Page 1

FACTORY AUTOMATION

MANUAL

WRM-F301-IO-B15-2V15

SmartBridge Interface

Page 2

WRM-F301-IO-B15-2V15

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

WRM-F301-IO-B15-2V15

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 5

2 Product Description ................................................................... 6

2.1 Use and Application............................................................................. 6

2.2 Application Types and Benefits .......................................................... 7

2.3 The Function of the SmartBridge Interface ....................................... 7

2.4 The Function and Structure of the SmartBridge App ....................... 9

2.5 LED Indicators and Operating Elements ......................................... 15

2.6 Interfaces and Connections.............................................................. 16

2.7 Delivery Scope and Accessories...................................................... 17

3 Installation................................................................................. 18

3.1 Installing the SmartBridge Interface ................................................ 18

3.2 Installing the SmartBridge App ........................................................ 19

3.3 Data Logging—Preparation and Activation ..................................... 20

4 Commissioning......................................................................... 22

4.1 Commissioning the SmartBridge® System..................................... 22

3

Page 4

WRM-F301-IO-B15-2V15

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dism ounting

■

Disposal

Note!

For full information on the product, refer to the further documentation on the Internet at

www.pepperl-fuchs.com.

The documentation comprises the following parts:

■

This document

■

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

■

EU-type examination certificate

■

EU declaration of conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Instruction manual

■

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the produ ct make yourself familiar with it. Read the document carefully.

2019-04

4

Page 5

WRM-F301-IO-B15-2V15

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property dam age.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2019-04

5

Page 6

WRM-F301-IO-B15-2V15

Bluetooth

1

2

3

4

Product Description

2 Product Description

2.1 Use and Application

Intended Use

The SmartBridge interface is mainly used to quickly and conveniently capture information on

individual IO-Link devices via the IO-Link protocol, parameterize these devices, or detect their

operating states. This is possible in the machine control without complicated program ming or

implementations. From the perspective of the machine control, this data is accessed

completely without reaction. The SmartBridge interface can be used as both an active (master

mode) and a passive communication interface (monitor mode).

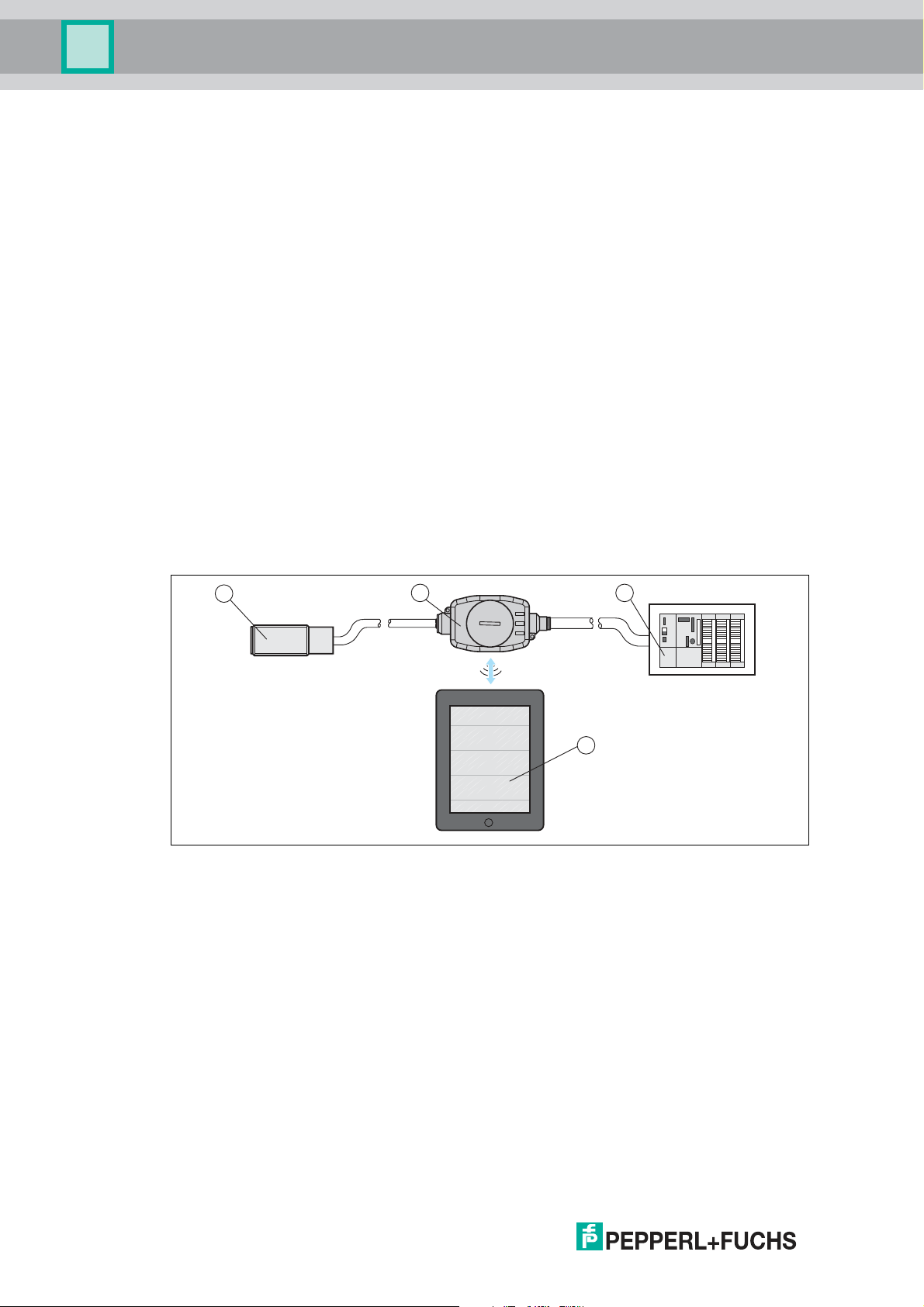

SmartBridge® System

The SmartBridge® system involves accessing sensor and actuator data in the field level of

automation technology on the basis of the IO-Link protocol. It serves as a simple operating and

display system for IO-Link devices (sensors and actuators), in which the data is read using the

SmartBridge interface and visualized in the SmartBridge app.

The SmartBridge system consists of the SmartBridge interface (hardware) and the

SmartBridge app (software) for mobile devices. The SmartBridge interface is placed between

an IO-Link-capable industrial sensor or actuator (IO-Link device) and the machine control unit

(PLC) in the connection line. The SmartBridge interface taps the IO-Link signal and transfers it

to a tablet or sm artphone via Bluetooth. The installed SmartBridge app visualizes the device

data.

Figure 2.1

1 Ultrasonic sensor UC500

2 SmartBridge interface

3 Machine control, e.g., PLC

4 Mobile device such as a tablet with the SmartBridge a pp

IO-Link devices, such as the Pepperl+Fuchs ultrasonic sensor UC500 shown in the figure,

provide a variety of process and device data (e.g., distance values, sound cone width,

switching delay, device name, etc.). This data can be read and modified using the SmartBridge

system.

2019-04

6

Page 7

WRM-F301-IO-B15-2V15

Product Description

2.2 Application Types and Benefits

For the following application types, the SmartBridge® system provides a valuable advantage:

Clearer Application Parameterization of IO-Link Devices

Intelligent sensors and actuators often have many functions w ith w idely differing parameters.

With the SmartBridge app, it is very simple to display and modify functions and the associated

parameters.

Easier Commissioning of Machines and Plants

When commissioning machines and plants, it is often the case that not all of the required

control functions are implemented. In this situation, the SmartBridge system will indicate

whether the parameters of the sensors and actuators are set correctly, and whether all of the

data is transferred in full.

Easier Troubleshooting in the Event of Repair or Maintenance

Troubleshooting is often a time-consuming task, especially if faults occur only sporadically. In

such a case, it is helpful to log the actual function for a certain period of time, and then

subsequently evaluate the data on a PC.

Continuous Status Monitoring of IO-Link Devices

Some sensors or actuators are located at critical points in a machine or plant. Here, repeated

deviations from the intended function can develop for a variety of reasons, such as mechanical

wear, electrical faults, or climatic changes. In situations like this, continuous monitoring of the

limit values or notification thresholds may be required. The SmartBridge system is also

designed for permanent use in a machine or system and therefore offers easy visual monitoring

of critical operation and status data.

2.3 The Function of the SmartBridge Interface

Overview

The SmartBridge interface can be used in the connection line between the IO-Link device and

machine control, or it can be used autonomously with one IO-Link device only. For autonomous

use, an external power supply via a 24 V power supply unit or battery is required.

The SmartBridge interface features the operating modes m aster mode and monitor mode,

which are designed for different application types. In monitor mode, the SmartBridge interface

is a passive communication component. In master mode, it serves as an active component. In

terms of the machine control, data is accessed via the SmartBridge interface without any

reaction.

While monitor mode is suitable for recording data in an existing IO-Link connection, master

mode also enables the active modification of device parameters.

Depending on the selected operating mode, the SmartBridge® system can be used for the

following tasks:

Monitor mode

■

Displaying and recording process data

Master mode

■

Displaying process and status data

■

Displaying and modifying parameter data

■

Recording process and status data

2019-04

7

Page 8

WRM-F301-IO-B15-2V15

IO-Link

Device

L +

L Q3

Q2

Q1

1

3

5

2

4

24 V DC

L+

L-

1

3

4 C/Q

4 C/Q

Bluetooth

PLC

IO-Link

Device

L +

L Q3

Q2

1

3

1

3

5

2

4

Q1

4 C/Q4 C/Q

I/O

D I/O

Bluetooth

Product Description

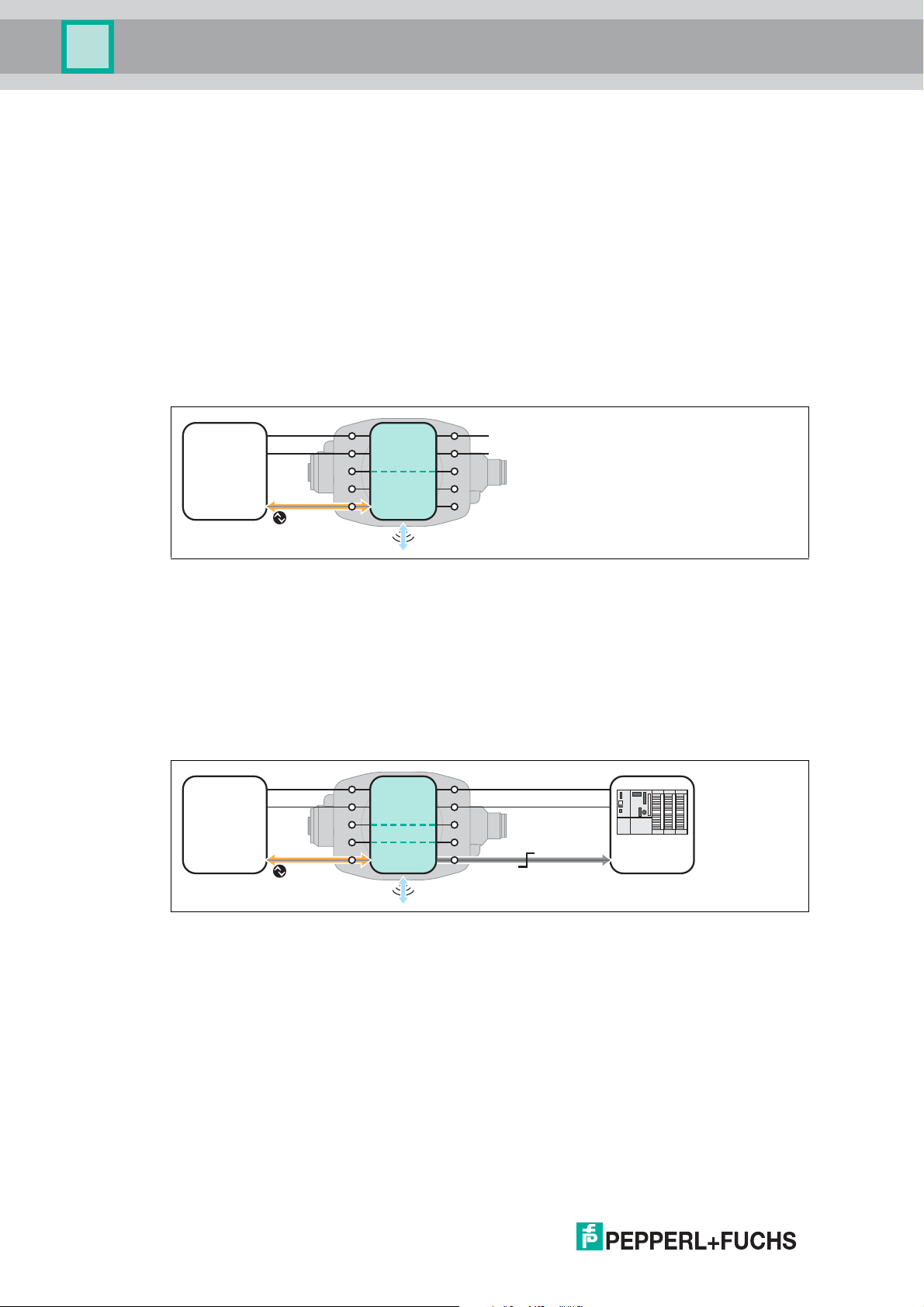

Master Mode

In master mode, the SmartBridge interface actively communicates with the connected IO-Link

device. This mode should be selected only if no additional IO-Link master module is connected

on the control side.

Depending on the type of connection, 3 application types can be identified in master mode:

■

Master Offline

This is the default function. In this case, 1 power supply only is connected on the

connection side of the SmartBridge interface directed toward the machine control. Any

signal lines belonging to the IO -Link device and SmartBridge interface remain

unconnected. The 24 VDC power supply can be supplied using either a power supply unit

or batteries. The respective connection method must be equipped with an M12 industrial

socket. Application scenarios for "offline" are pre-parameterization, function diagnostics,

and the commissioning of an IO -Link device.

Figure 2.2 Connection for "Master Offlin e"

■

Master Inline 3-pin

In this case, the SmartBridge interface is integrated into the supply line to a machine

control (PLC). For the IO-Link device, the interface serves as an IO-Link master. For the

control system, it emulates the binary standard input and output signal (SIO switching

signal) of the IO-Link device. Due to the emulation of the process data, this can lead to

delays in transferring process values. Application scenarios for "Inline 3-pin" consist of

diagnostics and parameterization of the IO-Link device within its machine or plant

application and the additional transmission of binary process data.

Figure 2.3 Connection for "Master Inline 3-pin"

8

2019-04

Page 9

WRM-F301-IO-B15-2V15

PLC

IO-Link

Device

L +

L -

1

3

4 C/Q Q2

I/O

1

3

5

22

4

Q2

Q1

Q3

4 C/Q

Bluetooth

PLC

IO-Link

Master

IO-Link

Device

1

3

4 C/Q

1

3

5

2

4

24 V DC

L+

L-

L +

L -

Q2

Q1

Q3

Bluetooth

Product Description

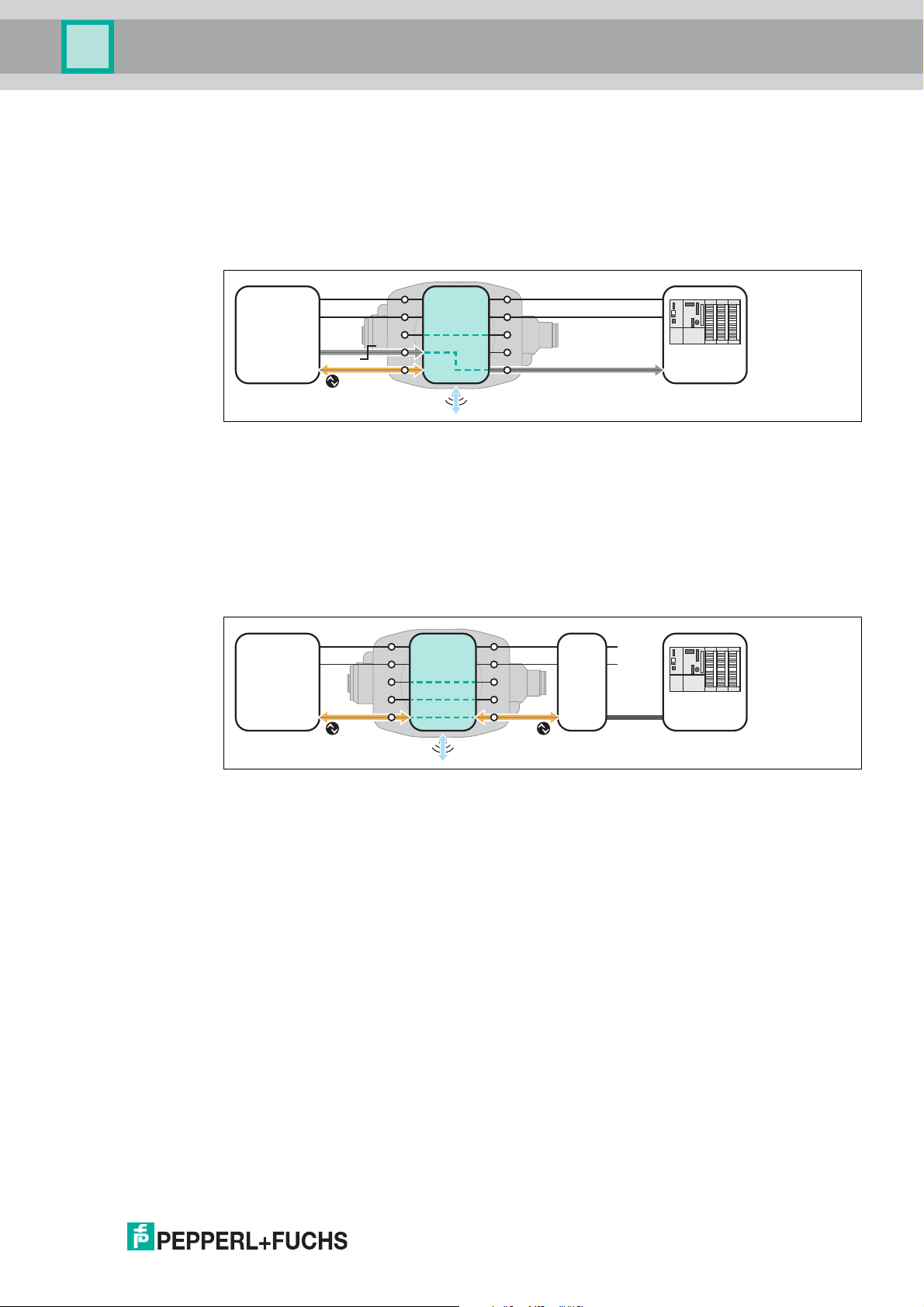

■

Master Inline 4/5-pin

In this case, the use of the SmartBridge interface is enabled without a time lag in the

process data on the machine control. In this "special case," signal line Q2 (pin 2, input) is

diverted without modification to Q 1 in the SmartBridge interface, and then connected to

the control system. Application scenarios for "Inline 4/5-pin" consist of diagnostics and

param eterization of the IO-Link device within its application in the time-sensitive

processing of process data.

Figure 2.4 Connection for "Master Inline 4/5-pin"

Monitor Mode

■

Monitor

In this mode, the SmartBridge interface behaves passively. It logs the IO-Link communication

(line C/Q) between the IO-Link device and an IO -Link-compatible control system or an

intermediate IO-Link master module. In this operating mode, the contents of the data log are

displayed in the SmartBridge® app. Alternatively, these contents can also be written onto the

internal microSD card with a time stamp.

Figure 2.5 Connection for "Monitor"

Application scenarios for monitor mode are:

■

Logging the status of the IO-Link device

■

Visualizing local process data using the SmartBridge® app

■

Analyzing faults in the IO-Link communication

2.4 The Function and Structure of the SmartBridge App

Function

To make sure that the process, status, and diagnostic data of an IO-Link device connected to a

Smar tBridge interface can be processed by the SmartBridge app, the appropriate drivers are

required. After the successful registration of the SmartBridge interface in the SmartBridge app,

the interface transmits the "Vendor ID" (=ma nufacturer) and the "Device ID" (=device type) of

the connected IO-Link device to the app. Using this information, the app automatically loads

the appropriate IODD (IO-Link Device Description) for the IO-Link device and, if available, the

relevant GDD (Graphical Device Description) from a central data server. This requires the

mobile device to have an Internet connection, at least during the initial com missioning of a new

2019-04

9

Page 10

WRM-F301-IO-B15-2V15

Device Discovery

Graphical View IODD View SmartBridge Settings App Settings

Product Description

IO-Link device. The GDD is responsible for the graphical representation of process data in the

form of scales, graphs, etc., as well as buttons for param eterization. If no GDD exists for a

particular sensor, a default GDD is displayed. The default GDD contains an image of the

connected device and information about the "Vendor Name," "Product N ame," and "Product

ID."

Structure of the SmartBridge App

The SmartBridge app consists of the menus shown below.

Figure 2.6

Depending on the user role and application type, the SmartBridge app provides different

information, parameterization, and diagnostic options for the connected IO-Link device. The

main functions of the 4 menus are introduced in the following section.

"Device Discovery" Menu

This menu is shown directly after the app starts.

Figure 2.7

The main functions of the m enu are:

■

Establishing a connection to the SmartBridge interface and a connected IO-Link device

■

Authenticating the SmartBridge interface in the SmartBridge app via an intermediate

dialog.

10

2019-04

Page 11

WRM-F301-IO-B15-2V15

Product Description

"Graphical View" Menu

Figure 2.8

If a GDD is available for the connected IO-Link device, the app will switch to the Graphical

View m enu right after the connection has been successfully established. If no GDD is

available, a default GDD is displayed. The default GDD contains an image of the connected

device and information about the "Vendor Name," "Product Name," and "Product ID."

The Graphical View menu graphically visualizes the IO-Link device's process data.

2019-04

11

Page 12

WRM-F301-IO-B15-2V15

1

2

1

2

Product Description

"IODD View" Menu

Figure 2.9 IODD View using the example of distance sens or OMT550-R 200-2EP-IO-V31

1 Line-by-line representation of information, functions, and device parameters in the re-

spective menu

2 Menu structure of the IODD View

You can use this menu to perform the following operations for the connected IO-Link device:

■

Display process data in text form,

■

Set the device parameters,

■

Retrieve diagnosis information.

Adjusting the Device Parameters in IODD View

12

Figure 2.10

1. Go to the device parameter settings in the "Parameter" menu (1).

Additional menus relating to parameters or parameter groups will be displayed

depending on the device.

2. Press the required value field for the parameter and change the setting or the numerical

value. Confirm the changes by pressing the check mark (2) so that the data can be

transferred to the device. After changing several parameters in a pa rticular menu, you can

also confirm all of your changes in a single step.

2019-04

Page 13

WRM-F301-IO-B15-2V15

Product Description

"SmartBridge Settings" Menu

This menu provides information about system data and settings for the SmartBridge interface.

Figure 2.11

Information

■

Displays the serial number and designation of the SmartBridge interface.

■

Displays the firmware version of the IO-Link processor and system processor.

Configuration Options

■

Location Mode: Pressing this button causes the LEDs to flash briefly so that the relevant

SmartBridge can be visually identified among a number of devices.

■

Local Nam e: Displays and offers the option to change the name of the SmartBridge

interface.

■

Interface Time: Indicates the time set on the SmartBridge and offers the option to

synchronize it with the time set on the mobile device (e.g., for evaluation of a log file).

■

Startup Mode (setting the application):

• Monitor in monitor operating mode

• Master Offline in master operating mode

• Master Inline 3-pin in master operating mode

• Master Inline 4/5-pin in master operating mode

2019-04

13

Page 14

WRM-F301-IO-B15-2V15

Product Description

"App Settings" Menu

This menu is used to adjust various settings within the SmartBridge® app.

Figure 2.12

Caution!

Resetting to factory settings clears data!

Please note that if you reset the SmartBridge app, all stored IODDs and GDDs belonging to

previously connected IO-Link devices will be deleted. This data can be reloaded if you connect

the relevant IO-Link device to the SmartBridge interface and connect to the SmartBridge app.

The prerequisite for this is a working Internet connection. Before resetting the SmartBridge

App, consider whether you can ensure that the conditions for reloading IODDs and GDDs are

met.

Configuration Options

■

Device Descriptor Index: Displays the time stamp of the locally available device catalog.

Pressing UPDATE updates the device catalog

■

Reset App Settings / Cache: Reset app settings to the factory settings

■

Reset GDD Cache: Clear the GDD cache

■

Demo Mode: Enable/disable demo mode

■

GDD Tester: Test page with GDD elements. For developing GDDs

■

Load custom IODD/GDD: Manually integrate an IODD/GDD

Information

■

Terms of use

14

■

Privacy policy

■

Imprint

■

Licenses

2019-04

Page 15

WRM-F301-IO-B15-2V15

SmartBridge

Connect

Mode

Power

Product Description

2.5 LED Indicators and Operating Elements

LED Indicators

The SmartBridge interface is equipped with 3 indicator LEDs for carrying out visual function

checks and rapid diagnostics. The "Connect" LED has 1 color (blue), while the "Mode"

(yellow/green) and "Power" (green/red) LEDs have 2 colors.

Figure 2.13

LED Operating mode Color Status Function

Connect Blue On Establishing a connection

Blue Flashing Transferring data

Power - Off No supply voltage available

Green On N ormal operation

Green Flashing Low voltage at L+

Red On Overload at C/Q

Red Flashing System error

Mode Monitor mode Yellow On Synchronization with IO-Link

device. Communication between

master and device.

Monitor mode Yellow Flashing Synchronization and data logging

active

Monitor mode Yellow/greenFlashing

alternately

Master mode Green On Communication with IO-Link

Master mode Green Flashing SmartBridge interface active, but

Table 2.1

SmartBridge interface active, but

no connection to the IO-Link

device

device

no connection to the IO-Link

device

2019-04

15

Page 16

WRM-F301-IO-B15-2V15

Connect

Powe

r

M

o

de

2

1

Connect

Power

Mode

2

3

1

Product Description

Operating Elements

The SmartBridge interface is mainly operated via the SmartBridge app. The only operating

element is the reset button. This is only accessible after opening the cover.

Figure 2.14

1. Open the cover (1) of the interface using a suitable tool (e.g., a coin) by turning it counterclockwise.

2. Remove the cover (1).

3. Press the reset button (2) with a pointed object such as a ballpoint pen refill.

The SmartBridge interface per forms a restart.

4. Place the cover (1) back in the opening and secure by turning it clockwise.

2.6 Interfaces and Connections

Interfaces

A separate microSD card (not included in the scope of delivery) is required for data logging.

The microSD card must be inserted into the intended SD card slot (2).

If you wish to transfer the data saved on the microSD card to a PC, you can choose between 2

options:

■

You can remove the microSD card and read in the data on the PC using an SD card

reader.

■

Alternatively, you can leave the microSD card inserted and connect a USB 2.0 cable with

micro USB plug to the SmartBridge interface (3).

Note: A USB 2.0 cable with micro USB plug is not included in the scope of delivery!

The Bluetooth connection to the mobile device is interrupted during data transfer via USB.

16

Figure 2.15

2019-04

Page 17

WRM-F301-IO-B15-2V15

1

4

Ub+

C/Q

3

0 V

2

5

1

4

3

IO-Link

2

5

1

3

4

5

2

1

5

3

2

4

21

Product Description

1 Cover

2 microSD card slot

3 USB 2.0 micro-B socket

Connections

Figure 2.16

1 M12x1 connector plug, 5-pin, connection to the machine control/external 24 VDC power

supply

2 M12x1 socket, 5-pin, connection for IO-Link device

2.7 Delivery Scope and Accessories

Scope of Delivery

The SmartBridge interface is supplied with a mounting bracket and a Quick Start Guide.

The desired mobile device app can be downloaded from the respective app store:

■

Android devices: Google Play Store

■

Apple devices: Apple App Store

Optional Accessories

Designation Description

V15-G-1M-PUR-V15-G M12 to M12 connection cable, 5-pin PUR cable, to connect the

IO-Link device to the SmartBridge module

MEMORYCARD MICRO

SD 2GB

MicroSD card with 2 GB storage capacity

2019-04

17

Page 18

WRM-F301-IO-B15-2V15

IO-Link

Device

L +

L Q3

Q2

Q1

1

3

5

2

4

24 V DC

L+

L-

1

3

4 C/Q

4 C/Q

Bluetooth

PLC

IO-Link

Device

L +

L Q3

Q2

1

3

1

3

5

2

4

Q1

4 C/Q4 C/Q

I/O

D I/O

Bluetooth

Installation

3 Installation

3.1 Installing the SmartBridge Interface

Mounting

If you wish to use the SmartBridge interface in a stationary position for longer periods, we

would recommend the use of the supplied mounting clamp.

The mounting clamp has two 4.5 mm holes to mount the interface using screws.

1. Drill 2 corresponding holes to secure the SmartBridge interface.

2. Push the m ounting clamp onto the SmartBridge interface.

3. Attach the SmartBridge interface in the desired location using screws. The interface is

clamped by tightening the screws.

Electrical Connection

Depending on the operating mode and the application, there are different connection types for

the Smar tBridge interface.

Master mode is split between the following applications:

■

Offline

Figure 3.1 Connection when "offline" in ma ster mode

In the "offline" application, an external 24 VDC voltage supply is required for the SmartBridge

interface via a power supply unit or battery/batteries.

■

Inline 3-pin

18

Figure 3.2 Connection for "inline 3-pin"

2019-04

Page 19

WRM-F301-IO-B15-2V15

PLC

IO-Link

Device

L +

L -

1

3

4 C/Q Q2

I/O

1

3

5

22

4

Q2

Q1

Q3

4 C/Q

Bluetooth

PLC

IO-Link

Master

IO-Link

Device

1

3

4 C/Q

1

3

5

2

4

24 V DC

L+

L-

L +

L -

Q2

Q1

Q3

Bluetooth

Installation

■

Inline 4/5-pin

Figure 3.3 Connection for "inline 4/5-pin"

Monitor mode has the following connection:

■

Monitor

Figure 3.4 Connection for "Monitor"

Note!

Use the machine control to ensure the correct wiring. The SmartBridge interface is ready for

operation as soon as it is connected to the 24 VDC supply voltage.

1. Fam iliarize yourself with the desired operating mode and application.

2. Connect the IO-Link device to the SmartBridge interface via a connecting cable (M12

connector). Note that a 3-pin, 4-pin, or 5-pin cable must be connected, depending on the

application.

3. Using a 2nd cordset, connect the SmartBridge interface (M12 connector) to the machine

control unit (PLC), an IO-Link master, or an external 24 VDC power supply.

3.2 Installing the SmartBridge App

System requirements

The SmartBridge® app is available in the respective app store (Apple App Store; Google Play).

You can install it on mobile devices such as smartphones and tablets that support "Bluetooth

LE" (low energy) or "Bluetooth 4.0" and use the iOS (from version 10) or Android (from version

6.0) operating systems.

Note!

An Internet connection is required to load the SmartBridge app during installation and to load

additional driver files for the initial commissioning of a new IO-Link device.

2019-04

19

Page 20

WRM-F301-IO-B15-2V15

Installation

Downloading the SmartBridge App

1. Go to the relevant app store.

2. Search for the "SmartBridge – Sensor Technology 4.0" app by Pepperl+Fuchs GmbH

Figure 3.5 App icon for SmartBridge

3. Follow the instructions to download and install the SmartBridge app.

Note!

Required driver files for IO-Link devices (IO DD: IO Device Description; GDD: Graphical Device

Description) are provided by the respective IO-Link device manufacturer. The SmartBridge®

app identifies a connected IO-Link device during commissioning and downloads the

associated driver file from the Internet. A functioning Internet connection is required for this.

Testing for Successful Installation

Open the SmartBridge® app on your mobile device by clicking on the SmartBridge icon.

Figure 3.6 App icon for SmartBridge

The "Device Discovery" menu is displayed if the app is installed correctly.

3.3 Data logging—Preparation and Activation

Prerequisites

The data logging function can only be used in the "Monitor" startup mode. A separate microSD

card (not included in the scope of deliver y) is required for this function. The microSD card must

be inserted into the designated SD card slot.

If you wish to transfer the data saved on the microSD card to a PC, you will need to use a USB

2.0 cable with a micro USB plug (3). If necessary, you can do this repeatedly when operating

the Smar tBridge interface.

Activation

20

If the SmartBridge is already active and the IO-Link device is excluded, recording of the IO-Link

communication begins as soon as an SD card is inserted into the designated slot. It is

recommended to insert the SD card first and then to switch on the SmartBridge. Completing

the steps in this order ensures that all comm unication data can be recorded.

Note!

The Bluetooth connection is disabled during a data connection via USB.

2019-04

Page 21

WRM-F301-IO-B15-2V15

Connect

Power

Mode

2

3

1

Installation

Figure 3.7

1. Open the cover (1) of the interface using a suitable tool (e.g., a coin) by turning it counterclockwise.

2. Remove the cover (1).

3. Insert the microSD card into the slot (2).

4. Place the cover (1) back in the opening and secure by turning it clockwise.

2019-04

21

Page 22

WRM-F301-IO-B15-2V15

Commissioning

4 Commissioning

4.1 Commissioning the SmartBridge® System

Note!

The process outlined below applies both to the initial commissioning of the SmartBridge

system and to recommissioning. Once the drivers for an IO-Link device have been downloaded

via the SmartBridge app, they are stored in a library on the mobile device. In this way,

recommissioning is possible with a previously known IO-Link device, even without an Internet

connection (e.g., when operating in areas/plants without an Internet connection).

Prerequisites

■

The SmartBridge interface and the IO-Link device are connected.

■

The SmartBridge interface is connected to a machine control or an external 24 VDC

voltage supply, depending on the application selected.

■

On the mobile device:

• The SmartBridge app is installed,

• The Bluetooth interface is activated,

• Access to the SmartBridge app location is permitted (positioning service is

enabled),

• An Internet connection is available.

Important: During initial com missioning and when connecting a previously

unregistered IO-Link device (driver download).

■

A microSD card (not included in the scope of delivery) is needed to change the interface

name and device key.

Activating the SmartBridge System

1. Start the SmartBridge app on the mobile device.

Figure 4.1

The mobile device displays the Device Discovery start menu and detects the

SmartBridge interfaces present within the detection range. All SmartBridge interfaces found

are then listed under "Devices in range."

22

2019-04

Page 23

WRM-F301-IO-B15-2V15

Commissioning

2. Press the button for the (desired) SmartBridge®.

The authentication dialog starts.

SmartBridge® Authentication

When establishing a connection between the mobile device and the SmartBridge interface, an

authentication process first takes place between the communication partners. For this, each

Smar tBridge interface has a unique device key. The device key is located on the back of the

Smar tBridge interface in the form of a QR code and as text with the name "Key." After the initial

connection, the SmartBridge app remembers the device key. The user does not need to enter it

again, but must simply confirm it to establish the connection.

1. From the menu, select the SmartBridge interface you would like to use and follow any further

instructions.

On delivery, the interface name is "SB_PF." The user can change this. To do so at a later

point, go to "SmartBridge Settings" and "Local Name."

2. Share the device key to the mobile device:

Either by typing in the key

or

by reading in the Q R code using the mobile device's camera. Tap the Scan Code button

when using the camera.

Figu re 4.2

2019-04

23

Page 24

WRM-F301-IO-B15-2V15

Commissioning

Figure 4.3

3. Select "SPECIALIST" as the user role to be able to use the entire range of programming

features.

4. The rights of each user role are defined in detail in the respective IODD. The "SPECIALIST"

role has the most privileges. Users with the "OBSERVER" role are restricted to read only

access to the data.

The SmartBridge® app automatically loads the driver files for the connected IO-Link

device from the default server. The drivers are loaded from the librar y if the connected

device type has already been connected to the SmartBridge® app.

If an associated GDD is loaded for the IO-Link device, the app will switch straight to the

Graphical View m enu. If no GDD is available, a default GDD is displayed. This contains

both an image of the connected device and information about the "Vendor Name," "Product

Name," and "Product ID." In this scenario, you will need to switch to IODD View to change

the parameters.

24

2019-04

Page 25

WRM-F301-IO-B15-2V15

Commissioning

Figu re 4.4

Note!

The respective manufacturer of the IO-Link devices is responsible for providing the driver files

(IODD, GDD). These files are stored in a central location online, to which the SmartBridge App

has access.

2019-04

25

Page 26

WRM-F301-IO-B15-2V15

Commissioning

Setting the Application

1. Set the desired application in the Startup Mode field.

Figure 4.5

■

Application setting:

• "Monitor" in monitor operating mode

• "Master Offline" in master operating mode

• "Master Inline 3-pin" in master operating mode

• "Master Inline 4/5-pin" in master operating mode

Changing the Interface Name and Device Key

Note!

If you only want to change the name of the interface, a simple way of doing this is to execute the

"Local Name" function in the "App Settings" menu (see chapter 2.4).

On delivery, the SmartBridge interface has the nam e "SB-PF" and a default device key (key,

QR code). You can change both to make your system more secure against access. The

interface name can be a maximum of 8 characters. The device key can be a maximum of 64

characters and consists of individual HEX numbers in the range of 0 – F. The interface name

and device key are changed using a microSD card. An INI file that has been created with a

simple text editor such as Notepad must be stored on this card.

1. Open a suitable editor such as Microsoft® Windows® Notepad.

2. Enter the desired data in the editor as follows:

ο LocalNam eString="max. 8 characters" then press the RETURN key

ο AuthKeyHex="max. 64 characters" in HEX code" then press the RETURN key

26

By pressing the RETURN key, each line is concluded with a line feed (CR/LF). This line feed

is absolutely necessary.

2019-04

Page 27

WRM-F301-IO-B15-2V15

Connect

P

ower

Mode

2

3

1

Commissioning

3. First, save the file under the name "ConfSBA.ini" on your PC.

Below is an example with the interface name "SBridge1" and the new device key "1A4F."

Figu re 4.6

4. Copy the file "ConfSBA.ini" from the PC to the microSD card.

Figu re 4.7

5. Open the cover (1) of the interface using a suitable tool (e.g., a coin) by turning it

counterclockwise.

6. Remove the cover (1).

7. Insert the microSD card into the slot (3).

8. Press the reset button (2) with a pointed object such as a ballpoint pen refill.

The SmartBridge interface performs a restart.

9. Press the reset button (2) again after approx. 5 s.

The SmartBridge interface performs an additional restart and adopts the new settings for

the interface name and the device key.

10.Remove the microSD card again or leave it inserted.

Important: If the microSD card is inserted, it is read again following a restart of the

SmartBridge interface, and the data in the INI file will be processed.

11.Place the cover (1) back in the opening and secure by turning it clockwise.

2019-04

27

Page 28

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

/ DOCT-5055A

04/2019

Loading...

Loading...