Driscopipe 8100

HDPE Gas Distribution Pipe

Driscoplex 6500

MDPE Gas Distribution Pipe

Yellowstripe 8300

HDPE Gas Distribution Pipe

Bulletin PP 310 / February 2019 Page 1 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Performance Pipe

Performance Pipe is a name you can trust in gas distribution piping. We specialize in natural gas distribution,

liquid propane gas (LPG), propane gas distribution, and yard gas products and fittings.

With more than fifty years of polyethylene pipe manufacturing experience, Performance Pipe has seven ISO

9001 certified manufacturing facilities strategically located across the United States.

The unmatched quality and performance of Performance Pipe polyethylene piping products is further

enhanced and strengthened by more than five decades of quality polyolefin plastic resin production from our

parent company Chevron Phillips Chemical Company LP.

As active members of the American Gas Association, ASTM International, Gas Piping Technology

Committee, Plastics Pipe Institute, American Society of Mechanical Engineers, and American Petroleum

Institute, we provide technical expertise and service to these organizations on an ongoing basis.

When you select Performance Pipe gas pipe and fittings, in addition to receiving quality products, you also

gain access to our team of experts for technical support and assistance. Topics range from assistance in

product applications and capabilities to installation and handling to testing and operating procedures. We are

here to help. Our territory sales teams are dedicated to the gas distribution industry and to the service of

Performance Pipe’s gas distribution product customers.

Products

Performance Pipe’s gas piping products are the material of choice for premium medium and high density

natural gas distribution, LPG, propane gas and yard gas piping systems. Performance Pipe’s products are

produced to meet or exceed the manufacturing and material requirements of the latest edition of ASTM D2513

Standard Specification for Polyethylene (PE) Gas Pressure Pipe, Tubing and Fittings, or applicable

international standards. The pipes meet the requirements of ANSI/NFPA 58 Standard for the Storage and

Handling of Liquefied Petroleum Gases.

Performance Pipe offers the following gas distribution products:

Driscoplex 6500 MDPE Gas Distribution Pipe

These medium density polyethylene (MDPE) PE2708 pipes and fittings

are used primarily in pressure-rated gas distribution systems. The

product is also suitable for LPG, propane, yard gas and most aftermeter applications. The product is a solid yellow medium density pipe

that meets ASTM D3350 Cell Classification of PE234373E and

APWA/ULCC Color Code Standards.

Bulletin PP 310 / February 2019 Page 2 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Yellowstripe® 8300 HDPE Gas Distribution Pipe

This high density polyethylene (HDPE) PE4710/PE100 pipe is used

primarily in pressure rated gas distribution systems. The product is

black pipe with four equidistant yellow stripes. The Yellowstripe® 8300

pipe series meets APWA/ULCC Color Code Standards and has an

ASTM D3350 Cell Classification of PE445574C when using HDB or

PE445576C using MRS.

Driscopipe® 8100 HDPE Gas Distribution Pipe

This high density polyethylene (HDPE) PE4710/PE100 pipe is also

primarily used in pressure rated gas distribution applications. The

Driscopipe® 8100 pipe series is a black pipe with a co-extruded yellowshell that complies with the APWA/ULCC Color Code Standards. The pipe

has an ASTM D3350 Cell Classification of PE445574C when using HDB

or PE445576C using MRS. The yellow shell helps reflect solar heat,

enabling retention of higher strength ambient temperature properties. It

also provides improved ability to detect damages and scratches.

Fittings

Performance Pipe manufactures medium density and high density molded butt, socket, and saddle fusion

fittings. The fittings are manufactured to meet the same requirements as our pipe series where applicable.

Quality

Performance Pipe’s polyethylene piping products for gas are unmatched in quality and performance. In

addition to meeting the manufacturing and quality requirements of ASTM D2513 Standard Specification for

Polyethylene (PE) Gas Pressure Pipe, Tubing and Fittings. Performance Pipe’s gas products also meet our

own internal quality assurance (QA) and quality control (QC) requirements. These internal QA/QC

requirements meet or exceed those required by industry standards. Each product line is continuously

monitored throughout the manufacturing cycle to ensure that the product adheres to all internal quality control

specifications and the manufacturing standard. All seven of Performance Pipe’s manufacturing facilities are

certified in accordance with the latest edition of ISO 9001. Individual plant certificates of conformance to ISO

9001 are available upon request.

Sizes

Performance Pipe manufactures its Driscoplex® 6500 pipe product in sized ½” CTS through 12” IPS. For

larger diameter gas applications (8” though 24”) we recommend our high density polyethylene pipes

Yellowstripe® 8300 pipe and Driscopipe® 8100 pipe. Both products are available in 1/2" through 24" (16 mm

through 630 mm) outside-diameter-controlled polyethylene pipe and tubing sizes. Specific sizes of pipe and

fittings available for each product can be found on Performance Pipe’s website at

www.PerformancePipe.com.

Bulletin PP 310 / February 2019 Page 3 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Available Certifications

Specific sizes of Driscoplex® 6500 (MDPE) pipe, Yellowstripe® 8300 (HDPE) pipe and Driscopipe® 8100

(HDPE) pipe and fittings are available with NSF certification to ASTM D2513, CSA (Canadian Gas

Association) B137.4, and the UPC (Uniform Plumbing Code) for yard gas piping, LPG, and other after-meter

applications.

Outdoor Storage

Performance Pipe polyethylene gas distribution piping products are protected from UV effects and outdoor

exposure to ensure pipe performance requirements are maintained.

Yellow pipes, such as Driscopipe® 8100 HDPE gas distribution pipe and Driscoplex® 6500 MDPE gas

distribution pipe, are protected against outdoor exposure through additive formulations and are defined as

Code E materials in accordance with ASTM D3350. Yellowstripe® 8300 HDPE gas distribution pipe is defined

as a Code C material and as such contains a minimum of 2-3 percent carbon black.

Accelerated laboratory weathering tests were conducted on the formulations that predict the yellow pipe

materials are sufficiently stabilized against UV deterioration for unprotected outdoor exposure of at least three

years.

Black (ASTM D3350 Code C) gas pipe materials are considered stabilized against UV degradation for

unprotected outdoor exposure of at least 10 years per ASTM D2513.

Based on the tests conducted, Performance Pipe provides the following specific unprotected outdoor storage

recommendations for Performance Pipe’s gas distribution piping products.

Driscoplex

®

6500 pipe 3 years

Driscopipe

®

8100 pipe 3 years

Yellowstripe

®

8300 pipe 10 years

Tracking and Traceability

Performance Pipe polyethylene gas distribution piping products are marked per ASTM D2513 and adhere to

Department of Transportation regulations for plastic pipe (49 CFR Part 192, §192.63). ASTM D2513-12ae1

requires a 16 character code generated per ASTM F2897 to be legibly printed on pipe in both alpha-numeric

and barcode form for tracking and traceability purposes. This 16 character code and corresponding barcode

provides information that identifies Performance Pipe as the manufacturer, our specific production location,

production run number, date, pipe or fitting type, and material grade.

Bulletin PP 310 / February 2019 Page 4 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Cautions

Polyethylene piping has been safely used in thousands of applications. However, there are general

precautions that should be observed when using any product. In this respect, polyethylene piping is no

different. Below is a list of some of the precautions that should be observed when using Performance Pipe’s

gas pipe and fittings.

• Fusion

During the heat fusion process, equipment and products can reach temperatures in excess of 450°F

(231°C). Caution should be taken to prevent burns.

Do not bend pipes into alignment against open butt fusion machine clamps. The pipe may spring out

and cause injury or damage.

Performance Pipe polyethylene piping products cannot be joined with adhesives or solvent cement.

Pipe-thread joining and joining by hot air (gas) welding or extrusion welding techniques are not

recommended for pressure service.

• Static Electricity

High static electricity charges can develop on polyethylene piping products, especially during

squeeze-off, when repairing a leak, purging, making a connection, etc.

Where a flammable gas atmosphere and static electric charges may be present, observe all company

(pipeline operator, utility, contractor, etc.) safety procedures for controlling and discharging static

electricity and all requirements for personal protection. See website for: Performance Pipe Technical

Note Polyethylene Pipe Squeeze Off; PP 801-TN.

• Weight, Unloading and Handling

Although polyethylene pipe is not as heavy as some other piping products, significant weight may be

involved. Care should be used when handling and working around polyethylene pipe. Improper

handling or abuse may cause damage to piping, compromise system quality or performance, or cause

personal injury. Observe the safe handling instructions provided by the delivery driver. See website

for Performance Pipe Video Gallery to view: Pipe Loading/Unloading-Truck Driver Safety Video.

• Coils

Coiled PE pipe may be restrained with strapping or shrink-wrap to contain the spring-like energy

retained within the coil. Cutting or breaking the strapping or removing the shrink-wrap can result in an

uncontrolled release. Take all necessary safety precautions and use appropriate equipment. Observe

the safe handling instructions provided by the delivery driver and available on the Performance Pipe

website at www.performancepipe.com.

Leak Testing

When testing is required, fuel gas distribution systems should be tested in accordance with applicable codes

and regulations and distribution system operator procedures. Observe all safety measures, restrain pipe

against movement in the event of catastrophic failure, and observe limitations of temperature, test pressure,

test duration, and procedures for making repairs.

Bulletin PP 310 / February 2019 Page 5 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Protection against Shear and Bending Loads

Measures such as properly placed, compacted backfill, protective sleeves, and structural support are

sometimes necessary to protect plastic pipe against shear and bending loads.

For additional installation information see ASTM D2774, Underground Installation of Thermoplastic Pressure

Piping.

Locating

Most polyethylene materials are not detectable with standard magnetic locating equipment. When installing

PE piping, a method or methods for future pipeline detection should be considered. Gas utilities in the area

should always be contacted before the start of any underground installation work such as excavation,

trenching, directional boring, etc.

Liquid Hydrocarbon Permeation

PE piping that has been in service conveying fuel gases that include liquid hydrocarbons or otherwise exposed

to liquid hydrocarbons can sometimes exhibit a bubbly appearance when melted for heat fusion. This bubbling

is the result of the rapid expansion (by heat) and passage of heavier, absorbed hydrocarbon gases through

the heated and molten polyethylene material. Studies* have shown that propane concentrations under 0.2%

is sufficient to sometimes show some bubbling but is not high enough to affect any significant degradation in

strength of the pipe or fusion joint. However, since there currently are no field tests to readily determine the

amount of absorbed hydrocarbons in PE pipe and their potential effect on the fusion joint, if bubbles are

encountered during a heat fusion process, heat fusion should be abandoned and mechanical connections

should be used. Substantial liquid hydrocarbon permeation may impact the hydrostatic strength of

polyethylene and thus operating conditions should be also be assessed to determine whether an adjustment

to the pipeline pressure is necessary. See additional information on the topic on page 15.

(*S.M. Pimputkar, J.A. Stets, and M.L. Mamoun, “Examination of Field Failures”, Sixteenth International Plastics Pipe

Symposium, New Orleans, Louisiana, November 1999.)

Gas Permeability and Permeation

Plastics are permeable to gases to varying degrees. Although the constituents of natural gas can permeate

through polyethylene, the volume of gas lost through permeation is generally so low as to have an insignificant

effect on the handling of natural gas in a piping system. The American Gas Association (AGA) Plastic Pipe

Manual for Gas Service lists the permeability of PE2708 polyethylene pipe to methane, the primary constituent

of natural gas, as 4.2 x10

-3

. Using the AGA factor, one mile of 2” SDR 11 PE2708 pipe carrying 100% methane

at 60 psi would lose less than 0.27 ft3 per day. Other constituents of natural gas are typically heavier than

methane, thus less permeable through polyethylene. Hydrogen is the exception; however, the concentration

of hydrogen in most natural gas is so low that the actual amount of hydrogen permeation would be

insignificant.

Bulletin PP 310 / February 2019 Page 6 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Joining

• D.O.T. Regulations require that each joint in a gas piping system must be made in accordance with

written procedures that have been proved by test or experience to produce strong gastight joints (49

CFR Part 192, §192.273(b)).

• D.O.T. Regulations require that written procedures for butt fusion, saddle fusion, and socket fusion

joining of polyethylene gas piping must be qualified before use by subjecting specimen joints to

required test procedures (49 CFR Part 192, §192.283(a)).

• D.O.T. Regulations require that all persons who make joints in polyethylene gas piping must be

qualified under the operator's written procedures (49 CFR Part 192, §192.285(a)).

• D.O.T. Regulations require that the gas system operator must ensure that all persons who make or

inspect joints are qualified (49 CFR Part 192, §192.285(d) & §192.287).

Performance Pipe recommends using Performance Pipe’s Fusion Joining Procedures Bulletin PP-750 Heat

Fusion Joining Procedures and Qualification Guide when making heat fusion joints with our 6500, 8300 and

8100 Series gas piping products. When PP-750 is used to join Performance Pipe polyethylene gas pipe and

fittings, Performance Pipe fusion joining procedures are qualified in accordance with U.S. Department of

Transportation Regulations. A copy of PP-750 may be obtained from our website at:

www.performancepipe.com.

Other qualified procedures used for butt and saddle fusion of polyethylene gas piping products are ASTM

F2620 Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings, the Plastic Pipe Institute’s,

PPI TR-33 Generic Butt Fusion Joining Procedure for Field Joining of Polyethylene Pipe and PPI TR-41

Generic Saddle Fusion Joining Procedure for Polyethylene Gas Piping.

Squeeze-Off

Squeeze-off is used to control flow in PE pipe by flattening the pipe between parallel bars. Squeeze-off is

used for routine and emergency situations. Do not squeeze-off more than once at the same point on the

pipe. For repeated flow control, throttling, or partial flow restriction, install a valve or an appropriate flow

control device.

Complete flow stoppage will not occur in all cases. For larger pipes, particularly at higher pressures, some

seepage is likely. If seepage is not permissible, the pipe should be vented in between two squeeze-offs.

Use squeeze-off procedures meeting ASTM F1041 and tools meeting ASTM F1563 with Performance Pipe

polyethylene pipes. The combination of pipe, tool, and squeeze-off procedures should be qualified in

accordance with ASTM F1734. Correct tool closure stops and closing and opening rates are key elements to

squeezing-off without damaging the pipe. Tool closure stops must be correct for the pipe size and wall

thickness (SDR). It is necessary to close slowly and release slowly, with slow release being more important.

See Performance Pipe Technical Note PP-801 Squeeze-Off on our website at: www.performancepipe.com.

Bulletin PP 310 / February 2019 Page 7 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Performance Characteristics

Cell Classification

ASTM D3350 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials standard cell

classification covers the identification of polyethylene materials for pipe and fittings according to a cell

classification system. Performance Pipe’s gas piping products are listed below.

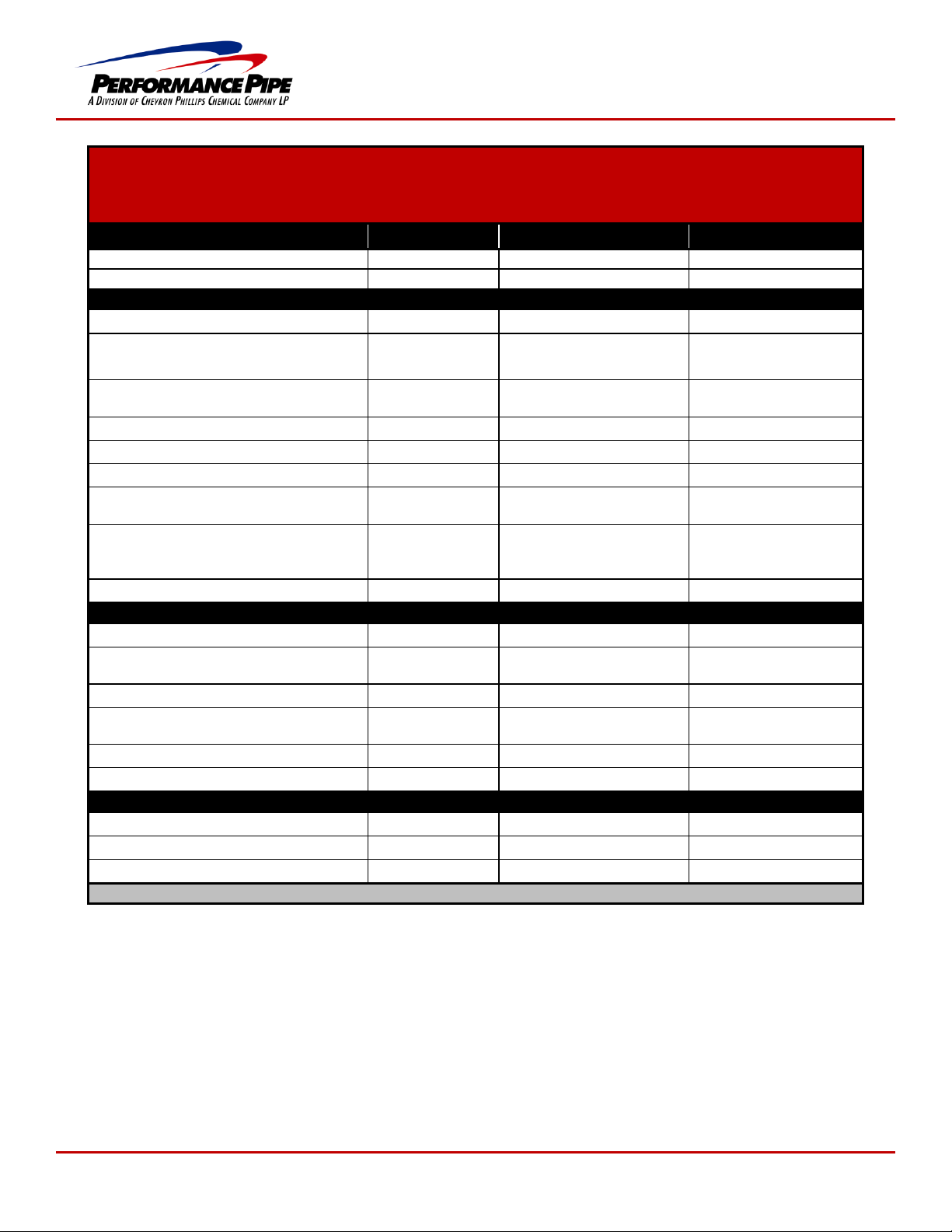

Table 1: Cell Classifications

Performance Pipe

Product Series

Material Designation Code

ASTM D3350 Cell

Classification

Driscoplex® 6500 Pipe (MDPE)

PE2708

234373E

Driscopipe® 8100 Pipe (HDPE)

PE4710-PE100

445574C (445576C*)

Yellowstripe® 8300 Pipe (HDPE)

PE4710-PE100

445574C (445576C*)

* When using the Minimum Required Strength (MRS) classification.

Long-Term Strength (HDB)

Performance Pipe’s polyethylene piping products for gas distribution are listed with the Plastics Pipe Institute

(PPI) and have PPI recommended Hydrostatic Design Basis (HDB) ratings as follows:

Table 2: Hydrostatic Design Basis

Performance Pipe Product

Series

Hydrostatic Design Basis (HDB)

73°F (23°C)

Hydrostatic Design Basis (HDB)

140°F (60°C)

Driscoplex® 6500 Pipe (MDPE)

1250 psi (8.62 MPa)

800 psi (5.52 MPa)

Driscopipe® 8100 Pipe (HDPE)

1600 psi (11.03 MPa)

1000 psi (6.89 MPa)

Yellowstripe® 8300 Pipe (HDPE)

1600 psi (11.03 MPa)

1000 psi (6.89 MPa)

HDB by Temperature Interpolation

Elevated temperature properties can be used to determine product capabilities for applications where

products will be exposed to elevated temperatures. The Hydrostatic Design Stress for polyethylene is

established by testing at 73oF. As with all thermoplastics, when operating temperature increases, pressure

capacity decreases.

When determining HDB values, use the interpolation protocol of PPI TR-3 D.2 Policy for Determining Long-

Term Strength (LTHS) By Temperature Interpolation.

The policy states that, for thermoplastic pipe that is going to be installed at a service temperature greater than

73ºF and less than that at which the next HDB has been established, the HDB at the anticipated service

temperature can be determined by interpolation.

Bulletin PP 310 / February 2019 Page 8 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Table 3: HDB in PSI by Temperature

Hydrostatic Design Basis , HDB (psi)

Performance Pipe Product Series

73F

100F

120F

140F

Data

Interpolated

Interpolated

Data

Driscoplex® 6500 Pipe (MDPE)

1250

1000

1000

800

Driscopipe® 8100 Pipe (HDPE)

1600

1250

1000

1000

Yellowstripe® 8300 Pipe (HDPE)

1600

1250

1000

1000

Slow Crack Growth (SCG) Resistance

Resistance to slow crack growth is measured using ASTM F1473 Standard Test Method for Notch Tensile

Test to Measure the Resistance to Slow Crack Growth of Polyethylene Pipes and Resins. ASTM D2513

requires that all PE materials used in gas distribution service meet a minimum of at least 500 hours when

tested per ASTM F1473. The University of Pennsylvania researchers early on concluded that one hour of

PENT roughly equated to 13 years of service life.* While that analysis may be limited it does illustrate the

tremendous slow crack growth resistance of the current materials.

(* N. Brown. (2007) “Intrinsic Lifetime of Polyethylene Pipelines”, Polymer Engineering and Science, 47 (4),

pg. 477-480.)

Table 4: Typical PENT Values for resins used in Performance Pipe Product Series

Performance Pipe Product Series

PENT, hours (ASTM F1473)

Driscoplex® 6500 Pipe (MDPE)

>2,000

Driscopipe® 8100 Pipe (HDPE)

>10,000

Yellowstripe® 8300 Pipe (HDPE)

>10,000

Rapid Crack Propagation

When a pressurized polyethylene pipe is subjected to an instantaneous and intense impact, a pre-existing or

consequently initiated crack or flaw can propagate axially at extremely high speeds. This mode of fracture is

referred to as Rapid Crack Propagation, or RCP. It is a property inherent in fracture mechanics of many pipe

materials, including polyethylene. Similarly, Rapid Crack Arrest (RCA) is a fast fracture property of the pipe

material that arrests the travel of the crack after initiation or before RCP can occur.

While RCP occurrences in PE pipes are extremely rare, the consequences can be significant. Because of the

catastrophic nature of a potential RCP event, pipe producers have begun to design pipes and applications

such that RCP may be avoided in most circumstances. This has led to the development of several tests, of

which the Full-Scale (FS) and Small-Scale Steady State (S4) tests are most relevant.

Bulletin PP 310 / February 2019 Page 9 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Full Scale Test (FST) ISO 13478

Polyethylene pipes that are approximately 40 times the diameter in length are pressurized at low

temperatures, and failure is initiated through blunt force impact with a striker at one end to initiate a

crack. The critical pressure and temperature are directly determined.

Small-Scale Steady State (S4) ISO 13477 and ASTM F1589

The S4 test pipe specimens are typically a minimum of seven times the diameter in length. Specimens

are conditioned at the test temperature, and then moved to the S4 test rig where they are sealed at

both ends and pressurized with air. A sharp chisel-edged striker impacts the pipe at one end to initiate

a fast-running crack. A containment cage around the specimen constrains the outside diameter of the

pipe and a series of baffles inserted into the pipe’s inside diameter restrains the decompression during

crack propagation. The results are correlated to the full scale critical pressure.

Performance Pipe’s gas piping products have been tested to ISO 13477 and/or ISO13478 with exceptional

RCP resistance.

ASTM Test Values

The charts below show material physical properties, ASTM test methods for the property, and nominal values

for Performance Pipe materials used for gas pipe. (Note - Per ASTM D748, the brittleness temperature is less

than <-103°F (<-75°C), therefore, Performance Pipe’s Yellowstripe® 8300 pipe, Driscopipe® 8100 pipe and

Driscoplex® 6500 pipe series may be used at operating temperatures down to or below <- 40°F (<-40°C)).

Typical physical properties for each pipe are included below.

Bulletin PP 310 / February 2019 Page 10 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Yellowstripe® 8300 HDPE Gas Distribution PIpe

PE4710-PE100

Typical Physical Property Pipe Data Sheet

Property

Unit

Test Procedure

Typical Value

Material Designation

--

PPI TR-4

PE4710

PE100

Cell Classification

--

ASTM D3350

445574C

445576C

Pipe Properties

Density

g / cm3

ASTM D1505

0.961 (black)

Melt Index (MI)

Condition 190/2.16

g / 10 minutes

ASTM D1238

0.08

Melt Index (HLMI)

Condition 190/21.6

g / 10 minutes

ASTM D1238

7.5

Hydrostatic Design Basis, (73°F)

psi

ASTM D2837

1,600

Hydrostatic Design Basis, (140°F)

psi

ASTM D2837

1,000

Minimum Required Strength

MPa (psi)

ISO 9080

10 (1450)

Rapid Crack Propagation

Critical Pressure (Pc), 0°C (32°F)

(1)

bar (psi)

ISO 13477

>12 bar (>174)

Color; UV Stabilizer [C]

%

ASTM D3350

Min. 2% Carbon Black

UV stabilized 10 years

Pipe Test Category

---

ASTM D2513

CEE

Material Properties

Flexural Modulus @2% strain

psi

ASTM D790

150,000

Tensile Strength at Yield

psi

ASTM D638 (Type IV)

>3,500

Elongation at Break

2 in/min., Type IV bar

%

ASTM D638

>500

Hardness

Shore D

ASTM D2240

65

PENT

hrs

ASTM F1473

10,000

Manufactured to ASTM D2513 for pipe. Fittings comply with ASTM D2513 and ASTM D3261.

Thermal Properties

Vicat Softening Temperature

o

F

ASTM D1525

255

Brittleness Temperature

o

F

ASTM D746

<-103

Thermal Expansion

in / in / oF

ASTM D696

1.0 x 10-4

(1) RCP properties determined by S4 test on 10 inch DR11.

(2) NOTICE: This data sheet provides typical physical property information for polyethylene resins used to manufacture

PERFORMANCE PIPE polyethylene piping products. It is intended for comparing polyethylene piping resins. It is not a

product specification, and it does not establish minimum or maximum values or manufacturing tolerances for resins or

for piping products. Some of these typical physical property values were determined using compression molded plaques.

Values obtained from tests of specimens taken from piping products can vary from these typical values. This data sheet

may be changed from time to time without notice. Contact Performance Pipe to determine if you have the most recent

edition.

Bulletin PP 310 / February 2019 Page 11 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

DRISCOPIPE® 8100 HDPE Gas Distribution Pipe

PE4710-PE100

Typical Physical Property Pipe Data Sheet

Property

Unit

Test Procedure

Typical Value

Material Designation

--

PPI TR-4

PE4710

PE100

Cell Classification

--

ASTM D3350

445574C

445576C

Pipe Properties

Density

g / cm3

ASTM D1505

0.961 (black)

Melt Index (MI)

Condition 190/2.16

g / 10 minutes

ASTM D1238

0.08

Melt Index (HLMI)

Condition 190/21.6

g / 10 minutes

ASTM D1238

8.0

Hydrostatic Design Basis, (73°F)

psi

ASTM D2837

1,600

Hydrostatic Design Basis, (140°F)

psi

ASTM D2837

1,000

Minimum Required Strength

MPa (psi)

ISO 9080

10 (1450)

Rapid Crack Propagation

Critical Pressure (Pc), 0°C (32°F)

(1)

bar (psi)

ISO 13477

>12 (>174)

Color; UV Stabilizer

---

ASTM D3350

Co-extruded yellow

shell UV stabilized for

3 years outdoor

storage

Pipe Test Category

---

ASTM D2513

CEE

Material Properties

Flexural Modulus @2% strain

psi

ASTM D790

140,000

Elastic Modulus @ Secant 2% strain

(2in/min, Type IV bar)

psi

ASTM D638

>200,000

Tensile Strength at Yield

psi

ASTM D638 (Type IV)

3,700

Elongation at Break

2 in/min., Type IV bar

%

ASTM D638

>700

Hardness

Shore D

ASTM D2240

65

PENT

hrs

ASTM F1473

>10,000

Pipe is manufactured to ASTM D2513. Fittings comply with ASTM D2513 and ASTM D3261.

Thermal Properties

Vicat Softening Temperature

o

F

ASTM D1525

255

Brittleness Temperature

o

F

ASTM D746

<-103

(1) RCP Properties determined by S4 test on 12 inch DR11 pipe.

(2) NOTICE: This data sheet provides typical physical property information for polyethylene resins used to manufacture

PERFORMANCE PIPE polyethylene piping products. It is intended for comparing polyethylene piping resins. It is not a

product specification, and it does not establish minimum or maximum values or manufacturing tolerances for resins or

for piping products. Some of these typical physical property values were determined using compression molded plaques.

Values obtained from tests of specimens taken from piping products can vary from these typical values. This data sheet

may be changed from time to time without notice. Contact Performance Pipe to determine if you have the most recent

edition.

Bulletin PP 310 / February 2019 Page 12 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Driscoplex® 6500 MDPE Gas Distribution Pipe

PE2708

Typical Physical Property Pipe Data Sheet

Property

Unit

Test Procedure

Typical Value

Material Designation

--

PPI TR-4

PE2708

Cell Classification

--

ASTM D3350

234373E

Pipe Properties

Density

g / cm3

ASTM D1505

0.939

Melt Index (MI)

Condition 190/2.16

g / 10 minutes

ASTM D1238

0.18

Melt Index (HLMI)

Condition 190/21.6

g / 10 minutes

ASTM D1238

20.0

Hydrostatic Design Basis, (73°F)

psi

ASTM D2837

1,250

Hydrostatic Design Basis, (140°F)

psi

ASTM D2837

800

Minimum Required Strength

MPa (psi)

ISO 9080

8.0 (1160)

Rapid Crack Propagation

Critical Pressure (Pc), 0°C (32°F)

(1)

bar (psi)

ISO 13478

8.5 bar (>123)

Color; UV Stabilizer

---

ASTM D3350

Yellow UV stabilized

for 3 years outdoor

storage

Pipe Test Category

---

ASTM D2513

CDE

Material Properties

Flexural Modulus @2% strain

psi

ASTM D790

90,000

Elastic Modulus @ Secant 2% strain

(2in/min, Type IV bar)

psi

ASTM D638

>86,000

Tensile Strength at Yield

psi

ASTM D638 (Type IV)

2,800

Elongation at Break

2 in/min., Type IV bar

%

ASTM D638

>800

Hardness

Shore D

ASTM D2240

63

PENT

hrs

ASTM F1473

>2000

Thermal Properties

Vicat Softening Temperature

o

F

ASTM D1525

227

Brittleness Temperature

o

F

ASTM D746

<-103

Thermal Expansion

in / in / oF

ASTM D696

1.0 x 10-4

Manufactured to ASTM D2513 for pipe. Fittings comply with ASTM D2513 and ASTM D3261.

(1) RCP Properties determined by full scale test on 8 inch DR11 pipe. See Technical Note PP 842-TN.

(2) NOTICE: This data sheet provides typical physical property information for polyethylene resins used to manufacture

PERFORMANCE PIPE polyethylene piping products. It is intended for comparing polyethylene piping resins. It is not a

product specification, and it does not establish minimum or maximum values or manufacturing tolerances for resins or

for piping products. Some of these typical physical property values were determined using compression molded plaques.

Values obtained from tests of specimens taken from piping products can vary from these typical values. This data sheet

may be changed from time to time without notice. Contact Performance Pipe to determine if you have the most recent

edition.

Bulletin PP 310 / February 2019 Page 13 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

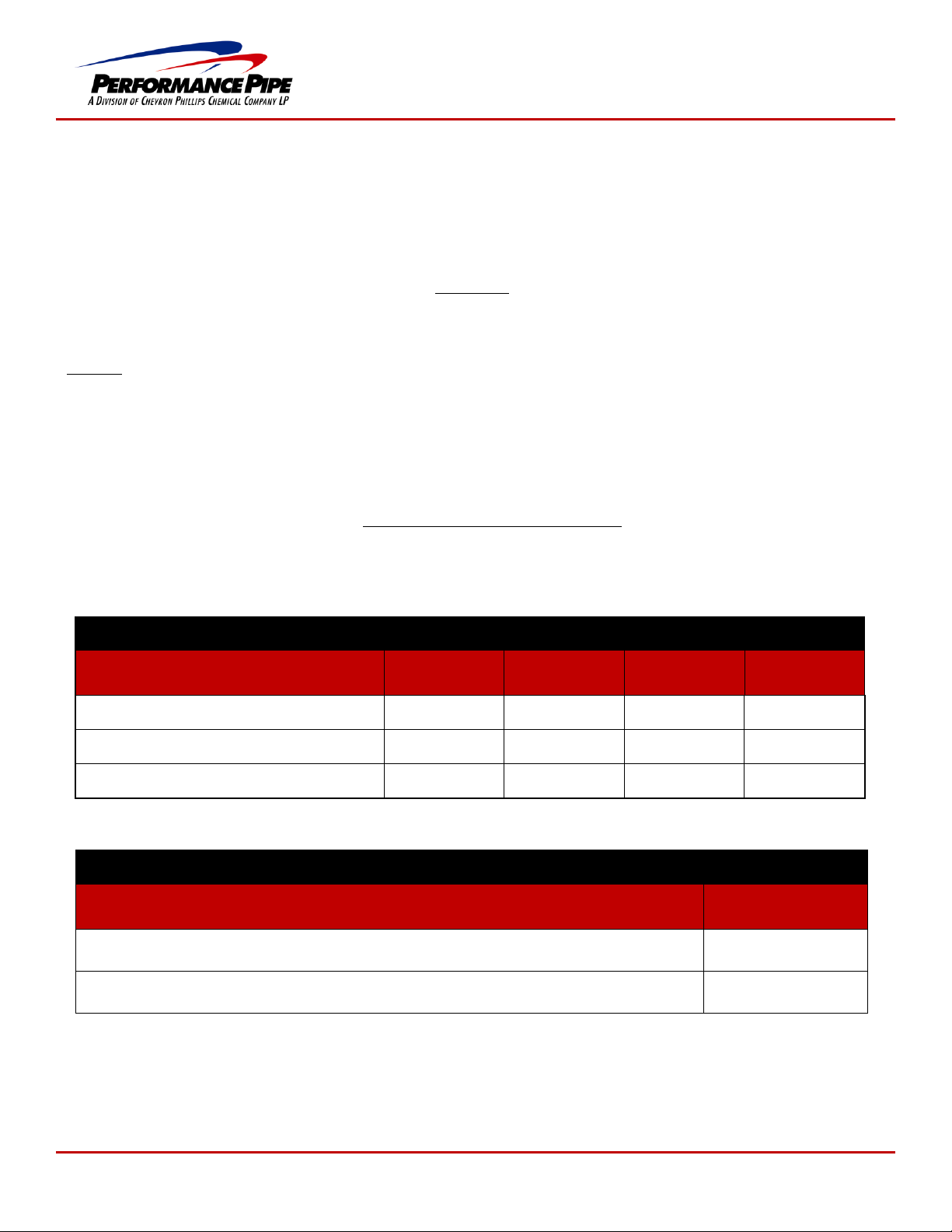

Design Pressure

The following formula is used to compute the design pressures for polyethylene piping systems for natural

gas service at operating temperatures up to but not over 140°F (60°C). For operating temperatures below

73°F (23°C), use 73°F (23°C) Design Pressures.

Where:

P = Design Pressure in pounds per square inch gauge (psig);

S = Hydrostatic Design Basis psi, at pipeline operating temperature; See Table 5.

DF = Design factor (specified in 49 CFR §192.121); See Table 6.

DR= Standard Dimension Ratio

DR =

Pipe Nominal Outside Diameter

Pipe Minimum Wall Thickness

Table 5: Hydrostatic Design Basis

Hydrostatic Design Basis , HDB (psi)

Performance Pipe Product Series

73F

100F

120F

140F

Data

Interpolated

Interpolated

Data

Driscoplex® 6500 Pipe (MDPE)

1250

1000

1000

800

Driscopipe® 8100 Pipe (HDPE)

1600

1250

1000

1000

Yellowstripe® 8300 Pipe (HDPE)

1600

1250

1000

1000

Table 6: Design Service Factor

Design Factor by Application

Application

Design (service)

Factor, DF

Gas distribution and transmission per 49 CFR Part 192, ≤12” PE pipe meeting minimum

wall thickness requirements per §192.121 and produced after January 22, 2019.

0.40

Gas distribution and transmission per 49 CFR Part 192, >12” pipe and pipe not meeting

the requirements for a 0.40 DF per §192.121

0.32

Bulletin PP 310 / February 2019 Page 14 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Design Pressure Ratings

The Pipeline and Hazardous Materials Safety Administration (PHMSA) issued the Plastic Pipe Rule amending

49 CFR Part 192. The revised §192.121 allows the use of a design factor of 0.40 to calculate the design

pressure rating for PE2708 and PE4710 pipes sizes 12” IPS and smaller meeting certain minimum wall

thickness requirements and manufactured after January 22, 2019. A 0.32 design factor would continue to be

applied to all other PE pipe.

The following table uses the design factors as specified by §192.121. A check should be made to determine

if these pressures apply under the state and/or local codes governing the specific application. Use 73°F (23°C)

pressure ratings for operating temperatures below 73°F (23°C).

Table 7: Maximum Design Pressure Ratings Performance Pipe Gas Distribution Products

Maximum Design Pressure Rating per §192.121 for Dry Natural Gas Service

Driscoplex® 6500 Pipe (Design Factor 0.40) PE2708

Size(s)

Dimension Ratio

(DR) / Wall

Thickness

[inches] (WT)

73ºF (23ºC)

(PSIG)

100ºF (38ºC)

(PSIG)

120ºF (48ºC)

(PSIG)

140ºF (60ºC)

(PSIG)

½” CTS

0.090” WT

125†

125†

125†

108

1” CTS

0.099” WT

77‡

62‡

62‡

49‡

½” IPS

DR 9.33

120

96

96

77

1 ¼” IPS

DR 10.0

111

89

89

71

¾” IPS – 12” IPS

DR 11.0

100

80

80

64

3” IPS – 12” IPS

DR 11.5

95

76

76

61

4” IPS – 12” IPS

DR 13.5

80

64

64

51

Driscopipe 8100 and Yellowstripe 8300 Pipe (Design Factor 0.40) PE4710/PE100

Size(s)

Dimension Ratio

(DR) / Wall

Thickness

[inches] (WT)

73ºF (23ºC)

(PSIG)

100ºF (38ºC)

(PSIG)

120ºF (48ºC)

(PSIG)

140ºF (60ºC)

(PSIG)

½” CTS

0.090” WT

125†

125†

125†

125†

1” CTS

0.090” WT

89‡

70‡

56‡

56‡

0.101” WT

101‡

79‡

63‡

63‡

½” IPS

DR 9.33

125†

120

96

96

¾” IPS – 12” IPS

DR 11.0

125†

100

80

80

6” IPS – 12” IPS

DR 13.5

102

80

64

64

> 12” IPS

DR 11.0

100† ‡

80‡

64‡

64‡

DR 17

64‡

50‡

40‡

40‡

† 49 CFR Part §192.121 limits design pressure to 125psig for pipe ≤12” IPS and 100psig for >12”IPS.

‡ Uses a Design Factor of 0.32; does not meet the size or wall requirement of 49 CFR Part §192.121 for 0.40.

Bulletin PP 310 / February 2019 Page 15 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Liquid Hydrocarbon Effect on Pressure Ratings

Dry gaseous hydrocarbons have no adverse effect on the expected service life. Liquid hydrocarbons such as

gasoline and gas condensates will permeate the wall and reduce hydrostatic strength, but do not degrade the

material. Upon evaporation of the hydrocarbon, the pipe will regain its original physical properties. PE pipe to

be exposed continuously to liquid hydrocarbons may require a reduction of the pipe’s design pressure rating.

Per ANSI GPTC Z380.1 Guide for Gas Transmission, Distribution, and Gathering Piping Systems, a 0.5

application factor is recommended as shown in the equation below.

Cold Bending Radius

The allowable cold bending radius for Driscoplex

®

gas distribution pipe is dependent upon the pipe OD, DR

and the presence of fittings in the bend. See Performance Pipe’s Technical Note PP-819-TN Field Bending

of Driscoplex® PE Piping.

Table 8: Allowable Cold Bending Radius

Pipe Dimension Ratio

Allowable Cold Bending Radius

9 or less

20 times the pipe OD

>9 to 13.5

25 times the pipe OD

13.5 or greater

27 times the pipe OD

Fitting or flange present in the bend

100 times the pipe OD

Special Considerations for Plowing and Planting

Plowing and planting involve cutting a narrow trench and feeding the pipe into the trench through a shoe or

chute fitted just behind the trench cutting equipment. The shoe or chute feeds the pipe into the bottom of the

cut. The minimum bend radius of the pipe through the shoe may be tighter than the minimum bend radius of

the pipe used for a permanent long-term installation, but it must not be so tight that the pipe kinks. Table 9

presents the minimum short-term bend ratio for applications such as plowing and planting. The pipe’s path

through the shoe or chute should be as friction free as practicable to reduce additional outerfiber tensile

stresses. Generally plowing and planting is limited to 12” and smaller pipes.

Table 9: Minimum Short-term Cold Bending Radius

Pipe Dimension Ratio

Minimum Short-Term bending Radius

9

10

>9 to 13.5

13

>13.5 to 17

17

Bulletin PP 310 / February 2019 Page 16 2019 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662

Propane (LPG) Gas Service

The Office of Pipeline Safety Advisory Bulletin No. 73-4, dated April 1973, states, "It is the operator's

responsibility to assure the integrity of the plastic pipe selected for use in the piping system, and this should

be based on a favorable recommendation from the manufacturer. Therefore, the Federal minimum safety

standards do permit the use of plastic in a properly engineered underground system of LPG distribution

conforming to the limitations of these regulations." Driscoplex

®

6500 pipe (PE2708), Driscopipe® 8100 pipe

(PE4710) and Yellowstripe

®

8300 pipe (PE4710) series products meet the requirements of ANSI/NFPA 58

Standard for the Storage and Handling of Liquefied Petroleum Gases.

The Plastics Pipe Institute has made the following "Use Recommendation" for polyethylene piping systems

for commercial propane systems (PPI Technical Report TR-22):

The information collected indicates that polyethylene plastic piping is satisfactory for transporting LPG and its

major component, propane gas. This information also indicates that pressure design parameters based on

propane gas should be adequate and reasonable. However, until more information is available, these use

recommendations cover only commercial propane vapor in detail.

1. The polyethylene plastic pipe, tubing and fittings should be only those specific types designated as

PE2708 or PE4710 and meeting the appropriate requirements of ASTM D2513.

2. A Hydrostatic Design Basis of 1000 psi should be used in the design of polyethylene pipe systems for

propane gas distribution at pipe temperatures of 73°F or lower. The long-term hydro static strength

measurements should be made in accordance with ASTM D2837.

3. Polyethylene should be used only in underground propane gas distribution systems designed to

operate at internal pressures and temperatures such that condensation will not occur.

It is also recommended that operating pressures be limited to 30 psig or less.

In cases where condensation does occur in a propane system or propane enriched system and the presence

of condensation is of relatively short duration, there is no indication of loss of physical integrity or observable

change in polyethylene pipe. Under actual operating conditions, in a properly designed system, the pressures

and temperatures are such that revaporization of any propane condensates will usually occur. Experience

with propane liquids in polyethylene shows that there is no cumulative effect of intermittent, short duration

exposure of propane condensate in polyethylene. For additional information, see PPI Technical Report TR-

22. Exposure to liquefied propane condensates for extended periods may affect joining.

Mercaptans

Mercaptans are a group of organic compounds containing a Sulfur-Hydrogen bond that have a distinct odor

in small concentrations. Natural gas is an odorless hydrocarbon. Natural gas carriers and distributors add

mercaptans to natural gas to warn of leaks and to alert the presence of natural gas atmospheres. New plastic

pipes have the tendency to absorb mercaptans, causing the odor to fade or become faint. The effect is not

long term and after a period of time the distinctive odor of mercaptan is readily detected when released.

Mercaptan enriched natural gas has the possibility of inducing a phenomenon known as “odor fatigue.” The

condition can cause nasal passages to become saturated with the smell of gas over time, making it difficult

to continue to detect the mercaptan odor.

CONTACT INFORMATION:

Performance Pipe

A Division of Chevron Phillips Chemical Company LP

5085 W. Park Blvd, Suite 500

Plano, TX 75093

Phone: 800-527-0662

Technical Services

Phone: 972-599-6632

Email: pipe-techsupport@cpchem.com

Visit Performance Pipe on the web for the latest literature updates.

www.performancepipe.com

NOTE: By using any Technical Information contained herein, Recipient agrees that said Technical Information is given by Performance Pipe, a

division of Chevron Phillips Chemical Company LP for convenience only, without any warranty or guarantee of any kind, and is accepted and used

at your sole risk. Recipients are encouraged to verify independently any such information to their reasonable satisfaction. As used in this paragraph,

"Technical Information" includes any technical advice, recommendations, testing, or analysis, including, without limitation, information as it may

relate to the selection of a product for a specific use and application.

Loading...

Loading...