Perfect Aire 2VPTH09A-3.6, 2VPTH12A-3.6, 2VPTH15A-5.0 User Manual

FOR MODELS:

2VPTH09A-3.6

2VPTH12A-3.6

2VPTH15A-5.0

Before using your air conditioner please

read this manual carefully and keep it for

future reference, along with your receipt.

USER MANUAL

PACKAGED TERMINAL

AIR CONDITIONER

HEAT PUMP DC INVERTER

CONTENTS

UNIT FEATURES .............................................................2

INSTALLATION INSTRUCTIONS ....................................4

WIRING ............................................................................6

OPERATING INSTRUCTIONS.........................................7

ADVANCED OPERATION ................................................8

FUNCTION OF DIP SWITCHES......................................9

MAINTENANCE AND CLEANING .................................10

NORMAL OPERATING SOUNDS & CONDITIONS.......11

DIAGNOSTIC CODES & SOLUTIONS ..........................13

TROUBLESHOOTING ...................................................14

-1-

IMPORTANT NOTE TO THE SERVICER

Read this manual and familiarize yourself with the specific

items which must be adhered to before attempting to

service this unit. The precautions listed in this Installation

M

anual are intended as supplemental to existing

practices. However, if there is a direct conflict between

existing practices and the content of this manual, the

precautions listed here take precedence.

REC

OGNIZE THIS SYMBOL

AS A SAFETY PRECAUTION

THE MANUFACTURER WILL NOT BE RESPONSIBLE FOR ANY

INJURY OR PROPERTY, DAMAGE ARISING FROM IMPROPER

SERVICE OR SERVICE PROCEDURES. IF YOU INSTALL OR

PER FO RM S ER VI CE ON T HIS U NIT, YOU ASSU ME

RESPONSIBILITY FOR ANY PERSONAL INJURY OR PROPERTY

DAM AGE WHICH MAY RESULT, MANY JURI SDIC TION S

REQUIRE A LICENSE TO INSTALL OR SERVICE HEATING AND

AIR CONDITIONING EQUIPMENT.

WARNING

IMPORTANT NOTES:

Before using this manual, check the serial plate for proper

model identification.

The installation

and servicing of this equipment must be

performed by qualified, experienced technicians only.

Due to policy of continual product improvement, the right is

reserved to change specifications and design without

notice.

IMPORTANT NOTE TO THE OWNER

This manual is to be used by qualified, professionally trained

HVAC technicians only. The manufacturer does not assume

any responsibility for property damage or personal injury for

improper service procedures or services performed by an

unqualified Person.

THE

FOLLOWING WARNINGS ARE

VERY IMP ORTANT FOR SAF ETY.

PLEASE READ THEM CAREFULLY

BEFORE INSTALLATION!

1. The air conditioner must be installed by

certified installer.

2. Check whether there is grounding wire

in the power supply system before

installation. If not, installers should refuse

installing and explain the safety principle to

users.

3. To avoid electric shock or even death,

the

socket or terminal blocks for power

supply to the air conditioner (include

277V and 115V and 208~230V series

and the units that have LCDI power

cord) must connect a Ground Fault Circuit

Interrupter.

4. During installation, the wire

connection must strictly follow the rule

zero line and fire line of unit should

be connected to the zero line and fire line

in the power system. The connection

in reverse is forbidden. Please be sure

the ground wire is firmly connected

otherwise it is possible to result in the

electrical shock or death.

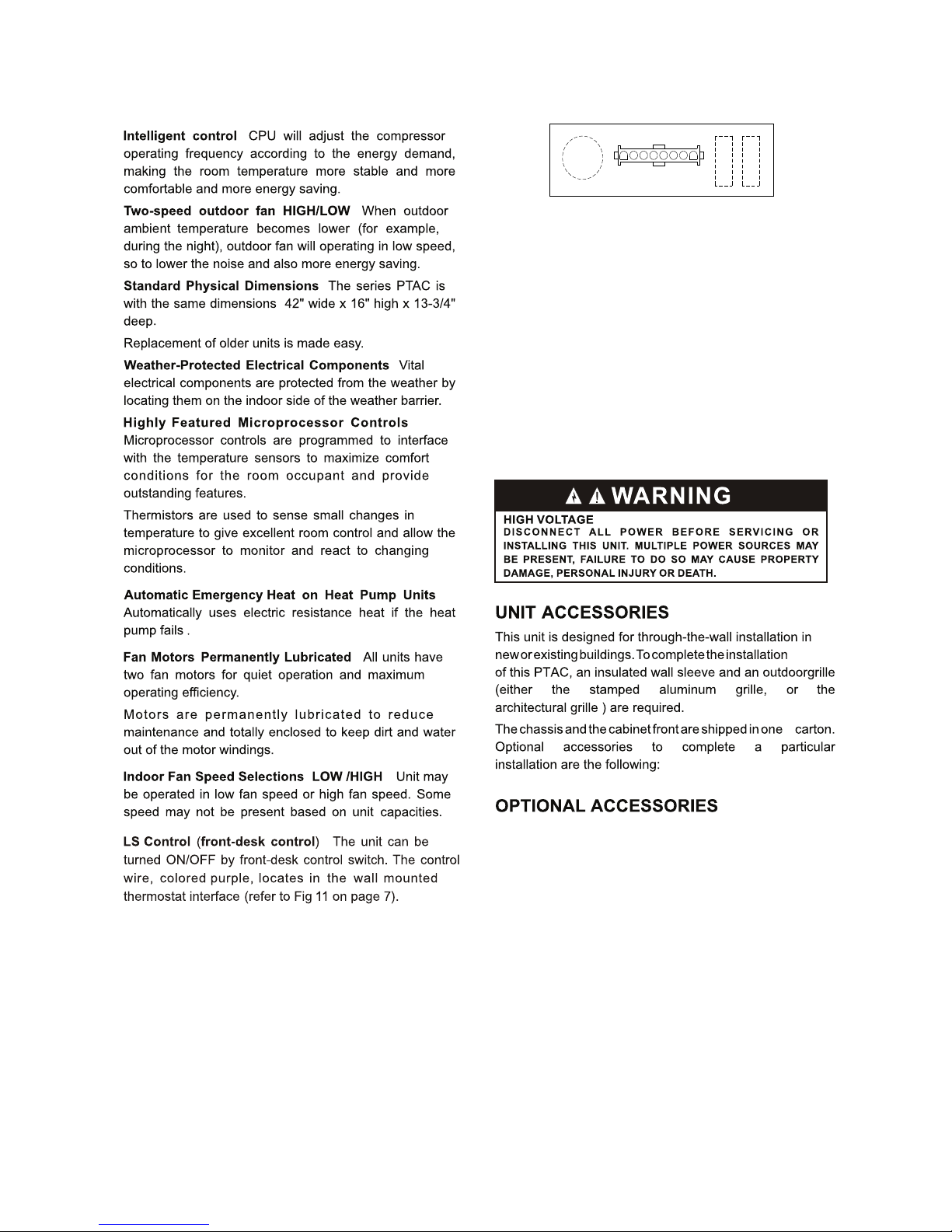

WARNING

HIGH VOLTAGE

DI SCONNECT ALL P OW ER B EFO RE S ERV ICING O R

INSTALLING THIS UNIT. MULTIPLE POWER SOURCES MAY

BE PRESENT, FAILURE TO DO SO MAY CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

LCDI power Cord

Automatic 3-minute compressor lockout: After

the compressor cycles off, it will not restart for three

minutes.

Random restart delay: To help eliminate power

surges after a power outage, the unit is equipped with

two to four minute random restart delay feature.

Whenever the unit is plugged in with the master

switch turned on and the mode switch set in the cool

or heat mode, a random restart will occur. A random

restart condition can be avoided by setting the mode

switch in the fan only or off position before applying

power to the unit.

Indication LEDs : The control panel has LEDs that

correspond to fan operation and to indicate unit status.

The LEDs next to the selections ON/OFF, FAN, COOL,

and HEAT indicate which mode is active.

- 2 -

Without frequently starting-stopping, the room

temperature is more stable & more comfortable.

a known brand providing

high performance, making the compressor more

:

:

System safety protection

To ensure the system is running safely, the electric

control has the following protections. For problem

solving, please refer to Diagnostic Codes & Solutions

and Troubleshooting sections, pages 13 & 14.

When condenser coil temperature exceeds the presetting point, compressor

decreases the operating frequency to

30Hz. If this protection is inactive and

condenser coil temperature reaches the

shut-down point, the compressor will

be turned off. Thus providing double

protection.

Outdoor unit

overload

protection in

COOLING mode

Evaporator freeze

protection (will

not display error

code)

When evaporator coil temperature drops

to 1°C and lasts for 5 minutes, compressor and outdoor fan will stop, indoor fan

keeps on running.

When compressor discharge temperature reaches protection point, compressor will decrease operating frequency

to 30Hz. If this protection is inactive and

discharge temperature reaches the shut

down point, compressor will be turned

off. Thus provide double protections.

Compressor

discharge

overheating

protection

When evaporator coil temperature

exceeds the presetting point, compressor decreases the operating frequency

to 30Hz. If this protection is inactive and

evaporator coil temperature reaches

the shut down point, compressor will

be turned off. Thus provide double protections. This time the back up electric

heater will be turned on.

Evaporator

overload

protection

(heat pump

mode)

When input current exceeds the presetting point, compressor will decrease

the operating frequency to 30Hz. If this

protection is inactive and current reaches the shut down point, compressor will

be turned off.

Input over

current

protection

Compressor over

current protection

When compressor operating current exceeds the shut down point, compressor

will be shut down.

When IPM faults, include over heat,

unit will be shut down, all outputs are

terminated, control panel displays the

error code.

IPM fault

protection

Temperature

sensor fault

Any temperature sensor faults, unit

stops and display the error code.

protection

For continuously 2 minutes communication faults between indoor unit and

outdoor unit, unit will shut down and

displays error code.

Communication

fault protection

If compressor starting fails, 3 minutes

later, it will try to start again. It will not

fault. If the 4th time fail again, it will not

start any more and display the error

code.

Compressor

starting fault

DC-DC-BUS o

voltage/under

voltage

protection

Once monitors the DC-BUS is over or

under voltage, unit stops and display

error code.

When the unit is powered on, if system

monitors the EEPROM fault, displays error code and will not operate any more.

EEPROM fault

:

Wall Sleeve Kit

Key Lock Kit

Drain Kit

Filter Kit

Wire Harness Kit

Architectural Grille Kit

Stamped Louver

Kit

LCDI Power Cord

Wireless IR Thermostat

Electric And Non Electric Sub Base Kit

IR REMOTE CONTROLLER

NOTE: Consult sales literatu re for the ap propr iate

volta ge and am perage sel ections, if appli cable.

- 3 -

R LS GH B Y W GL C

WALL MOUNTED THERMOSTAT INTERFACE

The control logic as

belw:

1.Turn ON unit:short circuit R and LS then release for

one time within 5 seconds.

2.Turn OFF unit:short circuit R and LS then release for

twice within 5 seconds.

3.Force unit shut down for one time:connect LS to R for

over 5 seconds.

NOTE: After force shut down, you can turn the unit ON

again by hand-held remote controller or the control panel.

:

:

:

:

:

:

:

:

:

(SOLD SEPARATELY)

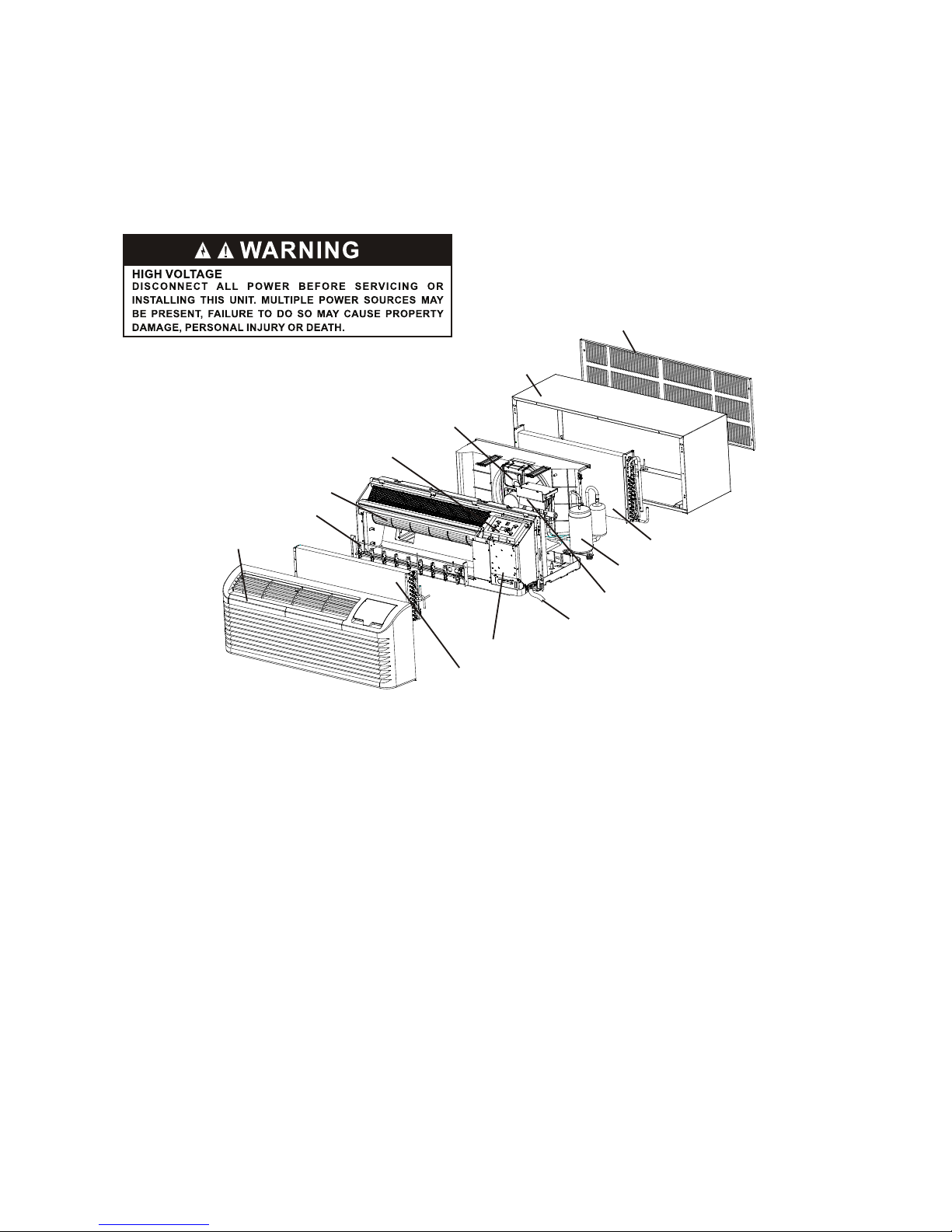

Wall sleeve

Outdoor coil

Outdoor grille

Front and discharge grille

Electric heater

Indoor Fan

Display Module

Outdoor Fan

Inverter compressor

Power cord coverplate(not show)

Electronic control module assembly

Control box

Indoor coil

- 4 -

INSTALLATION INSTRUCTIONS

To ensur e that the unit oper ates safe ly and effici ently, it must be i nstalled, oper ated and maintaine d accordi ng

to these inst allation and operating instr uctions and all local codes and ordina nces or, in their ab sence , with the

lates t ed ition of the Na tional Elect ric Code. The prop er installat ion of this unit is des cribe d in the following

secti ons. Fo llowing th e steps in the o rder pr esented sh ould ensure prope r installa tion.

Loading...

Loading...