DRISCOPLEX® 6400 Series

DriscoPlex® Series Pipe Material Physical Properties

Property

Standard

Typical Value

Material Designation

ASTM D2513

PE 4710

Cell Classification

ASTM D3350

445574C (Black)

Density [4]

ASTM D1505

0.960 g/cc (Black)

Melt Index [4]

ASTM D1238

0.08 g/10 min

Flexural Modulus [5]

ASTM D790

>120,000 psi

Tensile Strength [5]

ASTM D638 Type IV

>3,500 psi

SCG (PENT) [7]

ASTM F1473

>500 hours

HDB at 73°F (23°C) [4]

ASTM D2837

1,600 psi

Color; UV stabilizer [C]

ASTM D3350

Black

Oil

Raw Water

Process Water

Gas

Brine Water

Shale Recovery

Coal

Landfill

Process Slurry

Methane

Leachate

Dewatering

This is not a product specification and does not guarantee or establish specific minimum or maximum values or manufacturing tolerance for material or piping

DRISCOPLEX® 6400 Series

Oil and Gas Gathering HDPE Pipe

®

DRISCOPLEX

HDPE Pipe is available

to meet your needs in compliance with

ASTM D2513 and API 15LE product

standards.

Produced from only the highest rated

HDPE pipe material, DRISCOPLEX

®

6400 Series Pipe is manufactured from

PE4710 resin as listed in PPI-TR4 and

is known for its durability, chemical and

abrasion resistance.

DRISCOPLEX

®

HDPE Pipe Applications:

products to be supplied. Values obtained from tests of specimens taken from piping product may vary from these typical values.

Bulletin PP 683 | May 2013 www.performancepipe.com © 2013 Chevron Phillips Chemical Company LP

Performance Pipe, a division of Chevron Phillips Chemical Company LP | 5085 W. Park Blvd | Suite 500 | Plano, TX 75093 | Phone: 800-527-0662 | Fax: 972-599-7329

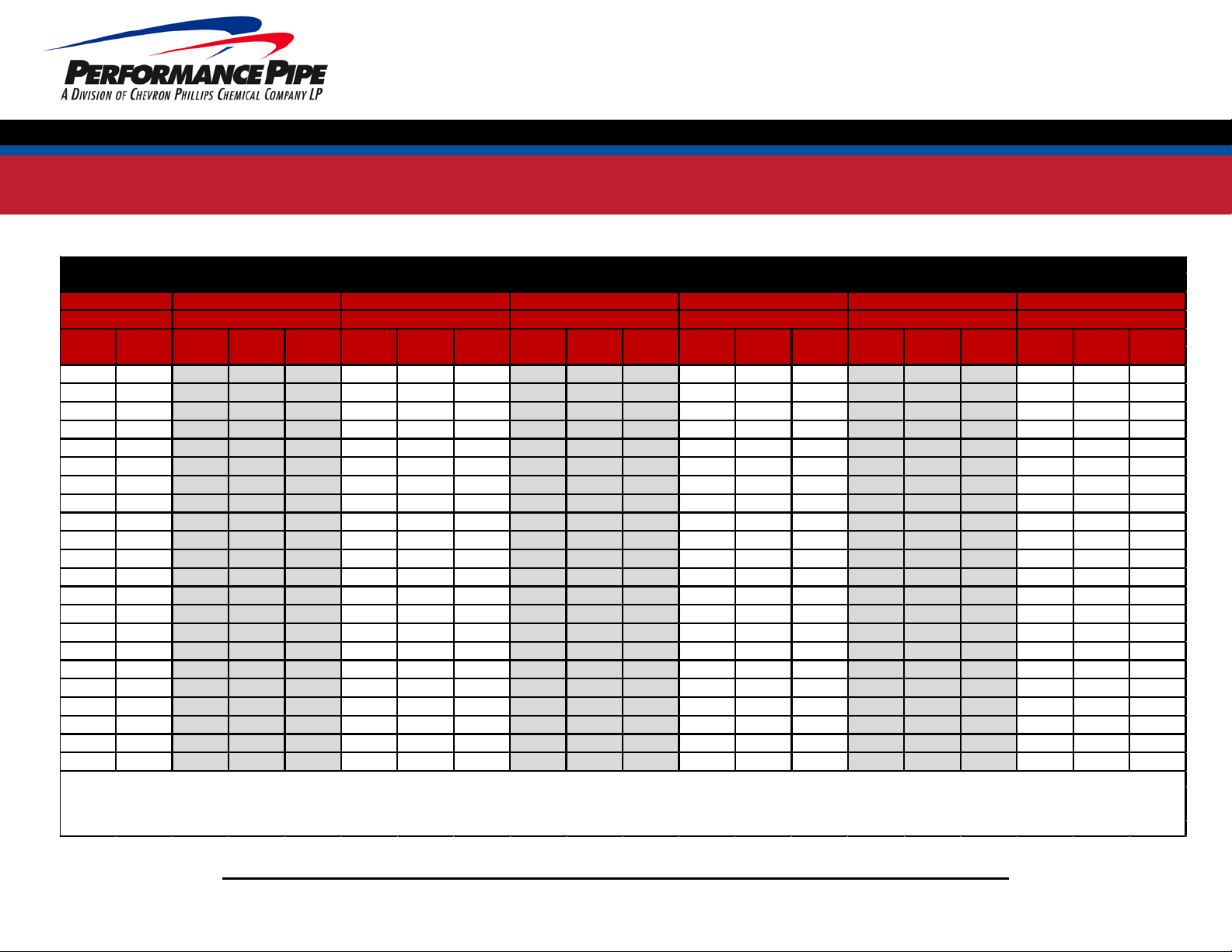

DRISCOPLEX® 6400 Series

Pipe Size Min. Avg. Wgt. Min. Avg. Wgt. Min. Avg. Wgt. Min. Avg. Wgt. Min. Avg. Wgt. Min. Avg. Wgt.

in. Wall, in. ID, in. lbs/ft Wall, in. ID, in. lbs/ft Wall, in. ID, in. lbs/ft Wall, in. ID, in. lbs/ft Wall, in. ID, in. lbs/ft Wall, in. ID, in. lbs/ft

1" 1.315 0.219 0.851 0.33 0.188 0.916 0.29

1 1/4" 1.66 0.277 1.073 0.52 0.237 1.158 0.46 0.184 1.270 0.37 0.151 1.340 0.31 0.123 1.399 0.26

1 1/2" 1.90 0.317 1.228 0.69 0.271 1.325 0.61 0.211 1.453 0.49 0.173 1.533 0.41 0.141 1.601 0.34

2" 2.375 0.396 1.535 1.07 0.339 1.656 0.95 0.264 1.815 0.77 0.216 1.917 0.64 0.176 2.002 0.53 0.140 2.078 0.43

3" 3.50 0.583 2.264 2.33 0.500 2.440 2.06 0.389 2.675 1.66 0.318 2.826 1.39 0.259 2.951 1.16 0.206 3.063 0.94

4" 4.50 0.750 2.910 3.85 0.643 3.137 3.40 0.500 3.440 2.75 0.409 3.633 2.31 0.333 3.794 1.92 0.265 3.938 1.55

6" 6.625 1.104 4.285 8.35 0.946 4.619 7.37 0.736 5.065 5.96 0.602 5.349 5.00 0.491 5.584 4.15 0.390 5.798 3.36

8" 8.63 1.438 5.576 14.15 1.232 6.013 12.50 0.958 6.594 10.11 0.784 6.963 8.47 0.639 7.270 7.04 0.507 7.550 5.69

10" 10.75 1.792 6.951 21.98 1.536 7.494 19.42 1.194 8.219 15.70 0.977 8.679 13.16 0.796 9.062 10.93 0.632 9.410 8.83

12" 12.75 2.125 8.245 30.92 1.821 8.889 27.31 1.417 9.746 22.08 1.159 10.293 18.51 0.944 10.749 15.38 0.750 11.160 12.43

14" 14.00 2.000 9.760 32.93 1.556 10.701 26.63 1.273 11.301 22.32 1.037 11.802 18.54 0.824 12.253 14.98

16" 16.00 2.286 11.154 43.01 1.778 12.231 34.78 1.455 12.915 29.15 1.185 13.488 24.22 0.941 14.005 19.57

18" 18.00 2.571 12.549 54.43 2.000 13.760 44.02 1.636 14.532 36.89 1.333 15.174 30.65 1.059 15.755 24.77

20" 20.00 2.857 13.943 67.20 2.222 15.289 54.34 1.818 16.146 45.54 1.481 16.860 37.84 1.176 17.507 30.58

22" 22.00 3.143 15.337 81.32 2.444 16.819 65.75 2.000 17.760 55.10 1.630 18.544 45.79 1.294 19.257 37.00

24" 24.00 3.429 16.731 96.77 2.667 18.346 78.25 2.182 19.374 65.58 1.778 20.231 54.49 1.412 21.007 44.03

26" 26.00 2.889 19.875 91.84 2.364 20.988 76.96 1.926 21.917 63.95 1.529 22.759 51.67

28" 28.00 3.111 21.405 106.51 2.545 22.605 89.26 2.074 23.603 74.17 1.647 24.508 59.93

30" 30.00 3.333 22.934 122.27 2.727 24.219 102.47 2.222 25.289 85.14 1.765 26.258 68.8

32" 32.00 2.909 25.833 116.58 2.37 26.976 96.87 1.882 28.01 78.28

34" 34.00 3.091 27.447 131.61

2.519 28.66 109.36 2 29.76 88.37

36" 36.00 3.273 29.061 147.55

2.667 30.346 122.6 2.118 31.51 99.07

PE 4710

PR = 400 psi

PR = 335 psi

PR = 250 psi

PR = 200 psi

PR = 160 psi

This product flyer is i ntended for reference purpos es . It shoul d not be used in plac e of the advice from a l i c ensed Profess i onal Engineer. Pressure Rati ng i s based on an operati ng temperature of 73°F for water, bri ne and

dry nat ural gas applic ations. F or wet nat ural gas or liquid hy drocarbons in ex cess of 2% concentration, apply a 0.5 des i gn factor to the l i sted pressure rating above. Pipe weights are c alculated i n accordance wi t h PPI TR-

7. A verage inside di am et er i s calculated us i ng Nom inal O D and Mi ni m um wal l plus 6% for use i n estimating fluid flow. A ctual ID will vary. When designi ng components to fit the pi pe ID, refer to pi pe di m ensions and

tolerances in t he appl i cable pipe manufac t uri ng specific ation.

DR 17

PR = 125 psi

Common Dimension Ratios for DriscoPlex® 6400 IPS Pipe

Pressure Rating for Water, Brine & Dry Natural Gas A pplic a tions

OD, in.

IPS

DR 6

DR 7

DR 9

DR 11

DR 13.5

Pressure Ratings for Water, Brine & Dry Natural Gas Applications

Additional Sizes and DR available. Contact Performance Pipe or visit www.performancepipe.com

Loading...

Loading...