301008301008

INSTALLATION MANUAL

PERFORMANCE EXHAUST

EGR & Cooler Delete for

EGR & Cooler Delete for

2010-2012 6.7L Cummins

2010-2012 6.7L Cummins

WARNING

ONLY install this kit if you are using a tuner

that disables the EGR sensors & circuit system.

Any product that requires the removal of ANY

emissions control device is strictly prohibited

and is intended for closed course racing only

for non-registered vehicles.

EGR Delete Will:

Allow removal of the EGR assembly

EGT solution for monitoring temperatures

Clean up the engine bay

Re-route coolant with provided hose

A

Your Kit Includes

H

B

G

C

D

F

A (1) Support Bracket

B (2) Exhaust Block-Off Plates

C (1) Coolant Hose

D (1) Coolant Hose Connector

E (1) Stand Off Bolt

F (1) M10 Flanged Nut

G (1) Intake Block-Off Plate

H (1) Hardware Bag Containing:

----------(2) 5/16 Bolts, Nuts & Flat Washers

----------(1) 1/4-20 Bolt, Nut & Lock Washer

----------(2) M10 Hex Head Bolts

----------(4) M8 by 1.25 by 20 Allen Head Bolts

E

Preparation

STEP 1: Un-hook negative battery terminals & drain

engine coolant.

STEP 2: Remove the plastic engine cover by removing

the four 8mm bolts as well as the dipstick.

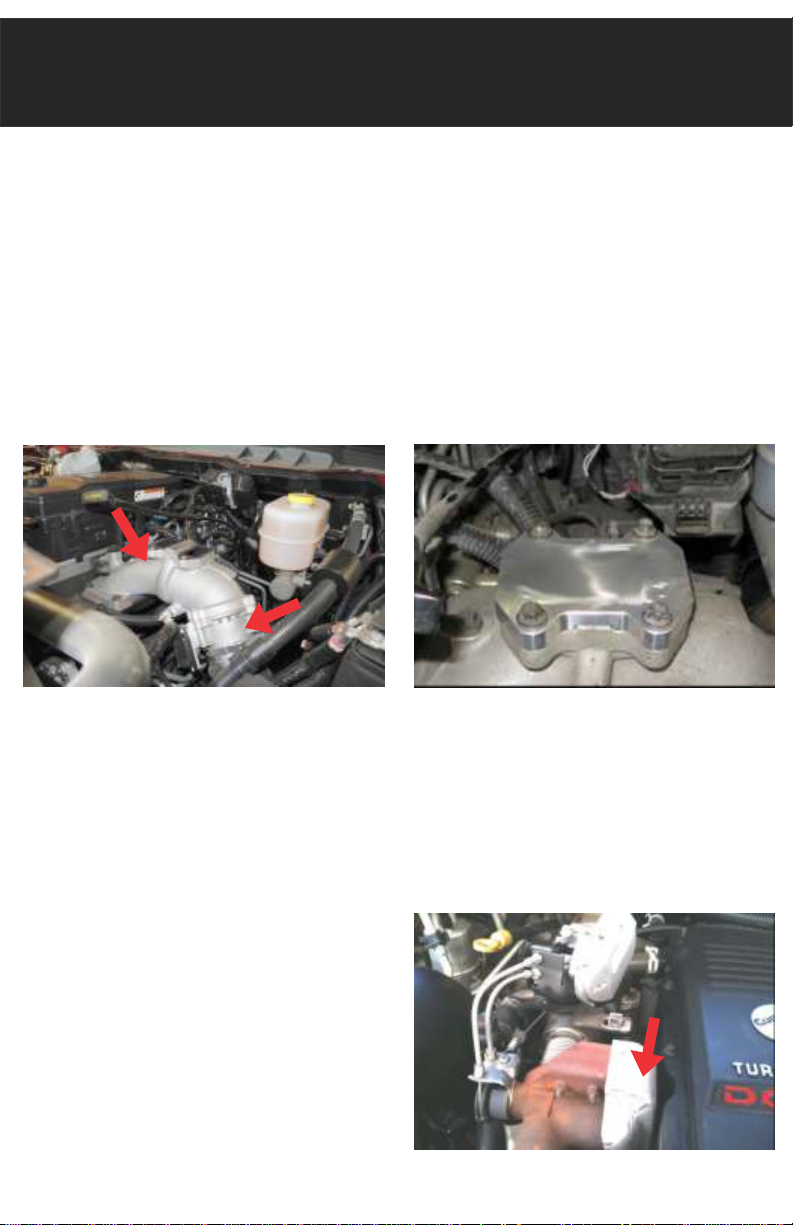

STEP 3: Loosen the two V-Band clamps and remove

the 10mm bolt in the center of the tube. Then

disconnect the sensor plug and remove the

EGR crossover tube. (Fig. 1)

EGR Valve

Fig. 1

STEP 4: Remove the electrical connector on the EGR

valve (Circled in Fig. 2) then remove the EGR

valve itself which is held in place with four

10mm bolts.

Fig. 2

Blocking the Intake

STEP 5: Ensure the mounting surface on the intake

elbow is clear of any gasket material.

STEP 6: Unplug the electrical connector from the

backside of the throttle valve. The throttle

valve is shown in Fig. 3.

Intake Elbow

Throttle Valve

Fig. 3

STEP 7: Install the intake block-off (G) with supplied

bolts. (Fig. 4) Ensure both O-Rings are fully

seated.

STEP 8: Remove heat shield from EGR bypass. This is

held in place by three 10mm nuts and two

8mm bolts. (Fig. 5)

Fig. 4

Fig. 5

Removing Bypass/Servo

STEP 9: Now that you've removed the heat shield,

remove the four 10mm bolts holding the

exhaust bypass in place. The bypass will be

removed with the servo in the next steps.

Servo

Bypass

Coolant Lines

Fig. 6

STEP 10: Remove the five 10mm bolts securing the

EGR servo mounting bracket in place.

Simultaneously remove the EGR servo & the

exhaust bypass from the vehicle. (Fig. 6)

Fig. 7

STEP 11: Remove the crankcase breather tube that

runs over the EGR cooler. Also, disconnect

the two coolant lines that run to the EGR

cooler. Be sure to remove the O-Ring fitting

from the engine block. (Fig. 7) Remove the

four 10mm EGR cooler mounting bolts

(Circled Fig. 7).

STEP 12: Remove the two 15mm nuts connecting to the

EGR cooler to the exhaust manifold near the

fire wall.

Removing EGR Cooler

STEP 13: Remove the V-Band clamp that is connecting

the EGR cooler and the exhaust crossover

elbow. (Fig. 8)

Exhaust

Crossover

EGR Cooler

Elbow

Fig. 8

STEP 14: Remove the exhaust crossover elbow that is

held in place by two 15mm nuts. Install the

smaller of the two exhaust block off plates.

Location noted in Fig. 9.

STEP 15: Remove the EGR cooler by pulling up and out

towards the front of the vehicle.

STEP 16: Remove the EGR cooler mounting bracket by

unbolting the two 14mm bolts that bolt

directly to the engine. Fig. 10

Fig. 9

Fig. 10

Block EGR & Reassemble

STEP 17: Install the other (ported) exhaust block-off

plate on the back side of the exhaust

manifold. Be sure to reuse the factory

hardware. (Fig. 11)

Fig. 11

STEP 18: Re-install the crankcase breather tube. Using

the new supplied coolant hose (C) and

adapter (D), connect the two coolant ports

that previously went to the EGR cooler and

secure with provided hose clamps.

STEP 19: Replace the manifold bolt with the supplied

stand off bolt (E). The bolt will be the third

bolt in from the back of the motor. The nut (F)

on the stand off bolt should be used as a jam

nut to secure it in place. (Fig. 12)

Fig. 12

Install Bracket & Test

STEP 20: Mount the supplied support bracket as seen

in Fig. 13. The back bolt screws into the

stand off bolt (G). Use the 1/4-20 bolt, nut,

washer to secure the trans dipstick to the

bracket. (Fig. 13)

STEP 21: Refill the coolant

to factory specs.

Fig. 13

STEP 22: Installation is now complete! Start the engine

to circulate coolant. Top off as necessary and

inspect for leaks. Install the plastic engine

cover and you're done!

Bracket Diagram

Dipstick

Mount

Crank Case

Tube Mount

Stand Off

Bolt Mount

Coolant Hose

Adapter Slot

Exhaust Pressure

Tube Mount

Factory Coolant

Tube Mount

PERFORMANCE EXHAUST

www.flopro.com

Loading...

Loading...