacity) N/A N/A N/A 17.8 32.0

MOCP (Max. over Current Protection) N/A N/A N/A 20.0 50.0

COMPRESSOR 1/3 HP 1/2 HP 3/4 HP 3/4 HP 1.5 HP

EVAPORATOR RATING

3420 3800 6000 6300 12000

@ 20°F (BTUH)

HEAT REJECTION (MAX) 4080 6080 9600 10080 19200

REFRIGERANT R-134a R-134a R-134a R-134a R-134a

SHIPPING WEIGHT LBS (kg) 140 (64) 153 (69) 180 (82) 205 (93) 255 (116)

CABINET Stainless Steel

CIRCULATING PUMP 100 GPH/130 PSIG

RESERVOIR CAPACITY 1.75 gal 1.75 gal 1.75 gal 1.75 gal 1.75 gal

REFRIGERATION Constant Pressure Expansion Valve, Condensing Unit with Service Valves

REFRIGERANT CHARGE (grams) 14.0 oz/397 g 12.0 oz/340 g 9.5 oz/269 g 11.0 oz/312 g 16.0 oz/453 g

GLYCOL CONCENTRATION 30% 30% 30% 30% 30%

OPTIONAL

ACCESSORIES

4430 115V pump kit for 4410 Power Pak (eld installed) 61790 Dual Tier Rack

4431 115V pump kit for 4414 Power Pak (eld installed) 61791+1 Triple Tier Rack

4432 208/230V pump kit for 4414/230V and 4420 Power Paks (eld installed) 61792+2 Quad Tier Rack

4435 BLM Receptacle C22296A-20 Cord Kit for 120V single pump Power Paks only (Field installed)

4408SS Wall Bracket for 4404 & 4410 only

C21499BSS Stainless Steel Table Stand

**Requires four wires (2 hot, 1 neutral and 1 ground).

1/4

” (616) 24

1/4

” (438) 17

1/2

” (648) 25

1/4

” (616) 26

1/4

” (438) 20

1/2

” (648) 31” (782) 31” (782)

3/4

” (679) 26

1/4

” (519) 20

3/4

1/4

” (679)

” (519)

C

US

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

2

Page 3

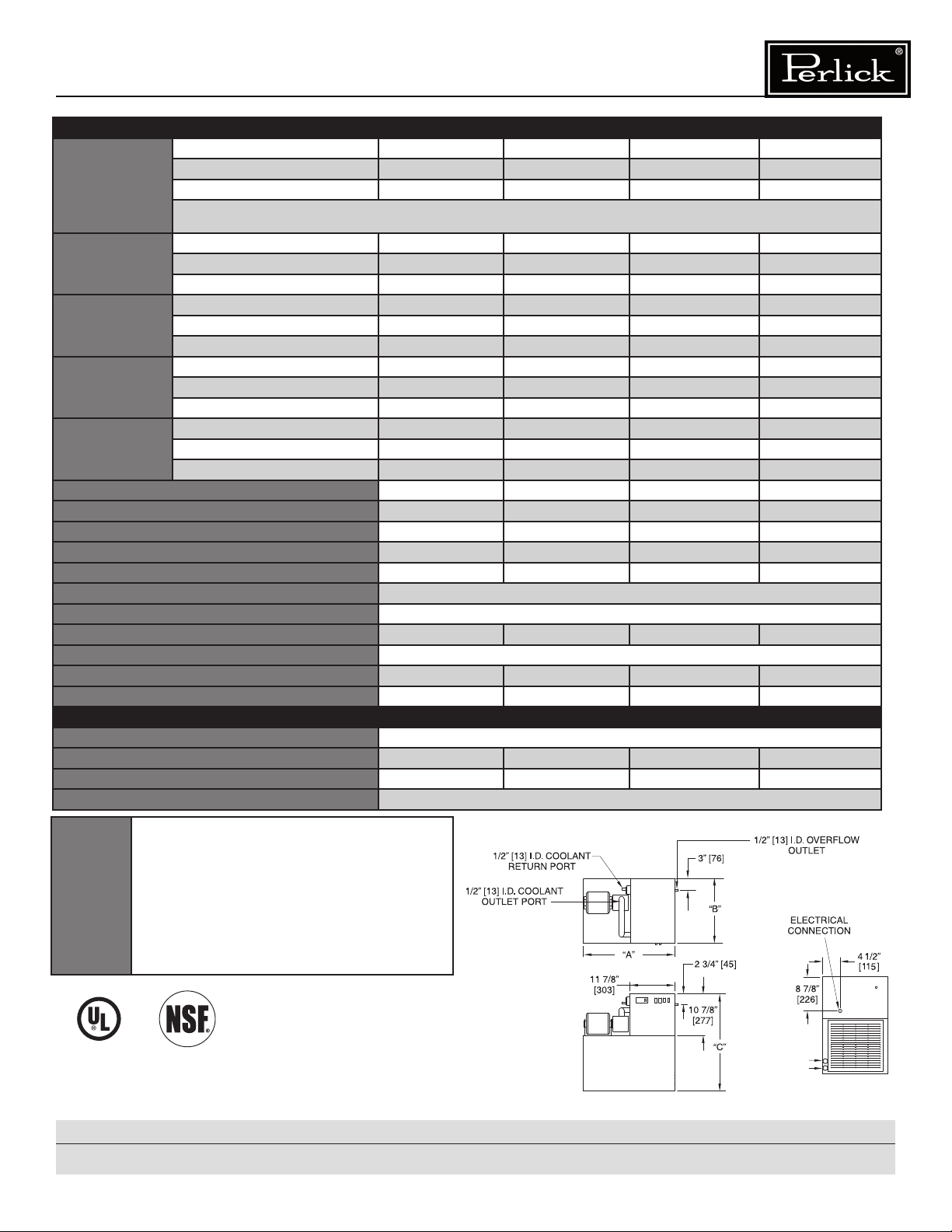

4400 SERIES POWER PAKS WATER COOLED

Operation/Installation Manual

MODEL NOS. 4404W 4410W 4414W 4420W

DIMENSIONS:

EXTERIOR (mm)

ELECTRICAL Voltage 120 V 120 V 120 V 208/230 V***

SINGLE PUMP RLA (Rated Load Amps) 15.4 17.1 17.4 20.8

DUAL PUMPS

(add -2 to model #)

TRIPLE PUMPS

(add -3 to model #)

COMPRESSOR 1/3 HP 1/2 HP 3/4 HP 1-1/2 HP

EVAPORATOR RATING @ 20°F (BTUH) 3420 4080 6870 13,800

HEAT REJECTION (MAX) 2050 2450 4122 6500

REFRIGERANT R-134a R-134a R-134a R-134a

SHIPPING WEIGHT LBS (kg) 141 (64) 143 (65) 205 (93) 255 (116)

CABINET Stainless Steel

CIRCULATING PUMP 100 GPH/130 PSIG

RESERVOIR CAPACITY 1.75 gal 1.75 gal 1.75 gal 1.75 gal

REFRIGERATION Constant Pressure Expansion Valve, Condensing Unit with Service Valves

REFRIGERANT CHARGE (grams) 14.5 oz / 410 g 14.5 oz / 410 g 22.0 oz / 623 g 22.0 oz / 623 g

GLYCOL CONCENTRATION 30% 30% 30% 30%

PLUMBING REQUIREMENTS

INLET & OUTLET All employ 1/2” O.D. Quick Connect Fittings

FLOW RATE (gpm) @ 75°F 0.5 0.6 0.9 1.2

PRESSURE DROP (psig) 0.1 0.2 0.4 0.5

MAX SUPPLY PRESSURE All Models: Incoming Water Pressure not to exceed 150 psig

Length “A” 24

Width “B” 17

Height “C” 25

A minimum of six inches of clearance should be allowed around the entire unit for proper performance.

Additional clearance should be considered for above the unit and in front of the unit for servicability.

Frequency 60 Hz 60 Hz 60 Hz 60 Hz

Phase 1 Ø 1 Ø 1 Ø 1 Ø

MCA (Min. Circuit Ampacity) 17.7 19.9 20.4 25.3

MOCP (Max. over Current Protection) 25.0 30.0 30.0 40.0

RLA (Rated Load Amps) 21.5 23.2 23.0 23.6

MCA (Min. Circuit Ampacity) 23.8 26.0 26.0 28.1

MOCP (Max. over Current Protection) 30.0 35.0 35.0 45.0

RLA (Rated Load Amps) N/A N/A 28.6 26.4

MCA (Min. Circuit Ampacity) N/A N/A 31.6 30.9

MOCP (Max. over Current Protection) N/A N/A 40.0 45.0

1/4

” (616) 24

1/4

” (438) 17

1/2

” (648) 25

1/4

” (616) 26

1/4

” (438) 20

1/2

” (648) 31” (782) 31” (782)

3/4

” (679) 26

1/4

” (519) 20

3/4

1/4

” (679)

” (519)

OPTIONAL

ACCESSORIES

C

4430 115V pump kit for 4410 Power Pak (eld installed)

4431 115V pump kit for 4414 Power Pak (eld installed)

4435 BLM Receptacle

4408SS Wall Bracket for 4404 & 4410 only

57782 Set of four adjustable legs

54838 Water hammer arrestor (add if incoming water is under 65°F)

61790 Dual tier rack

61791+1 Triple tier rack

61792+2 Quad tier rack

C22296A-20 Cord Kit for 120V single pump Power Paks only (Field

Installed)

C21499BSS Stainless Steel Table Stand

US

WATER INLET

WATER OUTLET

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

3

Form No. Z2020

Rev. 04.15.2015

Page 4

4400 SERIES POWER PAKS GENERAL INFORMATION

Operation/Installation Manual

Accessories

Power Cord Kit

C2296A-20--12/3 Cord, 20A, Nema Plug 5-20P,

Dedicated Circuit Models - See above electrical

specifications

Power Pak Racks

61790, 61790+1, 61790+2 - All Models

Power Pak Wall Mounting Brackets

4408 - For Models 4404 & 4410 only

Coolant Solution-63299-1

One gallon Perlick Coolant solution, 30% DowFrost

HD/70% Distilled Water

Coolant Connector Kit

63335 - All Models

Leg Set - All Models

57782 . . . Set of four, 5 3/4”-71/2” adjustable legs

Pump Kits

4430 - Pump kit, 115V, 6.1 A, 100 gph, 130 psig

Models 4410, 4410W

4431 - Pump kit, 115V, 5.6 A, 100 gph, 130 psig

Models 4414, 4414W

4432 - Pump kit, 230V, 2.8 A, 100 gph, 130 psig

Models 4414-230, 4420

PRODUCT DESCRIPTION

Power Paks have always been an integral part of a

Perlick Century Beer System. The 4400 Series Power

Pak product line has been expanded to satify longer

beer runs. A Power Pak circulates coolant solution

(food grade propylene glycol with distilled water) from

walk-in cooler to the dispensing station(s) and back,

maintaining the desired dispensing temperature at

the faucet. The 4400 series Power Pak incorporate

a 1/3 hp ball bearing, maintenance free motor with a

100 gallon per hour 150 psig positive displacement

pump for optimum performance. The 4400 series

Power Pak product line employs a direct expansion

form of refrigeration increasing the units’ efficency as

well as making the units more compact. These units

also employ an electronic temperature control with

digital readout. This state of the art control controls

the performance of the unit as well as giving the

user a visual indication of the how the unit is working

as well as giving the user a visual indication of the

how the unit is working as well as early indication if

something may be going wrong through the use of

internal alarms.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

4

Page 5

4400 SERIES POWER PAKS INSTALLATION

Operation/Installation Manual

INSTALLATION

IMPORTANT SAFETY WARNINGS!

• Follow all National and Regional Codes.

• Read Installation and Operating Instructions

carefully before attempting to install, operate or

maintain the product.

• Protect yourself and others by observing all safety

information.

• Electrical hazards exist and can cause injuries if

not serviced by properly trained personnel.

• Failure to comply with instructions could result in

personal injury and/or property damage!

• Retain instructions for future reference.

• Never operate the circulating pump without

coolant in the reservoir.

NOTE: Air-cooled Power Paks must be installed

in areas with adequate ventilation to maintain

ambient temperatures of less than 105°F to achieve

optimum performance and satisfy warranty

requirements.

INSTALLING THE POWER PAK

Prior to installing a 4400 Series Power Pak, it is

imperative that the method of connecting it to the

electrical service has been determined. Ensure that

the electrical service to power the Power Pak will

handle the load requirements. Perlick has a Power

Cord specifically designed for a Power Pak, which has

a RLA of 16 amps or less, and a MCA of 20 amps or

less. All units with RLA greater than 16 amps and a

MCA of greater than 20 amps should have the Power

Pak hard-wired to electrical service.

ALL MODELS

• Determine the ideal placement of the Power Pak.

Locate the connection point to the truck housing

and place the Power Pak as close to this point as

possible. NOTE: If the Power Pak is to be located

on top of the walk-in cooler, it is imperative

that proper ventilation is provided to prevent

system failure due to overheating. Inadequate

ventilation will void warranty.

• Place the Power Pak and Ensure that it is level to

provide proper overflow protection. REMINDER:

Allow a minimun of six inches of clearace on

the louvered ends of the cabinet for proper

airflow. Allow accessibility room on the top of

the cabinet for serviceability.

• Remove the top panels (2).

• Ensure Power Switches for Condensing Unit and

Pump(s) are in the OFF position. Make the electrical

connections per ther illustrations. NOTE: Electrical

circuit shold be a dedicated circuit for use only

with the Power Pak. The circuit should be sized in

accordance with the electrical requirements of each

unit as well as in compliance with all National and

Local Codes.

• Plumb overflow port to a suitable reservior/drain.

WATER-COOLED MODELS

• In addition to the above installation instruction:

• Care should be exercised in locating the Power

Pak so that the unit will never be exposed to

temperatures below freezing.

• If the Power Pak is installing more than 5 feet higher

than the remote outlet drain point (i.e., location of

the floor drain) of the condenser, a vacuum breaker

or open vent line should be provided to prevent

the discharge line from creating a partial vacuum

condition in the condenser water system.

• If a water-circulating pump is used it should be

placed on the water supply side of the condenser,

so water is being pushed through the condenser.

• A potable water supply is required as

well as a drain or reclamation system.

Make water supply connection to fitting labeled as

the water inlet. Make outlet connection to fitting

labeled as the water outlet connection. Both the

inlet and outlet fittings supplied with the Power Pak

are 1/2” Quick Connect fittings.

4400 SERIES POWER PAKS INSTALLATION

Operation/Installation Manual

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

5

Form No. Z2020

Rev. 04.15.2015

Page 6

4400 SERIES POWER PAKS GENERAL INFORMATION

Operation/Installation Manual

CONNECTING POWER PAK TO TRUNK HOUSING

400 Series Power Paks require rigid fittings with a

minimum pressure rating of 150 psig. Use Coolant

Connector Kit #63335 to connect Power Pak to Trunk

Housing.

• Inspect pump outlet port for debris. Insert barbed

fitting #63307 into pummp outlet port.

• Inspect Glycol Return Manifold inlet for debris.

Insert barbed fitting #63307 into return manifold

inlet port.

• Cut supplied coolant tubing, #54588, to required

length to reach from Power Pak to Trunk Housing

connection point.

• Cut tubular insulation sleeve, #C12700, in half and

install over previously cut coolant tubing.

• Take Oetiker clamps, #54871-210, and install over

coolant tubing ends.

• Push coolant lines, one each over pump outlet

barbed fitting #63307 and return manifold barbed

fitting #63307.

• Position Oetikers over barbed fitting and clamp

securely.

• Slide tubular insulation sleeves tightly against

connection points. Use insulation tape as necessary

to ensure an air tight seal to prevent excessive heat

gain or condensation problems.

• Drill a 3-1/2” diameter hole in walk-in cooler to

accommodate coolant lines.

• Install insulation donuts over hole (both inside and

outside of cooler walls.

• Slide large insulation sleeve, #57478, over

remaining coolant tubing exposed to warm air

conditions including inside walk-in cooler from

Power Pak to Trunk Housing connection point. Seal

and tape all seams to prevent excessive heat gain

or condensation problems.

• Slide coolant lines through 3-1/2” donut hole

previosly cut in walk-in cooler wall.

• Position Trunk Housing coolant lines and Coolant

Connector kit lines in horizontal position, to alleviate

condensation runoff into Trunk Housing.

• Cut Trunk Housing coolant lines with tubing cutter to

ensure clean burr free ends.

• Take Oetikers clamps #54871-210, and install over

coolant connector kit tubing ends.

• Slide coolant connector kit tubing over the trunk

housing coolant lines and secure using the Oetikers.

• Complete the insulation process by ensuring that all

coolant lines are well insulated including all seams

to prevent excessive condensation and heat gain.

• Seal donut hole to ensure an air tight seal to prevent

walk-in cooler problems as well as condensation.

CONNECTING TRUNK HOUSING COOLANT LINES

TO DISPENSING HEAD

• Position the trunk housing so that beverage lines

can be connected with a minimum cutting.

• Split trunk housing approximately 12 inches from

the end to allow working room for the connections.

• Cut and deburr copper coolant lines coming from

trunk housing and dispensing head. Stagger the

lengths.

• Connect trunk housing coolant lines to dispensing

head coolant lines using clamps, hose and 3/8”

x 1/2” union, included in Head connecting kit,

#63486. Ensure that coolant lines are fully clample

to guarantee a leak free connection.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

6

Page 7

4400 SERIES POWER PAKS INSTALLATION

Operation/Installation Manual

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

7

Form No. Z2020

Rev. 04.15.2015

Page 8

4400 SERIES POWER PAKS STARTUP

Operation/Installation Manual

SYSTEM START-UP

Use only Perlick Approved Coolant Solution, #632991, all other solutions and mixtures will void the Perlick

warranty. The Coolant Solution has been pre-mixed for

optimum performance and wear protection. The Power

Pak resevoir holds approximately 1.75 gallons of solution. It takes approximately 1 gallon of Coolant Solution

to fill every 60 feet of Perlick Trunk Housing.

• Never operate the circulating pumps without coolant

in the resevoir.

• Fill Power Pak resevoir with Perlick Coolant Solution.

• Turn condensing unit switch and pump switch to the

ON position. Coolant solution level will begin to drop

in resevoir.

• Continue adding Perlick Coolant Solution until no

air bubbles are apparent from the Coolant return

line. NOTE: Never allow for the Coolant level in

the resevoir to drop below the heat exchanger

tube inlet. Allowing the level to drop below the

inlet will allow air into the lines.

• Fill Power Pak reservoir until both the return

line fitting port and the overflow tube port are

submersed under Coolant Solution. Watch return

line fitting port for additional Coolant Solution may

need to be added.

• Thoroughly check all field connection points for

leaks.

• Monitor Power Pak Temperature read-out to ensure

Power Pak is working properly. Dependent on

length of trunk housing run(s) and surrounding

ambient conditions, these factors will determine

how long it takes for the Power Pak to cut-out on

the temperature control.

DIGITAL TEMPERATURE CONTROLLER

The 4400 Series Power Pak comes equipped with

a Factory Programmed Electronic Thermostat with

display. The Thermostat has numerous factory

settings, which should never be adjusted or tampered

with to ensure proper operation of the Power Pak. The

Thermostat has been factory programmed to cut-out at

30°F with a hysteresis/differential of 4°F.

Front Panel Commands–Normal Operation

SET:

To display target set point.

DEFROST:

To start a manual defrost. (This feature is available, however, the parameters for actuation are programmed, such that, no defrost is available).

Front Panel Commands–Programming Mode

SET:

Selects a parameter or confirms an operation.

UP ARROW:

Browses the parameter codes or increases the displayed value.

DOWN ARROW:

Browses the parameter codes or decreases the displayed value.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

8

Page 9

POWER PAKS LEDS & PREVENTATIVE MAINTENANCE

Operation/Installation Manual

Meaning of LEDS

LED MODE FUNCTION

SNOWFLAKE ON Compressor

Enabled

SNOWFLAKE FLASHING Programing

Phase (flashing

with DEFROST) Anti-short cycle

delay enabled

DEFROST FLASHING Programming

Phase (flashing

with SNOWFLAKE) Drip time in

progress

DISPLAY MESSAGE MEANINGS

MESSAGE MEANING

POF Keyboard is locked out. No

parameters can be adjusted

without unlocking the keyboard.

ALARM MEANING ACTION

EE Data or Consult Factory

memory failure

P1 Room probe Numerous - see

failure note 1

How to see the SETPOINT

• Press and immediately release the SET key: the

display will show the Set point value.

• Press and immediately release the SET key or wait

for 5 seconds to display the probe value again.

How to change the SETPOINT

• Press and hold the SET key for more than 2

seconds to change the Set point value.

• The value of the set point will be displayed and the

SNOWFLAKE LED starts blinking.

• To change the Set value, press the UP or DOWN

ARROWS, dependent on the new set point value.

• To memorize the new set point value, press the SET

key again or wait 15 seconds.

WARNING:

IF MESSAGE OR INFORMATION SHOWN ON

READOUT IS UNFAMILIAR, ALLOW CONTROL

TO SIT FOR A MINIMUN OF 15 SECONDS AND

CONTROLLER SHOULD RETURN TO DISPLAY

PROBE TEMPERATURE.

NOTE 1: Faulty probe, loose connection, broket

wire. (Power Pak will continue to operate with

a faulty probe. The controller has been factory

programmed to continue operation with the

compressor cycling on and off in 5 minute

intervals.

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

9

Form No. Z2020

Rev. 04.15.2015

Page 10

4400 SERIES POWER PAKS REPLACEMENT PARTS

Operation/Installation Manual

Replacement Parts

COMPONENT/MODEL 4404 4410 4414 4414-230 4420

Condensing Unit 572FG5108AA

(C22652)

559HG5110HA

(C22667) C22634 C22645 C22668

Compressor 262FG92UB.2 269HG9290AF AJ250AT-188-J7 RRT10K1E-

PFV-959

Cond Fan Motor 1450076 1450095 TFM351 950-0344-00 950-0265-00

Fan Blade 2455003 2455003 51541-1 083-0033-01

Start Components US-PBNE6210Z1 US-PBNEK6214Z1

Water Regulator N/A N/A N/A N/A N/A

Pump Motor 63292 63292 63293 63293 63293

Heat Exchanger 63303A 63300A 63301A 63301A 63301A

Gasket, Heat Exchanger 61758A 61758A 61758A 61758A 61758A

Grille 64197-1SS 64197-1SS 64197-1SS 64285-1SS 64286-1SS

Front Panel 64407-1SS 64407-1SS 64407-1SS 64285-1SS 64286-1SS

Contactor N/A N/A N/A 63359 63359

Relay, Pump N/A N/A N/A 63358 63358

COMPONENT/MODEL 4404W 4410W 4414W 4420W

Condensing Unit C22640 C22641 C22642 C22666

Compressor ARE51C4E-

CAA-901

Cond Fan Motor N/A N/A N/A N/A

Fan Blade N/A N/A N/A N/A

Start Components

RRT62C1E-

IAA-901

RRT10K1E-

PKA-959

CS18K6E-

PKV-970

ZS19KAE-

PFV-818

Water Regulator 510-0049-00 510-0049-00 510-0049-00 510-0049-00

Pump Motor 63292 63292 63293 63293

Heat Exchanger 63300A 63300A 63301A 63302A

Gasket, Heat Exchanger 61758A 61758A 61758A 61758A

Grille 64197-1SS 64197-1SS 64197-1SS 64285-1SS

Front Panel 64407-1SS 64407-1SS 64407-1SS 64286-1SS

Contactor N/A N/A N/A 63359

Relay, Pump N/A N/A N/A 63358

Common Components

COMPONENT/MODEL ALL MODELS

Expansion Valve 63826

Pump 63291-1

V-Clamp 63291-2

Pump Insulation 64425

Zip Tie, Pump Insul 57551

Temp Control Kit 67177

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

COMPONENT/MODEL ALL MODELS

Controller, Digital 67139

Compression Fitting 63296-3

Switch 63303

Drier 63297

Coolant Solution 63299-1

10

Page 11

4400 SERIES POWER PAKS WIRING DIAGRAMS

Operation/Installation Manual

Perlick is committed to continuous improvement. Therefore, we reserve the right to change specications without prior notice

11

Form No. Z2020

Rev. 04.15.2015

Page 12

Quality & Innovation

th at inspires

8300 West Good Hope Road • Milwaukee, WI 53223 • Phone 414.353.7060 • Fax 414.353.7069

Toll Free 800.558.5592 • E-Mail perlick@perlick.com • www.perlick.com

inspires

Form No. Z2020

Rev. 04.15.2015

Loading...

Loading...