2

查询PI6C2502供应商

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901

PI6C2502

Phase-Locked Loop Clock Driver

Product Features

• High-Performance Phase-Locked-Loop Clock Distribution

for Networking,

• Synchronous DRAM modules for server/workstation/

PC applications

• Allows Clock Input to have Spread Spectrum

modulation for EMI reduction

• Zero Input-to-Output delay

• Low jitter: Cycle-to-Cycle jitter ±100ps max.

• On-chip series damping resistor at clock output drivers

for low noise and EMI reduction

• Operates at 3.3V V

• Wide range of Clock Frequencies up to 80 MHz

• Package: Plastic 8-pin SOIC Package (W)

CC

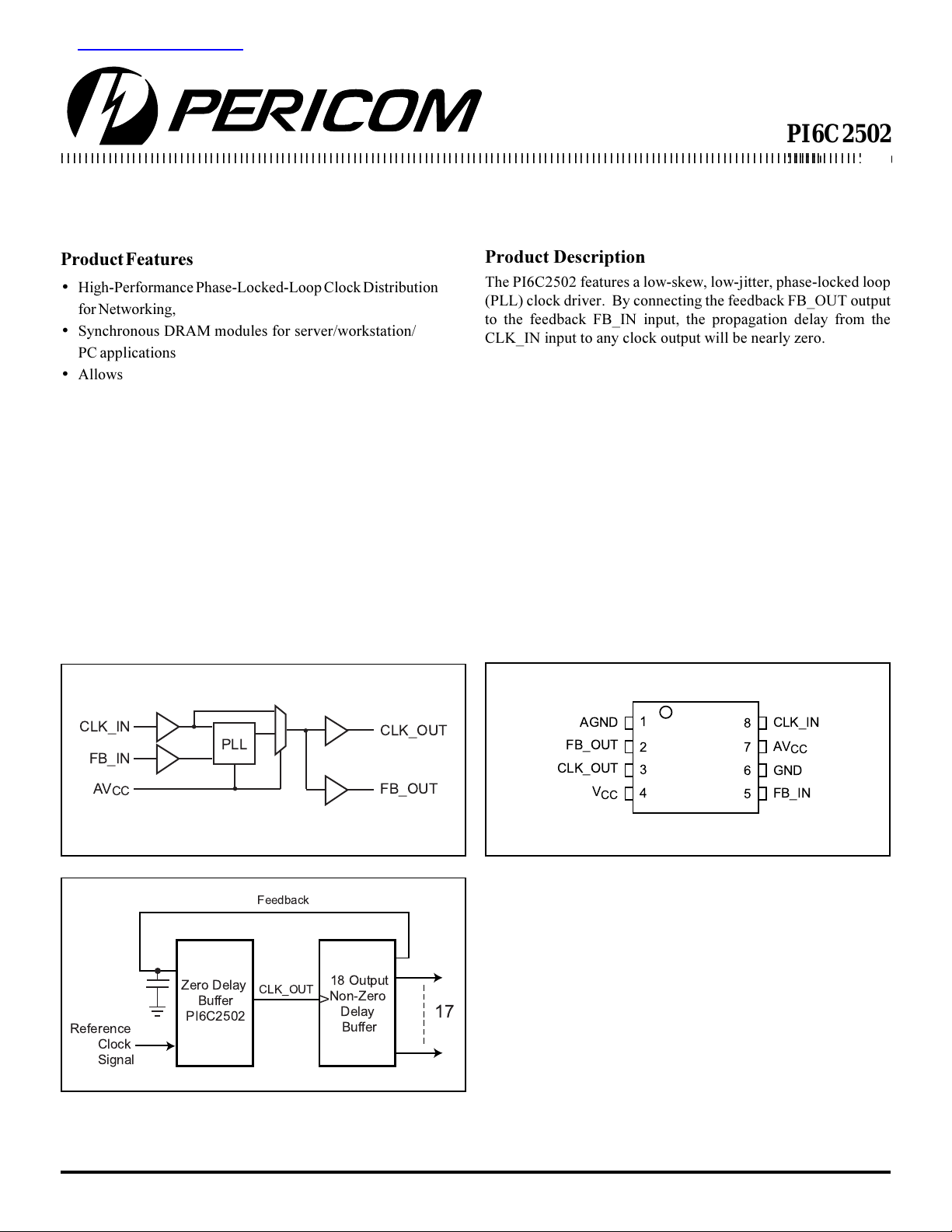

Product Description

The PI6C2502 features a low-skew, low-jitter, phase-locked loop

(PLL) clock driver. By connecting the feedback FB_OUT output

to the feedback FB_IN input, the propagation delay from the

CLK_IN input to any clock output will be nearly zero.

Application

If a system designer needs more than 16 outputs with the features

just described, using two or more zero-delay buffers such as

PI6C2509Q, and PI6C2510Q, is likely to be impractical. The

device-to-device skew introduced can significantly reduce the

performance. Pericom recommends the use of a zero-delay buffer

and an eighteen output non-zero-delay buffer. As shown in Figure

1, this combination produces a zero-delay buffer with all the signal

characteristics of the original zero-delay buffer, but with as many

outputs as the non-zero-delay buffer part. For example, when

combined with an eighteen output non-zero delay buffer, a system

designer can create a seventeen-output zero-delay buffer.

Logic Block Diagram

CLK_IN

FB_IN

AV

CC

Zero Delay

Buffer

Reference

Clock

Signal

PI6C2502

PLL

Feedback

CLK_OUT

18 Output

Non-Zero

V

Delay

Buffer

CLK_OUT

FB_OUT

17

Product Pin Configuration

CC

1

2

3

4

AGND

FB_OUT

CLK_OUT

V

8-Pin

W

8

7

6

5

CLK_IN

AV

CC

GND

FB_IN

Figure 1. This Combination Provides Zero-Delay Between the

Reference Clocks Signal and 17 Outputs

1

PS8382B 03/20/02

Pin Functions

emaNniPrebmuNniPepyTnoitpircseD

NI_KLC8I .tupnikcolCecnerefeRNI_KLC.tupnikcolcmurtcepsdaerpsswolla

NI_BF5I .tupnikcabdeeFNI_BF.LLPlanretniehtotlangiskcabdeefehtsedivorp

TUO_BF2O

PI6C2502

Phase-Locked Loop Clock Driver

tuptuokcabdeeFTUO_BF.kcabdeeflanretxerofdetacidedsi

eulavemasehtforotsisergnipmad-seiresdeddebmenasahTUO_BF

stuptuokcolcehtsa.TUO_KLC

TUO_KLC3O

VA.ylppusrewopgolanA

CC

VA

CC

7rewoP

VAnehW.sesopruptset

CC

dnaNI_KLC.stuptuoecivedehtotyltceriddereffubsi

DNGA1dnuorG .yrtiucricgolanaehtrofecnereferdnuorgehtsedivorpDNGA.dnuorggolanA

V

CC

4rewoP.ylppusrewoP

DNG6 dnuorG.dnuorG

DC Specifications (Absolute maximum ratings over operating free-air temperature range)

lobmySretemaraP.niM.xaMstinU

V

I

V

O

I

CD_O

T

GTS

rewoPTtanoitapissidrewopmumixaM

egnaregatlovtupnI

egnaregatlovtuptuO

tnerructuptuoCD 001Am

o

55=

A

riallitsniC0.1W

erutarepmetegarotS56051

foseipocweks-woledivorpstuptuoesehT.stuptuokcolC.NI_KLC

.rotsisergnipmad-seiresdeddebmenasahtuptuohcaE

5.0V

5.0+V

CC

rofLLPehtssapybotdesuoslaebnac

dessapybsiLLP,dnuorgotdeppartssi

o

C

Note: Stress beyond those listed under absolute maximum ratings may cause permanent damage to the device.

retemaraPsnoitidnoCtseTV

I

CC

C

I

VIV=

VIV=

CC

CC

I;DNGro

DNGro

)1(

0=

O

CC

V6.301

.niM.pyT.xaMstinU

4

V3.3

C

O

VOV=

CC

DNGro6

Note: 1. Continuous Output Current

2

µA

Fp

PS8382B 03/20/02

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

12345678901234567890123456789012123456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012123456789012

Recommended Operating Conditions

lobmySretemaraP.niM.xaMstinU

PI6C2502

Phase-Locked Loop Clock Driver

V

CC

V

HI

V

LI

V

I

T

A

egatlovylppuS0.36.3

egatlovtupnilevelhgiH0.2

egatlovtupnilevelwoL 8.0

egatlovtupnI0V

erutarepmetria-eerfgnitarepO007Cº

Electrical Characteristics

(Over recommended operating free-air temperature range Pull Up/Down Currents, VCC = 3.0V)

lobmySretemaraPnoitidnoC.niM.xaMstinU

I

HO

tnerrucpu-lluP

V

V

V

I

LO

tnerrucnwod-lluP

V

V4.2=

TUO

V0.2=

TUO

V8.0=52

TUO

TUO

V55.0=71

AC Specifications Timing Requirements

(Over recommended ranges of supply voltage and operating free-air temperature)

lobmySretemaraP.niM.xaMstinU

V

CC

− 81

− 03

Am

F

D

CLK

CYI

ycneuqerfkcolC5208zHM

elcycytudkcolctupnI0406%

purewopretfaemiTnoitazilibatS1sm

Switching Characteristics

(Over recommended ranges of supply voltage and operating free-air temperature, CL=30pF)

retemaraP)tupnI(morF)tuptuO(oT

rettijtuohtiwrorreesahptNI_KLC ↑ zHM66dnazHM001taNI_BF ↑ 051051+

elcyc-ot-elcyc,rettiJzHM66dnazHM001tATUO_KLC001001+

zHM001tawekS

zHM66dna

TUO_KLCroTUO_BF

elcycytuD

V0.2otV4.0,emit-esir,rt 0.1

V4.0otV0.2,emit-llaf,ft 1.1

Note: These switching parameters are guaranteed by design.

TUO_KLC

TUO_BFro

TUO_KLC

TUO_BFro

V

CC

C°07-0,V3.0±V3.3=stinU

.niM.pyT.xaM

sp

002

5455%

sn

3

PS8382B 03/20/02

Application Note

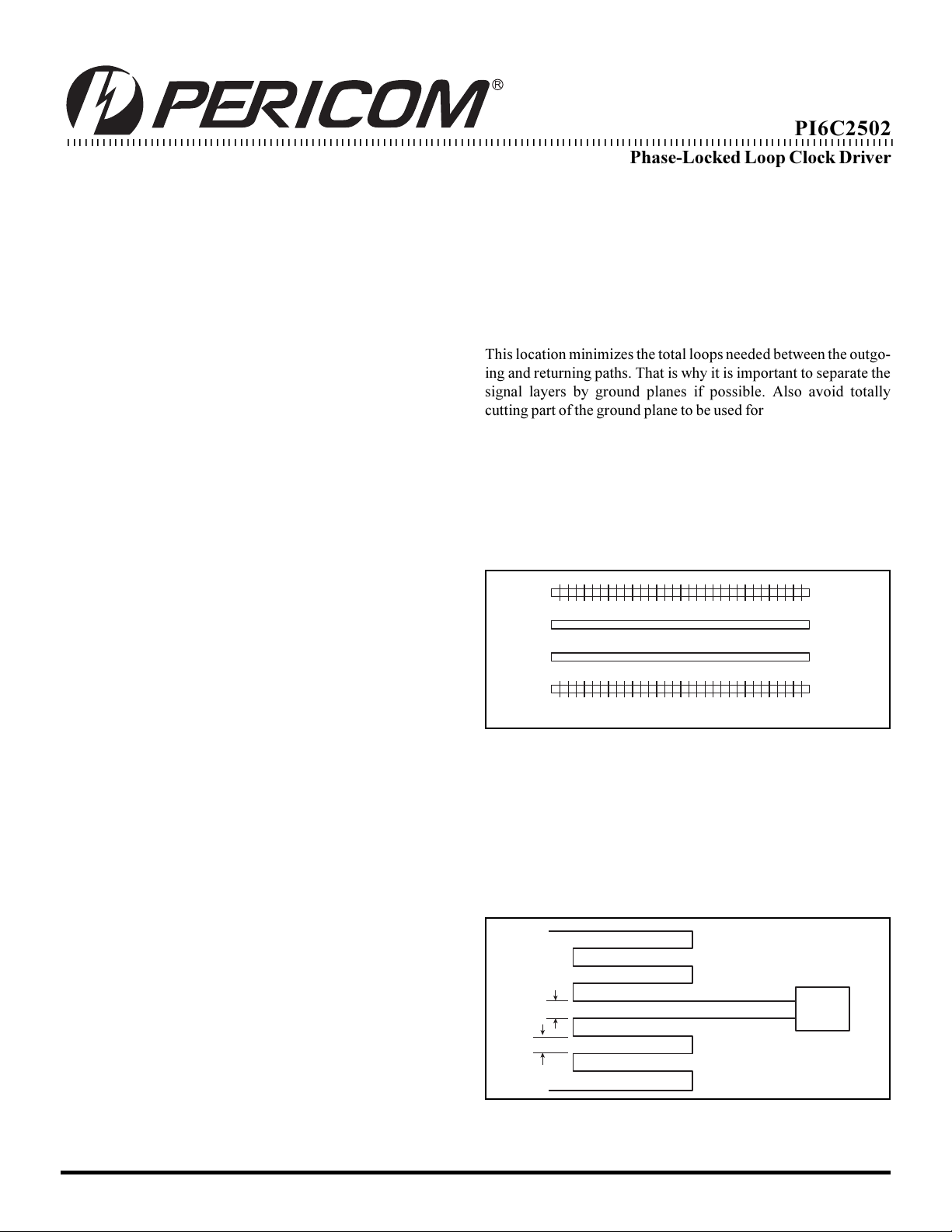

Layout and Schematic Guidelines

Introduction

Because of todays high-speed design demands, board designers

must have extensive knowledge concerning transmission line

effect, EMI, and crosstalk. They also need to understand board

materials, signal and power stacking, connectors, cables, vias, and

trace dimensions. Pericom Semiconductor Corporation offers an

extensive line of high-speed clock products for desktop, notebook,

set top boxes, information device, servers, and workstations. To

make high-speed chips function properly, a designer needs to rely

on accurate schematics and layout guidelines.

This application note focuses on Pericoms PI6C2502 Zero- Delay

Clock Buffer, presenting schematics and layout guidelines for the

chip. Also listed are some decoupling guidelines that are important

for this chips varied applications.

Decoupling Capacitors

Every printed circuit board needs large bypass capacitors to

balance the inductance of the power-supply wiring. These capacitors have some lead inductance that increase as the frequency goes

higher, which is why it is very important to place the capacitors as

close as possible to the V

To reduce the series lead inductance effect, avoid the following:

1. Long traces larger than 0.01 inch between capacitor pad and via

2. Use of capacitors other than surface mount

3. Via holes less than 0.035-inch diameter

Pericoms clocks use high-precision, integrated analog PLL that can

be effected by the power supply and ground pins. Noise on these

two pins can dramatically increase skew and output jitter.

To minimize these problems, connect a 4.7µF, a 220nF , and a 2.2nF

capacitor to the digital supply pin. Also use one 4.7µF , one 220nF,

and one 2.2nF capacitor on the analog supply pin. Connect the other

side to the analog ground pin.

Place a 10µF capacitor from the main power island to the power plane

that is supplied to the clock chip.

Use high-quality, low ESR, ceramic surface-mount capacitors.

and Ground Pins on the Chip.

CC

PI6C2502

Phase-Locked Loop Clock Driver

This location minimizes the total loops needed between the outgoing and returning paths. That is why it is important to separate the

signal layers by ground planes if possible. Also avoid totally

cutting part of the ground plane to be used for a signals path. That

is totally unacceptable, because it will increase crosstalk considerably and does not provide a clean return to those signals. Also use

lower trace impedance because it lowers undershoot and overshoot. Always use FR-4 material for board fabrication. Use 4- layer

stack-up arrangement. Make sure you have a signal layer that is

followed by the ground layer, then a power layer, and finally the

second signal layer. Please see Figure 1 below.

CORE

Clock

Primary Signal

Layer (½ oz. cu.)

Ground Plane

(1 oz. cu.)

Power Plane

(1 oz. cu.)

Secondary Signal

Layer (½ oz. cu.)

Z = 60 Ohms

5 mils

47 mils

5 mils

Z = 60 Ohms

PREPREG

PREPREG

Total Board Thickness = 62.6

Figure 1: Four-Layer Board Stack-up

Clock routing and spacing

To minimize crosstalk on the clock signals, use a minimum of

0.014-inch spacing between clock traces and others. If you have to

use serpentine to match trace lengths on similar chips, make sure

that you have at least 0.018-inch spacing for serpentines. Please see

Figure 2 below.

0.014"

Stacking

At low speeds, currents follow the least resistance path, but at high

speeds current follows the least inductance path. The lowest

inductance return path lies directly under the signal conductor.

0.018"

Figure 2: Clock Trace Spacing Guidelines

4

PS8382B 03/20/02

Schematic Drawing

PI6C2502

Phase-Locked Loop Clock Driver

3.3V

Power

Supply

1.5µH

Clock Chip Layout

4.7µF

.22µF

PI6C2502

AGND

FB_OUT

CLK_OUT

.002µF

VCC

Decoupling Capacitors

Series Terminating Resistor

PI6C2502

CLK_IN

AVCC

GND

FB_IN

INPUT_CLOCK

25-150 MHZ

4.7µF

5-12pF

Feedback

Capacitor

AVCC Island for PI6C2510

.22µF

.002µF

1.5µH

Board

AVCC

GND

AGND

FB_OUT

R

C

C

C

L

VCC

CLK_OUT

Use Wider Traces for Ground and Power

(0.034-inch width, 0.1-inch pitch)

Legend:

GND = Via to Digital Ground

AGND = Via to Analog Ground

VCC = Via to 3.3V Digital Power

AVCC = Via to 3.3V Analog Power

R = Termination Resistor 12-32Ω

C = Decoupling Capacitor

L = Inductor

CFB = Feedback Capacitor

GND

FB_IN

AVCC

L

CFB

C

C

C

5

CLK_IN

AGND

AGND

AGND

GND

PS8382B 03/20/02

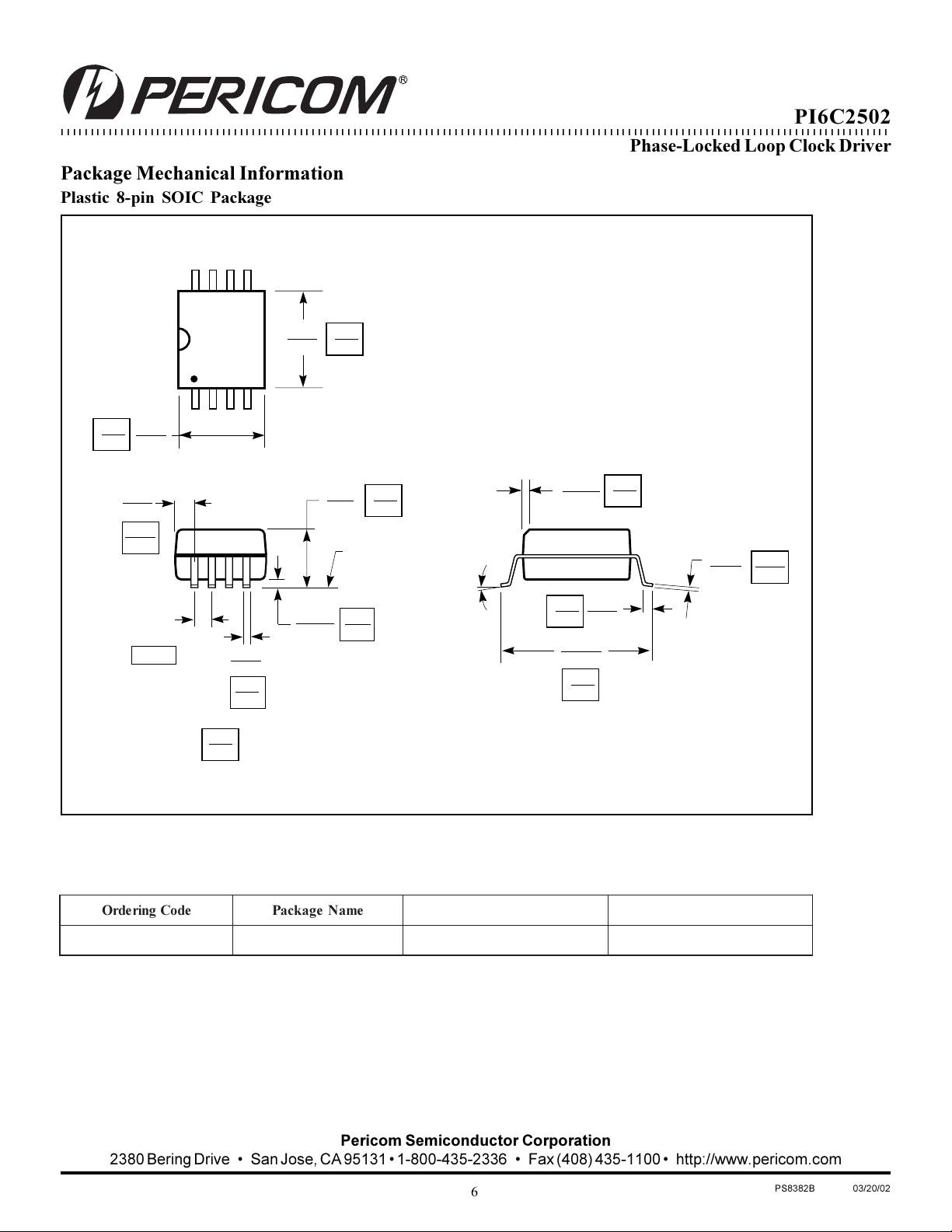

Package Mechanical Information

Plastic 8-pin SOIC Package

8

.149

.157

PI6C2502

Phase-Locked Loop Clock Driver

3.78

3.99

4.80

5.00

REF

.189

.196

.016

.026

0.406

0.660

.050

BSC

1.27

1

X.XX

X.XX

.053

.068

.0040

.0098

.013

.020

0.330

0.508

DENOTES DIMENSIONS

IN MILLIMETERS

1.35

1.75

SEATING PLANE

0.10

0.25

0-8˚

.0099

.0196

0.40

1.27

.2284

.2440

5.80

6.20

.016

.050

0.25

0.50

x 45˚

.0075

.0098

0.19

0.25

Ordering Information

edoCgniredrOemaNegakcaPepyTegakcaPegnaRgnitarepO

W2052C6IP8WCIOSlim-051nip-8laicremmoC

2380 Bering Drive San Jose, CA 95131 1-800-435-2336 Fax (408) 435-1100 http://www.pericom.com

Pericom Semiconductor Corporation

6

PS8382B 03/20/02

Loading...

Loading...