Controller

CT/L-04.2

ASSEMBLY AND OPERATION MANUAL

Controller

CT/L-04.2

Assembly & Operation Manual

CONTENTS

1 APPLICATION..............................................................................................................4

2 OPERATION CONDITIONS .........................................................................................4

3 TECHNICAL SPECIFICATIONS ..................................................................................5

4 DELIVERY SET............................................................................................................6

4.1 Standard delivery set ..............................................................................................6

4.2 Optional equipment .................................................................................................6

5 DESCRIPTION .............................................................................................................7

5.1 Design and operation ..............................................................................................7

5.2 Controller boards.....................................................................................................8

5.3 IP-address setting .................................................................................................10

5.4 Controller configuration templates.........................................................................11

5.5 Signals of inputs....................................................................................................12

5.5.1 Inputs IN1 – IN4............................................................................................12

5.5.2 Inputs DUA, DUSt, DUB, FA.........................................................................13

5.6 Settings of output signals ......................................................................................14

5.6.1 Relay outputs OUT1 – OUT4........................................................................14

5.6.2 Outputs OK1 and OK2..................................................................................14

5.6.3 Outputs LdA, LdSt, LdB ................................................................................15

5.7 Parameters of signals received on inputs ШC1 and ШC2 .....................................15

5.7.1 “Standard” input configuration.......................................................................15

5.7.2 “AL” input configuration.................................................................................16

5.8 Connection to RS-485 interface ............................................................................17

6 MARKING AND PACKAGING ....................................................................................18

7 SAFETY REQUIREMENTS........................................................................................18

7.1 Installation safety requirements.............................................................................18

7.2 Operation safety requirements ..............................................................................18

8 INSTALLATION ..........................................................................................................19

8.1 Cable lengths ........................................................................................................19

8.2 Installation order....................................................................................................20

8.2.1 Controller installation ....................................................................................20

8.2.2 Door control configuration.............................................................................22

8.2.3 Turnstile and electromechanical gates configuration ....................................24

8.2.4 Vehicle checkpoint configuration ..................................................................26

8.2.5 RC-panel configuration .................................................................................28

8.2.6 Connecting a Fire Alarm Device ...................................................................29

8.2.7 Connecting the alarm lines ...........................................................................29

8.2.8 Connection of optional equipment ................................................................30

9 CONFIGURATION......................................................................................................33

10 UPDATE OF EMBEDDED SOFTWARE.....................................................................34

11 OPERATION ..............................................................................................................35

11.1 Operation modes of ACS ......................................................................................35

11.2 Indication of ACS, events and controller configurations ........................................36

11.3 Troubleshooting ....................................................................................................37

11.3.1 The controller does not work.........................................................................37

11.3.2 Failure of communication with PC ................................................................37

12 MAINTENANCE .........................................................................................................39

13 TRANSPORTATION AND STORAGE........................................................................41

Appendix 1. Instruction on connection of the card capture reader .....................................42

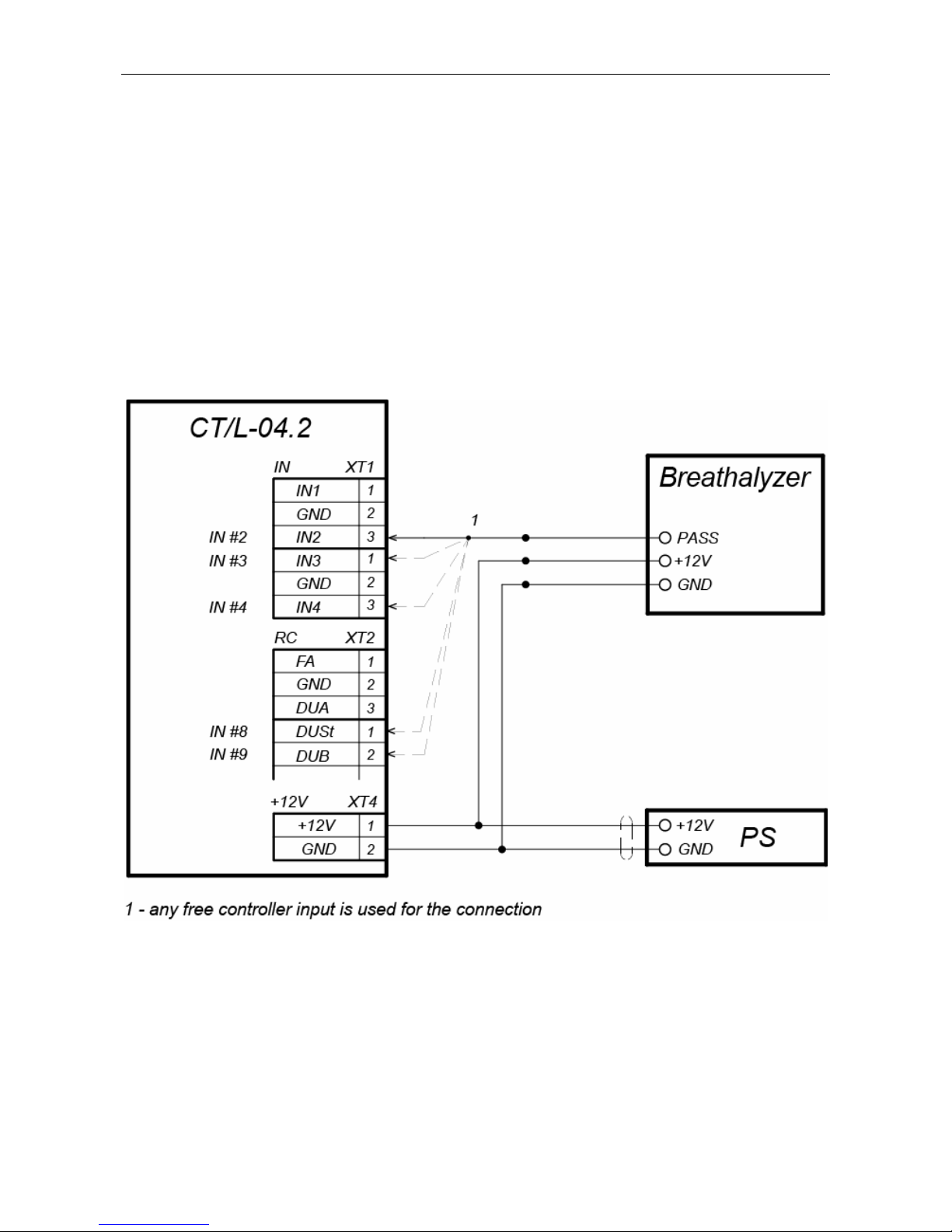

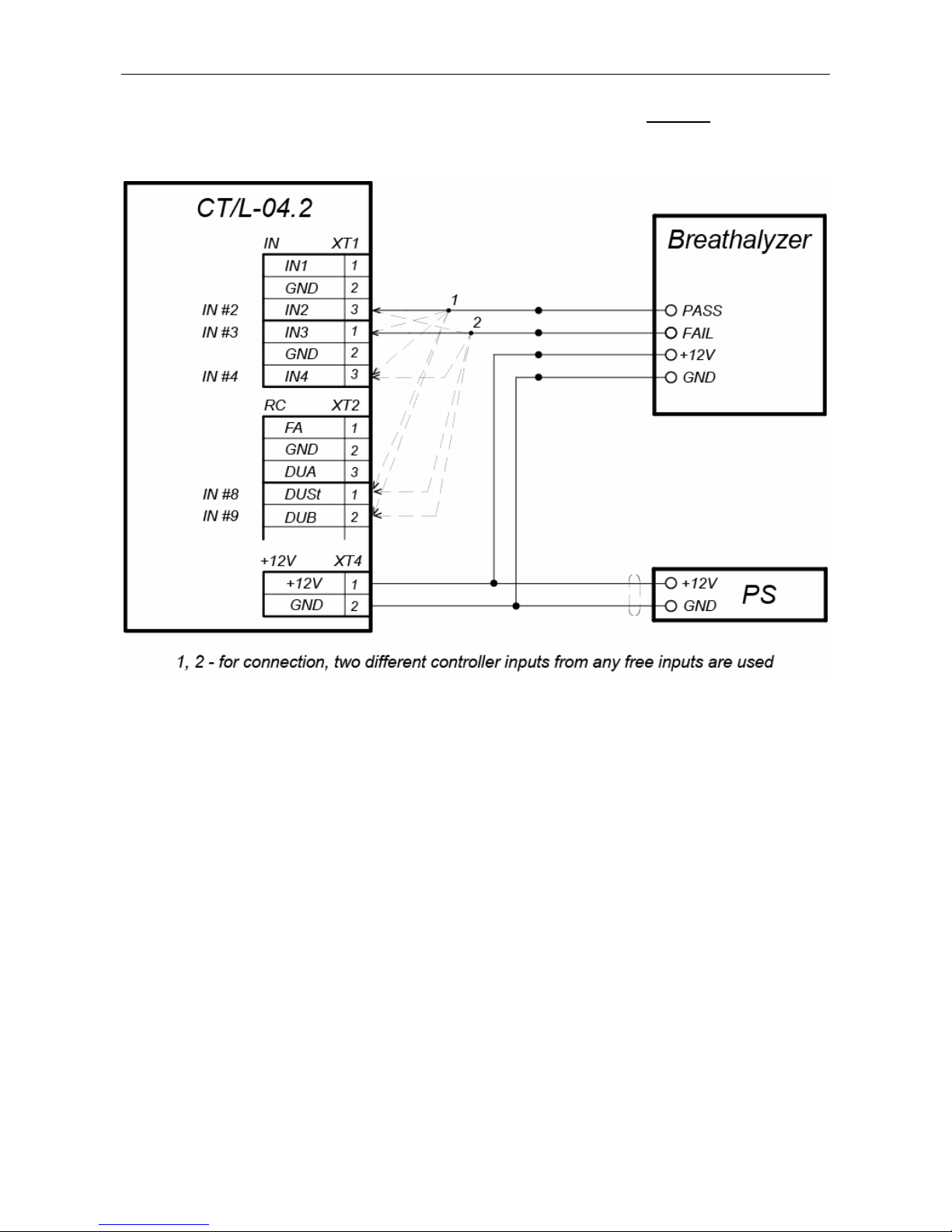

Appendix 2. Instruction on connection of the alcohol detection device ..............................45

Appendix 3. Instruction on connection of the controller through PoE-splitter .....................47

Appendix 4. Instructions for connecting biometric readers manufactured by Suprema .....49

Appendix 5. CT/L-04.2 Controller Web-interface. User Manual .........................................50

2

CT/L-04.2 Controller

Dear Customer!

Thank you for purchasing a controller manufactured by PERCo.

Please follow the instructions given in the Manual carefully,

and this quality product will provide many years of trouble-free use.

This Operation Manual (hereinafter – the Manual) provides information on technical

specifications and operation of CT/L-04.2 controller. The Manual aims to provide correct

operation of the controller and complete use of its technical capabilities. The Manual

contains data on installation and maintenance, and also a reference section.

The Manual is active together with Technical description of PERCo-Web and also with

certificates of devices connected to the controller.

Abbreviations adopted in the Manual:

ACM – access control mode;

ACS – access control system;

AL – alarm line;

LAN – local area network;

OD – operation device;

PC – personal computer;

PS – power supply;

RC– remote control;

RTC – real-time clock;

WRC – wireless remote control.

3

Assembly & Operation Manual

1 APPLICATION

CT/L-04.2 controller (hereinafter – the controller) is a part of PERCo-Web ACS.

The controller supports connection up to 8 different PERCo readers (Sect. 5.8) and

enables to organize up two two-way passages or up to four one-way passages.

Depending on configuration (Sect. 5.4) the controller can control the following ODs (in

different combinations):

One electromagnetic or electromechanical lock that supports two-way passage;

Up to four electromagnetic or electromechanical locks that support one-way

passage;

One turnstile or gate;

One boom barrier or an automatic gate of vehicle checkpoint.

Besides that, there can be connected up to 8 units of CL-201 lock controllers of the

second level, controlling one-way passage.

2 OPERATION CONDITIONS

The controller, with regard to resistance to environmental exposure complies to GOST

15150-69 category NF4 (operation in premises with climate control).

Operation of the controller is allowed at ambient air temperature from +1°C to +40°C and

relative air humidity up to 80% at +25°C.

4

CT/L-04.2 Controller

3 TECHNICAL SPECIFICATIONS

Operating voltage ................................................................................................... 12±1.2V

Consumption current (12V) .................................................................................. max. 0.2A

Power consumption ............................................................................................ max. 2.5W

Communication interface standard ................................................... Ethernet (IEEE 802.3)

Ethernet data transfer speed .......................................................................... 10/100 Mbps

Number of controlled ODs ...................................................................................... up to 41

Number of reading devices ....................................................................................... up to 8

Interface of reading devices ..................................................................................... RS-485

Number of access cards (users) ..................................... from 10,000 to 50,000 (see Note)

Event memory capacity

2

............................................. from 230,000 to 870,000 (see Note)

Note:

The user is able to change the memory allocation of the controller via the

Web-interface. Other options of memory allocation (see Appendix 5, Clause 3.4):

- 50 000 cards and 230 000 events (by default).

- 40 000 cards and 390 000 events.

- 30 000 cards and 550 000 events.

- 20 000 cards and 710 000 events.

- 10 000 cards and 870 000 events

Number of relay outputs for OD control ............................................................................. 4

Number of additional “open collector” outputs ................................................................... 2

Number of inputs with line control for short circuit and line break

(controlled by “dry contact” outputs) ................................................................. up to 8

Number of alarm lines ............................................................................................... up to 2

Number of remote control inputs ............................................................................... up to 4

Number of remote control indication outputs ..................................................................... 4

Electric shock protection class ...................................................................... III (IEC 61140)

Mean lifetime ........................................................................................................... 8 years

Dimensions ............................................................................................... 205×189×45 mm

Weight ............................................................................................................... max. 1.8 kg

1

Depends on the selected controller configuration (see Section 5.4).

2

Events from connected CL-201 controllers are stored in the memory of CT/L-04.2 controller.

5

Assembly & Operation Manual

4 DELIVERY SET

4.1 Standard delivery set

Controller ........................................................................................................................... 1

Jumper ............................................................................................................................. 11

Resistor С2-33H-0.25-4.7 kOhm ....................................................................................... 2

Suppressor 15-18 V ........................................................................................................... 4

Mounting hardware:

plastic dowel .................................................................................................................. 3

screw ............................................................................................................................. 3

self-adhesive cable tie mount ........................................................................................ 3

nylon cable tie 100 mm .................................................................................................. 5

Package ............................................................................................................................. 1

Certificate ........................................................................................................................... 1

Operation manual .............................................................................................................. 1

4.2 Optional equipment

Power supply ..................................................................................................................... 1

WRC kit 1............................................................................................................................ 1

PoE-splitter2 ....................................................................................................................... 1

Siren .................................................................................................................................. 1

CL-201 lock controllers ............................................................................................. up to 8

AU-05 system time display ................................................................................................ 1

1

WRC kit consists of a receiver and transmitters (tags) with operation range up to 40 m.

2

PoE-splitter – allows energizing of the controller via Ethernet network. Splitter can be used with

network switches that support PoE technology and that are compatible with IEEE 802.3af

standard.

6

CT/L-04.2 Controller

5 DESCRIPTION

5.1 Design and operation

The controller is produced in the form of electronics module in metal housing with a

removable cover. The cover houses power indication.

Following features are installed in the controller:

non-volatile memory;

non-volatile RTC-timer (real time clock);

8P8C (RJ45) connector for Ethernet local network;

housing opening sensor (the “tamper switch”).

The controller operates with cards the code of which does not exceed 64 bits.

The controller is able to store in non-volatile memory:

up to 50 000 card identifiers;

up to 230 000 events in the event log with the date and time of the event1.

The controller provides:

connection via Ethernet (IEEE 802.3) interface;

support of TCP/IP protocol suite (ARP, IP, ICMP, TCP, UDP, DHCP);

support of application layer of communications protocol of PERCo-Web system;

updating of embedded software through Ethernet.

On default, the controller has:

unique MAC-address (specified in the certificate and on the item board);

IP-address (specified in the certificate and on the item board);

Subnet mask (255.0.0.0);

IP-address of the gateway (0.0.0.0).

Following ways to set up IP-address, gateway and subnet mask are provided at the stage

of system configuration:

work with default settings;

manual input;

receipt from DHCP server.

Readers are connected to RS-485 interface of the controller. Connection variants are

provided in the Sect. 5.8.

Following optional equipment may be connected:

up to two Al-01 indication blocks with infrared-receiver;

up to four door sensors (reed switches);

two passage sensors (PASS-outputs of a turnstile);

up to four RC-buttons (“Exit”) for a lock;

one RC-panel of a turnstile (swing gate);

up to seven devices sending commands to additional inputs,

one AU-05 system time display;

emergency unlock devices Fire Alarm.

1

In case of event log overflow the oldest events will be replaced with the new ones (events are

deleted by blocks consisting of 256 events).

7

Assembly & Operation Manual

The controller as a part of ACS provides:

operation in ACM: “Open”, “Control”, “Security” 1, “Closed”;

saving of the set mode in the non-volatile memory, to avoid the turn-off of the mode in

case of power failure;

support of local and global control of zonality and verification.

The controller as a part of security alarm system provides:

connection and control of two alarm lines2;

connection of light and sound alarm devices;

possibility of arming and disarming of the protected zone;

sending of alarm notifications to central surveillance panel.

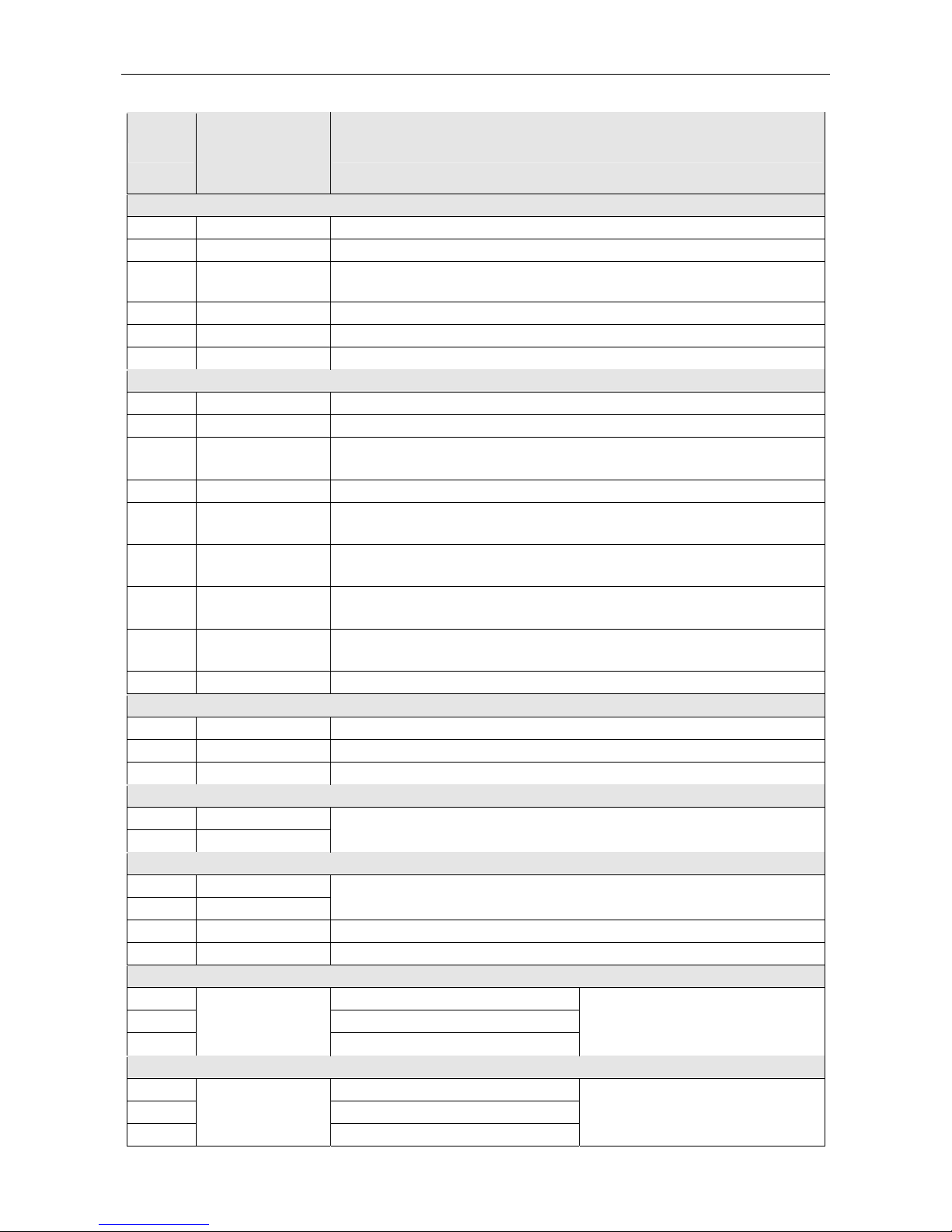

5.2 Controller boards

The controller includes two boards – top board (processor module) and bottom board

(process execution module). The connecting blocks XS1 – XS3 of the top board are fitted

in the connecting blocks XP1 – XP3 of the bottom board. The boards of the controller are

shown on Figure 1. The purpose of connecting blocks is given in the Table 1.

Figure 1. The top and bottom boards of the controller

1

The mode “Security” is available only for configurations “Controller for lock control” and

connected CL-201 lock controllers.

2

Depends on chosen controller configuration (see Sect. 5.4).

8

CT/L-04.2 Controller

Table 1. The purpose of connecting blocks of the bottom board

Contact

Name of the

physical contact

in the Web-

interface

Purpose

Connector ХТ1 (IN)

IN1 Input 1 “Door sensor #1” or “Input for PASS A signal”

GND –

“Common”

IN2 Input 2

“Door sensor #2” or “Input for PASS B signal”

or “Additional input IN #2”

IN3 Input 3

“Door sensor #3” or “Additional input IN #3”

GND –

“Common”

IN4 Input 4

“Door sensor #4” or “Additional input IN #4”

Connector ХТ2 (RC)

FA Input 10

“Input for emergency unlock (passage opening) Fire alarm”

GND –

“Common”

DUA Input 7

“Control input of the OD1 from the RC-button” or “Control input of

direction A from the RC-panel”

DUSt Input 8 “Input STOP from the RC-panel” or “Additional input IN #8”

DUB Input 9

“Control input of the OD2 from the RC-button” or “Control input of

direction B from the RC-panel” or “Additional input IN #9”

LdA Output 7

“Output for indication of direction A on the RC-panel” or “Additional

output OUT #7 (TTL- level)”

LdSt Output 8

“Output for indication STOP on the RC-panel” or “Additional output

OUT #8 (TTL- level)”

LdB Output 9

“Output for indication of direction B on the RC-panel” or “Additional

output OUT #9 (TTL- level)”

Buzz – “Output for sound indication on the RC-panel”

Connector ХТ3 (ОC)

ОК2 Output 6 “Additional output OUT #6 (open collector)”

ОК1 Output 5 “Additional output OUT #5 (open collector)”

+12V – “Output of +12VDC power for outputs ОК1 and ОК2”

Connector ХТ4 (+12VDC)

+12V –

GND –

“Input of controller + 12VDC power from external PS”

Connector ХТ5 (RS-485)

+12V –

GND –

“Output of +12VDC power for readers”

A –

“Connection of line A via RS-485”

B –

“Connection of line B via RS-485”

Connector ХТ6 (OUT1)

NO1 normally open contact

C1 central contact

NC1

Output 1

normally closed contact

“Relay control output OD #1”

Connector ХТ7 (OUT2)

NO2 normally open contact

C2 central contact

NC2

Output 2

normally closed contact

“Relay control output OD #2” or

“Additional output OUT #2”

9

Assembly & Operation Manual

Contact

Name of the

physical contact

Purpose

in the Web-

interface

Connector ХТ8 (OUT3)

NO3 normally open contact

C3 central contact

NC3

Output 3

normally closed contact

“Relay control output OD #3” or

“Additional output OUT #3”

Connector ХТ9 (OUT4)

NO4 normally open contact

C4 central contact

NC4

Output 4

normally closed contact

“Relay control output OD #4” or

“Additional output OUT #4”

Connector ХТ10 (AL)

ШС1+ “Alarm line input AL #1 (contact +)”

ШС1-

Input 5 (loop)

“Alarm line input AL #1 (contact -)” or “Additional input IN #5”

ШС2+ “Alarm line input AL #2 (contact +)”

ШС2-

Input 6 (loop)

“Alarm line input AL #2 (contact -)” or “Additional input IN #6”

Controller has on the top board:

XP1 – connector to choose the method of the IP-address of the controller; by default,

the jumper is not installed - user mode (Sect. 5.3);

S1 – connector for the Ethernet cable.

Controller has on the bottom board:

XP1 – XP3 – connecting blocks for the top board;

XP4 – connecting block for power indication on the housing;

XP5.1, XP5.2 – XP8.1, XP8.2 – connectors (in pairs) to select the type of connected

lock (see Section 8.2.2):

jumpers pair are removed – if a standard electromechanical or electromagnetic

lock is connected to the corresponding output,

jumpers are installed – locks of LB- or LBP-series are without installed door

sensor (reed switch). The controller traces the passage on condition of the

contact group of the lock;

XP9 and XP10 – are connectors for selection of input ШC1 and ШC2 configurations

where (see Section 5.7):

jumper in position 1-2 – ''alarm line'' input type,

jumper in position 2-3 – ''standard'' input type.

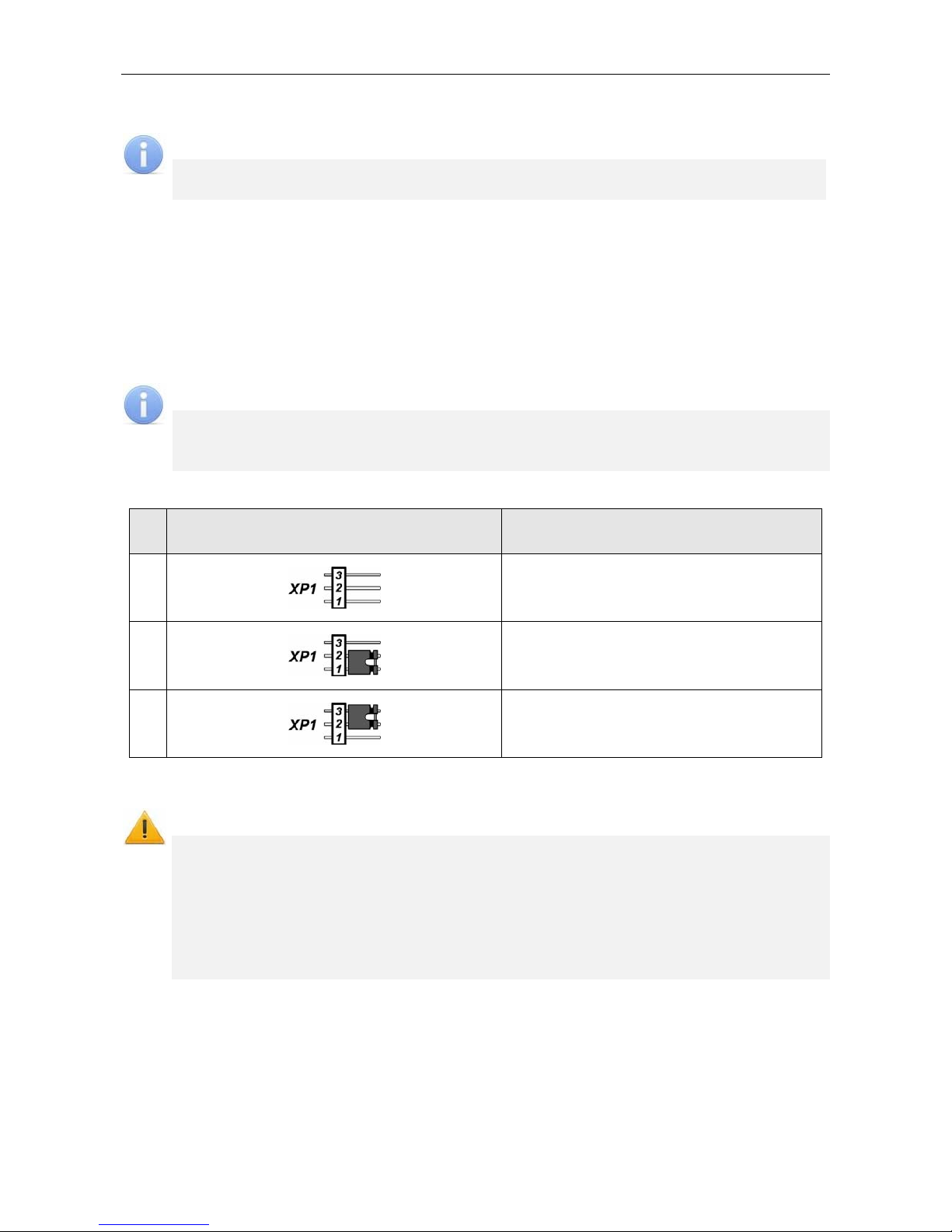

5.3 IP-address setting

The way of IP-address setting is selected by installation or removing of jumper on XP1

connector on the controller top board.

Attention!

Jumpers should be installed and removed only when the power is off.

Following ways of IP-address setting are possible (see Table 2):

1. User mode. Jumper is removed.

If the IP-address (gateway, subnet mask) is not changed by the user, the controller

works with default settings: IP-address and MAC-address are specified in the

certificate of IP-stile and on the controller board; subnet mask 255.0.0.0;

IP-address of the gateway 0.0.0.0.

10

CT/L-04.2 Controller

If the IP-address (gateway, subnet mask) is changed by the user, the controller

starts to work with the new settings immediately without switching power supply.

Note:

It is possible to change network settings of the controller from PC via Web-interface

or software. The controller and PC must be on the same subnet.

2. “IP MODE”. Jumper is in the position 1–2.

Work in networks with dynamic allocation of IP-addresses, the controller can

receive IP-address (gateway, subnet mask) from DHCP-server.

3. “IP DEFAULT”. Jumper is in the position 2–3.

The controller works with default settings: IP-address and MAC-address are

specified in the certificate of IP-stile and on the controller board; subnet mask

255.0.0.0; IP-address of the gateway 0.0.0.0.

The password for controller is reset.

Note:

User settings of IP-address (gateway, subnet mask), if they were set, are saved

during the switch into “IP DEFAULT” mode. The controller will operate with them at

next turn-on, if jumper is not installed.

Table 2. Jumper installation on XP1 connector

№ Jumper position on XP1 Method of specifying IP addresses

1

User mode

2

“IP MODE”

3

“IP DEFAULT”

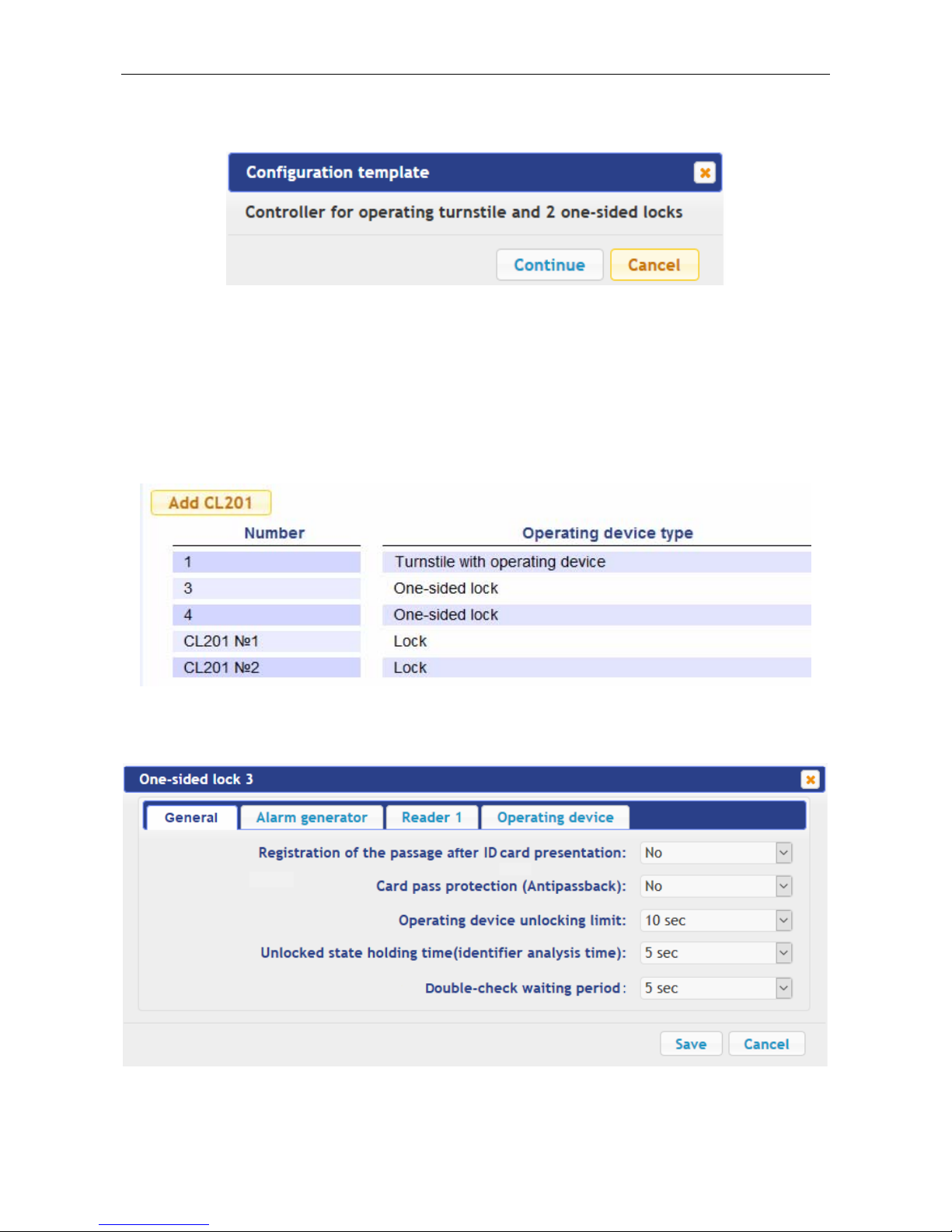

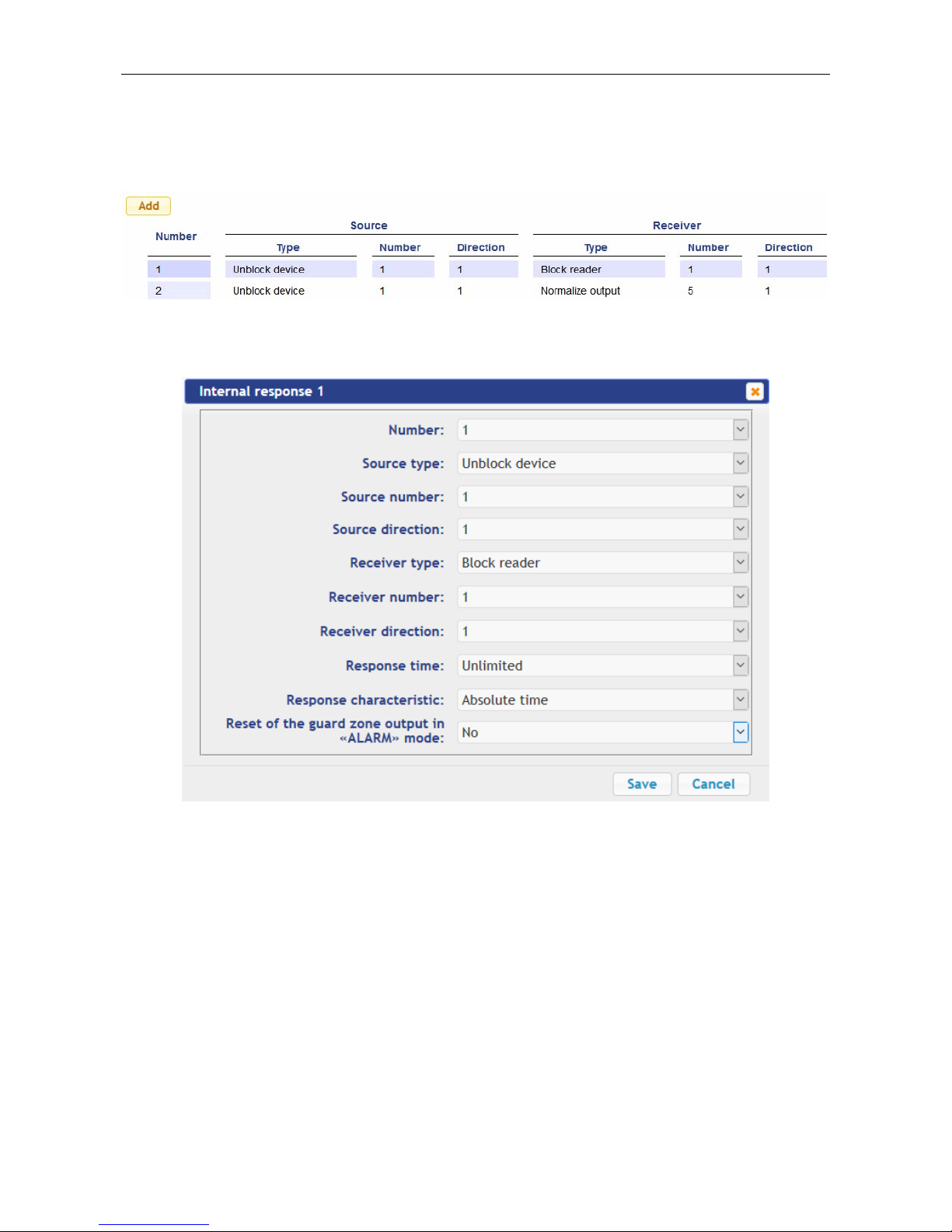

5.4 Controller configuration templates

Attention!

Change of the controller configuration template, adding of the of the second level

controllers and optional card readers are available only using the Web-interface

of the controller (see Appendix 5, Clause 4.1).

If you change the template, you delete the configuration and internal responses

of all resources of the controller. The configuration “Default” is set for resources

of the selected configuration. Meanwhile the information of access cards

identifiers, data of users, rights and access settings are saved.

Following configuration templates are available for the controller:

1. The controller to operate the turnstile (without additional locks);

2. The controller to operate the turnstile and one one-way lock;

3. The controller to operate the turnstile and two one-way locks;

4. The controller to operate the turnstile and one two-way lock;

5. The controller to operate the vehicle checkpoint (without additional locks);

11

Assembly & Operation Manual

6. The controller to operate one vehicle checkpoint and one one-way lock;

7. The controller to operate one vehicle checkpoint and two one-way locks;

8. The controller to operate one vehicle checkpoint and one two-way lock;

9. The controller to operate one one-way lock (without alarm lines);

10. The controller to operate one one-way lock with one alarm line;

11. The controller to operate one one-way lock with two alarm lines;

12. The controller to operate two one-way locks (without alarm-lines);

13. The controller to operate two one-way locks and one alarm line;

14. The controller to operate two one-way locks and two alarm lines;

15. The controller to operate three one-way locks (without alarm lines);

16. The controller to operate three one-way locks with one alarm line;

17. The controller to operate four one-way locks;

18. The controller to operate one two-way lock (without alarm lines);

19. The controller to operate one two-way lock and one alarm line;

20. The controller to operate one two-way lock and two alarm lines;

21. The controller to operate one two-way lock and one one-way lock (without alarm lines);

22. The controller to operate one two-way lock and one one-way lock with one alarm line;

23. The controller to operate one two-way lock and two one-way locks;

24. The controller to operate two two-way locks (without alarm lines);

25. The controller to operate two two-way locks with one alarm line.

By default, the configuration №1 “The controller to operate the turnstile (without additional

locks)” is configured.

5.5 Signals of inputs

5.5.1 Inputs IN1 – IN4

The controller provides status control of four inputs controlled by “dry contact” or “open

collector” (OK): IN1-IN4. Connection to the outputs is performed via XT1 connecting block

of the controller bottom board (Figure 1 and 3).

Note:

To create a high-level signal on all input contacts IN1 – IN4, resistors with 2 kOhm

resistance, connected to +3.3V power line, are used.

Inputs can be used for following connections:

IN1:

o door sensor 1 (reed switch),

o PASS output of a turnstile,

o passage sensor of a vehicle checkpoint;

IN2:

o door sensor 2 (reed switch),

o PASS output of a turnstile,

o optional equipment (IN #2);

IN3, IN4:

o door sensor 3, 4 (reed switch),

o optional equipment (IN #3, IN #4).

12

CT/L-04.2 Controller

Signals activation depends on description of their default status in Normal status of

contact parameter in PERCo-Web software):

If input is described as Opened, it is activated by a turn-on of low-level signal

relative to GND contact. In such case a normally opened relay contact or a scheme

of open collector output may be a control element.

If input is described as Closed, it is activated by a turn-off of low-level signal relative

to GND contact. In such case a normally closed relay contact or a circuit of open

collector output may be a control element.

Note:

Input IN1 is configured as “Closed” by default.

If according to the configuration of the controller input IN2, IN3 or IN4 is used to

connect the door sensor / passage sensor / PASS, that by default is configured

as Closed with the possibility of further changes.

Control element “relay contact” should provide following characteristics of signals:

Minimum commutating current ........................................................................ max. 1 mA

Closed contact resistance

(with resistance of the connection cable)................................................ max. 300 Ohm

Control element of circuit with open drain output should provide following characteristics of

signals:

Voltage at the closed contact

(low-level signal at input of the controller)...................................................... max. 0.8 V

5.5.2 Inputs DUA, DUSt, DUB, FA

The controller provides status control of four inputs under control of “dry contact” or “open

collector” (OK): DUA, DUSt, DUB, FA. Connection to the inputs is performed via XT2

connecting block of the controller bottom board.

Note:

To create a high-level signal on all input contacts DUA, DUSt, DUB, FA, resistors

with 1 kOhm resistance, connected to +3,3V power line, are used.

Inputs can be used for following connections:

DUA, DUSt, DUB:

o RC-buttons,

o RC-panel (WRC),

DUSt, DUB:

o optional equipment (IN #7, IN #8);

FA:

o emergency unlock devices (passage opening) Fire Alarm.

Activation and characteristics of signals of the control element are specified in the

Sect. 5.5.1.

Note:

Input FA is uniquely configured as “Closed”.

Input DUA is uniquely configured as “Opened”.

If according to the configuration of the controller input DUSt or DUB used to

connect RC-buttons, it is uniquely configured as Opened without any possibility

being modified.

13

Assembly & Operation Manual

5.6 Settings of output signals

5.6.1 Relay outputs OUT1 – OUT4

The controller is equipped with four relay outputs OUT1 – OUT4. Connection to the

outputs is performed via XT6 – XT9 connecting blocks of the controller bottom board.

Every output has a complex group of contacts: normally open NO, normally closed NC and

common output C.

Outputs may be used for (Figure 3):

OUT1:

o as a control output of operation unit OD #1;

OUT2, OUT3, OUT4:

o as a control output of OD #2, OD #3 and OD #4,

o as outputs to control optional equipment (OUT #2, OUT #3, OUT #4).

Characteristics of output signals:

Maximum commutating voltage of direct current ......................................... max. 30 V

Maximum commutating voltage of alternate current .................................... max. 42 V

Maximum commutated direct/alternate current for outputs Out ..................... max. 5 A

Resistance of closed contact .............................................................. max. 0.15 Ohm

Control outputs support potential and pulse operation modes of OD. Selection of mode is

performed with Operation mode of control output parameter of OD.

In potential mode of OD:

In case of single passage relay output is activated for a period of time, set in

software by Unlocked state holding time software parameter or till the moment of

passage.

In case OD is set into “Open” mode relay output is activated till the mode change.

In pulse mode of OD:

In case of single passage relay output is activated for a period of time, set by

Control pulse duration parameter of OD. In such case OD remains unlocked until

the passage is performed.

In case OD is set into “Open” mode output is activated for a period of time, set by

Control pulse duration parameter of OD, and after that it will be activated each

time for the same period in one second after the normalization of OD.

Activation of inputs IN1 – IN4, configured as door sensor or signal PASS, define that the

passage was performed in the set direction.

5.6.2 Outputs OK1 and OK2

The controller is equipped with two outputs “open collector”: OK1 and OK2 (in

configuration OUT #5 and OUT #6, Figure 3). Connection to the outputs is carried out via

XT3 connecting block of the controller bottom board.

+12VDC supply is derived to the same connecting block for easy connection.

Outputs can be used for following functions:

connection of light and sound alarm devices,

sending of alarm notifications to central surveillance panel,

connection of other optional equipment.

Characteristics of output signals:

Maximum commutation voltage of direct current ...........................................max. 30 V

Maximum commutated current...................................................................max. 0.25 A

14

CT/L-04.2 Controller

5.6.3 Outputs LdA, LdSt, LdB

The controller is equipped with three outputs type “TTL”: LdA, LdSt, LdB. Connection should

be performed to the contacts of XT2 connecting block of the controller bottom board.

Outputs can be used (Figure 3):

as outputs of connection of indication of the RC-panel,

as outputs of control of other optional equipment (OUT #7, OUT #8, OUT #9).

Characteristics of output signals:

Maximum voltage of direct current ................................................................. max. 3 V

Maximum current....................................................................................... max. 0.01 A

5.7 Parameters of signals received on inputs «ШC1» and «ШC2»

The controller provides the status control of two inputs ШC1 and ШC2. Connection to the

inputs is carried out via the connecting block XT10 of controller bottom board.

Every input can be used as input of alarm line or as standard input to connect the lock

RC-button or to connect optional equipment (IN #5, IN #6), see Figure 3. The input

selection depends on the selected controller configuration and the position of the jumper

on the connector XP9 or XP10 on the controller bottom board. Installation of the jumper in

the position 2-3 corresponds to the configuration “standard input”.

Attention!

When you select the controller configuration with one or two ALs (see Sect. 5.4),

you need to put jumpers on the controller bottom board in the position 1-2 (see

Figure 1):

on the connecting block XP10 with configuration “1 AL”,

on the connecting blocks XP9 and XP10 with configuration “2 ALs”.

5.7.1 “Standard” input configuration

Jumper XP9 (for ШC1) or XP10 (for ШC2) is in the position 2-3. The controller provides the

control input status ШC1- ÷ GND (ШC2- ÷ GND) under control output type “dry contact” or

“open collector” (OК).

Note:

To create a high-level signal on inputs contacts ШC1- and ШC2- relative to GND,

the resistors with 1kOhm resistance are used. They are connected to +5 V power

line. The resistors with 392 Ohm are connected to the minus of power supply.

In this configuration input can be used:

ШC1- ÷ GND:

o as input for connection of RC-button for the lock (RC OD #3);

o as input for connection of optional equipment (IN #5).

ШC2- ÷ GND:

o as input for connection of RC-button for the lock (RC OD #4);

o as input for connection of optional equipment (IN #6).

Activation of all signals depends on description of their initial status in Normal status of

contact parameter in PERCo-Web software:

If input is described as Opened, it is activated by a turn-on of low-level signal relative

to GND contact. In such case a normally open relay contact or a scheme of open

collector output may be a control element.

If input is described as Closed, it is activated by a turn-off of low-level signal relative to

GND contact. In such case a normally closed relay contact or a circuit of open

collector output may be a control element.

15

Assembly & Operation Manual

Note:

If according to the configuration, input of the controller is used for connection of the

RC-button, that it is configured as “Opened” without any possibility being modified.

Control element “relay contact” should provide following characteristics of signals:

Minimum commutating current ........................................................................ max. 1 mA

Closed contact resistance

(with resistance of the connection cable) ............................................. max. 300 Ohm

Control element of circuit with open collector output should provide following

characteristics of signals:

Voltage at the closed contact

(low-level signal at input of the controller .................................................... max. 0.8 V

5.7.2 “AL” input configuration

Jumper XP9 (for ШC1) or XP10 (for ШC2) is in the position 1-2.

Only security detectors may be used as detectors, connected to alarm line:

Electrical contact detectors and magnetic contact detectors (reed switches, fuses);

Those that have relay on output (4-wire line).

Table 3. Status and thresholds of alarm line

Alarm line resistance, Ohm Status of alarm line defined by a device

Configuration: “Security”

Less than 2 kOhm Violation – short circuit

2,4 kOhm - 7 kOhm Normal

More than 9 kOhm Violation – line break

Configuration: “Security with tamper-evidence examination of detectors housings”

Less than 1,3 kOhm Violation – short circuit

1,5 kOhm - 2,3 kOhm Normal

2,5 kOhm - 3,6 kOhm Violation – detector housing is opened

4 kOhm - 6 kOhm Violation – detector activation

More than 7 kOhm

Violation – detector activation and detector housing is opened or

line break

Specifications of input signals of alarm line:

Voltage in alarm line .................................................................................................... 5 V

Short circuit current in alarm line ................................................................... max. 12 mA

Resistance of remote element .......................................................................... 4.7 kOhm

Resistance of alarm line wires

(without regard to resistance of remote element) .................................... max. 1 kOhm

Resistance of alarm line wires during tamper-evidence examination of detectors

housings (without regard to resistance of remote element) ................ max. 0.22 kOhm

Leakage resistance between alarm line wires and “ground”....................... min. 20 kOhm

Note:

Alarm line specifications are controlled by their resistance.

AL integration time – maximum period of time during which the change of alarm line

resistance is not regarded as a violation and does not cause the turn of alarm line into

alarm state.

16

CT/L-04.2 Controller

When AL is armed, its resistance is constantly measured with necessary averaging. AL

integration time is set by Violation duration parameter and it is equal to 70 ms or 300 ms.

The requirements for detecting the AL state at these AL integration time are shown in

Table 4:

Table 5. Alarm line integration time

Integration time (Violation duration) 70 ms 300 ms

Alarm line violations should not cause a device to detect “violation” alarm line

status, in case they were in process during the period of time not exceeding

50 ms 250 ms

Alarm line violations should cause a device to detect “violation” alarm line

status, in case they were in process during the period of time exceeding

70 ms 300 ms

5.8 Connection to RS-485 interface

Readers, Al-01 display unit with infrared-receiver, CL-201.1 lock controller and AU-05

system time display are connected to the controller via RS-485 interface. The

communication line of the RS-485 interface is being implemented over twisted pair with the

polarity observance according to the principle of the direct topology of the «common bus»

(the communication line is paved in series to all devices, and the devices to the

communication line are connected in parallel, the contact A to the line A, the contact B to

the line B).

At the end of the communication line of RS-485 interface should be mounted limit

resistors-terminators Roк with nominal value of 120 Ohms. On products with built-in

terminal resistor, which are not end devices of the communication line, it is necessary to

remove the jumper by cord “disconnection of end-of-line resistor”. The position of jumper is

indicated in the operational documentation of a specific product. If the controller is located

at one of the end of the communication line, the terminal resistor with nominal value of 120

Ohms is installed between A and B contacts of XT5 connecting block.

When connecting to RS-485 interface, follow the instructions of the connected device and

the scheme presented in Figure 3. To connect a communication line of RS-485 to the

controller, the cable type №2 is applied (Table 6).

Attention!

When installing each type of device (readers, controllers, display units) they need to

set different addresses, otherwise devices of the same type with the same

addresses will not work. The address is determined by the status of the jumper

(jumper) "number" on the chassis or on the product board (see the operating

documentation for this product).

Contact +12V and GND of XT5 connecting block can be used as power supply for

devices under condition that the maximum load current must not exceed 0.5A.

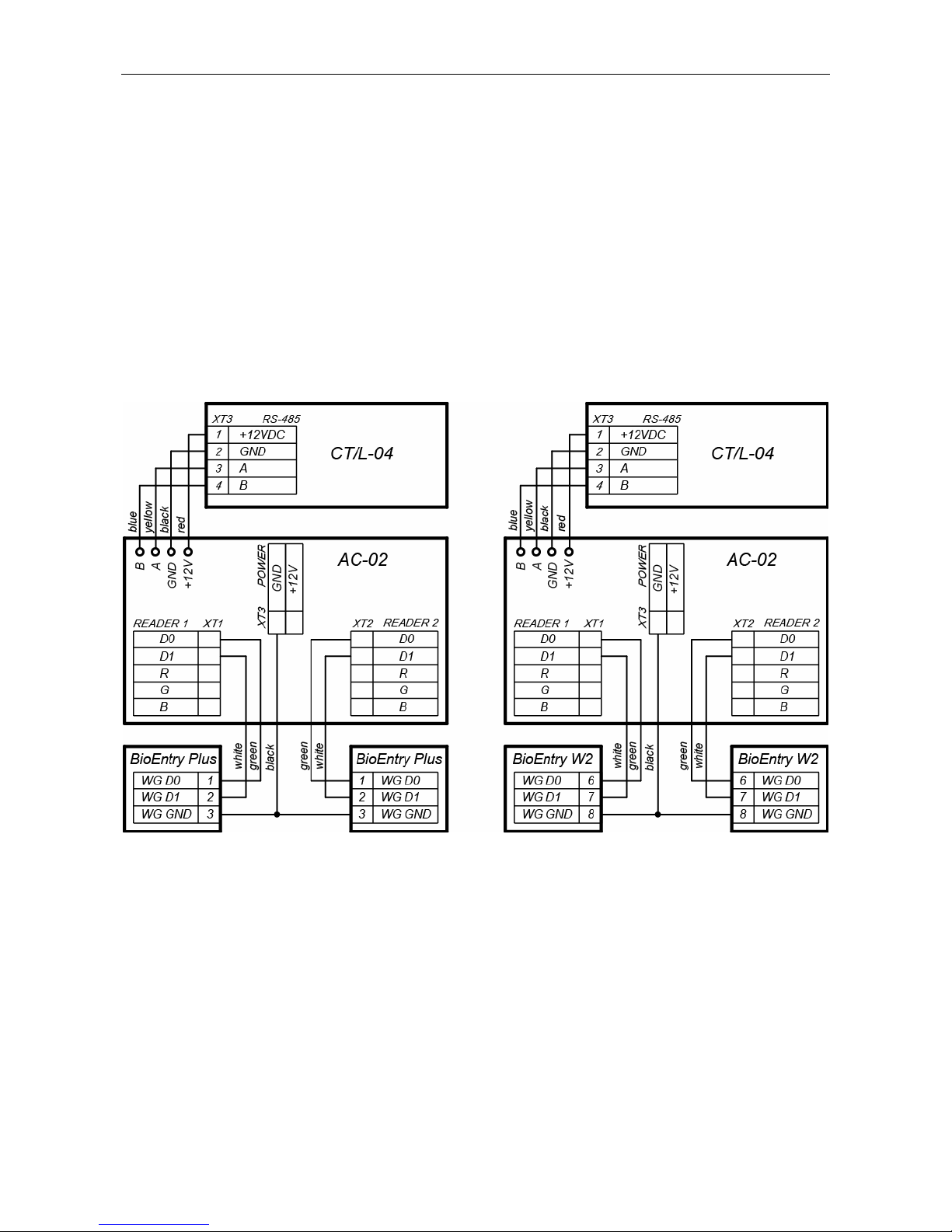

Following variants of reader connection are possible (Figure 3):

Up to eight IR-03.1, IR-04.1, IRP-01.2, IR-10 card readers, IC-02.1, IC-05 card capture

readers (in any combination).

Up to eight MR-07.1 card readers.

Up to eight readers with Wiegand (Wiegand-26, -34, -37, -40, -42) interface. The

connection requires up to 4 AC-02.1 interface converters. Each converter allows you

to connect two Wiegand readers on the RS-485 bus. Connection diagram and

description of indication of the readers are given in the operational documentation of

the interface converter.

17

Assembly & Operation Manual

6 MARKING AND PACKAGING

The marking label of the controller is placed on the back of the housing. The marking label

provides following information concerning the controller:

trade mark and contact details of the manufacturer;

name and number of model;

serial number;

date and month of manufacture;

allowed power voltage range;

consumption current.

The controller board contains labels with default MAC-address and IP-address of the

controller.

The controller is packed into a paperboard box, preventing it from damages during

transportation and storage.

7 SAFETY REQUIREMENTS

7.1 Installation safety requirements

Installation and technical maintenance of the controller should be performed by qualified

staff, after getting acquainted with the Operation manual and safety rules. Installation

should be performed in accordance with general electrical and work safety rules.

Attention!

All connections and jumper installations should be carried out only when the

equipment is powered off and power supply is disconnected.

During mounting use only proper tools.

Cabling should be performed in accordance with general requirements for

electrical equipment.

Do not use the controller if it is not properly installed and connected.

7.2 Operation safety requirements

Operation should be performed in accordance with general electrical and work safety

rules.

Do not use!

The controller under conditions that do not comply with the requirements of

Section 2 of this Manual.

The controller at supply voltage that does not comply with the requirements of

Section 3 of this Manual.

The device in hostile environment that contains acids, alkalis, oils etc.

Power supply should be used accordingly to safety rules given in the Operation manual.

18

CT/L-04.2 Controller

8 INSTALLATION

Installation should be performed in accordance with work safety noted in Sect. 7.1.

Installation should be done in accordance with local building requirements.

8.1 Cable lengths

Cables for mounting are shown in Table 6.

Mounting of communication lines should comply with EIA/TIA RS-422A/485 standards.

Do not lay cables at a distance less than 50 cm from a source of electromagnetic

interference.

Crossing of all cables with power cables is allowed only at a right angle.

Lengthening of cables should be performed by soldering only.

All cables, entering controllers, should be fixed with plastic ties to self-adhesive cable

tie mount, included into delivery set and installed inside the housing. Lay and fix

cables using plastic fixing brackets, if necessary.

After cables are laid, check if there are no line breaks and short circuits at all lines.

It is not allowed to lay power cables for lock, sensor cables, remote control cables and

reader cables at a distance more than 1 m from ground cables.

Table 6. Cables used for installation

№ Equipment

Cable

length, m,

max

Cable type

Cross

section,

mm² min.

able example

1 Ethernet (IEEE 802.3) 100

Four twisted

pairs (starting

from Category 5)

4×2×0.52 F/UTP2Cat5e

Reader, card capture

reader, Al-01 indication

block

50 (total)

2

CL-201 lock controller,

AU-05 system time

display

1200 (total)

Twisted pairs

(starting from

Category 5)

0.2

2×2×0.52 F/UTP2Cat5e

3 Power source 10 Twin cable 0.75

Flat cord with sheath

and outer sheath of

PVC

4

RC-button (“Exit”); Door

sensor (reed switch);

Additional sensor

(to input of the controller);

Additional equipment

(to output of the

controller)

30 Twin cable 0.2

RAMCRO SS22AF-T

2×0.22

CQR-2

5 Remote control board 40 Eight-core cable 0.2 CQR CABS8 8×0.22c

7 Lock 30

Double-core

cable

0.75

PVC twin cable

2×0.75

8 Turnstile 30 Six-core cable 0.2 CQR CABS6 6×0.22c

9 Vehicle checkpoint 30 Four-core cable 0.2 CQR CABS4 4×0.22c

10 Alarm line Twin cable 0.5 PVC twin cable 2×0.5

19

Assembly & Operation Manual

8.2 Installation order

Connection to the controller is performed in accordance with scheme shown on

Figures 3 - 13 with the use of cables from Table 6. The position of connecting blocks on

the controller’s board is presented on Figure 1.

Installation of connected devices (turnstiles, locks, power supply, etc.) is performed

according to the instructions given in technical documents of corresponding devices.

8.2.1 Controller installation

1. Unpack the box and check completeness of package contents according to Sect. 4.

Make sure that the equipment is not mechanically damaged.

2. Define the place for installation of the controller. Location of the controller should

comply with operational conditions. When choosing a location, make sure that it will be

convenient to perform service maintenance of the controller.

Attention!

Do not install the controller at a distance less than 1 m from a source of

electromagnetic interference.

3. Mark and drill holes in the surface to install the controller and connect cables in

accordance with Figure 2. Lay and mount communication cables, power cables and

Ethernet cables to the location.

Figure 2. Marking of holes for the controller installation

20

CT/L-04.2 Controller

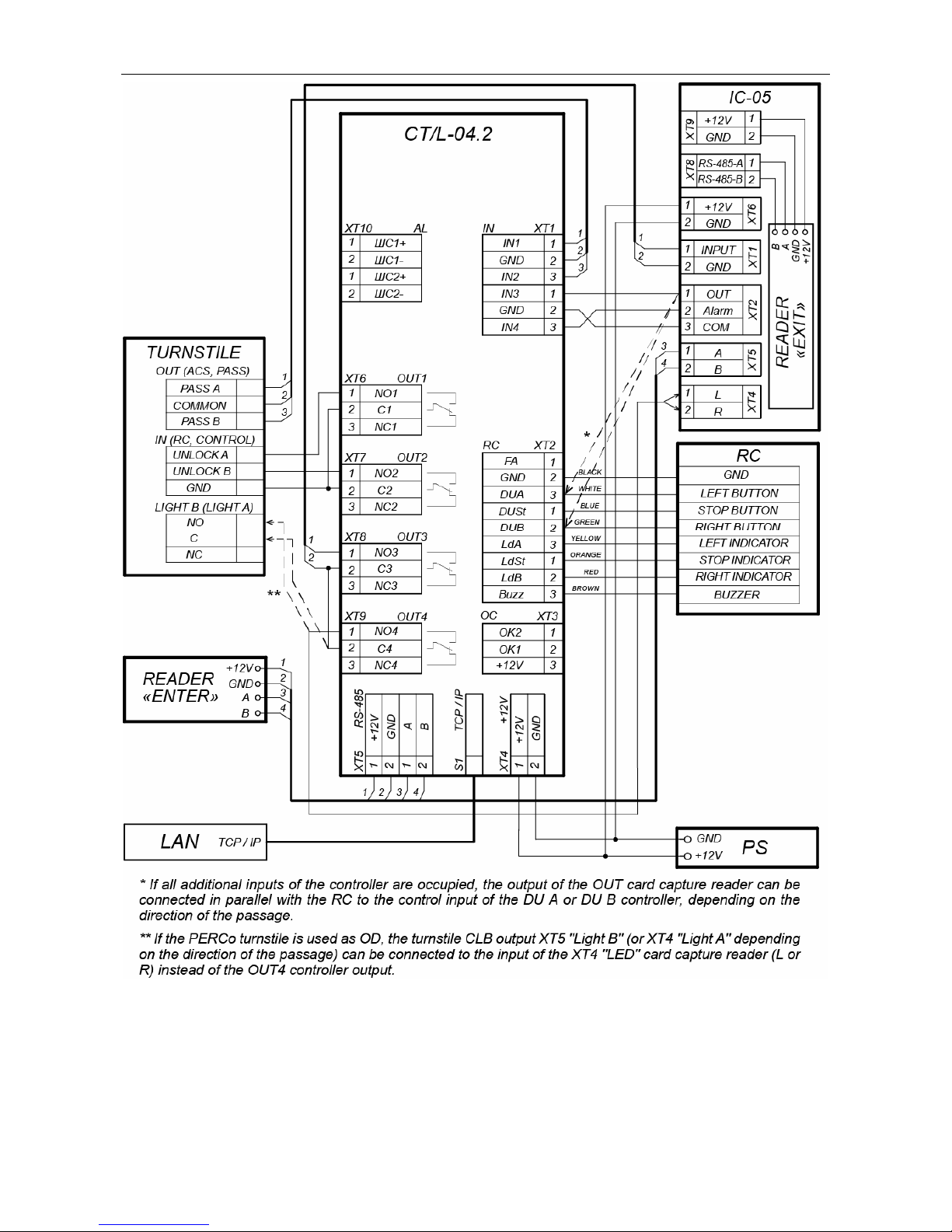

Figure 3. Common scheme of connections

21

Assembly & Operation Manual

4. Fix the controller with three screws through holes in the controller housing (use dowels

from the delivery set if necessary).

5. Select the way to set IP-address of the controller (Sect. 5.3) and install a jumper on

XP1 connector in accordance with the Table 2, if necessary.

6. Connect Ethernet cable to S1 connector of the top board of the controller.

7. Connect power source cable to XT4 connecting block of the lower board of the

controller in accordance with the scheme, shown on Figure 3.

Note:

The order of power connection of the controller via PoE-splitter is described in

Appendix 3.

8. Connect necessary equipment to RS-485 controller interface (Sect. 5.8).

9. Connect t

he rest of necessary equipment. Follow the next recommendations in

connection of:

electromechanical (electromagnetic) locks (Sect. 8.2.2);

turnstile (Sect. 8.2.3);

vehicle checkpoint (Sect. 8.2.4);

RC-panel (WRC) (Sect. 8.2.5);

emergency unlock devices Fire Alarm (Sect. 8.2.6);

alarm lines (Sect. 8.2.7);

other optional equipment (Sect. 8.2.8).

Note:

Installation order of external verifying devices to the controller is described in

Appendix 2 (an example of the alcohol detection device).

8.2.2 Door control configuration

When you connect the lock (latch) to the controller, follow the next recommendations:

1. To dissipate static electricity, is recommended to ground the housing or locking bar of

the lock. In case of lock installation on a metal door, it is recommended to ground the

door leaf. It is necessary to use the cable with cross section minimum 0.75 mm

2

.

Attention!

If the connected lock is not equipped with built-in spark protection circuit, it is

necessary to use the suppressor from the delivery set or Schottky diode for

operating current not less than 1A (1N5819). The suppressor is installed close to

the lock (VD1 on Figure 4).

If the connected electromagnetic lock is not equipped with demagnetizing circuit,

it is necessary to install a bidirectional suppressor from the delivery set (VD1 on

Figure 4).

If the controller is connected via PoE-splitter, it is recommended to use only

electromechanical locks with spark protection diodes (VD1 on Figure 4), type

1N5819. The use of suppressor in such case is FORBIDDEN.

22

CT/L-04.2 Controller

Figure 4. Connection schemes of the locks

2. Connect the lock (the latch) to XT6 or XT9 connecting blocks on the lower board of the

controller is made in accordance with scheme (Figures 3 - 5).

3. If you need to connect

remote control button, connect it to XT2 (XT10) of lower board

of the controller (Figure 5).

4. The reed switch is connected to XT1

connecting bloc of lower board (Figure 5). The

door sensor with the lock controlled by OUT1 is connected to IN1 input, OUT2 to IN2,

etc. The door sensor must be mounted that when the door is closed, the sensor can

always actuate.

Note:

The locks LB-, LBP-series do not require mounting of the door sensor (the

CT/L-04.2 controllers can trace the door opening based on the contact group of the

lock). In this case, is necessary to installed jumpers on the lower board of the

controller: for OUT1 – XP5.1 and XP5.2, for OUT2 – XP6.1 and XP6.2, for OUT3 –

XP7.1 and XP7.2, for OUT4 – XP8.1 and XP8.2 (Figure 1).

23

Assembly & Operation Manual

5. Emergency devices Fire Alarm are connected to XT2 connecting block of bottom

board of the controller (in this case it is necessary to remove jumper by cord), Figure 5

and Sect. 8.2.6.

6. Fix cables with plastic ties to self-adhesive cable tie mount, included into delivery set,

by installing them inside of the controller the housing.

Figure 5. Connection scheme for RC-button and door sensors

8.2.3 Turnstile and electromechanical gates configuration

Notes:

The Device output mode of operation parameter of OD should be in Potential

for PERCo turnstiles.

The Registration of the passage after ID card presentation parameter of OD

should be in Yes for swing gate WMD-05S and WMD-06.

Follow the next recommendations to connect the turnstile (the gate) to controller:

1. To dissipate static electricity, is recommended to ground the housing of turnstile. It is

necessary to use the cable with cross section minimum 0.75 mm.

2. Connect the turnstile (the control unit of the turnstile) to XT1, XT6, XT7 connecting

blocks of the controller bottom plate in compliance with the scheme (Figure 6).

3. Connect the swing gate (the control unit of the turnstile) to XT1, XT6, and XT7

connecting blocks of the bottom board of the controller in compliance with the scheme

(Figure 7).

Note:

Connection scheme of power circuit of the controller and the turnstile (the gate) in

case of connection via PoE-splitter is given on Figure 19.

4. Connect RC-panel (or WRC) to XT2 connecting block of the lower board of the

controller in compliance with the scheme (Figure 10).

5. Fix cables with plastic ties to self-adhesive cable tie mount, included into delivery set,

by installing them inside the housing of the controller.

24

CT/L-04.2 Controller

Figure 6. Connection schemes of “Turnstile control” configuration

25

Assembly & Operation Manual

Figure 7. Connection schemes of the gates

8.2.4 Vehicle checkpoint configuration

When installing a controller, is necessary to correspond with operation logic of control unit

of vehicle checkpoint:

Operation of control unit of vehicle checkpoint is performed via two relays – when

passage is allowed OUT1 relay is activated and held, sending “Open” signal. After a

vehicle has passed through the checkpoint (detected by passage detector), or after

waiting period is over, OUT1 relay switches to normal, after that OUT2 relay is

activated for 1 sec, sending “Close” signal. Also, OUT2 relay is activated for 1 sec by

Close button of RC-panel.

If Automatic closing function is turned on in the control unit of OD of vehicle

checkpoint, operation from vehicle checkpoint is performed via one relay. When

passage is allowed OUT1 relay is activated and held, sending “Open” signal. After a

vehicle has passed through the checkpoint (detected by passage detector), or after

waiting period is over, OUT1 relay switches to normal, after that boom barrier is closed

automatically (it is recommended to set a minimum possible waiting period for

automatic closing). In such case OUT2 relay it is not used.

Installation of OD of vehicle checkpoint to the controller is performed in accordance with

instructions, given in technical documents of corresponding devices. Follow the next

recommendations (the position of the connecting blocks on the controller board. 1):

1. To dissipate static electricity is recommended to ground the housing of the OD.

Grounding should be performed with a cable with wire section not less than 0.75 mm2.

2. General connection schemes of OD of vehicle checkpoint re given on Figure 8.

26

CT/L-04.2 Controller

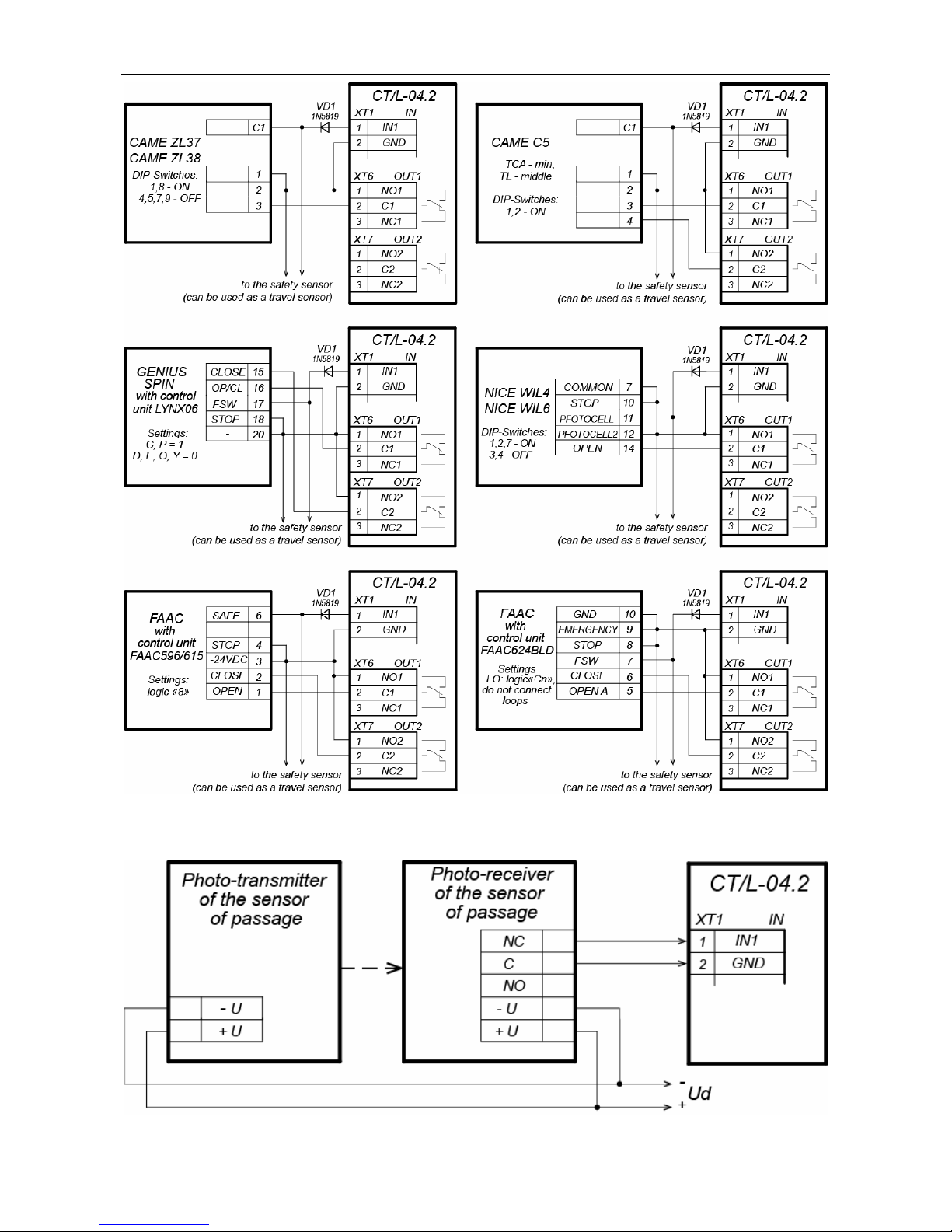

Figure 8. Connection scheme of boom barriers to the controller of vehicle checkpoint

Figure 9. Connection scheme of passage sensors

27

Assembly & Operation Manual

Note:

Output normalization parameter of OD should be set into After closing mode.

If operation is performed via one relay, Automatic closing function should be

turned on in the control unit of OD of vehicle checkpoint, in such case a

minimum waiting period for automatic closing should be set - Regulation

Т.C.V. (for CAME) and PAUSE TIME (for NICE).

3. Connect passage sensor to XT1 connector block of the bottom board of the controller

in accordance with the scheme, shown on Figure 9. Use cable №4 for connection

(Table 6). If several sensors are connected, their outputs should be turned on

successively.

For CAME and GENIUS boom barriers infrared security sensors should be used as

passage sensors, connected to the control unit of ODs of vehicle checkpoint in a

standard way. In such case they are connected to the controller of vehicle checkpoint

with parallel connection.

For NICE and FAAC boom barriers the general principle of connection of infrared

sensor to the controller of vehicle checkpoint is depicted in examples of connection

schemes for control unit of corresponding model. Instead of VD1 diode some other

decoupling circuit might be necessary.

Attention!

To ensure correct passage detection of a vehicle with a trailer or other parts

transparent for passage sensors, it is recommended to install several spacedapart sensors, or to set value of Recovery delay of passage sensors

parameter sufficient for passage of transparent part of a vehicle by the sensor.

If there is no passage sensor is necessary to put tick at Absence of passage

sensor parameter in the software. In such case malfunction of OD of vehicle

checkpoint is possible, due to the impossibility to choose the optimal passage

period.

4. Fix cables with plastic ties to self-adhesive cable tie mount, included into delivery set,

by installing them inside the housing of the controller.

8.2.5 RC-panel configuration

The controller in the relevant configuration allows connecting the RC-panel to control

turnstiles, swing gates or OD of vehicle checkpoint. To connect the RC-panel to the

controller are used:

Three inputs to control the passage: DUA, DUSt, DUB;

Four outputs to control the indication of the RC-panel: LdA, LdSt, LdB, Buzz.

The connection is made to contacts of XT2 connecting block (Figure 10).

The inputs DUA, DUSt and DUB in these configurations of the controller are activated by

low-level signals (normally opened contact) regarding GND contact. Settings of signals

that can be used for connection of the RC-panel are specified in Sections 5.5.2 and 5.6.3.

28

CT/L-04.2 Controller

Figure 10. Connection scheme of RC-panel or WRC of “Turnstile control” and

“Vehicle checkpoint control” configurations

8.2.6 Connecting a Fire Alarm Device

In case of fire alarm or other emergency situation, there is possibility of automatic

unlocking (passage opening) of all ODs connected to the controller board and the

controllers of the second level. As an exception are ODs which are in operating mode

“Security” (the possibility of emergency unlocking are configured in their configuration).

Emergency release (emergency passage opening) of ODs is produced by the command of

the emergency device Fire Alarm. The emergency device Fire Alarm is connected to the

input of the controller FA (contacts FA and GND of XT2 connecting block, Figures 3, 5,

10). If the device Fire Alarm is absent, on the input should be installed jumper by cord

(default installation). Settings for signal FA are indicated in Sect. 5.5.2. When the control

signal is applied to the input FA, the controller operates in the mode Fire Alarm. In this

mode, all connected devices open for passage in both directions. Other control commands

are ignored.

8.2.7 Connecting the alarm lines

To connect Alarm lines, follow the next recommendations:

1. In case of use of the controller inputs for connection of Alarm lines, switch the jumper

on XP9 and XP10 connecting blocks of the bottom board of the controller according to

Sect. 5.7. The position of connecting blocks is indicated on Figure 1.

2. Alarm lines are connected to XT10 connecting block of the lower board of the

controller, cable type №10 (Table 6).

29

Assembly & Operation Manual

Figure 11. Connection scheme for configuring “ШC” inputs as “AL”

8.2.8 Connection of optional equipment

To connect optional equipment, follow the next recommendations:

1. The typical connection schemes of the optional equipment are shown on Figures 12,

13, 14.

Figure 12. Connection scheme of optional equipment to relay outputs

30

CT/L-04.2 Controller

Figure 13. Connection scheme of optional equipment to controller inputs

31

Assembly & Operation Manual

Figure 14. Connection scheme of optional equipment to “Open collector”

outputs

2. To connect the optional equipment, use cable type №4 (Table 6).

3. Fix cables with plastic ties to self-adhesive cable tie mount, included into delivery set,

by installing them inside the housing of the controller.

Attention!

To connect the optional equipment with inductive load (Rn) to the outputs, it is

necessary to use spark protection diode (VD1 on Figure 12). For example, Schottky

diode for operating current not less than 1A (1N5819).

32

CT/L-04.2 Controller

9 CONFIGURATION

The main controller configuration (select the configuration, adding and removing

controllers of the second level and optional readers) is possible only via the Web-interface

of the controller (Appendix 5).

The order of configuration of the controller:

1 Verify all connections (Sect. 8.2). Connect the power source to the circuit with voltage

and frequency indicated in its operational documentation. Turn on the power source,

on the controller housing should light up LED indication. It means that the controller is

switched on.

2 Connect to the Web-interface of the controller via Ethernet network (Appendix 5,

Clause 2).

Note:

The computer should be in the same subnet with the controller. At first turn-on, it

might be necessary to change network settings of the computer. The controller is

equipped with IP-addresses from 10th subnet on default. Add IP-address:

10.x.x.x (x- random numbers) and subnet mask 255.0.0.0. to TCP

/

IP

additional settings of the computer. No such servers or services like DNS and WINS

are necessary. After turn-on network settings of the controller can be changed to

settings recommended by system administrator in the software or via the Webinterface.

3 Via the Web-interface perform the initial configuration of the controller according to the

connected equipment:

note the settings of the memory of the controller (on default is “50 000 access cards

230 000 events”), Appendix 5, Clause 3.4;

select the controller configuration (on default is “Turnstile configuration”),

Appendix 5, Clause 4.1;

if necessary, add to the configuration lock controllers of the second level CL-201

and optional readers, Appendix 5, Clause 4.2.

4 Further configuration of the controller and devices connected to it can be changed

either via Web-interface or with optional software installed on the computer:

PERCo-SL01 “local software” (does not require licensing);

PERCo-SL02 “local software with visual verification”;

Note:

Local software does not support configurations of the controller with the vehicle

checkpoint.

Network software PERCo-Web.

Note:

You may buy optional software from official PERCo distributors. Also, specified

software, the procedure of his licensing and electronic versions of the operating

manual are available on the website of the company PERCo http://www.perco.com

in the section Support > Software.

33

Assembly & Operation Manual

10 UPDATE OF EMBEDDED SOFTWARE

To update embedded software and format the memory controller, the program “Firmware

updater” is used. This program goes together with files “Software to change firmware”. The

current version of the program is available on the website of the company www.perco.com

in the section Support > Software.

Also, update embedded software and format the memory is possible using the Webinterface of the controller in the section Diagnostic (Appendix 5, Clause 9).

34

CT/L-04.2 Controller

11 OPERATION

When operating the controller, follow security measures indicated in Sect. 7.2.

After the configuration, the controller can operate in the following modes:

Without connection to the security system server.

If connection to Ethernet network and PC is also unavailable, the controller can perform

the following functions:

Receives identifiers of the presented cards from the readers, and grants or denies

access, depending on their presence in the list.

Controls connected ODs.

Arms and disarms the protected zone; controls alarm line and ODs in “Security”

mode; activates additional outputs in “Alarm” mode.

Records events in event log in the memory of the controller.

Supports functions of local location monitoring, T&A and double-check access.

If the controller is connected to the network and other controllers of the system, the

function of global location monitoring is available.

Connected to the PC with “Local software” installed:

Data from event log is automatically transferred to the program database at each

start-up of the program. Data can be also transferred with the use of the related

button in the program.

Data (name) owners are stored in the program database.

Verification function is available if “Local software with verification” is installed.

With connection to the security system server.

Besides those that are supported in the stand-alone, the following functions are available:

Data from event log are automatically transferred to the database on security

system server.

Availability of verification function depends on installed extensions of network

software.

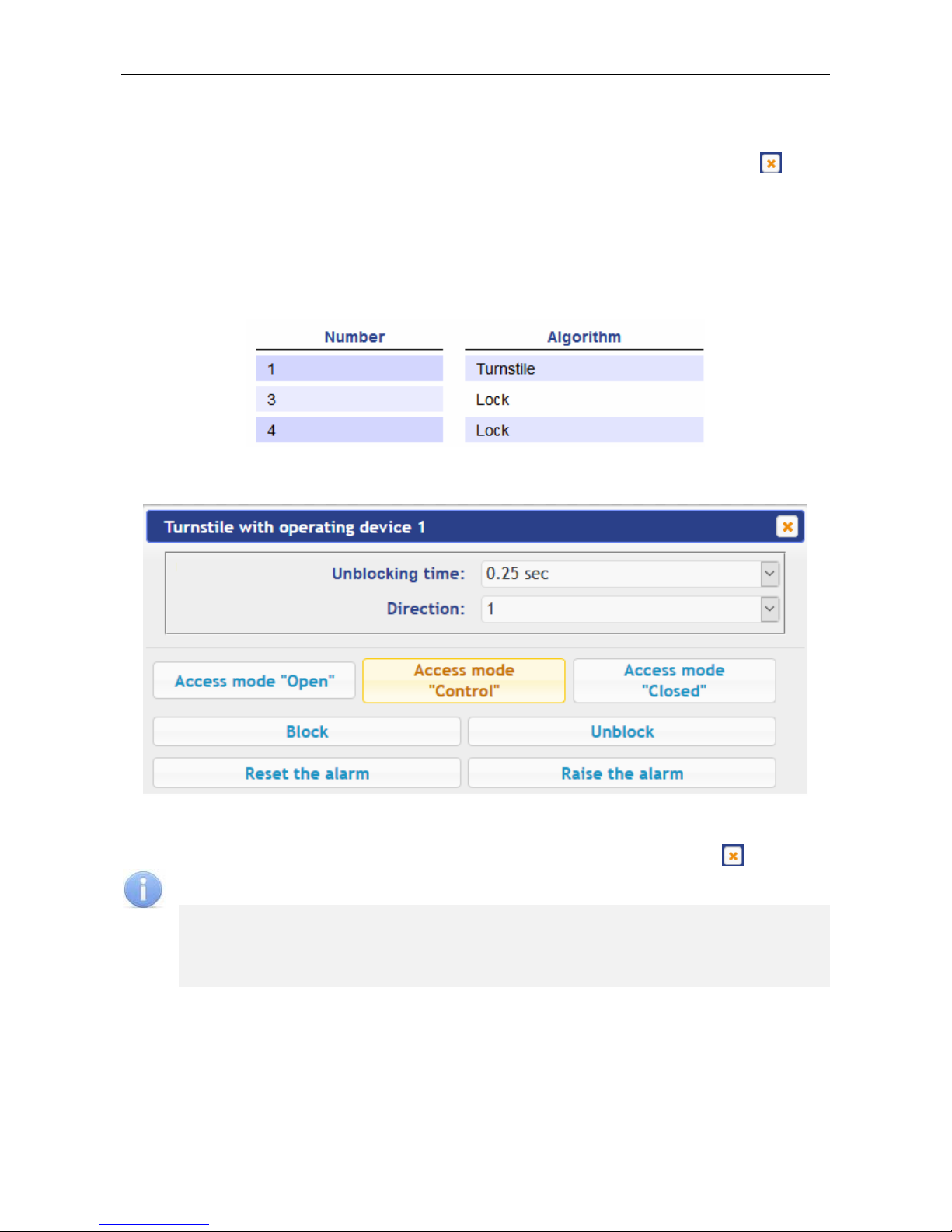

11.1 Operation modes of ACS

The change of operation mode is carried by the command of software or Web-interface.

Note:

In configuration “Controller for one two-way lock” and “Controller for vehicle

checkpoint” should be made simultaneously for both directions.

Operation mode in configuration “Controller for turnstile” is set independently for

each direction.

The controller, which is operated as a part of ACS, provides following operation modes of

ODs (indication of ACS is given in the Table 7):

Operation mode “Open” - the mode of free passage.

OD will be unblocked before the change of operating mode.

Pressing of buttons of RC-panel and RC-button (“Exit”) are ignored.

Operation mode “Control” - the basic operation mode as a part of ACS.

OD is blocked.

When an access granting card is presented to the reader, OD is unblocked for

Unblocked state holding period.

35

Assembly & Operation Manual

Operation mode “Closed” is mode of passage prohibition.

OD will be unblocked before the change of operating mode.

Pressing of buttons of remote control board and RC-button (“Exit”) are ignored.

When any card is presented, an event of access violation is registered.

Operation mode “Security”1.

OD will be unblocked before the change of operating mode.

Pressing of buttons of RC-panel is ignored.

Protected zone is armed including the selected OD.

Passage through the OD (forced entry) sets the system into “Alarm” state.

11.2 Indication of ACS, events and controller configurations

Indication of operation modes, states and reactions of the controller to the presented

identifiers is performed on connected remote readers and indication blocks. Possible

variants of indications are shown in Table 7.

Note:

When reading an access control card in any operation mode, an audible signal

lasting 0.2 seconds is performed, yellow indicator changes his state for

0.2 seconds. The state of other indicators is not changed.

After the access is granted, indication is turned on for Unblocked state holding

period or until the passage is performed. When access is denied indication is

turned on for 1 second.

Table 7. Indication of the controller

Indicators

Card presentation

Operation

mode

Green Yellow Red

Sound

(sec.)

Configuration is not selected No 5 Hz 5 Hz 5 Hz off

Activating of input Fire Alarm

Any card

1.3/0.2

2

off off off

“Open”

on off off off

“Control”

off on off off

“Security”

off 1 Hz 1 Hz off

No

“Closed”

off off on off

“Open”

on off off 0.2

“Control”

Card is not authorized for access

“Security”

Any card

“Closed”

off off on 0.5

“Open”

“Control”

on off off 0.2

Card is authorized for access

“Security”

off off on 0.5

“Open”

“Control”

Card is authorized for access and for

arming/disarming

“Security”

1

on off

off 0.2

1

Operation mode is available only for configuration “Controller for the locks” and for connected

CL-201 lock controllers.

2

Blinking (going off briefly) – 1.3 seconds is on, 0.2 seconds is off.

36

CT/L-04.2 Controller

Indicators

Operation

Card presentation

Sound

mode

Green Yellow Red

(sec.)

Change to the

mode “Security”

“Security”

off 1 Hz 1 Hz 0.2

“Open”

Waiting for double

check

Before to return

to initial mode

“Control”

off off 1 sec 1

Waiting for verification Any off 2 Hz off 0.2

11.3 Troubleshooting

The elimination of possible malfunctions listed below is made by the buyer. If the fault

persists, we recommend you to contact one of the service centers of PERCo company. A

list of service centers is given in the Certificate.

Before the diagnostics you need to open the housing of the controller.

Each relay output of the controller is equipped with diagnostic LED indicator for

convenience. The turn on/off of LED indicators identifies that relay is activated/deactivated.

Possible faults:

11.3.1 The controller does not work

Possible causes of the controller malfunction:

1. Malfunction of connection lines used to connect various devices (reader, indication

block with infrared detector, lock, turnstile, door sensor, remote control button, siren,

etc.) to the controller – check connection lines.

2. Malfunction of power source of the controller – check the power source.

3. Malfunction of connection lines used to connect various devices (reader, indication

block with infrared detector, lock, turnstile, door sensor, remote control button, siren,

etc.) to the controller – check connection lines.

4. Identical addresses of connected devices are set – set different addresses. Check

the connection of address lines.

5. Failure of devices connected to the controller – check the operation of devices.

6. Failure of radioelectronic components, installed on the controller board – contact

PERCo service in order to replace this board.

11.3.2 Failure of communication with PC

Possible causes of this malfunction:

1. Network Settings in the computer are missing – set IP-address and subnet mask of

the computer. The controller should be connected either directly to network connector

of network card of the computer or to the same Hub / Switch the computer is

connected to.

2. Invalid password of the controller. Check the password entered in the software.

1

In the mode “Security” after presentation of access card disarming the protected zone occurs

disarming of protected zone with OD and unlocking of OD for Unlocked state holding period.

After this time expires the OD switches to the operating mode stated before capture of protected

zone (“Open” or “Control”, if the previous mode was “Closed” that operating mode is “Control”).

37

Assembly & Operation Manual

3. Malfunctions of the computer (software, databases etc.).

To detect this malfunction, start the command:

ping x.x.x.x

where x.x.x.x is the IP-address of the controller.

If there is a communication, you will see lines similar to the following:

Reply from x.x.x.x: bytes=32 time<10ms TTL=128

If there is no communication (response), check routing Settings of your network.

4. Malfunctions of equipment of Ethernet network, installed between the computer

and the controller: hub, switch and other network equipment including communication

cables.

To detect this malfunction, start the command:

ping x.x.x.x -l 576

where x.x.x.x is the IP-address of the controller.

If there is a communication and standard minimal packets (576 bytes) are not

fragmented, you will see lines similar to the following:

Reply from x.x.x.x: bytes=576 time<10ms TTL=128

In such case IP-packets are not fragmented to the size less than 576 bytes and the

selected connection should be operative.

If the positive answer is not received, the problem might be with network switching

equipment that fragments IP-packets to the size less than 576 bytes. Check settings of

this equipment, enlarge the size of MTU. This parameter is usually specified as

MaxMTU or IPMTU.

5. If several variants of switching are possible, use command:

ping x.x.x.x -l 576 -t

By switching with various variants, look at response time and choose the connection

with the fastest response.

6. Malfunctions of the controller. Failure of elements providing connection via Ethernet

interface (IEEE 802.3).

To detect this malfunction, have a look at two indicators, installed 8P8C (RJ45)

connector of Ethernet connection:

LINK – connection:

o Green light is on – the controller detects connection to Ethernet network,

o Green light is off – the controller does not detect connection to Ethernet

network;

ACT – data exchange

o Yellow light is blinking – the controller detects data exchange via Ethernet

network,

o Yellow light is off – the controller does not detect data exchange via Ethernet

network.

If the controller does not detect connection to Ethernet network (light indicators are off),

connect it to the cable that connects the other controller or computer.

If the controller still does not detect connection to Ethernet network or the communication

is not reestablished, contact PERCo service in order to repair this controller.

38

CT/L-04.2 Controller

12 MAINTENANCE

Technical staff performing maintenance of the controller should be acquainted with

construction and operating procedures of the controller.

All works should be done by high-skilled electricians.

Information about scheduled maintenance is recorded in the log of maintenance and

monitoring of the technical condition of means of the security fire alarm system.

Respecting of periodicity, technological order and methods of execution of maintenance

work are required.

Please refer to section 7 “Safety requirements” of this Manual when performing technical

maintenance.

Following types and periodicity of maintenance work should be provided:

planned work according to the regulation №1 – once per three months;

planned work according to the regulation №2 – receiving of two or more false

alarms from the protected object within 30 days.

List of work for the regulations is shown in Tables 8 and 9.

De-energize the controller prior to maintenance.

All control instrumentations should be calibrated.

Maintenance of the lock controller CL-201 consists in periodic cleaning of the controller

housing and checking all the connections to the cable coming out of the controller (see

Operation manual CL-201).

Maintenance of other devices of the system, such as locks, turnstiles, swing gates,

security detectors, power supply, etc. refer to operating manuals for these devices.

39

Assembly & Operation Manual

Table 8. List of maintenance works according to the regulations №1 (checklist №1)

Work Procedure

Devices,

instrument,

equipment

Norms and

events

1.1 Disconnect power supply from AC

current, clean up the controller and power

supply surface from dust, dirt and damp.

Rags, brush, flat

brush

There should not

be traces of dirt

and damp.

1.2 Remove the controller and power supply

housing, clean up surface from dust and

damp. Measure the voltage of the extra

power supply. In case you may charge or

replace the battery.

Screwdriver,

rags, flat brush,

measuring

device

Voltage should

correspond to

certificate on the

battery (min.

12,6V)

1.3 Remove dust, dirt, corrosion from the

surface of connecting blocks, jumpers and

protectors

Rags, flat brush,

grease

It should not be