Pepperl+Fuchs VisuNet GMP DM200 Series, VisuNet GMP DM219, VisuNet GMP DM222, VisuNet GMP DM221 Hardware Manual

Page 1

PROCESS AUTOMATION

MANUAL

VisuNet GMP DM200 Series

Hardware Manual

Page 2

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

VisuNet GMP DM

Page 3

VisuNet GMP DM

3

1 Safety .......................................................................................... 5

1.1 Validity................................................................................................... 5

1.2 Symbols Used ...................................................................................... 5

1.3 System Operator and Personnel ........................................................ 5

1.4 Pertinent Laws, Standards, Directives, and further Documentation5

1.5 Intended use......................................................................................... 6

1.6 Installation and commissioning ......................................................... 6

2 Product Specifications............................................................... 7

2.1 Overview ............................................................................................... 7

2.2 Technical Data ...................................................................................... 8

2.3 Dimensions VisuNet GMP DM series ................................................. 9

2.4 Interfaces and connectionsVisuNet GMP DM ................................. 10

2.4.1 VGA interface................................................................................... 10

2.4.3

Supply Voltage 24 V......................................................................... 11

2.4.4 Supply Voltage 120/230 V (AC)........................................................ 11

2.5 Accessories........................................................................................ 12

2.5.1

Keyboards........................................................................................ 12

2.5.2

Pedestals ......................................................................................... 15

2.5.3

Wall arm versions............................................................................. 16

2.5.4

Wall bracket ..................................................................................... 16

2.5.5

Hole pattern of the mounting versions.............................................. 17

2.5.6 Power supply accessories................................................................ 18

2.4.2

DVI interface..................................................................................... 10

2.5.7 Barcode reader................................................................................. 18

2.5.8 Dimensions with barcode handheld.................................................. 19

2.5.9 Holder for handheld barcode reader................................................. 20

3 Installation an

d Commissioning ............................................. 21

3.1

Preparation ......................................................................................... 21

3.2 Mounting in the field.......................................................................... 21

3.2.1 Grounding at pedestal an

d wall arm................................................. 21

3.3 Commissioning VisuNet GMP .......................................................... 22

2.4.5

Supply voltage 12 V (PA version) ..................................................... 11

Page 4

4

VisuNet GMP DM

4.1

On Screen Display..............................................................................24

4.1.1

Audio menu ...................................................................................... 26

4.1.2

Bright-Contrast menu ....................................................................... 27

4.1.3

Menu Color ...................................................................................... 28

4.1.4

Image menu ..................................................................................... 29

4.1.5

Tools menu ....................................................................................... 30

4.1.6

Input menu ....................................................................................... 31

4.1.7

Exit menu ......................................................................................... 32

5 Appendix ................................................................................... 33

5.1 Chemical resistance of keyboard foil ...............................................33

5.2 Chemical resistances of the touch screen ......................................33

4 Operation................................................................................... 24

Page 5

VisuNet GMP DM

Sicherheit

219365 2017-02

5

1

1.1

1.2

Safety

Validity

The chapter “Safety” is valid as inst

ruction manual.

Specific processes and instructions in this instruction manual require special provisions to

guarantee the safety of the operating personnel.

Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Informative Symbols

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

1.3 System Operator and Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry out mounting,

installation, commissioning, operation, maintenance, and dismounting of the device. The

trained and qualified personnel must have read and understood the instruction manual.

1.4 Pertinent Laws, Standards, Directives, and further Documentation

Observe laws, standards, and directives applicable to the intended use and the operating

location. Observe Directive 1999/92/EC in relation to hazardous areas.

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Note!

This symbol brings important information to your attention.

Page 6

219365 2017-02

6

VisuNet GMP DM

Sicherheit

1.5

1.6

The corresponding datasheets, manuals, declarations of conformity, EU-type examination

certificates, certificates, and control drawings if applicable (see datasheet) are an integral part

of this document. You can find this information under www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change. Please refer only to

the most up-to-date version, which can be found under www.pepperl-fuchs.com.

Intended use

The device is only approved for appropriate and intended use. Ignoring these instructions will

void any warranty and absolve the manufacturer from any liability.

The devices must not be repaired, changed or manipulated. If there is

a defect, the product

must always be replaced with an original device.

Installation and commissioning

The device must only be operated in the specified ambient temperature range and at the

specified relative humidity without condensation. The device is rated up to 2000 m and is

intended to be used in a Pollution Degree 2 environment.

Overcurrent protection is achieved external to the equipment: 15 A overcurrent protection must

be provided by the building installation.

A readily accessible disconnect device must be incorporated external to the equipment.

Use shielded cable

To connect interfaces only use shielded cable.

Screwing/locking connectors

To advance the cable shield screw/lock the connectors.

The device must be disconnected from the power supply prior to installation and maintenance.

The power supply may be activated only after all the circuits required for operation have been

fully assembled and connected.

Leading of data cables and power circuit lines

Lead data cable and power circuit line in separate cable channels.

Check cables and connectors

Before commissioning the system check all cables and connectors.

Page 7

VisuNet GMP DM

Product Specifications

219365 2017-02

7

2

2.1

Product Specifications

Overview

GMP (“Good Manufacturing Practice”) is a set of guidelines for assuring the quality of

production processes in controlled industries and closely follow th

e guidelines issued by the

European Commission or the FDA in the US. GMP applications are typically used in the

pharmaceutical and food industries. However, products that conform with GMP guidelines are

also required for the manufacture of cosmetics and fragrances or flavors.

The materials selected, design of the surfaces, and architecture of the overall system should

prevent the accumulation of fluids and dirt. Cleaning, maintenance, inspection and servicing

must be as safe and easy as the processes employed for the disinfection of mechanical

components.

The VisuNet GMP product portfolio extends from simple direct monitors and remote monitor

systems with Ethernet connection to a host, to complete PCs available with single or dual

monitor systems and various mounting options. Models feature a 19-inch, 21-inch, or 22-inch

display with an optional touch screen. The stainless steel housings have an IP65 degree of

protection. Remote monitors and PCs are equipped with Ethernet, USB, PS/2, and RS232

interfaces.

The VisuNet GMP product family guarantees a perfect fit for every system infrastructure.

Four models are available depending on the functions required, the display and input unit, and

the distance over which the data is transferred. This manual describes the VisuNet GMP direct

monitor (DM):

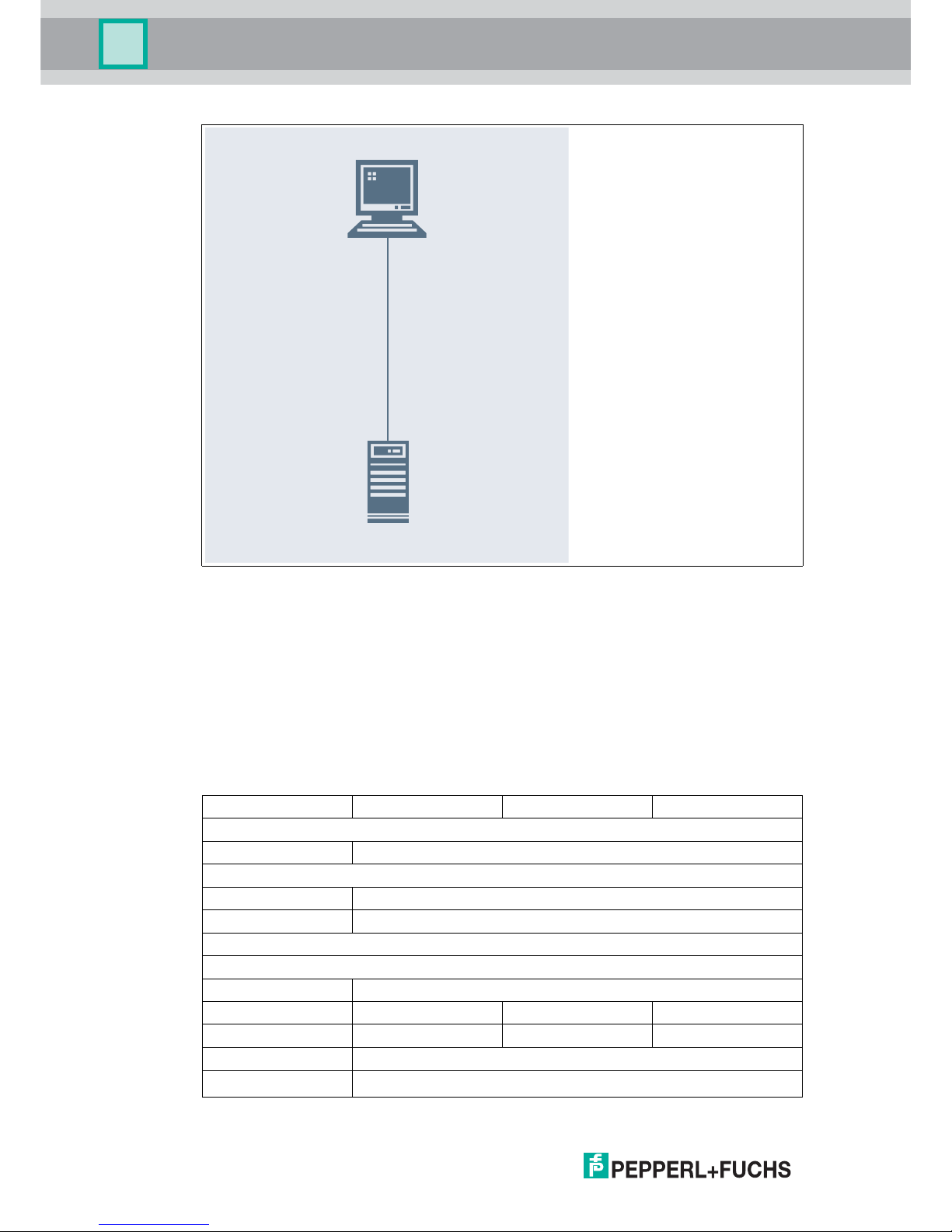

VisuNet GMP DM are direct monitors that are directly connected to the VGA or DVI interface

of the host. Industrial keyboards with integral mouse connected directly to the host are

available as accessories.

Page 8

219365 2017-02

8

VisuNet GMP DM

Product Specifications

Overview of features

■ The brilliant display provides high meter-reading comfort

■ Easy, user-friendly operation due to optionally available touch screen

■ Image position, pixel frequency, and phase will be detected and

synchronized automatically

■ Rugged

stainless steel housing (304/1.4301 - others on demand)

■ Degree of protection IP65

■ High-end finish of all surfaces

2.2 Technical Data

max. 5 m

DM

HOST

VisuNet GMP DM219 VisuNet GMP DM221 VisuNet GMP DM222

General specifications

Ty p e Direct monitor

Supply

Power supply

20 ... 30 V DC; 90 ... 240 V AC, 50 ... 60 Hz

Power consumption 40 W

Indicators/operating means

Display

Ty p e TFT, LCD, High Color (24 bit)

Screen diagonal 19 ''

21.5 "

22 "

Resolution 1280 x 1024 Pixel 1920 x 1080 Pixel 1680 x 1050 Pixel

Representable colors 16,7 Mio.

Brightness

300 cd/m

2

Page 9

VisuNet GMP DM

Product Specifications

219365 2017-02

9

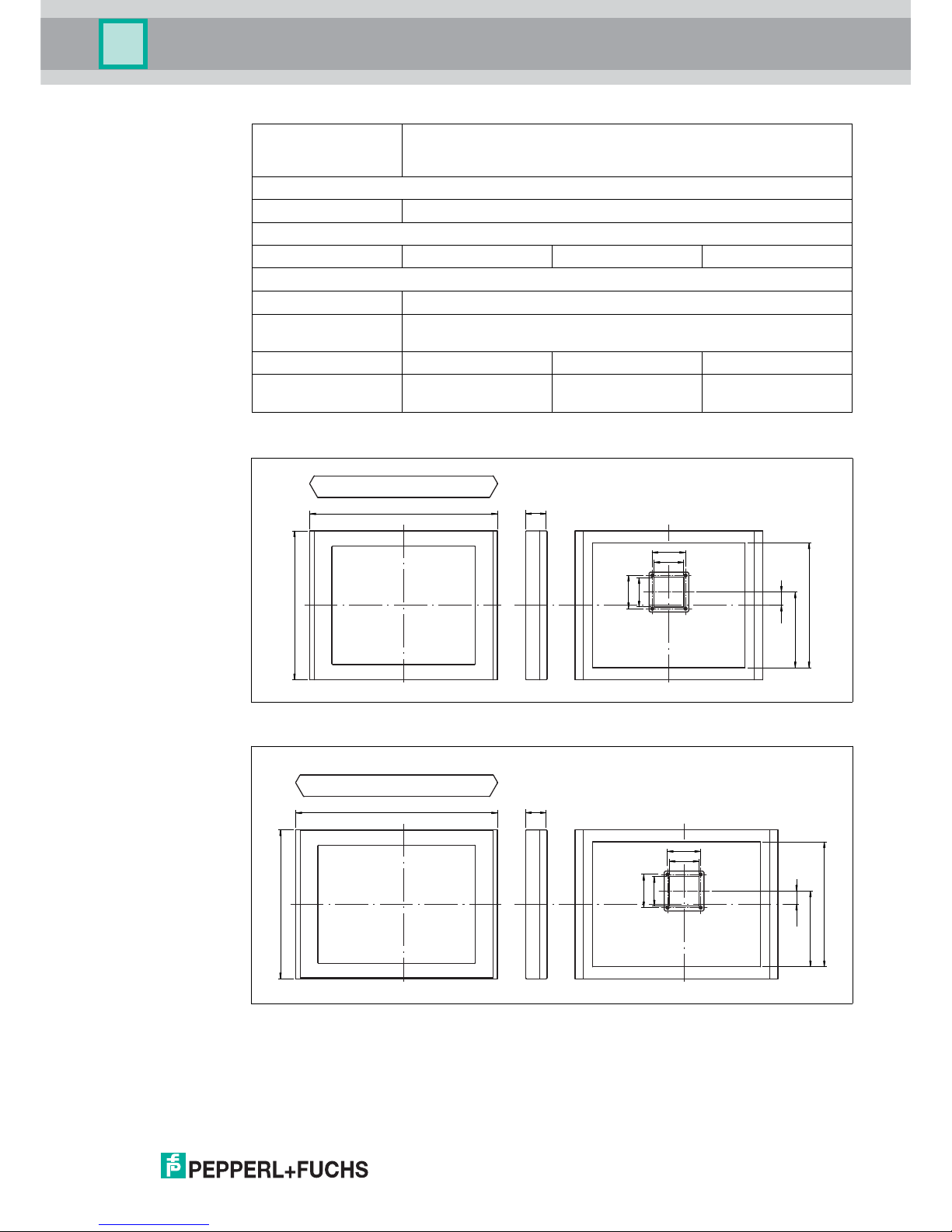

2.3 Dimensions VisuNet GMP DM series

Figure 2.1 Dimensions DM219

Figure 2.2 Dimensions DM221/DM222

Input devices Analog resistive touchscreen (optional) ,

Input device combined with keyboard and optional trackball/touch

screen/joystick

Interface

Interface type

VGA or DVI

Ambient conditions

Ambient temperature 0 ... 50 °C 0 ... 50 °C

0 ... 45 °C

Mechanical specifications

Protection degree IP65

Installation panel mounting

several mounting devices (rotatable/fix) available

Mass 18 kg 20 kg 20 kg

Dimensions 568 mm x 450 mm x

65 mm

625 mm x 450 mm x

73 mm

625 mm x 450 mm x

73 mm

9

10

9

10

228.5

378

39.5

568

450

73

9

10

9

10

228.5

378

39.5

625

450

73

Page 10

10

VisuNet GMP DM

Product Specifications

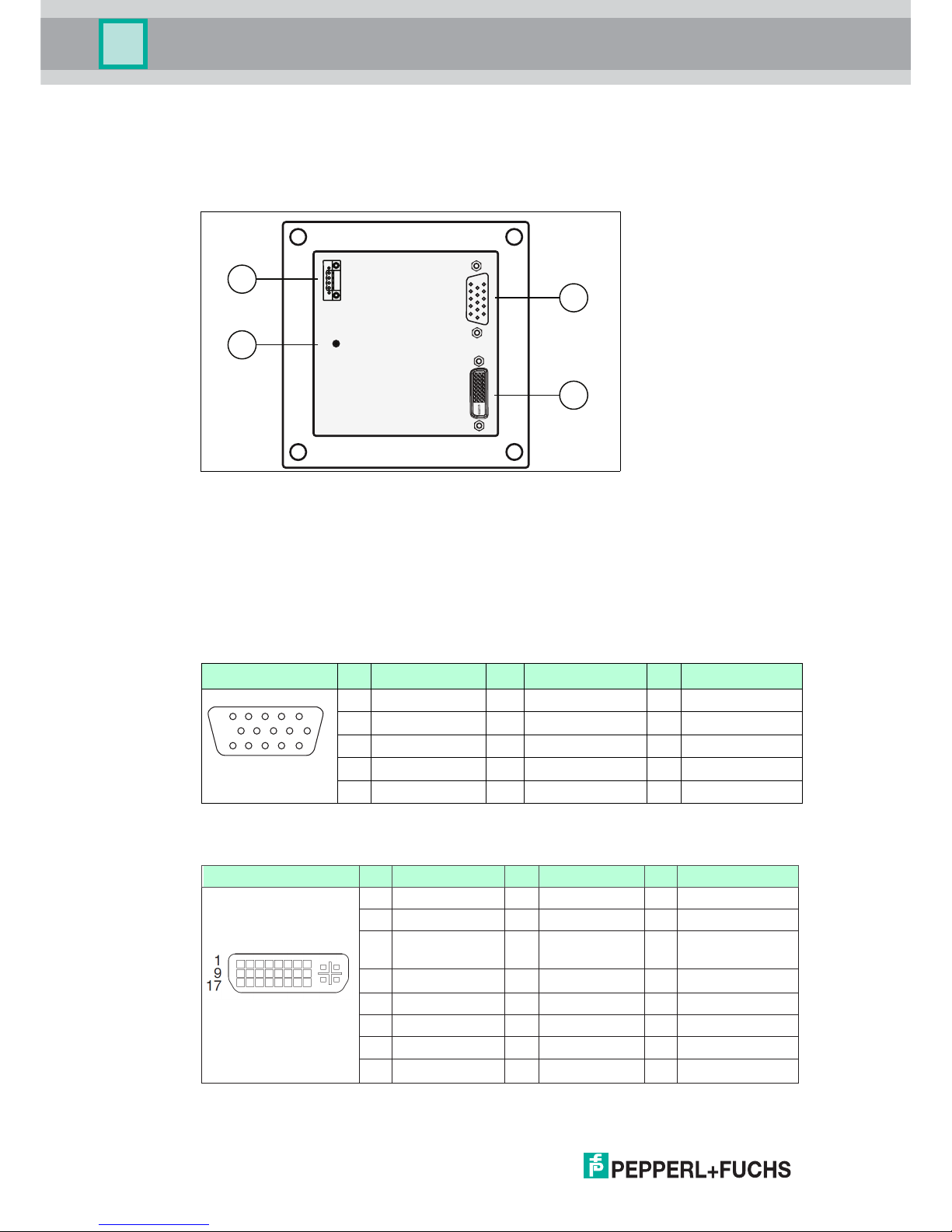

2.4

Interfaces and connections VisuNet GMP DM

The interfaces and connections of the VisuNet GMP are located within the VESA adapter at the

back of the housing.

The following interfaces are available:

Figure 2.3 VESA adapter at the back of the VisuNet GMP housing

2.4.1

VGA interface

15-pin HD-D-Sub socket "VGA" required for monitor/host connection.

Picture Pin Signal Pin Signal Pin Signal

1 RED 6 RED_GND 11 not in use

2 GREEN 7 GREEN_GND 12 IIC-DATA

3 BLUE 8 BLUE_GND 13 HSYNC

4 not in use 9 + 5 V 14 VSYNC

5 GND 10 GND 15 IIC-CLOCK

1

6

5

15 11

A

B

C

D

Phoenix DFK-MSTB 2,5/4-GF-5,08

Ground connection (M4)

VG interA face

DVI interface

C

D

A

B

2.4.2

DVI interface

Picture Pin DVI-D Pin DVI-D Pin DVI-D

1 TMDS data 2 - 9 TMDS data 1 - 17 TMDS data 0 -

2 TMDS data 2 + 10 TMDS data 1 + 18 TMDS data 0 +

3 TMDS data 2/4

shield

11 TMDS data 1/3

shield

19 TMDS data 0/5

shield

4 TMDS data 4 - 12 TMDS data 3 - 20 TMDS data 5 -

5 TMDS data 4 + 13 TMDS data 3 + 21 TMDS data 5 +

6 DDC clock (SCL) 14 +5 VDC 22 TMDS clock shield

7 DDC data (SDA) 15 Ground 23 TMDS clock +

8 Not used 16 Hot plug detect 24 TMDS clock -

219365 2017-02

Page 11

VisuNet GMP DM

Product Specifications

219365 2017-02

11

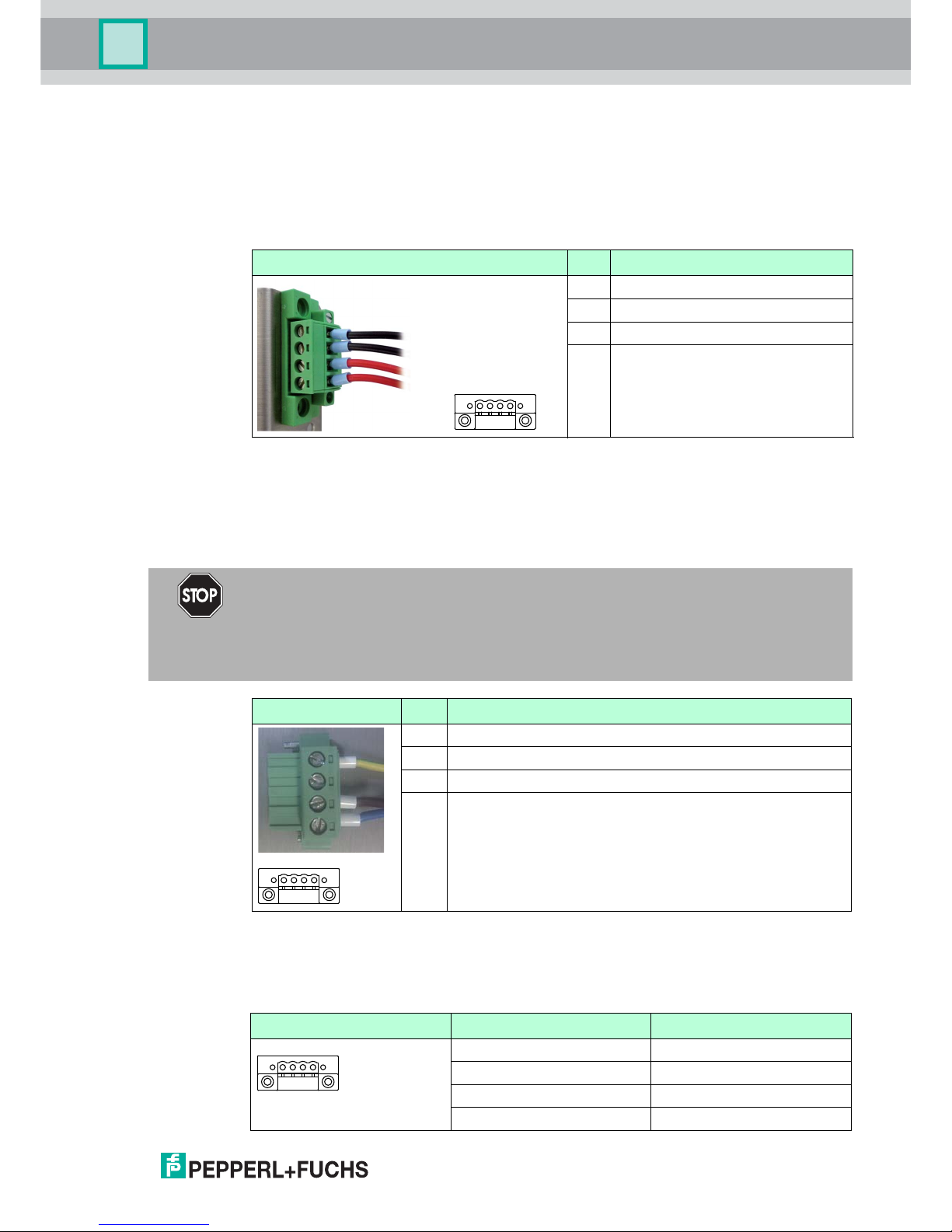

2.4.3

Supply Voltage 24 V

4-pin socket required for supply voltage connection (Phoenix Contact DFK-MSTB 2,5/ 4-GF5,08).

The VisuNet GMP KM has inverse-polarity protection.

Matching plug: Phoenix Contact MSTBT 2,5/ 4-STF-5,08

2.4.5 Supply voltage 12 V (PA version)

Required for supply voltage connection via terminal block.

Picture Pin Signal

1 GND

2 GND

3 + 24 V DC

4 + 24 V DC

1

2

3

4

41

Picture Pin Signal

1 GND

2 GND

3 + 12 V DC

4 + 12 V DC

41

2.4.4 Supply Voltage 120/230 V (AC)

4-pin socket required for supply voltage connection (Phoenix Contact DFK-MSTB 2,5/ 4-GF5,08).

Matching plug: Phoenix Contact MSTBT 2,5/ 4-STF-5,08

Danger!

Electric shock

Substantial material damage, personal injury, or even death.

Connect the 4-pin socket as shown in the following table. Only connect the voltage

supply when the device is completely installed.

Picture Pin Signal 120/230 V AC

1 PE

2 n. c.

3 L

4 N

1

2

3

4

41

Page 12

VisuNet GMP DM

Product Specifications

12

2.5

2.5.1

Accessories

The following accessories are available.

Keyboards

There are several keyboard models available. All keyboards

have an antibacterial coating.

For this reason, the keyboards are perfectly suitable for environments with high hygienic

standards.

Keyboard TA3-K4

Keyboard with touchpad for controlling the mouse pointer.

2 separate buttons below the touchpad assume the function of left and right mouse button.

Figure 2.4 Keyboard with touchpad

TA 3- K 4

General specifications

Ty p e Keyboard with touchpad

Supply

Rated voltage via data line

Indicators/operating means

Keyboard 105 short stroke keys

Keyboard layout: US international, German, French, (further

keyboard layouts on demand)

Touchpad

Active Principle capacitive

Resolution 40 Pts./mm

Dimensions 66 x 50 mm

Driver Microsoft Mouse ® , USB

Interface

Interface type USB

Conformity

Protection degree IP65

Ambient conditions

Ambient temperature -20 ... 50 °C (-4 ... 122 °F)

219365 2017-02

Page 13

13

VisuNet GMP DM

Product Specifications

Keyboard TA3-K6

Keyboard with joystick for controlling the mouse pointer.

2 separate buttons below the joystick assume the function of left and right mouse button.

Figure 2.5

Keyboard with joystick

Sto rage tempe rat ure -20 ... 70 °C (-4 ... 158 °F)

Relative humidity max. 85 % , non-condensing

Mechanical specifications

Material anodized aluminium , Polyester foil

Mass 1.2 kg

Dimensions 482.6 mm x 177.8 mm x 45 mm

Cable length 1.8 m , wire end ferrule

TA 3- K 6

General specifications

Ty p e Keyboard with joystick

Supply

Rated voltage via data line

Indicators/operating means

Keyboard 105 short stroke keys

Keyboard layout: US international, German,

French, (further keyboard layouts on demand)

Joystick

Driver Microsoft Mouse ® , USB

Interface

Interface type USB

Conformity

Protection degree IP65

TA 3- K 4

219365 2017-02

Page 14

VisuNet GMP DM

Product Specifications

14

Keyboard TA3-K8

Keyboard with optical trackball for controlling the mouse pointer.

2 separate buttons below the trackball assume the function of left and right mouse button.

Figure 2.6

Keyboard with optical trackball

Ambient conditions

Ambient temperature -20 ... 50 °C (-4 ... 122 °F)

Sto rage tempe rat ure -20 ... 70 °C (-4 ... 158 °F)

Relative humidity max. 85 % , non-condensing

Mechanical specifications

Material anodized aluminium , Polyester foil

Mass 1.2 kg

Dimensions 482.6 mm x 177.8 mm x 45 mm

Cable length 1.8 m , wire end ferrule

TA 3- K 8

General specifications

Ty p e Optical trackball

Supply

Rated voltage via data line

Indicators/operating means

Keyboard 105 short stroke keys

Keyboard layout: US international, German,

French, (further keyboard layouts on demand)

Trackball

Diameter 50 mm

Material Phenolic resin, polyester, epoxide resin (grey)

Driver Microsoft Mouse ® , USB

TA 3- K 6

219365 2017-02

Page 15

15

VisuNet GMP DM

Product Specifications

2.5.2

Pedestals

Figure 2.7

Pedestal models for VisuNet GMP

Interface

Interface type USB

Conformity

Protection degree IP65

Ambient conditions

Ambient temperature 0 ... 50 °C (32 ... 122 °F)

Sto rage tempe rat ure -10 ... 70 °C (14 ... 158 °F)

Relative humidity max. 85 % , non-condensing

Mechanical specifications

Material anodized aluminium , Polyester foil

Mass 1.2 kg

Dimensions 482.6 mm x 177.8 mm x 45 mm

Cable length 1.8 m , wire end ferrule

TA 3- K 8

AA ABB B

A

1500

500

1000

155

300

1270

1000

560

750

420

225

350

540

2 3 4 5 6 71

Model number Description

1 PEDESTAL1-150-1V-KP-G-T-304 Pedestal, turnable approx. 350°, inclination of monitor 10°, with pipe

for keyboard

2 PEDESTAL1-150-1V-KP-G-F-304 Pedestal, fix mounted, inclination of monitor 10°, with pipe for

keyboard

3 PEDESTAL1-150-1V-NP-G-T-304 Pedestal, turnable approx. 350°, inclination of monitor 10°

4 PEDESTAL1-150-1V-NP-G-F-304 Pedestal, fix mounted, inclination of monitor 10°

5 PEDESTAL1-130-3V-NP-G-T-304 Pedestal, turnable approx. 350°, inclination of monitor 30°

6 PEDESTAL1-130-3V-NP-G-F-304 Pedestal, fix mounted, inclination of monitor 30°

7 PEDESTAL1-56-3V-NP-G-T-304 Pedestal turnable approx. 350°, inclination of monitor 30°

219365 2017-02

Page 16

219365 2017-02

16

VisuNet GMP DM

Product Specifications

2.5.3 Wall arm versions

Figure 2.8 Wall arms for VisuNet GMP

2.5.4 Wall bracket

Figure 2.9 Wall bracket for VisuNet GMP

Model number Description

1 WALL-ARM1-55-

1V-NT-G-*-304

Wall arm, inclination of monitor 10°, without pipe for keyboard

2 models available:

■ WALL-ARM1-55-1V-NT-G-F-304: fix

■ WALL-ARM1-55-1V-NT-G-T-304: approx. 350° turnable

2 WALL-ARM1-55-

0V-KT-G-*-304

Wall arm, without inclination of monitor, with pipe for keyboard

2 models available:

■ WALL-ARM1-55-0V-KT-G-F-304: fix

■ WALL-ARM1-55-0V-KT-G-T-304: approx. 350° turnable

21

B B

500

775

575

100

250

815

520

865

990

285

Model number Description

1 WALL-

BRACKET1-0-0VG-304

Wall bracket

1

C

Page 17

VisuNet GMP DM

Product Specifications

219365 2017-02

17

2.5.5 Hole pattern of the mounting versions

Figure 2.10 Bottom attachment, turnable, fastening at front

Figure 2.11 Bottom attachment, fix mounted

Figure 2.12 Wall bracket

129

9

40

A

42-50

90

9

63-64

B

Ø

17

280

9

15

105

C

Page 18

219365 2017-02

18

VisuNet GMP DM

Product Specifications

2.5.6 Power supply accessories

Power supply

Model number Description

BN-24/5000-HS-10 Power supply

DATL-A2-2.5-0 Power cable 2x 2.5mm², wire end ferrule, max. length 80 m

DATL-A2-4.0N/2.5F-1 Power cable 2x 4.0mm² +2.5m 2.5mm², wire end ferrule, length:

110 m

2.5.7 Barcode Reader

The VisuNet GMP has an option for connection of a handheld barcode reader. The

following products can be used at present:

Barcode handheld Powerscan PSCAN-D-1D-N0-R3-10-N

The PSCAN-D-1* consists of a barcode handheld with connecting cable. The

connecting cable is a ʾ m long cable, and an 8-pin M12 connector is mounted.

Order designation PSCAN-D-1*

Device Order designation Description

PSCAN-D-1* PSCAN-D-1D-N0-R3-10-N Barcode handheld

NON-Ex

Sparepart cable SPAREPARTS-PSCAN-D-GP-CABLE-20 Sparepart cable for

PSCAN-D-1D-N0-R3-10-N

Page 19

19

VisuNet GMP DM

Product Specifications

2.5.8 Dimensions with Barcode handheld

Dimensions VisuNet GMP DM 219 with Barcode handheld

Dimensions VisuNet GMP DM 221 and DM 222 with Barcode handheld

682

29,5

~187

~97

131

74

152

85

152

13

450

73

740

29,5

~187

~97

131

74

152

85

152

13

450

74

219365 2017-02

Page 20

VisuNet GMP DM

Product Specifications

20

2.5.9

Holder for handheld barcode reader

Dimensions

85

30

71,5

90

120

152

14

67,6

219365 2017-02

Page 21

VisuNet GMP DM

Installation and Commissioning

219365 2017-02

21

3 Installation and Commissioning

3.1 Preparation

Unpacking the unit

1. Check that all package contents are present and undamaged.

If anything is damaged, inform the shipper and contact the supplier.

2. Check that all items are present and correct based on your order and the shipping

documents.

3.2

If you have any questions, please contact Pepperl+Fuchs.

3. Keep the original packing material in case you need to store or ship the unit at a later time.

Mounting in the field

The device is licensed for operation in confined spaces.

The cooling of the device does not require active components like CPU fan or water cooling

systems. For that

reason there are no ventilation slots in the housing.

To avoid overheating during operation, follow the guidelines below for field installation:

■ Do not expose the device to direct solar radiation or other heat sources.

■ Since the heat will dissipate via the housing, provide sufficient air circulation.

■ Keep the ambient temperature below the specified maximal value.

3.2.1 Grounding at pedestal and wall arm

Figure 3.1 Ground connection at pedestal/wall arm

Note!

The device is not delivered in sterile condition.

Note!

Pepperl+Fuchs recommends using a cable with a core-cross section of 4 mm2 for

grounding.

Page 22

219365 2017-02

22

VisuNet GMP DM

Installation and Commissioning

Grounding VisuNet GMP at pedestal and wall arm

1. Insert the grounding cable into a cable lug (4).

2. Unscrew the M4 screw on ground connection.

3. Insert the cable of the cable lug between the 2 washers (1).

4. Tighten the screw.

Figure 3.2 Grounding at Pedestal/Wall Arm

3.3

Commissioning VisuNet GMP

Use a low-restistance connection between device and control cabinet. Use

cables with a minimum cross core-section of 2,5 mm2 for power supply.

Turning on the VisuNet GMP

1. Connect the 4-pin plug with the 4-pin power supply socket at the back of the housing.

2. Fix and tighten the screws of the plug.

3. Switch on the power supply at source.

After establishing the power supply, the VisuNet GMP starts automatically. The

green LED on the right-hand side of the housing indicates a correct power supply.

Note!

Depending on the grounding cable, you need the adequate cable lug (not included in

delivery).

1 washer

2 lock washer

3 M4 screw

4 cable lug

1

2

3

4

Page 23

VisuNet GMP DM

Installation and Commissioning

219365 2017-02

23

Turning off the VisuNet GMP

1. Disconnect the

device from the power supply.

2. After that, unscrew the power plug at the VisuNet GMP.

Note!

Use the VisuNet GMP only with safety-low voltage (protective extra-low-voltage). The power

supply needs to be in line with applicable standards.

Page 24

219365 2017-02

24

VisuNet GMP DM

Operation

4

4.1

Operation

On-Screen Dis

play

VisuNet GMP features a graphical user interface for setting up the display via the on-screen

display (OSD menu). A control panel with four buttons for operating the system is located on

the right-hand side of the housing.

The following table describes the buttons and their functions.

Selecting the OSD menu

To s

elect the OSD menu, press the button.

The OSD menu is divided in the following menu items:

■ Color

■ Image Setting

■ Position

■ OSD Menu

■ Language

■ Misc.

■ Exit

Picture Button Function Description

Menu Menu selection

1. First click: activates menu

2. Second click: quits sub

menu/menu

Select menu

access/selection

1. Select menu entries

2. Confirm active menu entries

– downwards/left

1. Navigate in menus: downwards/left

2. Decrease a value

3. shortcut for audio volume

+ upwards/right

1. Navigate in menus: upwards/right

2. Increase a value

LED Stat us red light: no signal

green light: operating status

"on"

Menu

Select

–

+

Menu

Page 25

VisuNet GMP DM

Operation

219365 2017-02

25

Navigating in the OSD menu

1. If applicable select the OSD menu.

2. Navigate to the designated tab with the button (scroll to the right) and button

(scroll to the left) respectively.

The active tab will be marked.

3. To select a tab, press the button.

The sub menu will be opened.

4. Navigate to the designated sub menu entry with the button and the button

respectively

5. To select a sub menu, press the button.

Depending on the menu you will get to another sub menu or to a dialog box.

Adjusting values

1. To

adjust values (e.g. brightness or contrast) in a sub menu, press the

button and the

button respectively.

2. After adjusting the value, quit the active dialog box by pressing the button.

The adjusted value will be adopted and you will return to the designated sub menu.

Quitting OSD menu/sub menus

To quit a sub menu, select the menu item Back or press the button.

The sub menu will be quit.

+

–

Select

+

–

Select

+

–

Menu

Menu

Note!

Image Sticking

Displaying a fixed pattern may cause burn-in-effects (image sticking due to the LCD

characteristics).

To avoid image sticking, change

pattern frequently or activate screen saver.

Please note that display damage caused by burn-in effects is not included in the

warranty.

Page 26

219365 2017-02

26

VisuNet GMP DM

Operation

4.1.1 Audio menu

Menu item Name Description

Volu me Change the volume

Mute Mute the audio

Exit Quit the sub menu and return

to the menu one lever higher.

Note!

The VisuNet GMP has no audio speaker.

Page 27

VisuNet GMP DM

Operation

219365 2017-02

27

4.1.2 Bright-Contrast menu

Menu Item Name Description

Brightness Decrease/increase brightness

Contrast Decrease/increase contrast

Exit Quit the sub menu and return

to the menu one lever higher.

Page 28

219365 2017-02

28

VisuNet GMP DM

Operation

4.1.3 Menu Color

Sub menu Description

Contrast Adjust the contrast of the image

Brightness Adjust the brightness of the image

Color Adjust

Adjust the value of red, green, and blue

Color Temp Adjust the color temperature

Auto Color Run the auto config of the color

Back Back to main menu

Page 29

VisuNet GMP DM

Operation

219365 2017-02

29

4.1.4 Image menu

Sub menu Description

Clock Adjust the clock of the image

Phase Adjust the phase of the image

Ga m m a Adjust the gamma level of the image

Sharpness Adjust the sharpness of the image

Auto Adjust... Run the auto config of the image

Back Back to main menu

Page 30

219365 2017-02

30

VisuNet GMP DM

Operation

4.1.5 Tools menu

Menu item Name Description

OSD Select more sub menus: time,

horizontal,vertical, OSD menu

direction, exit

Reset Reset to factory settings

Sharpness Change sharpness

Language Change language of OSD

menu

Exit Quit the sub menu and return

to the menu one lever higher.

A

AA

Page 31

VisuNet GMP DM

Operation

219365 2017-02

31

4.1.6 Input menu

Menu item Name Description

VGA Activate VGA interface

DVI Activate DVI interface

Exit Quit the sub menu and return

to the menu one lever higher

1

2

Page 32

219365 2017-02

32

VisuNet GMP DM

Operation

4.1.7 Exit menu

Page 33

VisuNet GMP DM

Appendix

219365 2017-02

33

5

5.1

Appendix

Chemical resistance of keyboard foil

The keyboard foil is manufactured from a biaxially aligned polyester-based material and

therefore has a greater restistance to solvents. The foil is stronger and more durable than other

standard foils used on keyboards and front pa

nels, such as polycarbonate and PVC.

The keyboard foil is resistant against the following substances: (Test method: DIN42115):

■ Alcohols

■ Dilute acids

■ Dilute alkalis

■ Esters

■ Hydrocarbons

■ Household cleaning

5.2 Chemical resistances of the touch screen

The foil is manufactured from a biaxially aligned polyester-based material and therefore has a

greater restistance to solvents. It is physically resistant to pencil lead with a maximum hardness

of 3HB.

The foil is resistant against the following substances (concenration 100 % - unless otherwise

specified):

Aldehyde:

Acetataldehyde Formaldehyde 37 - 42 %

Alcohols:

Ethanol Hexahydrophenol

Tr i a c e t i n Dowandol DRM/PM

Glycol Glycerin

Isopropanol Methanol

Diacetone alcohol

Hydrocarbons:

Aliphatic hydrocarbons generally gasoline

Kerosene To l u o l

Xylene Benzene

Chlorinated hydrocarbons:

Chlorofluorocarbons Perchloroethylene

III-Trichloroethylene Diethyl ether

Methyl ethyl ketone Trichloroethylene

Acids:

Formic acid <10 % acetic acid <10 %

Phosphoric acid <10 % Hydrochloric acid <10 %

Nitric acid <10 % Trichloroacetic acid <10 %

sulfuric acid <10 %

Other organic solvents:

Ether Acetone

Page 34

219365 2017-02

34

VisuNet GMP DM

Appendix

Dimethylformamide Dioxane

Ethyldioctyl Dibutyl phthalate

Phthalate Butyl cellosolve

Iron chlorid (FeCl2) Iron chlorid (FeCl3)

Lyes:

Ammonia <10 % Sodium hydroxide <10 %

Alkali carbonate

Ester:

Ethylacetate N-butyl acetate

Amyl acetate

Technical oils and greases:

Drilling emulsion Diesel oil

Varnish Heating oil

Liquid paraffin Castor oil

Silicone oil Turpentine oil substitute

Brake fluid Decon

Saline solutions:

Alkali carbonate Bichromate

Potassium hydroxide <30 % Acetonitrile

sodium bisulfate potassium ferrocyanide

Sodium hypochlorite <20 %

Various other substances:

Molecular chlorine Cresol phenol soaps in hydrogen soution

Oxygen Tricresyl phosphate

Water <100 °C Hydrogen peroxid <25%

Saline water Solvent (white spirit)

Grape juice Milk

Coffee

Detergent, rising agent, cleaning agent:

Potash soap Detergent solutions (surfactants)

Fabric softener Sodium carbonate

Household chemicals (24 hours of exposure at 50 °C)

To p Jo b Jet Dry

Gumption Fantastic

Formula 409 Ariel

Persil Wisk

Lenor Downey

Ajax Vim

Domestos Vortex

Windex0

Aldehyde:

Page 35

VisuNet GMP DM

Appendix

219365 2017-02

35

Resistance to surface desinfectant can be determined on request.

Slight discoloration

Intense examinations established that the following products caused slight discoloration:

■ Mustard

■ Tomato juice

■ To m at o k e tch up

■ Lemon juice

No resistance

Not resistant to:

■ concentrated mineral acids

■ concentrated alkaline solutions

■ High-pressure steam over 100 °C

Note!

Various other substances may cause the surface structure to alter. Testing and subsequent

assessment still require clarification.

Page 36

Subject to modifications

Copyright PEPPERL+FUCHS •

Printed in Germany

www.pepperl-fuchs.com

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

For the

Pepperl+Fuchs representative

closest to you check www.pepperl-fuchs.com/contact

PROCESS AUTOMATION –

PROTECTING YOUR PROCESS

219365 / TDOCT-1800A_ENG

02/2017

Loading...

Loading...