DirectVision®

TECHNICAL REFERENCE

MANUAL

DirectVision® Technical Reference Manual

Page ii

DirectVision® Technical Reference Manual

Table of Contents

WARNINGS & CAUTIONS ................................................................... 1

DOCUMENTATION CONVENTIONS .............................................................. 1

GENERAL WARNINGS .............................................................................. 1

GENERAL CAUTIONS ............................................................................... 2

PRODUCT DESCRIPTION ..................................................................... 4

CAMERA HANDPIECE............................................................................... 4

Visual Guide Interface ................................................................... 5

Camera Control Unit Interface ...................................................... 6

Storage during Transportation ..................................................... 7

CAMERA CONTROL UNIT ......................................................................... 8

Front Panel Controls ...................................................................... 8

Electronic Interfaces ...................................................................... 9

COLOR MONITOR DISPLAY ..................................................................... 10

LED Indicator ............................................................................... 10

Control Dial ................................................................................. 11

Monitor Power ON/OFF .............................................................. 11

Menu Control .............................................................................. 11

CART ................................................................................................. 13

Workspace .................................................................................. 13

Storage Area ............................................................................... 13

Swivel Arm .................................................................................. 13

Power .......................................................................................... 13

Height Adjustment ...................................................................... 14

Casters ........................................................................................ 14

Power Cord .................................................................................. 15

DIRECTVISION® GUIDE .......................................................................... 16

Features ...................................................................................... 16

DIRECTVISION® CATHETER ..................................................................... 18

Features ...................................................................................... 19

Page iii

DirectVision® Technical Reference Manual

INITIAL SYSTEM ASSEMBLY .............................................................. 21

REQUIRED COMPONENTS ....................................................................... 21

REQUIRED HARDWARE AND TOOLS .......................................................... 21

INITITAL ASSEMBLY & TEST..................................................................... 21

MONITOR SETUP ............................................................................. 31

CONTROL DIAL DEFINITIONS ................................................................... 31

MONITOR DEFAULT VALUES ................................................................... 31

CAMERA CONTROL UNIT CALIBRATION PROCEDURES ..................... 33

PRECONDITIONS ................................................................................... 33

CAMERA CONTROL UNIT FRONT PANEL .................................................... 33

PROCEDURES ....................................................................................... 34

Window Size ................................................................................ 34

Auto Gain Control ........................................................................ 35

White Balance Adjustment .......................................................... 36

Focus ........................................................................................... 39

SYSTEM MAINTENANCE .................................................................. 40

CAMERA CONTROL UNIT FUSE ................................................................ 40

TROUBLESHOOTING ........................................................................ 41

TECHNICAL SPECIFICATIONS ............................................................ 46

DIMENSION & WEIGHT ......................................................................... 46

Camera Control Unit .................................................................... 46

Monitor ....................................................................................... 46

Cart .............................................................................................. 46

ELECTRICAL SPECIFICATIONS ................................................................... 46

Camera Control Unit .................................................................... 46

Monitor ....................................................................................... 47

CAMERA SPECIFICATIONS ....................................................................... 47

VISUAL GUIDE SPECIFICATIONS ................................................................ 48

OPERATING ENVIRONMENT .................................................................... 48

Camera Control Unit and Camera Handpiece ............................. 48

Monitor ....................................................................................... 48

Page iv

DirectVision® Technical Reference Manual

Cart ............................................................................................. 48

STORAGE ENVIRONMENT ....................................................................... 49

SPARE PARTS ....................................................................................... 49

Camera Control Unit ................................................................... 49

WARRANTY, SERVICE & CLAIMS....................................................... 49

REFERENCES ..................................................................................... 49

Page v

DirectVision® Technical Reference Manual

!

Warnings & Cautions

Documentation Conventions

Please read this manual and follow its instructions carefully. The

words: Warning, Caution, and Note carry special meaning and

should be reviewed carefully:

The personal safety of the patient or user may

Warning:

be involved. Disregarding this information could

result in injury to the patient or user.

Caution:

Note:

Special service procedures or precautions must

be followed to avoid damage to the equipment.

Special information to make maintenance easier

and important information more clear.

An exclamation point within a triangle alerts the

user of risk of danger; attention, consult

company documents.

General Warnings

It is important to read and understand this manual. Failure to

follow these instructions may cause damage to the product or

harm to the patient and/or the user. The user should do the

following:

1. Warning: Read the DirectVision

Manual before assembling and using the product.

2. Warning: Federal (USA) Law restricts this device to use by

or on the order of a physician.

3. Warning: Never look directly at the light emitted from the

light source of the camera handpiece or the DirectVision

Guide. Damage to eye may result.

®

Technical Reference

®

Page 1 of 49

DirectVision® Technical Reference Manual

4. Warning: Never leave the DirectVision® System powered

and unattended. Heat from the light source could ignite

drapes or other materials.

5. Warning: Do not store or use the DirectVision® System in

an environment that contains flammable gases which can

result in an explosion.

6. Warning: The DirectVision® System must only be repaired

by personnel authorized by PercuVision®. Unauthorized

repairs could compromise the safety and integrity of the

product and voids the warranty.

Failure to follow the instructions in this manual could void the

warranty.

PercuVision® reserves the right to improve our product. As a

result, product may not conform in detail to published design or

specifications. Improvements are subject to change without

notice. Please contact PercuVision® customer care department

for information on improvements and new products.

General Cautions

1. Caution: Carefully unpack the shipment and check for

physical damage. If damage is observed, please refer to the

Service and Claims Section in DirectVision® Technical

Reference Manual.

2. Caution: Do not use the DirectVision® System until you have

verified that it is properly assembled, setup and functioning

correctly.

3. Caution: Use only in conjunction with other Type BF or CF

rated medical electrical equipment approved to IEC 60601-1

or equivalent standard.

4. Caution: Never attempt repairs or maintenance to the

DirectVision® System before reviewing the Service and

Claims Section of DirectVision® Technical Reference

Manual.

Page 2 of 49

DirectVision® Technical Reference Manual

5. Caution: To prevent damage to the DirectVision® Guide and

camera handpiece, always handle with care. Do not drop,

crush, cut, or bend any portion of the visual guide beyond

a 2” radius. Although the visual guide is flexible, bending

beyond the specified radius could cause breakage in the

fiber optic bundle, which reduces its useful life. Kinking the

visual guide could break the entire fiber optic bundle which

can render it non-operational.

6. Caution: Do not expose the DirectVision® System to

excessive heat which can cause damage.

7. Caution: Never place heavy objects on the DirectVision®

System.

Page 3 of 49

DirectVision® Technical Reference Manual

Product Description

DirectVision® product line consists of:

• DirectVision® System

– Camera Handpiece

– Camera Control Unit (CCU)

– Monitor Display

– Cart

• DirectVision® Guide

• DirectVision® Catheter

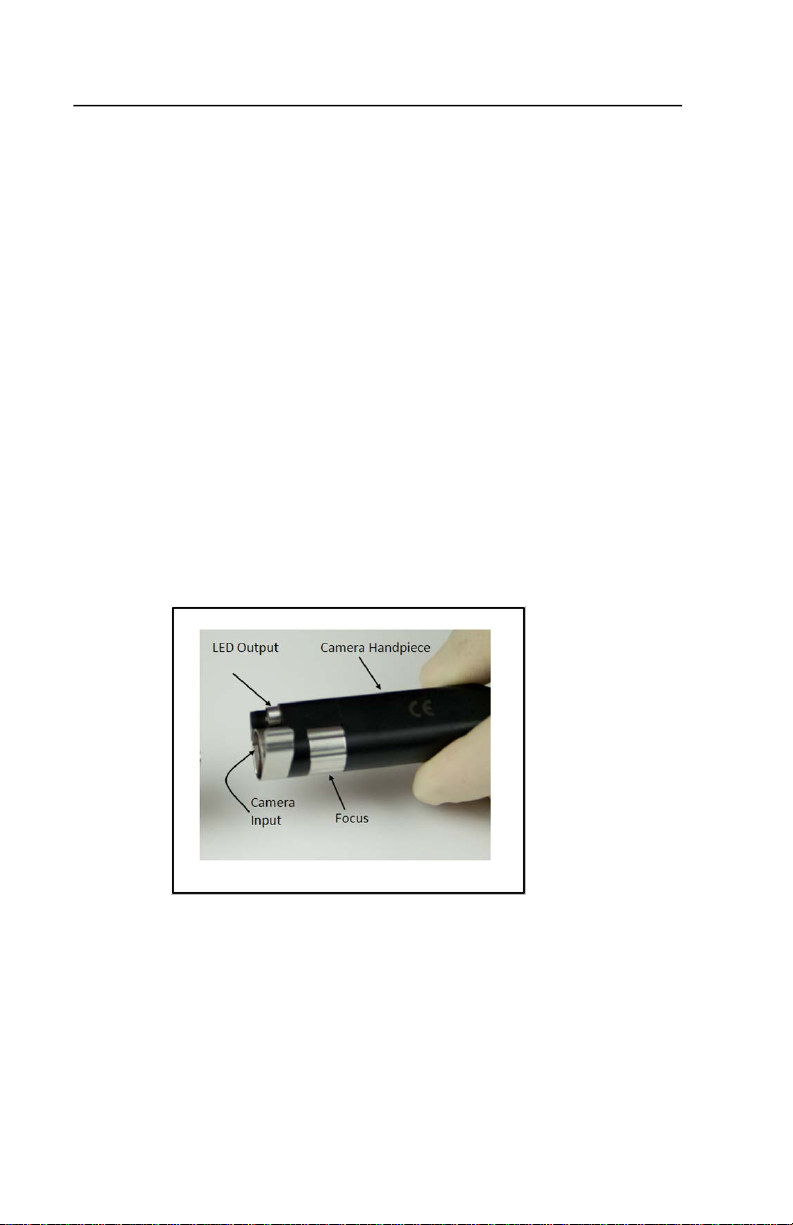

Camera Handpiece

The camera handpiece contains the camera, optics to focus the

video image and an LED white light source. Camera operation is

dependent on receiving power and input video control signals

from the CCU. It uses the input control signals to produce

streaming video output .

The camera handpiece has a locking swing arm to securely couple

the camera handpiece to the DirectVision® Guide. The body of

the camera handpiece has a Focus Ring, which provides focus for

the video image.

Page 4 of 49

DirectVision® Technical Reference Manual

The camera handpiece provides two interfaces:

• Visual Guide

• CCU

Visual Guide Interface

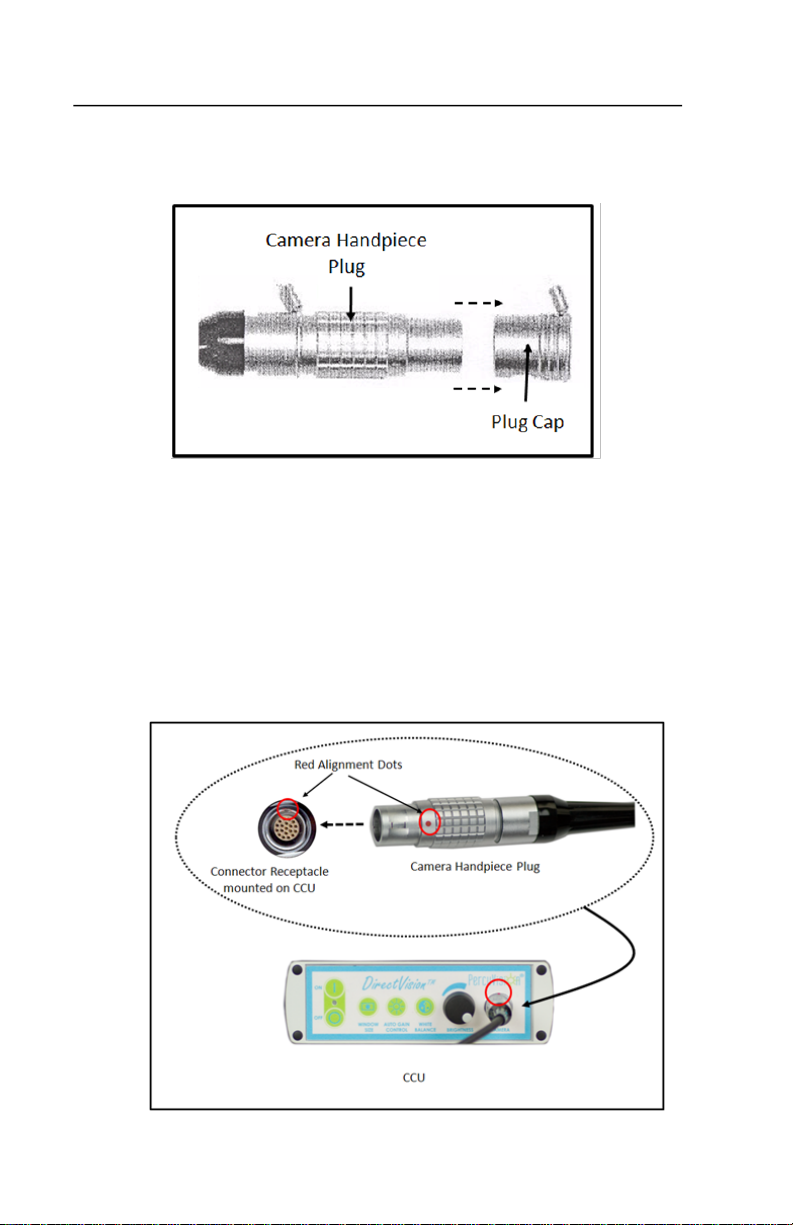

The camera handpiece provides alignment and a locking

mechanism for the camera handpiece- visual guide interface.

When the camera handpiece is not attached to the visual guide, a

protection cap is locked into place.

Page 5 of 49

DirectVision® Technical Reference Manual

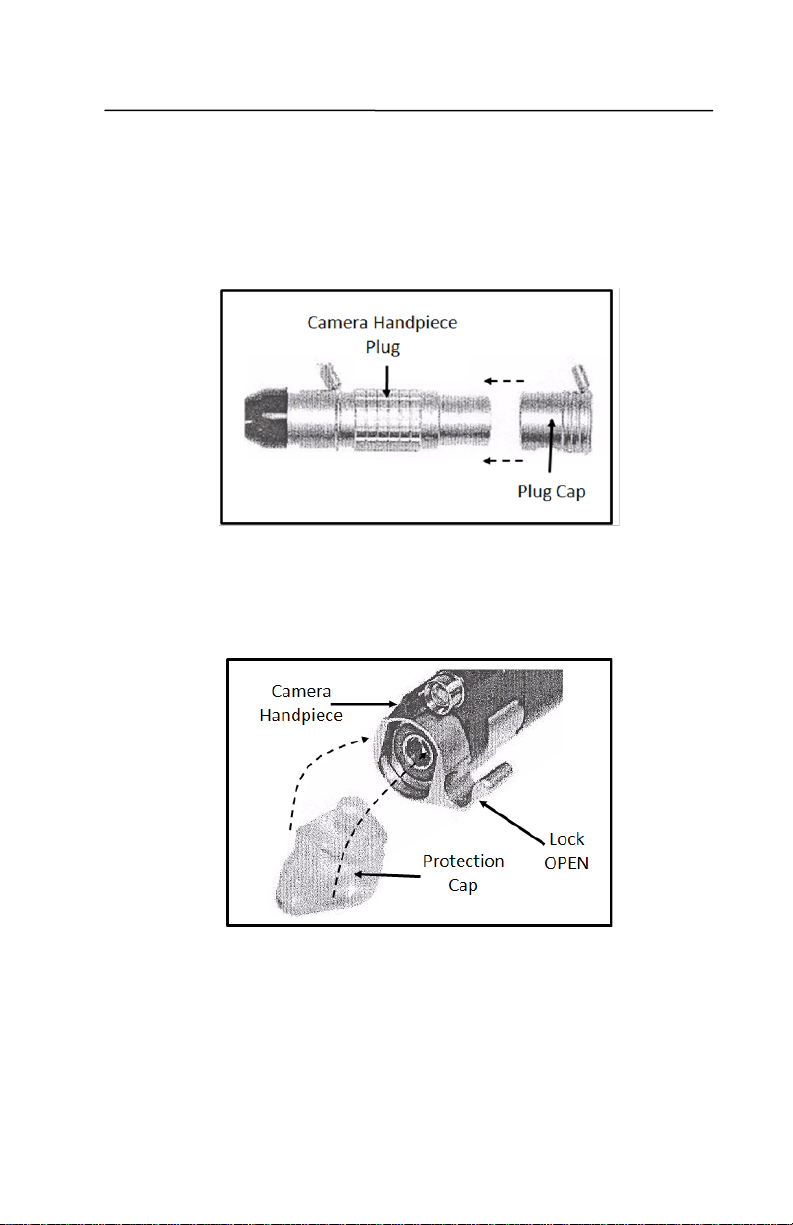

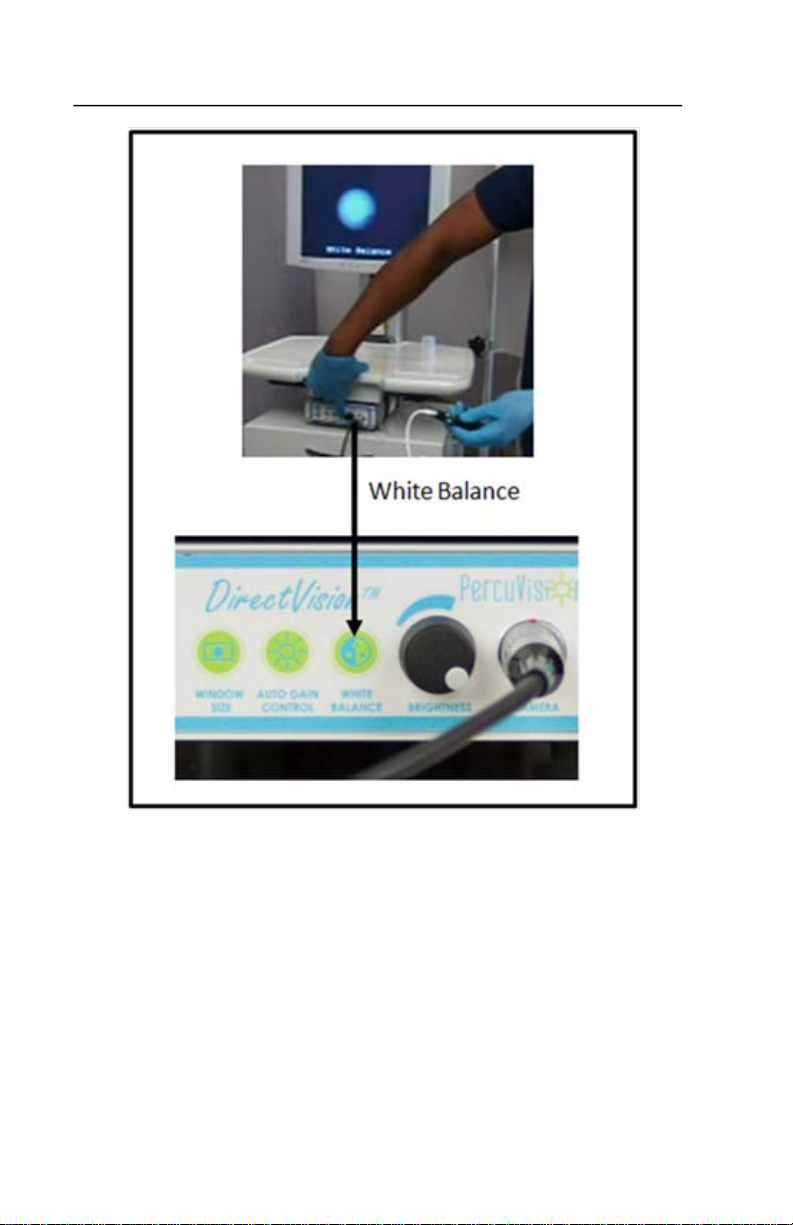

Camera Control Unit Interface

A shielded cable attached to the camera connector plug provides

the wired electrical interface between the Camera Control Unit

(CCU) and the camera handpiece. When plugging the camera

connector into the CCU, use the red dots on the camera connector

and CCU receptacle to align the recessed connector pins for

proper insertion.

Caution: Be careful how you align the Camera Handpiece Plug into

the CCU Connector Receptacle. Failure to align pins with the

corresponding pin hole could cause damage to the pins.

Page 6 of 49

DirectVision® Technical Reference Manual

Storage during Transportation

When the camera handpiece is not in use,

1. The wired attached Plug Cap is locked to the Camera

Handpiece Plug. The Plug Cap protects the receded gold

connector pins.

2. Protection cap is locked into place. The cap protects the

front glass of the LED light source and camera from

accumulating dust. It also protects the outside rim of the

lock mechanism of the handpiece from damage.

3. The handpiece is stored in the cart storage drawer.

Page 7 of 49

DirectVision® Technical Reference Manual

Camera Control Unit

The Camera Control Unit (CCU) provides power and control signals

to the camera. It converts video signal received from the camera

to several standard output video formats for video display. It also

provides the power for the LED light source.

The CCU is permanently mounted to the cart. Power and video

cables are pre-connected to the CCU. It is powered by a 12 VDC

medical grade power supply which is housed under the top tray of

the cart. It utilizes an LED to indicate the power ON state.

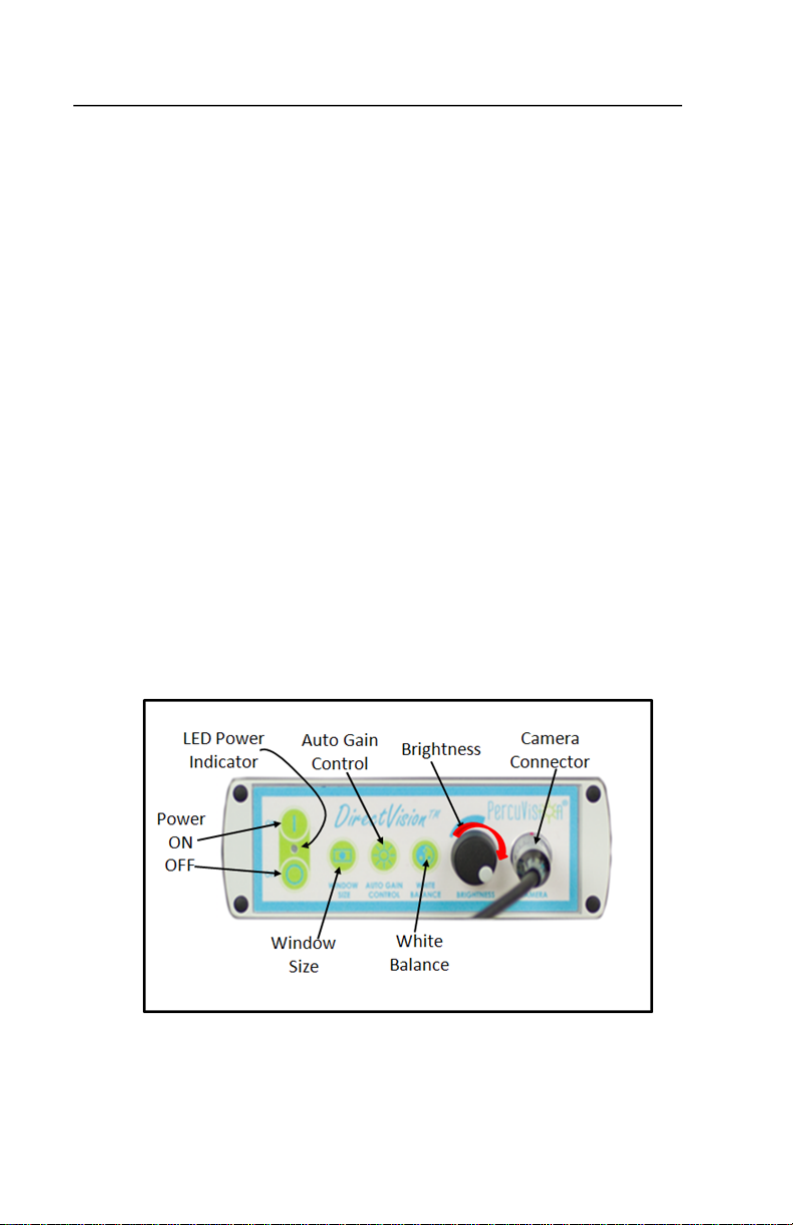

Front Panel Controls

The front panel of the CCU provides the following controls:

• ON/OFF switch

• LED Power Indicator

• Window Size

• Auto Gain Control

• White Balance

• Brightness adjustment

• Camera Connector

Page 8 of 49

DirectVision® Technical Reference Manual

Electronic Interfaces

The rear of the CCU provides interfaces for:

• Power (IN) 12 VDC

• RS 232 ( for internal service use)

• S-Video (OUT)

• Composite Video (OUT)

• USB 2.0 (OUT)

• FUSE

Page 9 of 49

DirectVision® Technical Reference Manual

Color Monitor Display

The color monitor display is a 17” high resolution LCD monitor. It is

mounted on a swivel bracket on the cart which enables easy

viewing angle adjustment. The monitor is powered by a 12 VDC

medical grade power supply located under the top tray.

LED Indicator

The LED Indicator provides the current power state of the

monitor. It is located in front at the lower right corner of the

Monitor screen bezel. It can display two colors: GREEN indicates

the Power ON State and a video signal is received. ORANGE

indicates that the monitor is in either the Power Saving State or

No Video Signal State.

Page 10 of 49

DirectVision® Technical Reference Manual

Control Dial

The Control Dial is a multi-functional device located behind the

LED Indicator on the right side of the front bezel. It has three

movements: rotate upward, rotate downward and press inward

as a button.

Monitor Power ON/OFF

Press the Control Dial inward to power the Monitor ON. To turn

the Monitor power OFF, press the Control Dial inward and hold for

at least 1 second until the LED turns off.

Menu Control

While the monitor is ON (i.e. Green LED and image on the screen),

press the Control Dial inward to activate the monitor menu

system. When the menu system is active, use the three-way

movement of the Control Dial to adjust the monitor:

• Rotate Downward: Move Down/Right, Increase

• Rotate Upward: Move Up/Left, Decrease

• Button Press: Execute, Do, Save

Page 11 of 49

DirectVision® Technical Reference Manual

Main menu selections for the Display Monitor are:

• Color

• Picture

• Auto

• OSD Menu (On Screen Display)

• MISC

• Exit

A plastic cover on the left side of the monitor screen hides the

cable connectors. Upon removal of the cover, the following cable

connectors are exposed:

• Power (IN) 12 VDC

• VGA Video (IN)

• Composite Video (IN)

• S-video( IN)

Note: the two monitor connectors used by the DirectVision®

System are: Power(IN) 12VDC and Composite Video (IN).

Page 12 of 49

DirectVision® Technical Reference Manual

Cart

The cart is mobile and features a small footprint. It is easily

moved from one patient location to another.

Workspace

The cart features a 15½“ x 21” work space integrated with two

steering handgrips.

Storage Area

There are three storage drawers, two of which are lockable. Keys

are provided.

Swivel Arm

A swivel arm bracket in the back of the cart houses a camera

handpiece holder and a telescoping IV pole. The camera

handpiece holder serves as a temporary holder of the camera

handpiece when the camera handpiece is being prepared to be

connected to the visual guide.

Power

Two medical power supplies are housed beneath the top tray, one

for the Camera Control Unit and the other for the display monitor.

Page 13 of 49

DirectVision® Technical Reference Manual

Height Adjustment

A yellow gas spring height adjustment lever enables positioning of

the monitor to a height for comfortable use.

Casters

The cart features four, 4 inch casters: two locking casters, one

swivel caster and one tracking caster. The locking casters are the

rear two wheels. During the catheterization procedure, the rear

two casters must be locked to prevent cart movement. The lock

levers for these wheels are gray.

The right front wheel is a tracking caster. It serves as a steering

wheel when the cart is moved. The lock lever for this wheel is

black.

Page 14 of 49

DirectVision® Technical Reference Manual

Power Cord

The cart’s power cord is 18 feet in length with a hospital-grade

power plug. The power cord is wrapped around two hooks

positioned on the cart’s adjustable column. The power cord plug is

placed on the hanger, which is located above the power cord

hanger. The cart must be plugged into a hospital-grade receptacle

for proper grounding. Proper grounding is essential for safety and

reliable operation.

Page 15 of 49

DirectVision® Technical Reference Manual

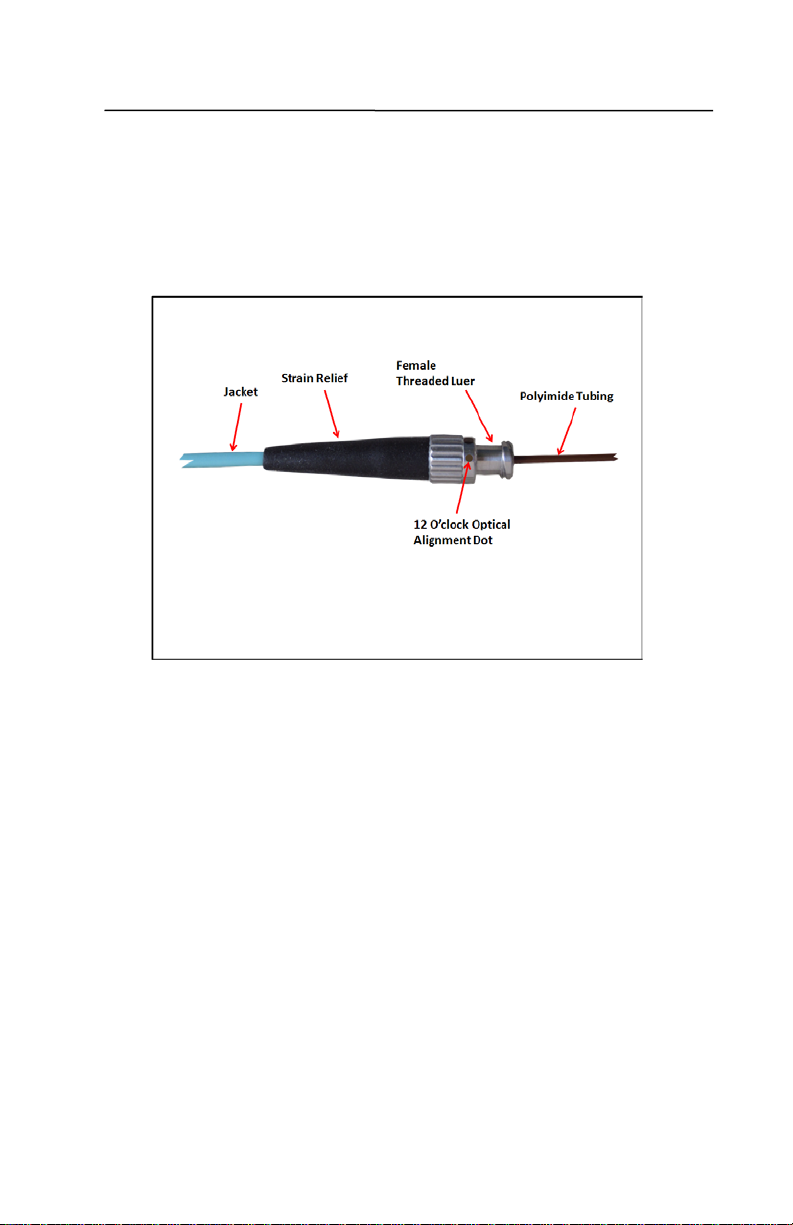

DirectVision® Guide

The DirectVision® Guide is a fiber optic element which transports

light and video information between the distal tip of the fiber

optic element and its proximal end. It consists of two fiber

channels encased in a sub-milimeter diameter polyimide sleeve.

One channel carries illumination light. The other channel carries

the video image.

Features

The visual guide is designed with a sleeve ridge (Internal Stop)

which abuts to a retaining wall in the catheter to stop the visual

guide from extending beyond the distal tip of the catheter. The

DirectVision® Guide is securely connected to the DirectVision®

Catheter by a Catheter Hub Lock. The camera handpiece is locked

to the visual guide by the handpiece’s locking swing arm.

Page 16 of 49

DirectVision® Technical Reference Manual

Optical Alignment Dot

The visual guide has an alignment “dot” on the female threaded

luer. This “dot” assists in locating the 12:00 o’clock position of the

visual guide.

Page 17 of 49

DirectVision® Technical Reference Manual

DirectVision® Catheter

The DirectVision® Catheter is a 3-lumen, 100% silicone, Foley

catheter that comes either uncoated or with water activated

lubricious coating. The first lumen is used for irrigation and

drainage. The second lumen is used for balloon inflation and

deflation. The third lumen is used to insert and remove the visual

guide

Page 18 of 49

DirectVision® Technical Reference Manual

Features

Balloon

The balloon is 10cc and is inflated with no more than 10cc sterile

water using a needleless syringe.

Angled Tip

The distal tip is angled (similar to a Coud

insertion.

é catheter) to facilitate

Retainer

The catheter has a built-in retainer to prevent the visual guide

from extending beyond the distal tip of the catheter.

Index Marks

Graduated index marks on the catheter shaft assist the user to

judge catheter penetration distances.

Page 19 of 49

DirectVision® Technical Reference Manual

Catheter Manifold

Tip of catheter is

curved up

Catheter dot

aligned to 12 O’clock

Catheter Alignment Dot

The alignment “dot” on the catheter manifold is on the same

plane as the angled tip. When the “dot” on the manifold is in the

12:00 o’clock position, the catheter tip is in the 12:00 position and

the catheter tip is curved up.

Catheter and Visual Guide Alignment Dots

When initially inserting the catheter, the “dot” on the visual guide

luer fitting and the “dot” on catheter irrigation/drainage port

should both be aligned to 12:00 o’clock position. This alignment

orientation ensures the tip of the catheter is pointing up and

orients the relative position of the image displayed on the monitor

to the 12:00 o’clock position.

Page 20 of 49

DirectVision® Technical Reference Manual

!

Initial System Assembly

Required Components

• DirectVision® System in its shipping box

• Color Monitor in its shipping box

• Camera handpiece

Required Hardware and Tools

• 4 Phillips head mounting metric screws (M4, 12mm)

• 1 Phillips #2 screw driver

Note: The DirectVision® Guide is not required for assembly and/or

to verify basic operation for DirectVision® System.

Initital Assembly & Test

1. Unpack and inspect shipment.

• Unpack cart from its shipping crate. With assistance, lift

the cart from the packaging riser.

Caution: Do not lift the cart by the tray or tray

handgrips. This action could result in damage to the

cart.

• Hold the cart by the base and support the sides as you

lift it.

Warning: The cart is heavy (about 140 pounds). Do not

lift the cart from the packaging riser without assistance.

Use proper lifting techniques when lifting heavy objects.

• Inspect the cart for shipping damage.

• Unpack color monitor from its shipping box

• Inspect the color monitor for shipping damage.

• If damage is identified, contact PercuVision®. Do not

assemble.

Page 21 of 49

DirectVision® Technical Reference Manual

2. Mount and connect power and video cables to monitor.

• Locate four (4) mounting screws in an envelope in the

top drawer

• Use Phillips #2 screw driver and 4 (M4, 12mm)

mounting screws to secure the monitor to the cart’s

monitor bracket.

• Facing the front of the monitor, remove plastic cover

located on left rear side of the monitor to expose the

power and video connectors.

• Connect the input power plug from the cart to the

display monitor.

• There are two input BNC video connectors on the

monitor. Connect the video cable from cart to display

monitor’s upper video BNC connector.

Page 22 of 49

DirectVision® Technical Reference Manual

• Replace plastic cover.

3. Plug in camera handpiece to CCU.

• Retrieve the camera handpiece from storage drawer of

cart.

• Place the camera handpiece into camera handpiece

holder located on the Swivel Arm.

Page 23 of 49

DirectVision® Technical Reference Manual

• Remove the metal Plug Cap from camera handpiece

connector.

• Attach the camera handpiece plug to the camera

connector receptacle on the CCU’s front panel. Use red

dots on the camera connector plug and the Connector

Receptacle on the CCU for proper plug alignment.

Caution: Be careful in how you align the Camera

Handpiece Plug into the CCU Connector Receptacle.

Failure to align pins with the corresponding holes could

cause damage to the pins.

Page 24 of 49

DirectVision® Technical Reference Manual

• Remove the Protection Cap from the camera handpiece.

3. Turn on power and verify correct basic operation.

• Remove the cart’s power plug from its holder on the

cart. Unwrap the power cord then plug it into a

110/120 VAC wall receptacle.

Page 25 of 49

DirectVision® Technical Reference Manual

• Turn on the Monitor power by pressing in on the

Control Dial on the right side of the monitor. The

monitor’s LED Indicator should be illuminated ORANGE,

indicating that the power is ON but no video signal is

received. If the LED Indicator is not illuminated, go to

the Troubleshooting Section of this Manual .

• Perform Monitor Setup Procedure. For details see

Monitor Setup Procedure Section of this Manual.

• Turn on CCU power by pressing the Power ON Button.

CCU LED turns ON.

Page 26 of 49

DirectVision® Technical Reference Manual

• The color of the monitor’s LED Indicator changes from

ORANGE to GREEN, indicating a video signal is being

received.

Note: The word PercuVision appears briefly on the monitor,

each time the CCU power is turned on.

• Verify that a video image appears on the monitor and the

tip of DirectVision® Guide is illuminated. Go to the

Troubleshooting Section of this Manual if no video appears

on the monitor or no illumination appears at the tip of the

DirectVision® Guide.

Page 27 of 49

DirectVision® Technical Reference Manual

• Turn the CCU off by pressing the Power OFF Button. LED

should turn off.

4. Return camera handpiece to cart storage drawer.

• Place the plastic Protection Cap on camera handpiece

and lock it into position.

Page 28 of 49

DirectVision® Technical Reference Manual

• Remove the Camera Handpiece Plug from the camera

Connector Receptacle on the CCU’s front panel.

• Attach Plug Cap to camera handpiece connector.

• Place camera handpiece into cart storage drawer.

Page 29 of 49

DirectVision® Technical Reference Manual

5. Prepare DirectVision® System for next use.

• Remove the 110/120 VAC cart plug from wall receptacle

then return it to its holder on the cart.

• Stock the cart drawers with inventory in accordance to

Cart Stocking Section of the DirectVision® Instruction

Manual.

• Place the DirectVision® System in holding area, waiting

to be used.

• Operation of the DirectVision® System has been verified

and is now ready for use.

Page 30 of 49

DirectVision® Technical Reference Manual

Monitor Setup

Control Dial Definitions

The Control Dial on the right side of the monitor provides control

to navigate and select menu entries. The main menu is invoked

when the Control Dial is pressed in momentarily (i.e. < 1 second).

When the Control Dial is rotated UP or DOWN and the menu is

active, the position of the menu item to be selected is

incremented or decremented by one. Pressing the Control Dial in

monentarily causes the viewed item to be selected. Selected items

can be either a menu item or a setup parameter. Parameters

become stored and effective upon exiting the main menu.

Monitor Default Values

Initially set the monitor parameters to PercuVision®

recommended values. Only two parameters need to be changed

from the factory default values.

• Black Level = 70

• Video Source = Composite

The Black Level can only be set when video is detected (LED =

GREEN). The Video Source can be assigned to Composite

independent of the Video Detect State (LED = ORANGE or LED =

GREEN). If for some reason the display monitor becomes

suboptimal, reset the monitor to default values and then define

video source to be Composite and increase Black Level to 70. If still

suboptimal, call customer support.

Page 31 of 49

DirectVision® Technical Reference Manual

Main

Menu

Sub

Menu

PercuVision®

Recommend

Contrast

80

80

Brightness

50

50

Black Level

50

70

Color Temp

Neutral

Neutral

Exit

H-Position

50

50

V-Position

50

50

Phase 0 0

Clock

50

50

Exit

Exit

Language

English

English

OSD H. Pos.

50

50

OSD V. Pos.

50

50

Exit

Source

VGA

Composite

Recall

Yes

Yes

Volume

50

50

Exit

Exit

Monitor Default Parameter Values

Default

Color

Picture

Auto

Auto Setup Yes Yes

OSD

Menu

Misc.

Page 32 of 49

DirectVision® Technical Reference Manual

Window

Size

Auto Gain

Control

White

Balance

Brightness

Camera Control Unit Calibration Procedures

Preconditions

The calibration procedures described in this section require the

following preconditions:

• The cart power cord is plugged into a 110/120 VAC wall

receptacle.

• The CCU and Display Monitor power switches are in the ON

position.

• The camera handpiece is plugged into the CCU.

• The camera handpiece is securely locked to visual guide.

Camera Control Unit Front Panel

Refer to the diagram below during the calibration procedure for

button control definitions

Page 33 of 49

DirectVision® Technical Reference Manual

Procedures

There are four calibration procedures for the CCU:

• Window Size

• Auto Gain Control

• White Balance Adjustment

• Focus

Each procedure is described in this section. Factory default

settings are provided where appropriate.

Window Size

The Window Size Button controls what part of the image seen by

the camera chip will be used for controlling camera sensitivity.

One of four different window presets can be selected.

1. Press the Window Size Button sequentially four times.

Windows 1 through Window 4 will be displayed.

2. Cycle through the four windows. Stop at the window which

produces the best optimized image on the monitor display.

3. Wait about 4 to 5 seconds. The Window Display on the

Monitor Display should disappear.

4. The size for the last window displayed is stored.

5. The selection in the last window displayed is used to

optimize the image displayed on the monitor.

Page 34 of 49

DirectVision® Technical Reference Manual

Default Factory

Setting

Window 1

Window 2

Window 3

Window 4

Default

Available

Choices

Default

Factory Setting

AGC-MAX 00 dB

AGC-MAX 10 dB

Default

AGC-MAX 12 dB

CCU Button Available Choices

Window Size

Auto Gain Control

The Auto Gain Control Button activates three different factory

presets. These presets affect the color and contrast of the image.

Toggle through these presets until you are satisfied with the

picture on the monitor screen.

1. Press the Auto Gain Control Button.

2. The monitor screen will display one of the following

settings:

• AGC-Max 00db

• AGC-Max 10db (Default)

• AGC-Max 12db

3. Push the Auto Gain Control Button once for preset no. 1,

again for preset no. 2, again for preset no. 3 and again to

return to preset no. 1.

4. Cycle through the three choices. Stop at the screen which

produces the best optimized image on the monitor display.

5. Wait about 4 to 5 seconds. The Window Display on the

Monitor Display should disappear.

6. The last preset view is stored until CCU powered off.

CCU Button

Automatic Gain

Control

Page 35 of 49

DirectVision® Technical Reference Manual

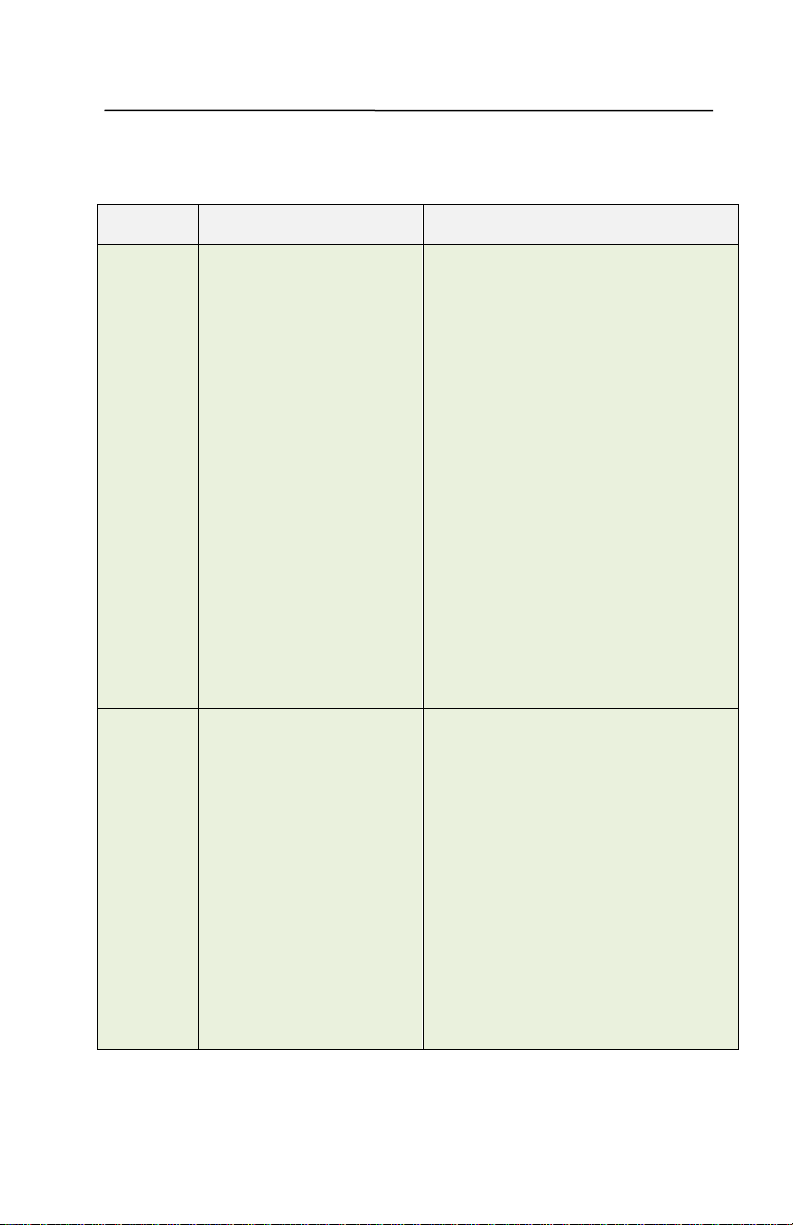

White Balance Adjustment

To adjust the white balance, proceed as follows:

1. Aim the illuminated tip of the catheter with the

DirectVision® Guide inserted into the visual guide lumen or

the visual guide tip itself to within approximately 5mm of a

white object.

If the monitor background color appears red or blue or green,

press and release the WHITE BALANCE Button on the CCU to

correct the background color.

Page 36 of 49

DirectVision® Technical Reference Manual

White Balance text string will appear on monitor screen as the

CCU begins executing the white balance operation. When the

white balance operation is completed, the text string changes to:

White Balance OK. The image will change to an accurate white.

The white balance operation enables the camera to reproduce all

colors in a natural tone.

Page 37 of 49

DirectVision® Technical Reference Manual

Page 38 of 49

DirectVision® Technical Reference Manual

Focus

1. Point the illuminated tip of DirectVision® Guide to within

approximately 5 mm of a white object with text.

2. Observe and assess video image sharpness (e.g. especially

vertical and horizontal lines) on display monitor.

Page 39 of 49

DirectVision® Technical Reference Manual

3. Adjust the focus ring on the camera handpiece until the video

image is sharp.

System Maintenance

Camera Control Unit Fuse

1. Open the fuse holder with flathead screwdriver.

o

2. Turn the fuse holder 90

3. Exchange with proper fuse.

4. Close the fuse holder by turning it 90

counter-clockwise.

o

clockwise.

The DirectVision® System is designed to require no other

maintenance.

Page 40 of 49

Troubleshooting

Step #

Problem

Potential Solution

• Check to see if unit is plugged

• Cycle Power Switch on for

No image on Display

Monitor

1

No Power Light on CCU

No Power Light on

Display Monitor

DirectVision® Technical Reference Manual

into a working 110-120 VAC

socket

• Check different outlet

• Check cart extension cord

• Confirm two power supplies

are plugged into cart

extension cord (must remove

top tray of cart)

• Verify 12VDC output for two

power supplies

• Verify 12V cables are correctly

connected to CCU and Display

Monitor

• Check CCU Fuse

• Cycle Power Switch on for CCU

and Display Monitor

• Call Customer Service

No image on Display

Monitor

2

No Power Light on CCU

Power Light on Display

Monitor

CCU

• Check CCU Fuse

• Confirm CCU power supply is

plugged into cart extension

cord (must remove top tray of

cart)

• Verify 12VDC output for CCU

power supply

• Verify 12V cable is correctly

connected to CCU

• Cycle Power Switch on CCU

• Call Customer Service

Page 41 of 49

DirectVision® Technical Reference Manual

• Cycle Power Switch on

•

OFF

• Verify camera handpiece cable

Step # Problem Potential Solution

Display Monitor

• Confirm CCU power supply is

No image on Display

Monitor

3

Power Light on CCU

No Power Light on

Display Monitor

plugged into cart extension

cord (must remove top tray of

cart)

• Verify 12VDC output from

Display Monitor power supply

• Verify 12V cable is correctly

connected to Monitor Display

• Cycle Power Switch on

Monitor Display

• Call Customer Service

No image on Display

Monitor

4

5

Power Light on CCU

Power Light on Display

Monitor (ORANGE

color)

No image on Display

Monitor

Power Light on CCU

Power Light on Display

Monitor (GREEN color)

Turn CCU

• Verify Composite Video cable

is correctly connected

• Verify video source for the

Display Monitor is Composite

• Call Customer Service

is properly connected to CCU

and the cable has no defects

• Verify visual guide is properly

aligned and locked to camera

handpiece

• Increase the light intensity by

turning the dial to MAX

position on the CCU

• Call Customer Service

then ON

Page 42 of 49

DirectVision® Technical Reference Manual

• Verify camera handpiece cable

• Cycle Power Switch on for

• Verify there is light from

Step # Problem Potential Solution

is properly connected to CCU

No light from camera

6

7

Power Light on CCU

No light from camera

No Power Light on CCU

and the cable has no defects

• Increase the light intensity by

turning the dial to MAX

position on the CCU

• Call Customer Service

CCU

• Check CCU Fuse

• Confirm CCU power supply is

plugged into cart extension

cord (must remove top tray of

cart)

• Verify 12VDC output for CCU

power supply

• Verify 12V cable is correctly

connected to CCU

• Cycle Power Switch on CCU

• Go to Step 6

No light from

8

DirectVision® Guide

Power Light on CCU

camera

• Verify alignment and lock

between visual guide and the

camera handpiece

• Increase the light intensity by

turning the dial to MAX

position on the CCU

• Replace DirectVision® Guide

• Call Customer Service

Page 43 of 49

DirectVision® Technical Reference Manual

• Cycle Power Switch on for

Step # Problem Potential Solution

CCU

• Check CCU Fuse

• Confirm CCU power supply is

No light from

9

10 Blurred image

DirectVision® Guide

No Power Light on CCU

plugged into cart extension

cord (must remove top tray of

cart)

• Verify 12VDC output for CCU

power supply

• Verify 12V cable is correctly

connected to CCU

• Cycle Power Switch on CCU

• Go to Step 8

• Turn the focus ring on the

camera handpiece until the

image is in focus

• Clean the tip of DirectVision®

Guide

• Replace DirectVision® Guide

• Replace camera handpiece

• Turn the focus ring on the

camera handpiece until the

image is in focus

• Call Customer Service

11 Image is too dark

Page 44 of 49

• Increase the light intensity by

turning the dial on the CCU

• Re-adjust white balance

• Re-adjust Display Monitor

setting

• Replace DirectVision® Guide

• Call Customer Service

DirectVision® Technical Reference Manual

•

Color bands seen

• Replace camera handpiece

•

• Call Customer Service

Damaged

Step # Problem Potential Solution

Re-adjust white balance

12

Inaccurate colors

• Re-adjust monitor settings

• Call Customer Service

13

14 Poor Visibility

15

on monitor

Cannot Insert

DirectVision®

Guide into

catheter

• Call Customer Service

• Confirm all connections are

properly placed.

• Check monitor settings

• Check CCU settings (Refer to

CCU Calibration Procedures

Section)

• Confirm camera-visual guide

connection is free of debris.

• Check focus

• Replace visual guide

• Check focus

• Call Customer Service

Confirm you are using the

proper catheter.

• Confirm that the visual guide

channel is sufficiently

irrigated.

• Confirm visual guide is not

damaged

• Confirm catheter is not

damaged

• Try a new catheter

• Try a new visual guide

16

DirectVision®

Guide or

catheter

• Replace damaged item(s)

with new one.

• Call Customer Service

Page 45 of 49

DirectVision® Technical Reference Manual

21 x 63.5 x 18 inches

(533x1613x457mm) (W x H x D)

141.5 1bs (63.5 kg approx.)

Monitor

Parameter

Value

Power Supply Module: Input:

mains voltage

Power Supply Output:

12 VDC, max. 1.25 A

Power Consumption:

12 VA

Technical Specifications

Dimension & Weight

Camera Control Unit

Parameter Value

Dimension:

Weight: 2.641bs (1.2kg)

Monitor

Parameter Value

Dimension:

Weight: 17.6 lbs (8 kg approx.)

Cart

Parameter Value

Dimension

Weight

6.65 x 2.44 x 9.72 inches

(169x62x247mm) (W x H x D)

17 x 14.65 x 7.91 inches

(432x372x201mm) (W x H x D)

excluding weight of CCU and

Electrical Specifications

Camera Control Unit

Page 46 of 49

100-240 VAC, max 0.5A, 50/60 Hz

Monitor

Monitor Power Supply module:

Input mains voltage

Monitor Power Supply Output

Monitor Power Consumption

32 W (Typical)

2.5 W at power saving

Sensor Size

1/4” Charge Couple Device (CCD)

Detection

2:1 line interlacing

PAL: 752 (H) x 582 (V)

NTSC: 786 (H) x 494 (V)

PAL 625 lines,

NTSC 525 lines

Brightness

Automatic

Signal/Noise ratio

46dB

S-Video (Y/C)

USB 2.0

DirectVision® Technical Reference Manual

Parameter Value

100-240 VAC, max 1.5A, 50/60Hz

12 VDC, max. 5.0A

Monitor Power Consumption

38 W (maximum) at full

brightness

Camera Specifications

Parameter Value

TV System PAL or NTSC

Picture Elements

Resolution

Output signal

Composite Video (CVBS)

Page 47 of 49

DirectVision® Technical Reference Manual

Parameter

Value

Field of View

70 o

Direction of View

0 o

Optical Resolution

4.9 lp/mm at 5mm distance

50

o

F up to 104

o

F

(10o C up to 40

C)

Humidity

up to 90%

+41o F to +95o F

(+5o C to +35o C)

Humidity

20% to 80% RH

+59o F to +95o F

(+15o C to +35o C)

Humidity

30% to 90% non-condensing

Visual Guide Specifications

Operating Environment

Camera Control Unit and Camera Handpiece

Parameter Value

Temperature

Monitor

Parameter Value

Temperature

Cart

Parameter Value

Temperature

o

Page 48 of 49

DirectVision® Technical Reference Manual

Storage Environment

The DirectVision® System and its consumables are to be stored at

room temperature in a controlled environment.

Spare Parts

Camera Control Unit

Name Description

Main fuse T800, 250V, 5x20mm

Warranty, Service & Claims

Do not attempt to service this product or you risk voiding the

warranty.

Contact PercuVision, LLC at 1-877-913-6333

References

DirectVision® Instruction Manual, PL000013.

Page 49 of 49

PercuVision® LLC

2030 Dividend Drive

Columbus, Ohio 43228

877-913-6333

www.percuvision.com

PL000032 Rev 05

Loading...

Loading...