SKYDECK

Panel Slab Formwork

Instructions for Assembly and Use – Standard Confi guration

Edition 09 | 2016

Content

Overview

Main components 1

Key 2

Presentational reference 2

Introduction

Target groups 3

Additional technical documentation 3

Intended use 4

Care and maintenance instructions 5

Instructions for Use 5

Safety instructions

Cross-system 6

System-specific 7

Storage and transportation 7

Standard configuration

A1 Storage and transportation 8

A2 System components 11

A3 System dimensions 14

Notes regarding static calculations 14

Internal forces and rigidity 15

Load combinations 15

A4 Shuttering 17

Starting bay 17

Transverse bay 19

Longitudinal bay 20

Standard bay 21

A5 Compensations 24

System components 24

Edge Beam SRT 150, SRT 75 24

Filler Timber SPH 24

End Support SSL 24

Combihead SCK 25

Triangular Frame SDR 150/75, 75/75 28

Longitudinal compensations 28

Transverse compensations 31

A6 Shuttering around columns 34

1 recessed panel 34

2 recessed panels 35

3 recessed panels 36

Recessed main beams 37

Shifting the main beam axis 37

A7 Horizontal bracing 38

Transfer of horizontal loads into the

columns of the building 38

General 39

Bracing of the inner bay 39

Transfer of horizontal loads from a

casting segment 40

A8 Cantilevers, Guardrails 42

Bracing on leading edges to prevent

tipping 42

Guardrails with Handrail Unit SD 43

SKYDECK Guardrail Holder SGH and

Guardrail Post SGP 44

A9 SKYDECK platforms 46

Corner table (Area l) 47

Cantilevers (Area ll) 51

Open edge areas (Area lll) 52

Slab areas (Area lV) 52

Infill areas 52

Platform installation 53

Striking 54

Working and safety scaffold 55

A10 Changing direction 56

– System with Prophead SSK 56

– System with Drophead SFK 58

A11 Inclined slabs 60

Bracing with Tension Sleeve SAO and

Chain 3.0 kN 60

Bracing with Tension Unit SD 61

A12 Striking 62

A13 Site record 64

Design tables

A14 Horizontal loads with Slab Props PEP 65

A15 Inclined slabs 66

Maximum permissible slab inclination with

Tension Sleeve SAO and Chain 3.0 kN 66

Tension Unit SD – bracing angle 66

Tensile force of Tension Unit SD and

prop loads

– System with Drophead SFK 67

– System with Prophead SSK 70

A16 SKYDECK standard configuration 73

Prop loads

– System with Drophead SFK 73

– System with Prophead SSK 74

– Panel system 75

Striking guide values 75

A17 Filler plates, forming around columns 76

A18 Slab props 77

– PEP 20 77

– PEP 20 with Base MP 50 78

– PEP 30 79

– PEP 30 with Base MP 50 80

– PEP Ergo B 81

– PEP Ergo D 82

– PEP Ergo E 83

– MULTIPROP 250, 350, 480, 625 84

Components

Components

86

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

Overview

Main components

4

3

1

2

1 Drophead SFK

2 Main Beam SLT 225

3 Panel SDP

4 Cover Strip SAL

1

2

1

Instructions for Assembly and Use – Standard Configuration

3

4

SKYDECK Panel Slab Formwork

Overview

Key

Pictogram | Definition

Safety instructions

Note

Load-bearing point

Visual check

Tip

Personal protective equipment

to prevent falling from a height

(PPE)

Misapplication

Correct application

Dimension specifications

Dimensions are usually given in cm.

Other units of measure, e.g. m, are

shown in the illustrations.

Load details are usually given in kg.

Other measurement units, e.g. t, are

specified in the illustrations.

Conventions

Instructions are numbered with:

1. ..... , 2. ...... , 3. .....

The result of an instruction is shown

by:

Position numbers are clearly provided

for the individual components and are

given in the drawing, e.g. 1, in the

text in brackets, for example (1).

Multiple position numbers, i.e. alter-

native components, are represented

with a slash, e.g. 1 / 2.

Arrows

Arrow representing an action

Arrow representing a reaction of an action*

Forces

Presentational reference

The illustration on the front cover of

these instructions is understood to be a

system representation only. The assembly steps presented in these Instructions for Assembly and Use are shown

in the form of examples with only one

component size. They are valid accordingly for all component sizes contained

in the standard configuration.

For a better understanding, detailed illustrations are partly incomplete. The

safety installations which have possibly

not been featured in these detailed

drawings must nevertheless still be

available.

* If not identical to the action arrow

2

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

Introduction

Target groups

Contractors

These Instructions for Assembly and

Use are designed for contractors who

use the formwork systems for

assembling, modifying and disman-

tling, or

use them, e.g. for concreting, or

for other operations, e.g. carpentry or

electrical work.

Construction site coordinator

The Safety and Health Protection Coordinator*

is appointed by the client,

must identify potential hazards during

the planning phase,

determines measures that provide

protection against risks,

creates a safety and health plan,

coordinates the protective measures

for the contractor and site personnel

so that they do not endanger each

other,

monitors compliance with the protec-

tive measures.

Competent persons

Due to the specialist knowledge gained

from professional training, work experience and recent professional activity,

the competent person has a reliable understanding of safety-related issues and

can correctly carry out inspections. Depending on the complexity of the test to

be undertaken, e.g. scope of testing,

type of testing or the use of a certain

measuring device, a range of specialist

knowledge is necessary.

Qualified persons

Formwork systems may only be assembled, modified or dismantled by personnel who are suitably qualified to do so.

For the work to be carried out, the qualified persons must have received instructions** which contain at least the

following points:

Explanation of the plan for the assem-

bly, modification or dismantling of the

formwork in an understandable form

and language.

Description of the measures for as-

sembling, modifying or dismantling

the formwork.

Designation of the preventive meas-

ures to avoid the risk of persons and

objects falling.

Designation of the safety precautions

in the event of changing weather conditions which could adversely affect

the safety of the formwork system as

well as the personnel concerned.

Details regarding the permissible

loads.

Description of any other risks that are

associated with the assembly, modification or dismantling procedures.

In other countries, ensure that the

relevant national guidelines and regulations in the respective current

version are complied with!

* Valid in Germany: Regulations for Occupa-

tional Health and Safety on Construction

Sites 30 (RAB 30)-

** Instructions are given by the contractor him-

self or a competent person selected by him.

Additional technical documentation

Poster: SKYDECK

MULTIPROP Slab Props: Instructions for Assembly and Use

PEP Ergo Slab Props: Instructions for Assmbly and Use

Instructions for Use:

– Pallet Lifting Truck

– Pallets and Stacking Devices

– Stripping Cart ASW 465

– Stripping Cart Alu

– Transportation Fork SKYDECK SUG

Technical Data Sheet for Anchor Bolt PERI 14/20 x 130

PERI Design Tables – Formwork and Shoring

Brochures:

– SKYDECK

– SKYDECK Beam Waler SD

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

3

Introduction

Intended use

Product description

PERI products have been designed for

exclusive use in the industrial and commercial sectors by qualified users only.

PERI SKYDECK is a panel slab formwork system used for constructing slab

thicknesses up to 109 cm. Depending

on the slab thickness and concrete

strength, the SKYDECK Drophead allows striking to take place after only 1

day: see table containing minimum concrete strength and striking guide values.

The SKYDECK Platform is a prefabricated, folding scaffold platform for use as

working and safety scaffold according

to DIN 4420 Part 1. Immediately after

concreting, it is available as safety scaffold to provide safe and secure working

conditions on rising structures.

Classification is effected in Scaffold

Group 2 (useful load per surface

150 kg/m²) . It is required for concreting

floor slabs in skeleton construction

(high-rise buildings) and for securing the

open edges of the SKYDECK Slab

Formwork System. A 1.30 m wide platform with guardrails provides safe working conditions on the slab edges.

Features

The panels and main beams are made

of aluminium which means they are

very light.

Accessories for infill areas, shuttering

around columns and the slab edges are

also available.

Due to early striking, the panels and

main beams can be used for the next

concreting cycle.

Only the props with dropheads and the

cover strips remain in position until the

full concrete strength has been reached.

On-site material requirements are therefore clearly reduced.

For supporting the SKYDECK panels,

PERI MULTIPROPs or PEP Slab Props

can be used.

The SKYDECK Platform consists of:

– 39 mm thick plywood decking fixed

to a supporting frame,

– a folding handrail unit that is screwed

to the supporting frame as a framed

construction, and held by a securing

lever when opened up.

The platform can be used on the edge

of the floor slab as well as in the corner

table area. For the various applications,

three lengths are available.

SDB 150 L = 1.50 m

SDB 225 L = 2.25 m

SDB 300 L = 3.00 m

The SDB 225 Platform can also be used

for side cantilevers of 75 cm to the right

or left of the main beam.

Technical data

System dimensions

With Drophead SFK,

Main Beam SLT 225

230 x 150 cm, slab thickness max.

43 cm, as standard case presented in

the Instructions for Assembly and

Use

230 x 75 cm, slab thickness max.

90 cm

115 x 75 cm, slab thickness max.

109 cm with centre support

With Drophead SFK,

Main Beam SLT 150

155 x 150 cm, slab thickness max.

52 cm

155 x 75 cm, slab thickness max.

109 cm

With Prophead SSK,

Main Beam SLT 225

225 x 150 cm, slab thickness max.

43 cm

225 x 75 cm, slab thickness max.

90 cm

112.5 x 75 cm, slab thickness max.

109 cm with centre support

With Prophead SSK,

Main Beam SLT 150

150 x 150 cm, slab thickness max.

55 cm

150 x 75 cm, slab thickness max.

109 cm

For permissible slab thicknesses and

available prop loads: see PERI Design

Tables.

Assembly of the platform takes place

with the crane from the outside of the

building. It is set down on the cantilevered main beams and automatically

locks in position.

All steel parts are galvanized while all

safety components are red powder-coated.

4

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

Introduction

Care and maintenance instructions

In order to maintain the value and operational readiness of the formwork materials over the long term, clean the elements after each use.

Some repair work may also be inevitable due to the tough working conditions.

The following points should help to keep

care and maintenance costs as low as

possible.

Spray the formwork on both sides with

concrete release agent before each use;

this allows easier and faster cleaning of

the formwork. Spray the concrete release agent very thinly and evenly!

Spray the rear side of the formwork

with water immediately after concreting; this avoids any time-consuming and

costly cleaning operations.

When used continuously, spray the panel formlining with the concrete release

agent immediately after striking; then

clean by means of a scraper, brush or

rubber lip scraper.

Important: do not clean formlining made

of plywood with high-pressure equipment; this could result in the formlining

being damaged.

Fix box-outs recesses and mounting

parts with double-headed nails; as a result, the nails can be easily removed later, and damage to the formlining is

largely avoided.

Close all unused anchor holes with

plugs; this eliminates any subsequent

cleaning or repair work.

Anchor holes accidentally blocked with

concrete are freed by means of a steel

pin from the formlining side.

When placing bundles of reinforcement

bars or other heavy objects on horizontally-stored formwork elements, suitable support, e.g. square timbers, is to

be used; as a result, impressions and

damage to the formlining are largely

avoided.

Internal concrete vibrators should be fitted with rubber caps if possible; as a result, any damage to the formlining is reduced if the vibrator is accidently “inserted” between the reinforcement and

formlining.

Never clean powder-coated components, e.g. elements and accessories,

with a steel brush or hard metal scraper;

this ensures that the powder-coating remains intact.

Use spacers for reinforcement with

large-sized supports or extensive areas

of support; this largely avoids impressions being formed in the formlining

when under load.

Mechanical components, e.g. spindles

or gear mechanisms, must be cleaned

of dirt or concrete residue before and after use, and then greased with a suitable lubricant.

Provide suitable support for the components during cleaning so that no unintentional change in their position is possible.

Do not clean components when suspended on a crane.

Instructions for Use

The use in a way not intended according

to the Instructions for Assembly and

Use, or any use deviating from the

standard configuration or the intended

use represents a misapplication with a

potential safety risk, e.g. risk of falling.

Only PERI original components may be

used. The use of other products and

spare parts is not allowed.

Changes to PERI components are not

permitted.

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

5

Safety instructions

Cross-system

General

The contractor must ensure that the Instructions for Assembly and Use supplied by PERI are available at all times

and are understood by the site personnel.

These Instructions for Assembly and

Use can be used as the basis for creating a risk assessment. The risk assessment is compiled by the contractor. The

Instructions for Assembly and Use do

not replace the risk assessment!

Always take into consideration and comply with the safety instructions and permissible loads.

For the application and inspection of

PERI products, the current safety regulations and guidelines must be observed

in the respective countries where they

are being used.

Materials and working areas are to be

inspected on a regular basis especially

before each use and assembly for:

signs of damage,

stability and

function.

Damaged components must be exchanged immediately on site and may

no longer be used.

Safety components are to be removed

only when they are no longer required.

Components provided by the contractor

must conform with the characteristics

required in these Instructions for Assembly and Use as well as with all valid

construction guidelines and standards.

In particular, the following applies if

nothing else is specified:

Timber components: Strength

Class C24 for Solid Wood according

to EN 338.

Scaffold tubes: galvanised steel

tubes with minimum dimensions of

Ø 48.3 x 3.2 mm according to

EN 12811-1:2003 4.2.1.2.

Scaffold tube couplings according

to EN 74.

Deviations from the standard configuration are only permitted after a further

risk assessment has been carried out by

the contractor.On the basis of this risk

assessment, appropriate measures for

working and operational safety as well

as stability are to be determined.

Corresponding proof of stability can be

provided by PERI on request if the risk

assessment and resulting measures to

be implemented are made available.

Before and after exceptional occurrences that may have an adverse effect regarding the safety of the formwork system, the contractor must immediately

create another risk assessment,

with appropriate measures for ensuring the stability of the formwork

system being carried out based on

the results,

and arrange for an extraordinary in-

spection by a competent person.

The aim of this inspection is to

identify and rectify any damage in

good time in order to guarantee the

safe use of the formwork system.

Exceptional occurrences can include:

accidents,

longer periods of non-use,

natural events, e.g. heavy rainfall,

icing, heavy snowfall, storms or

earthquakes.

Assembly, modification and dismantling work

Assembly, modification or dismantling

of formwork systems may only be carried out by qualified persons under the

supervision of a competent person. The

qualified persons must have received

appropriate training for the work to be

carried out with regard to specific risks

and dangers.

On the basis of the risk assessment and

Instructions for Assembly and Use, the

contractor must create installation instructions in order to ensure safe assembly, modification and dismantling of

the formwork system.

The contractor must ensure that the

personal protective equipment required

for the assembly, modification or dismantling of the system, e.g.

safety helmet,

safety shoes,

safety gloves,

safety glasses,

is available and used as intended.

If personal protective equipment against

falling (PPE) is required or specified in

local regulations, the contractor must

determine appropriate attachment

points on the basis of the risk assessment.

The personal protective equipment

against falling to be used is determined

by the contractor.

The contractor must

provide safe working areas for site

personnel which are to be reached

through the provision of safe access ways. Areas of risk must be

cordoned off and clearly marked.

ensure the stability during all stag-

es of construction, in particular during assembly, modification and dismantling of the formwork.

ensure and prove that all loads can

be safely transferred.

Utilisation

Every contractor who uses or allows

formwork systems or sections of the

formwork to be used, has the responsibility for ensuring that the equipment is

in good condition.

If the formwork system is used successively or at the same time by several

contractors, the health and safety coordinator must point out any possible mutual hazards and all work must be then

coordinated.

6

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

Safety instructions

System-specific

Retract components only when the concrete has sufficiently hardened and the

person in charge has given the goahead for striking to take place.

Anchoring is to take place only if the anchorage has sufficient concrete

strength.

In order to avoid an overloading of the

integrated temporary props, the

load-bearing capacity of the slabs,

plates and beams which have already

been completed must be activated. For

this, a free deflection possibility of

these components is required. This

takes place by releasing and re-installing

all existing temporary props, and is also

required for formwork systems where

the prop head is an integral part of the

slab formwork.

The load-distributing support used, such

as planking, must match the respective

base. If several layers are required,

planks are to be arranged crosswise.

During striking, do not tear off the formwork elements with the crane.

The existing prop loads (see Tables)

must be safely transferred by means of

sufficiently load-bearing slab props or

shoring systems.

SKYDECK Platforms are classified in

Load Class 2 (permissible load

1.5 kN/m² – 150 kg/m²). They are available as working scaffold.

The horizontal fixed position of the slab

formwork must be guaranteed. This is

given with circumferential walls and

pre-concreted beams. Otherwise, the

transfer of the horizontal loads has to be

guaranteed by means of other measures

supplied by the contractor, e.g. bracing.

Load assumptions for horizontal loads in

accordance with DIN EN 12812.

When storing heavy items on the formwork, the load-bearing capacity must be

taken into consideration.

Cantilevers may only be accessed after

bracing has been mounted.

With all-round enclosed structure geometries, panels are to be fixed to the main

beams by means of two Panel Clips

SPK (21) each for wind speeds between

0.033 kN/m² (26 km/h) and dynamic

pressure 0.061 kN/m² (36 km/h).

For unfavourable structure geometries

or larger wind speeds, additional securing measures are to be implemented,

e.g.:

– ballast,

– bracing,

– dismantling the formwork etc.

Storage and transportation

Store and transport components ensuring that no unintentional change in their

position is possible. Detach lifting accessories and slings from the lowered

components only if they are in a stable

position and no unintentional change is

possible.

Do not drop the components.

Use PERI lifting accessories and slings

as well as only those load-bearing

points provided on the component.

During the moving procedure

ensure that components are picked

up and set down so that unintentional

falling over, falling apart, sliding, falling down or rolling is avoided.

no persons are allowed to remain un-

der the suspended load.

Always guide pre-assembled scaffolding bays, scaffolding units or scaffolding

sections with ropes when moving them

by crane.

The access areas on the jobsite must be

free of obstacles and tripping hazards as

well as being slip-resistant.

For transportation, the surface must

have sufficient load-bearing capacity.

Use original PERI storage and transport

systems, e.g. crate pallets, pallets or

stacking devices.

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

7

A1 Storage and transportation

– Instructions for Use for PERI Pallet

and Stacking Devices must be

followed at all times!

– Manually-created transport units

must be correctly stacked and

secured!

– Pallets and stacked components

are to be protected against the effects of the weather, e.g. secure

packed components with tension

straps against lifting!

– Always attach the 4-sling lifting

gear using the four load-bearing

points!

Tra n s por t

PERI pallets and stacking devices are

suitable for lifting by crane or forklift.

They can also be moved with the PERI

Pallet Lifting Trolley. All pallets and

stacking devices can be lifted using

both the longitudinal and front sides.

The following are some examples.

Fig. A1.01 Fig. A1.02

Stacked with Panels SDP 150 x 75

Pallet SD: 48 pieces

(Fig. A1.01 + A1.02)

Pallet SD: 14 pieces

(Fig. A1.04 + A1.05)

The Pallet SD can also be used for

storing other SKYDECK components,

e.g. Main Beam SLT. (Fig. A1.03)

Lashing straps are manufactured according to DIN EN 12195-2, and are to

be regularly checked in accordance with

this standard.

Stacking:

2 loaded pallets, one on top of the other.

Fig. A1.04 Fig. A1.05Fig. A1.03

8

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A1 Storage and transportation

Pallet: Handrail Unit SD 150

Pallet: Handrail Unit SD 75

Number of handrail units per pallet

Handrail Unit SD 150: 10 pieces

(Fig. A1.06)

Handrail Unit SD 75: 10 pieces

(Fig. A1.07)

Stacking:

2 loaded pallets, one on top of the other.

Loading sequence

1. Open locking mechanism on the pallet frame.

2. Slide in one handrail unit and close

locking mechanism.

3. Slide in additional handrail units.

Handrail units lock automatically

above the red bars.

4. Secure handrail units on the front side

against sliding out. Insert retaining bar

and lock in place.

Due to the powder coating, cleaning

requirements are kept to a minimum.

Panels and main beams are equipped

with self-draining edges. They prevent

the side areas from getting dirty and

make cleaning easier.

(Fig. A1.08)

Fig. A1.06

Fig. A1.07

Fig. A1.08

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

9

A1 Storage and transportation

SKYDECK Platforms

The platforms can be stored in stacks of

up to 5 elements.

Weights:

SDB 300 184 kg / piece

SDB 225 155 kg / piece

SDB 150 108 kg / piece

Stacks of platforms can be lifted with a

fork-lift truck using the long side.

(Fig. A1.09)

The stack can be moved with the crane

by means of the external crane eyes.

(Fig . A1.10 )

Ensure the platforms are evenly secured

on lorries but not too tightly.

Fig. A1.09

Crane Eye

Fi g. A1.10

31,4

Crane Eye

10

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A2 System components

Propheads

Drophead SFK (1)

Prophead SSK (6)

Combihead SCK (7)

Transition Head SDSK (26)

Transition Head SDFK (27)

The Drophead SFK can be used for all

standard situations and allows the removal of main beams and panels while

simultaneously supporting the slab.

The Prophead SSK must be used in all

starting fields. Prophead SSK and

Combihead SCK are used, e.g. for compensations.

Prophead SDSK and Prophead SDFK are

used when changing direction.

1

26

6

7

27

Main beams

– Main Beam SLT 225

– Main Beam SLT 150

For the exclusive use with the

SKYDECK Platform SDB, a main beam

which can accommodate the Platform

SDB is available.

It may only be used for the described

purposes.

– Main Beam SLT 375

Panel SDP

The Panel SDP is available with the following dimensions:

– Panel SDP 150x75

– Panel SDP 150x50

– Panel SDP 150x37.5

– Panel SDP 75x75

– Panel SDP 75x50

– Panel SDP 75x37.5

Fig. A2.01

Fig. A2.02

Fig. A2.03

Cover Strip SAL

The Cover Strip SAL is available with

the following dimensions:

– Cover Strip SAL 150

– Cover Strip SAL 75

– Cover Strip SAL 50

– Cover Strip SAL 37.5

Fig. A2.04

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

11

A2 System components

Slab props

Dropheads SFK, Propheads SSK, SDFK

or Combiheads SCK fit on props with a

hole diameter of ø 38 – 40 mm.

With hole diameters > 40 mm, the

heads must be bolted diagonally using 2

Bolts ISO 4016 M12 x 40-4.6 galv., Mu,

item no. 035440. (Fig. A2.01)

26

1.2

1.1

II.

I.

Transition Heads SDSK (26) must always be bolted: see A9 Changing direction.

Prop loads over 33.3 kN:

bolting on of drophead for use with PEP

Slab Props using 2 Bolts DIN EN ISO

4016 M12 x 40-4.6 galv., Mu.

Preparing the Drophead

1. Push drophead wedge (1.1) and Drophead (1.2) upwards as far as possible.

(Fig. A2.06)

2. Insert drophead wedge.

3. Secure with hammer blow = shuttering position.

Drophead SFK is ready for use.

Preparing the slab props

1. Adjust the extension lengths of the

props. Clear room height minus

dimension x (Fig. A2.07). Take into

consideration the different overall

heights of the main beams: Main

Beam SLT 225 = 24 cm / Main Beam

SLT 150 = 19 cm.

2. Insert the prepared Drophead (1),

Prophead (6) or Combihead (7) into

the prop. The self-locking coupling is

secured automatically. (Fig. A 2.01)

The prop is ready for use.

Fig. A2.05

Starting bay

Main Beam SLT 225

x = 41

6

Starting bay

Main Beam SLT 150

1, 6, 7, 27

Fig. A2.06

End bay

Main Beam SLT 225

x = 41

1

6

x = 33

End bay

Panel SDP

12

Fig. A2.07

x = 36

6

1

x = 41

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

x = 17

6

A2 System components

SKYDECK Platforms SDB

SKYDECK Platform SDB 150

SKYDECK Platform SDB 225

SKYDECK Platform SDB 300

External crane eye

Frame

Handrail

Internal crane

eye, retracted

Decking

Box out for shuttering aid

Abb. A2.08

Preparation for Use:

Slide

Stacking base

Internal crane eye,

retracted

External crane eye

Securing lever

Internal crane eye,

raised

Slide

Internal crane eye

Take individual platforms from the stack,

fold open the handrail and the securing

lever drops down and secures it in a

vertical position. (Fig. A2.09)

Is the securing lever engaged? Otherwise it may be necessary to secure it by

hand.

For transportation by crane, the platform is attached to the concealed crane

eyes with the two-sling lifting gear.

(Fig . A 2.10)

Fig. A2.09

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

Fi g. A 2.10

Handrail

Securing lever

13

A3 System dimensions

Notes regarding static calculations

This design information is used for the design and planning of the SKYDECK Slab Formwork System.

It covers standard configurations for slab thicknesses from 0.14 m to 1.09 m.

Comparison of the design method

The design concept with partial safety

factors

R

k

R

d

E

d

γ

F

F

k

Method of proof Method of proof

R

k

≥

Fk · γ

γ

M

R

≥

d

F

E

d

Key

= characteristic resistance

R

k

= design value of the resistance

R

d

= F

F

k

= design value of the action

E

d

= Rk = characteristic resistance (e.g. breaking load)

F

ult.

F

= permissible load-bearing capacity

perm.

= actual or characteristic action

actual

Rd ≥ E

The old design concept with the

global safety factor

(see PERI Design Tables)

(= Rk)

F

ult.

γ

tot.

d

F

perm.

F

≥ F

F

(= Fk)

actual

F

ult.

≥

F

(= Fk)

γ

tot.

perm.

= partial safety factor for the material

γ

M

actual

≥

F

actual

(= Fk)F

perm.

actual

(steel ≈ 1.1 / concrete ≈ 1.5)

= partial safety factor for the load

γ

F

(permanent = 1.35 / changeable = 1.5)

= global safety factor ≈ γM · γF

γ

tot.

(steel ≈ 1.65 / concrete ≈ 2.25)

Design method used in this design

information

This design information is based on the

design concept with the global safety

factor.

The tables of the prop loads include the

permissible load-bearing capacities

F

perm.

After multiplication using γF = 1.5, the

maximum load-bearing capacity can

also be converted into a design value of

the resistance R

for the method with

d

partial safety factors.

14

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A3 System dimensions

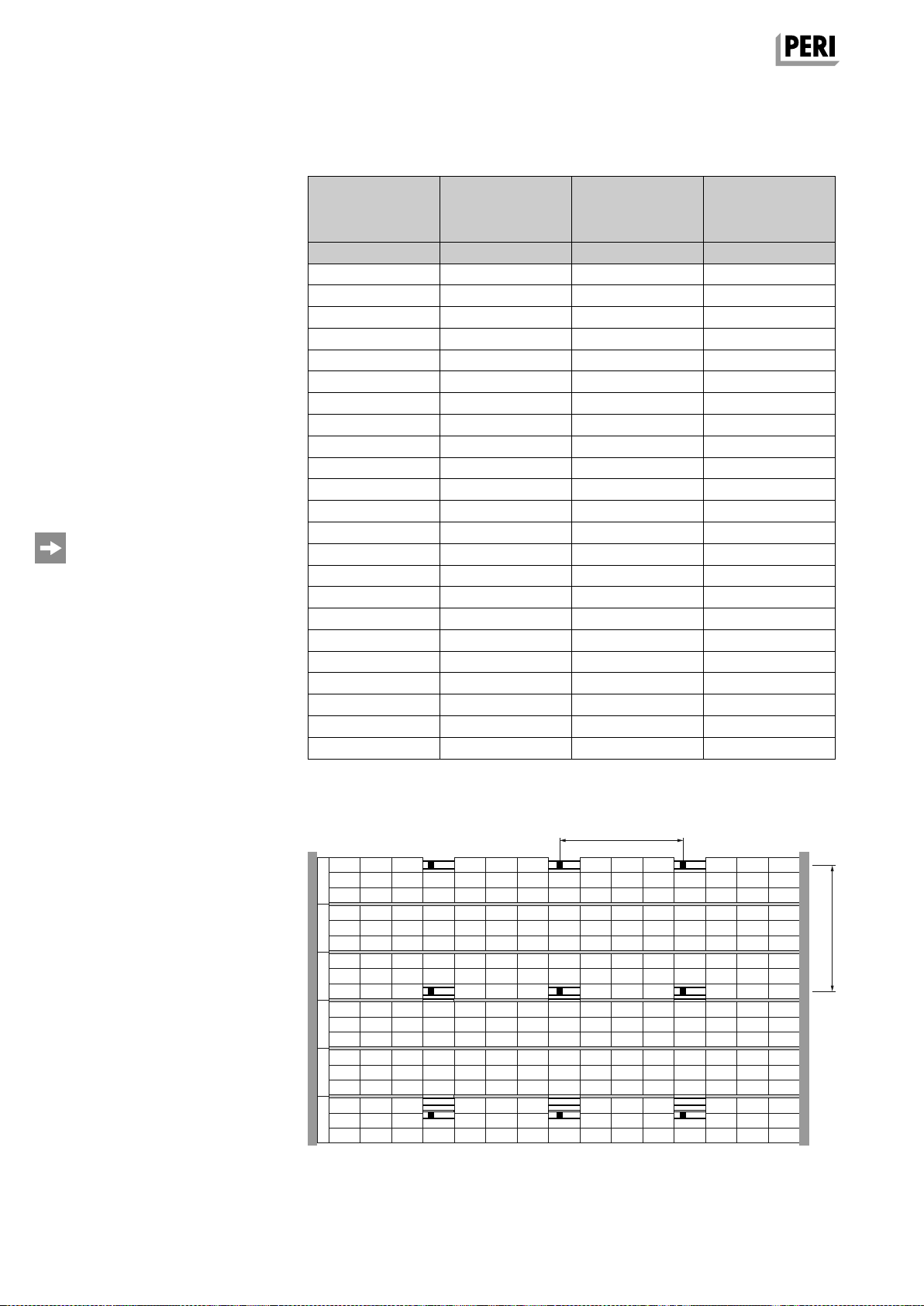

Internal forces and rigidity

Permissible internal forces and rigidity for the design with single-span girders

perm. M

Item no. Designation

061100 16.0 22.0 119 8

06116 0 12.6 22.0 1198

061110 11.3 18.0 656

061045 2.9 8.0 91

061045 2.1 8.0 31

061047 3.0 8.0 88

061047 2.1 8.0 28

061049 0.7 2.4 32

061049 0.4 1.7 7

061050 0.6 2.4 29

061050 0.3 1.3 7

Main Beam SLT 225

Main Beam SLT 375

Main Beam SLT 150

Edge Beam SRT-2 150

Edge Beam SRT-2 turned

Edge Beam SRT-2 / 27

Edge Beam SRT-2 / 27 turned

Filler Timber SPH 150

Filler Timber SPH turned

Filler Timber SPH / 27

Filler Timber SPH / 27 turned

[kNm]

perm. Q

[kN]

Load combinations

Vertical loads

Concreting

(according to DIN EN 12812)

SKYDECK dead load Q

Concrete load Q

Equivalent load concreting Q

0.75 kN/m² ≤ Q4 ≤ 1.75 kN/m²

Equivalent load working

conditions Q

= 0.20 kN/m²

1

= 24.5 kN/m³ x d [m]

2,b

= 0.10 x Q

4

= 0.75 kN/m²

2,p

2,b

El

[kNm

2

]

Table A3.01

+ Q

+ Q

Total loa d Q = Q

1

2,b

2,p

+ Q

4

SKYDECK Platforms SDB

(according to DIN EN 12811)

Load Class 2 q

F

= 1.50 kN/m²

1

= 1.50 kN (500 x 500 mm²)

1

Horizontal loads

Horizontal load from working operations = 1% of the vertical load (DIN EN 12812; 8.2.2.2)

Horizontal load from the tilting position = 1% of the vertical load (DIN EN 12812; 9.3.4.2)

Wind loads

Working wind dynamic pressure q

Maximum wind speed dynamic pressure q

= 0.20 kN/m² (DIN EN 12811-1; 6.2.7.4.2)

W,A

= 0.60 kN/m²

W,max

Height of the substitute area for equipment and materials on the scaffold level

LF working wind h

= 0.40 m (DIN EN 12811-1, 6.2.7.4.2)

W,A

Height of the substitute area for equipment and materials on the scaffold level

LF maximum wind speed h

= 0.20 m (DIN EN 12811-1, 6.2.7.4.1)

W,max

Wind on the side protection

Working wind speed on SKYDECK Guardrail Holder SGH and Guardrail Post SGP

q

= 0.183 kN/m

W,A, S

Maximum wind speed with SKYDECK Guardrail Holder SGH and Guardrail Post SGP

q

= 0.550 kN/m²

W,max,S

SKYDECK Paneel Deckenschalung

Aufbau- und Verwendungsanleitung – Regelausführung

15

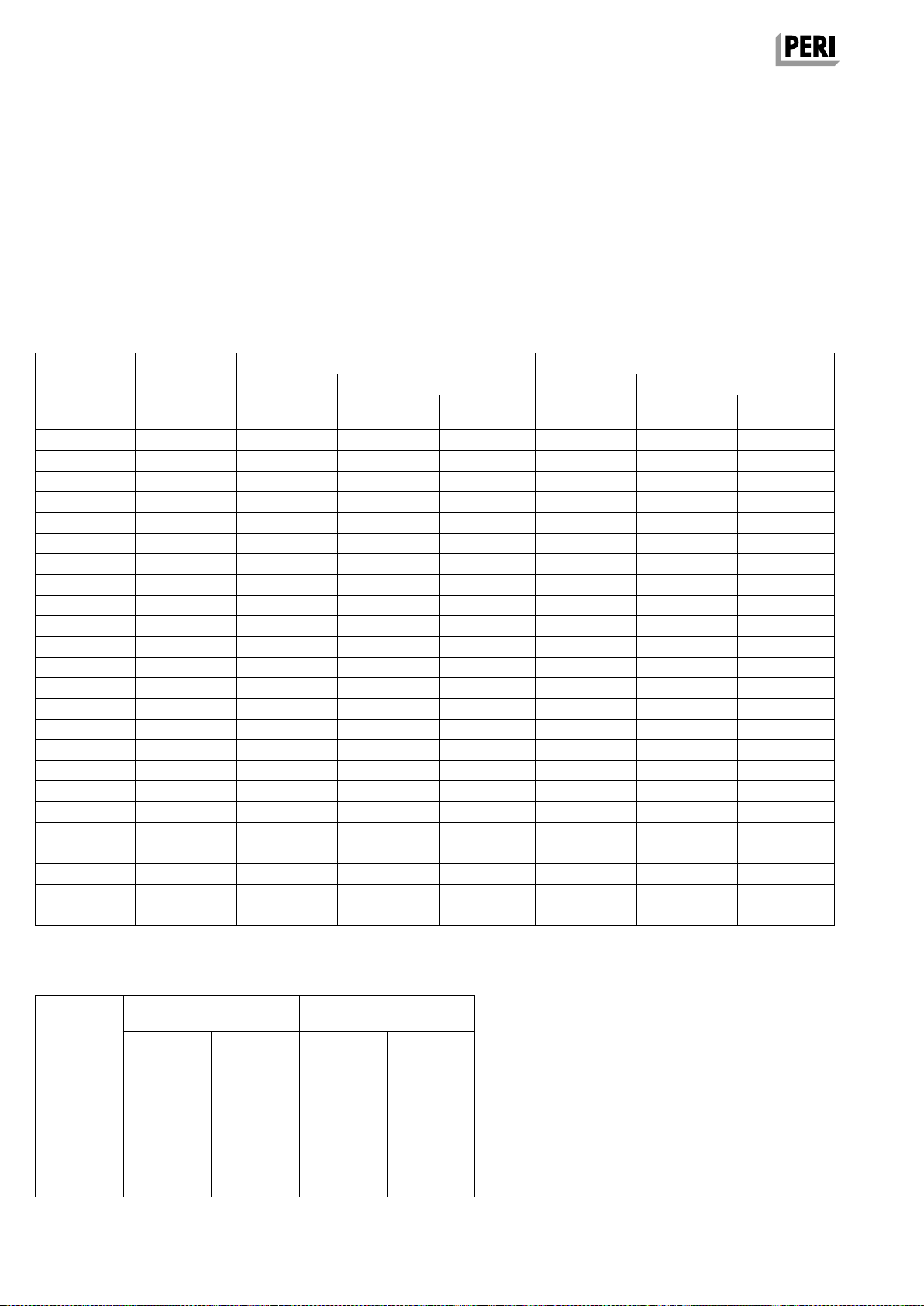

A3 System dimensions

Overview of the required frames:

MRK with the use of MULTIPROP Towers

PRK with the use of PEP Props

Frames

62.5 Steel

75 Steel

137.5 Steel

150 Steel

201.5 Alu

225 Alu

230 Alu

Table A3.0 2

MRK

Item no.

PRK

Item no.

028390 111811

028400 111812

028380 1118 13

028350 1118 14

028460 111815

028360 1118 16

028470 111817

SKYDECK system

– Inset beam at wall beginning with 75 cm panel span.

– Inset prop at wall beginning with Combihead.

– Panel span 75 cm.

– Inset beam at wall beginning with 150 cm panel span.

– Panel span 150 cm.

– Inset prop at wall beginning under SLT 225 with Prophead

or Combihead.

– SLT 225 on Prophead or Combihead.

– Use of Cantilever Beam SLT 375 on Prophead/Combihead

or corner tables.

– SLT 225 on Dropheads.

625

125

235

2015

2250

Fig. A3.01 Fig. A3.02

MRK

PRK

62,5

MRK / PRK 201,5

MRK

PRK

62,5

MRK / PRK 225

750

MRK

PRK

75

MRK / PRK 201,5MRK / PRK 225

MRK

PRK

75

MRK / PRK 201,5

125

235

2015

2300

1375 1500

MRK / PRK 137,5

MRK / PRK 201,5

MRK / PRK 137,5

MRK / PRK 230

MRK / PRK 150

MRK / PRK 201,5

MRK / PRK 150

MRK / PRK 230

150 0

MRK / PRK 150

2250

MRK / PRK 201,5

MRK / PRK 225

MRK / PRK 150

Fig. A3.03

MRK / PRK 225

3750

16

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A4 Shuttering

Starting bay

Shuttering using a safe mobile

scaffold!

Position props and main beams

1. Position prop with Prophead (6) in

one corner of the room (spacing: see

Fig. A4.05).

2. Secure with tripod to prevent it from

falling over.

3. Position prop with Drophead (1). Distance from the wall 2.275 m.

(Fig. A4.01)

4. Secure with tripod to prevent it from

falling over.

5. Insert Main Beam SLT 225 (2) into the

beam support of the Prophead and

Drophead. The main beam connection (2.1) must be mounted in the

middle of the beam support (1.2) of

the SKYDECK heads. (Fig. A4.02a /

A4.02b / A4.02c)

6. Secure Main Beam SLT 225 (2) with

Wall Holder SWH-2 (8).

7. Position second pair of props at a distance of 1.50 m from the wall.

8. Insert Main Beam SLT 225 (2) in the

beam support. (Fig. A4.02a / A4.02b /

A4.02c / A4.04)

6

Fig. A4.01

2.1

2

1

1.2

Fig. A4.02a

1.2

Fig. A4.02b

Fig. A4.02c

1

8

Does the main beam connection (2.1)

enclose the beam support (1.2)?

(Fig. A4.02c)

Set up drophead props on the wall so

that the drophead wedge can be removed during striking.

The Main Beam SLT is always positioned parallel to the longer wall side.

Always check the rectangularity of the

first bay.

Components

1 Drophead SFK

2 Main Beam SLT

6 Prophead SSK

8 Wall Holder SWH-2

Fig. A4.03

A

125

1375

Fig. A4.04

Section A-A

150 0

A

250

Fig. A4.05 Fig. A4.05a

2025

2275

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

17

A4 Shuttering

Insert panels

1. Install panels (3) on the Main Beam

SLT 225 (2).

The rack of the Main Beam SLT

fixes the panel in position.

2. Secure wall-side panel and Main

Beam SLT with Wall Holder SWH-2

(8). (Fig. A4.06)

3. Install two additional panels.

(Fig. A4.07)

The starting bay is complete.

(Fig. A4.08)

8

Spray the edge of the panel with release agent before positioning.

Wall Holder SWH-2

The formwork surface area may only

be accessed or loaded when Wall

Holders SWH-2 have been installed!

The Wall Holder SWH-2 (8) is used to

hold the slab formwork in a horizontal

position during the assembly. It is installed in longitudinal and transverse directions, and can fix the main beam as

well as the panel. The Wall Holder

SWH-2 (8) is mounted in every second

bay.

Fig. A4.06

3

Fig. A4.07

Assembly

1. Insert tie rod with wingnut pivot plate

through the available tie hole.

2. Place Main Beam SLT into the Wall

Holder SWH-2 or push into the edge

of the panel.

3. Tighten Wall Holder SWH-2 with

Wingnut Pivot Plate on the wall.

4. Remove tripods. (Fig. A4.08)

The wall holder isassembled.

18

8

Fig. A4.08

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

A4 Shuttering

Transverse bay

1. Position prop with Prophead SSK (6).

Spacing 1.50 m.

2. Secure with tripod.

3. Position prop with Drophead SFK (1).

Spacing 2.275 m.

4. Insert Main Beam SLT 225 (2) into the

beam support of the Prophead and

Drophead. (Fig. A4.09)

5. Secure with tripod.

6. Insert panels (3). (Fig. A 4.10 )

The transverse bay is complete.

(Fig. A4 .11)

Shuttering is carried out using a safe

mobile scaffold!

Working in a transverse direction is recommended.

Use tripods again in the next bay.

1

2

6

Fig. A4.09

3

Components

1 Drophead SFK

2 Main Beam SLT

3 Panel SDP

6 Prophead SSK

8 Wall Holder SWH-2

Fi g. A 4.10

8

1,50 m

2,275 m

Fi g . A4.11

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

19

A4 Shuttering

Longitudinal bay

Based on the risk assessment, the

contractor must decide whether

forming takes place from above or

below!

1. Attach Main Beam SLT 225 (2) to the

Drophead.

2. Connect prop with Drophead in the

main beam. (Fig. A4.12)

3. Place prop in a vertical position.

(Fig . A 4.12a)

4. Secure with tripod.

5. Proceed likewise with the second

main beam and prop.

6. Insert panels (3). (Fig. A4.13)

7. Remove tripod and use again in the

next bay.

The longitudinal bay is now com-

plete. (Fig. A4.14)

α

Fi g. A 4.12 Fig. A4.12a

Optimum angle for mounting the Main

Beam SLT up to α 45°.

α

The main beam is correctly fitted only if

the corner of the recess hangs under

the prop without obstruction.

2

The Wall Holder SWH-2 (8) is mounted in every second bay.

Risk of falling!

– When lingering on the slab form-

work, measures must be taken to

prevent falling, e.g. PPE.

– When shuttering from below, use

a safe and secure mobile scaffold;

install panels overhead.

If the SKYDECK Guardrail Holder is

used, this must be installed during setting of the panels. For details, see Section A8.

Components

2 Main Beam SLT

3 Panel SDP

4 Cover Strip SAL

5 Pallet SD

8 Wall Holder SWH-2

21 Panel Clip SPK

Fi g. A 4.13

3

During forming

from above, press

panel down with

the foot when installing.

8

8

8

8

20

Fi g. A 4.14

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

A4 Shuttering

Standard bay

Due to the recurring assembly sequence, always continue in the same

way.

With all-round enclosed structure geometries, panels are to be fixed by means

of two Panel Clips SPK (21) each time to

the main beams for wind speeds between 0.033 kN/m² (26 km/h) and dynamic pressure 0.061 kN/m² (36 km/h).

For unfavourable structure geometries

or larger wind speeds, additional securing measures are to be implemented,

e.g.:

– ballast

– bracing (Fig. A4.16)

– dismantling the formwork etc.

1. Attach Main Beam SLT 225 (2) to the

Drophead.

2. Connect prop with Drophead SFK in

the raised main beam. (Fig. A4.15)

3. Place prop in a vertical position.

4. Insert panels (3).

The standard bay is now complete.

3

2

Fi g. A 4.15

21

21

Fi g. A 4.16

Fi g. A 4.17

50 mm

The Prophead SSK is not a substitute for the Drophead.

4

Without the Drophead, the Cover

Strip (4) has no supporting effect.

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

21

A4 Shuttering

Shuttering the casting segment

Set down Pallet SD (5) with panels (3)

onto the forming area. Place panels in

the main beams. Make empty pallets

available in preparation for the striking

process. (F ig. A 4 .18)

1. Shutter the standard fields until there

is no more space for the Main Beam

SLT 225 or Compensation Beam

SLT150.

2. Form the infill areas. See A5.

3. Continually insert Cover Strip SAL (4).

(Fig . A 4.19)

4. Thinly spray the forming area with a

release agent – also from below if

used for the first time.

Risk of slipping!

The forming area becomes slippery

through the use of release agents!

– Be extremely careful when access-

ing forming areas after spraying!

– Weather conditions are to be tak-

en into account!

5

3

Fi g. A 4.18

Regarding the tightness of the panel

joints, e.g. for casting segments/setting

of stopends, push the panels tightly

together and secure on the last main

beam with Panel Wedge Clips SPKK

(20).

(Fig. A4.20 – Fig. A4.22)

Panel Wedge Clip SPKK

The panel wedge clip is used to connect

2 panels with one main beam.

Possible applications

1. Panel joint in the middle of main

beam

20

Fi g. A 4.19

2. Overlapping panel Side view

125

20

4

20

Fig. A4.20

22

Fig. A4.21 Fig. A4.22

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

23

A5 Compensations

System components

For the realization of compensations

and shuttering of columns, a range of

system components is available.

Secure filler plates with nails!

Edge Beam SRT 150-2,

SRT 75

Install vertically (Fig. A5.01) or

suspended. (Fig. A5.02)

The locking pin (9.1/10.1) secures

the Edge Beam SRT 150 (9) or

SRT 75 (10):

– to the Main Beam SLT in a longitudi-

nal direction. (Fig. A5.01 + A5.02)

– to the Prophead SSK in a transverse

direction. (Fig. A5.03)

– to the Combihead SCK (7) in a longi-

tudinal direction. (Fig. A5.04)

– in the End Support SSL (11) in a longi-

tudinal direction. (Fig. A5.07)

SRT vertical

9/10

Fig. A5.01 Fig. A5.02

9

Fig. A5.03 Fig. A5.04

9.1/10 .1

The asterisk (*) refers to the installation

in a suspended position.

SRT suspended*

9*/10*

7

12

9

Filler Timber SPH

Install Filler Timber SPH (12) vertically or

horizontally.

– to the Combihead SCK. (Fig. A5.04)

– nailed laterally on the panel.

– horizontally, transverse to the sus-

pended Edge Beam SRT. (Fig. A5.05

+ A5.06)

End Support SSL

Use the End Support SSL as height adjustment for the transition from a standard bay to an infill area.

(Fig. A5.07)

The End Support SSL must always be

directly supported by means of a Prophead, Drophead or Combihead.

(Fig. A5.08)

Components

2 Main Beam SLT

3 Panel SDP

7 Combihead SCK

9 Edge Beam SRT-2 150

9* Edge Beam SRT-2 150, suspended

10 Edge Beam SRT-2 75

10* Edge Beam SRT-2 75, suspended

11 End Support SSL

12 Filler Timber SPH

Fig. A5.05

11

Fig. A5.06

Fig. A5.07

End Support SSL

11

Fig. A5.09Fig. A5.08

No End Support SSL without any direct

support through Prophead, Drophead or

Combihead.

24

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A5 Compensations

Combihead SCK

Use of longitudinal and transverse infills

up to 25 cm.

The cantilever of the Head Plate is in

longitudinal direction ≤ 19 cm, in transverse direction ≤ 12.5 cm.

The Combihead (7) (Fig. A5.11) is a secure, non-movable and non-twisting

support for:

– Main Beam SLT 225 (2).

– SLT 150 (2.5). (F i g. A5.10)

– Panel SDP (3). (Fig. A5.12)

– Edge Beam SRT (9) and Filler Timber

SPH (12) or timber provided by the

contractor with b = 3.8 – 8 cm and

h = 9.8 cm. (Fig. A5.13)

– End Support SSL (11). (Fig. A5.14)

Mounting the main beam

The Main Beam SLT must be mounted

in the middle of the beam support of

the SKYDECK Heads. The main beam

connection (2.1) encloses the main

beam support (7.1) of the head.

(Fig . A 5 .10)

The Combihead SCK has 2 main beam

supports and can be installed in both

directions. In infill areas, the cantilever

points towards the compensation.

2.1

7.1

2/2.5

Fi g. A 5 .10 Fig. A5.11

3

Fi g. A 5 .12

11

7.1

Fi g. A 5 .13

7

9 12

Exceptions:

The cantilever points towards the main

beam

– when using the End Support,

(Fig. A5.14)

– when infill ≤ cantilever. (F i g. A5 .14a)

Placing the main beam

With inset props, the cantilever of the

Combihead always points towards the

main beam.

Position the Combihead so that the

main beam support is securely positioned in the groove (2.8) of the main

beam.

(Fig. A5.15)

Fi g. A 5 .14 Fig. A5.14 a

2.8

7

Fi g. A 5 .15

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

25

A5 Compensations

Insert panels

With direct panel support, install the

cantilever of the Combihead in the direction of the infill area. (Fig. A5.16)

The teeth in the plastic racks (7.2) on

the cantilever hold the panels (3) in 5

different positions. Select support position according to the compensation

width. Position the cantilever of the

Combihead SCK as close as possible to

the wall in order to provide maximum

support for the infill area.

(Fig. A5.17c – A5.17d)

7

7.2

3

≤ 25

Fi g. A 5 .16 Fig. A5.17

Do not install panels in a longitudinal direction outside of the longitudinal axis

of the Combihead.

(Fig. A5.17e + A5.17f)

Components

1 Drophead SFK

2 Main Beam SLT

3 Panel SDP

7 Combihead SCK

14 Triangular Frame SDR

Fi g. A 5 .17a

Fi g. A 5 .17c

Fi g. A 5 .17e Fi g. A 5 .17 f

Fig. A5.17b

Fi g. A 5 .17d

26

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A5 Compensations

With a transverse positioned Combihead, e.g. in compensation areas, place

panels at least as far as the central axis

or further!

Fi g. A 5 .18a Fig. A5.18 bFi g. A 5 .18

In corners where longitudinal and transverse compensations meet, the Combihead (7) is aligned in the direction of the

main beam. (Fig. A5.19 A)

Install the cantilever of the Combihead

(7) up to the compensation area.

(Fig. A5.19 B)

A

7

B

7

B

7

2

In the system with the Drophead (1), the

Combihead (7) is always installed transversely if it is positioned under a cover

strip. As a result, the panels are prevented from slipping out of position.

(Fig. A5.19 C)

Fi g. A 5 .19

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

7

1

C

27

A5 Compensations

Triangular Frame SDR

150/75, 75/75

Form infill areas with inclined walls using triangular frames.

Forming the infills

1. Continue forming in the system as

long as possible.

2. Carry on forming operations with filler

panels as well as transversely

inserted panels – as for longitudinal

and transverse compensations.

3. Lay Triangular Frame (14) on the support (Main Beam, Prophead or Combihead, End Support). (Fig. A5.20)

4. Place the support on the wall side.

5. Install formlining and secure in position with nails.

14

Fig. A5.20

Longitudinal compensations

Secure filler plates with nails!

Drophead infills up to 2.25 m + 5 cm.

Prophead infills up to 2.25 m.

Length of room minus n x 2.30 m

(2.25 m) = compensation area.

See Tables: Fillers / Forming around

columns.

Forming longitudinal compensations

between 75 cm and 2.25 m

1. Continue forming with prop, Compensation Beam SLT 150 (2.5) and Panel

SDP (3) as in the standard bay.

(Fig. A5.21)

2. Depending on the required load-bearing capacity, continue forming with

filler panels. See PERI Tables.

3. Forming of gaps up to 75 cm, see

following pages.

Fig. A5.21

1,5 m

2,25 m (+5 cm)

31 1

2.5

≤ 75 cm

11

– Take into account the load-bearing

capacity and supporting direction of

the formlining. See PERI Tables.

– Timbers are securely nailed on the

panel inner side before panels are

assembled. Use the nail holes in the

panel edge struts.

28

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A5 Compensations

Gap 0 – 6 cm

1. Place Combihead SCK (7) or Prophead SSK (6) in a recessed position

under the Main Beam SLT (2.5).

2. Nail Filler Timber SPH (12) or timber

up to max. 6 cm on the panel.

3. Install formlining (16) and secure with

nails. (Fig. A5.22 + A5.23)

Gap 5 – 12.5 cm

1. Place Main Beam SLT (2) on inset

prop with Combihead SCK (7) or

Prophead SSK (6).

2. Place additional props with transversely positioned Combiheads SCK

(7a) in an offset arrangement.

3. Install Filler Timber SPH (12) or Edge

Beam SRT (9).

4. Position the formlining and secure

with nails. (Fig. A5.24 + A5.25)

0 – 6 0 – 6

16

2.5

7

7 6

12

Fig. A5.23Fig. A5.22

5,1 – 12,4 5,1 – 12,4

12

7a

6

Components

1 Drophead SFK

2.5 Main Beam SLT 150

3 Panel SDP

6 Prophead SSK

7 Combihead SCK

9 Edge Beam SRT-2 150

11 End Support SSL

12 Filler Timber SPH

13 Timber

14 Triangular Frame

15 Additional prop with crosshead and

formwork girder

16 21 mm formlining provided by the

contractor

Fig. A5.24 Fig. A5.25

Offset prop arrangement.

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

29

A5 Compensations

Gap 12.5 – 20 cm

1. Mount Combihead SCK turned by

180° (7) or Prophead SSK in the main

beam support.

2. Install End Support, Filler Timber and

Edge Beam.

3. Install formlining and secure in position with nails. (Fig. A5.26 + A5.27)

Gap 20 – 75 cm

1. Install Main Beam in Drophead SFK

(1) (Fig. A5.31), with 180° turned

Combihead SCK (7) (Fig. A5.32) or

Prophead SSK (6) (Fig. A5.33).

2. Mount End Support (11) and Edge

Beam (9).

3. Position additional prop with crosshead and formwork girder (15).

4. Install formlining and secure in position with nails. (Fig. A5.28 – A5.30)

Fig. A5.26

12

7

12 – 20 12 – 20

16

9

11

6

Fig. A5.27

20.1 – 79.9

9

11

15

1

Fig. A5.28

Fig. A5.29

20.1 – 74.9

7

20.1 – 74.9

30

6

Fig. A5.30

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

A5 Compensations

Transverse compensations

Secure filler plates with nails!

Max. infills are 1.50 m.

Infills are calculated based on length of

room – n x 1.50 m.

See Tables: Fillers / Forming around columns.

Forming the infills

3a

75

≤ 1.50 m

≤ 75

Transverse infill between 75 cm and

1.50 m

1. Continue forming with prop, Main

Beam SLT 225 (2) and transversely-positioned panel (3). Close the

spacing to the next prophead with

Panel SDP 75 x 75 (3a).

(Fig. A5.31 + A5.32)

2. Depending on the required load-bearing capacity, continue forming with

filler panels. See PERI Tables.

3. Form gaps up to 75 cm; see following

pages.

– Take into account the load-bearing ca-

pacity and supporting direction of the

formlining. See PERI Tables.

– Timbers are securely nailed or

screwed on the panel inner side before panels are assembled. Use the

nail holes in the panel edge struts.

1 151

Fig. A5.31

3

3a

2

Components

1 Drophead SFK

3 Panel SDP

6 Prophead SSK

7 Combihead SCK

9 Edge Beam SRT-2 150

11 End Support SSL

12 Filler Timber SPH

15 Additional prop with crosshead and

formwork girder

16 21 mm formlining provided by the

contractor

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

Fig. A5.32

31

A5 Compensations

Gap 0 – 12 cm

1. Place Panel SDP (3) over the Main

Beam SLT (2) and secure with Panel

Wedge Clips (20). (Fig. A5.33 –

A5.35)

2. Nail Filler Timber SPH (12) or timber

(13) up to max. 6 cm on the panel.

(Fig. A5.35) Screw Filler Timber SPH

(12) or timber (13) up to max. 6 cm on

the panel. (Fig. A5.36)

3. Install formlining (16) and secure with

nails.

If panels (3) are placed over the main

beam (2), the panel edge can not laterally

stabilize the main beam.

Secure every main beam with a Panel

Wedge Clip SPKK to prevent

overturning!

Fig. A5.33

12

0 – 6

0 – 12

1616

33

13

2

2020

11

Fig. A5.34

2 3

20

Gap 5 – 12.5 cm

1. Position Combihead SCK (7) with cantilever in the direction of the infill.

2. Install Panel (3).

3. Install Edge Beam SRT-2 (9) or Filler

Timber SPH (12) in the Combihead

(7).

4. Install formlining (16) and secure with

nails. (Fig. A5.36)

32

Fig. A5.35

Fig. A5.36

5.1 – 12.4

16

9/12

3

7

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A5 Compensations

Gap 12.5 – 25 cm

1. Position Combihead SCK (7) with cantilever in the direction of the infill.

2. Install Panel (3).

3. Install Edge Beam SRT-2 (9) or Filler

Timber SPH (12) in the Combihead.

4. Install formlining (16) and secure with

nails. (Fig. A5.37)

Alternatively

1. Place Panel SDP (3) over the Main

Beam SLT (2) and secure with Panel

Wedge Clip (20).

2. Screw Filler Timber SPH (12) or timber on the panel.

3. Position additional prop with crosshead (15) and formwork girder.

4. Install formlining (16) and secure with

nails. (Fig. A5.38)

Gap 25 – 75 cm

1. Mount the Panel SDP (3) in the Main

Beam (2).

2. Insert Edge Beam SRT-2 (9) in the

Main Beam.

3. Position additional prop with crosshead (15) and formwork girder.

4. Install formlining (16) and secure with

nails. (Fig. A5.39 + A5.40)

Fig. A5.37

12.5 – 24.9 12 – 24

9

3

7

20

16

12

12

20

1

Fig. A5.38

24 – 75

9

3

2

2

15

16

15

1

Components

1 Drophead SFK

2 Main Beam SLT

3 Panel SDP

6 Prophead SSK

7 Combihead SCK

9 Edge Beam SRT-2 150

12 Filler Timber SPH

13 Timber

15 Additional prop with crosshead and

formwork girder

16 Formlining

20 Panel Wedge Clip SPKK

Fig. A5.39

Fig. A5.40

3a

9

2

15

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

33

A6 Shuttering around columns

1 recessed panel

Maximum column dimensions

x = 55 cm, y = 138 cm.

Secure filler plates with nails!

Install Edge Beam SRT-2 150 vertically

(9) or Filler Timber SPH 150 (12).

During use, permissible loads must be

observed; see Tables: Fillers / Forming

around columns

Take into account the supporting

direction of the formlining.

Alternatively:

Install Edge Beam SRT-2 150 (9*) in a

suspended position. (Fig. A6.03)

Flatly position Filler Timber SPH or install timber (13) supplied by the contractor.

Fig. A6.01

Width of Influence

y

x

9/12

For 27 mm formlining: height of

timber = 47 mm.

Permissible widths of influence for

flat Filler Timber SPH, see Table A6.02.

Components

9 Edge Beam SRT-2 150

10 Edge Beam SRT-2 75

9* Edge Beam SRT 150, suspended

10* Edge Beam SRT 75, suspended

12 Filler Timber SPH

13 Timber

Fig. A6.02

Fig. A6.04

Fig. A6.03

y

x

13

9*

34

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A6 Shuttering around columns

2 recessed panels

Maximum column dimensions

x = 65 cm, y = 138 cm.

Secure filler plates with nails!

y

x

10*

Install Edge Beam SRT 150 (9) vertically

at the panel edge. Insert Edge Beam

SRT 150 (9*) in a suspended position at

the column.

Likewise, insert Edge Beam SRT 75

(10*) in the Edge Beam (9*) in a suspended position. (Fig. A6.05 + A6.06)

Maximum column dimensions

x = 130 cm, y = 138 cm.

Depending on the slab thickness and

prop width, the transverse-positioned

filler plates are to be additionally supported, see Table A6.02.

Fig. A6.05

Fig. A6.06

9* 9/129/12

y

x

12

Insert Edge Beam SRT-2 150 (9*) in a

Fig. A6.07

suspended position. Lay Filler Timber

SPH 150 (12) in a flat position. Permissible widths of influence for flat Filler Timber SPH, see Table A6.02 on next page.

(Fig. A6.07 + A6.08)

With smaller cross-sections, form infill

areas with Panel SDP 37.5.

Take into account the supporting direction of the formlining.

Fig. A6.08

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

9*

35

A6 Shuttering around columns

3 recessed panels

Maximum column dimensions

x = 138 cm, y = 142 cm.

L

SPH

L

SPH

Secure filler plates with nails!

Install Edge Beam SRT-2 150 (9) vertically,

Edge Beam SRT-2 150 (9*) suspended,

Filler Timber SPH 150 (12) horizontally.

(Fig. A6.09, Fig. A6.10)

Fig. A6.09

Fi g. A 6 .10

y

x

12

9

129*

9

Additional Edge Beam SRT-2 150 (9)

required with:

Slab thickness

d [m]

≤ 0.20

Column side

y [m]

no additional SRT

0.25 ≤ 0.40

0.30 ≤ 0.70

0.40 ≤ 1.15

Table A6.01

For other slab thicknesses, the values

are interpolated linearly.

Take into account the supporting

direction of the formlining.

Permissible width of influence of flat Filler Timber SPH,

maximum deformation l/500

permissible width of influence Filler Timber SPH flat e

Slab thickness

with span L

100 80 60

SPH

[cm]

14 30 58 137

16 26 51 121

18 23 46 108

20 21 41 98

22 19 38 89

24 18 35 82

25 17 33 79

26 16 32 76

28 15 30 71

30 14 28 66

35 12 24 57

40 11 21 50

43 10 20 46

Table A6.02

SPH,fl at

[cm]

36

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A6 Shuttering around columns

Recessed main beams

Secure filler plates with nails!

Secure props of the Edge Beam

SRT (**) with tripod!

Components

9 Edge Beam SRT-2 150

6 Prophead SSK

11 End Support SSL

Only used if moving the main beam axis

is not desired. (Fig. A6.11, Fig. A6.12)

Additional formlining support depending

on the situation on site.

Fi g . A6.11

9

**

11

9

6

9

6

Shifting the main beam axis

(Fig. A6.13)

Secure Main Beam SLT (**) props

that have been shifted with tripods!

In the area of the box out, screw timber

(13) on the panel as filler support.

Take into account the supporting

direction of the formlining.

Components

6 Prophead SSK

9 Edge Beam SRT-2 150

9* Edge Beam SRT 150, suspended

10 Edge Beam SRT-2 75

11 End Support SSL

12 Filler Timber SPH

13 Timber

Fi g. A 6 .12

Fi g. A 6 .13

Secure props by means of tripod.

**

13

**

9

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

37

A7 Horizontal bracing

Transfer of horizontal loads

into the columns of the

building

The horizontal loads according to DIN

EN 12812 are to be accommodated by

the building walls, columns or bracings.

SKYDECK is able to transfer these loads

into the building columns according to

Table A7.01 without requiring any additional bracing.

The prerequisite is that the building columns can accommodate the horizontal

loads according to the table.

At the edge of the slab, corresponding

loads, e.g. from the stopend formwork

pressure, platforms or wind, must be

separately anchored.

With a rectangular column grid, the

largest column spacing is decisive.

Slab thickness Panel span Maximum perm.

column grid

(building columns)

[cm] [cm] a [m] H [kN]

14 150 10.31 9.44

16 150 9.26 8.48

18 150 8.39 7.6 9

20 150 7.6 8 7. 0 3

22 150 7.07 6.48

24 150 6.56 6.00

25 150 6.32 5.79

26 150 6 .11 5.59

28 150 5.71 5.23

30 150 5.37 4.92

35 150 4.63 4.24

40 150 4.06 3.72

43 150 3.77 3.45

45 75 3.59 3.29

50 75 3.21 2.94

55 75 2.90 2.66

60 75 2.68 2.45

65 75 2.48 2.27

70 75 2.31 2.12

75 75 2.17 1.99

80 75 2.05 1.8 8

85 75 1.95 1.78

90 75 1.85 1.70

Horizontal load

per column

(building column)

Example

Slab thickness 30 cm, panel span 150

cm.

permissible column grid without

bracing the SKYDECK: = 5.37 m (a).

Horizontal load to be transferred: H =

4.92 kN.

This load must be verified by the structural engineer regarding the respective

column in the actual building condition.

(Fig. A7.01)

Tabl e A7.01

≤ a

≤ a

Fig. A7.01

38

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A7 Horizontal bracing

General

– Do not access the forming area be-

fore the formwork has been horizontally anchored!

– Do not access the cantilevers be-

fore the bracing has been mounted in a form-fitting manner!

Formwork positioned on open building

edges or concreting sections, is to be

secured against horizontal loads by

means of bracing.

Cantilevers, e.g. on edge bay, must be

additionally vertically braced in order to

prevent any tilting.

Example calculation: see Transfer of

horizontal loads from a casting segment.

Bracing of the inner bay

– Maintain spacings

– Bays must be braced longitudinally

and horizontally

Schematic representation

Influencing area,

e.g. slab d = 25 cm.

Fig. A7.02

Longitudinal direction

Lateral direction

Assembly

1. Mount Base Plate on a sufficiently

load-bearing surface area, e.g. using

PERI Anchor Bolt 14/20x130, Item no.

124777. Take into consideration the

Technical Data Sheet!

2. Attach Anchor Chain to the panels:

– In the longitudinal direction, attach

Anchor Chain (23) to the Tension

Sleeve SAO (39). (Fig. A7.03)

– In the transverse direction, connect

panels to scaffold tube (31). Wrap

Chain (23) around the scaffold tube.

(Fig. A7.03a)

3. Secure Anchor Chain to Base Plate

using bolts, and secure bolts by

means of cotter pins. (Fig. A7.03b)

Components

23 Anchor Chain (permissible ten-

sion force = 3 kN)

24 Base Plate RS

24.1 Anchor Bolt PERI 14/20 x 130

31 Scaffold Tube

39 Tension Sleeve SAO

39

23

Fig. A7.03 Fig. A7.03a

24

31

23

Fig. A7.03b

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

24.1

39

A7 Horizontal bracing

Transfer of horizontal loads from a casting segment

Example 1

Open building edge on one side

Bracing in one building direction. (Fig. A7.05)

Values: see Table A14.01.

Requirements

– Load Case Combination LFK 1:

Concreting

– Load Case Combination LFK 2: Storm

– Slab thickness d = 25 cm

– Panel span = 1.50 m

– 1 edge area

– 9 inner bays

Number of chains

– The load case combination which re-

sults in the biggest value is decisive.

– Permissible horizontal component of

the tension load on the anchor chain

= 3 kN x cos 60° = 1.5 kN. (Fig. A7.04)

1.50 kN

3.00 kN

60°

Fig. A7.04

2.60 kN

Calculation

Load Compilation LFK 1 Concreting

1 x H

edge area + 9 x H

load

inner bay = ∑H

load

2.447 kN + (9 x 0.54 kN) = 7.307 kN

Load Compilation LFK 2 Storm

1 x H

edge area + 9 x H

load

inner bay = ∑H

load

1.291 kN + (9 x 0.033 kN) = 1.588 kN

Number of chains

∑H = 1.588 kN < 7.307 kN

LFK 1 Concreting is decisive

= ∑H / perm. tension force of chain

n

chain

= 7.31 kN : 1.5 kN = 4.87 chains = 5 chains

2.447 0.54 0.54 0.54 0.54 0.54 0.54 0.54 0.54 0.54 kN

Cycle joint

Chain 1 Chain 2 Chain 3 Chain 4 Chain 5

Fig. A7.05

2.447 kN 0.54 kN0.54 kN0.54 kN

60°

Fig. A7.06

Load

Slab

thickness

[cm]

25 7.83 1.430 0.715 0.540 0.270 2.447 1.224 0.033 0.016 1. 291 0.645

Excerpt from Table A14.01

according

to DIN

EN 12 812

[kN/m²]

Horizontal Load

c = 1.50 m c = 0.75 m

from

stopend

formwork

pressure

edge area

from

stopend

formwork

pressure

Load Case Combination LFK 1: Concreting*

[kN]

Horizontal Load

Panel span

c = 1.50 m

[kN] Horizontal Load

inner bay

Panel span

c = 0.75 m

Panel span

c = 1.50 m

edge area

Panel span

c = 0.75 m

Load Case Combination LFK 2: Storm**

[kN] Horizontal Load

Panel span

c = 1.50 m

inner bay

Panel span

c = 0.75 m

[kN]

Horizontal Load

Panel span

c = 1.50 m

[kN]

edge area

Panel span

c = 0.75 m

40

Instructions for Assembly and Use – Standard Configuration

SKYDECK Panel Slab Formwork

A7 Horizontal bracing

Example 2:

Open building edge on both sides

Bracing in both building directions. (Fig. A7.08)

Values: see Table A14.01.

Requirements

– Load Case Combination LFK 1:

Concreting

– Load Case Combination LFK 2: Storm

– Slab thickness d = 25 cm

– Panel span = 1.50 m

– 2 edge areas

– 8 inner bays

Number of chains

– The load case combination which re-

sults in the biggest value is decisive.

– Permissible horizontal component of

the tension load on the anchor chain

= 3 kN x cos 60° = 1.5 kN. (Fig. A7.04)

1.50 kN

3.00 kN

60°

Fig. A7.04

2.60 kN

Calculation

Load Compilation LFK 1 Concreting

2 x (H

edge area − stopendformwork pressure*)

load

+ (8 x H

inner bay) = ∑H

load

2 x (2.447 kN − 1.43 kN) + (8 x 0.54 kN) = 6.354 kN

Load Compilation LFK 2 Storm

2 x H

edge area + (8 x H

load

inner bay) = ∑H

load

2 x 1.291 kN + (8 x 0.033 kN) = 2.846 kN

Number of chains

∑H = 2.846 kN < 6.354 kN

LFK 1 Concreting is decisive

= ∑H / perm. tension force of chain

n

chain

= 6.54 kN : 1.5 kN = 4.236 chains = 5 chains per load direction

2.447

1.4 3 1.4 3

Chain 1 Chain 2 Chain 3 Chain 4 Chain 5

Fig. A7.07

0.540.540.540.540.540.540.540.54 2.447 kN

Fig. A7.08

1.02 kN*

1.4 3 k N

2.447 kN

60°

1.4 3 k N

2.447 kN

0.54 kN 0.54 kN0.54 kN

1.02 kN*

1.4 3 k N

2.447 kN

*The stopend formwork pressure is already included in Load Case Combination

=

1.02 kN

LFK 1 for edge areas. Through reciprocal elimination on both sides of the

open building edge, this value must be deducted from both sides.

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

41

A8 Cantilevers, Guardrails

Bracing on open building

edges to prevent tipping

39

Horizontal loads must be additionally taken into consideration and

transferred, e.g. with bracing; see

Sect i o n A7.

Cantilevers with Panels SDP

Mount Tension Sleeve SAO (39) on

main beam. Distance to inner prop max.

50 cm. Brace using Anchor Chain (23),

Base Plate (24) and Anchor Bolt (24.1).

(Fig. A8.01)

Max. slab overhang: 37.5 cm.

Cantilevers with SKYDECK

Platforms SDB

(Fig. A8.02 + A8.03) See Cantilevers

with Panels SDP.

Corner table:

The Main Beams SLT “A + B” receive

2-fold horizontal load from the wind and

1-fold load from the stopend formwork

pressure. Additional bracing is required.

Fig. A8.03 shows only bracing from

Load Case Tilting.

Take into account Section A9

SKYDECK Platforms!

Fig. A8.01

Fig. A8.02

90°

≤ 54

2.25 m

90°

≤ 50

2.25 m

39

23

24

24.1

23

24

24.1

≤ 3 7. 5

≤ 3 7. 5

Components

23 Anchor Chain (permissible ten-

sion force = 3 kN)

24 Base Plate RS

24.1 Anchor Bolt PERI 14/20 x 130

39 Tension Sleeve SAO

45 SKYDECK Platform SDK

45c

45a B

45a

Fig. A8.03

42

≤ 37,5 cm

A

≤ 37,5 cm

45c 45b

SKYDECK Panel Slab Formwork

Instructions for Assembly and Use – Standard Configuration

A8 Cantilevers, Guardrails

Guardrails with Handrail