Page 1

VisuNet GXP

RM-GXP1100 and

RM-GXP1200

System Manual

PROCESS AUTOMATION

MANUAL

Page 2

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

VisuNet GXP RM-GXP1100 and RM-GXP1200

Page 3

VisuNet GXP RM-GXP1100 and RM-GXP1200

3

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 4

2 Product Description ................................................................... 6

2.1 Overview ............................................................................................... 6

2.2 Technical Specifications...................................................................... 8

2.3 Dimensions......................................................................................... 10

2.4 Scope of Delivery............................................................................... 10

3 Mechanical Installation ............................................................ 11

3.1 Unpacking........................................................................................... 11

3.2 System Installation............................................................................. 13

3.2.1 Preparing the Pedestal..................................................................... 13

3.2.2 Mounting the Housing...................................................................... 13

3.2.3 Closing the Housing......................................................................... 16

3.2.4 Mounting the Keyboard.................................................................... 18

3.2.5 Mounting the Scanner Holder to the Housing .................................. 19

3.2.6 Installing the Scanner Cable ............................................................ 21

3.2.7 Dismounting the Display Unit ........................................................... 22

3.3 Panel Mount Installation .................................................................... 25

4 Electrical Installation................................................................ 29

4.1 Grounding the Housing to the Pedestal .......................................... 30

4.2 Grounding the Housing to the Wall-Bracket.................................... 31

5 Appendix ................................................................................... 32

5.1 Accessories ........................................................................................ 32

Page 4

302041 2017 -05

4

VisuNet GXP RM-GXP1100 and RM-GXP1200

Introduction

1 Introduction

1.1 Content of this Document

This document contains information that you need in order to use your product throughou t the

applicable stages of the produ ct life cycle. These can include the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dism ounting

■

Disposal

The docum entation consists of the following parts:

■

Present document

■

Instruction manual

■

Datasheet

Additionally, the following parts m ay belong to the documentation, if applicable:

■

EU-type examination certificate

■

EU declaration of conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Additional docum ents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out m ounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further docu mentation.

Prior to using the produ ct make yourself familiar w ith it. Read the document carefully.

Note!

This document does not substitute the instruction manual.

Note!

For full information on the product, refer to the instruction manu al and further documentation on

the Internet at www.pepperl-fuchs.com.

Page 5

VisuNet GXP RM-GXP1100 and RM-GXP1200

Introduction

302041 2017 -05

5

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandator y

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Informative Symbols

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause persona l injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Note!

This symbol brings important information to your attention.

Page 6

302041 2017 -05

6

VisuNet GXP RM-GXP1100 and RM-GXP1200

Product Description

2 Product Description

2.1 Overview

The Pepperl+Fuchs VisuNet Remote Monitors GXP RM-GXP1100-* and RM-GXP1200-* are

explosion-protected apparatuses certified for use in hazardous areas rated according to IECEx

& ATEX Zone 1/21 and Zone 2/22 type designations.

The VisuNet GXP serves as a thin-client based operator workstation that uses standard

Ethernet technology to transmit process information from a process control or manufacturing

execution system into hazardous areas.

The assembly consists of three core devices which can be replaced by the customer:

■

The display units DPU1100-* and DP U1200-* are display panels with optionally available

10-finger m ulti-touch sensors, rated for zones 1/21 and 2/22, respectively. The displays

and touch-sensors are optically bonded with the hardened front glass.

■

The thin client units TCU1100-* and TCU1200-* are computing units running the latest

Pepperl+Fuchs RM shell 4.x firmware. They allow connecting to various sets of host

systems in the safe are, using standard Ethernet technology.

■

The power supply units PSU1100-* and PSU1200-* provide the above mentioned devices

with 24 V DC power. They are available as DC and as wide-range AC versions.

As the standard mounting option, a bezel is avaible which allows mounting the panel into a

system housing or cabinet (mounting kit required). The panel can also be flush-mounted into a

cabinet from behind, using additionally available mounting brackets.

Page 7

VisuNet GXP RM-GXP1100 and RM-GXP1200

Product Description

302041 2017 -05

7

2.2 Technical Specifications

Technical Data

Hardware

Processor Intel® Atom™ Bay Trail E3827 1.75 GHz

RAM 2 GB DDR3L

Mass storage 32 GByte industrial grade MLC SSD

Supply

Power consumption max . 72 W , typ. 55 W

Interface

Interface type 1 x Ethernet 100/1000BASE-T 1000 MBit/s (Ex e) or fiber optic

1000Base-SX, 1000 MBit/s

1x USB 2.0 (Ex e)

2x USB 1.1 (Ex i; intended for P+F keyboard and mouse)

optional: 1x barcode reader interface P+F Pscan-D/B (Ex i)

1x DC or AC power in (via power supply unit)

Software

Operating system VisuNet RM Shell 4.x (based on Microsoft Windows

Embedded Standard 7)

Supports Microsoft DRDP, VNC, and other remote desktop

protocols

Ambient conditions

Operating temperature 0 ... 50 °C (32 ... 122 °F) (norm al operation) ;

-20 ... 50 °C (-4 ... 122 °F) (after 1 hour of operation)

Storage temperature -20 ... 60 °C (-4 ... 140 °F)

Relative h umidity 93% at 40°C, non-condensating, according to EN60068-2-78

Vibration resistance 10 ... 150 Hz, +/- 0.075 mm , 1g, 10 cycles per axis according

to EN 60068-2-6

Mechanical specifications

Degree of protection IP66 (panel with system housing)

Material Panel: anodized aluminum (TCU, PSU), powder coated

aluminum (DPU)

Bezel: stainless steel AISI 304 (1.4301)

System housing: s tainless steel AISI 304 (1.4301), ceramic

blasted

Page 8

302041 2017 -05

8

VisuNet GXP RM-GXP1100 and RM-GXP1200

Product Description

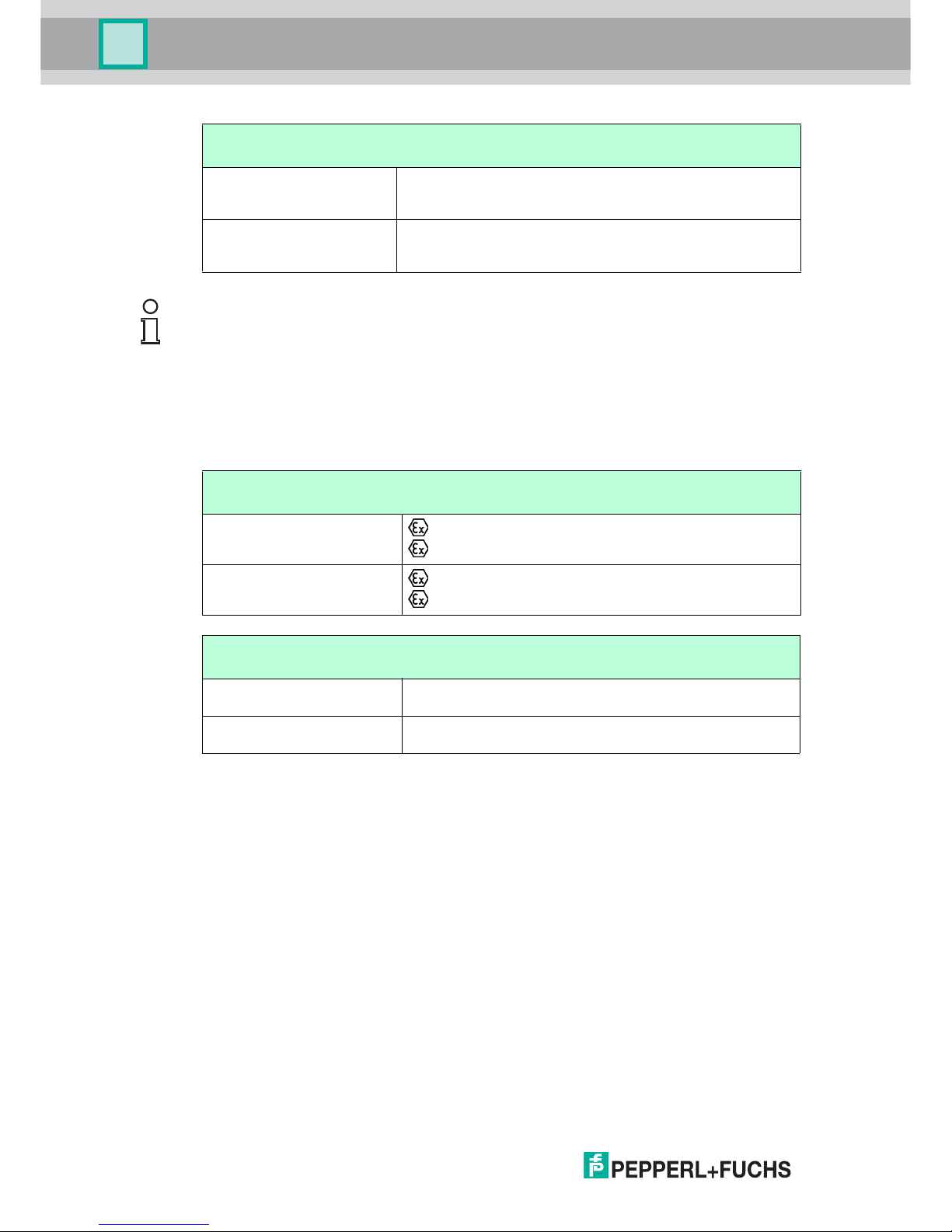

Marking

Mass Panel (DPU with bezel, TCU, PSU DC): approx. 17.5 kg

Panel (DPU with bezel, TCU, PSU AC): approx. 18 kg

System housing: approx. 11 kg

Dimensions Panel (DPU with bezel, TCU, PSU DC): 625x459x120 mm

Panel (DPU with bezel, TCU, PSU AC): 625x459x137 mm

Panel with system housing: 625x459x173 mm

Mechanical specifications

Note!

For more technical information, please refer to the datasheets of the individual components:

■

Display Units DPU1100-J1* and DPU1200-J2*

■

AC Power Supply Units PSU1100-J1-AC-N0 and PSU1200-J2-AC-N0

■

DC Power Supply Units PSU1100-J1-DC-N0 and PSU1200-J2-DC-N 0

■

Thin Client Units TCU1100-J1-* and TCU1200-J2-*

ATEX

RM-GXP1100-J1-*

II 2G Ex eb q ib [ib] IIC T4 IP66 Gb

II 2D Ex tb [ib] IIIC T85°C IP66 Db

RM-GXP1200-J2-*

II 3G Ex ec [ib] q IIC T4 IP66 Gc

II 3D Ex tc [ib] IIIC T85 °C IP66 Dc

IECEx

RM-GXP1100-J1-* Ex eb q ib [ib] IIC T4 IP66 Gb

Ex tb [ib] IIIC T85°C IP66 Db

RM-GXP1200-J2-* Ex ec [ib] q IIC T4 IP66 Gc

Ex tc [ib] IIIC T85 °C IP66 Dc

Page 9

VisuNet GXP RM-GXP1100 and RM-GXP1200

Product Description

302041 2017 -05

9

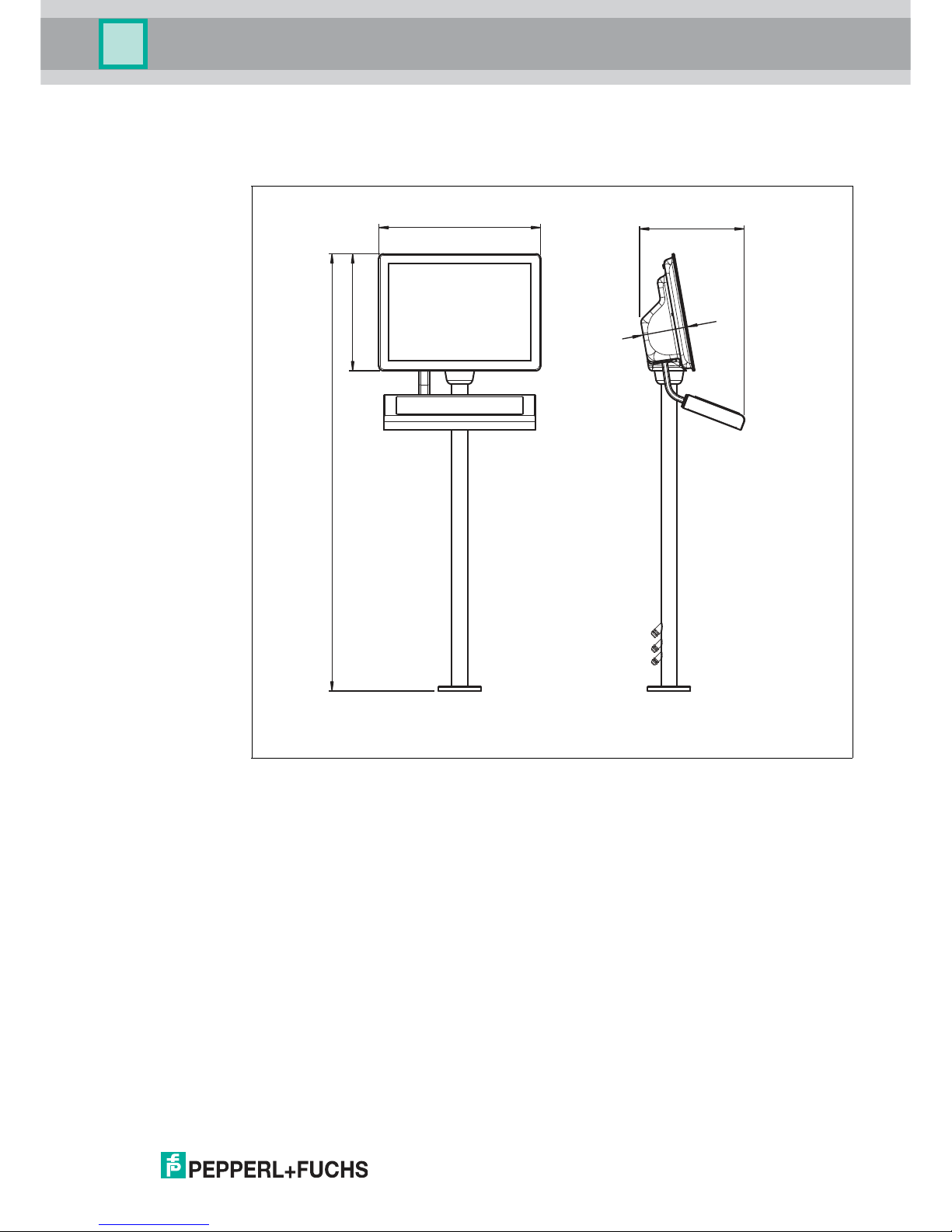

2.3 Dimensions

Dimensions

2.4 Scope of Delivery

■

1x Pre-assembled VisuNet RM-GXP Panel

■

(Option: Panel mounted into AG-XX00 housing)

■

2x Protective tubes

■

Screws for housing

624

451

1687

~ 400

173

Page 10

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

11

3 Mechanical Installation

3.1 Unpacking

The VisuNet GXP is sent pre-assembled consisting of the core components Display Unit,

Power Supply Unit and Thin Client Unit. If the housing option is chosen, the pan el is sent premounted into the housing.

Warning!

Risk of injuries

Handling the devices with bare hands may cut fingers, hands, or wrists.

Make sure to wear gloves during the installation process at all times.

Caution!

Scratches and damages to the devices

The devices may become scratched or damaged if they a re placed onto or moved over hard

surfaces.

Use the foam brackets enclosed when taking the device out of the box or moving it around. Use

these brackets for placing the device and place it face down onto them, i.e. onto the display

front.

Warning!

Danger resulting from scratched display unit front screen

Scratches in a display unit front screen weaken the glass structure and may thus, in the event

of an explosion within the display unit, result in glass breakage. Explosion protection is no

longer ensured if a display unit with a scratched screen is used.

NEVER use a display unit with a scratched front screen in a hazardous area. If the surface is

damaged in any way, return the display unit to Pepperl+Fuchs at once and replace it with a new

one. To this end, remove the display unit. See chapter 3.2.7

Page 11

302041 2017 -05

12

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

Page 12

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

13

3.2 System Installation

3.2.1 Preparing the Pedestal

For floor mounting, the preferred installation option is using PEDESTAL-XX00-*. This is shipped

with a pre-installed rotating coupling with four headless screws an d a grounding cable which is

fixed to the pedestal tube.

Preparing the Pedestal for Connection

1. Bend the grounding cable and place it within the pedestal tube.

2. Route the field installation cables (power cable, Ethernet cable) through the cable glands at

the pedestal bottom into the pedestal, through the pedestal tube, and out at the top.

3. Place the O-ring into the channel of the coupling.

The pedestal is now ready for connection.

Figure 3.1 Pedestal with PE cable

1 PE cable

1

Page 13

302041 2017 -05

14

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

3.2.2 Mounting the Housing

Mounting the AG-XX00 Housing onto the Pedestal

1. Align the rotatable coupling of the pedestal to match the hole pattern of the housing.

2. With the help of a crane or another person, place the housing onto the pedestal in such

a way that the screws align with the key slot hole and the housing rests on the pedestal.

Warning!

Risk of injuries

Lifting the device on your own may lead to injury.

Do not attempt to lift the device on your own. Use a crane or get another person to help you.

Warning!

Risk of injuries

While the device is resting on the pedestal and the nuts have not yet been fixed to the screws,

the device may tip over and fall off the pedestal, become damaged and cause injury.

Make sure to prevent the housing from tipping over by securing it manually (e.g. holding on to

it) until the nuts have been firmly attached to the screws and the housing is securely attached to

the pedestal.

Warning!

Damage to the PE cable

The PE cable may become damaged if it gets stuck between the pedestal and the housing.

Bend the PE cable in s uch a way that it does not get stuck between the pedestal and the

housing.

Page 14

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

15

1. While manually securing the housing (e.g. by holding on to it), remove all screws from its

back.

2. While manually securing the housing (e.g. by holding on to it), slowly pull on both lower

corners of the display bezel until the display slides out of the housing completely.

3. While manually securing the housing (e.g. by holding on to it), slide the display panel

about 8 mm to the left to unlock the panel mechanism securing the display.

4. While manually securing the housing (e.g. by holding on to it), open the housing by

moving the display away from it.

Page 15

302041 2017 -05

16

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

While manually securing the housing (e.g. by holding on to it), tip the display panel towards

you until the display comes to rest in its fully openend position, hanging down at an angle from

its tightened strings.

Place the washers onto the screws and then use a tightening torque to attach the nuts to the

headless screws using a torque of 7.5 Nm.

1.

1.

2.

3.

Tip

Secure the screws with a medium strength bolt adhesive (e.g. Loctite® Threadlocker Blue

242®)

Page 16

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

17

3.2.3 Closing the Housing

Closing the AG-XX00 Housing

1. To close the housing, put the display in an upright position by slowly moving it backwards

until the bolts touch the inner fram e of the housing and the panel is in its parking position.

2. To unlock the display panel, slide it about 8 mm to the right until the bolts match with the cutout holes of the inner frame.

3. Slowly and evenly push both lower corners of the display panel into the housing.

4. Press together display panel and housing at the top end of the system and place a screw

each in the holes at the upper left and upper right corners of the housing back.

Warning!

Risk of finger injury

Fingers can become squeezed in and stu ck when the display is moved backed into the

housing.

Wear protective gloves, hold the display panel by the fram e when moving it and mind your

fingers.

Warning!

Risk of cable damage

The cables may become squeezed in during the closing process.

Make sure to properly fix all the cables, place them in a protective tube and push that tube into

the pedestal before closing the housing.

1.

2.

3.

3.

Page 17

302041 2017 -05

18

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

5. Fasten the the two screws with a torque of 6 Nm .

6. Repeat the last step with all other screws following a diagonal pattern.

Page 18

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

19

3.2.4 Mounting the Keyboard

The TASTEX EXTA 2 keyboard is the system keyboard available with a mounting option for the

VisuNet GXP housing AG-XX00.

Mounting the EXTA2-*-G-* Keyboard to Housing AG-XX00

1. Open and remove the four cover plate screws on the left side of the AG-XX00 housing bottom.

2. Route the keyboard cable with the protective tube through the hole of the AG-XX00.

1. Using the screws delivered with the EXTA2-*-G-* keyboard, attach the keyboard to the AGXX00 housing.

2. Fasten the the four screws w ith a torque of 6 Nm.

Tip

Secure the s crews with a medium strength bolt adhesive (e.g. Loctite® Threadlocker Blue

242®)

Page 19

302041 2017 -05

20

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

3.2.5 Mounting the Scanner Holder to the Housing

The SCANN ER-HOLDER-PSCAN-XX00-N0 (#548121) is a scanner holder for the PSCAN-*

scanner family that is compatible with the VisuNet GXP housing AG-XX00.

We recommend using the following tools for the installation:

■

Split socket pliers

■

Gloves

■

Hex key drivers (2.5 mm and 3 mm)

■

Flat wrench (10 m m)

Mounting SCANNER-HOLDER-PSCAN-XX00-N0 to Housing AG-XX00

1. Open the housing.

2. Remove the cover plate on the right side of the AG-XX00 housing by opening the w ing

screw which is located within the housing.

3. Affix the scanner holder with the first screw that is contained in the scope of delivery of the

scanner holder.

4. Use a hex key to put the first screw (with lock washer and sealing washer) through the

drilled hole at the left side of the AG-XX00 housing.

1.

1.

2.

3.

Page 20

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

21

5. Press the scanner holder against the housing from the outside and fasten the screw using a

torqu e of 6 Nm.

6. Use the hex key to put the second screw (with lock washer and sealing washer) through the

drilled hole at the right side of the AG-XX00 housing and fasten the screw using a torque of

6 Nm .

The scanner holder is now fixed to the housing.

Page 21

302041 2017 -05

22

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

3.2.6 Installing the Scanner Cable

The DATL-PSCAN-D-XX00-N0 (#548133) is a cable for the installation of the PSCAN-D

barcode reader to the VIsu Net GXP RM/PC. The scanner cable is compatible with the VIsuNet

GXP housing AG-XX00 and allows to install the scanner interface plug into the housing.

Installing Scanner Cable DATL-PSCAN-D-XX00-N0

1. Open the housing.

2. To remove the plug at the bottom right side of the housing, hold its screw steady from below

using a screwdriver, while unwinding the screw from above usin g a wrench.

3. Put the cable through the hole with its open wire ending facing foward.

4. Add the M16 counter nut over the end of the cable.

5. Pull the socket into the housing and tighten it with the M16 counter nut. Tighten the screw

with a torque of 5 Nm.

6. Protect the cable from mechanical da mage by fixing it with a cable tie.

7. Route the cable into the computing unit by using the cable gland of the computing unit (TCU

or PCU). Install the cable ends as per the table below.

Wire Colors and Signals

Connect the plug of the PSCAN-D* barcode reader to the socket and tighten it firmly.

Wire Color Signal

Yellow US

White TxD

Green RxD

Brown a nd Gray GND

Note!

For more information regarding electrical installation, please refer to the computing unit (TCU or

PCU) manual or the PSCAN barcode reader ma nual.

Note!

The plug is secured with a nose. Ensure to match the nose with the socket during installation.

Page 22

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

23

3.2.7 Dismounting the Display Unit

Dismounting the Display Unit

1. Open the housing (1). After de-energizing (s ee above), open the compartment room of the

computing unit. Then, remove all 10 screws from the back of the computing unit and take the

computing unit off from the display unit (2).

2. To ease the replacement of the display unit, temporarily affix the computing unit, e.g. by

using cable ties. To this end, put a cable tie through either m ounting hole at its top left and

top right, and hang the computing unit from the top of the enclosure frame.

Note!

For repair purposes, the display unit can be dismounted from the computing unit (TCU or PCU)

and be replaced individually.

Warning!

Danger of Explosion

An ignition may be triggered if the computing unit is still energized when its compartment room

is opened.

Make sure the computing unit is switched off and wait 3 minutes after de-energizing before

opening the compartment room of the computing unit.

1 Cable Ties

1.

2.

1

Page 23

302041 2017 -05

24

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

3. Remove the grounding cable from the grounding bolt at the back of the display unit.

1

4. Now the display unit can be rem oved from the enclosure completely. During the rem oval

process, make sure to hold the display unit steady so it cannot fall down, preferably with the

help of another person, and to place it on an upholstered and even surface after removal. To

remove the display unit from the enclosure, take the two strings out of the carabiners and

remove the 4 screws w ith which the 2 angle brackets are attached to the display unit (1).

Then remove the display unit from the h ousing (2).

1. Ple ase use a torque of 4 Nm for tightening t he grou nding bolt during th e displ ay unit reassembly proces s where

these steps are performed in reverse order.

2.

1.

Page 24

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

25

5. Remove the two brackets (1) as well as the 10 bolts at the top, sides, a nd bottom of the

display unit (2). Then, remove the carabiners (3) from their brackets, take out the six bracket

screws (4), and remove the carabiner brackets.

1.

2.

4.

3.

Note!

To mount the new display unit, perform all of the above steps in reverse, mounting the items

you dismounted.

Page 25

302041 2017 -05

26

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

3.3 Panel Mount Installation

If the Panel Mount Option is chosen, you will receive a pre-assembled package consisiting of a

display unit, a computing unit, and a power supply unit.

The following kit for panel mounting can be ordered separately:

■

2x L-shaped panel mount brackets (1 left, 1 right)

■

1 rectangular stiffener frame

■

14x M5x25 socket head cap screw (torque: 1.8 Nm)

■

10x M5 lock nut (torqu e: 4 Nm)

For ordering details, see chapter 5.1

Panel Mounting the RM-GXP

1. Mount the first L-shaped bracket to the back of the display unit. Make sure to use the bracket

with the four extra holes at the bottom.

Note!

Please note that the mounting brackets are not identical, but two different items.

1 L-shaped bracket with extra holes at the bottom

1

Page 26

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

302041 2017 -05

27

2. From the front, place the panel in the cabinet cutout hole (1) and move it to an upright

vertical position (2).

3. From inside the cabinet, add the stiffener frame, position it (1)-(3), and press it against the

back of the cabinet wall.

1 Cabinet wall (back)

2 Stiffener Frame

1.

2.

3.

2

1

1.

2.

1.

Page 27

302041 2017 -05

28

VisuNet GXP RM-GXP1100 and RM-GXP1200

Mechanical Installation

4. Prepare the other L-shaped bracket with the mounting screws.

5. Mount the prepared L-shaped bracket to the display unit housing (1), then affix both Lshaped brackets with all screws to the stiffener frame (2).

6. Finally, tighten all the screws in a criss-cross pattern using 1.8 Nm torque for the 14x M5x25

socket head cap screws and 4 Nm for the 10x M5 lock nuts.

1.

2.

Page 28

VisuNet GXP RM-GXP1100 and RM-GXP1200

Electrical Installation

302041 2017 -05

29

4 Electrical Installation

When installing the VisuNet GXP system, always ensure a proper grounding of all components

including housing and mounting parts (e.g. pedestal, wall-bracket) with an area of at least 4

mm2according to IEC 60079-14.

The VisuNet GXP is shipped with the following PE wiring connections, if the housing option is

selected:

■

PE wire from the display unit grounding bolt to the housing AG-XX00 grounding bolt.

■

PE wire from the power supply unit grounding bolt to the housing AG-XX00 grounding

bolt.

Warning!

Danger of Explosion

Disconnecting cables too quickly may trigger an ignition, as device-internal cable capacitances

need some time to discharge.

After de-energizing, wait 3 m inutes before opening the compartment room or disconneting the

device from the display unit.

Warning!

Danger of Explosion

Cable insulation m ay become damaged if cables and connection lines are not used in

adequate temperature ranges. Thus, short circuits within the cable may occur which in turn may

give rise to sparks and/or surface temperatures capable of triggering an ignition.

Only use cables and connection lines which are suitable to be used within a temperatu re rating

of 80 °C if the system components are used within an ambient operating temperature of Ta > 40

°C.

Note!

Please refer to the manuals of the individual com ponents for further information on electrical

installation and wiring.

Danger!

Explosion hazard from wrong or missing grounding

Wrong or missing grounding can cause sparks. This can ignite the surrounding potentially

explosive atmosphere.

■

Ground the device. Observe th e grounding requirements.

■

Ensure that external ground connections exist, are in good condition, and are not

damaged or corroded.

Warning!

Risk of electric shock or property damage from inadequate grounding

If you do not ground the device correctly, this could result in potential equalization currents.

These currents could hurt operating personnel or cause property damage.

Ground the device via the grounding bolt. Ensure that a correct potential equalization is

guaranteed at all times.

Page 29

302041 2017 -05

30

VisuNet GXP RM-GXP1100 and RM-GXP1200

Electrical Installation

4.1 Grounding the Housing to the Pedestal

Grounding the AG-XX00 Housing to PEDESTAL-XX00-*.

1. Connect the pre-installed PE wire of the pedestal to the grounding bolt of the AG-XX00 housing.

2. Ground the pedestal with the grounding stud on the bottom plate of PEDESTAL-XX00-*.

3. Fasten the screw with a torque of 7.5 Nm .

Figure 4.1 Grounding Concept

1 Housing

2 Ground bolt (hexagon socket)

3 Contact washer

4 Nut

5 Cable lug

6 Flat washer

7 Spring washer

8 Nut

1

2

3

4

5

6

7

8

Page 30

VisuNet GXP RM-GXP1100 and RM-GXP1200

Electrical Installation

302041 2017 -05

31

4.2 Grounding the Housing to the Wall-Bracket

Grounding the AG-XX00 Housing to WALL-BRACKET-XX00-*

1. Ground the wall bracket with the grounding bolt on the bottom of the WALL-BRACKETXX00-*.

2. Fasten the screw with a torque of 6 Nm.

Note!

The AG-XX00 housing is grounded indirectly via the wall bracket. It does not require an

additional PE wire between housing and wall bracket.

Page 31

302041 2017 -05

32

VisuNet GXP RM-GXP1100 and RM-GXP1200

Appendix

5 Appendix

5.1 Accessories

Mounting and Installation

Barcode Reader

Item Number Name Description

#548003 PEDESTAL-XX00-124-3-304-TRN-N0 Turnable pedestal, floor mount

Compatible with AG-XX00-* housing

#548071 WALL-BRACKET-XX00-3-304-N0 Adapter for wall mounting installation

Compatible with AG-XX00-* housing

#548004 KIT-PM-XX00-22F-304-N0 Kit for panel mounting

Compatible with 21.5'' display unit

(option 22F)

Item Number Name Description

#548121 SCANNER-HOLDER-PSCAN-XX00-N0 Scanner holder for PSCAN-

D/PSCAN-M barcode reader

Compatible with AG-XX00-* housing

#548133 DATL-PSCAN-D-XX00-N0 Connector cable for PSCAN-D

barcode reader

Compatible with AG-XX00-* housing

Note!

For more options and accessories, please contact your local Pepperl+Fuchs sales

representative.

Page 32

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

www.pepperl-fuchs.com

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

For the Pepperl+Fuchs representative

closest to you check www.pepperl-fuchs.com/contact

PROCESS AUTOMATION –

PROTECTING YOUR PROCESS

302041 / DOCT-5482

05/2017

Loading...

Loading...