Peri MULTIPROP MP 120, MULTIPROP MP 250, MULTIPROP MP 350, MULTIPROP MP 480, MULTIPROP MP 625 Instructions For Assembly And Use

MULTIPROP MP 120, 250, 350, 480, 625

Slab Props

Edition 05 | 2015

Instructions for Assembly and Use – Standard Confi guration

Introduction

Overview, main components 1

Standard configuration 2

Intended use 2

Safety instructions 3

General 3

Standard configuration

A1 Assembly

Pre-assembling the slab prop 4

Assembly with Universal Tripod 6

A2 Dismantling

Releasing the slab prop under load 7

A3 Accessories

Brace Clamp 8

Base MP 50 9

A4 Foreseeable misapplications 10

A5 Storage and Transportation 13

Tables

Permissible prop loads

MULTIPROP MP 120, 250, 350, 480, 625 14

MULTIPROP MP 120, 250, 350, 480,

625 with Base MP 50 15

Components

Components 16

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Content

Key

Safety instructions Note

Visual check

Tip

Load-bearing

point

1 Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Introduction

Overview, main components

MULTIPROP MP

1 Outer Tube

2 Inner Tube

3 Securing Hook

4 Adjusting Collar

5 Pressure Spring

6 Measuring Tape

7 Rubbing Plate

8 End Plate

Base MP 50

11 Base MP 50

11a Head Plate

11c Clamping Claw

11b Centering Pin

6

2

1

4

7

8

11

11a

11b

11c

8

5

3

2 Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Introduction

Area of application

MULTIPROP Slab Props

– are props made of aluminium,

– correspond to the load requirements

of DIN EN 1065,

– are used as vertical supports for tem-

porary constructions.

Standard configuration

Intended use

1. PERI products have been designed

for exclusive use in the industrial and

commercial sectors by suitably trained

personnel only.

2. These Instructions for Assembly and

Use serve as basis for the project-related risk assessment and the instructions

for the provision and use of the system

by the contractor (user). However, they

do not replace them.

3. Only PERI original components may

be used. The use of other products and

spare parts represents a misapplication

with associated safety risks.

4. The components are to be inspected

before each use to ensure that they are

in perfect condition and function correctly.

5. Changes to PERI components are

not permitted and represent a misapplication with associated safety risks.

6. Safety instructions and permissible

loads must be observed at all times.

7. Components provided by the contractor must correspond to the characteristic features required in these Instructions for Assembly and Use as well as

all current laws and standards.

In particular, the following applies if

nothing else is specified:

– timber components: Strength Class

C24 for Solid Wood EN 338.

– scaffold tubes: galvanised steel tubes

with minimum dimensions of Ø 48.3

x 3.2 mm according to EN 128111:2003 4.2.1.2.

– scaffold tube couplings according to

EN 74.

8. Deviations from the standard configuration may only be carried out after a

separate risk assessment has been

completed by the contractor (user).

On this basis, appropriate measures for

the working safety and stability are to

be implemented.

Main components

MULTIPROP

MP 120, L = 0.80 – 1.20 m

MP 250, L = 1.45 – 2.50 m

MP 350, L = 1.95 – 3.50 m

MP 480, L = 2.60 – 4.80 m

MP 625, L = 4.30 – 6.25 m

System dimensions

Assembly heights as individual props

according to the permissible extension

lengths 0.80 m – 6.25 m or 1.30 m –

6.75 m for use with Base MP 50.

Technical data

– Approval Z-8.312-824.

– For load-bearing capacities,

see Tables.

Features

MULTIPROP slab props are used in

shoring operations in a planned perpendicular position for the transfer of vertical loads. In particular, they also provide

support for slab formwork systems.

The outer tubes of the MULTIPROP

Slab Props are powder coated.

The integrated measuring tape and

free-running collar allow accurate and

fast height adjustment.

The height is continuously adjustable

by means of the end-to-end thread

without pegging. The MULTIPROP Slab

Prop has a fail-safe feature which prevents the inner tube from unintentionally slipping out.

3Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Introduction

Safety instructions

Brochure:

– MULTIPROP Aluminium Slab Props

Type tests for:

– MULTIPROP Props

– MULTIPROP System

– MULTIPROP Props with Base MP 50

– MULTIPROP System with Base MP 50

General

1. Deviations from the standard configuration and/or intended use present a

potential safety risk.

2. All country-specific laws, standards

and other safety regulations are to be

taken into account whenever our products are used.

3. During unfavourable weather conditions, suitable precautions and measures are to be taken in order to ensure

both working safety and stability.

4. The contractor (user) must ensure

the stability throughout all phases of

construction. He must ensure and verify that all occuring loads are safely

transferred.

5. The contractor (user) has to provide

safe working areas for site personnel

which can be reached through the provision of safe access means. Areas of

risk must be cordoned off and marked.

Hatches and openings on accessible

working areas must be kept closed during working operations.

6. For better comprehensibility, detailed

drawings are partly incomplete. The

safety installations which have possibly

not been included in these detailed

drawings must nevertheless still be

available.

System-specific

1. Retract components only when the

concrete has sufficiently hardened and

the person in charge has given the

approval for striking to take place.

2. Anchoring is to take place only if the

anchorage has sufficient concrete

strength.

3. After exceptional occurrences or long

periods of downtime at the location

where the formwork or shoring is used,

the unit and its components must be

checked for stability and functionality.

Care and maintenance

1. MULTIPROP Slab Props have been

designed for long-term use on the construction site.

2. In order to maintain the value and

operational readiness of the MULTIPROP

Slab Props over a long period of time,

the props should be carefully handled at

all times.

3. Occasionally grease the rubbing plate

to ensure easier handling.

4. Only PERI qualified personnel are

allowed to carry out repairs on the

MULTIPROP Slab Props.

Storage and transportation

1. Do not drop the components.

2. Store and transport components

ensuring that no unintentional change

in their position is possible. Detach lifting gear from the lowered units only if

these are in a stable position and no

unintentional change is possible.

3. When moving the components,

make sure they are lifted and set down

in a way that any unintentional tilting

over, falling apart, sliding or rolling away

is prevented.

4. Use only suitable load-carrying

equipment to move the components as

well as the designated load-bearing

points.

5. During the lifting and moving procedure, ensure that all loose parts are

removed or secured.

6. Assemble and move components on

clean, flat and sufficiently load-bearing

surfaces only.

General

The structures shown in these Instructions for Assembly and Use are examples and feature only one component

size. They are valid accordingly for all

component sizes contained in the

standard configuration.

Instructions for Use:

– Pallets and Stacking Devices

Instructions for Assembly and Use:

– MULTIFLEX

– SKYDECK

– TABLE MODULES / SLAB TABLES

– SKYTABLE

– VARIODECK

Additional PERI product information

PERI design tables

4 Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A1 Assembly

Pre-assembling the slab

prop

For the safety of the user, the

following should be checked before

every use to see whether

– the slab prop is complete,

– the slab prop has no cracks, holes

or broken parts,

– the inner tube and collar are freely

movable and

– the end plates are level.

– Shown here is the assembly of a

free-standing MULTIPROP Slab Prop.

– When used in the system, the

“MULTIPROP System” Instructions

for Assembly and Use must be

adhered to.

– The numbers on the integrated

measuring tape show the complete

length (L) of the MULTIPROP Slab

Prop in metres [m], e.g. 1

25 = 1.25 m.

– The complete length of the

MULTIPROP Slab Prop can be read

at the top edge of the collar (4a).

– Adjusting range per complete turn:

36 mm.

– The prop can be continuously

readjusted by means of the adjusting

collar if partially loaded up to 15 kN.

Preparation

MULTIPROP Slab Props are delivered

with retracted inner tubes in a Pallet

RP-2 as standard.

Place the prop on an available work

trestle or the Pallet RP-2.

(Fig. A1.01a + A1.01b)

Fig. A1.01a

Fig. A1.01b

5Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A1 Assembly

Fig. A1.02a

Inner tube bottom

Fig. A1.02c

4

6

2

3

7

adjusted

overall length

Position

Turn adjusting collar

“L” is:

Outer tube

bottom

(Fig. A1.02b)

anti-clockwise

smaller

anti-clockwise

larger

clockwise larger

clockwise smaller

Inner tube

bottom

(Fig. A1.02c)

L

Rough adjustment of the extension

length

1. Press down safety hook (3).

–> Inner tube (2) together with the

adjusting collar (4) is released.

(Fig. A1.02a)

2. Pull out inner tube until the length

indicated on the measuring tape (6) is

slightly more than the required prop

length.

3. Turn the adjusting collar until the

required extension length is reached.

4. Push in the inner tube until the

adjusting collar lies against the rubbing

plate (7).

–> Safety hook locks the inner tube in

position.

5. Fine adjustment of adjusting collar

(4) to specified length.

Is the safety hook engaged?

Quick adjustment of the smoothrunning adjusting collar is carried

out by “fast spindling“.

Outer tube bottom

Fig. A1.02b

4a

6

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A1 Assembly

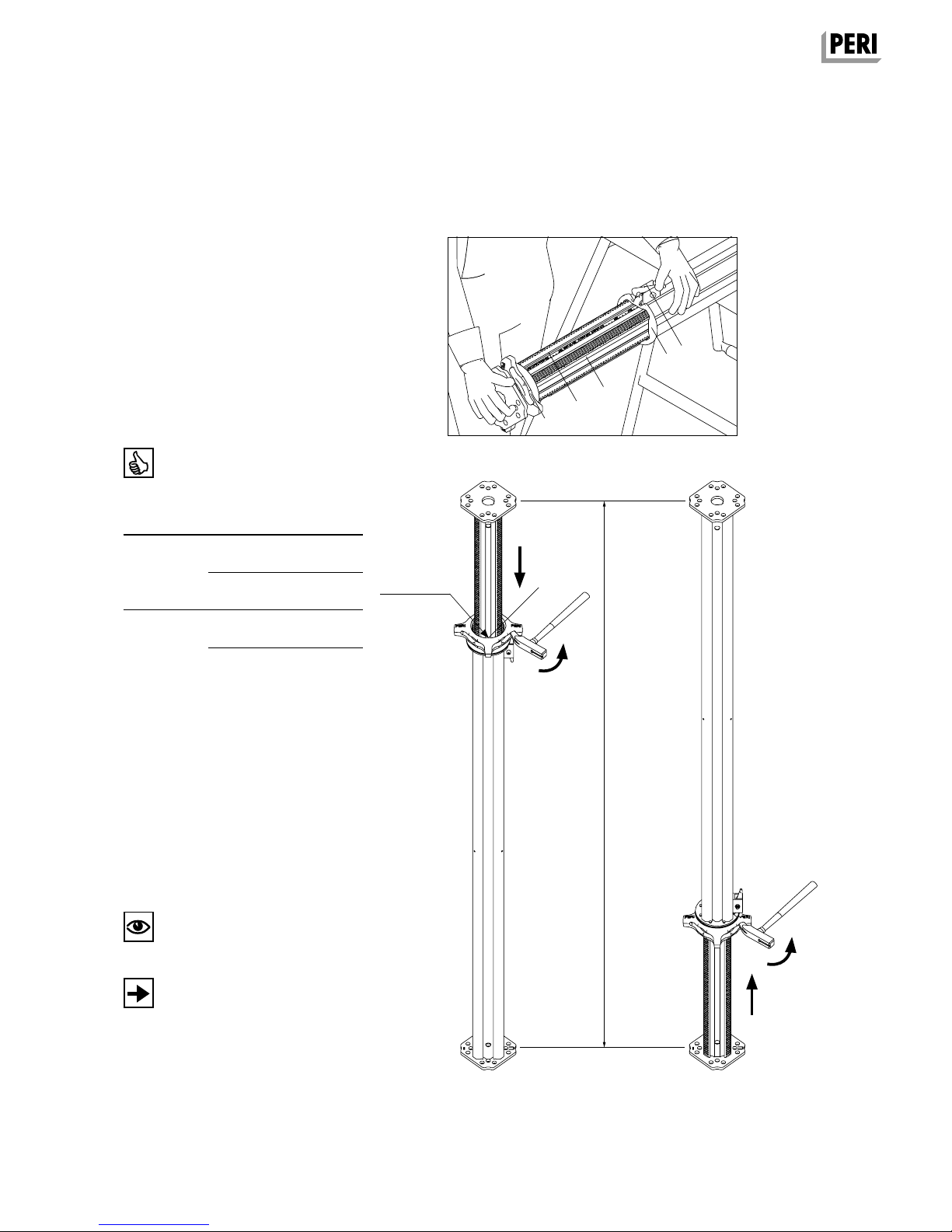

Assembly with Universal

Tripod

For slab props with tube Ø 48 mm to

Ø 120 mm.

Slab Props and Tripods

– place on clean, flat and sufficiently

load-bearing surface only!

– are not suitable for planned transfer

of horizontal loads!

– Shown here is the assembly of a

free-standing slab prop.

– When used in the system, the

respective Instructions for Assembly

and Use are to be taken into account.

– Universal Tripods (9) are pure assem-

bly aids for shuttering and striking up

to heights of approx. 3 m.

Universal Tripod assembly

1. Insert pre-assembled slab prop into

the Universal Tripod (9).

(Fig. A1.03)

2. Tighten clamp (9a).

Ensure that the slab prop lies flat

against the top and bottom connection

plates (9b and 9c).

(Fig. A1.03)

– Does the slab prop lie flat to the top

and bottom connection plates?

– Has the clamp been tightened?

– Is the slab prop in a perpendicular

position?

3

9a

Fig. A1.03

9c

9

9b

7Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Releasing the slab prop

under load

For loads > 60 kN, use the Wing Nut

Spanner HD!

Dismantling:

1. Release adjusting collar and set loadfree with:

– hammering the lowering cam.

(Fig. A2.01a)

– Wing Nut Spanner HD Item no.

022027. (Fig. A2.01b)

2. Remove slab prop.

3. Dismantle slab prop.

– Press down safety hook.

–> Inner tube with adjusting collar is

disengaged.

– Pull out inner tube a short distance

and spindle adjusting collar back to

the end plate.

– Push in the inner tube until the

adjusting collar lies against the rubbing plate.

–> Safety hook locks the inner tube in

position.

4. Place slab prop in the pallet.

See Section A5 “Storage and Transportation”.

The Wing Nut Spanner HD facilitates

energy-saving and noiseless loosening

of the adjusting collar – even if the

props are placed under maximum load.

Fig. A2.01a

Fig. A2.01b

A2 Dismantling

Outer tube bottom

Outer tube bottom

8

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A3 Accessories

Fig. A3.01

10

Brace Clamp

Item no. 027790

Used as an alternative assembly aid

with high slab props as of approx. 4 m

using bracing boards 3 x 15 cm.

Brace Clamps are not suitable for a

planned transfer of horizontal loads!

– Brace Clamps (10) are simply assem-

bly aids for shuttering and striking

procedures.

– As an option, universal tripods can be

used as additional assembly aids.

Assembly

1. Pull the narrow side of the wedge

(10a) out of the clamp.

2. Place Brace Clamp (10) around the

tube of the slab prop.

3. Insert board in the open side of the

clamp.

4. Put wedge back into recess of the

clamp and hammer in securely.

–> The wedge secures the board.

5. Mount additional bracing boards by

means of Brace Clamps.

(Fig. A3.01)

– Are the slab props in a perpendicular

position?

– Are all wedges securely fixed?

– Have all wedges secured the boards?

10a

9Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A3 Accessories

Base MP 50

Take into account separate tables

with permissible prop load!

– Used for extending the slab prop by

50 cm.

– Automatic centering of the slab prop

by means of centering pins.

– Two clamping claws connect the

Base MP 50 with the slab prop.

– The MULTIPROP Slab Prop can be

mounted on the Base MP 50 with the

inner or outer tube.

Assembly

1. Place the slab prop on the head plate

(11a) of the Base MP 50 that the two

centering pins (11b) lock into the holes

of the end plate.

2. Position clamping claws (11c) with

the hammer on the end plate of the

slab prop. Base MP 50 (11) is now

connected to the prop. (Fig. A3.02)

Are the two clamping claws fully set on

the end plate?

Through the use of the Base MP 50,

the same type of prop can be used at

different heights.

Dismantling

Release clamping claws with a hammer.

Fig. A3.02

11b11a

11c

11

10

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A4 Foreseeable misapplications

Applications of this type or similar are prohibited!

Ensure that slab props are always in

a perpendicular position!

Fig. A4.01

Non-loadable installation surface!

Fig. A4.03a

Only use full-faced support surfaces!

Fig. A4.02a Fig. A4.02b

Fig. A4.03b

Slab props must always be in a vertical

position.

End plates of the slab props must always lie completely flat.

If necessary, fill the gap and secure the wedge.

Slab props must always be positioned

on sufficiently load-bearing and flat surfaces.

11Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A4 Foreseeable misapplications

Do not use with Tilting Forkhead

MKK or Tilting Base MKF!

Fig. A4.05

Use designated support equipment,

e.g. Push-Pull Props or Brace Frames.

Do not use for supporting formwork

elements!

Fig. A4.06

If the clear height is too large, a longer

slab prop or shoring tower must be

used, e.g. MULTIPROP System with

MRK Frames.

Do not connect the slab props to

each other!

Fig. A4.04

Applications of this type or similar are prohibited!

12

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

A4 Foreseeable misapplications

Use designated trench strut.

Do not use as a trench strut!

Fig. A4.07

Do not use as anti-fall protection!

Use designated anti-fall protection, e.g.

PROKIT EP 110 or EP 200.

Fig. A4.08

Use designated anti-fall protection, e.g.

PROKIT EP 110 or EP 200.

Do not use as a guardrail holder!

Fig. A4.09

Applications of this type or similar are prohibited!

13Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

– Instructions for Use for PERI Pallet

and Stacking Devices must be fol-

lowed at all times!

– Follow PERI packaging guidelines!

– Transportation units must be cor-

rectly stacked and secured!

PERI Pallets (14) are suitable for lifting

by a crane or forklift.

When using a crane, 4-sling lifting gear

is used to move the pallets.

During fork-lift operations, the pallets

can be moved either by a fork-lift truck

or by using the PERI Lifting Trolley. All

pallets can be lifted using the longitudinal as well as front sides.

Max. number of pallets in accordance

with packaging guidelines.

The safety hook (3) prevents the inner

tube (2) from slipping out and must be

engaged.

Storage

Store and transport slab props of the

same size! (Fig. A5.01 + A5.02)

Transportation

– Ensure loads are correctly secured

during transport!

– Use tension belts or steel bands.

The number of pallets that can be

transported depends on the respective

national transport regulations.

Fig. A5.01

Fig. A5.02

Example: MULTIPROP Slab Props

stacked using battens and secured by

means of a steel band.

2

3

Example: MULTIPROP Slab Props

positioned horizontally in a Pallet RP-2

and secured by means of a tension belt.

A5 Storage and Transportation

14

MP 250

L = 1.45 – 2.50 m

MP 350

L = 1.95 – 3.50 m

MP 480

L = 2.60 – 4.80 m

MP 625

L = 4.30 – 6.25 m

1.45 75.5 78.5

1.50 75.5 78.5

1.60 75.5 78.5

1.70 75.5 78.5

1.80 73.8 78.5

1.90 70.6 78.5

1.95 68.0 78.5 91.0 90.1

2.00 67.3 78.5 91.0 90.1

2.10 65.7 76.8 86.0 90.1

2.20 64.1 75.1 80.6 90.1

2.30 62.5 72.6 75.1 89.8

2.40 60.8 69.1 70.7 87.9

2.50 59.2 65.6 66.4 86.1

2.60 63.7 83.1 88.5 73.6

2.70 61.1 80.1 83.7 73.3

2.80 59.2 77.1 78.8 72.9

2.90 57.4 74.1 74.0 72.6

3.00 56.0 70.3 69.1 72.2

3.10 54.5 66.6 64.9 71.4

3.20 52.9 61.8 60.7 70.7

3.30 51.3 57.1 56.5 70.0

3.40 47.7 51.7 54.1 68.2

3.50 44.2 46.4 51.8 66.5

3.60 49.4 64.7

3.70 47.5 60.4

3.80 45.7 56.1

3.90 43.8 51.8

4.00 41.8 48.4

4.10 39.7 45.0

4.20 37.7 41.6

4.30 35.8 39.3 57.9 45.7

4.40 33.9 37.0 56.3 45.7

4.50 32.0 34.8 54.7 45.7

4.60 30.2 32.5 52.5 45.1

4.70 28.3 30.2 50.3 44.4

4.80 26.4 27.9 47.9 43.5

4.90 45.2 42.4

5.00 42.5 41.3

5.10 39.9 39.9

5.20 37.2 38.5

5.30 34.9 37.1

5.40 32.8 35.6

5.50 30.8 34.1

5.60 29.3 32.6

5.70 27.8 31.2

5.80 26.4 29.6

5.90 25.1 27.9

6.00 23.8 26.2

6.10 22.7 24.8

6.20 21.6 23.4

6.25 21.0 22.7

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Table for MULTIPROP 250, 350, 480, 625

Permissible prop load [kN] according to the type test

Extension

length [m]

Outer tube

bottom

Inner tube

bottom

Outer tube

bottom

Inner tube

bottom

Outer tube

bottom

Inner tube

bottom

Outer tube

bottom

Inner tube

bottom

MULTIPROP Props are classified according to official approval as follows:

MP 250 = Class T 25

MP 350 = Class R 35

MP 480 = Class D 45

MP 625 = Class D 60

Note:

To release the loads > 60 kN we recommend using the HD Wingnut Spanner,

Item no. 022027.

When using PERI slab tables, the permissible load on the MULTIPROP MP 350

Prop is a minimum of 56 kN and a minimum of 36 kN for the MULTIPROP MP

480 over the entire extension length – this is due to the props being clamped in

the Table Swivel Head or UNIPORTAL Head.

15

MP 250 + MP 50

L = 1.95 – 3.00 m

MP 350 + MP 50

L = 2.45 – 4.00 m

MP 480 + MP 50

L = 3.10 – 5.30 m

MP 625 + MP 50

L = 4.80 – 6.75 m

2.25 76.6 73.6

2.30 74.5 72.9

2.40 72.4 72.1

2.50 66.1 69.8 87.6 84.2

2.60 63.3 67.7 83.8 82.9

2.70 60.5 65.6 79.9 81.7

2.80 57.7 63.1 76.1 80.5

2.90 55.1 60.1 70.0 77.0

3.00 52.4 57.1 63.9 73.5

3.10 60.8 70.6 76.8 73.3

3.20 57.6 67.6 74.4 72.8

3.30 55.2 64.7 71.9 72.3

3.40 52.7 61.8 69.4 71.8

3.50 50.8 59.1 67.0 71.3

3.60 48.8 56.4 62.6 70.0

3.70 46.9 52.2 58.2 68.7

3.80 45.0 48.0 53.9 67.4

3.90 41.8 43.9 51.2 62.9

4.00 38.5 39.8 48.6 58.4

4.10 45.9 53.9

4.20 43.9 50.1

4.30 41.9 46.3

4.40 39.8 42.5

4.50 37.7 40.0

4.60 35.5 37.5

4.70 33.3 35.0

4.80 31.7 33.2 48.7 44.5

4.90 30.0 31.4 47.5 44.4

5.00 28.4 29.6 46.2 44.3

5.10 26.7 27.8 44.5 43.1

5.20 25.1 26.0 42.8 41.8

5.30 23.4 24.2 41.1 40.4

5.40 40.1 39.6

5.50 37.3 37.2

5.60 35.3 35.6

5.70 33.3 34.0

5.80 31.5 32.5

5.90 30.6 31.7

6.00 28.1 29.5

6.10 26.7 28.1

6.20 25.3 26.7

6.30 24.1 25.4

6.40 23.5 24.8

6.50 21.8 22.9

6.60 20.8 21.7

6.70 19.8 20.6

6.75 19.3 20.0

Instructions for Assembly and Use – Standard Configuration

MULTIPROP Slab Props

Table for MULTIPROP 250, 350, 480, 625

with Base MP 50

Permissible prop load [kN] according to the type test

Overall height

[m]

(prop extension

+ 50 cm)

Outer tube

bottom

Inner tube

bottom

Outer tube

bottom

Inner tube

bottom

Outer tube

bottom

Inner tube

bottom

Outer tube

bottom

Inner tube

bottom

Note:

To release the loads > 60 kN we recommend using the HD Wingnut Spanner,

Item no. 022027.

MULTIPROP Slab Props

16

Item no. Weight kg

028000 9.170 Universal Tripod, galv.

Erection aid for slab props with Ø 48 – 120 mm

and 120 x 120 mm. Can also be used in combination with MULTIPROP MP slab props and all slab

props with Base MP 50.

Note

Only use as erection aid!

5

5

5

8

0

0

027288

027289

027290

027291

027305

10.200

15.400

19.500

24.900

34.700

MULTIPROP MP

MULTIPROP MP 120

MULTIPROP MP 250

MULTIPROP MP 350

MULTIPROP MP 480

MULTIPROP MP 625

Slab prop made of aluminium. Used as individual

prop as well as in combination with MULTIPROP

Frames MRK to form towers.

min. L max. L

800 1200

1450 2500

1950 3500

2600 4800

4300 6250

Note

Approved by the German Building Authorities No.

Z-8.312-824.

Technical Data

Permissible load: see PERI Design Tables.

1

0

1

0

m

i

n

L

m

a

x

L

150

648

0

1

2

0

Ø40

Ø14

100

8

7

MULTIPROP Slab Props

17

Item no. Weight kg

027310 8.900 Base MP 50

For use with slab props with an end plate thickness of 6 – 10 mm. With clamped quick-release

fastener.

Note

Permissible load: see PERI Design Tables.

5

0

0

89Ø

2

0

0

150

8

0

Ø12,5Ø42

022027 3.600 Wing Nut Spanner HD

For easy release of the Head Spindle HDK 45, the

Head Spindle TR 110-80/55 and the MULTIPROP

slab prop.

983

Ø38

027790 2.460 Brace Clamp HL, galv., 76 – 120 mm

For assembly of 3 x 15 cm stiffening boards at

slab props Ø 76 – 89 mm and 100 x 100 mm to

120 x 120 mm.

210

2

3

9

40450

MULTIPROP Slab Props

18

Item no. Weight kg

103434

103429

38.500

45.300

Pallets RP-2, galv.

Pallet RP-2 80 x 120, galv.

Pallet RP-2 80 x 150, galv.

For stacking and transportation of formwork and

scaffolding components.

Note

Follow Instructions for Use!

Technical Data

Permissible load-bearing capacity 1.5 t.

1200 / 1500

1080 / 1380

8

5

3

6

0

0

1

0

0

800

680

19

DE en 04 | 2016 3sm 793297 © PERI GmbH

The optimal System for every

Project and every Requirement

PERI GmbH

Formwork Scaffolding Engineering

Rudolf-Diesel-Strasse 19

89264 Weissenhorn

Germany

Tel. +49 (0)7309.950-0

Fax +49 (0)7309.951-0

info@peri.com

www.peri.com

System-Independent Accessories

Wall Formwork

Column Formwork

Slab Formwork

Climbing Systems

Tunnel Formwork Bridge Formwork

Shoring Systems

Facade ScaffoldConstruction Scaffold Industrial Scaffold

Access

Protection Scaffold Services

Loading...

Loading...