Page 1

FACTORY AUTOMATION

MANUAL

WCS-PG310

WCS PROFIBUS DP

Interface Module

Page 2

WCS-PG310

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

WCS-PG310

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 4

2 Product Description ................................................................... 6

2.1 Use and Application............................................................................. 6

2.2 Dimensions........................................................................................... 6

2.3 Design of the Device............................................................................ 7

3 Installation................................................................................. 10

3.1 Mounting ............................................................................................. 10

3.2 Electrical Connection ........................................................................ 11

3.3 Dismounting ....................................................................................... 14

4 Commissioning......................................................................... 15

4.1 Introduction ........................................................................................ 15

4.2 Connecting the WCS Reader ............................................................ 16

4.3 Connecting the WCS-PG310 to the Network ................................... 16

4.4 Integrating WCS-PG310 into the PROFIBUS System...................... 17

4.5 Data Format for Modules ................................................................... 23

5 Appendix ................................................................................... 25

5.1 Cable Routing in the RS-485 Bus ..................................................... 25

5.2 Data Cables and Accessories ........................................................... 28

3

Page 4

WCS-PG310

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dism ounting

■

Disposal

Note!

Visit www.pepperl-fuchs.com to access further documentation for full information about the

product.

The documentation comprises the following parts:

■

This document

■

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

■

EU-type examination certificate

■

EU declaration of conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Instruction manual

■

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

2018-03

4

Page 5

WCS-PG310

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you obser ve these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prom pted to perform an action or

a sequence of actions.

2018-03

5

Page 6

WCS-PG310

117

100

23

Product Description

2 Product Description

2.1 Use and Application

The WCS-PG 310 acts as an interface between the WCS reader and the PROFIBUS DP input

card of the control panel. The data is transferred between the WCS reader(s) and the WCSPG310 via the RS-485 interface, and from the WCS-PG310 to the control panel via the

PROFIBUS DP protocol.

You can connect up to four WCS readers of type LS221 or LS121. If you connect several

readers, they m ust have different addresses. The WCS-PG310 interface module constantly

queries the position values of the readers and always has the current reader data. The update

cycle for a reader is approximately 1 ms.

The WCS-PG310 interface module has the following configuration:

Baud rate: Max. 12 MBaud (automatic detection)

Diagnostic data: Max. 8 bytes

Sync: Supported

Freeze Supported

ID no.: 0x2079

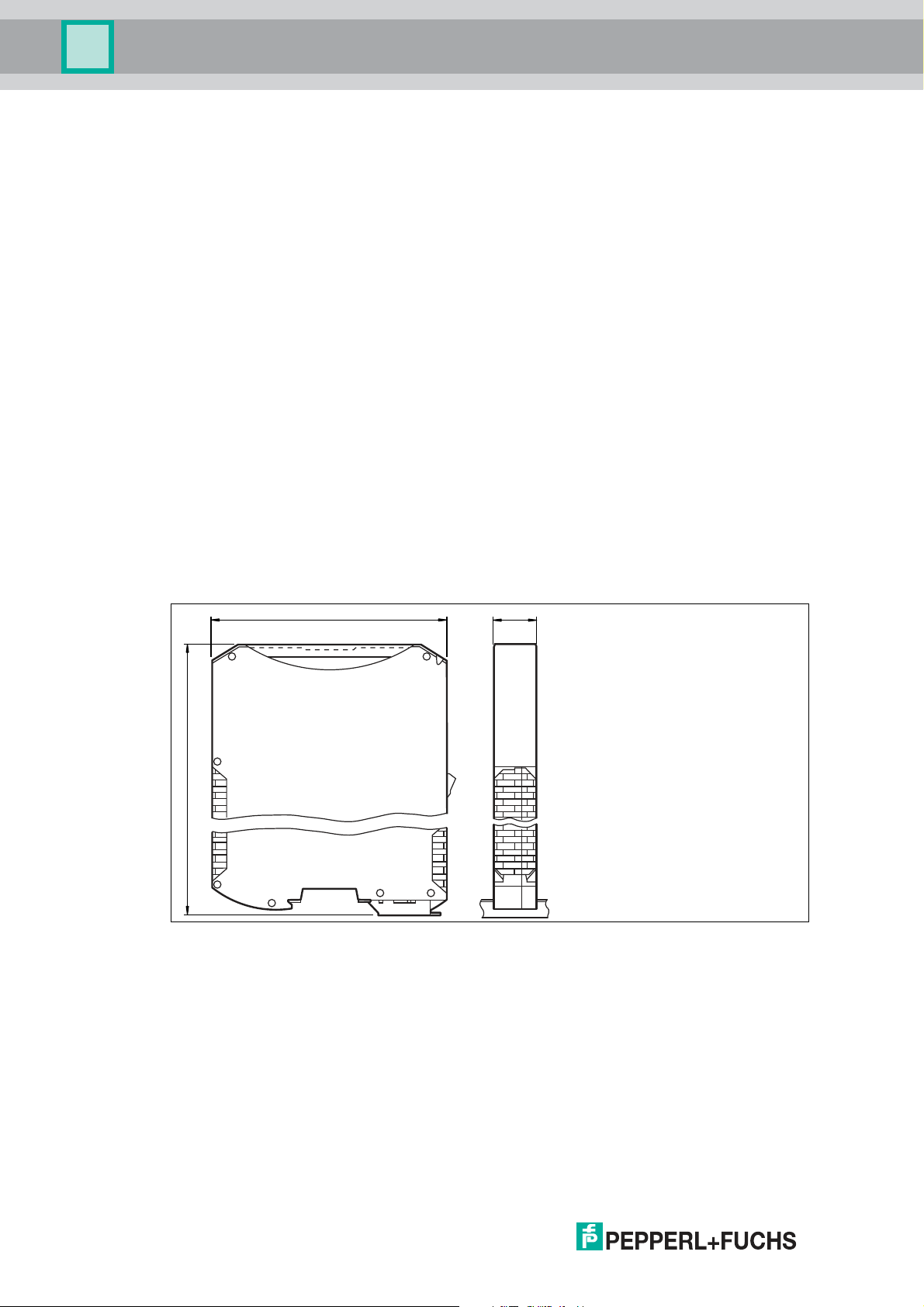

2.2 Dimensions

The interface module housing has the following dimensions.

Figure 2.1 Dimen sions

2018-03

6

Page 7

WCS-PG310

3

4

7

1

5

2

6

Product Description

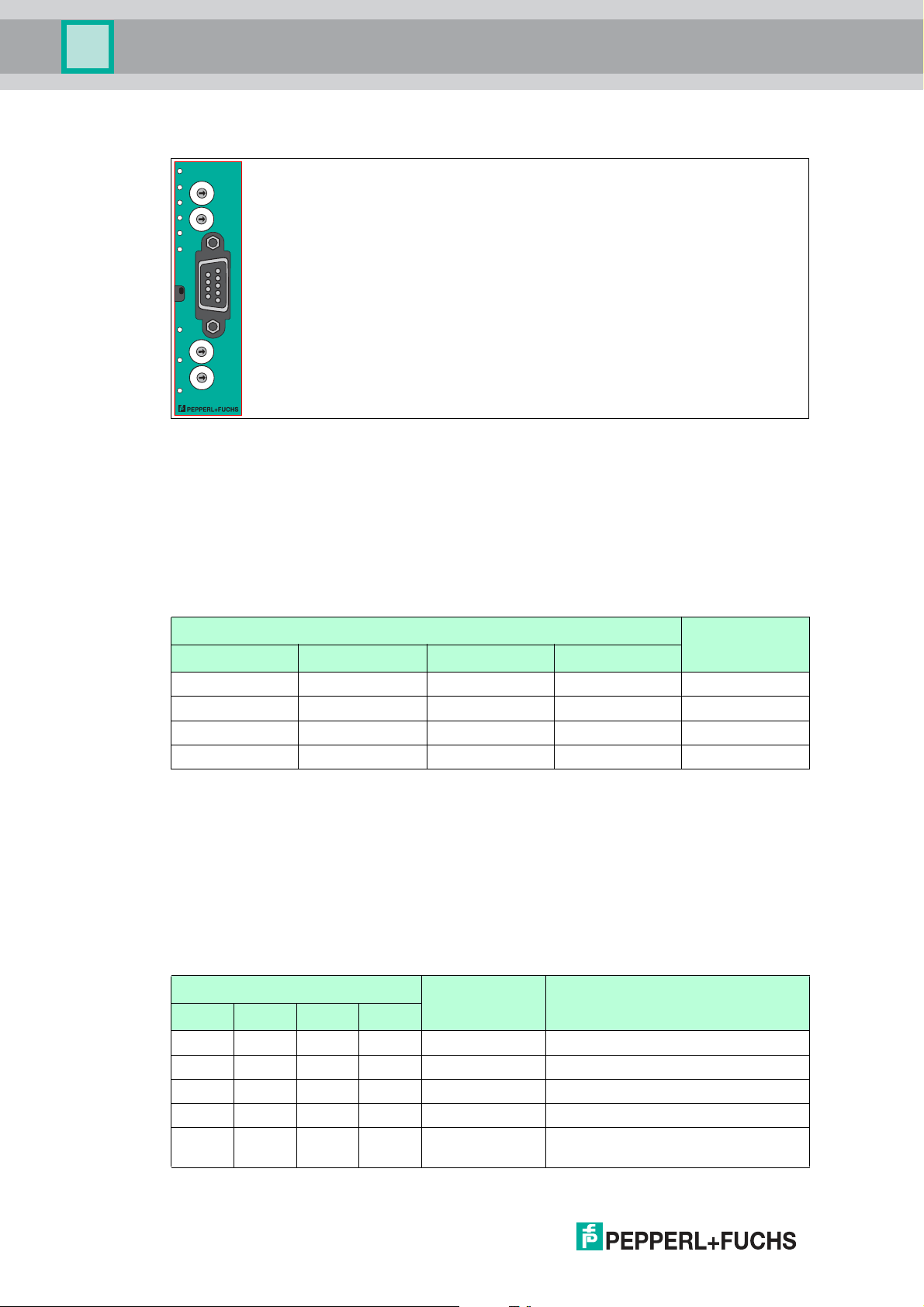

2.3 Design of the Device

Device components

Figure 2.2 Interface module overview

1 Slide switch for RS-485 terminator

2 X1: RS-485 interface

3 Mounting bracket

4 X2: Connection for power supply

5 PROFIBUS communication interface

6 Slide switch for PROFIBUS DP terminator

7 Front panel with rotary coding switches and indicator lights

2018-03

7

Page 8

WCS-PG310

PROFIBUS

Termination

Power/State

Bus

Power

1

2

4

8

S4

S5

State

Bus

State

Low

High

ID

Bus

o

n

o

f

f

WCS-PG310 Modul

A

B

C

D

0

1

2

3

4

5

6

7

8

9

A

B

C

D

0

1

2

3

4

5

6

7

8

9

A

B

C

D

0

1

2

3

4

5

6

7

8

9

A

B

C

D

0

1

2

3

4

5

6

7

8

9

Product Description

Front panel

Figure 2.3 Front panel overview

Power:

The "Power" LED is green: The WCS-PG310 interface module is correctly connected to the

power supply.

State:

The "State" LED is green: Data is being exchanged with the WCS readers. The four

"ErrorNo/Select ID" LEDs are used to display the number of the currently polled reader.

ErrorNo/Select ID Reader address

8 4 2 1

0 0 0 1 0

0 0 1 0 1

0 1 0 0 2

1 0 0 0 3

Table 2.1 Display via the four "ErrorNo/Select ID" LEDs when the "State" LED lights up green

The "State" LED is red: The interface module has detected an error or a warning. The interface

module uses the "ErrorNo/Select ID" LEDs to display the binary coded error number or warning

number, and sends the num ber to the PROFIBUS master via the external diagnostic byte.

Error (no. 1...5): Switch the interface module off and back on. If the error occurs

again, the module must be replaced.

Warning (no. 6...15): The warning provides information. The interface module displays

the warning for one m inute and then resets automatically.

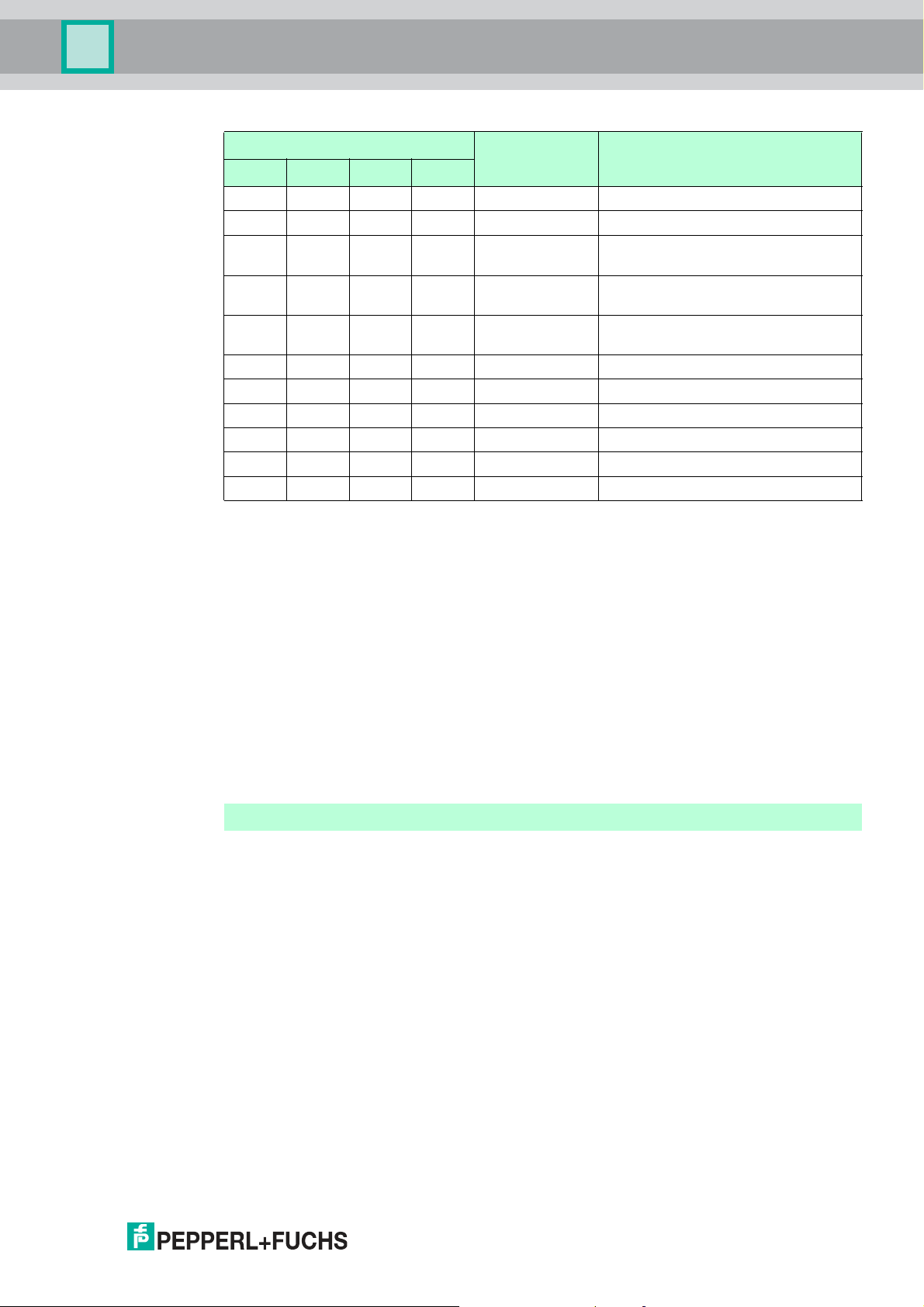

ErrorNo/Select ID LED Error number Error description

LED8 LED4 LED2 LED1

0 0 0 0 0 Reserved

0 0 0 1 1 Hardware error

0 0 1 0 2 EEPROM error

0 0 1 1 3 Internal memory error

0 1 0 0 4 Fieldbus hardware error or incorrect

8

fieldbus ID

2018-03

Page 9

WCS-PG310

Product Description

ErrorNo/Select ID LED Error number Error description

LED8 LED4 LED2 LED1

0 1 0 1 5 Script error

0 1 1 0 6 Reserved

0 1 1 1 7 WCS reader communication, RS

1 0 0 0 8 WCS reader communication, RS

1 0 0 1 9 WCS reader communication, RS

1 0 1 0 10 General fieldbus error

1 0 1 1 11 Parity error or frame check error

1 1 0 0 12 Reserved

1 1 0 1 13 Fieldbus configuration error

1 1 1 0 14 Fieldbus data buffer overflow

1 1 1 1 15 Reserved

Table 2.2 Meaning of the error codes (display via the four "Error No/S elect ID" LEDs when the "State"

send buffer overflow

receive buffer overflow

timeout

LED lights up red and thus indicates an error or a warning)

Rotary coding switches S4 and S5

The rotary switches S4 and S5 have no function. Ensure that the two switches are at position 0

to enable the data exchange mode.

Bus Power:

The "BusPower" LED is green: The LED is connected directly to the electrically isolated supply

voltage for the PROFIBUS side.

Bus:

The "Bus" LED is red: The interface module cannot exchange any data on the PROFIBUS.

Bus State:

“BusState" LED PROFIBUS DP interface state

Lights up green Data exchange on the PROFIBUS

Flashes red/green Interface module is waiting for PRO FIBUS parameter data

Lights up red Error on the PROFIBUS

Flashes green Interface module is waiting for configuration data

ID High and ID Low rotary coding switches

You can set the PROFIBUS address with the two ID High and ID Low rotary switches. The digits

selected via the two rotary switches together form the P ROFIBUS address in hexadecimal

format.

Example: To set the address 19 (= 13h), set the ID High rotary switch to position "1" and the ID

Low rotary switch to position "3."

2018-03

9

Page 10

WCS-PG310

2

1

Installation

3 Installation

3.1 Mounting

Mounting the modules

The module is fastened to a DIN mounting rail with a width of 35 mm using a snap-on fixing

method.

Figure 3.1 Mounting

1. Hook the module (1) into the DIN mounting rail (2) from above and press it down until it snaps

into place.

The module is mounted.

Note!

Heat dissipation

You may place other modules to the left and right of the module.

Above and below the modules, there must be at least 5 cm of free space for heat dissipation.

2. You must connect the DIN mounting rail to the sw itch cabinet's equipotential busbar. The

connection wire must have a cross section of at least 10 mm2.

Note!

Vertical installation

You can also install the DIN mounting rail vertically, so that the modules can be rotated by 90°

for mounting.

2018-03

10

Page 11

WCS-PG310

Reader

WCS-LS221

WCS-PG310

RS 485 -

RS 485 +

24 V (Pwr)

0 V (Pwr)

X2-1

X2-2

X1-4

X1-5

X1-6

X1-7

GND UB+

PE

PE

UB+

GND

RS 485 +

RS 485 -

B-LineB-Line

A-Line

Probus-DP

1

2

3

4

5

6

7

8

9

Installation

3.2 Electrical Connection

Danger!

Device damage due to incorrect installation

Faulty installation of cables and connection lines can endanger the function and the electrical

safety of the device.

■

Note the permissible core cross section of the conductor.

■

If you are using stranded conductors, crimp the stranded conductors with wire end

ferrules.

■

Make sure that the insulation on the conductors extends all the way to the term inal.

■

Observe the tightening torque for the screws on the terminal. The tightening torque is

0.5 Nm.

■

Using an inappropriate tool may damage the screw heads. Use a slot-head screwdriver of

size 3.5 x 0.5.

■

Connecting an alternating current can damage the device or cause the device to

malfunction. Connect the device to direct current (DC).

Figure 3.2 Electrical connection

Plug X1 is located on the top side of the interface module, and plug X2 is located on the

underside.

Connection technology

You must/may use the following connection technology when wiring the assembly:

■

Standard screw/plug connection (supply + RS)

■

9-pin, D-SUB connector (PROFIBUS DP connection)

When using standard screw terminals, one line per connection point can be clamped. To

tighten the screws, use a screwdriver with a blade width of 3.5 mm.

Permissible cable cross section:

■

Flexible cable with wire end ferrule: 1 x 0.25 ... 1.5 mm

■

Solid cable: 1 x 0.25 ... 1.5 mm

2

The plug-in terminal strip combines a standard screw connection and a plug connector. The

plug connector is coded and can therefore not be plugged in incorrectly.

The 9-pin D-SUB connector is secured with two screws with a "4-40 UNC" thread. To tighten

the screws, use a screwdriver with a blade width of 3.5 mm. Observe the maximum tightening

torque of 0.4 Nm.

2018-03

2

11

Page 12

WCS-PG310

Installation

Connecting the power supply

Connect the operating voltage (10 VDC...30 VDC ) to terminals 1 and 2 of the 4-pin plug X2 on

the interface module. In addition, note the label on the module.

The "Power" LED lights up green.

Terminal Description

1 UB (Pwr) Operating voltage for interface m odule/

2 0 V (Pwr) Ground for interface module/ground for

3 Not used Not used

4 Not used Not used

Table 3.1 Terminal X2

Equipotential bonding connection

The connection to equipotential bonding occurs automatically when attaching to the DIN

mounting rail.

operating voltage for WCS reader

WCS reader

PROFIBUS DP communication interface

This interface can be found on the front of the housing in the form of a 9-pin D-SUB socket.

1. Connect the PROFIBUS connector to the D-SUB socket labeled "PROFIBUS."

2. Tighten the lock screws on the connector using a screwdriver.

3. If the assembly is at the beginning or at the end of the PROFIBUS cable, you must connect

the term inator that is integrated in the interface module. To do this, slide the slide switch to

the "on" position or to the upper end position.

4. If the assembly is not at the beginning or at the end, you must slide the slide switch to the

"off" position or to the lower end position.

Preparing for operation on the RS-485 interface

For operation on an RS-485 interface, the terminals on connector X1 must be connected as

follows:

1. Connect terminal 4 "Rx 422+" to terminal 6 "Tx 422+."

2. Connect terminal 5 "Rx 422-" to terminal 7 "Tx 422-."

Terminal Description

4 Rx 422+ RS-485+ data line to WCS reader

5 Rx 422- RS-485- data line to WCS reader

6 Tx 422+ Connect terminal 6 "Tx 422+" to terminal 4 "Rx 422+"

7 Tx 422- Connect terminal 7 "Tx 422-" to terminal 5 "Rx 422-"

Table 3.2 Terminal X1

12

2018-03

Page 13

WCS-PG310

*) RS485-Termination:

Rx422 = o

Tx422 = on

1

2

3

4

5

6

7

Rx232

Tx232

AP-GND

Rx422+

Rx422-

Tx422+

Tx422-

RS485+

RS485-

Rx422* Termination Tx422*

On O On O

X1

PROFIBUS

Termination

Power/State

Bus

Power

1

2

4

8

S4

S5

State

Bus

State

Low

High

ID

Bus

o

n

o

f

f

WCS-PG310 Modul

A

B

C

D

0

1

2

3

4

5

6

7

8

9

A

B

C

D

0

1

2

3

4

5

6

7

8

9

A

B

C

D

0

1

2

3

4

5

6

7

8

9

A

B

C

D

0

1

2

3

4

5

6

7

8

9

Termination

o

n

o

f

f

Installation

Note!

RS-485 bus termination

2018-03

If the interface module is operated as the first or last physical device in an RS-485 bus, there

must be a bus term ination on this module. To do this, set the "Rx 422 Termination" slide switch

to "Off" and the "Tx 422 Termination" slide switch to "On." This activates the RS-485 terminator

(150 Ω) built into the interface module.

If you only connect one WCS reader to the interface module, you must always activate the RS485 terminator; see also Cable routing in the RS-485 bus.

Note!

PROFIBUS termination

If the interface module is located at the beginning or end of the data cable to the control panel,

there must be a bus termination at this interface module. To do this, set the "Termination"

(PROFIBUS) slide switch to "On." This activates the PROFIBUS terminator built into the

interface module.

More information about bus termination can be found in the general fieldbus literature.

13

Page 14

WCS-PG310

4

3

2

1

Installation

3.3 Dismounting

Dismounting the modules

Use a suitable slot-head screwdriver for dismounting the module.

1. Disconnect all the supply and signal lines.

Figure 3.3 Dismoun ting

2. Insert the screwdriver (2) into the groove of the mounting bracket (3).

3. Press the screwdriver (2) in the specified direction until the lock on the DIN mounting rail (4)

opens, see figure.

4. Then press the module (1) upwards and lift it out of the DIN mounting rail.

2018-03

14

Page 15

WCS-PG310

Commissioning

4 Commissioning

4.1 Introduction

Warning!

Danger to life due to defective work

Errors during installation and commissioning can cause life-threatening injuries and significant

property damage.

■

Installation and commissioning m ust only be carried out by trained personnel in

accordance with the safety regulations.

Components

To comm ission the module, you will require the following components:

■

WCS-PG310 interface module

■

Connection cable from the interface module to the reader

■

Connector for the PROFIBUS connection to the interface m odule

■

PROFIBUS cable (this cable is usually already installed on site)

■

10 VDC...33 VDC power supply

■

GSD file (the GSD file can be obtained free of charge from our website w ww.pepperlfuchs.com)

Connecting the interface module

To ensure that the assembly functions correctly, you must carry out the following steps during

commissioning:

1. Set the PROFIBUS address on the front side of the module, using the two rotary switches

labeled "PROFIBUS ID High" and "PROFIBUS ID Low."

Note!

The PROFIBUS address that is set must match the configured address. It is only read in when

the module is switched on.

2. Connect the module to PROFIBUS using the interface labeled "PROFIBUS."

3. Connect the process device (reader). For information on commissioning the process device

(reader), please refer to its manual.

4. Ground the DIN mounting rail onto which the assembly is snapped.

5. Connect the direct current to the terminals provided.

6. Use any programming tool for configuration. The GSD file can be downloaded from our

website: ww w.pepperl-fuchs.com. Simply enter the product name or item number in the

Product/Keyword field and click the "Search" icon.

Note!

A more detailed description of the individual steps is provided on the following pages.

2018-03

15

Page 16

WCS-PG310

Commissioning

4.2 Connecting the WCS Reader

If you connect several WCS readers to one interface module, the WCS readers must have

different addresses. This will allow the programmable logic controller to allocate the data to the

correct WCS readers. If you only connect one WCS reader to an interface module, this WCS

reader always receives the address 0. You can connect up to four WCS readers to an interface

module via an RS-485 cable. Each WCS reader is supplied with the default address of 0.

Details of how to change the address of the WCS reader can be found in the configuration

instructions for the WCS reader.

The number of connected readers and their operating mode is configured in the hardware

project settings. Use the GSD file for the hardware project settings. This file can be

downloaded from our website: http://www.pepperl-fuchs.com.

Connection pin on reader Terminal on

WCS2A WCS2B WCS3A WCS3B

2 2 1 1 X2-1

4 4 2 2 X1-4

1 1 3 4 X1-5

3 3 5 3 X2-2

Table 4.1 Connecting the WCS reader(s)

interface module

4.3 Connecting the WCS-PG310 to the Network

A 9-pin connector is used to connect to the PROFIBUS DP, in accordance with the PROFIBUS

standard. You therefore need a 9-pin D-sub connector that you can plug into the 9-pin D-sub

socket on the device. This plug is not supplied with the interface module.

Pin Designation

1 Protective earth

2 Not used

3 B line

4 Control signal/repeater

5 Ground

6 5 V

7 Not used

8 A line

9 Ground

Table 4.2 Pin assignment for the 9-pin connector

1. Connect the PROFIBUS connector to the D-SUB socket labeled "PROFIBUS."

2. Tighten the lock screws on the connector using a screwdriver.

3. If the assembly is at the beginning or at the end of the PROFIBUS cable, you must connect

the term inator that is integrated in the gateway. To do this, slide the slide switch to the "on"

position.

4. If the assembly is not at the beginning or at the end, you must slide the slide switch to the

"off" position.

5. Set the PROFIBUS address on the fieldbus side of the assem bly, using the two rotary

switches labeled "PROFIBUS ID High" and "PROFIBUS ID Low." This setting uses

hexadecimal format.

DC

16

2018-03

Page 17

WCS-PG310

Commissioning

Example!

The PROFIBUS ID is 26 decimal = 1A hexadecimal. The "PROFIBUS ID High" switch must be

set to 1 and the "PROFIBUS ID Low" switch must be set to A.

6. If the rotary switch on the PROFIBUS side (PROFIBUS ID) is set to "7E" (= 126), the

gateway uses a PROFIBUS address that is stored in the EEPROM. This address is 126 by

default and can only be changed by a PROFIBUS master via PROFIBUS itself. The address

126 is reserved for this purpose in PROFIBUS, i.e., a slave with this address can never

exchange data, but can only be configured with a new ID.

7. If the rotary switch is set to a value between 0 and 125, the gateway uses this PROFIBUS ID

and it is not possible to change the setting via a master.

4.4 Integrating WCS-PG310 into the PROFIBUS System

Warning!

Risk of injury due to incorrect configuration

An error during the configuration of the device can override the fail-safe function, causing a

danger to people and machinery.

■

Ensure that the device is programmed exclusively by qualified personnel.

■

Only put devices into operation after they have been configured correctly.

You will need a GSD file to operate the module described in this manual. The GSD file must be

imported into the corresponding configuration tool before commissioning the module. The

GSD file can be downloaded from our website: www.pepperl-fuchs.com. Simply enter the

product name or item number in the Product/Keyword field and click the "Search" icon.

Select your product from the list of search results. Click on the information you require in the

product information list, e.g., Software.

A list of all available downloads is displayed.

Note!

Various configuration tools are available to allow you to configure the interface module. By way

of example, this manual describes the configuration of a Siem ens control panel with the WCSPG310 interface module using the TIA Portal V14. If you are using a programmable logic

controller (PLC) from a different manufacturer, the process will be similar to the one described

here.

2018-03

17

Page 18

WCS-PG310

1

1

2

3

Commissioning

Installing the GSD file

Figure 4.1 GSD file manage

1. In the menu bar, click the "Options" button and select the function "Install device description

file (GSD)."

The "Install device description file" window opens.

18

Figure 4.2 Search GSD file

2. Click the button with the three dots (1), which allows you to search for your GSD file on the

storage medium.

3. Select the folder containing the GSD file (2) and click "OK" (3) to confirm your selection.

2018-03

Page 19

WCS-PG310

1

2

Commissioning

Figu re 4.3 Install GSD file

4. Select the GSD file to install by checking the box (1) to the left of the filename.

5. Click the "Install" button (2). The installation process m ay take a few minutes.

Once the file is installed successfully, the system issues a notification that the installation

was successful. Close this window. The device data is added to the hardware catalog.

2018-03

19

Page 20

WCS-PG310

1

Commissioning

Integrating a module into the project

20

Figure 4.4 Hardware catalogue

1. Open the hardware catalog and browse through the tree structure until you see the icon labeled "276147" (1) (Other field devices > PROFIBUS DP > Gateways > PEPPERL+FUCHS

> Pepperl+Fuchs > WCS > WCS-PG310 > Header module > 276147).

2018-03

Page 21

WCS-PG310

2

1

Commissioning

Figu re 4.5 Integrating gsd file

2. Select module "276147" (1) from the hardware catalog and drag this module into the

network view (2).

The selected module is displayed in the network view window (2).

3. Connect the module to the control panel. To do this, move the mouse onto the PROFIBUS

interface that is highlighted in purple on the control panel, click the left mouse button, and

drag the line show n to the PROFIBUS interface on the module. O nce there, release the left

mouse button again.

A PROFIBUS subsystem is created.

Setting the number of readers, operating mode, and addresses

You have the option to connect up to four readers to the interface module. To do this, you must

specify the number of modules and their properties in the control panel. Several selection

options are available in the hardware catalog.

Note!

Do not use the "universal module" when configuring the device.

2018-03

21

Page 22

WCS-PG310

2

1

3

Commissioning

Figure 4.6 Device view

1. Switch to the "Device view" tab (1) in the "Devices & Networks" window.

2. Double-click to select the module with the appropriate number of readers and operating

mode from the hardware catalog (2).

Note!

Depending on your application, select one, two, three, or four connected WCS readers and the

operating mode. When in the "only Position" operating mode, the WCS readers output their

position. In the "Position and Speed" operating mode, the WCS readers output their position

and the speed at which they are currently moving.

Regardless of the number of WCS readers, 1 byte is reserved for querying the diagnostics for

the WCS readers in the master. For the response data, 4 bytes are reserved for each WCS

reader in the "only Position" operating mode (configuration data for four WCS readers: 0x20,

0xD1, 0xD1, 0xD1, 0xD1). In the "Position and Speed" operating mode, 6 bytes are reserved

for each WCS reader (configuration data for four WCS readers: 0x20, 0xD2, 0xD2, 0xD2,

0xD2).

The selected module is added to the device view (3).

22

2018-03

Page 23

WCS-PG310

1

2

3

Commissioning

Figu re 4.7 Network view

3. Switch to the "Network View" tab (1) in the "Devices & Networks" window.

4. To change the input and output address for the module, double-click on the module (2) in

the hardware catalog.

5. Selecting the Properties > General tab displays the control panel properties (3) in the

inspector window below the network view.

6. If necessary, enter the new address of the module in the input field under PROFIBUS

address > Parameters > Address.

Note!

You must assign unique addresses for data communication between the module and the

reader. If you connect several readers to one module, the readers must have different

addresses. This will allow the control panel to allocate the data to the correct module and

readers. If you only connect one reader to a module, this reader always receives the address 0.

You can connect up to four readers to a module via an RS-485 cable. Each reader is supplied

with the default address of 0. Details of how to change the address of the reader can be found

in the configuration instructions for the reader.

4.5 Data Format for Modules

In "only Position" operating mode, 4 bytes are reserved for each WCS reader.

Bit 7 6 5 4 3 2 1 0

Byte 0 0 0 0 0 0 P18 P17 P16

Byte 1 P15 P14 P13 P12 P11 P10 P09 P 08

Byte 2 P07 P06 P05 P04 P03 P02 P01 P 00

Byte 3 0 0 0 DB ERR OUT A1 A0

Table 4.3 Data format for each connected WCS reader in "only Position" ope rating mode, reader

address = 0... 3

In "Position and Speed" operating mode, 6 bytes are reserved for each WCS reader.

2018-03

23

Page 24

WCS-PG310

Commissioning

Bit 7 6 5 4 3 2 1 0

Byte 0 0 0 0 0 0 P18 P17 P16

Byte 1 P15 P14 P13 P12 P11 P10 P09 P08

Byte 2 P07 P06 P05 P04 P03 P02 P01 P00

Byte 3 0 0 0 DB ERR OUT A1 A0

Byte 4 0 0 0 0 0 0 0 0

Byte 5 0 S06 S05 S04 S03 S02 S01 S00

Table 4.4 Data format for each conn ected WCS reader in "Position and Speed" operating mode,

Pxx: position data, P00 = LSB

Sxx: speed (in multiples of 0.1 m/s), S00 = LSB

Example: Byte 5 = 00011011 = 27, corresponds to 2.7 m/s

A1, A0: reader address, 00 = WCS reader address #1

DB: pollution display, 1 = cleaning necessary

OUT: code rail loss, 0 = code rail recognized

ERR: error display, error code (LEDs)

reader addres s = 0...3

Address bits A1 and A0

A1 A0 Reader address

0 0 Reader address 0

0 1 Reader address 1

1 0 Reader address 2

1 1 Reader address 3

Status bits

DB ERR OUT Description

0 0 0 Current position value binary coded in

P00...P18

0 0 1 WCS reader outside of the code rail,

not a position value

P0...P18=0: WCS reader partly

outside the code rail

P0=1, P2...P18=0: WCS reader

completely outside of the code rail

1 0 0 Current position value binary coded in

P00...P18

1 0 1 No position value, WCS reader

outside of the code rail

X 1 X No position value, error message from

WCS reader, error num ber binary

coded in P00...P18

Optical state of WCS

reader

Good

Good

Poor

Poor

-

24

2018-03

Page 25

WCS-PG310

Reading head

Interface or control

(PLC)

Appendix

5 Appendix

5.1 Cable Routing in the RS-485 Bus

The data cables must always form an in-line connection between the first and the last node.

This in-line connection must end with a terminator.

The RS-485 terminators are integrated in the WCS readers and can be switched on and off

with the interface module.

If only one WCS reader is connected, one device is connected at the beginning and one

device is connected at the end of the data line.

2018-03

Figure 5.1 Connection of one reading head

If two WCS readers are connected to one inter face module, there are two wiring versions:

■

Version A:

One WCS reader is located at the beginning and one WCS reader at the end of the data

line. For both WC S readers, the RS-485 terminator is activated. The interface module is

located between these two readers and does not have an RS-485 terminator. Each WCS

reader is connected to the interface module by a separate data cable.

25

Page 26

WCS-PG310

Interface or control

(PLC)

Reading head

Reading head

Appendix

Figure 5.2 Connection o f two reading heads, Version A

■

Version B:

The interface module is located at the beginning of the data line; one WCS reader is

located at the end of the data line. Both need the RS-485 terminator. The second WCS

reader is connected to the line connection between the interface module and the first

WCS reader through a short spur (length <1 m). Use a bus term inal to connect the spur.

26

2018-03

Page 27

WCS-PG310

Reading head

Reading head

Interface or control

(PLC)

Spur line (max. 1 m)

Bus terminal

Appendix

Figure 5.3 Connection of two reading heads, Version B

The wiring version used depends on which is best suited for the application. If three or four

WCS readers are used on the same interface module, connect these using spurs as shown in

variant B.

2018-03

27

Page 28

WCS-PG310

Appendix

5.2 Data Cables and Accessories

RS-485 data cable

For the RS-485 data transfer path, a four-wire, shielded, twisted pair data cable must be used.

One wire pair is used for the supply voltage, and one pair for the RS-485 data connection. The

maximum length of the cable depends on the data transfer capacity of the data cable—corecore—and on the cross section of the cables for power supply of the WCS readers. For data

transfer, a small core cross section, and thus small cable capacitance is an advantage,

whereas for the power supply the largest possible cross section is required. The table below

shows the possible cable lengths depending on the cable cross section.

In the calculations, the worst-case scenario was assum ed: All WCS readers are located at the

end of the data line. In the case of large cable lengths, and when connecting multiple WCS2

readers with heating, six-wire data cable (3 x 2) can be used. These data cables use two pairs

for the power supply (doubling the cable cross section), and one pair for the RS-485 data line.

Capacitance (corecore)

60 pF 500 m 500 m 300 m

90 pF 500 m 450 m 275 m

120 pF 500 m 400 m 250 m

The table shows the possible cable lengths depending on the cable capacitance (core-core).

The number of connected WCS readers is of no significance.

RS-485 interface

19.2 KB (LS246) 62.5 KB (LS221) 187.5 KB (LS211)

WCS-DCS / WCS-DCF data cables

There are 2 types of data cable available:

. WCS-DCS for stationary cable routing

. WCS-DCF for trailing cable and drag chain installations.

The data cables are twisted pairs and have a tinned copper braided shield. The braided shield

surrounds all wire pairs. The parameters of the data cable for RS-485 and SSI data transfer

applications are listed in the table below.

WCS-DCS WCS-DCF

Capacitance (core-core) 95 pF/m 60 pF/m

Cross section

Number of wires 6 (3 x 2) 6 (3 x 2)

External diameter 5.8 mm 7.5 m m

Temperature range -30 °C ... 70 °C -40 °C ... 70 °C

Order designation WCS-DCS WCS-DCF

0.14 mm

2

0.25 mm

2

28

2018-03

Page 29

WCS-PG310

Appendix

Single-ended female cordsets and adapter cables

Field-attachable female connectors M12 x 1

straight 4 6 mm – 8 mm V1-G-PG9

angled 4 6 mm – 8 mm V1-W-PG9

straight 5 6 mm – 8 mm V15-G-PG9

angled 5 6 mm – 8 mm V15-W-PG9

straight 6 6 mm – 8 mm V17-G-PG9

angled 6 6 mm – 8 mm V17-W-PG9 *)

Table 5.1 *) Cable outle t on top, not variable

Shielded connection cable with molded single-ended female cordset

straight 4 2 m V1-G-2M-PUR-ABG

straight 4 5 m V1-G-5M-PUR-ABG

angled 4 2 m V1-W-2M-PUR-ABG

angled 4 5 m V1-W-5M-PUR-ABG

straight 5 5 m V15-G-5M-PU R-ABG

angled 5 5 m V15-W-5M-PUR-ABG

straight 8 2 m V19-G-2M-PU R-ABG

straight 8 5 m V19-G-5M-PU R-ABG

Number of poles Cable diameter Order designation

Number of poles Cable length Order designation

2018-03

29

Page 30

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

/ TDOCT5979__ENG

03/2018

Loading...

Loading...