Page 1

FACTORY AUTOMATION

MANUAL

WCS

position encoding system

Mechanics

Page 2

WCS position encoding system

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

WCS position encoding system

1 Introduction................................................................................. 5

2 Declaration of conformity .......................................................... 6

2.1 CE conformity....................................................................................... 6

3 Safety........................................................................................... 7

3.1 Symbols relevant to safety.................................................................. 7

3.2 General safety instructions ................................................................. 7

4 Product Description ................................................................... 8

4.1 Functional Description ........................................................................ 8

4.2 Application areas ............................................................................... 10

5 Readers ..................................................................................... 13

5.1 Mounting ............................................................................................. 16

5.2 Plastic Lenses .................................................................................... 18

6 Code Rail ................................................................................... 20

6.1 Grounding the Code Rail................................................................... 21

6.2 Clamping Fixture for the Stainless Steel Code Rail ........................ 21

6.3 Identification....................................................................................... 22

7 Mounting the Code Rail............................................................ 24

7.1 Mounting the Code Rail with Mounting Brackets............................ 26

7.1.1 Mounting the Code Rail on a Straight Route .................................... 29

7.1.2 Mounting the Code Rail on Curves .................................................. 30

7.2 Mounting WCS2 Code Rail with the Aluminum Profile System ..... 31

7.3 Rail Holders ........................................................................................ 35

7.3.1 Adapter Plates for Profile Rails......................................................... 36

7.3.2 Mounting the Code Rail ................................................................... 39

7.3.3 Fixed Points ..................................................................................... 41

7.3.4 The Guide Trolley............................................................................. 42

7.3.5 Grounding the Aluminum Profile System.......................................... 44

3

Page 4

WCS position encoding system

7.4 Mounting WCS3 Code Rail with the Aluminum Profile System .....45

7.4.1 Rail Holders......................................................................................48

7.4.2 Adapter Plates for Profile Rails ......................................................... 49

7.4.3 Mounting the Code Rail....................................................................51

7.4.4 Fixed Points...................................................................................... 52

7.4.5 Vertical Curves .................................................................................54

7.4.6 Interruptions in the Profile Rail..........................................................55

7.4.7 Suspended Mounting with Stainless Steel Code Rail ....................... 55

7.4.8 Grounding the Aluminum Profile System .......................................... 56

7.4.9 Integration of the WCS Code Rail in Conductor Lines ......................56

4

Page 5

WCS position encoding system

Introduction

1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops,

produces and distributes electronic sensors and interface modules for the market of

automation technology on a worldwide scale.

Symbols used

The following symbols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

Contact

If you have any questions about the device, its functions, or accessories, please contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

2014-10

5

Page 6

WCS position encoding system

Declaration of conformity

2 Declaration of conformity

2.1 CE conformity

This product was developed and manufactured under observance of the applicable European

standards and guidelines.

Note!

A declaration of conformity can be requested from the manufacturer.

2014-10

6

Page 7

WCS position encoding system

Safety

3 Safety

3.1 Symbols relevant to safety

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt devices and any connected facilities or systems, or result in

their complete failure.

3.2 General safety instructions

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the system operator.

Installation and commissioning of all devices must be performed by a trained professional only.

User modification and or repair are dangerous and will void the warranty and exclude the

manufacturer from any liability. If serious faults occur, stop using the device. Secure the device

against inadvertent operation. In the event of repairs, return the device to your local

Pepperl+Fuchs representative or sales office.

Note!

Disposal

Electronic waste is hazardous waste. When disposing of the equipment, observe the current

statutory requirements in the respective country of use, as well as local regulations.

2014-10

7

Page 8

WCS position encoding system

Product Description

4 Product Description

4.1 Functional Description

The WCS position encoding system consists of two main components:

1. The code rail

The code rail carries information for the absolute code. The code rail is routed parallel to

the track for the material handling equipment and assigns a unique position to every point

on the track. It is possible to route the code rail only at points where positioning is required.

The system allows the code rail to be routed along curves and allows branches to be created. The code rail is built to order and delivered in a bundle. Unless otherwise ordered,

the code rail always starts w ith the position value 0. The maximum length of the code rail

is 327 m (WCS2) or 314.5 m (WCS3). Brackets are available for mounting the code rail.

2. The reader

The U-shaped reader scans the code rail photoelectronically without touching it. Every

0.833 mm (WCS2) or 0.8 mm (WCS3), the reader detects a new position value. After insertion into the code rail, the reader determines the position value without reference or delay. The code rail can be scanned at very high speeds. The scanning is reproducible,

reliable, and independent of temperature fluctuations. The position value can be transferred directly from the reader to the controller via a serial RS485 interface. For connection

to standard interfaces, there is a wide range of interface modules available:

• Parallel

• SSI

• PROFIBUS DP

• DeviceNet

• CANopen

• Ethernet

• InterBus-S

• PROFINET

• MODBUS RTU

Up to four readers can be connected simultaneously to all interface modules with the exception of the SSI interface module.

2014-10

8

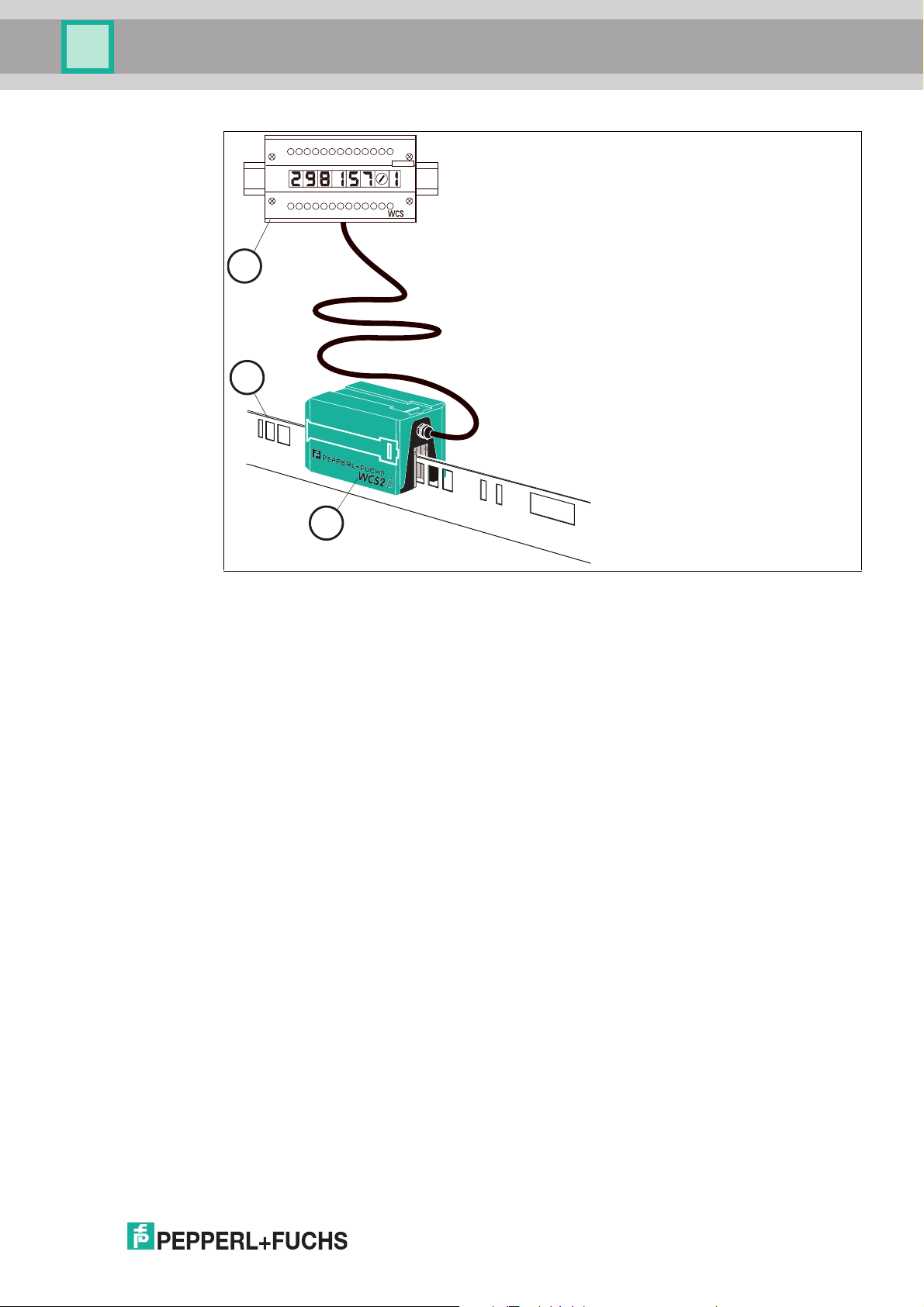

Page 9

WCS position encoding system

1

2

3

Product Description

1. Interface module

2. Code rail

3. Reader

Properties of the WCS

■

Absolute position encoding system

■

Photoelectric principle (infrared range)

■

Proven and robust

■

Easy to maintain

■

No reference points required

■

No calibration and adjustment work necessary

■

Resistant to power failure

■

Millimeter-precise positioning with absolute repeat accuracy

■

Determination of position value in real time and regardless of temperature fluctuations

■

Guaranteed reading up to a speed of 12.5 m/s

■

High resolution = ±0.4 mm

■

Variable route length: 0.1 m to 327 m

■

Coding system also suitable for curves with up to 0.5 m radius

■

A wide variety of applications, such as stock feeders, trolleys, monorail conveyors,

galvanic plants, automatic and slewing cranes, as well as elevators

■

Various mounting systems available for installing the code rail

■

Connection to any controller possible, either directly or via interface module

■

Connectivity to many fieldbus systems available

■

Support during commissioning and maintenance with extensive system diagnostics

options

2014-10

9

Page 10

WCS position encoding system

Product Description

■

High functional reliability as a result of permanent self-diagnostics

■

Contamination warning

■

Optional heating for ambient temperatures down to -40 °C

■

Digital output of an adjustable limit speed (optional)

4.2 Application areas

The WCS can be used anywhere where material handling equipment has to be positioned

precisely. The functional principle of the WCS enables it to be used in a diverse range of

applications, such as:

■

Interruptions in the code rail (lane changes, track switches)

■

Applications with curves and circular paths

■

Use of multiple vehicles in a row

Due to the larger tolerances of the reader in relation to the code rail, in most applications the

WCS3 system can be used. In some circumstances, however, it is advantageous to use the

WCS2 in conjunction with the aluminum profile system. Here are some exam ples from the

variety of application options:

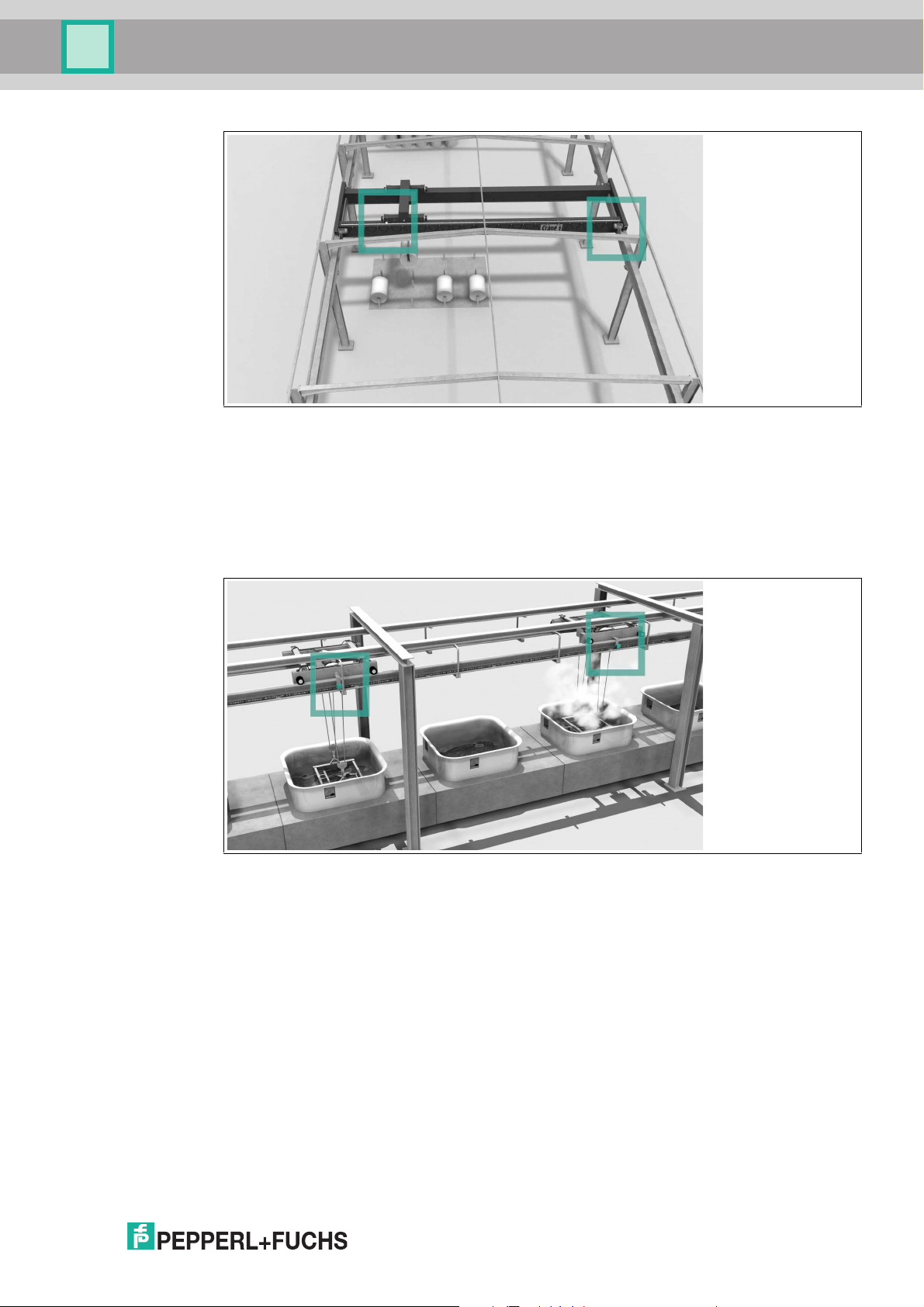

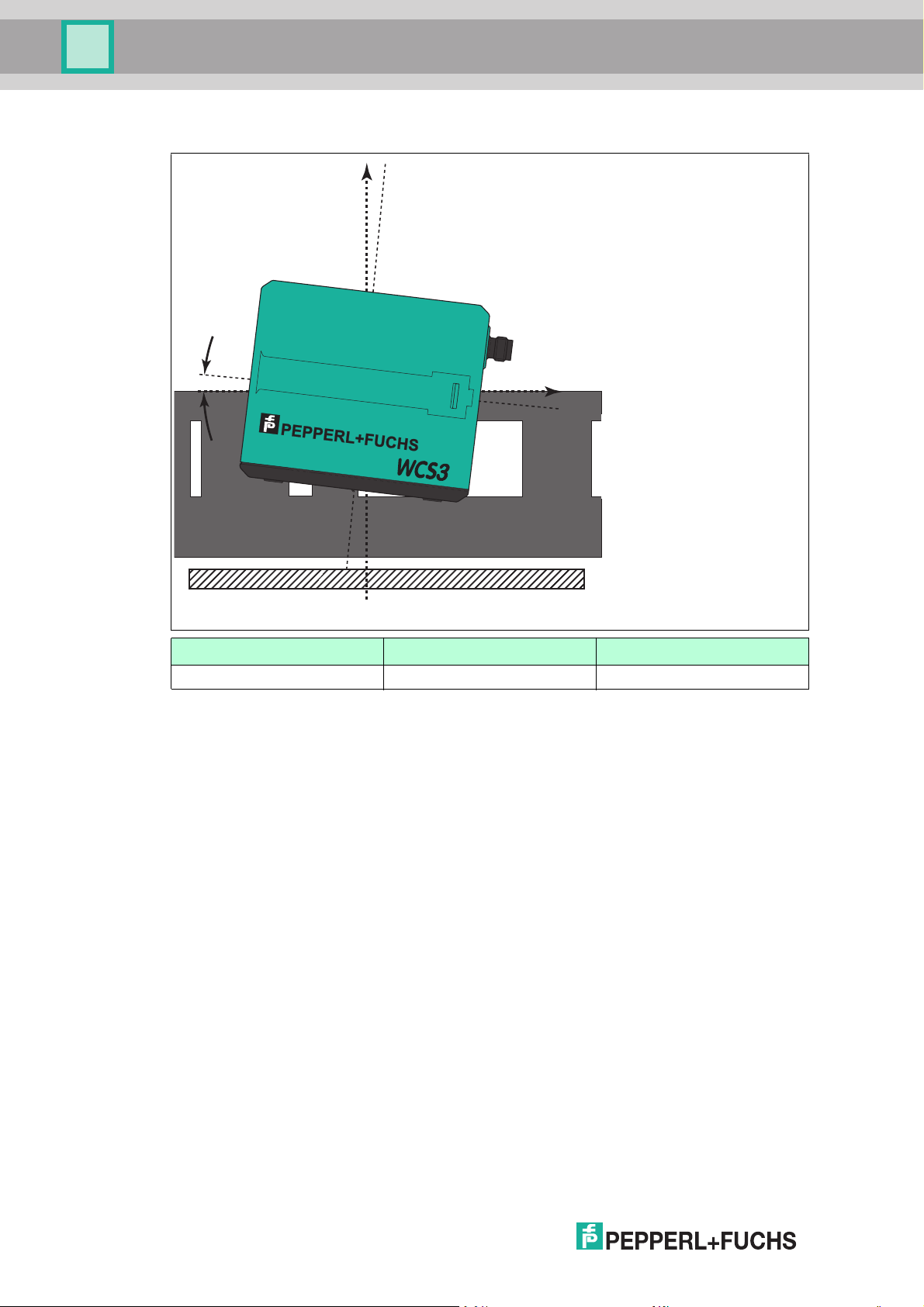

Stock Feeders (High-Bay Warehouse)

Trolleys, lifting gear, and transversing carriages are each positioned with one reader. The

positioning is independent of the length of the code rail and always absolutely reproducible. For

new high-bay warehouses we recommend the WCS3 system. For retrofits in older warehouses,

it may be beneficial to use the WCS2 in conjunction with the aluminum profile system:

■

Easy to retrofit

■

High mechanical tolerances between the measuring system and moving carriages

possible

■

Decoupling of vehicle vibrations

10

Figure 4.1 Stock feeder (high-bay warehouse)

Automatic Cranes

Automatic cranes are a typical application for the WCS2 in conjunction with the aluminum

profile system. The crane is positioned using one reader each for the crane and the trolley

movement. At each point, the guide trolley ensures the optimum position of the reader in

relation to the code rail and decouples any vibrations from the crane track. Optional cleaning

brushes for the code rail can be attached to the guide trolley. This means that the WCS2 can be

used in a very dusty environment, su ch as in cement works or foundries.

2014-10

Page 11

WCS position encoding system

Product Description

Figure 4.2 Automati c crane

Galvanic plants

One or more vehicles moving in a line along a straight route. The vehicles bring the material to

be galvanized into the corresponding bath automatically. The high and adaptable light output of

the readers has enabled the WCS position encoding system to perform extremely well even

under these difficult conditions. In addition to the WCS3 system, the WCS2 with the aluminum

profile system, which is also available powder-coated, can be used.

Figure 4.3 Ga lvanic plant

Overhead Conveyors

Many vehicles have to be positioned on a circular track— the WCS offers the optimal solution

for this. Branches (track switches) and curves can be created. The WCS3 is particularly wellsuited for this task. After a power failure, the current position of the vehicle is transferred to the

controller immediately; the vehicle does not have to be moved. The WCS can also be used for

distances longer than 314 m.

2014-10

11

Page 12

WCS position encoding system

Product Description

Figure 4.4 Overhea d conveyor

12

2014-10

Page 13

WCS position encoding system

129

10

75

40

38

33

75

115

57

M12 x 1

Readers

5 Readers

The reader housing is m ade from a robust plastic and has IP54 protection. The product

contents include the mounting bracket for mounting the reader. On the inside of the reader

there are easily rem ovable, transparent plastic lenses that protect the reading area against dirt

and damage. Identification notches can be found on these lenses. The notches are used for

adjustment of the zero point for the vertical play of the reader (= Z-axis). see image on page

14. The reference point is the top edge of the code rail. Within specified tolerances, the reader

may move around this reference point: if the vertical play on the Z-axis is exceeded, the reader

repor ts "OUT" to the controller (reader outside the code rail). The tolerances for the lateral play

on the Y-axis result from the gap width of the reader. The positions are reliably determined up

to a minimum of 500 m m for both an inclined position in the vertical direction and in the

horizontal direction, as well as in curves. If the position value cannot be determined, for

example due to contamination of the optical system, the reader reports a unique error code.

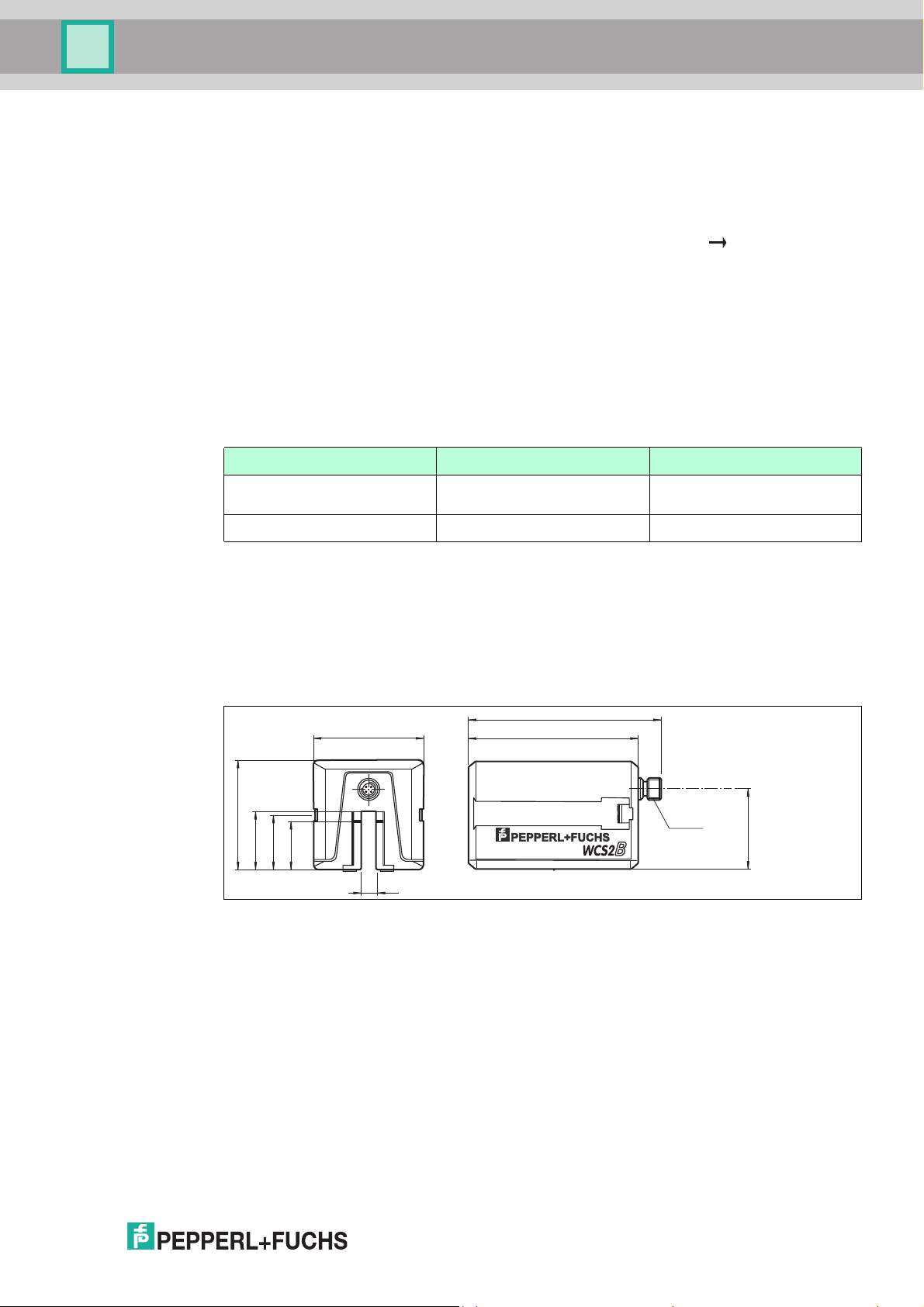

From a technological point of view, the WCS2B and WCS3B readers are very similar. The

resolution and the signals to the interface are almost identical. However, there are differences

in the mechanical systems and in the accessories.

Resolution ± 0.42 mm

v

max

WCS2B WCS3B

± 0.40 mm

1200 pos./m

1250 pos./m

12.5 m/s 12.5 m/s

WCS2B

WCS2B readers have a gap width of only 10 mm. This close proximity between the emitter and

receiver provides high contaminate burn-through power. This makes the WCS2B reader

suitable for ver y dirty environments such as galvanizing plants, foundries, and steel mills. An

optional guide trolley and the WCS2B rail system are specially designed for operation with

imprecise mechanical connections and w here vibrations occur, for example, with automatic

cranes.

Figure 5.1 WCS2B dimen sional drawing

WCS3B

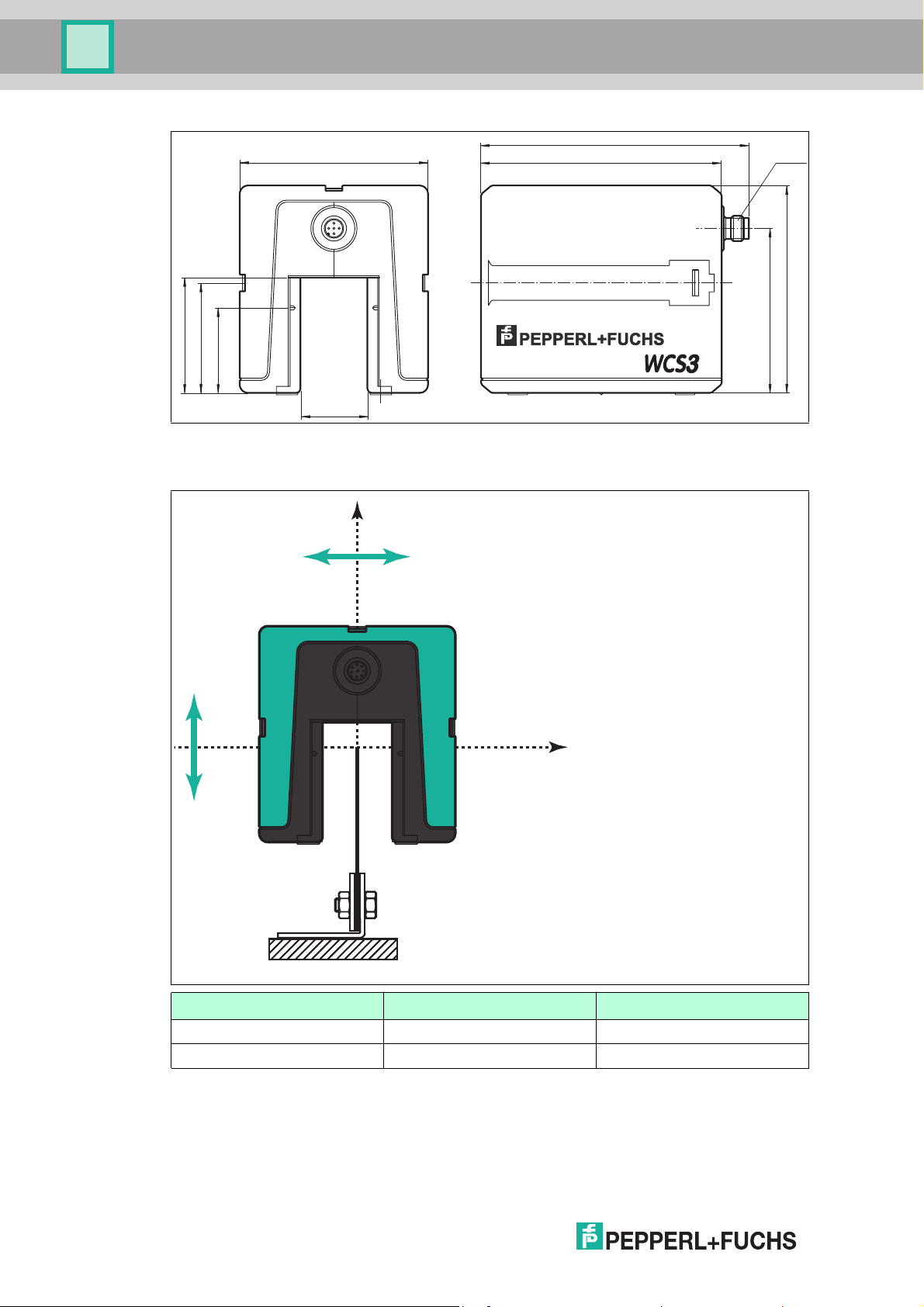

WCS3B readers have a gap width of 31 mm. This results in a greater tolerance when mounting

the reader and aligning it in relation to the code rail. WCS3B systems are ideal for monitoring

conveyor belts and automated warehouse and lifting systems.

Special features of the WCS3B readers include the status LEDs for the alignment and

performance display, an optional "overspeed" output, and an optional 7-segment display for

position and diagnostic data.

2014-10

13

Page 14

WCS position encoding system

53

40.5

99

78.5

55

90

128

115

31

M12 x 1

B

Y

Z

Readers

Figure 5.2 WCS3B dimen sional drawing

Tolerance for Y- and Z-axis

WCS2B WCS3B

Y-axis ± 5 m m ± 15.5 mm

Z-axis ± 5 m m ± 14 mm

14

2014-10

Page 15

WCS position encoding system

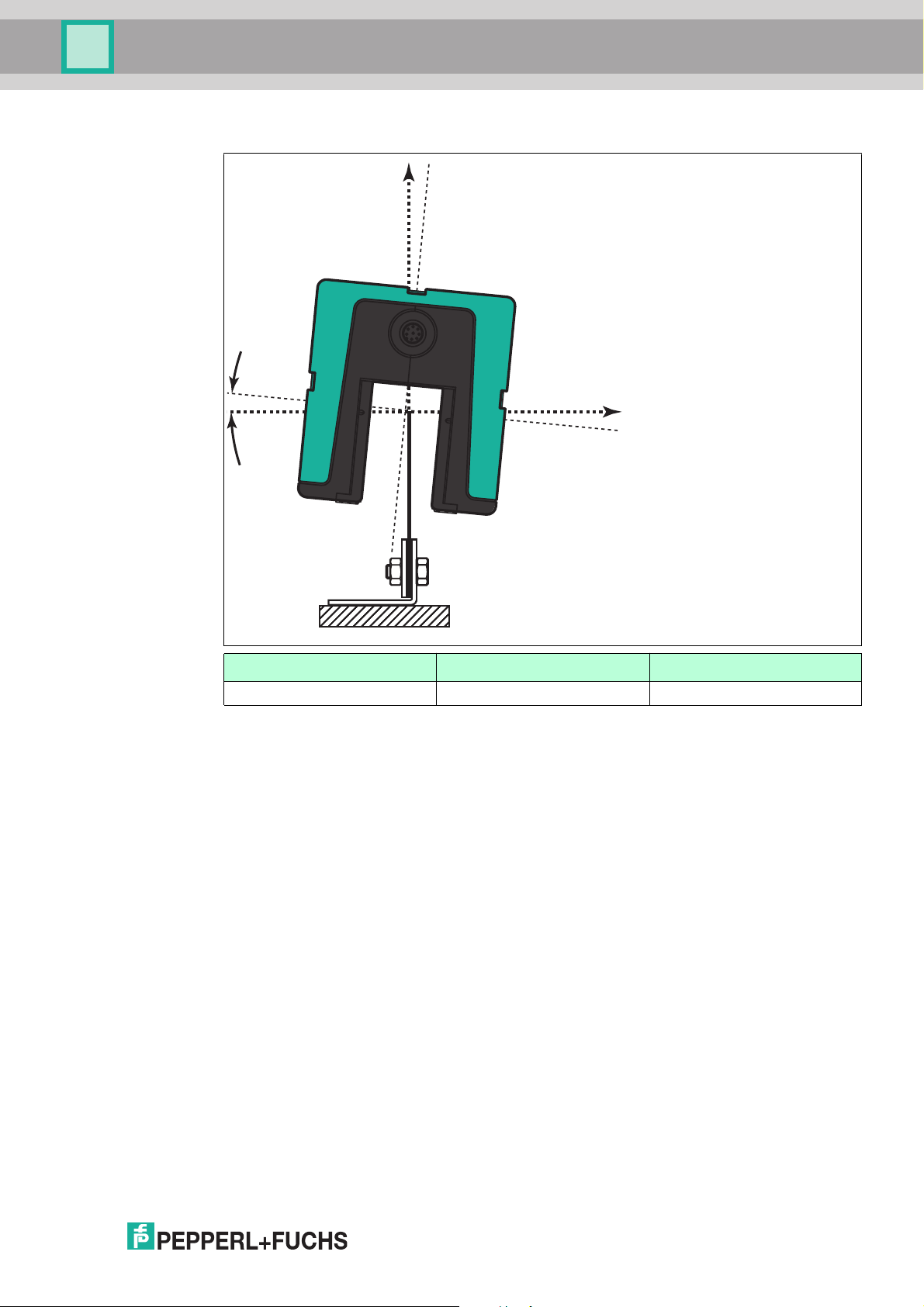

Y

Z

Readers

Tolerance for inclined position α

WCS2B WCS3B

α ±10° ±10°

2014-10

15

Page 16

WCS position encoding system

X

Z

β

B

Readers

Tolerance for inclined position β

5.1 Mounting

WCS2B WCS3B

β ±5° ±5°

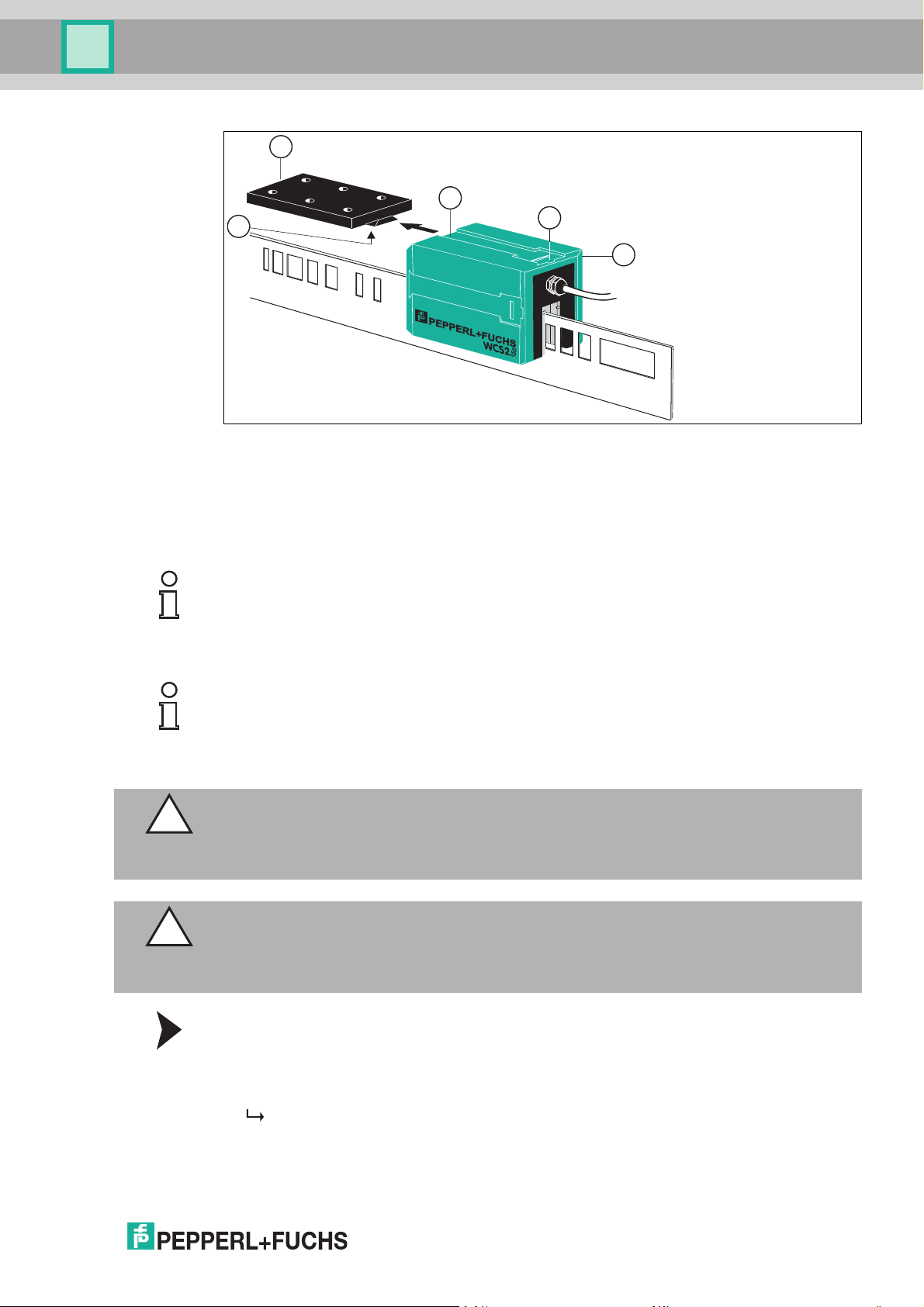

As a rule, the reader is mounted on the vehicle. However, the reader can also be mounted

stationary. A code rail unit can also be mounted on the carriage (vehicle identification).

A special mounting bracket is supplied with the reader. This is mounted on the carriage. If the

WCS2 is used with an aluminum profile rail system and guide trolley, the mounting bracket is

already installed in the guide trolley. On three sides of the reader housing, dovetail grooves are

integrated with a quick-action lock. If required, the reader is pushed onto the base module of

the mounting bracket via one of these grooves and engaged w ith a spring tongue. This quickaction lock makes it easy to m ount and quickly replace the reader when necessary without any

adjustment work. The installation location of the reader is arbitrary. The reader is not sensitive

to extraneous light.

16

2014-10

Page 17

WCS position encoding system

1

2

3

4

5

Readers

1. Reader

2. Quick-action lock

3. Groove

4. Mounting base

5. Base module with spring tongue

Note!

Mounting Direction

Mount the reader so that the electrical connecting plug points in the direction of the ascending

position values on the code rail.

Tip

Securing the Mounting Bracket

Plan elongated holes in the design of the end stop on the carriage. These allow you to correct

the position of the mounting bracket and the reader during mounting.

Caution!

Interference from strong sunlight

When planning the plant, make sure that no strong sunlight can shine directly into the reader

gap.

Caution!

Interference from contamination

When installing the reader, make sure that the reader gap is protected against dirt and any

vapors. This allows for long-term, trouble-free function.

2014-10

1. Secure the mounting bracket to the carriage with size M4 screws.

2. Slide the dovetail groove on the reader onto the base module of the mounting bracket. In the

end position, the spring tongue engages audibly in the quick-action lock.

The reader is mounted.

3. For dismounting, unlock the spring tongue with a screwdriver.

4. Push the reader off the base module of the mounting bracket.

17

Mounting and Dismounting with the Mounting Bracket

Page 18

WCS position encoding system

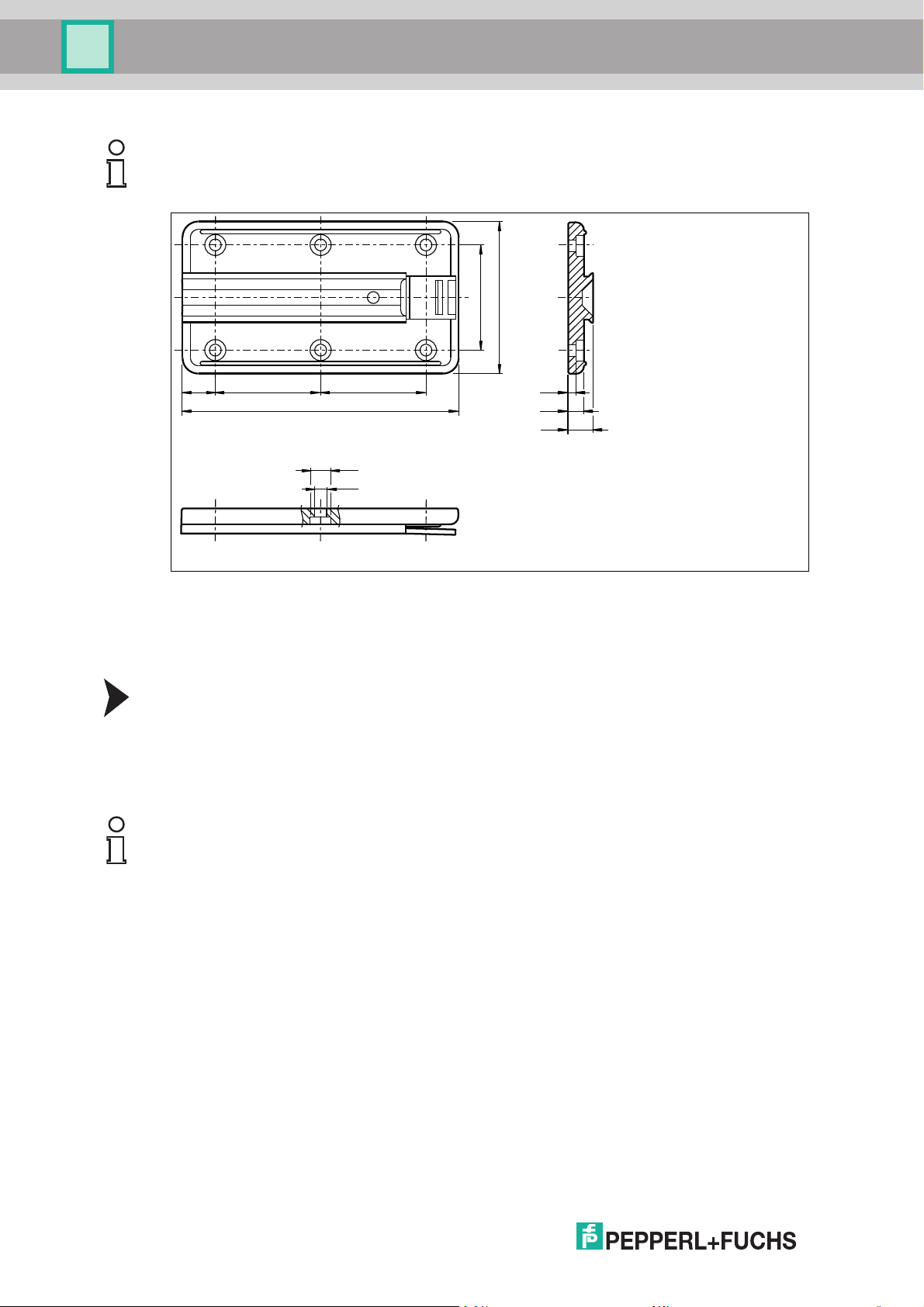

12.5 40 40

105

40

58

3

6

9.5

ø 4.5

3

6

9.5

ø 8

Readers

Note!

The mounting bracket is identical for all readers.

Figure 5.3 WCS-MP1 mounting bracket

5.2 Plastic Lenses

In the event of damage or contamination, you can replace the reader's plastic lenses.

Replacing the Plastic Lenses

1. Loosen two cross-head screws on each lens.

2. Remove the lens.

3. Slide the new lens into the intended position on the inside of the reader gap.

4. Secure the lens with the cross-head screws. The maximum torque is 0.8 Nm.

Tip

Always replace the lenses in pairs and also replace the seals.

The plastic lenses are available in pairs as spare parts.

18

2014-10

Page 19

WCS position encoding system

Readers

Model number for two lenses

with seals

WCS2B WCS3B

WCS2-PL2 WCS3B-PL2

2014-10

19

Page 20

WCS position encoding system

Code Rail

6 Code Rail

The absolute code rail is different for the WCS2 system and WCS3 system Therefore, the code

rails are not interchangeable. For WCS3, the height of the code rail is always 70 mm; for

WCS2, the rail can be su pplied at a height of 55 mm or 70 mm. Two different materials that

have proven successful in practice are available for the code rail: plastic laminate and stainless

steel. The code rail is delivered in a coil. Unless otherwise ordered, the code rail always starts

with the position value 0.

Laminate Code Rail

The black laminate code rail consists of a special polyester laminate. It is characterized by

good physical and chemical properties and has a low weight. The material has a high tensile

strength and behaves neutrally to oils, greases, and solvents. Because of its good resistance to

acids, alkalis, and aggressive gases, the laminate code rail is suitable for use in electroplating.

The laminate code rail is delivered with mounting holes as standard (WCS3-CS70-L1, see also

the drawing below). If you use a bracket system to mount the code rail, use of a code rail

without mounting holes is recommended (WCS3-CS70-L0).

The laminate code rail can be used in a temperature range from -40 °C ... 60 °C. Temperatures

above 70 °C lead to material deformation.

The specific thermal expansion coefficient is approximately 2.8 x 10-5 K-1.

Due to its material properties, the laminate code rail must not be mounted at temperatures

below 10 °C. In applications with large temperature fluctuations (> 50 K), we recomm end the

use of the stainless steel code rail.

Warning!

Sanding dust

When mounting the laminate code rail, make sure that sanding dust from current collectors

cannot fall directly onto the surface of the code rail. When mounting the laminate code rail on

the side, mount it above the sanding lines.

Stainless Steel Code Rail

The stainless steel code rail is m ade from corrosion-resistant spring steel. It is rust-free and is

characterized by high mechanical stability and low thermal expansion.

The stainless steel code rail can be used in the temperature range -40 °C ... 80 °C.

The specific thermal expansion coefficient is 1.6 x 10-5 K-1.

Caution!

Risk of injury

Wear protective gloves when mounting the stainless steel code rail.

20

2014-10

Page 21

WCS position encoding system

1

1

Code Rail

WCS2B code rail

1. 6-digit position identifier

Dimensions [mm] a b c

Code rail 55 x 0.5 55 7.5 25

Code rail 70 x 0.5 70 15 41

WCS3B code rail

1. 6-digit position identifier

6.1 Grounding the Code Rail

When installing the WCS code rail made from lam inate or stainless steel, make sure that the

code rail is connected with the plant potential ever y 30 m with low resistance.

6.2 Clamping Fixture for the Stainless Steel Code Rail

Using the clamping fixture prevents the stainless steel code rail from warping due to

temperature fluctuations after mounting. It also makes mounting easier.

Note!

Pretensioning of the stainless steel code rail is not necessary for system function.

Pretensioning is useful only if large temperature fluctuations can occur within a short time.

The clamping fixture can only be used together with the stainless steel code rail.

Three mounting holes are stamped in a row at the beginning and end of the stainless steel rail.

They are used for screwing on the clamping fixture. There are two options for installing the

clamping fixture:

1. The code rail is fastened at one end and tensioned at the other end with the clamping fixture.

2. The code rail is fastened in the middle and tensioned with the clamping fixture at both

ends. This method is advantageous for longer distances (> 50 m).

2014-10

21

Page 22

WCS position encoding system

Code Rail

WCS-MT1 clamping fixture

Stainless steel code rail Tightening torque

WCS2B, 55 m m 6 Nm

WCS2B, 70 m m 9 Nm

WCS3B, 70 m m 7 Nm

6.3 Identification

In applications where the vehicle num ber is recognized in the plant, special code rail units

known as ID pads are available for the WCS3 system. In these applications, the reader is

generally mounted in a fixed position. The ID pads mounted on the chassis pass through the

reader at certain points in the plant. The controller can use the position value read by the reader

to calculate the integer vehicle number based on a formula. In total, 1260 different ID pads are

available.

Vehicle number = INT((WCS position value - 30) / 312) + 1

In addition to the calculation of the vehicle number, the position value determined by the reader

enables fine positioning of the ID pad in the reader gap and thus exact positioning of the

vehicle.

22

2014-10

Page 23

WCS position encoding system

70

7.5

6.5

12

240 ... 264

19.2 192 19.2

57.5

25.5

XXXX

Code Rail

ID pad WCS3-ID70-M1

Figure 6.1 XXXX = 0001 - 1260

Designation Part number Material

WCS3-ID70-M1

WCS3-ID70-L1

Table 6.1

1)

1)

1)

: When ordering, please specify the desired ID pad number

184073 Stainless steel

184761 Laminate

2014-10

23

Page 24

WCS position encoding system

Mounting the Code Rail

7 Mounting the Code Rail

With continuous position measurement for a route, you have to mount the code rail in one

piece. Depending on the usage conditions, there are various options for securing the code rail:

■

Mounting bracket

■

Aluminum profile rails

Installation position

The installation position of the code rail is arbitrary. When m ounting the code rail, make sure

that all mounting brackets or rail holders of the profile system are at one level. The area on

which the m ounting bracket or rail holders are mounted must be level.

Note!

The following examples show the installation positions with mounting brackets. The installation

positions are equally valid for mounting with the aluminum profile system.

Figure 7.1 Horizontal install ation

24

2014-10

Page 25

WCS position encoding system

Mounting the Code Rail

Figure 7.2 Vertical installation

2014-10

25

Page 26

WCS position encoding system

Mounting the Code Rail

Figure 7.3 Installation on a wall

Figure 7.4 Installation on a ceiling

7.1 Mounting the Code Rail with Mounting Brackets

The bracket system is an easy way to mount laminate or stainless steel code rails. It consists of

brackets for routing the code rail in straight sections, as well as brackets for routing the code rail

on curves and circular paths. The brackets are made from galvanized sheet steel and are

supplied pre-assembled. The mounting brackets for installation of the WCS code rail can be

delivered in three different versions:

26

■

Without fastening screws

■

With fastening screws

■

With fastening screws for mounting in C profile rails

2014-10

Page 27

WCS position encoding system

70

38

26

M6 x 12

6

16

26

6

20

60

90

M4 x 12 3.5 x 6.5

40

24

20

40

ø 6

16

Mounting the Code Rail

Mounting brackets without fastening screws

WCS-MB/WCS-MB-C WCS-MB-B

Designation Part num ber Function/use Support distance

WCS-MB 184236 Bracket for straight

1.25 m

sections

WCS-MB-C 184099 Bracket for straight

1.25 m

sections,

powder coated, stainless

steel clamping screws

WCS-MB-B 184237 Bracket for curve 0.5 m – max. 0.7 m

WCS-MB-R1 215230 End mounting -

WCS-MB-R2 215231 Guide brackets -

2014-10

27

Page 28

WCS position encoding system

M6 x 12

M6 x 12

38

26

83

70

6

16

26

10 x 6

20

206

60

90

Mounting the Code Rail

Mounting bracket with fastening screws

WCS-MB1

Designation Part number Function/use Support distance

WCS-MB1 184098 Bracket for straight

1.25 m

sections

WCS-MB1-B 184100 Bracket for curve 0.5 m – 0.7 m

28

2014-10

Page 29

WCS position encoding system

20

5

20

40

25

M6

M6 x 12

M6 x 12

38

26

83

70

6

60

90

6

16

26

10 x 6

24

83

20

40

5

M6 x 20

20

40

40

M4 x 12 3.5 x 6.2

25

Mounting the Code Rail

Mounting bracket with fastening screws for mounting in C profile rails

30 mm x 32 mm

WCS-MB2/WCS-MB2-C WCS-MB2-B

Designation Part num ber Function/use Suppor t distance

WCS-MB2 184101 Bracket for straight

WCS-MB2-C 184102 Bracket for straight

WCS-MB2-B 184103 Bracket for curve 0.5 m – 0.7 m

7.1.1 Mounting the Code Rail on a Straight Route

Mounting the Code Rail — Straight Route

1. Mount the mounting brackets at an offset of max. 1.25 m along the route on the substructure.

2. Align the mounting brackets.

3. Slide the code rail up to the stop in each bracket.

4. Tension the code rail by pulling gently on the free end.

5. C lamp the code rail securely into the bracket by tightening the two M6 x 12 hexagonal

screws.

Tightening torque:

For laminate code rail: max. 8 Nm

For stainless steel code rail: max. 5 Nm

When mounted correctly, the tensioning force on the brackets is so great that the code

rail can no longer be pulled out of the bracket.

1.25 m

sections

1.25 m

sections,

powder coated,

stainless steel

clamping screws

2014-10

29

Page 30

WCS position encoding system

max. 1.25 m

max. 1.25 m

70

83

Mounting the Code Rail

Tip

In addition to clamping, you can screw the code rail to the bracket. To do so, use the top two

free holes (M6) of the bracket. Screwing the rail to the bracket creates a fixed point between the

code rail and the substructure.

The screws for the fixed point are not included in the product contents.

The use of C profiles is advantageous for bracket mounting. They are arranged lengthwise or

crosswise to the intended route. The brackets for mounting in C profile can be easily secured to

them and aligned.

Example

Figure 7.5 Application exam ple: mountin g brackets, straight

7.1.2 Mounting the Code Rail on Curves

To create curves, the m ounting brackets for curves are used together with a special WCS-SP2

stabilizing profile. The stabilizing profile is delivered in a bundle in the length ordered.

Note!

The curve brackets are designed so that there is no height or transverse offset of the code rail

in the transition from the straight section into the curve.

Mounting the Code Rail — Curve

1. Mount the curve brackets tangentially along the bend of the arc or curve at an offset of max.

0.7 mm.

2. Cut the WCS-SP2 stabilizing profile to the length of the arc or curve.

3. Insert the stabilizing profile into the curve bracket.

4. Press the code rail completely into the groove of the stabilizing profile.

5. Using the M4 hexagon socket head clamping screws, securely clamp the code rail together

with the stabilizing profile into the curve brackets.

6. Lock the code rail together with the stabilizing profile using the self-tapping screws

supplied.

2014-10

30

Page 31

WCS position encoding system

Mounting the Code Rail

Note!

Circular Path

Note the following special features of a closed route (circular path, oval, etc.): due to the

operating mode of the WCS, you cannot route the code rail continuously along the entire

circuit.

Maintain an offset of at least 85 mm between the beginning and the end of the code rail. Where

the code rail is interrupted, the controller receives the value "OUT"— reader outside the code

rail—from the reader. Using two consecutive staggered heads enables continuous route

information at all points of the circular path. In this case, when it receives the "O UT" message,

the controller switches to the position value of the second reader.

Example

Figure 7.6 Application example: mounting brackets, straight section and curve

7.2 Mounting the WCS2 Code Rail with the Aluminum Profile System

A special aluminum profile system has been developed for quick mounting of the 55 mm WCS2

code rail made from plastic laminate or stainless steel. The alum inum profile is designed to

support the code rail and the guide trolley. The guide trolley safeguards the optimum position of

the reader in relation to the code rail at all times and compensates for running tolerances

between the vehicle and the WCS system. At the same time, the reader is decoupled from

vehicle vibrations. The aluminum profile system can be mounted in any location. The profile

rails are supplied in 5 m long pieces and are sawed with a 45° miter at the ends. The aluminum

profile rail is powder-coated and can be supplied in bend segm ents on request.

Tip

For normal industrial applications, using the laminate code rail has proven successful. With its

low weight and cost advantages, the benefits of the code rail include installation, in particular

when installing longer sections.

For extreme operating conditions, we recommend the stainless steel code rail:

■

Flying sparks in a welding shop

■

Heavy contamination during operation (e.g., waste incineration)

■

Use of the cleaning brushes on the guide trolley

2014-10

31

Page 32

WCS position encoding system

1

2

3

5

4

6

1

2

3

4

5

6

Mounting the Code Rail

Fixing cord

Reader

Guide trolley

Aluminum profile rail

Rail holder

Code rail

Mounting the Profile Rail

Rail holders are available for mounting the aluminum profile rail quickly. The profile rail snaps

into the rail holders. The rail holder is available in three different versions:

■

Without fastening screws

■

With fastening screws

■

With fastening technology for mounting in C profile rails

The support distance for the profile rail must not exceed 1.5 m for perpendicular and

suspended mounting. This corresponds to three rail holders for each 5 m rail. If the WCS2

aluminum profile system is mounted laterally, a support distance of 1.25 m is recommended.

This corresponds to four rail holders for each 5 m rail.

2014-10

32

Page 33

WCS position encoding system

79

24

32

68

118.5

147

2

65.3

92.2

68

59.332.7

92

Mounting the Code Rail

Figure 7.7 WCS2 profile system with rail holder mounted on C profile rail, with reader in the guide

trolley

Rail Holder without Fastening Screws

Figure 7.8 WCS2-MH

2014-10

33

Page 34

WCS position encoding system

59.332.7

92

115.5

68

Mounting the Code Rail

Designation Part number Function/use Support distance

WCS2-MH 184641 Rail holder Perpendicular/suspended

Rail Holder with Fastening Screws

mounting: 1.5 m

Lateral mounting: 1.25 m

Figure 7.9 WCS2-MH1

Designation Part number Function/use Support distance

WCS2-MH1 184052 Rail holder with screw

connection

Perpendicular/suspended

mounting: 1.5 m

Lateral mounting: 1.25 m

34

2014-10

Page 35

WCS position encoding system

59.332.7

92

124.5

68

Mounting the Code Rail

Rail holder with fastening screws for mounting in C profile rails 30 mm x

32 mm

Figure 7.10 WCS2-MH2

Designation Part num ber Function/use Support distance

WCS2-MH2 184053 Rail holder with screw

Mounting the Rail Holders

1. Mount the rail holders at an offset of 1.25 m along the route on the substructure for a lateral

mounting and 1.5 m for a perpendicular or suspended mounting.

2. Align the rail holders along a taut cord.

7.2.1 Rail Holders

2014-10

connection for C

profile rails

Perpendicular/suspended

mounting: 1.5 m

Lateral mounting: 1.25 m

35

Page 36

WCS position encoding system

21

16

25

25

10

20

120

20

10

45.0

Mounting the Code Rail

Figure 7.11 Aligning the rail holders (example for WCS2-MH2)

3. Snap the profile rail into the rail holder by pressing lightly.

7.2.2 Adapter Plates for Profile Rails

Adapter plates are required for connecting aluminum profile rails. The WCS2-MC* adapter

plate consists of two flat pieces and four self-tapping screws.

36

Figure 7.12 WCS2-MC1/WCS2-MC2

2014-10

Page 37

WCS position encoding system

Mounting the Code Rail

Designation Part num ber Function/use Material/mounting

WCS2-MC1 184050 Adapter plate for

WCS2-MC2 184051 Adapter plate for

Assembling the Adapter Plate

1. Slide the two flat pieces into the bottom grooves of the two profile rails that you want to connect. The end of the flat pieces that has the holes should be pushed in first.

aluminum profile rails

powder-coated

aluminum profile rails

Aluminum/steel self-tapping

screws M3 x 4.5 m m

Stainless steel/stainless steel

self-tapping screws M3 x 4.5

mm

2. Screw the self-tapping screws into the 1.8 mm diameter holes in the flat pieces.

2014-10

37

Page 38

WCS position encoding system

Mounting the Code Rail

38

The tips of the screws press into the aluminum profile and fix the adapter plate in place.

3. Slide the profile rails together with the adapter plates.

2014-10

Page 39

WCS position encoding system

Mounting the Code Rail

Note!

When you slide the aluminum profile rails together with the butt connectors, make sure there is

a gap to compensate for thermal expansion. A gap is necessar y if the maximum possible

operating temperature is greater than the temperature during the assembly.

Calculate the necessary gap width as follows:

Gap width in m m = 0.11 * ∆ϑ

∆ϑ = ϑ

max . operating temp.

Examples:

∆ϑ = 10 K, gap width = 1.1 m m

∆ϑ = 20 K, gap width = 2.2 m m

∆ϑ = 30 K, gap width = 3.3 m m

- ϑ

assem bly temp.

7.2.3 Mounting the Code Rail

Mounting the Code Rail in the Profile Rail

1. Insert the code rail into the groove of the profile rail.

2014-10

39

Page 40

WCS position encoding system

Mounting the Code Rail

2. Fix the code rail in place by pressing the plastic fixing cord into the groove of the profile rail

and simultaneously pressing on the code rail.

Caution!

Operational safety

Pressing the cord in correctly is important for the operational safety of the aluminum profile

system, particularly if it is mounted suspended.

Mounting Tool

A special mounting tool is available for fixing the code rail in place securely and quickly. The

mounting tool is recommended if the aluminum profile system is installed suspended. The tool

consists of a housing with casters, similar to the guide trolley.

Mounting the Code Rail with the Mounting Tool

1. Insert the code rail into the groove of the profile rail.

2. Place the plastic fixing cord on the groove of the profile rail.

3. Pull the mounting tool over the profile rail.

The code rail is held in position by the guide roller and contact pressure roller.

The fixing cord is pressed into the groove of the profile rail by the pressing wheel.

4. Move the mounting tool back and forth on the profile rail.

40

2014-10

Page 41

WCS position encoding system

Mounting the Code Rail

This ensures that the fixing cord sits correctly in the groove.

The contact pressure of the fixing cord is so great that the code rail cannot slip out of the

profile rail even when it is mounted suspended.

Note!

As part of regular plant maintenance, check that the fixing cord and code rail are securely in

place, especially if the profile rail is mounted suspended.

7.2.4 Fixed Points

When the rails are mounted horizontally, a locking bracket is required to prevent the aluminum

profile rails from slipping in the rail holders.

Designation Part num ber Function/use Material

WCS2-LB1 184048 Locking bracket for

WCS2-LB1-C 184049 Locking bracket for

Mounting the Locking Bracket

1. Mount the locking bracket around a rail holder in the middle of the section that you want to

fix in place.

2. Pierce the profile rail with a metal drill, Ø 7 mm. The drill hole m ust be aligned with the hole

in the locking bracket.

3. C onnect the profile rail and the locking bracket with the screw provided.

aluminum profile rails

powder-coated

aluminum profile rails

Sheet steel, galvanized

Sheet steel, galvanized,

powder coated

2014-10

41

Page 42

WCS position encoding system

Mounting the Code Rail

Tip

For vertical mounting, secure the aluminum profile with a suitable support bracket (on site).

To ensure that the code rail does not slip in the aluminum profile rail, you can fix the code rail in

place by using a spring dowel pin or a self-tapping screw in the middle of the section.

Figure 7.13 Code rail fixed point

7.2.5 The Guide Trolley

42

The guide trolley for the reader always guarantees the optimal position between the reader and

the code rail.

2014-10

Page 43

WCS position encoding system

Mounting the Code Rail

Designation Part number Function/use Material Max. speed

WCS2-GT09-P1 184046 Guide trolley for reader

WCS2-GT09-P1-C184047 Guide trolley for reader

WCS2-GT09-M1 184480 Guide trolley for reader

WCS2-GT-BR 184057 Cleaning brushes Polyamide (PA) -

Table 7.1

1)

: In dusty applications, such as in foundries or in the building materials industry, use th e

guide trolley with metal rollers.

for aluminum profile

rails

for powder-coated

aluminum profile rails

for aluminum profile

rails

Plastic rollers

Sheet steel,

galvanized

Plastic rollers

Sheet steel,

galvanized, powder

coated

Metallic rollers

Sheet steel,

galvanized

1)

8 m/s

8 m/s

8 m/s

If the WCS2 aluminum profile system is mounted laterally, you can use the extended WCS2GT09-P2 or WCS2-GT09-M2 guide rails.

Tip

The guide trolley housing has holes for mounting cleaning brushes for the code rail. The

cleaning brushes (optional) are only necessary if the code holes in the WCS code rail can

become clogged as a result of the application, e.g., with bird feathers or leaves. The brushes

can also be retrofitted.

Mounting the Reader in the Guide Trolley

The mounting bracket for the reader is pre-assembled in the guide trolley, which means that the

reader only has to be pushed on:

1. Slide the dovetail groove on the reader onto the base module of the mounting bracket. In the

end position, the spring tongue engages audibly in the quick-action lock.

The reader is mounted.

2. For dismounting, unlock the spring tongue with a screwdriver.

3. Push the reader off the base module of the mounting bracket.

Connect the guide trolley on the profile rail with the vehicle via a free-running tappet of diameter

8 mm and a slot. This decouples the movement between the vehicle and the reader and

compensates for mechanical running tolerances.

2014-10

43

Page 44

WCS position encoding system

ø 8 mm

Mounting the Code Rail

Figure 7.14 WCS2 guide trolley and tappet

Caution!

When mounting and using the tappet, make sure that the guide trolley is not subjected to any

forces.

There must be no rigid connection between the vehicle and the guide trolley.

Note!

Slide the guide trolley with the reader into the profile rail such that the electrical connector

points in the direction of the ascending position values.

7.2.6 Grounding the Aluminum Profile System

Connect the aluminum profile with the plant potential at low resistance at least every 30 m.

44

2014-10

Page 45

WCS position encoding system

Mounting the Code Rail

Figure 7.15 Grounding

7.3 Mounting the WCS3 Code Rail with the Aluminum Profile System

A special aluminum profile system has been developed for quick mounting of the 70 mm WCS3

code rail made from plastic laminate or stainless steel. The alum inum profile is designed to

support the code rail and the guide trolley. The guide trolley safeguards the optimum position of

the reader in relation to the code rail at all times and compensates for running tolerances

between the vehicle and the WCS system. At the same time, the reader is decoupled from

vehicle vibrations. The aluminum profile system can be mounted in any location. The profile

rails are supplied in 6 m long pieces. The aluminum profile rail is powder-coated and can be

supplied in bend segments on request.

Tip

For normal industrial applications, using the laminate code rail has proven successful. With its

low weight and cost advantages, the benefits of the code rail include installation, in particular

when installing longer sections.

For extreme operating conditions, we recommend the stainless steel code rail:

■

Flying sparks in a welding shop

■

Heavy contamination during operation (e.g., waste incineration)

2014-10

45

Page 46

WCS position encoding system

1

2

3

5

4

6

7

1

2

3

4

5

6

7

Mounting the Code Rail

Fixing cord

Rail holder

Aluminum profile rail

Reader

Mounting base

End stop to the vehicle

Code rail

Mounting the Profile Rail

Rail holders are available for mounting the aluminum profile rail quickly. The profile rail snaps

into the rail holders. The rail holder is available in three different versions:

■

Without fastening screws

■

With fastening screws

■

With fastening technology for mounting in C profile rails

The support distance for the profile rail must not exceed 2.5 m for perpendicular and

suspended mounting. This corresponds to two to three rail holders for each 6 m rail. If the

WCS3 aluminum profile system is mounted laterally, a support distance of 2 m is

recommended. This corresponds to three rail holders for each 6 m rail.

2014-10

46

Page 47

WCS position encoding system

M12

90

17.1 5517.128

70

1183

138

32

32

28

6

13

Mounting the Code Rail

Figure 7.16 WCS3 profile system with rail holder mounted on C profile rail, with reader

Rail Holder without Fastening Screws

Figure 7.17 WCS3-MH

Designation Part num ber Function/use Support distance

WCS3-MH 184711 Rail holder Perpendicular/suspended

mounting: 2.5 m

Lateral mounting: 2 m

2014-10

47

Page 48

WCS position encoding system

32

28

6

13

32

28

6

13

Mounting the Code Rail

Rail Holder with Fastening Screws

Figure 7.18 WCS3-MH1

Designation Part number Function/use Support distance

WCS3-MH1 184075 Rail holder with screw

Rail holder with fastening screws for mounting in C profile rails 30 mm x

32 mm

connection

Perpendicular/suspended

mounting: 2.5 m

Lateral mounting: 2 m

Figure 7.19 WCS3-MH2

Designation Part number Function/use Support distance

WCS3-MH2 184076 Rail holder with screw

7.3.1 Rail Holders

Mounting the Rail Holders

1. Mount the rail holders at an offset of 2 m along the route on the substructure for a lateral

mounting and 2.5 m for a perpendicular or suspended mounting.

2. Align the rail holders a long a taut cord.

connection for C

profile rails

Perpendicular/suspended

mounting: 2.5 m

Lateral mounting: 2 m

48

2014-10

Page 49

WCS position encoding system

Mounting the Code Rail

Figu re 7.20 Aligning the rail holders (example for WCS3-MH2)

3. Snap the profile rail into the rail holder by pressing lightly.

7.3.2 Adapter Plates for Profile Rails

Adapter plates are required for connecting aluminum profile rails. The WCS3-MC1 connector

consists of a 170 mm long extruded aluminum profile and two self-tapping screws.

Designation Part num ber Function/use Material/mounting

WCS3-MC1 184074 Adapter plate for

Assembling the Adapter Plate

1. Slide the adapter plate into the bottom grooves of the two profile rails that you want to connect. The end of the connector that has the holes should be pushed in first.

aluminum profile rails

Aluminum/steel selftapping screws M3 x 4.5

mm

2014-10

49

Page 50

WCS position encoding system

Mounting the Code Rail

2. Screw the self-tapping screws into the 1.8 mm diameter holes in the flat pieces.

50

The tips of the screws press into the aluminum profile and fix the adapter plate in place.

3. Slide the profile rails together with the adapter plates.

2014-10

Page 51

WCS position encoding system

Mounting the Code Rail

Note!

When you slide the aluminum profile rails together with the adapter plates, make sure there is a

gap to compensate for thermal expansion. A gap is necessary if the maximum possible

operating temperature is greater than the temperature during the assembly.

Calculate the necessary gap width as follows:

Gap width in m m = 0.12 * ∆ϑ

∆ϑ = ϑ

max . operating temp.

Examples:

∆ϑ = 10 K, gap width = 1.2 m m

∆ϑ = 20 K, gap width = 2.4 m m

∆ϑ = 30 K, gap width = 3.6 m m

- ϑ

assem bly temp.

7.3.3 Mounting the Code Rail

Mounting the Code Rail in the Profile Rail

1. Insert the code rail into the groove of the profile rail.

2014-10

51

Page 52

WCS position encoding system

Mounting the Code Rail

2. Fix the code rail in place by pressing the plastic fixing cord into the groove of the profile rail

and simultaneously pressing on the code rail.

Caution!

Operational safety

Pressing the cord in correctly is important for the operational safety of the aluminum profile

system, particularly if it is mounted suspended.

Mounting Tool

A special mounting tool is available for fixing the code rail in place securely and quickly. The

mounting tool is recommended if the aluminum profile system is installed suspended. The tool

consists of a housing with casters, similar to the guide trolley.

Mounting the Code Rail with the Mounting Tool

1. Insert the code rail into the groove of the profile rail.

2. Place the plastic fixing cord on the groove of the profile rail.

3. Pull the mounting tool over the profile rail.

The code rail is held in position by the guide roller and contact pressure roller.

The fixing cord is pressed into the groove of the profile rail by the pressing wheel.

4. Move the mounting tool back and forth on the profile rail.

This ensures that the fixing cord sits correctly in the groove.

The contact pressure of the fixing cord is so great that the code rail cannot slip out of the

profile rail even when it is mounted suspended.

Note!

As part of regular plant maintenance, check that the fixing cord and code rail are securely in

place, especially if the profile rail is mounted suspended.

7.3.4 Fixed Points

To prevent the aluminum profile rails from slipping in the rail holders when mounted horizontally,

the profile m ust be securely connected to the substructure.

Mounting Fixed Points

1. Mount a fixed point in the middle of the section that you want to fix in place.

2. Pierce the rail holder on both sides with a metal drill with 1.8 mm diameter.

52

2014-10

Page 53

WCS position encoding system

Mounting the Code Rail

Figu re 7.21

3. Drill two 3 x 6 mm self-tapping screws into these holes. The self-tapping screws are not

included in the product contents.

The screws press into the aluminum profile, establishing a tight-fitting connection

between the rail holder and the aluminum profile.

Figu re 7.22

Tip

We recommend that you fix the aluminum profile in place at multiple points along a route using

the method described. Make sure that there are sufficient expansion gaps between the

aluminum profiles. (see chapter 7.3.2)

Tip

For vertical mounting, secure the aluminum profile with a suitable support bracket (on site).

2014-10

53

Page 54

WCS position encoding system

Mounting the Code Rail

7.3.5 Vertical Curves

In addition to horizontal curves, vertical curves are required to create inclines/declines.

Figure 7.23

Vertical curves up to a minimum radius of 4 m can be created with the alum inum profile in

conjunction with the laminate code rail.

Routing Vertical Curves

1. Mount the required rail holder along the desired route.

2. Carefully bend the required aluminum profiles into the corresponding radius > 4 m.

3. Engage the aluminum profiles in the rail holders.

4. Cut into the required code rail from the beginning to the end of the curve at intervals of

approximately 50 mm

Make sure that you cut into the code rail from below, i.e., from the wider side up into the

code window. Cut a small triangle off from each cut to prevent the code rail from overlapping

in the aluminum profile.

54

5. Insert the code rail into the aluminum profile together with the fixing cord. Secure the code

rail with the fixing cord using the mounting tool in the aluminum profile rail. See chapter

7.3.3.

2014-10

Page 55

WCS position encoding system

Mounting the Code Rail

7.3.6 Interruptions in the Profile Rail

In some applications, it is necessary to interrupt the course of the code rail, e.g., for crane

crossings, for fire protection gates, or for large expansion joints in buildings.

Caution!

Make sure that interruptions in the code rail are at least 85 mm and the two code rail parts are

aligned.

The maximum distance from one end of an aluminum profile rail to the next rail holder must not

be larger than 0.5 m.

7.3.7 Suspended Mounting with Stainless Steel Code Rail

If you want to mount the stainless steel code rail suspended, you have to secure the code rail

against falling down. This applies in particular when there are frequent changes in temperature.

For lengths up to 25 m, using the clamping fixture (see chapter 6.2) is sufficient.

For lengths beyond this, we recommend further securing the stainless steel code rail every 12

m with a self-tapping screw or a spring dowel pin in the aluminum profile.

Securing the Code Rail

1. Pierce the aluminum and the code rail from the side.

2. Screw a suitable self-tapping screw into the hole. Alternatively, you can use a suitable spring

dowel pin.

The self-tapping screw or spring dowel pin is not included in the product contents.

2014-10

55

Page 56

WCS position encoding system

Mounting the Code Rail

7.3.8 Grounding the Aluminum Profile System

Connect the aluminum profile with the plant potential at low resistance at least every 30 m.

Figure 7.24 Grounding

7.3.9 Integration of the WCS Code Rail in Conductor Lines

56

In many applications, electrical energy is transferred to the carriage via conductor lines.

Pepperl+Fuchs offers an integrated solution of power transmission and position measurement.

This requirement was taken into account in the development of the new Vahle VKS 10

conductor line. The VKS 10 is flexible in terms of the number of conductors and cross-sections

and facilitates cost-effective integration of the WCS code rail in the plastic base body of the

conductor line.

2014-10

Page 57

WCS position encoding system

WCS3B-Lesekopf

WCS3-CS70-L2

Mounting the Code Rail

Figure 7.25 Integration of the WCS3-CS70-L2 code rail in the Vahle VKS 10 power rail

To mount the WCS3 code rail in the VKS 10 system, a special mounting hole and a special

code rail are required. The laminate code rail is characterized by a high degree of flexibility and

tear resistance. Using the code rail guarantees the reproducibility of the local coordinates

regardless of the prevailing ambient conditions. Due to the light transmission method used with

the WCS, reliable system function is guaranteed even in very harsh industrial environments.

Designation Part num ber Function/use Material

WCS3-CS70-L2 184070 Code rail with Vahle

Polyester laminate

VKS hole

For product information on the VKS 10 see www.vahle.de.

2014-10

57

Page 58

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

/ DOCT3785

10/2014

Loading...

Loading...