Page 1

OWNER’S MANUAL

ELECTRIC COMPACT CONVECTION OVEN

MODELS: 4200

4292

FORM NO.: S-2374 REV: A 02/07 An Employee Owned Company

PRINTED IN U. S. A. 35 Garvey Street • Everett • MA • 02149

Tel: (617) 387-47100 • Fax: 1-800-227-2659 (Ex. MA) • (617) 387-4456 (MA and Overseas)

E-mail: CUSTSERV@mi.com • Website: www.mi.com

Page 2

TABLE OF CONTENTS

INTRODUCTION

DESCRIPTION.................................................................................................................................1

OVEN COMPONENTS ...................................................................................................................1

BASIC FUNCTIONING ...................................................................................................................1

SERVICE ........................................................................................................................................1

INSTALLATION

RECEIVING ....................................................................................................................................2

ASSEMBLY - VENT BOX ATTACHMENT .......................................................................................2

SINGLE OVEN - 4” LEGS & 28” LEGS WITH SHELF ....................................................................2

STACKED OVENS - 18” LEGS WITH SHELF ................................................................................3

ELECTRICAL CONNECTION .........................................................................................................3

OVEN CHECKOUT & ADJUSTMENTS ..........................................................................................4

THERMOSTAT CALIBRATION (OLD & NEW STYLES) .................................................................4

THERMOSTAT DIAL PLATE CALIBRATION (NEW STYLE) ..........................................................4

WIRING DIAGRAM .........................................................................................................................5

OPERATION

PRINCIPLES OF OPERATION .......................................................................................................6

CONTROLS ....................................................................................................................................6

PRE-HEATING ................................................................................................................................6

OPERATION ...................................................................................................................................6

MAINTENANCE

CLEANING ......................................................................................................................................7

REMOVAL & REPLACEMENT PARTS ...........................................................................................7

DOOR REMOVAL ...........................................................................................................................7

DOOR REPLACEMENT (OLD STYLE) ...........................................................................................7

OVEN LINER GASKET REMOVAL .................................................................................................7

GASKET REPLACEMENT ..............................................................................................................7

BLOWER WHEEL REMOVAL & REPLACEMENT .........................................................................7

MOTOR REMOVAL & REPLACEMENT .........................................................................................7

SWITCH REMOVAL & REPLACEMENT ........................................................................................8

CONTACTOR REMOVAL & REPLACEMENT .................................................................................8

THERMOSTAT REMOVAL & REPLACEMENT ..............................................................................8

HEATER ELEMENT REMOVAL & REPLACEMENT ......................................................................8

DOOR INTERLOCK SWITCH BRACKET (OLD STYLE) REMOVAL &

REPLACEMENT .............................................................................................................................8

NEW STYLE INTERLOCK SWITCH REMOVAL, REPLACEMENT & PARTS ................................9

HI-LIMIT REMOVAL & REPLACEMENT .........................................................................................9

TROUBLE-SHOOTING

GENERAL .......................................................................................................................................10

TROUBLE-SHOOTING GUIDE ......................................................................................................10

WIRING ...........................................................................................................................................11

ELECTRICAL FAULT ISOLATION GUIDE ......................................................................................11

ELECTRICAL CONNECTIONS - CONTROL BOARD ....................................................................12

ILLUSTRATED PARTS LIST

GENERAL .......................................................................................................................................13

ORDERING INFORMATION ...........................................................................................................13

4200 COMPACT CONVECTION OVEN & PARTS .........................................................................13-14

CONTROL PANEL, OPEN & PARTS .............................................................................................15

RIGHT SIDE VIEW & PARTS ........................................................................................................16

DOOR ASSEMBLY & PARTS ........................................................................................................17

INSIDE OVEN COMPARTMENT PARTS LIST ...............................................................................18

4200/4292 REVERSING SWING OF DOOR (S) ............................................................................18

Page 3

INTRODUCTION

This service and parts manual contains general information, installation, operation, principles

of operation, trouble-shooting and maintenance information for the Market Forge Model 4200

Electric Compact Convection Oven. Also included are parts lists, in which each replaceable

part is identied and shown in an accompanying illustration.

DESCRIPTION

The Market Forge Model 4200 Electric Compact Convection Oven is an electrically powered convection oven designed to achieve

high volume cooking with a minimum of power consumption. The unit consists of a heavily

insulated cooking compartment tted with a

two speed convector blower and heated by

electric elements. All oven controls are located on a panel on the right front of the oven as

seen from the front.

OVEN COMPONENTS

The major assemblies of the model 4200 are

the stainless steel and at back painted steel

cabinet enclosure, door with window, porcelain cooking compartment with nine-position

shelf supports, heating element and contractor assembly, and control panel assembly.

Controls and indicators include the thermostat, main power switch, blower speed switch,

cool down/switch, elements on indicator light,

60-minute timer, and elements only switch.

The oven is available in variety of mounting congurations: 4” 102mm high-legs, 27”

686mm legs with shelf, or stacked on top of

another Model 4200 with the bottom unit on

18” 457mm stainless steel legs with shelf.

BASIC FUNCTIONING

The Model 4200 becomes operational when

the power switch is placed in the ON position,

door is closed, and thermostat set. Contrac-

tors located in the control section close the

circuit to heating elements located at the right

of the cooking chamber. When the chamber

reaches the preset temperature, the thermostat contacts open, causing the contractors to

interrupt the circuit to the heating elements.

When the temperature in the chamber drops

enough to close the thermostat contacts, the

circuit closes again. Any number of such cycles might occur during the cooking time, ~indicated by the element indicator light coming

on and off.

SERVICE

Required service, both preventive and corrective, is explained in section 5. Should repairs

be required, a network of authorized agencies

is available to assist with prompt service. A

current directory of Authorized Service Agencies may be obtained by contacting:

Product Service Department

Market Forge Company

35 Garvey Street

Everett, MA 02149-4403

(617) 387-4100

The model and serial number must be referenced when corresponding with Market

Forge. The data plate with serial number is

located on the right of the bottom front trim

ledge.

* We recommend that service be performed by a qualied Market Forge Authorized Service.

Service performed by others will void warranty. Market Forge is not responsible for repairs

made by other than authorized service agents.

1

Page 4

INSTALLATION

RECEIVING

Examine shipment for external and inter-

1.

nal damage and completeness. Transport

crated oven through building, to installation area before unpacking.

2. Report any damage or shortages to car-

2.

rier and Market Forge immediately.

DO NOT AT ANY TIME LAY THE OVEN

3.

DOWN ON ITS TOP, RIGHT SIDE, OR

FRONT. TO DO SO MAY DAMAGE THE

EQUIPMENT AND VOID THE WARRANTY.

ASSEMBLY - VENT BOX ATTACHMENT

Remove steam vent box and packet of

1.

screws from inside oven and attach vent

box to back of oven over vent opening using ve #8 sheet metal screws.

Single Oven on 4” Legs

Fasten legs to the weld nuts located on bottom panel of oven. The hex foot on the leg is

adjustable.

Single Oven on 28” Legs with Shelf

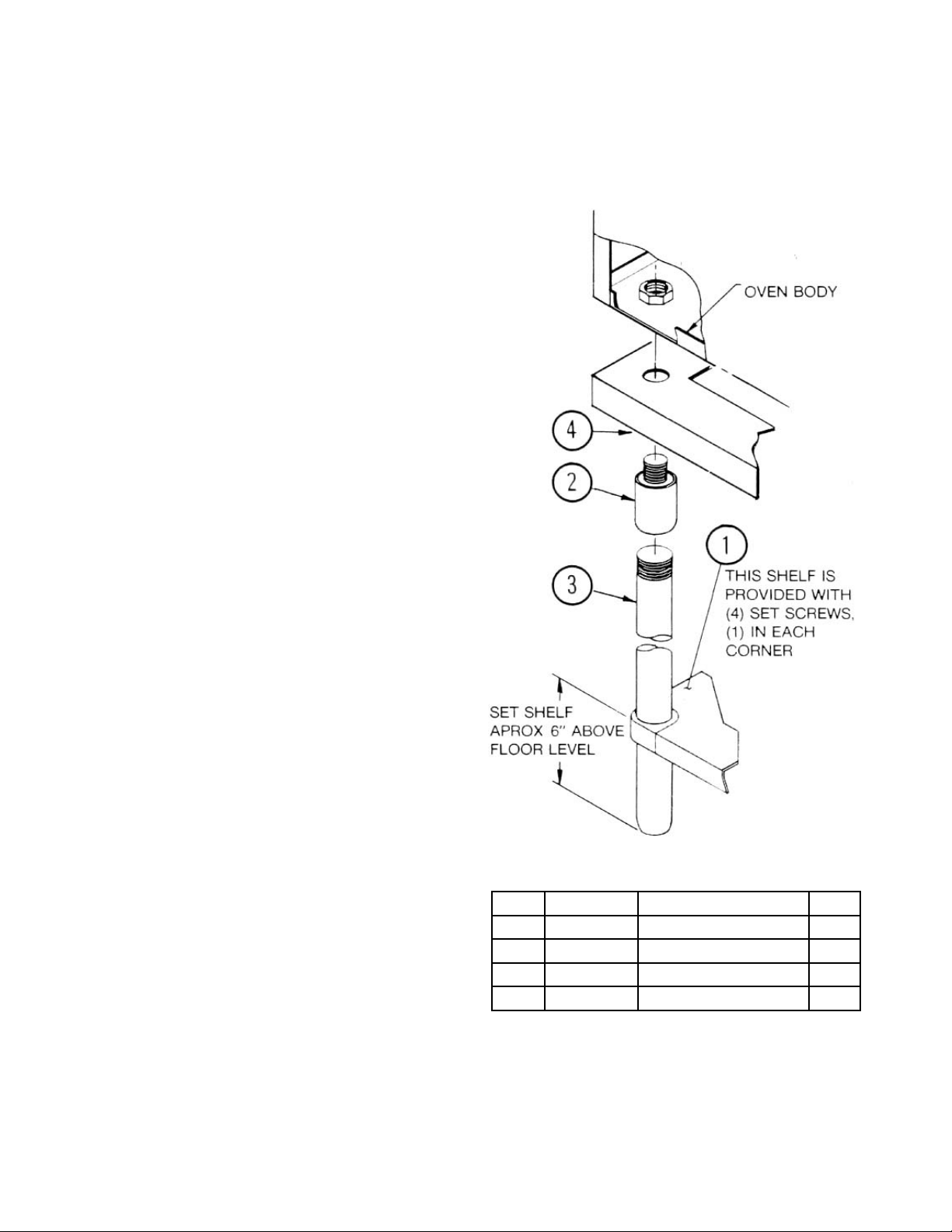

Insert legs (Fig. 1 No. 3) through holes

1.

in shelf (Fig. 1 No. 1) Do not tighten setscrews in corners of shelf.

Screw leg tops (Fig. 1 No. 2) onto legs.

2.

(Fig. 1 No. 3)

Insert leg tops (Fig. 1 No. 2) through holes

3.

in angle iron frame (Fig. 1 No. 4) into weld

nuts in bottom of oven.

Screw leg tops (Fig. 1 No. 2) into weld

4.

nuts by turning leg and top assemblies.

Raise shelf (Fig. 1 No. 1) to desired height

5.

and tighten set screws in shelf corners.

Fig. 1

ITEM PART NO. DESCRIPTION QTY.

1 99-6180 SOLID SHELF ST/ST 1

2 A10-0635 LEG TOP 4

3 A10-0634 FLOOR LEG 28” HIGH 4

4 D99-6183 SHELF 1

2

Page 5

INSTALLATION

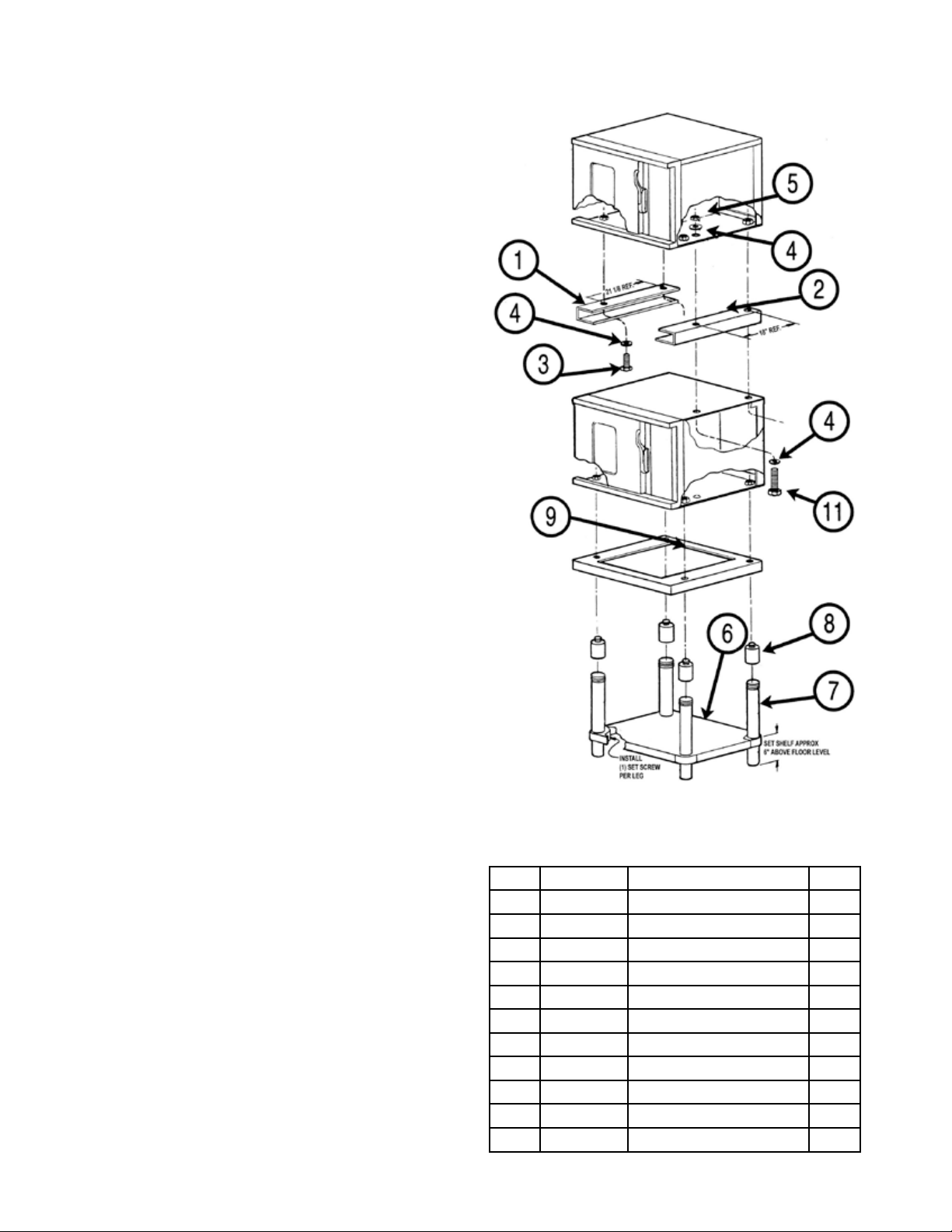

Stacked Ovens on 18” Legs with Shelf

STACKING INSTRUCTIONS:

Fasten Item No. 1, stacking channel, to

1.

the bottom left side of top oven. Note - left

channel has (2) holes. Use nut & washer

(Item 3 & 4) front & rear.

Remove access panel from the right side

2.

of both ovens.

Remove knockouts from the top of the

3.

bottom oven and from the bottom of the

top oven.

Place upper oven on top of lower oven

4.

with the right side stacking channel placed

between. Line up holes in both ovens with

the holes in the channel.

Fasten ovens together with the washer

5.

(Item No. 4) and the bolt (Item No. 11)

Inserted up thru top of lower oven, thru

stacking channel and into bottom of upper oven, using the existing weld nut to

fasten the rear and the nut provided with

the stacking kit (Item No. 5) to fasten the

front.

ELECTRICAL CONNECTION:

Read data plate located on top surface of

1.

right side of bottom trim just below control

panel before connecting electrical supply

to oven. Make sure electrical supply is

the same voltage, phase, and frequency

called for on date plate.

All ovens are shipped three phase and

2.

may be converted to single phase as per

alternate single phase wiring diagram.

Feed supply through opening in rear of

3.

oven (Fig. 2-1 No. 2) and connect supply wires to terminal block behind control

panel.

Wiring diagram label is located on control

4.

bracket, accessible by opening control

panel.

NOTE: Improper connection to power supply

or connection to power supply other than that

designated on data plate will void the warranty.

Assemble stand, as shown, before stacking

ovens.

Fig. 2

ITEM PART NO. DESCRIPTION QTY.

1 B99-6203 Stacking Channel Left 1

2 B99-6204 Stacking Channel Right 1

3

3 10-2564 Hex Bolt

4 10-2411 Plain Washer -

5 10-2320 Nut, Hex -

6 99-6180 Solid Shelf 1

7 A09-5271 Floor Leg 18” High 4

8 A10-0635 Leg Top 4

9 D99-6183 Shelf 1

10 A25-3263 Set Screw & Wrench Kit 1

11 08-3426 Hex Bolt

/

-10 x 1

4

3

/

3

/

-10 x 4 Lg. 2

4

1

/

Lg. 2

2

3

/

4

-10 1

4

3

5

Page 6

INSTALLATION

OVEN CHECKOUT & ADJUSTMENTS:

Door Adjustment (Old Style):

The door was properly adjusted at the factory,

if door does not open or close properly adjust

the ball plunger catch as .follows:

1. Remove adjusting wrench from back of

1.

manual and insert in notches on sides of

ball plunger.

Loosen jam nut with wrench.

2.

Turn adjusting wrench left or right until ball

3.

plunger engages in door striker plate for

best operation.

Tighten jam nut with wrench while adjust-

4.

ing wrench is still engaged in notches.

Return adjusting wrench to back of man-

5.

ual.

THERMOSTAT CALIBRATION

(OLD STYLE):

The thermostat is a device which automatically limits heat input at or below the dial setting.

Repeat steps 4 to 7 until oven tempera-

7.

ture stabilizes at 350°F+/- 5°F

Apply Glyptol or Duco Cement to set pot

8.

to prevent rotation.

THERMOSTAT DIAL PLATE CALIBRATION

(NEW STYLE):

Clamp thermocouple sensor in the center

1.

of the middle rack in compartment.

Pass the thermocouple sensor wire

2.

through the door gasket and close the

door.

Plug the sensor lead into the pyrometer.

3.

Set the oven power switch to ON.

4.

Set the thermostat knob to 3500 (191°C).

5.

Allow the oven to warm up for a minimum

6.

of (3) three ON/OFF cycles.

Before attempting to calibrate thermostat,

make sure that the thermostat is the cause

of problems experienced. Check for improper

electrical service, incorrect mixes over and

under proong, incorrect temperatures, and

warping pans. Thermostats are calibrated

and sealed by the original manufacturer before leaving their plant. Only a qualied service person should make calibration adjustments, if they become necessary.

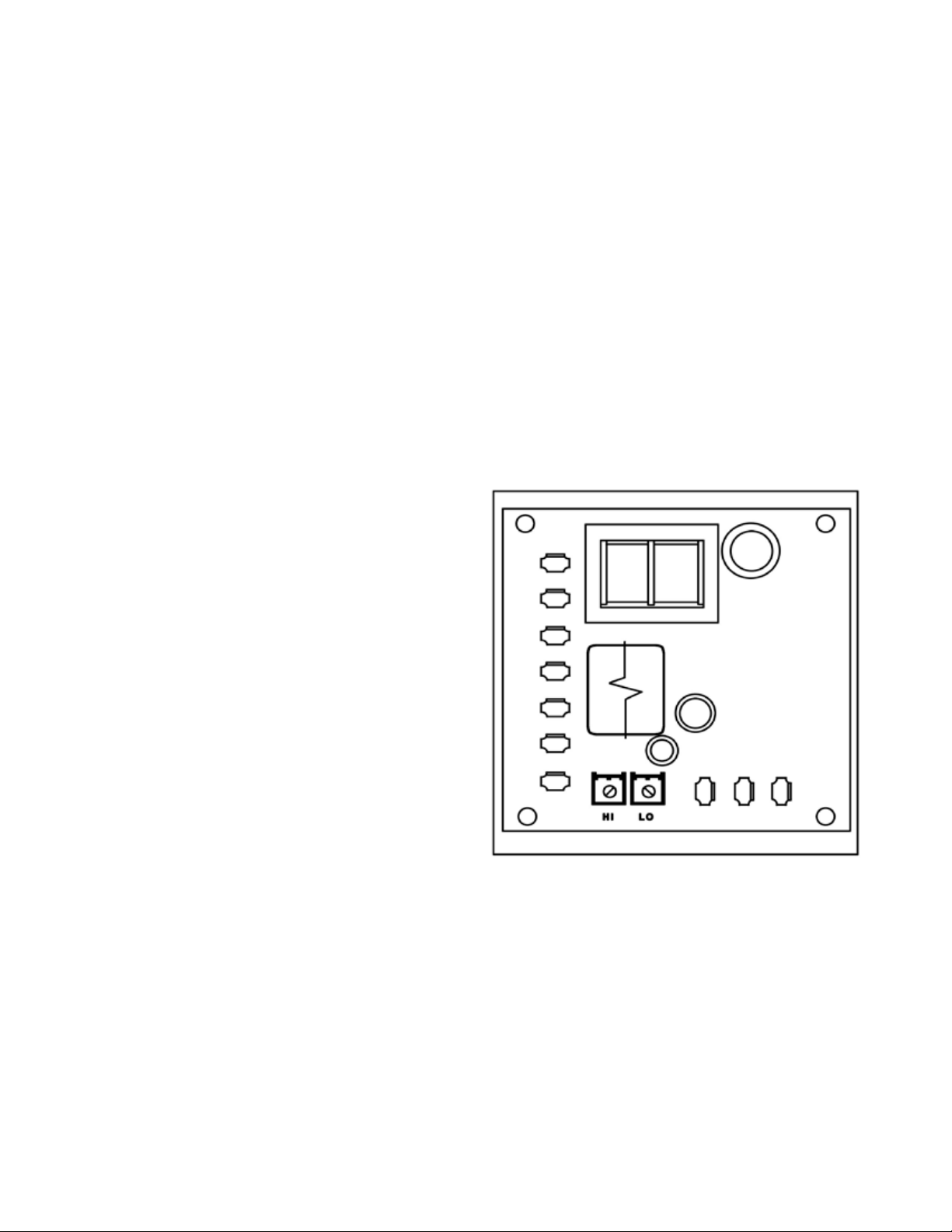

CALIBRATE ELECTRONIC THERMOSTAT

(NEW STYLE):

Set oven thermostat knob at 350°F.

1.

Allow oven to preheat to 350°F.

2.

Observe temperature with digital ther-

3.

mometer.

If temperature goes above 350°F turn set

4.

pot labelled HI (on circuit board) counterclockwise. % turn should be sufcient.

Allow time for oven temperature to drop,

5.

then recheck temperature.

If temperature is below 350°F turn set pot

6.

labelled HI (on circuit board) clockwise.+/5°F turn should be sufcient.

Fig. 3

7. Record the temperature when the element indicator light goes off. If a temperature of 345°-355° is attained, no calibration is necessary .

8. If the temperature differs more than +/-

5°F from the dial setting:

Pencil mark the knob pointer position as a

•

reference point on the control panel next

to the dial plate

Loosen the dial plate mounting screws

•

only enough to move the plate.

Move the dial plate until calibration match-

•

es thermometer reading (350°F).

4

Page 7

INSTALLATION

5

Page 8

OPERATION

PRINCIPLES OF OPERATION:

Uniform distribution of heat within the oven

is assured by continuous operation of a convector blower. Moving air continuously strips

away a thin layer of moisture and cold air from

the top of the food allowing more rapid heat

penetration. Lower temperatures and shorter

times than those used in conventional deck

ovens ‘Can be used. In general, temperature

settings can be reduced by 50°F (28°C) from

recipe temperatures for conventional ovens.

Some products may require slightly higher

or lower temperatures. Product should be

checked for doneness in about half the time it

would take in a conventional oven. Time savings may be about 15% to 20%.

CONTROLS:

All controls for the Model 4200 oven are located on the control panel on the front of the

oven (Fig. 5). These controls are; a thermostat to control oven temperature (Fig. 5 No.

1), an Elements On indicator light (Fig. 5 No.

2), a power switch with ON and OFF positions (Fig. 5 No. 3), a blower switch with high

and low positions (Fig. 5 No. 4), a cool down

switch with manual and auto positions (Fig.

5 No. 5) and a 60 minute electro-mechanical

timer (Fig. 5 No. 6). Heating Elements Only

Switch (Fig. 5 Not Shown).

PRE-HEATING:

Set thermostat to desired temperature, set

1.

blower switch to desired speed, and turn

on power switch. Blower wheel should rotate clockwise when viewed from front of

oven. Low speed is suggested for fragile

products ie those levened by beaten egg

whites such as soufes, angel food cake

and popovers.

Indicator light will go out when desired tem-

2.

perature is reached. Oven will pre-heat to

350°F 180°C in about 10 minutes. Large

differences in time from this indicate faulty

heating elements, or connection to wrong

electric power supply.

Fig. 5

OPERATION:

Set temperature about 50°F (28°C) less

1.

than what recipe calls for when using

standard oven.

Load pans evenly on shelves making sure

2.

pans don’t touch sides of oven or other

pans.

Check food for doneness in about half the

3.

time it would take in a conventional deck

oven. Visual inspection of food can be

made without opening the door by looking

through tempered glass window.

Blower will automatically shut off by a door

4.

interlock switch when door opens. Closing

the door will restart the blower.

Blower may be operated with door open

5.

by placing cool down switch in manual

position. No power is suppled to heating

elements with cool down switch in manual

position, allowing rapid lowering of oven

temperatures with door open.

Heating elements only without blower fan

6.

when door is shut. (For delicate products)

6

Page 9

MAINTENANCE

CLEANING:

Clean interior of oven with a commercially

1.

available oven cleaner suitable for use on

porcelain.

Racks, rack supports, and blower wheel

2.

may be cleaned by soaking in ammonia

and water solution after removing them

from oven.

Stainless steel parts maybe cleaned using

3.

a commercially available stainless steel

cleaner.

REMOVAL & REPLACEMENT OF PARTS:

WARNING: Disconnect oven from main

power supply before working on oven.

DOOR REMOVAL:

Remove lower screw (Fig. 6, #1) from up-

1.

per hinge assembly of door.

Loosen top screw (Fig. 6, #2) from upper

2.

assembly.

Push upper hinge pin (Fig. 6, #3) into

3.

door.

Rotate top of door forward to clear upper

4.

frame.

Pull up and out on door to remove.

5.

OVEN LINER GASKET REMOVAL:

Remove all screws from gaskets.

1.

Remove all gaskets.

2.

GASKET REPLACEMENT:

Replace top and bottom metal gaskets on

1.

front off oven liner and screw in place.

Replace left and right side metal gaskets

2.

and screw in place.

BLOWER WHEEL REMOVAL:

Shut off main power supply.

1.

Remove bafe by placing hard under back

2.

end and rotating bafe up and out.

Loosen set screws located in the center of

3.

the blower wheel on the wheel hub.

Pull blower wheel off of shaft.

4.

BLOWER WHEEL REPLACEMENT:

Remove metal burrs and foreign matter

1.

from motor shaft with emery cloth or sandpaper.

Lubricate blower wheel hub with high

2.

graphite grease. (Remove blower and lubricate at least once every six months).

Place blower wheel on shaft. Make sure

3.

set screws are positioned over the ats on

the shaft. Make sure there is 3/16” clearance between blower wheel and oven

wall.

Tighten set screws to 160 in-lbs torgue.

4.

Fig.6

DOOR REPLACEMENT (OLD STYLE):

Revere above procedure being sure to put as

many washers under as there were before removal.

MOTOR REMOVAL:

Make sure main power supply is discon-

1.

nected from oven.

Remove bafe and blower wheel.

2.

Remove right side panel.

3.

Open control compartment cover.

4.

Remove motor bolt access plate.

5.

Remove four nuts and blots holding motor

6.

to motor mount.

Remove cover from wiring box mount on

7.

motor and disconnect wires.

7

Page 10

MAINTENANCE

MOTOR REPLACEMENT:

Revere procedure above.

1.

Check motor wiring to make sure blower

2.

turns clockwise when seen from front of

oven.

SWITCH REMOVAL:

Make sure power supply to oven is off.

1.

Open control compartment cover.

2.

Disconnect wire to switch.

3.

Depress spring clips on switch and push

4.

forward.

SWITCH REPLACEMENT:

Push switch into proper control panel

1.

opening until spring clips catch.

Reconnect wire to switch.

2.

Close control cover.

3.

CONTACTOR REMOVAL:

Make sure power supply to oven is off.

1.

Open control comportment cover.

2.

Disconnect wire from appropriate compo-

3.

nent.

Unscrew fasteners of appropriate compo-

4.

nents and remove.

CONTACTOR REPLACEMENT:

Attach components to mounting.

1.

Replace and tighten fasteners.

2.

Reconnect wires.

3.

THERMOSTAT REMOVAL:

Make sure power supply to oven is off.

1.

Open control compartment cover.

2.

Remove racks and rack supports from

3.

oven compartment.

Remove bafe.

4.

Disconnect thermocouple lead wires from

5.

circuit board.

Unscrew thermocouple from oven liner.

6.

Pull thermocouple and wires through oven

7.

liner into oven compartment and remove.

Remove circuit board from bracket.

8.

THERMOSTAT REPLACEMENT:

Follow Thermostat Removal in reverse order.

HEATER ELEMENT REMOVAL:

Make sure power supply to oven is off.

1.

Remove right side panel.

2.

Remove element terminal cover above

3.

motor and disconnect wires.

Remove element plate and insulation

4.

spacer.

Remove racks and rack supports from

5.

oven cavity.

Remove bafe.

6.

Remove eight screws holding element as-

7.

sembly to the oven wall.

Remove elements.

8.

ELEMENT REPLACEMENT:

Follow Element Removal in reverse order.

DOOR INTERLOCK SWITCH BRACKET

REMOVAL (OLD STYLE):

Make sure power supply to oven is off.

Open control compartment cover.

Remove wires to door interlock switches.

Remove two bracket retaining screws.

Remove interlock switch assembly.

DOOR INTERLOCK SWITCH BRACKET

REPLACEMENT (OLD STYLE):

Insert long end of door activated plunger

1.

through hole in left front side of control

compartment.

Replace spring and switches in bracket

2.

and secure switch assembly with two

screws.

Position switches so that push buttons

3.

on switches just touch actuator plate on

plunger rod.

Replace wires using wiring diagram as

4.

guide.

Replace control compartment cover.

5.

8

Page 11

MAINTENANCE

NEW STYLE INTERLOCK SWITCH

REMOVAL:

Make sure power supply to oven is off.

1.

Remove lower bottom trim, remove screws

2.

on end.

Remove screws from switch, to remove

3.

switch.

Remove marr connectors from leads, then

4.

remove switch.

REPLACEMENT OF SWITCH:

Follow New Style Interlock Switch Removal in

reverse order.

HI-LIMIT REMOVAL:

Make sure power supply to oven is off.

1.

Open oven door.

2.

Remove all shelves and rack supports.

3.

Remove bafe from right sire.

4.

Unscrew fasteners from Hi-Limit on liner

5.

wall and pull out.

Remove wire leads from Hi-Limit.

6.

HI-LIMIT REPLACEMENT:

Follow Hi-Limit Removal in reverse order.

Fig. 7

NEW STYLE INTERLOCK LOCATION

ITEM PART NO. DESCRIPTION

1 08-6308 Reed switch (fan interlock)

2 99-6168 Reed switch mounting bracket

3 REF. Marr connectors, two

9

Page 12

TROUBLE-SHOOTING

GENERAL:

The information in this section is intended to

assist both the operator and service personnel in locating the general source of problems

which may occur with the model 4200 compact convection oven. Before following any of

the procedures gives in this section, the op-

TROUBLE-SHOOTING GUIDE:

PROBABLE CAUSE REMEDY

1. Convector fan fails to operate.

Power to oven is off.

a.

ON-OFF switch off.

b.

Oven door open.

c.

Faulty cool down switch ON-OFF switch,

d.

door switch, fan motor, wiring.

2. Oven will not heat with thermostat at maximum setting, fan operating.

Faulty thermostat wiring.

a.

Thermostat contacts or coil faulty.

b.

3. Indicator light fails to light with thermostat set, fan operating, oven hot.

Indicator light burned out.

a.

Faulty wiring.

b.

4. Erratic oven temperature.

Faulty thermostat operation.a. Recalibrate or replace as required.a.

5. Uneven heating.

One or more heating elements inopera-

a. Check wiring to elements; check for

tive.

erator should be thoroughly familiar with the

operating instructions and the function of all

controls described on page 6 of this manual.

If the problem cannot be readily corrected,

the operator should contact the nearest Authorized Market Forge Service Agency for assistance.

Locate external circuit breakers for

a.

power and place in ON position.

Place in ON position.

b.

Close door.

c.

Test each component and connecting

d.

wire, replace as required.

Test thermostat and connecting wiring.

a.

Replace as required.

Replace thermostat.

b.

Replace light.

a.

Check wiring and repair as needed.

b.

a.

burned out elements. Replace as required.

WE RECOMMEND THAT SERVICE BE PREFORMED BY A QUALIFIED MARKET

FORGE AUTHORIZED SERVICER. SERVICE PERFORMED BY OTHERS WILL VOID

WARRANTY. MARKET FORGE IS NOT RESPONSIBLE FOR REPAIRS MADE BY

OTHER THAN AUTHORIZED SERVICE AGENTS.

10

Page 13

TROUBLE-SHOOTING

WIRING:

All the electrical components of the model

4200 (ON-OFF switch, door switch, thermostat control, contactors, fan motor, and indicator light) are connected to each other by

wiring shown on page 5. If all the electrical

components are operating correctly and the

incoming power has been checked, but the

unit fails to operate, the fault lies in the wiring.

ELECTRICAL FAULT ISOLATION GUIDE

FAILURE FAULT LOCATION

1. Oven will not operate when the thermostat is set. Incoming power

2. Intermittent operation of heaters. Thermostat control

3. Convector fan fails to operate. Cool down switch

4. Indicator light off, heater under power. Indicator light

5. Uneven heating. Heating elements

6. (Elements Only) fails to come on. Check switch

Using an ohmmeter, wiring continuity between

the connections, shown in the wiring diagram

is readily veried. This is best done in stages,

removing only those wires required for each

continuity check. As each lead is replaced, it

should be checked for evidence of corrosion

and cleaned if necessary. All leads must be

tightly attached to provide a good electrical

connection.

a.

Door switch

b.

Thermostat control

c.

ON-OFF switch

d.

Cool down switch

e.

Contactor

f.

Wiring

g.

a.

Contactor coil

b.

Wiring

c.

a.

ON-OFF switch

b.

Door Switch

c.

Fan motor

d.

Wiring

e.

a.

Wiring

b.

a.

Wiring

b.

a.

Check hi-limit switch

b.

Check wiring

c.

WE RECOMMEND THAT SERVICE BE PREFORMED BY A QUALIFIED MARKET

FORGE AUTHORIZED SERVICER. SERVICE PERFORMED BY OTHERS WILL VOID

WARRANTY. MARKET FORGE IS NOT RESPONSIBLE FOR REPAIRS MADE BY

OTHER THAN AUTHORIZED SERVICE AGENTS.

11

Page 14

TROUBLE-SHOOTING

ELECTRICAL CONNECTIONS

CONTROL BOARD:

NOTE: New style board CANNOT BE CALIBRATED. Check thermocouple for fault in temperature control. If thermocouple is good, replace temperature control board.

Fig. 8

12

Page 15

ILLUSTRATED PARTS LIST

GENERAL:

This section contains a complete listing of all

replaceable parts for the 4200 compact convection oven. For the purpose of parts identication, the unit is broken down into functional assemblies, and each assembly is shown

in a pictorial view which is keyed to the accompanying part list. Each parts list contains

the gure item number, the Market Forge part

number and an abbreviated description.

ORDERING INFORMATION:

Orders for repair parts should be directed to

the nearest authorized parts distributor. For

a current Market Forge Authorized Parts and

Service Distributor list go to our web site or

contact:

Market Forge Industries Inc.

Toll Free: (866) 698-3188

www.mi.com

Parts, Service and Availability Toll Free No.:

(888) 259-7076

Fig. 9

13

Page 16

ILLUSTRATED PARTS LIST

Fig. 9 4200 Compact Convection Oven

ITEM NO. PART NO. DESCRIPTION

1 99-5826 CONTROL PANEL K-MART ONLY

2 09-5268 THERMOSTAT KNOB

3 09-6440 RED PILOT 250V

4 09-7231 SWITCH DPDT 250V, 10 AMP, RED, ON-OFF SWITCH

5 09-7244 SWITCH DPDT 250V, 10 AMP, BLUE, BLOWER SWITCH

6 09-7235 SWITCH DPDT 250V, 10 AMP, WHITE, COOL DOWN SWITCH

7 09-7231 SWITCH DPDT 250V, 10 AMP, RED, HEATING ELEMENTS ONLY

8 08-5839 THERMOSTAT DECAL

9 99-5830 TIMER DECAL

10 99-6136 SIDE GASKET

11 99-6101 TOP AND BOTTOM GASKET

12 09-5269 BLOWER WHEEL

13 09-7259 THERMOCOUPLE AND WASHER

14 09-7241 HEATING ELEMENT, OUTER, 280V-2500W, 220V-2800W (EXPORT)

14A 09-7242 HEATING ELEMENT, OUTER, 230V-2571W, 240V-2800W

15 097336 HEATING ELEMENT, INNER, 280V-2500W, 220V-2800W

15A 09-7337 HEATING ELEMENT, INNER, 230V-2571W, 240V-2800W

16 99-6102 HEATING ELEMENT BRACKET

17 99-6130 BAFFLE SUPPORT

18 99-5054 BOTTOM TRIM

19 99-5055 TOP TRIM

20 99-6107 OVEN INTERIOR COVER PLATE

21 09-5267 60 MINUTE TIMER KNOB

22 08-6351 HI-LIMIT THERMOSTAT

14

Page 17

ILLUSTRATED PARTS LIST

Fig. 10

Fig. 10 Control Panel, Open

ITEM NO. PART NO. DESCRIPTION

1 10-6293 60 MINUTE TIMER, 240V, 50/60 HZ

2 REF. REMOTE POTENTIOMETER, PART OF THERMOSTAT 08-6355

3 10-6649 TERMINAL BLOCK

4 10-5551 GROUND LUG

5 99-5822 CONTROL CIRCUIT WIRE HARNESS

6 10-5476 CONTACTOR, 280V, 40 AMP, 50/60 HZ

6A 10-5943 CONTACTOR, 240V, 40 AMP, 50/60 HZ

7 08-6355 TEMPERATURE CONTROLLER, 208 OR 240V

15

Page 18

ILLUSTRATED PARTS LIST

Fig. 11

Fig. 11 Right Side View

ITEM NO. PART NO. DESCRIPTION

1 09-7230 BLOWER MOTOR, 208/230V, 1/4 HP, 2 SPEED

2 REF. TEMPERATURE CONTROLLER, 208-240V

3 REF. TERMINAL BLOCK

4 10-6874 S.P.S.T. RELAY, FOR REED SWITCH, 240V

5 REF. CONTACTOR, 208V, 40 AMP, 50/60 HZ

6 99-6108 HEATING ELEMENT COVER PLATE

6A 99-6109 HEATING ELEMENT COVER GASKET

7 99-6140 ASSEMBLY, BLOWER MOTOR AND BRACKET

8 09-6516 SIREN AUDIO ALERT, 120V

8A 09-6599 6.8 K CERAMIC RESISTOR FOR ALTER, NOT SHOWN

16

Page 19

ILLUSTRATED PARTS LIST

Fig. 12 Door Assembly

ITEM NO. PART NO. DESCRIPTION

1 08-5205 DOOR HANDLE ASSEMBLY

2 REF. CATCH, PART OF 08-5205

3 99-6115 SPACER CATCH

4 99-6170 DOOR ASSEMBLY

5 99-6153 HINGE PIN

6 99-6154 HINGE PIN PLATE

Fig. 12

17

Page 20

ILLUSTRATED PARTS LIST

INSIDE OVEN COMPARTMENT

PART NO. DESCRIPTION

99-5027 BAFFLE

99-5057 RACK SUPPORTS

99-5056 RACKS

99-5052 EXTERIOR TOP PANEL

99-5058 EXTERIOR REAR PANEL

99-5020 RIGHT SIDE ACCESS PANEL

99-5035 LEFT SIDE PANEL

10-0633 4” ADJUSTABLE LEGS

99-6176 28” HIGH STAND

99-6177 18” STACKED KIT WITH STAND

4200/4292 REVERSING SWING OF DOOR (S):

Remove door handle, P/N 08-5205, by removing three slotted screws located on

1.

edge of handle.

Loosen two upper hinge pin screws. Pin will drop into door.

2.

Remove door by tilting top of door outward while lifting door off of lower hinge pin.

3.

Remove catch plate assembly from face of oven.

4.

Remove four round head machine screws from opposite side of oven face.

5.

Re-install on other side of oven face, the four round head machine screws removed

6.

in step 5.

Re-locate and install catch plate assembly at new location.

7.

Hold door in new position and allow hinge pin to slide out. Tighten two screws to

8.

hold pin in this position.

Release the (new) top hinge pin and re-install door in the new position. Push up

9.

hinge pin and tighten two screws to hold upper hinge pin in place.

Replace handle using hardware removed in step 1.

10.

Adjust door by resetting adjustment on catch plate assembly.

11.

18

Loading...

Loading...