Instruction Manual

Thermal cycler

peqSTAR 2X Double block thermal cycler

peqSTAR 96X, 384X and in situ X thermal cycler

v1212E

Creating the future together

.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

I

CONTENT

page

1 System Overview 1

2 Safety instructions 1

3 License Notice 2

4 Installation 2

4.1 Content of delivery 2

4.2 Installing the thermal cycler 2

4.3 Operation of the thermal cycler 2

4.4 Connections of the thermal cyclers 3

5 General Operation 3

6 Main menu 4

6.1 Run 4

6.2 Programs 4

6.3 Diagnostics 4

6.4 GLPs 4

6.5 System 4

6.6 Help Button 4

7 Run dialogue 5

7.1 Run dialogue: Overview 5

7.2 Run dialogue: Operating elements 5

7.2.1 Incubation mode 5

7.2.2 Start 5

7.2.3 Stop 5

7.2.4 Pause 5

7.2.5 Info button 6

7.2.6 Lid lock / unlock 6

7.2.7 Select program 6

7.3 Select Program dialogue 6

7.4 Info Button 6

7.4.1 Steps 6

7.4.2 Program Options 7

7.4.3 Print 7

7.5 Lid lock / unlock 7

7.6 Starting a program 7

7.7 A program is running 8

7.7.1 General: 'Pause' and 'Stop' button 8

7.7.2 'Pause' button 8

7.7.3 'Stop' button 8

7.7.4 Status Display 8

7.7.5 Program window 9

7.7.6 Save GLP Report 9

7.7.7 Not create GLP Report 9

7.7.8 Switch off the GLP report query 9

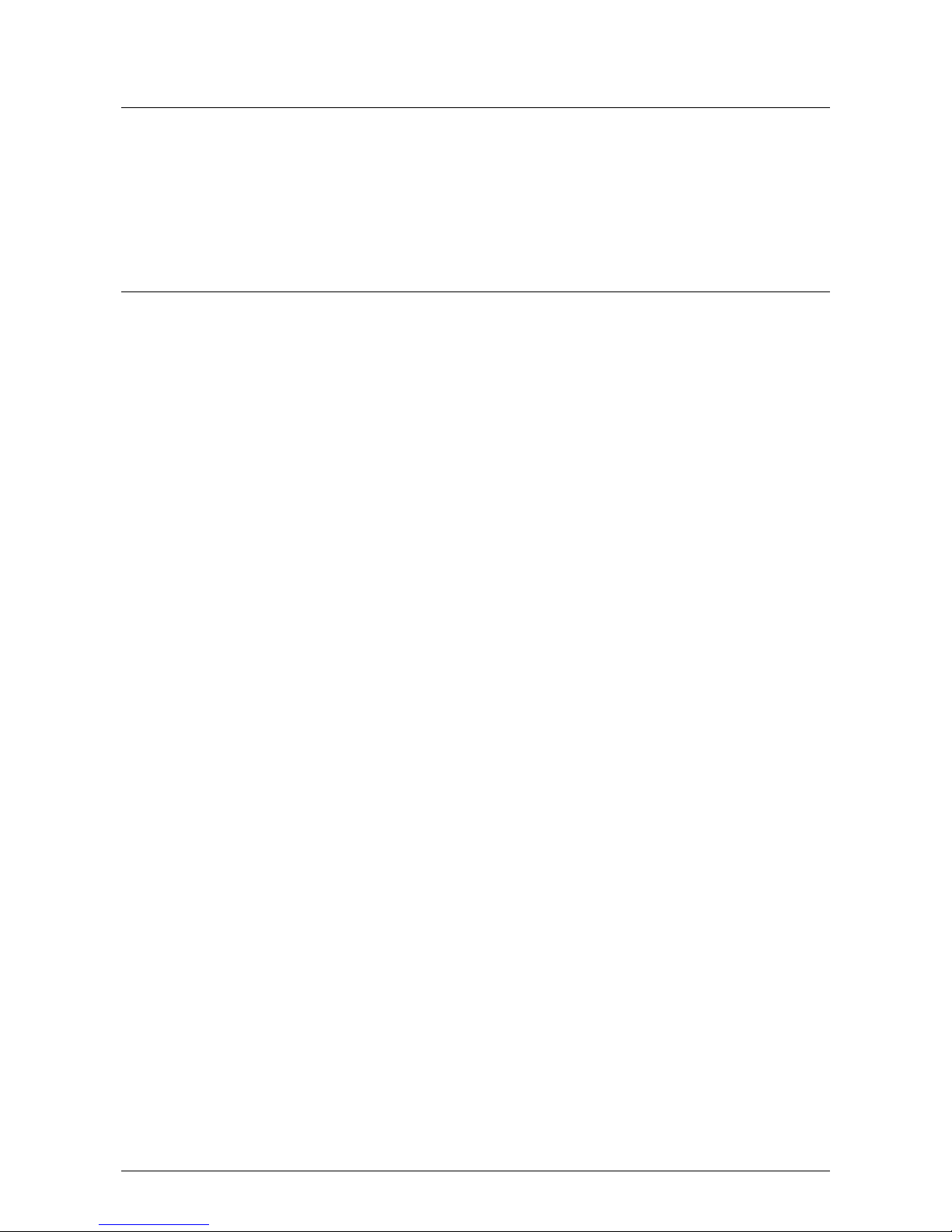

8 Incubation mode 10

8.1 Run incubation 10

8.2 Setting the block and lid temperature 10

8.2.1 Stop 10

8.2.2 Lid lock / unlock 10

8.2.3 Timer 10

8.2.4 Block 10

8.2.5 Lid 10

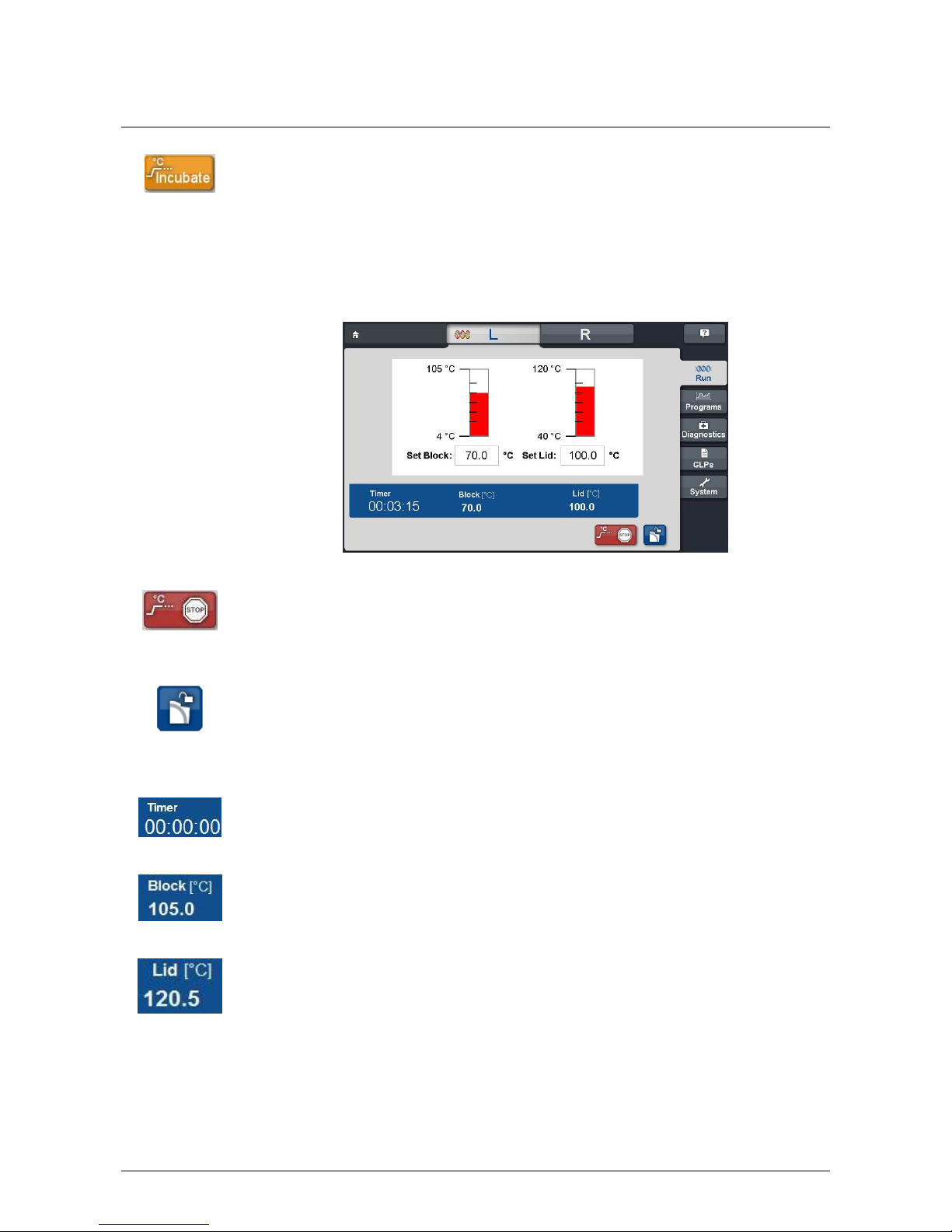

9 Programs 11

9.1 Program selection 11

9.1.1 Open a program 11

9.1.2 Copy 11

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

II

9.1.3 New program 12

9.1.4 New folder 12

9.1.5 Delete 12

9.1.6 'Info' button 12

9.2 Operating elements of the 'Programs' dialogue 13

9.2.1 Entering a command 13

9.2.2 List view 13

9.2.3 Diagram view 13

9.2.4 New program 14

9.2.5 Open a program 17

9.2.6 Info-Button 17

9.2.7 Deleting a command from the program 17

9.2.8 Saving a program 17

9.2.9 Save & Run 17

9.2.10 Editing a command 17

9.3 Available commands (program steps) 18

9.3.1 Unlock 18

9.3.2 Lock 18

9.3.3 Heat Lid 18

9.3.4 Temperature 19

9.3.5 'Elongation Time' and 'Melting Temp.' 19

9.3.6 Gradient step 19

9.3.7 Cycle: 21

9.3.8 Start Cycle - Manual cycle beginning 21

9.3.9 Close Cycle - Manual cycle ending 21

9.3.10 Pause 21

9.3.11 Store 21

10 Diagnostics 22

10.1 Operation of the 'Diagnostics' dialogue 22

10.2 General view 23

10.2.1 Zones 23

10.2.2 Single view 23

10.2.3 Automatic scrolling active 23

10.2.4 Automatic scrolling inactive 23

11 GLPs dialogue 24

11.1 Displaying a GLP report 24

11.2 Operating elements of the 'GLPs' dialogue 24

11.2.1 Select GLP 24

11.2.2 Open GLP report 24

11.2.3 Printer 24

11.2.4 Delete 25

11.2.5 Copy 25

11.2.6 New folder 25

12 System 26

12.1 Time / Date 26

12.2 Show/Hide mouse cursor 26

12.3 User Call 26

12.3.1 Sound 26

12.3.2 Email 27

12.4 User Management 28

12.4.1 Change User 29

12.4.2 User Management 29

12.4.3 Setting up a new user group 30

12.4.4 User logout 31

12.5 Network Settings 32

12.6 Hardware 33

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

III

12.6.1 Overtemp test 33

12.7 Firmware 33

12.7.1 Control Unit 33

12.7.2 Power Unit 35

12.8 Print 35

12.9 Display 36

12.9.1 Brightness 36

12.10 Protocol 36

12.11 LAN Control 36

12.11.1 New Lan Connect 36

12.11.2 Lan Connect 37

12.11.3 Lan Disconnect 37

12.11.4 Zigbee Configure 37

12.11.5 Zigbee Connect 38

12.11.6 Zigbee Disconnect 39

12.12 USB Recovery 39

12.13 Service 39

13 Maintenance & repair of the Thermal cycler 40

13.1 Cleaning, maintenance and repair of the thermal cycler 40

13.2 Test of the overtemperature protection 40

13.3 Temperature check-up 40

13.4 Calibration 40

14 Warranty 40

15 Disposal Instruction 41

16 Technical data 41

16.1 General characteristics 41

16.2 Gradient feature (optional) 41

16.3 User interface/functions 41

16.4 Block capacity 42

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

1

1 SYSTEM OVERVIEW

The peqSTAR X thermal cyclers are the ideal PCR devices for all molecular biological and biochemical laboratories

working in the field of basic research or routine diagnostic. The 250 °C HTR (High Temperature Range) Peltier

technology allows quick changes in temperature up to 5 °C/sec (max). The individual monitoring and controlling

of each of the eight or 16 Peltier elements per block equipped with 'Long Life Technology' ensure the tightest

correlation of target and actual temperature across the entire thermal plate leading to highest reproducibility of the

results. To avoid condensation each block is equipped with a heated lid (except for the in Situ block).

The peqSTAR X thermal cyclers are equipped with a touch-sensitive, graphic colored TFT display of the newest

generation, allowing operation of the device by simply touching symbols and graphic elements on the screen. This

leads to easy and intuitive handling and programming of the device. Additionally a mouse can be connected via

USB.

Furthermore an Ethernet port is available to connect the devices with the Microsoft Windows® or Linux network. It

is therefore possible to use an external server for archiving programs and GLP reports which will be available

globally in the network (e.g. for other thermal cyclers).

Transfer of data can be done by using commercially available USB memory sticks enabling a nearly unlimited

saving space for programs and GLP reports, which can be printed using a printer connected to the thermal cycler

via the network.

Notice:

Notice:Notice:

Notice: The USB ports support only standard cable mice and standard USB sticks.

The maximum acceptable length of the connecting cable of the port is 3 m!

2 SAFETY INSTRUCTIONS

Before the first use of the thermal cycler please read the instruction manual entirely.

Special notice should be taken of the following

Caution of dangerous voltage

Please ensure the voltage indicated on the device exactly matches your local electrical supply.

Caution of dangerous explosive material

Explosive or reactive material mustn’t be heated in the thermal cycler.

Caution - liquids

Ensure that no liquids can enter the device.

Reaction tubes must be filled outside of the thermal cycler.

Caution - hot surfaces

The thermal plate, the heated lid and the reaction tubes quickly reach temperatures above

50 °C. There is danger of burning! Keep the lid closed until the temperature reaches 30 °C or

less. Only use materials (tubes, tube caps, plates and sealing films) which are heat resistant to

120 °C.

Caution – environment

The ventilation of the device must not be covered.

Note:

Note:Note:

Note: If the thermal cycler is used in any manner not specified in these instructions, the intended protection of the

user can not be guaranteed.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

2

3 LICENSE NOTICE

This instrument is licensed for research and development and for uses other than human in vitro diagnostics under

one or more of the following patens of Applera Corporation: U.S. Patent Nos. 5,656,493, 5,038,852,

5,333,675, 5,475,610 (claims 1-159 and 164-166), 6,703,236 (claims 7-10) and 7,238,517 or corresponding

claims in their non-U.S. counterparts. No right is conveyed expressly, by implication or by estoppels under any

other patent of Applera, including but not limited to U.S. Patent No. 6,814,934 and its non-U.S. counterparts,

which describe and claim thermal cyclers capable or real-time detection.

4 INSTALLATION

4.1 Content of delivery

1 Thermal cycler

1 Power cord

1 Instruction manual

1 CD PC-software 'peqSTAR Manager'

Please check delivery for completeness and transport damage upon arrival. If any transport damage is noticed,

contact your distributor or manufacturer immediately.

IMPORTANT NOTICE: IF YOU FIND ANY DAMAGE OF THE DEVICE, DO NOT USE THE DEVICE!

4.2 Installing the thermal cycler

Check the packaging for any transport damage. Remove the packaging and place the thermal cycler onto a solid

surface. The device should not be exposed to direct sunlight. There should be enough space to make sure that the

ventilator grills on the front and back are not covered and sufficient ventilation is provided. The accessibility of the

mains switch must be assured and not hindered. There should be a distance of at least 25 cm (10 inch) to the wall

or the next device. Two thermal cyclers should not be placed back-to-back or back to front. Room temperature

between 4 °C und 25 °C is advised.

All original packaging should be stored in case a need arises to return the instrument to the supplier.

4.3 Operation of the thermal cycler

Before starting up the thermal cycler for the first time make sure that your local power supply is matching the

voltage and frequency range of the device. Plug in the mains plug of the thermal cycler to an electricity supply with

PE connection. The outlet and the power switch are located at the back of the device. The mains switch serves as

disconnection from the mains supply. The serial number is written onto a typed label at the bottom of the device.

The device should only be used by authorized staff. To ensure this, a user management with appointing rights for

specific users is available in the device.

More details about this and a detailed instruction manual can be found in the following chapters.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

3

4.4 Connections of the thermal cyclers

5 GENERAL OPERATION

The operation of the thermal cycler can be run by the internal touch screen, either using the touch sensitive surface

of the display or by using a mouse connected to a free USB port. Furthermore the thermal cycler can also be

controlled by computer integrated to a net work or wireless ZigBee connection (option). The supplied application

software offers the same functions as the internal software of the thermal cycler, except for some system settings.

If the user has to enter numbers or text the corresponding field has to be touched on the touch screen or clicked

with the mouse. An appropriate keyboard will appear on the screen according to the expected entry.

All functions of the thermal cycler will be served by operating elements explained in the following chapters. An

operating element is activated by touching or clicking with the mouse.

Operating elements which are not available in an actual operating mode are displayed in a grey color. Not all

operating buttons are available in each operating mode.

2x USB interface

2x USB interface

Ethernet interface

Mains power inlet

Mains switch

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

4

6 MAIN MENU

The main menu consists of five dialogues, which can be selected via tabs at the right side of the screen. PeqSTAR

2X thermal cyclers offer two tabs 'L' (left) and 'R' (right) for choosing the desired block. This option is not available

for peqSTAR 96X, 384X und in situ X systems. Each dialogue contains a help button for direct help function. The

functions of the individual dialogues are explained below.

6.1 Run

This dialogue is used for selecting, executing and monitoring existing PCR protocols. A detailed

description of the 'Run' dialogue is given in chapter 7. Additionally, the incubation mode can

be activated here in order to manually program temperatures of the thermal plate and heated

lid. This is useful for fast and easy incubations similar to a digital dry bath. Further instructions

for the Incubation Mode are given in chapter 8.

6.2 Programs

This dialogue is used for creating, editing and organizing PCR protocols (see chapter 9).

6.3 Diagnostics

This dialogue is used for monitoring the actual temperature profile of the thermoplate. Also the

temperature of the heated lid and the temperature of the cycler interior are displayed (see

chapter 10).

6.4 GLPs

This dialogue is used for displaying and organizing GLP reports created by the thermal cycler

(see chapter 11).

6.5 System

This dialogue is used for changing the general settings of the device and for the user

management functions (see chapter 12).

. .

. The 'System' dialogue is also used for checking serial

and version numbers of hardware and software, respectively.

6.6 Help Button

Use this button to activate (deactivate) the direct help mode. The help function is active, when

the button appears pressed. If the mouse pointer is visible a question mark appears alongside.

By touching a function button or other dialogue element the corresponding help window will

appear. Closing the opened window or pressing the help button again, will deactivate the

direct help mode and the system returns to normal operation.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

5

7 RUN DIALOGUE

The Run dialogue is used for running and monitoring existing PCR protocols.

7.1 Run dialogue: Overview

The following functions are found in the 'Run' dialogue:

7.2 Run dialogue: Operating elements

7.2.1 Incubation mode

Using this button the incubation mode can be activated. In this mode block and lid temperatures

can be adjusted manually (see chapter 8).

7.2.2 Start

Use this button to start a PCR protocol.

7.2.3 Stop

Use this button to stop a PCR protocol which is in progress.

7.2.4 Pause

Use this button to pause a PCR protocol which is in progress.

Program window

Block selection left / right

(only for peqSTAR 2X systems)

Direct help

List view /

diagram view

Lid lock /

unlock

Incubation Mode /

Stop Button

Start Button

Info Button

Select program

Program name

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

6

7.2.5 Info button

Use this button to display details of a PCR protocol (name, program options, author, settings,

comments and program steps).

7.2.6 Lid lock / unlock

Use this button to lock or unlock the lid. Furthermore the button shows the current status of the

lid.

7.2.7 Select program

Using this button a stored PCR protocol can be selected and loaded.

7.3 Select Program dialogue

Stored programs can be selected and

loaded by using this button.

If a program is selected the adjoining

window appears.

If a program is marked, the 'i' button

appears.

By 'Open' the chosen program will be

loaded in the run dialogue.

Further information on this dialogue can be found at chapter 9.1.1

7.4 Info Button

Using this button a new window will open, which shows detailed information of the chosen

program. If wanted, this information could be printed. The header contains program name and

the link to the program.

You will have the following options:

You will have the following options:You will have the following options:

You will have the following options:

7.4.1 Steps

Using this tab, the single steps of

the selected program are listed.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

7

7.4.2 Program

Options

Using this tab, the settings of

the selected program are

shown.

7.4.3 Print

With peqSTAR X thermal

cyclers, PCR programs and

GLPs could be printed on a

network printer. Using this

dialogue, you can type in the

path for a printer in the

network.

Please refer to your local

network administrator for the

required settings.

If the path for the printer is already entered, simply click for printing.

Using the button , a test printing will be performed to check the correct settings.

7.5 Lid lock / unlock

Use this button to lock or unlock the lid.

For systems with HPL lids(High Pressure Lid) there is the option to define the lid pressure in an

opening dialogue.

7.6 Starting a program

If a program is opened, the

content of the program can be

seen in the program window.

The loaded program is started

by using the 'Start' button.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

8

7.7 A program is running

7.7.1 General: 'Pause' and

'Stop' button

After starting the chosen program, you

can use these buttons to either pause or

to stop the program.

7.7.2 'Pause' button

If the 'Pause' button is pressed during the operating

sequence, the adjoining window appears. If this

request is confirmed, the program is paused and the

'Start' button appears which can be used to continue

the program.

During the break the status 'Paused' is shown.

7.7.3 'Stop' button

If this button is pressed after starting a program, the

adjoining security query appears.

By confirming the security query with 'Yes', the

program will be stopped.

7.7.4 Status Display

In this window the following information on the status is shown during a run:

Cycle:

Cycle:Cycle:

Cycle:

The number of

finished cycles is

shown

Lid:

Lid: Lid:

Lid:

Temperature of the

heated lid

Time remain.:

Time remain.: Time remain.:

Time remain.:

Remaining time of

PCR program

Total Progress:

Total Progress: Total Progress:

Total Progress:

Total progress of

PCR program in %

Block:

Block:Block:

Block:

Average temperature of

the thermoblock

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

9

7.7.5 Program window

In the program window the blue flashing bar is

showing the actual program step.

7.7.6 Save GLP Report

If stopping the program after the security query, the

adjoining query to create a GLP report appears.

Note: The GLP report query also appears when a

program is finished.

Will the query be confirmed by 'Yes', a GLP report

will be created and shown on the display. It will be

saved under the file name <program name>_<date>_

<time>.glp if not deleted by the user. For this the

adjoining window is shown.

The GLP report can be opened and printed in the

'GLPs' dialogue (see chapter 11).

7.7.7 Not create GLP Report

There will be no GLP report created for the aborted program. At the next run the GLP report query will

appear again. You will return to the 'Run' dialogue, which shows the last chosen program, which can be

started again.

7.7.8 Switch off the GLP report query

When you press this button, there will be no GLP reports created in the future. After the abort or end of a

program no GLP report query will appear again. The setting can be reset in the system dialogue (see

chapter 12.7.1.2).

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

10

8 INCUBATION MODE

8.1 Run incubation

Use this button to set the device into the incubation mode. The temperature for the thermal plate

and lid can be set manually.

8.2 Setting the block and lid temperature

Set temperatures of block and lid by entering the values of choice in the corresponding editor

fields. By entering values < 40 °C the lid heating will be turned off.

8.2.1 Stop

Use this button to quit the incubation mode. Heating of the thermal plate and lid are then

deactivated.

8.2.2 Lid lock / unlock

Use this button to lock or unlock the lid.

For systems with HPL lids(High Pressure Lid) there is the option to define the lid pressure in an

opening dialogue.

8.2.3 Timer

The clock shows the time passed by in the incubation mode.

8.2.4 Block

Actual temperature of the thermal plate.

8.2.5 Lid

Actual temperature of the lid heat.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

11

9 PROGRAMS

The 'Programs' dialogue serves for generating and editing PCR protocols (programs). This is a list of commands,

which the thermal cycler performs in sequence after starting the program. The 'Programs' dialogue provides an

editor for this purpose.

9.1 Program selection

By touching the 'Programs' dialogue the selection dialogue shows up where a new program can be set or an

existing program can be opened to edit.

The selection dialogue can be opened at any time in the program editor by using the adjoining button .

Existing programs can be selected and opened for editing, folders can be created and new programs can be

generated, copied and deleted.

The operation of the dialogue is as follows:

The operation of the dialogue is as follows:The operation of the dialogue is as follows:

The operation of the dialogue is as follows:

9.1.1 Open a program

Saved programs can be selected with this button. By touching the desired program it will be

selected of the file list and opened by using the 'Open' button. After this the thermal cycler

returns to the 'Pograms' dialogue. After the selection of a program several operating elements

are available, which are described in chapter 9.2 and 9.3.

Note: The command 'Open' is only active, when only one program is marked. Via 'Open' the

chosen program will be loaded in the 'Programs' dialogue.

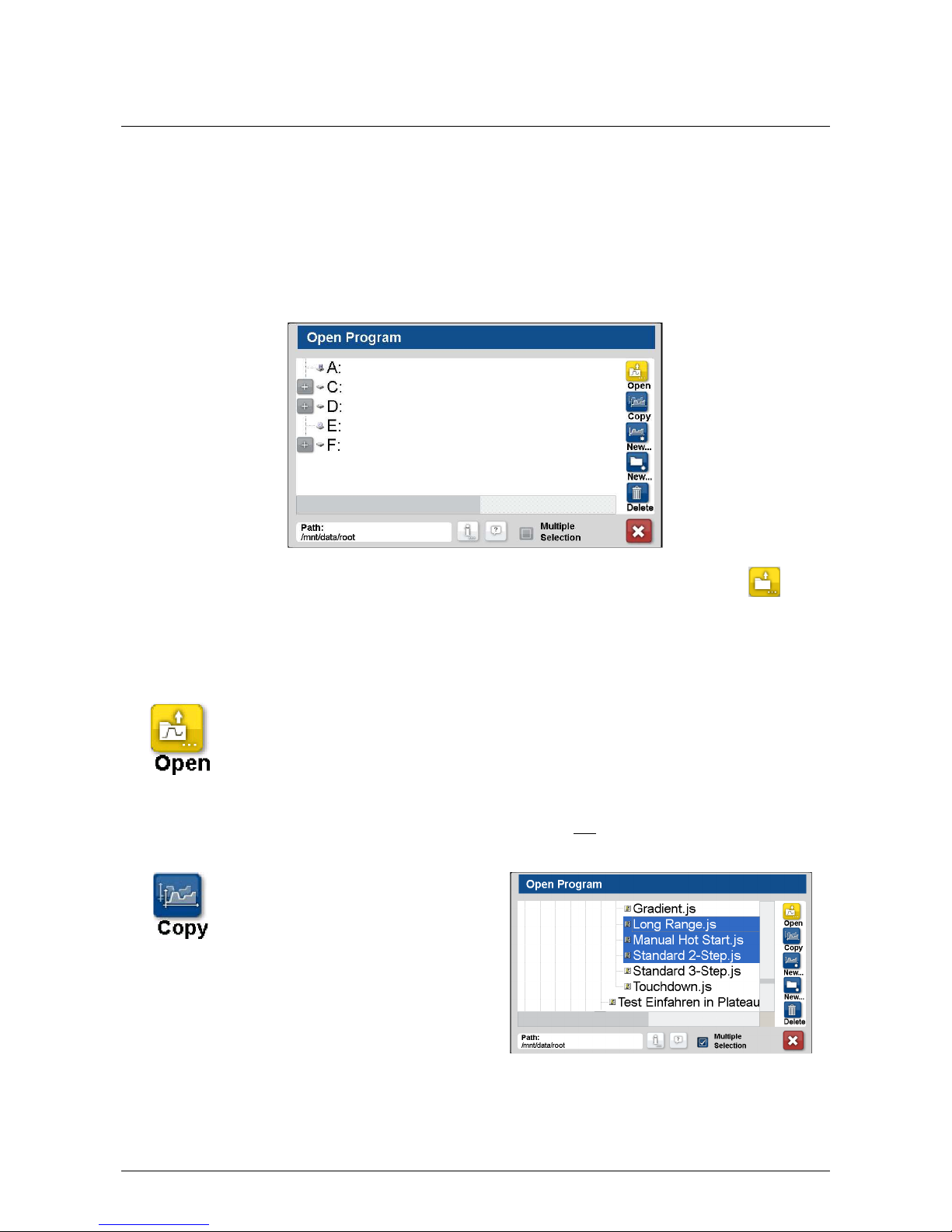

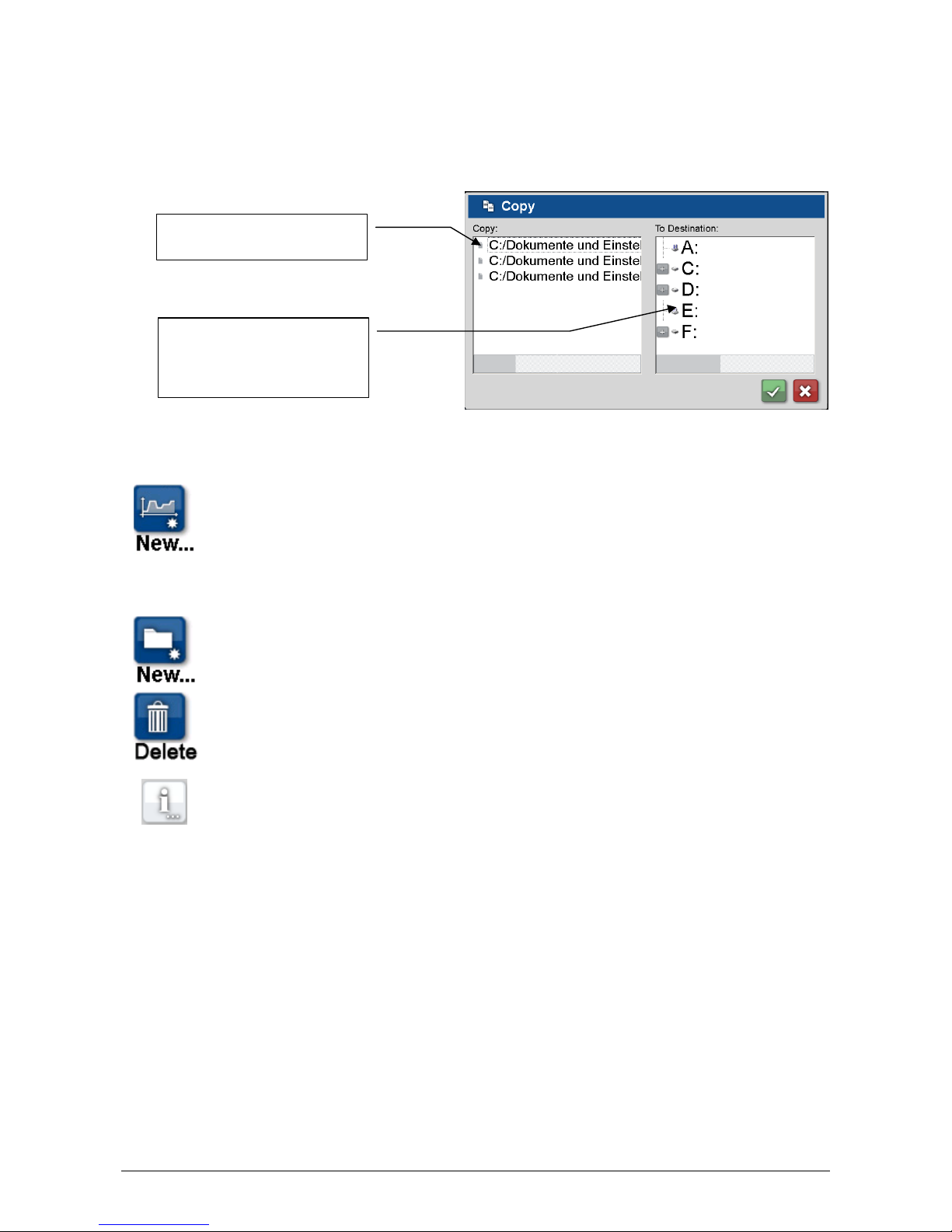

9.1.2 Copy

Pushing this button saved programs or

folders can be copied. Several

programs/folders can be marked via

mouse click simultaneously if the option

'Multiple Selection' is chosen. Marked

programs/folders are shown with a blue

background.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

12

By using the 'Copy' button the following dialogue appears:

In this dialogue the directory can be selected.

Copy the files with 'OK' or quit the operation with 'Cancel'.

9.1.3 New program

A new program can be generated, after pushing this button the program’s name has to be

defined. Optionally author, user, any comment and different program options can be entered.

These data serve for information and can also be retrieved in the 'Run' dialogue.

9.1.4 New folder

Use this button to create a new subfolder after selecting an existing folder, in which the new

subfolder should be created.

9.1.5 Delete

Programs or folders can be deleted with this button.

9.1.6 'Info' button

Further details at chapter 7.4.

Destination for the copied files

(desired folder has to be selected

by clicking)

List of the selected files to copy

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

13

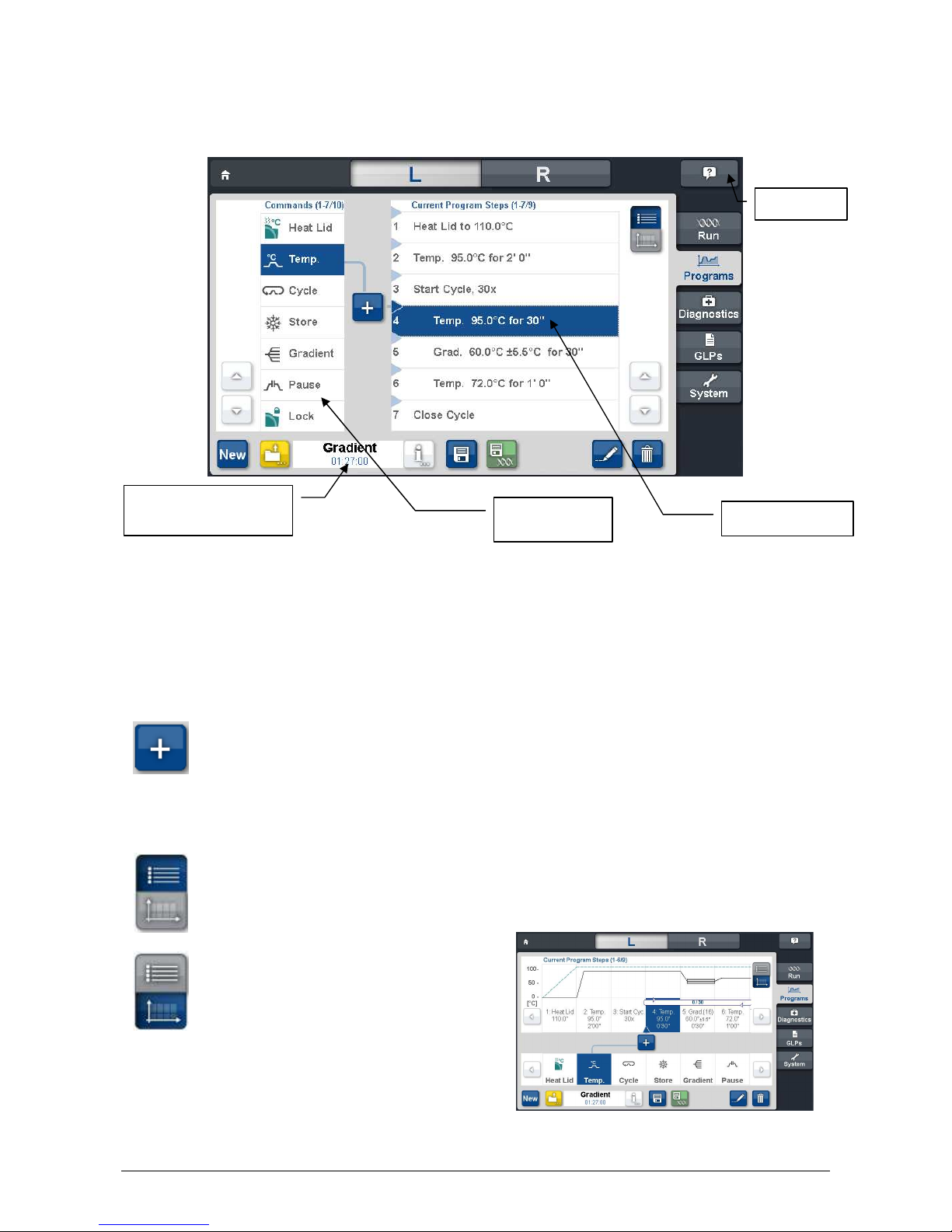

9.2 Operating elements of the 'Programs' dialogue

The 'Program window'

'Program window''Program window'

'Program window' displays the list of commands (steps) the program is composed of. The 'List of available

'List of available'List of available

'List of available

commands'

commands' commands'

commands' is displaying all steps which can be entered into a program. The meaning of the single commands is

explained in chapter 9.3. The function buttons

function buttonsfunction buttons

function buttons serve for editing of programs and the administration of program

files on the system and will be described in the following.

Function buttons of the 'Programs' dialogue:

9.2.1 Entering a command

To enter a new command into a program the desired line has to be selected. From the left side of the

program window a blue arrow will point on the desired line. After selecting the program command of

the list in the left window it can be inserted into the desired place via the '+' button. Alternatively this

can be made by double click on the program command. Thereupon the corresponding parameters will

be asked. To enter a parameter the desired input field has to be touched. A keyboard will be shown

on the screen.

9.2.2 List view

Pushing this button, the selected program will be displayed in the list view, like shown in chapter 9.2.

9.2.3 Diagram view

Pushing this button, the selected program will

be displayed in the diagram view, like shown

at the right.

Program window

Name of the PCR program and total time

List of available

commands

Direct help

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

14

9.2.4 New program

A new program can be generated, after pushing this button the program’s name has to be defined.

Optionally author, user, any comment and the program options can be entered.

9.2.4.1 New Cyclerprogram

Enter the name of the PCR program,

optionally also add name of the author and

a comment.

‘Path’ shows you the directory where the

program is stored. Over the button

you could change the path.

9.2.4.2 Program Options

Using the button the

adjoining window appears:

9.2.4.3 Power Fail Denaturation

If 'Power Fail Denaturation' is activated by

pushing the 'checkbox' the

adjoining dialogue appears:

If a power failure had happened while a program was

running the thermal cycler restarts the program at the

point it was stopped as soon as the power returns

(Autorestart after power failure).

Additionally, if the option 'Power Fail Denaturation' is

activated the thermal block will heat to the stated

temperature for the set time before continuing with the

program.

9.2.4.4 Global Program Ramp

Using the Checkbox a global

ramp rate in °C/s can be programmed. This global ramp

rate will be used in all temperature and gradient steps of

the PCR program, but could be changed in a single

temperature or gradient step manually by entering the

desired value at the step.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

15

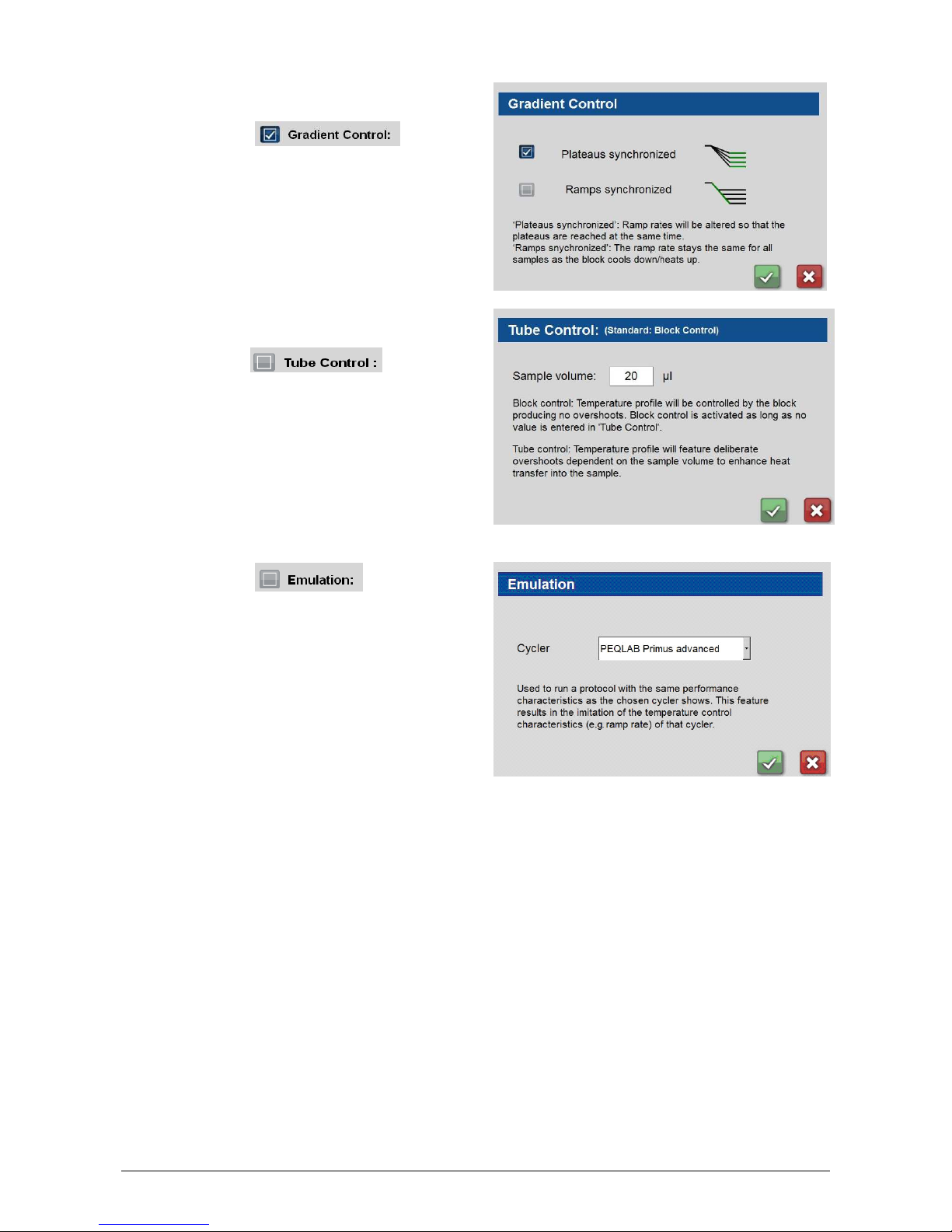

9.2.4.5 Gradient Control

Using the Checkbox you can

decide whether in a gradient step the plateaus (Plateaus

synchronized) or the Ramps (Ramps synchronized) should

be synchronized for all rows.

9.2.4.6 Tube Control

With the Checkbox you have the

possibility to adjust temperature regulation for a

temperature step accordingly to sample volume. If

necessary, the temperature regulation will perform shortterm deliberate overshoots and undershoots depending

on the entered sample volume during PCR run.

9.2.4.7 Emulation

Using the Checkbox the thermal cycler

will perform PCR like the chosen cycler, emulating its

performance. This function could be useful if a PCR

program should be transferred to the peqSTAR from

another type and model of thermal cycler.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

16

How to emulate a protocol ABC from cycler XY on a peqSTAR in the right way?

Program:

Enter the protocol ABC in the program editor

of the peqSTAR the same way you did it on

the cycler XY.

Emulation:

Go to ‚Program Options’ => ‚Emulation’ and

choose the cycler XY that you have used

previously.

Tube Control:

Did you had to enter a volume setting in your

cycler XY (Tube Control mode)?

If yes, please enter the same volume in the

peqSTAR in the ‚Program Options’ under

‚Tube Control’.

Ramp Rate:

Have you worked on cycler XY with a

reduced ramp rate?

Throughout the whole protocol?

Then you could adjust the ramp rate in the

‚Program Options’ under ‚Global Program

Ramp’ for the whole protocol.

Only for single steps in the protocol?

Then you could adjust the ramp rate for each

single temperature or gradient step.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

17

9.2.5 Open a program

See chapter 9.1.1.

9.2.6 Info-Button

See chapter 7.4.

9.2.7 Deleting a command from the program

The command has to be selected by marking it and then pushing the 'Delete' button.

9.2.8 Saving a program

Use this button to save a program. The

adjoining window appears and the

corresponding information can be entered or

changed in the dialogue window. Further

information regarding program options can

be found at chapter 9.2.4.2.

9.2.9 Save & Run

A program can be saved and run

immediately using this button. In advance

there will be a security check which needs to

be confirmed with 'Yes'. The program is then

loaded to the 'Run' tab and started.

At the peqSTAR 2X the desired block can be

chosen by using this dialogue.

9.2.10 Editing a command

The parameters of a command can be modified by touching the corresponding command line of the

program and changing it with the 'Edit' button. (The same function has a double click on the command

line).

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

18

9.3 Available commands (program steps)

Unlock

9.3.1 Unlock

Use this command to unlock the lid in case that it has been locked in a previous program step.

Lock

9.3.2 Lock

Use this button for lid locking in order to

avoid accidental opening while a

program is running. Using this

command, the adjoining window

appears.

9.3.2.1 Lid Pressure On

By activating

you can set lid pressure on the samples

between 100 – 250 N. When using a

thermal cycler without High Pressure Lid

(HPL) the inserted pressure value will be

ignored. When using a thermal cycler

with HPL and not inserting any pressure

value, the lid will automatically set the

pressure on the samples to 50 N.

Heat Lid

9.3.3 Heat Lid

Using this command you can activate or

deactivate lid heat and the adjoining

window appears.

By activating 'Lid heat on' it is possible

to insert the desired lid temperature. The

temperature needs to be in a range of

40 - 120 °C. When 'Lid heat on' is not

activated, the lid heat is switched off.

When creating a new program, the step 'Heat Lid' will be automatically inserted at the beginning

of the PCR. This stetting can be changed at the tab System (see chapter 12.7.1.2).

Please note:

• When reaching a 'Store'-Step the 'Heat Lid' is deactivated automatically.

• Furthermore the 'Heat Lid' is deactivated automatically during temperature steps < 30 °C.

When temperature steps ≥ 30 °C will follow, the 'Heat Lid' is reactivated automatically in

case it was activated before the temperature step < 30 °C.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

19

Temp

9.3.4 Temperature

Use this button to insert a temperature

step in the PCR program.

9.3.4.1 Temperature

Set the temperature, which should be held

during the step.

9.3.4.2 Time

Set the time how long the desired

temperature should be held.

9.3.4.3 Ramp-Rate

When activating the checkbox a ramp rate can be set. The setting here will overwrite the 'Global

Program Ramp' in the program options.

9.3.4.4 Temp-Incr./Decr

Change of temperature within a program cycle. The sign indicates, whether the temperature will be

increased or decreased.

9.3.4.5 Time Incr./Decr

Change of time within a program cycle. The sign here defines whether the time will elongate or

reduce.

9.3.5 'Elongation Time' and 'Melting Temp.'

The elongation time and the melting temperature of the primers can be calculated by using this

button. They have to be considered as guideline values. Depending on the application of the user

further optimization might be necessary. Typically the optimal annealing temperature is about 3 °C

lower than the calculated melting temperature.

Gradient

9.3.6 Gradient step

Use this button to enter a temperature gradient.

The following dialogue appears:

9.3.6.1 Center

The temperature desired in the middle of

the Gradient can be set in 'Center

Temperature'.

9.3.6.2 Gradient ±

The field 'Gradient ±' shows the difference

in temperature between the middle and the

right and left side of the thermal plate. The

resulting temperatures in the 8 rows are

given on the buttons at the left side of the

window.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

20

9.3.6.3 Time

Set the duration of this step in the field 'Time'.

9.3.6.4 Ramp Rate

When activating the checkbox a ramp rate can be set. The setting here will overwrite the 'Global

Program Ramp' in the program options. This command will only be available, if 'Ramps

synchronized' was activated in the program options under 'Gradient Control'.

9.3.6.5 Temp-Incr./Decr.

Change of temperature within a program cycle. The sign indicates, whether the temperature will be

increased or decreased.

9.3.6.6 Time-Incr./Decr.

Change of time within a program cycle. The sign here defines whether the time will elongate or

reduce.

For the peqSTAR 2X the gradient is realised

over the 8 rows of the block from the top to

the bottom (as displayed in 9.3.6.1).

This is also the default setting for gradients

in the peqSTAR 96X, where the complete

row (from well 1 to well 12) has the same

temperature.

Furthermore there is the possibility of a 16

gradient distribution. Different temperatures

are regulated in the left and right half of the

block leading to a gradient within a single

row from the left to the right. The

temperatures displayed in the software

window are only reached in rows 3 and 10,

so the user is asked to put the tubes only in

the specified wells, when programming or

using a program with such a gradient step.

By selecting one of the temperature buttons

different options will be available:

When the checkbox was

deactivated before, the single temperatures

of each row can be adjusted within a special

range using the button 'Adjust Temperature'.

Moreover the selected temperature can be

used as new center value or the gradient

step can be changed in a temperature step

using the selected temperature. These two

functions are independent of the settings

regarding gradient linearity.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

21

Cycle

9.3.7 Cycle:

Use this button to define a program cycle

(loop), consisting of several individual

program steps.

In the field 'Number of Cycles' the amount

of cycles is entered.

In the following dialogue the commands

'Temp' and 'Gradient' can be entered in

the cycle. The corresponding values are

explained in chapter 9.3.4 and 9.3.6.

When all steps of the cycle are

programmed, the dialogue could be left

using the button 'Close Cycle'.

Start Cycle

9.3.8 Start Cycle - Manual cycle beginning

Close Cycle

9.3.9 Close Cycle - Manual cycle ending

Pause

9.3.10 Pause

Use this button to interrupt the running

program temporarily.

The adjoining window appears where you

can enter a temperature value for the

pause

Store

9.3.11 Store

This command keeps the thermal plate

temperature on the set value.

Automatically the lid heat is turned off.

This command usually is the last program

step, and is used to store the samples at a

constant temperature until removal.

If the exact time of sample removal is

uncertain activate the 'Infinite' field to store

for an infinite time.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

22

10 DIAGNOSTICS

The 'Diagnostics' dialogue visualizes the temperature profile of the thermal plate. The actual values will be shown

for lid and cycler temperature. While a PCR protocol or incubation is running, the thermal cycler automatically

records all temperatures. The record will be finished as soon as the PCR program or the incubation has been

stopped.

10.1 Operation of the 'Diagnostics' dialogue

Different operating elements for indication and navigation within a diagram are available:

Navigation button:

To the end of the

record

Navigation button:

One page forward

Navigation button:

To the beginning of

the record

Zoom 0.5 fold

Zoom 2

-

fold

Time scale

Help Mode

Lid

: Lid temperature

Cycler: Temperature

of cycler interior

Selection of single view or

complete view of the eight zones

Automatic

scrolling

active or

inactive

Navigation button:

One page back

Temperature scale

Display of the selected zones (8 zones each block for

the peqSTAR 2X, 16 zones for the peqSTAR 96X)

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

23

10.2 General view

General view of the zones of the thermal plate showing the temperature profile of the eight or 16 zones in one

combined diagram (see 10.1) when choosing the 'Diagnostics' dialogue. The temperature profile of the single

zones is shown in one window lying upon another.

10.2.1 Zones

By selecting the chosen zones these will be shown or

hidden in the general view. Hidden zones won’t be

shown in the diagram window anymore, but the

record of the corresponding temperatures will be

continued.

10.2.2 Single view

By pushing the button the single view of the

zones will be shown.

Using the single view of the zones the temperature

profile of each zone will be shown in separate

diagrams. The arrangement of the single diagrams

match to the arrangement of the zones on the

thermal plate.

10.2.3 Automatic scrolling active

10.2.4 Automatic scrolling inactive

For convenient view of the PCR record the automatic scrolling can be inactivated. Using

this function, already recorded parts of the diagram can be looked at without

automatic screen scrolling.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

24

11 GLPS DIALOGUE

The 'GLPs' dialogue is used for the administration, viewing and printing of the GLP reports generated by the

thermal cycler.

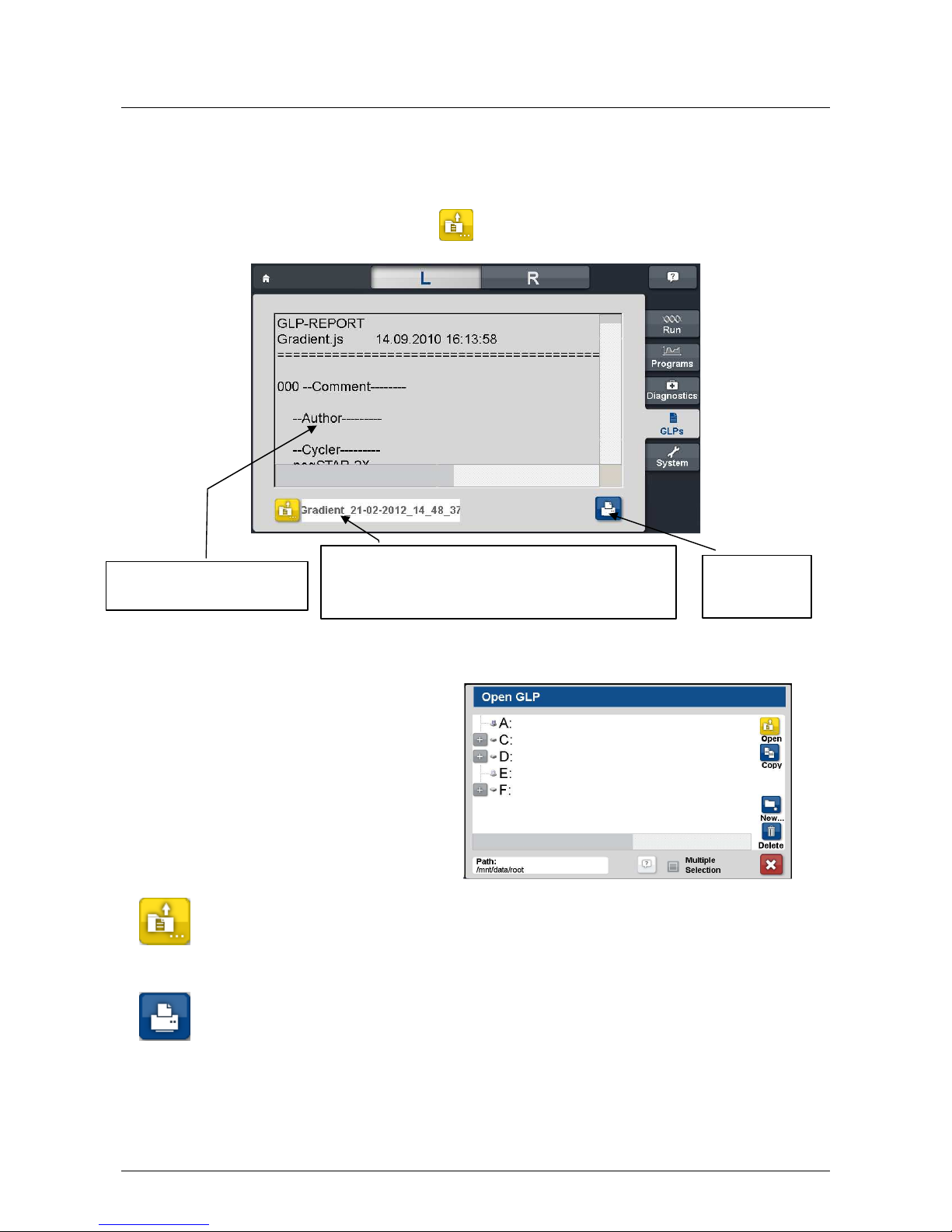

11.1 Displaying a GLP report

After pushing the GLP button a dialogue appears to select a GLP report, which will be directly shown. The

dialogue can also be opened by pushing the button .

11.2 Operating elements of the 'GLPs' dialogue

11.2.1 Select GLP

Select a GLP report (shown in

the adjoining text window). GLP

reports can also be copied or

deleted and a new folder can be

created for GLP reports.

11.2.2 Open GLP report

Use this button to open a stored GLP report. Select the desired GLP report of the file list and open it

by pushing the button 'Open'. The GLP report is shown as displayed in chapter 11.1.

11.2.3 Printer

Use this button to print out the selected GLP report.

This window shows the

content of the GLP report.

Shows the name of the selected GLP report. The name

of the GLP is composed of the name of the PCR

program, date and time.

Printing of the

GLP report.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

25

11.2.4 Delete

Use this button to delete a GLP report.

11.2.5 Copy

Pushing this button saved GLP reports

or files can be copied. Several GLP

reports/files can be marked via mouse

click simultaneously if the option

'Multiple Selection' was chosen.

Marked GLP reports/files are shown

with a blue background.

By using the 'Copy' button the

adjoining dialogue appears.

Pushing 'OK' the files will be copied;

the operation can be aborted with

Cancel.

11.2.6 New folder

A new folder can be created using this button.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

26

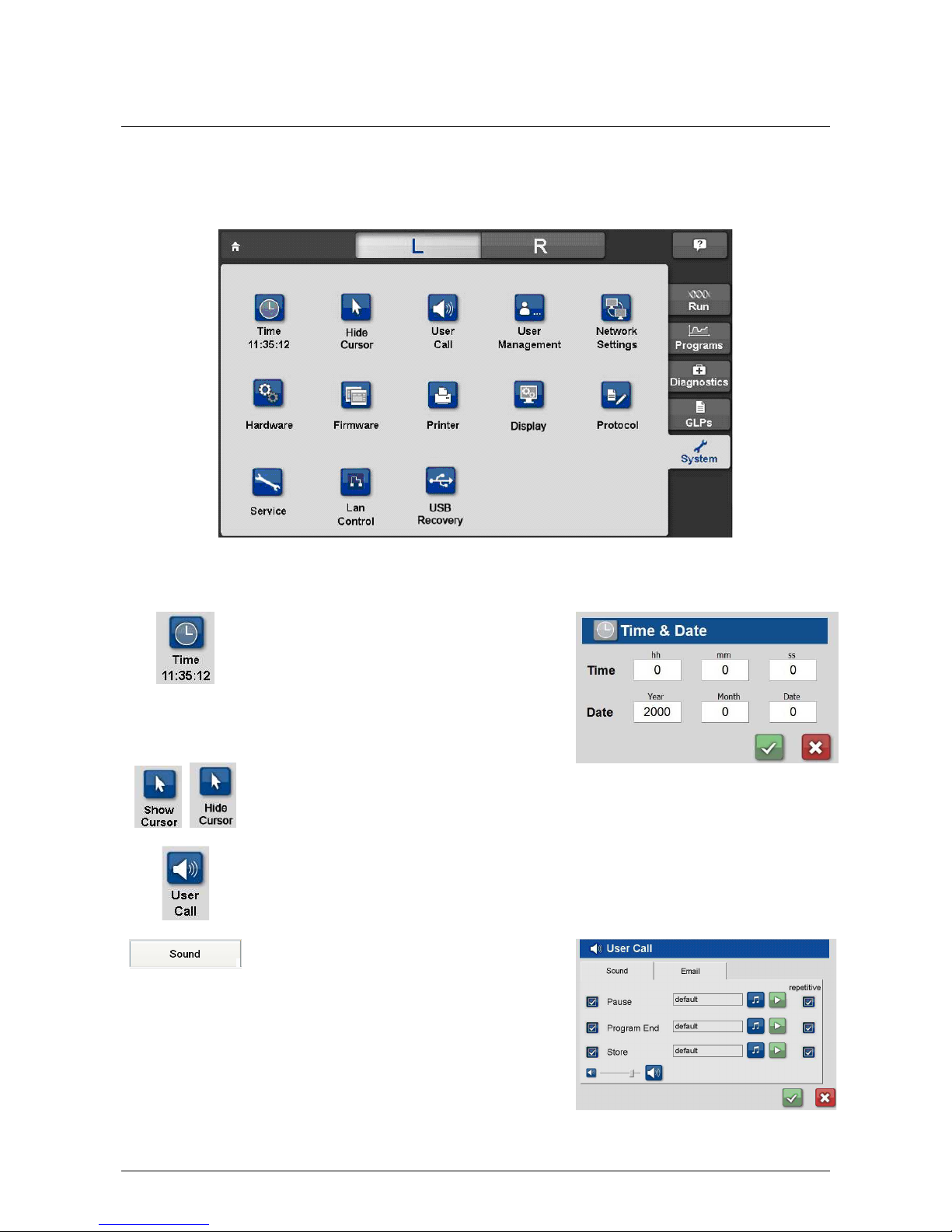

12 SYSTEM

In this dialogue the configuration and settings of general parameters of the device can be carried out.

Elements of the 'System' dialogue: Overview

Having selected one of the symbols the function is called up and the corresponding settings can be executed or

changed as explained in the following dialogue.

12.1 Time / Date

Setting of actual time and date:

By pushing the clock button, the adjoining window

appears and time and date can be set.

12.2 Show/Hide mouse cursor

Use the button to show or hide the cursor on the screen.

12.3 User Call

Using this button different user calls can be set.

12.3.1 Sound

Selecting the tab 'Sound', the adjoining window

opens and the settings for sounds can be changed:

For activating the appropriate sound mark the

checkbox. It can be chosen between single

(standard setting) or repetitive signal in case of

occurrence of an event.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

27

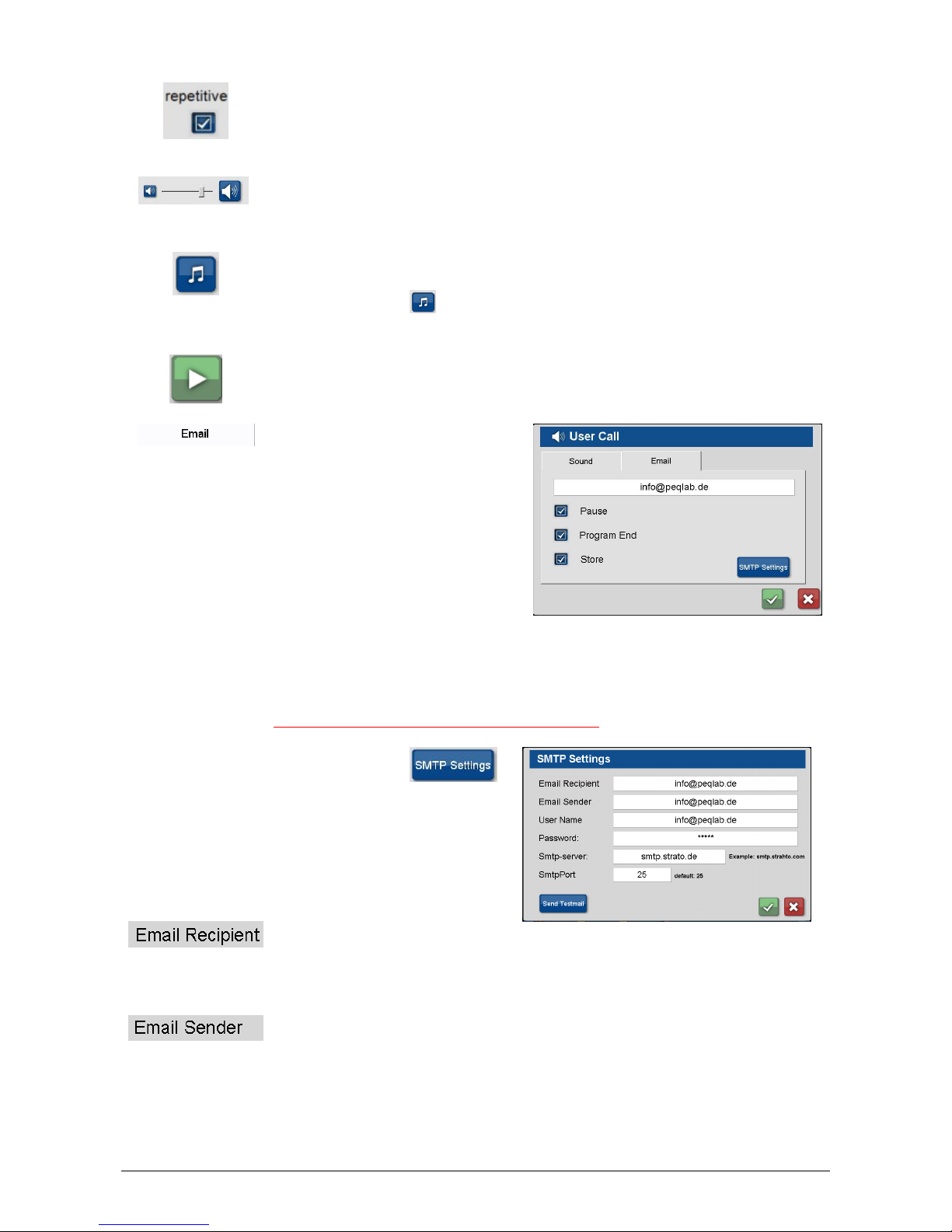

12.3.1.1 Repetitive

When this checkbox is activated, the user call will be repeated periodically as long as the

event is open.

12.3.1.2 Sound intensity:

Set the desired sound intensity.

12.3.1.3 Select sounds

By pushing the button a selection window will appear. Different MP3 sounds can be

chosen and stored for the events 'Pause', 'Store' and 'Program End'.

12.3.1.4 Play melody

The selected sound can be listened to when pushing this button.

12.3.2 Email

By selecting the tab 'Email' the

adjoining window appears. When

activating a checkbox the cycler will

send an Email in case of occurrence of

the corresponding event.

Note: The peqSTAR X needs to be installed in a network with access to the internet so that

it can send an email to the user when needed. Please check settings under System →

Network, as for example the entry of the DNS Server is necessary for sending emails.

Please ask the administrator for the required settings.

Please ask the administrator for the required settings.Please ask the administrator for the required settings.

Please ask the administrator for the required settings.

By pushing the button

the settings could be entered.

12.3.2.1 Email Recipient:

Please enter the email address where the info should be sent to from the cycler in case of

occurrence of an event.

12.3.2.2 Email Sender:

Here you could enter the name of the email sender, e.g. the cycler name or the same email

address as for ‘Email Recipient’:

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

28

12.3.2.3 User name

Please enter the user name of the used email account. Please note that you have to enter

the SMTP settings here. In case you have defined different user names for incoming and

outgoing mail server in your account settings, enter here the user name for the outgoing

mail server.

12.3.2.4 Password

Please enter the email password of the used email account. Please note that you have to

enter the SMTP settings here. In case you have defined different passwords for incoming

and outgoing mail server in your account settings, enter here the password for the

outgoing mail server.

12.3.2.5 SMTP-Server:

Please enter the outgoing mail server which should be used for sending the email.

12.3.2.6 SMTP Port:

Please enter the SMTP port which should be used for sending the email. Standard setting

for the port is 25.

12.3.2.7 Send Testmail:

By pushing this button a test mail is sent, to check whether the settings are correct and

emails could be send by the cycler.

In case the test mail could not be sent successfully, please ask your network administrator

for the required settings.

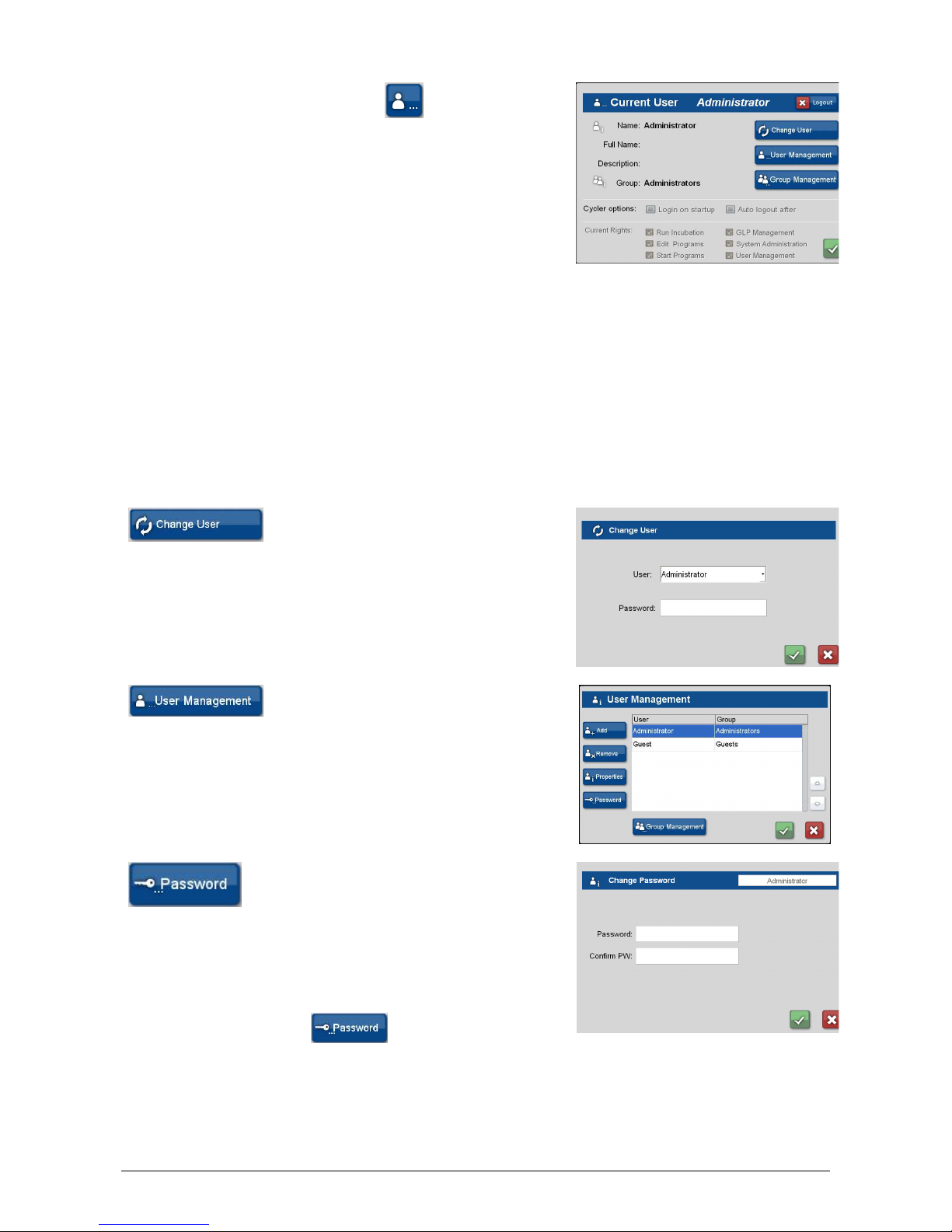

12.4 User Management

In the user accounts management, user groups or single users can be configured and their

settings e.g. right of access (reading programs, edit programs etc.) will be administered.

The users are assigned to given or predefined user groups which are assigned to rights of

access.

Important: the thermal cycler supports the assignment of rights of access to certain user

groups. This means that rights for the operation of functions are given or refused to certain

user groups. In the user administration, user groups are configured and equipped with

rights. Single users of those groups are limited to the appropriate rights.

Rights are not assigned to single users but user groups. Users of a certain user group

inherit the rights of the related group.

The name of a user appears in the program header of a program generated by the user as

well as in the GLP report of a program run by the user.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

29

After pressing the button the adjoining

dialogue appears:

To call up the user administration the user has

to log in with his password. The user (in

general the administrator) must have the

appropriate right for the administration of

users. At the state of delivery (condition) an

'administrator' with the required access is

configured.

Using the 'Logout' button the current user can log out. The user 'Guest' is then

automatically logged in, who has only minimal rights as factory settings. The administrator

can change these settings (see 12.4.3.1 and 12.4.3.3).

At 'Cycler options' you could activate the function 'Login on startup' with the checkbox. Is

this option activated, when turning on the instrument, an obligatory Login request appears.

By using the checkbox 'Auto logout after' the user can define a time span when the logged

in user is automatically logged out.

Originally the password for the

Originally the password for theOriginally the password for the

Originally the password for the 'administrator' is admin.

'administrator' is admin. 'administrator' is admin.

'administrator' is admin.

12.4.1 Change User

Using this dialogue window, users can be

changed.

Please select the user and enter the appropriate

password.

Originally the password for the 'administrator'

is admin

adminadmin

admin.

12.4.2 User Management

The adjoining dialogue window appears. In

this dialogue single users can be added,

changed or deleted. Use the button 'Group

Management' to call up the administration of

groups.

12.4.2.1 Change Password

In case that any user forgot his password or

wants to change it, the administrator can

allocate a new password. This could also be

done by a user with the right for 'User

Management'. Select the user and allocate a

new password by pushing the

button .

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

30

12.4.2.2 Set up a new user and assign a

password

Use this button to set up a new user. The

adjoining dialogue window appears where

several data can be added.

Save the data with the button and the newly set up user is displayed in the user list

among the related user group.

Important:

Important: Important:

Important: If a new user should only have limited rights, it might be useful to set up a new

user group with the appropriate rights to access. (see chapter 12.4.3)

12.4.2.3 Administration of user groups

See chapter 12.4.3.

12.4.2.4 User Information

Use this button to get further information on the

user (user name, full name, description and

group membership).

12.4.2.5 Delete a user

Select a user and remove it with this button. For safety reasons a query appears if the user

should be removed for sure.

12.4.3 Setting up a new user group

12.4.3.1 Add a new user group

Using this button a new user group and its

description can be set up.

It is possible to allow/refuse access to certain

functions of the instrument.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

31

List of available rights:

List of available rights:List of available rights:

List of available rights:

Run incubation Run incubation mode

Edit programs Edit programs

Start programs Start programs

GLP management Watch GLP reports

User management Administrate user and user groups

System administration Modify/administrate configurations

12.4.3.2 Delete a group

Select the group and delete it using this button.

For safety reasons a query appears if the group should be removed for sure.

12.4.3.3 Show and change group information

12.4.4 User logout

If a user logs out by using the button 'Logout' the user 'Guest' is automatically logged on.

The user 'Guest' initially does not have any rights. This is to make sure that a new user,

who wants to work with the peqSTAR X, must log in first. The Administrator or other users

with the right 'User Management' can assign more rights to the user 'Guest' if required

(see 12.4.3.1).

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

32

12.5 Network Settings

Using this button, network settings can be changed.

At the tab the adjoining

dialogue appears and the required

settings for network integration can be

entered.

Please ask your network administrator for

the required settings.

At the tab the adjoining

dialogue appears:

The entered cycler name appears when

using the email user call in the sent mail

notification.

At the tab the adjoining

dialogue appears and the required

settings for access to a released network

device can be entered.

Username: to log on the network

Password: to log on the network

Network path: which is available for

the user as additional

path for cycler pro grams and GLP reports

after the successful

network connection.

This path is assembled of:

//<IP address, where release network path is located>/<directorypath>

Please note that there need to be the corresponding access authorities (write and read

access) for the indicated path.

Please ask the administrator for the required settings.

At the tab the adjoining

dialogue appears:

By activating the checkbox ‘always

accept remote control’, it is not necessary

any more to confirm cycler access when

performing PC or master/slave control.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

33

12.6 Hardware

Shows actual version of thermal block,

control and power unit.

Changes can only be made by authorized

technical service.

12.6.1 Overtemp test

At Hardware => Thermo Block =>

Overtemp Test a periodical test (e.g. every

month) of the overtemperature protection

can be found according to the following

procedure:

First the result of the last check of the

overtemperature protection is reported. To

continue with the test, confirm the dialogue

with ‘Yes’. Initialization and

overtemperature test is done automatically

for both blocks at the peqSTAR 2X.

Press OK after the test has finished.

If one or both results are not “OK”, the

overtemperature protection is damaged. In

In In

In

this case, the therm

this case, the thermthis case, the therm

this case, the thermal

al al

al cycler must not

cycler must notcycler must not

cycler must not be

be be

be

used anymore and must be sent back to the

used anymore and must be sent back to the used anymore and must be sent back to the

used anymore and must be sent back to the

manufacturer for a check.

manufacturer for a check.manufacturer for a check.

manufacturer for a check. (see chapter

13.1).

12.7 Firmware

12.7.1 Control Unit

Display and administration of the

firmware versions of the control unit with

the adjoining dialogue.

12.7.1.1 Info Button

Shows the current version of the control unit firmware.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

34

12.7.1.2 Settings

Pushing this button the adjoining dialogue

appears. The following menu items are

available: 'Programs…', 'GLP…' and

'Factory Settings'.

12.7.1.2.1 Programs Settings

Setting a check mark in this box, a 'Lid Heat'

step will be automatically inserted as first

step when generating a new program. In the

field next to 'Default LidTemp' the

temperature can be entered which shall

appear as preset value within the insertion

dialogue of a new temperature step. This

value can be changed manually in the PCR

program.

12.7.1.2.2 GLP Settings

Setting a check mark in this box, a GLP

report will be created after every run after

the query. If the box is not marked, no GLP

report will be created. No according query

will appear.

12.7.1.2.3 Factory Setting

The configurations set under Firmware >

Control Unit >Settings can be changed to the

factory settings.

12.7.1.3 Update

Updates the firmware of the control unit. The

firmware must be available on a USB

memory stick connected to the device.

Next it will be asked whether the software of control unit should be updated. If you confirm with

'Yes' the update starts.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

35

Important:

Important:Important:

Important:

The USB memory stick may not be removed during update proces

The USB memory stick may not be removed during update procesThe USB memory stick may not be removed during update proces

The USB memory stick may not be removed during update process!

s!s!

s!

After a successful update the display shows the corresponding message and the software starts

again. The USB memory stick can be removed then.

12.7.2 Power Unit

Display and administration of the firmware

version of the power unit. The adjoining

dialogue appears.

12.7.2.1 Info

Shows the current version of the power unit firmware.

12.7.2.2 Update

Updates the firmware of the power unit.

The firmware must be available on a USB

memory stick connected to the device.

Next it will be asked whether the software of power unit should be updated. If you confirm with

'yes' the update starts.

Important:

Important:Important:

Important:

The USB memory stick may not be removed during the update process!

The USB memory stick may not be removed during the update process!The USB memory stick may not be removed during the update process!

The USB memory stick may not be removed during the update process!

After a successful update the display shows the corresponding message and the USB memory

stick can be removed then. After the successful update the instrument has to be switched off and

on again.

12.8 Print

The peqSTAR X thermal cyclers can print

PCR programs and GLPs on a network

printer. Using this dialogue, the path for

the network printer, which the peqSTAR X

should use, can be entered.

Please refer to your local network administrator for the correct printer path.

Using the button a test printing will be performed to check the correct settings.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

36

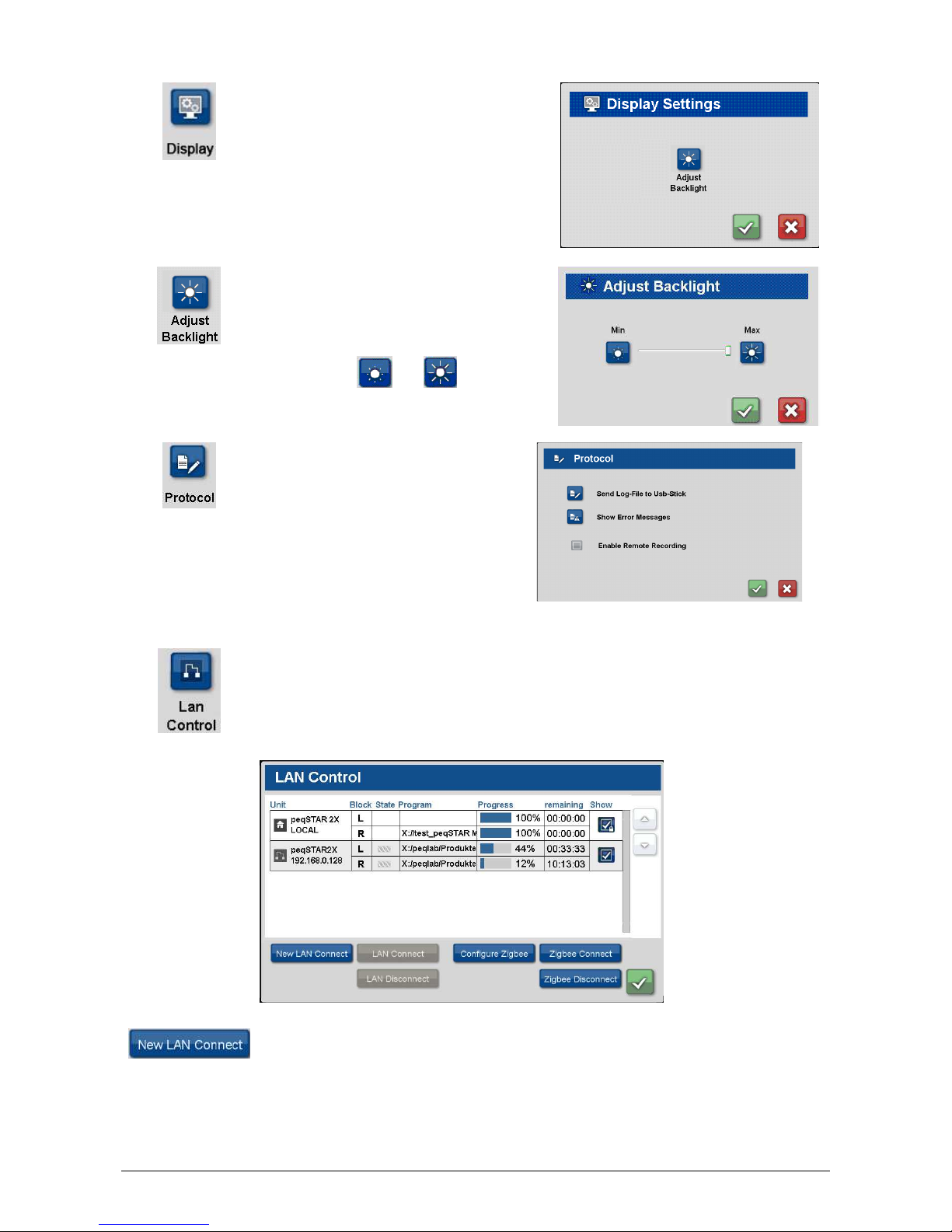

12.9 Display

Pushing this button, the adjoining window

opens:

12.9.1 Brightness

The following dialogue appears after

pressing the button:

By pressing the and buttons or

moving the roll bar the backlight of the

display can be adjusted.

12.10 Protocol

For troubleshooting, the thermal cycler can

record its own internal communication. The

protocol file „log.txt“ can be stored on a

USB stick. By using the button 'Send LogFile to Usb-Stick' the protocol file 'log.txt'

can be saved on a USB stick. Alternatively

possible error messages can be shown by

pressing the button 'Show Error Messages'.

12.11 LAN Control

This dialogue is used to connect with a thermal cycler via network or zigbee, to be able to

remote control the instrument.

When instruments should be available using the instrument button at the top of the display,

the checkbox under 'Show' needs to be activated.

The following command buttons are available:

12.11.1 New Lan Connect

Using this button a LAN connection to a new cycler for remote control can be set up. Enter the

IP address of the cycler, which should be available for remote control, in the input box.

The following message appears, when the connection starts:

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

37

'The connection to

'The connection to 'The connection to

'The connection to

IP Address Remote Cycler

IP Address Remote CyclerIP Address Remote Cycler

IP Address Remote Cycler

will be done as so

will be done as so will be done as so

will be done as soon as the o

on as the oon as the o

on as the other part confirms

ther part confirms ther part confirms

ther part confirms

the request.

the request.the request.

the request.''''

The cycler which should be available for remote control shows the following message:

'Do you want to accept connection to

'Do you want to accept connection to 'Do you want to accept connection to

'Do you want to accept connection to

IP Address Control Unit

IP Address Control UnitIP Address Control Unit

IP Address Control Unit

?'

?' ?'

?'

If this message will be confirmed with 'Yes' and the remote control accepted, the display of the

control unit shows the following message then:

'User from

'User from 'User from

'User from

IP Address Remote Cycler

IP Address Remote CyclerIP Address Remote Cycler

IP Address Remote Cycler

has accepted LAN remote.'

has accepted LAN remote.' has accepted LAN remote.'

has accepted LAN remote.'

If a check mark is set at 'Always accept remote control' under 'System' => 'Network Settings'

=> 'Remote' the link connection is carried out without any further queries.

The cycler will then be entered in the display overview and is marked with the LAN sign ,

which confirms the active LAN connection.

When the instrument should be available using the instrument buttons at the top of the display,

the checkbox under „Show“ needs to be activated.

As soon as the cycler is displayed, it can be remote controlled by the control unit.

12.11.2 Lan Connect

As soon as a cycler was once remote

controlled via LAN connection, it will be

displayed in the LAN control window (in our

example: peqSTAR 2X 192.168.0.121) and

marked as non connected.

For a new LAN connection with this cycler,

mark it in the overview and use the button

'LAN Connect' to start a new connection.

12.11.3 Lan Disconnect

For disconnect a LAN connection with a cycler, mark the chosen unit in the overview and use

the button 'LAN Disconnect'. The cylcer could then be controlled again via touch screen.

Alternatively the LAN connection will be stopped when the cycler will be switched off or in

case that the software at the PC will be closed.

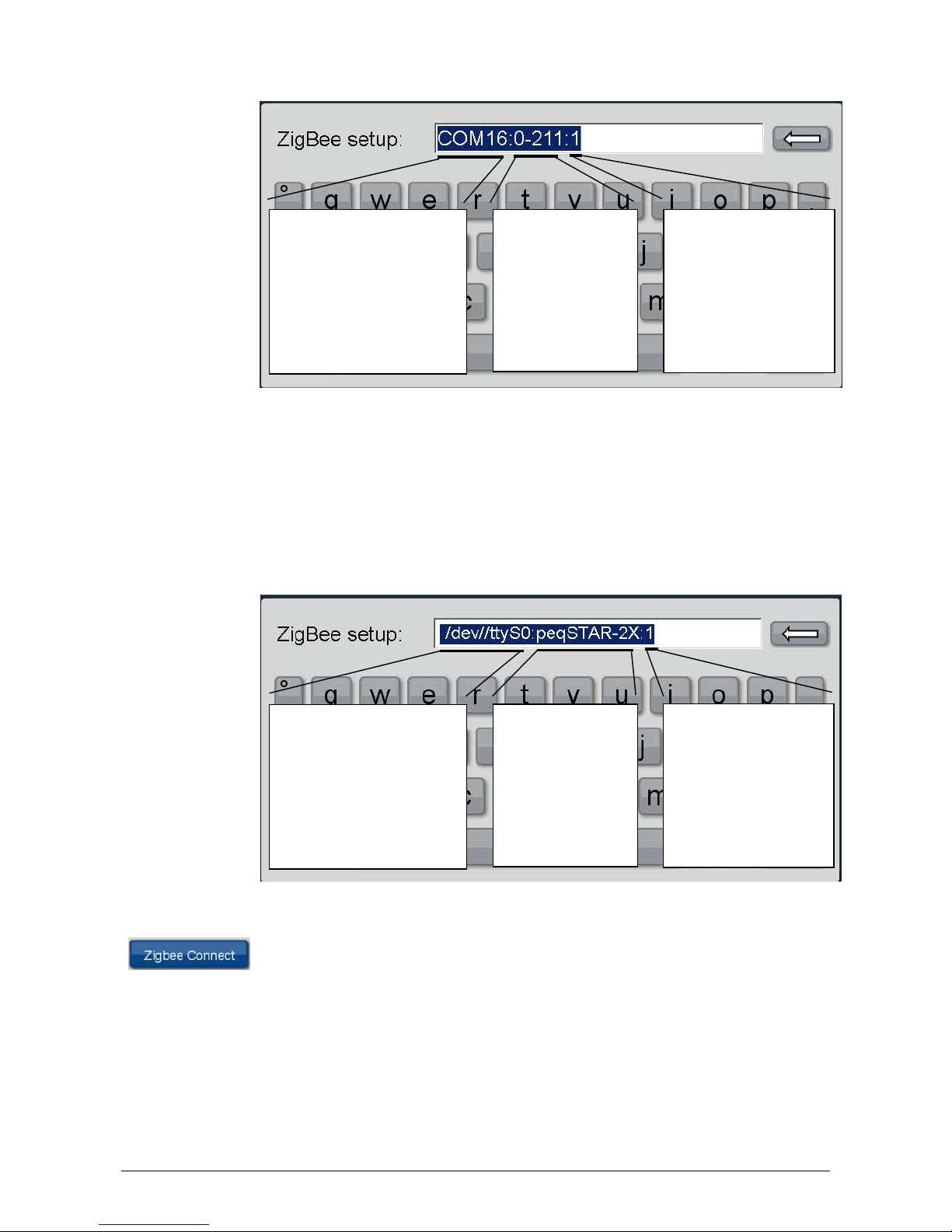

12.11.4 Zigbee Configure

The optional available ZigBee module is needed for wireless remote control (order number:

95-0ZIG). It consists of one module which is installed in the remote cycler and a ZigBee dongle

for the PC as control unit.

To start a connection between the remote cycler and the PC as control unit, both ZigBee

modules need to be configured.

At the PC:

At the PC:At the PC:

At the PC:

The message 'ZigBee dongle detection' appears if the peqSTAR Manager' software is opened

while the ZigBee dongle is connected or will be connected subsequently. The message also

shows at which COM port the ZigBee dongle is installed at the PC.

To configure the ZigBee dongle choose 'ZigBee Configure' at 'System' => 'LAN Control' in the

'peqSTAR Manager' software. A dialogue will appear with an automatic Setup window that

might/must be adapted accordingly.

Enter: COM#:PC name:Network level

Example: COM16:0-211:1

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

38

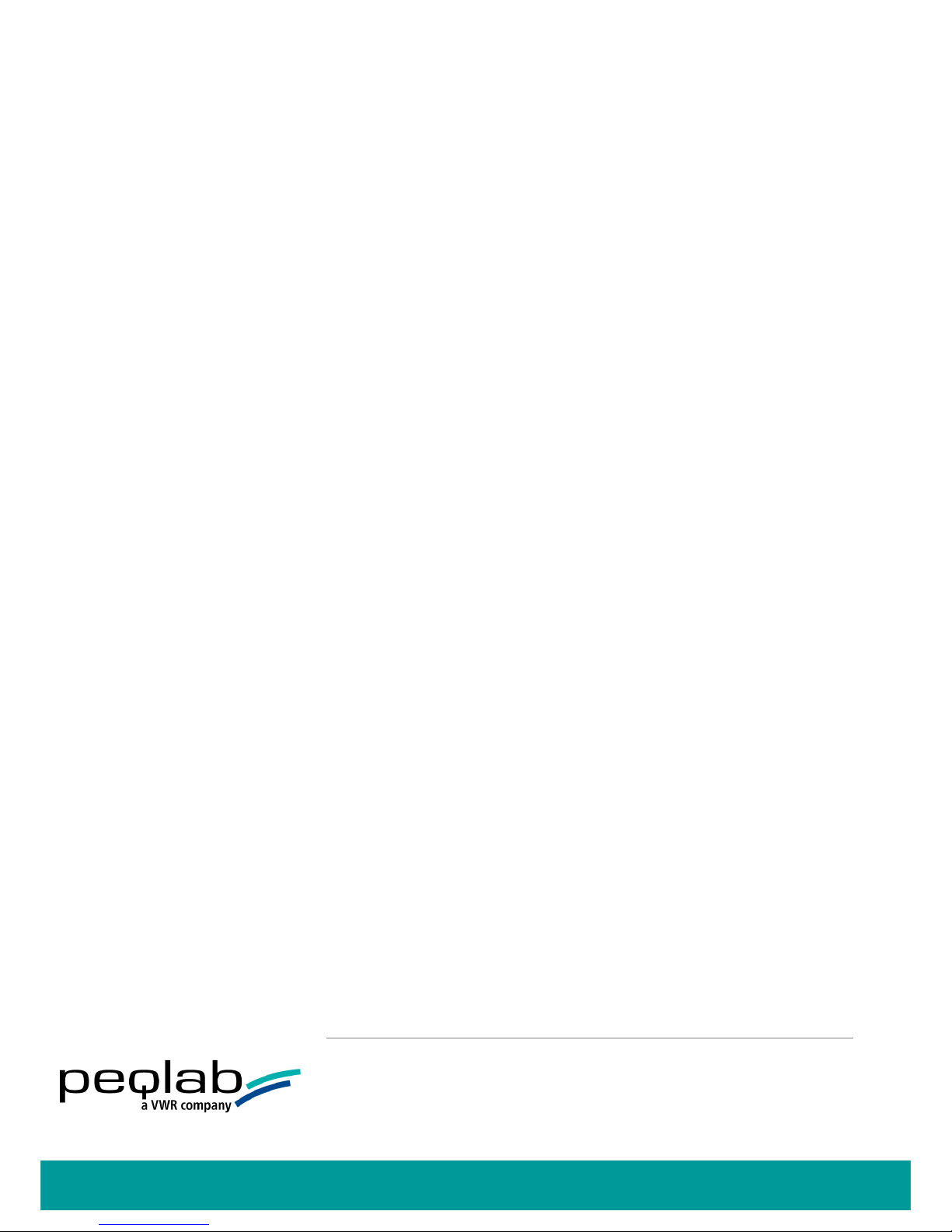

At the Remote Cycler:

At the Remote Cycler:At the Remote Cycler:

At the Remote Cycler:

To configure the ZigBee dongle choose 'ZigBee Configure' at 'System' => 'LAN Control' in the

'peqSTAR Manager' software. A dialogue will appear with an automatic Setup window that

might/must be adapted accordingly.

Enter: Interface:Cycler name:network level

Example: /dev/ttyS0:peqSTAR-2X:1

The adresses for PC and remote cycler need to be different.

The adresses for PC and remote cycler need to be different.The adresses for PC and remote cycler need to be different.

The adresses for PC and remote cycler need to be different.

12.11.5 Zigbee Connect

To start the wireless connection between PC and remote cycler, push the button 'ZigBee

Connect' at the PC.

Enter the name of the remote cylcer, e.g. 'peqSTAR-2X'.

If the connection is successful the following message appears:

'The connection to IP Address Remote Cycler will be done as soon as the other part confirms

the request.'

Then the following message appears on the system that shall be controlled:

'Do you want to accept connection to

IP Address Control Unit

?'

COM Interface

COM InterfaceCOM Interface

COM Interface

As COM number use the

COM port where the ZigBee

dongle was installed (this

can be checked in the

Device Manager if

necessary).

PC name,

PC name,PC name,

PC name,

that is shown at the

thermal cycler

(„ZigBee remote

control by

PC-

Name

“)

Network level

Network levelNetwork level

Network level

Default setting is '1' for

cycler and PC. Cycler

and PC must always be

configured at the same

network level.

Interface

InterfaceInterface

Interface

The cycler automatically

enters the interface of the

ZigBee module.

Cycler name,

Cycler name,Cycler name,

Cycler name,

that must be

entered at the PC to

connect the Remote

cycler.

Network level

Network levelNetwork level

Network level

Default setting is '1' for

cycler and PC. Cycler

and PC must always be

configured at the same

network level.

.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

39

If this message is confirmed with 'Yes' and therefore the remote control authorized, the

following message appears on the control unit.

'User from IP Address Remote Cycler has accepted LAN remote.'

If a check mark is set at 'Always accept remote control' under 'System' => 'Network Settings'

=> 'Remote' the link connection is carried out without any further queries.

The cycler will then be displayed in the overview and is marked with the ZigBee sign ,

which shows the active wireless connection.

If the system shall be addressed directly through the buttons at the top of the screen, a check

mark must be set at 'Show'. As soon as the cycler is displayed, it can be controlled via

operating software as usual.

12.11.6 Zigbee Disconnect

To disconnect a ZigBee connection with a cycler, mark the chosen unit in the overview and use

the button 'Zigbee Disconnect'. The cylcer could then be controlled again via touch screen.

Alternatively the LAN connection will be stopped when the cycler will be switched off or in

case that the software at the PC will be closed.

12.12 USB Recovery

USB sticks are differently formatted by

manufacturers. The actual type of format

is not obvious to the customer. Therefore

some USB sticks are not automatically

detected by the peqSTAR X system. In

this case the USB stick can be manually

mounted by using the function 'USB

recovery'.

12.13 Service

Use of the service function is restricted to

authorised, technical service. Access to

this function is therefore password

protected.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

40

13 MAINTENANCE & REPAIR OF THE THERMAL CYCLER

13.1 Cleaning, maintenance and repair of the thermal cycler

For safety reasons the device must be switched off and the mains plug pulled before cleaning is carried out!

For safety reasons the device must be switched off and the mains plug pulled before cleaning is carried out!For safety reasons the device must be switched off and the mains plug pulled before cleaning is carried out!

For safety reasons the device must be switched off and the mains plug pulled before cleaning is carried out!

The surface of the thermal cycler can be wiped off with a damp cloth or ethanol. Do not use aggressive or

Do not use aggressive or Do not use aggressive or

Do not use aggressive or

scouring cleaners or organic solvents for cleaning. The device must be protected from aggressive chemicals. Make

scouring cleaners or organic solvents for cleaning. The device must be protected from aggressive chemicals. Make scouring cleaners or organic solvents for cleaning. The device must be protected from aggressive chemicals. Make

scouring cleaners or organic solvents for cleaning. The device must be protected from aggressive chemicals. Make

sure that no liquid penetrates into the interior of the device.

sure that no liquid penetrates into the interior of the device. sure that no liquid penetrates into the interior of the device.

sure that no liquid penetrates into the interior of the device. If sample liquids penetrates into the drill holes of the

thermal cycler clean them immediately with mild soap followed by distilled water. You can use mild disinfectants

You can use mild disinfectants You can use mild disinfectants

You can use mild disinfectants

for decontamination.

for decontamination.for decontamination.

for decontamination.

Maintenance (test of the overtemperature shutdown and temperature check-up see 13.2. and 13.3) should be

carried out regularly to detect possible technical failures.

The electric fuses are placed at the back of the device between the power switch and the mains plug. After pulling

off the mains plugs and pushing upwards a safety catch the fuses can be changed. Use only fuses with correct

values (indications about the fuse type are placed at the back of the device).

The device may only be opened by a qualified specialist. Unauthorized work on the device voids the warranty. All

kinds of repairs may only be carried out by authorized persons using original replacement parts.

The replacement of single components of the device must not be done by the user but exclusively by authorized

specialists. Therefore the device must be sent to the manufacturer. The surface of the device should be

The surface of the device should be The surface of the device should be

The surface of the device should be

decontaminated with a lint free cloth soaked with 70 % ethanol before sending.

decontaminated with a lint free cloth soaked with 70 % ethanol before sending.decontaminated with a lint free cloth soaked with 70 % ethanol before sending.

decontaminated with a lint free cloth soaked with 70 % ethanol before sending. The drill holes of the thermoblock

shall be cleaned with a 1.5 % hypochlorite solution with the help of a cotton bud. Please fill in and sign the

Please fill in and sign the Please fill in and sign the

Please fill in and sign the

decontamination certificate and send it to the manufacturer together with the device.

decontamination certificate and send it to the manufacturer together with the device.decontamination certificate and send it to the manufacturer together with the device.

decontamination certificate and send it to the manufacturer together with the device.

13.2 Test of the overtemperature protection

A periodical test of the overtemperature protection is recommended (see chapter 12.6.1).

13.3 Temperature check-up

Maintenance of the temperature at regular intervals is recommended. The thermometer for use should be equipped

with wired sensing devices (e.g. Pt1000) and should have an accuracy of measurements of 1/10 class B (∆T =

±0.03 °C) in the range of 0 to 100 °C. While processing the temperature control the room temperature should be

25 °C at maximum.

13.4 Calibration

If there is a reasonable suspicion that the device has deviated from the calibration range, because the variations of

the temperature check-up are considerably out of the acceptable tolerance, a new calibration must be carried out

by the manufacturer. Please contact your local distributor.

14 WARRANTY

The period of warranty for the product at hand is 24 month from date of purchase. The warranty does not apply

for defects caused by incorrect, improper or inappropriate use. The customer has to check up on obvious defects

promptly upon receipt of the device and send a written report. Otherwise the claim for warranty expires. The

manufacturer reserves the right to carry out changes to the thermal cycler or to the technical documentation of the

thermal cycler on the basis of product development or improvement without prior notice.

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

41

15 DISPOSAL INSTRUCTION

This product is subject to the WEEE disposal regulations and cannot be disposed of with regular

waste.

Please contact PEQLAB Biotechnologie GmbH or your local distributor for disposal of peqSTAR

X thermal cyclers. Old electronic equipment is not useless waste. Environmentally friendly

disposal can help to retrieve valuable resources. Thereby you contribute to the protection of the

environment and human health.

16 TECHNICAL DATA

16.1 General characteristics

2 x 8 or 16 Peltier elements with Long-Life-technology and 2 x 8 or 16 control circuits with Pt 1000

temperature sensors, respectively

Maximal heating and cooling rate: 5 °C/s

Block uniformity (at 72 °C): ± 0.2 °C

Temperature range thermoblock: 4 to 105 °C

Control accuracy thermoblock: ± 0.1 °C

Variable ramping: 0.1 to 3.0 °C/s

Increment/Decrement time: 0:00:01 to 9:59:59

Increment/Decrement temperature: 0.1 to 9.9 °C

Lid heating temperature range: 40 to 120 °C

Programmable Lid locking mechanism

4 x USB, 1 x Ethernet interfaces (MS Windows

®

or Linux), maximal length of USB cords 3 m!

Note: USB interfaces only support standard USB sticks, cord mouse and keyboards!

Dimensions (B x H x D): 30 x 28 x 38 cm

Weight incl. block: 13.3 kg

Electrical power supply: 90 – 264 V AC, 50 – 60 Hz, 850 VA

Fuse: 10 A time lag

Pollution rate: 2

Environmental temperature range: +10 °C to +30 °C

Max. relative humidity: 70 %

Maximum height above sea level: 2000 m

For indoor use only!

Noise level: < 37 dB (A)

16.2 Gradient feature (optional)

Maximal gradient range over 8 or 16 columns, respectively: 30 °C (± 15 °C)

Temperature range Gradient: 35 to 105 °C

Gradient accuracy: ± 0.1 °C

16.3 User interface/functions

Touch sensitive TFT-Display (VGA, Graphic, 65535 colours), operation via USB mouse possible

Direct help function, Tm- and elongation time calculator

Internal flash memory for 500000 typical PCR programs in free configurable folders/subfolders

Unlimited number of programs via network PC or USB memory stick

Free PC software for the generation of PCR programs on the computer

Unlimited number of steps per program

Password protected user accounts with variable access rights

GLP reports for complete recording of all runs

Quickstart function of the last used program

Instruction Manual peqSTAR X thermal cyclers

PEQLAB_v1212E

42

Automatic restart after power failure, Power-Fail-Denaturation, Instant Incubation

Remote control and monitoring of instruments via PC-software

MP3 sounds free of choice

User call per email

Master-/Slave-control (optionally also wireless available)

16.4 Block capacity

peqSTAR 2X/2X Gradient:

Two 48 well Universal blocks with: lid heating and automatic height adaption for 48 x 0.2 ml tubes, 48 well PCR

plates or 24 x 0.5 ml tubes with flat caps.

peqSTAR 96X/96X Gradient:

96 well Universal block with: lid heating and automatic height adaption for 96 x 0.2 ml tubes, 96 well PCR plates

or 48 x 0.5 ml tubes with flat caps.

peqSTAR 96X HPL/96X HPL Gradient:

96 well block with High Pressure lid (HPL, 100 – 250 N) for the safe sealing of 96 well PCR plates

peqSTAR 384X HPL:

384 well block with High Pressure lid (HPL, 100 – 250 N) for the safe sealing of 384 Well PCR plates

peqSTAR In situ X:

In situ block with integrated buffer reservoir, for up to 4 microscope slides

D PEQLAB Biotechnologie GmbH, 91052 Erlangen, Freecall (D): 0800 100 20 16, info@peqlab.de, www.peqlab.de

AT PEQLAB Biotechnologie GmbH, 6404 Polling, Tel: +43 (0) 5238 84 169, info@peqlab.at, www.peqlab.at

UK PEQLAB Ltd., Southampton SO31 7ZN, Freephone (UK): 0808 202 1302, info@peqlab.co.uk, www.peqlab.co.uk

USA PEQLAB LLC, Wilmington, DE 19810, Toll-Free (US): 877 737 5220, info@peqlab.us, www.peqlab.us

Creating the future together

. Creating the future together

.

Loading...

Loading...