Page 1

VISUNET GMP DM

DIRECT MONITOR

HARDWARE MANUAL

PROCESS AUTOMATION

MANUAL

Page 2

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical In-

dustry, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

VISUNET GMP DM

Page 3

VISUNET GMP DM

Contents

3

1 Safety................................................................................................. 4

1.1 Validity....................................................................................................................................4

1.2 Symbols used ........................................................................................................................4

1.3 System Operator and Personnel..........................................................................................5

1.4 Pertinent Laws, Standards, Directives and further Documentation .................................5

1.5 Intended use...........................................................................................................................5

1.6 Installation and commissioning...........................................................................................5

2 Product Specifications .................................................................... 6

2.1 Overview.................................................................................................................................6

2.2 Technical Data .......................................................................................................................8

2.3 Dimensions ............................................................................................................................9

2.4 Interfaces and connectionsVisuNet GMP DM .....................................................................9

2.5 Accessories.......................................................................................................................... 11

2.5.1 Pedestals............................................................................................................................... 11

2.5.2 Wall mounting........................................................................................................................12

2.5.3 Hole drilling templates ...........................................................................................................13

2.5.4 Power supply accessories .....................................................................................................14

3 Installation and Commissioning................................................... 15

3.1 Preparation...........................................................................................................................15

3.2 Mounting in the field............................................................................................................15

3.3 Commissioning VisuNet GMP RM/PC................................................................................ 16

4 Operation ........................................................................................ 17

4.1 On Screen Display...............................................................................................................17

4.1.1 Audio menu...........................................................................................................................19

4.1.2 Bright-Contrast menu ..........................................................................................................20

4.1.3 Color menu ...........................................................................................................................21

4.1.4 Image menu ..........................................................................................................................22

4.1.5 Tools menu ...........................................................................................................................23

4.1.6 Input menu ............................................................................................................................24

4.1.7 Exit menu ..............................................................................................................................25

5 Appendix......................................................................................... 26

5.1 How to contact Pepperl+Fuchs GmbH ..............................................................................26

Page 4

219365 2006-06

4

VISUNET GMP DM

Safety

1Safety

1.1 Validity

The chapter “Safety” is valid as operating instructions.

Specific process and instructions in this document require special precautions to guarantee

the safety of personnel.

1.2 Symbols used

This document contains information that you must read for your own personal safety and to

avoid property damage. The warning signs are displayed in descending order depending

on the hazard category, as follows:

Safety-relevant symbols

Informative symbols

Action

This symbol marks an acting paragraph.

Danger!

This symbol indicates a warning about a possible danger.

In the event the warning is ignored, the consequences may range from personal injury to

death.

Warning!

This symbol indicates a warning about a possible fault or danger.

In the event the warning is ignored, the consequences may course personal injury or

heaviest property damage.

Caution!

This symbol warns of a possible fault.

Failure to observe the instructions given in this warning may result in the devices and any

connected facilities or systems develop a fault or fail completely.

Note!

This symbol brings important information to your attention.

Page 5

VISUNET GMP DM

Safety

219365 2006-06

5

1.3 System Operator and Personnel

The operator of the system is responsible in terms of planning, mounting, commissioning,

operating and maintenance.

Assembly, commissioning, operation, maintenance and dismounting of any devices may

only be carried out by trained, qualified personnel who have read and understood the

instruction manual.

1.4 Pertinent Laws, Standards, Directives and further Documentation

Laws, standards, or directives applicable to the intended use must be observed. In relation

to explosive areas, Directive 94/9 EC must be observed.

The corresponding data sheets, the declaration of conformity, the EC-type-examination

certificate and applicable certificates (see data sheet) are an integral part of this document.

1.5 Intended use

The devices are only approved for appropriate and intended use. Ignoring these

instructions will invalidate any warranty and absolve the manufacturer from any liability.

1.6 Installation and commissioning

The device must only be operated in the ambient temperature range and at the relative

humidity (noncondensing) specified.

To connect interfaces only use shielded cable.

To advance the cable shield screw/lock the connectors.

Lead data cable and power circuit line in separate cable channels.

Before commissioning the system check all cables and connectors.

Page 6

219365 2006-06

6

VISUNET GMP DM

Product Specifications

2 Product Specifications

2.1 Overview

GMP (“Good Manufacturing Practice”) is a set of guidelines for assuring the quality of

production processes in controlledindustries and closely follow the guidelines issued by the

European Commission or the FDA in the US. GMP applications are typically used in the

pharmaceutical and food industries. However, products that conform with GMP guidelines

are also required for the manufacture of cosmetics and fragrances or fl avors.

The materials selected, design of the surfaces and architecture of the overall system

should prevent the accumulation of fl uids and dirt. Cleaning, maintenance, inspection and

servicing must be as safe and easy as the processes employed for the disinfection,

pasteurization and sterilization of mechanical components. The VisuNet GMP product

portfolio extends from simple direct monitors and remote monitor systems with Ethernet

connection to a host, to complete PCs available with single or dual monitor systems and

various mounting options. All models feature a 19-inch display with an optional touch

screen. The stainless steel housings have an IP65 degree of protection. Remote monitors

and PCs are equipped with RS232, PS/2, Ethernet and USB interfaces.

The VisuNet GMP product family guarantees a perfect fit for every system infrastructure.

Four models are available depending on the functions required, the display and input unit

and the distance over which the data is transferred. This manual describes the VisuNet

GMP Direct Monitor (DM):

Page 7

VISUNET GMP DM

Product Specifications

219365 2006-06

7

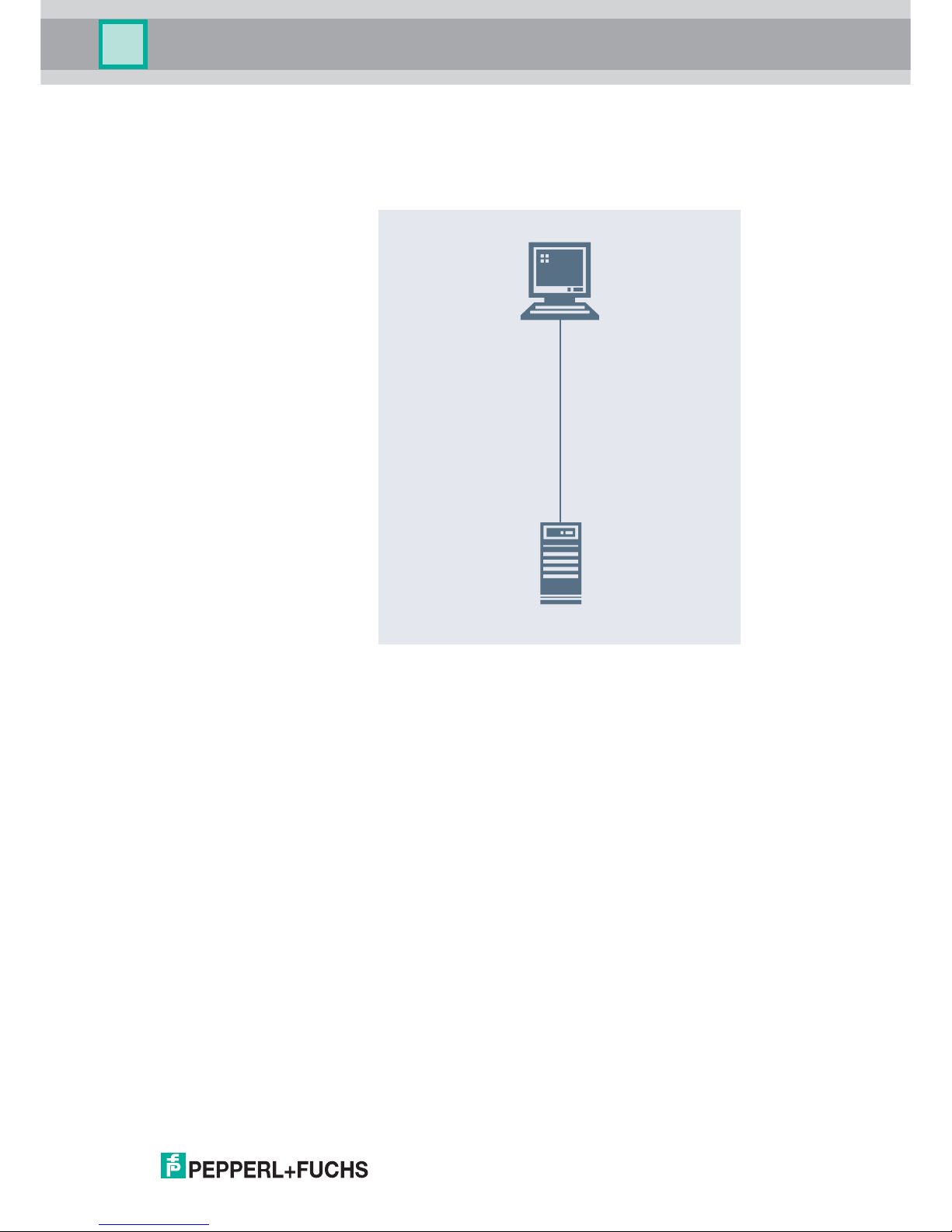

VisuNet GMP DM are direct monitors, which are directly connected to the VGA interface of

the host. Industrial keyboards with integral mouse connected directly to the host are

available as accessories.

Overview of features

• The brilliant display provides high meter-reading comfort

• Easy, user-friendly handling due to optionally available touch screen

• Image position, pixel frequency and phase will be detected and synchronized

automatically

• Rugged stainless steel housing

• Degree of protection IP65

max. 15 m

DM

HOST

Page 8

219365 2006-06

8

VISUNET GMP DM

Product Specifications

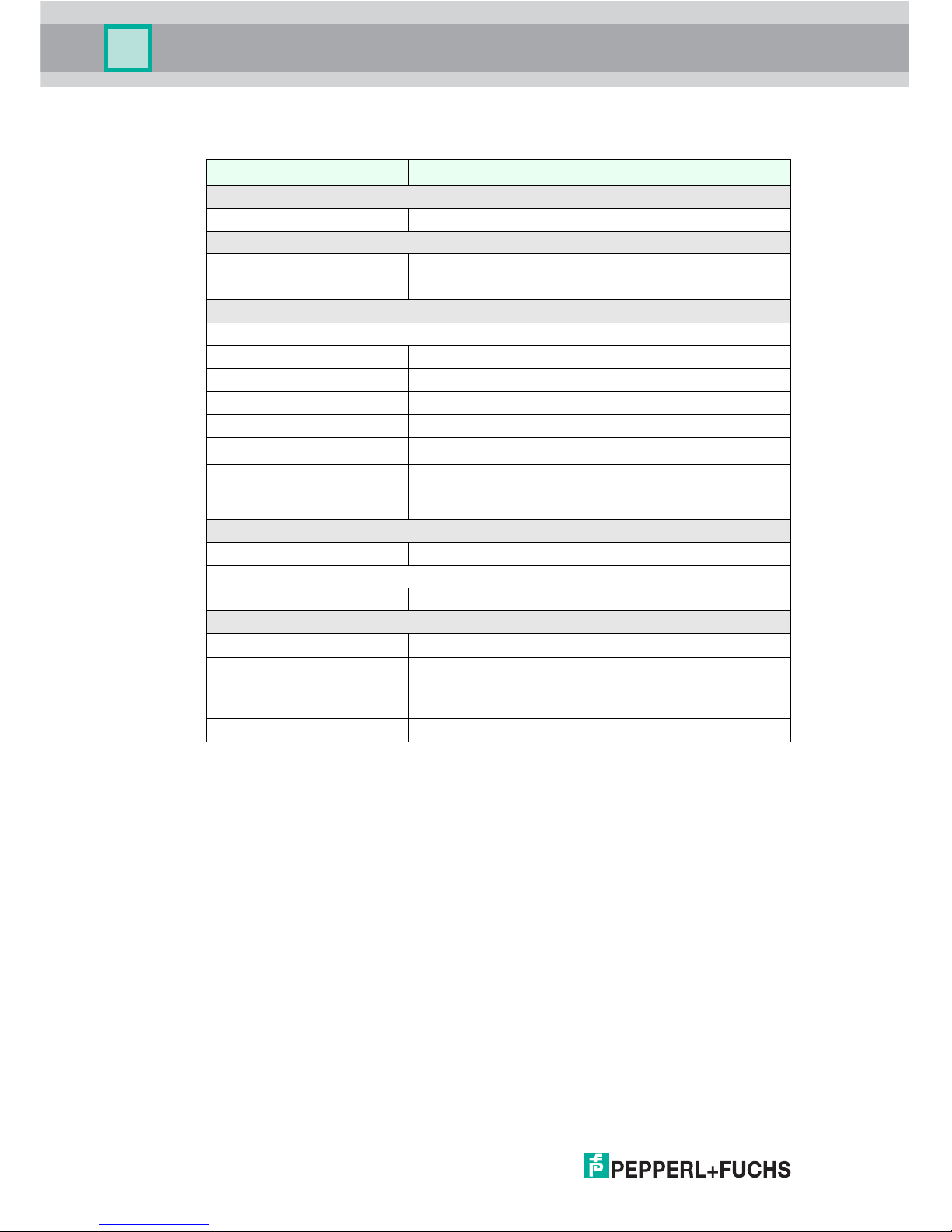

2.2 Technical Data

VisuNet GMP DM

General specifications

Type Direct monitor

Supply

Power supply 20 ... 30 V DC

Power consumption 40 W

Indicators/operating means

Display

Type TFT, LCD, High Color (19 bit)

Screen diagonal 19 ''

Resolution 1280 x 1024 Pixel

Representable colors 16,7 Mio.

Brightness

300 cd/m

2

Input devices Analog resistive touchscreen (optional) ,

Input device combined with keyboard and optional

trackball/touch screen/joystick

Interface

Interface type VGA

Ambient conditions

Ambient temperature 0 ... 50 °C

Mechanical specifications

Protection degree IP65

Installation panel mounting

several mounting devices (rotatable/fix) available

Mass 18 kg

Dimensions 568 mm x 450 mm x 65 mm

Page 9

VISUNET GMP DM

Product Specifications

219365 2006-06

9

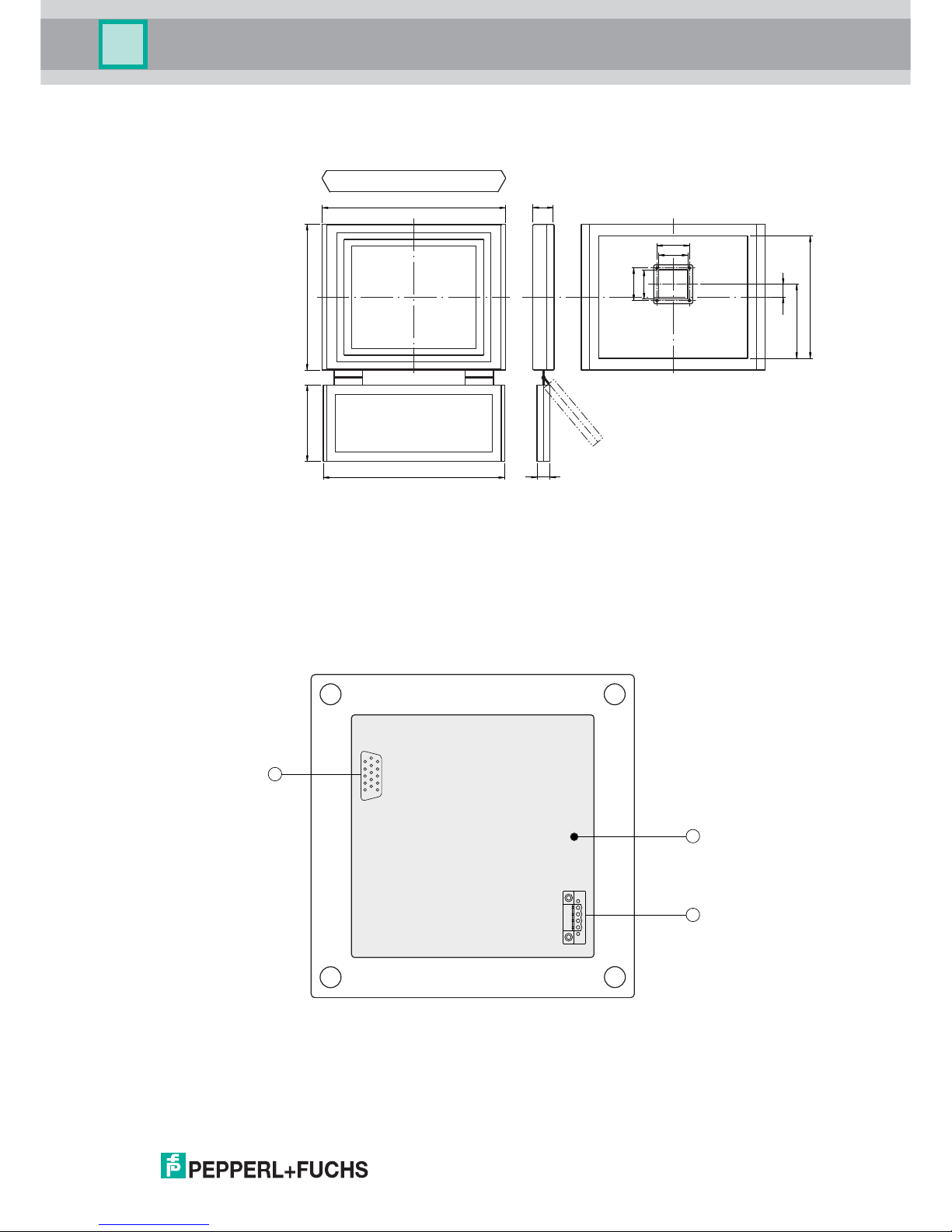

2.3 Dimensions

Figure 2.1: VisuNet GMP model with inclinable keyboard (90°-180°)

2.4 Interfaces and connectionsVisuNet GMP DM

The interfaces and connections of the VisuNet GMP are located within the VESA adapter

at the back of the housing.

The following interfaces are available:

Figure 2.2: VESA adapter at the back of the VisuNet GMP housing

9

10

9

10

228.5

378

39.5

567.8

450

65

235

559

40

A grounding bolt

B Phoenix DFK-MSTB 2,5/ 4-GF-5,08

C VGA interface

B

C

1

4

A

1

6

515

11

Page 10

219365 2006-06

10

VISUNET GMP DM

Product Specifications

Power supply

4-pin socket for power supply connecting (Phoenix Contact DFK-MSTB 2,5/ 4-GF-5,08).

Matching plug: Phoenix Contact MSTBT 2,5/ 4-STF-5,08

VGA interface

15-pin HD-D-Sub socket "VGA" for connecting the monitor to the host.

Picture Pin Signal

1 -

2 -

3 +

4 +

Picture Pin Signal Pin Signal Pin Signal

1 RED 6 RED_GND 11 not used

2 GREEN 7 GREEN_GND 12 IIC-DATA

3 BLUE 8 BLUE_GND 13 HSYNC

4 not used 9 + 5 V 14 VSYNC

5 GND 10 GND 15 IIC-CLOCK

41

1

6

5

15 11

Page 11

VISUNET GMP DM

Product Specifications

219365 2006-06

11

2.5 Accessories

The following accessories are available.

2.5.1 Pedestals

Model number Description

1 Pedestal1-150-1V-KP-G-T-304 Pedestal, turnable 340°, inclination of monitor 10°,

with pipe for keyboard

2 Pedestal1-150-1V-KP-G-F-304 Pedestal, fix mounted, inclination of monitor 10°,

with pipe for keyboard

3 Pedestal1-150-1V-NP-G-T-304 Pedestal, turnable 340°, inclination of monitor 10°,

without pipe for keyboard

4 Pedestal1-150-1V-NP-G-F-304 Pedestal, fix mounted, inclination of monitor 10°,

without pipe for keyboard

5 Pedestal1-130-3V-NP-G-T-304 Pedestal, turnable 340°, inclination of monitor 30°,

without pipe for keyboard on pedestal (shown in

figure with inclinable keyboard at monitor housing,

which is optional available)

6 Pedestal1-130-3V-NP-G-F-304 Pedestal, fix mounted, inclination of monitor 30°,

without pipe for keyboard on pedestal (shown in

figure with inclinable keyboard at monitor housing,

which is optional available)

1 2

3

4 5 6

AAABB B

1500

500

1000

Page 12

219365 2006-06

12

VISUNET GMP DM

Product Specifications

2.5.2 Wall mounting

Model numer Description

1 Wall-Arm1-55-1V-NT-G-*-304 Wall arm, inclination of monitor 10°, without

pipe for keyboard on wall arm (shown in figure

with inclinable keyboard at monitor housing,

which is optional available)

2 models available:

• Wall-Arm1-55-1V-NT-G-F-304: monitor fix

mounted

• Wall-Arm1-55-1V-NT-G-T-304: monitor

turnable

2 Wall-Arm1-55-1V-KT-G-*-304 Wall arm, without inclination of monitor, with

pipe for keyboard

2 models available:

• Wall-Arm 1-55-1V-KT-G-F-304: monitor fix

mounted

• Wall-Arm 1-55-1V-KT-G-T-304: monitor

turnable

3 Wall-Bracket1-0-0V-G-304 Wall bracket

2 31

B B

C

500

Page 13

VISUNET GMP DM

Product Specifications

219365 2006-06

13

2.5.3 Hole drilling templates

Bottom attachment, turnable, fastening at front:

Bottom attachment, fix mounted:

Wall bracket:

129

9

40

A

42-50

90

9

B

Ø

17

280

9

15

105

C

Page 14

VISUNET GMP DM

Product Specifications

219365 2006-06

14

2.5.4 Power supply accessories

Power supply

Model number Description

BN-24/5000-HS-10 Power supply

DATL-A2-2.5-0 Power cable 2x 2.5mm², wire end ferrule, max. length 80 m

DATL-A2-4.0N/2.5F-1 Power cable 2x 4.0mm² +2.5m 2.5mm², wire end ferrule,

length: 110 m

Page 15

VISUNET GMP DM

Installation and Commissioning

219365 2006-06

15

3 Installation and Commissioning

3.1 Preparation

Unpacking the unit

1. Check that all package contents are present and undamaged.

If anything is damaged, inform the shipper and contact the supplier.

2. Check that all items are present and correct based on your order and the shipping

documents.

If you have any questions, please contact Pepperl+Fuchs.

3. Keep the original packing material in case you need to store or ship the unit at a later

time.

3.2 Mounting in the field

VisuNet GMP is licensed for operation in confined spaces.

The cooling of VisuNet GMP does not require active components like CPU fan or water

cooling systems. For that reason there are no ventilation slots in the housing.

To avoid overheating during operation, follow the advices below for field installation:

• Do not expose the VisuNet GMP to direct solar radiation or other heat sources.

• As the heat will dissipate via the housing of the VisuNet GMP, provide sufficient air

circulation.

• Keep the ambient temperature below the specified maximal value.

Mounting the VisuNet GMP

1. If you mount the VisuNet GMP on a pedestal, lead all connection cables from the buttom

up through the pedestal pipe (towards VESA adapter).

2. Lead the connection cables through the VESA adapter.

3. Attach the connection cables to the respective interface.

4. Screw the VisuNet GMP with 4 countersunk head screws (M5) on the VESA adapter at

the back of the housing.

Grounding the VisuNet GMP

Ground the VisuNet GMP via the VESA adapter grounding bolt with the back of the

housing. If you mount the VisuNet GMP on a pedestal, you will be able to use the

grounding bolt with the pedestal.

Note!

The VisuNet GMP is not delivered in sterile condition. Desinfect the device before using it

(spray/wipe disinfectant).

Page 16

219365 2006-06

16

VISUNET GMP DM

Installation and Commissioning

3.3 Commissioning VisuNet GMP RM/PC

Use a low-impandance connection between device and control cabinet.

Use cables with a minimum cross core-section of 2,5 mm

2

.

Turning on the VisuNet GMP

1. Connect the 4-pin plug with the 4-pin power supply socket at the back of the housing.

2. Bolt together the screw plug.

3. Establish the power supply.

After establishing the power supply the VisuNet GMP starts automatically. The LED on

the right hand side of the housing lights green.

Turning off the VisuNet GMP

1. Disconnect the device from the power supply.

2. After that pull out the plug.

Note!

Use the VisuNet GMP only with safety-low voltage (protective extra-low-voltage). The

power supply needs to be in line with applicable standards.

Page 17

VISUNET GMP DM

Operation

219365 2006-06

17

4 Operation

4.1 On Screen Display

VisuNet GMP features a graphical user interface for setting up the display via the On

screen display (OSD menu). A control panel with four buttons for operating the system is

located on the right hand side of the housing.

The following table describes the buttons and their function.

Selecting the OSD menu

To select the OSD menu, press the button.

The OSD menu is divided in the following menu items :

•Audio

• Bright-Contrast

•Color

•Image

•Tools

• Input

• Exit

Bild Taste Funktion Beschreibung

AUTO

adjust

Atuomatic

adjustment

1. Automatic adjustment

2. 2nd click: quit sub menu/menu

MENU/

SELECT

menu access/

selection

1. 1st click: activate the OSD menu

2. Select menu entries

3. Confirm active menu entries

– downwards/

left

1. Navigate in menus: downwards/left

2. Decrease a value

3. shortcut for audio volume

+ upwards/

right

1. Navigate in menus: upwards/right

2. Increase a value

LED Status red light: no signal

green light: operating status "on"

AUTO

adjust

MENU/

SELECT

–

+

MENU/

SELECT

Page 18

219365 2006-06

18

VISUNET GMP DM

Operation

Navigating in the OSD menu

1. If applicable select the OSD menu.

2. Navigate to the designated tab with the button (scroll to the right) and button

(scroll to the left) respectively.

The active tab will be marked.

3. To select a tab, press the button.

The sub menu will be opened.

4. Navigate to the designated sub menu entry with the button and the button

respectively.

5. To select a sub menu entry, press button.

Depending on the menu you will get to another sub menu or to a dialog box.

Adjusting values

1. To adjust values (i.g. brightness or contrast) in a sub menu, press the button and the

button respectively.

2. After adjusting the value, quit the active dialog box by pressing the button.

The adjusted value will be adopted and you will return to the designated sub menu.

Quitting OSD menu/sub menus

1. To quit a sub menu, select the menu item .

2. Confirm the selection by pressing the button.

The sub menu will be quit.

+ –

MENU/

SELECT

+ –

MENU/

SELECT

+

–

AUTO

adjust

MENU/

SELECT

Page 19

VISUNET GMP DM

Operation

219365 2006-06

19

4.1.1 Audio menu

Menu item Name Description

Volume Change the volume

Mute Mute the audio

Exit Quit the sub menu and return to the menu one lever

higher.

Note!

The VisuNet GMP has no audio speaker.

Page 20

219365 2006-06

20

VISUNET GMP DM

Operation

4.1.2 Bright-Contrast menu

Menu Item Name Description

Brightness Decrease/increase brightness

Contrast Decrease/increase contrast

Exit Quit the sub menu and return to the menu one lever

higher.

Page 21

VISUNET GMP DM

Operation

219365 2006-06

21

4.1.3 Color menu

Menu item Name Description

Color Auto Automatic adjustment of color

Color Temperature Adjustment of color temperature. Choose between

2 default settings (9300 K; 6500 K) in the sub menu

or create your own color settings.

Exit Quit the sub menu and return to the menu one lever

higher.

Page 22

219365 2006-06

22

VISUNET GMP DM

Operation

4.1.4 Image menu

Menu item Name Description

Image Auto Automatic adjustment of image position and width.

Width Adjust the image width

Phase Adjust the phase. Changes effect the display

sharpness

Horizontal Scroll the display to the right and to the left

respectively

Vertical Scroll the display upwards and downwards

respectively

Display Mode Choose between 6:10 or 4:3 format in this sub menu

Exit Quit the sub menu and return to the menu one lever

higher

Page 23

VISUNET GMP DM

Operation

219365 2006-06

23

4.1.5 Tools menu

Menu item Name Description

OSD Select more sub menus: time, horizontal, vertical, OSD

menu direction, exit

Reset Reset to factory settings

Sharpness Change sharpness

Language Change language of OSD menu

Exit Quit the sub menu and return to the menu one lever

higher.

A

A

A

Page 24

219365 2006-06

24

VISUNET GMP DM

Operation

4.1.6 Input menu

Menu item Name Description

VGA Activate VGA interface

DVI Activate DVI interface

Exit Quit the sub menu and return to the menu one lever

higher

1

2

Page 25

VISUNET GMP DM

Operation

219365 2006-06

25

4.1.7 Exit menu

Page 26

219365 2006-06

26

VISUNET GMP DM

Appendix

5 Appendix

5.1 How to contact Pepperl+Fuchs GmbH

Should you encounter any problems with the device, please consult the technical manual

first of all. If you are still anable to solve the problems after studying the above information

carefully you can contact the following places:

If you need to contact the support hotline, please make sure you have the Technical

manual handy!

Region Phone / mail address

Western Europe and South Africa

France, Belgium, Netherlands, Luxemburg,

South Africa

+33-1 60 92 13-13

commercial@fr.pepperl-fuchs.com

Northern Europe

Great Britain, Sweden, Norway, Denmark +44-161-633 6431

sales@gb.pepperl-fuchs.com

Ireland +353-21-4883798

info@insteco.iol.ie

Finnland +358-9-477720-0

joel.patrikka@sensonor.fi

Southern Europe

Italy, Spain, Greece, Switzerland, Israel +39-039 6292-1 ,

info@it.pepperl-fuchs.com

Eastern Europe

Russia, Austria, Czech Rep., Hungary,

Poland, Croatia, Slovenia, Turkey,

Romania

+39-039 6292-1

info@it.pepperl-fuchs.com

Germany +49-621-776-3712

support_hmi@de.pepperl-fuchs.com

Northern America

USA, Canada, Mexiko +1-330-486-0002

sales@us.pepperl-fuchs.com

Southern America

Brasil, Chile, Middle-America +55-11-4339-9935

vendas@br.pepperl-fuchs.com

Argentinia +54-11-4730 1100

schillig@schillig.com.ar

Middle East / India

Dubai, UA, Kuwait, Pakistan, Iran, Irak 971-4-8838378

info@ae.pepperl-fuchs.com

India +91-80 2837-8030

pa-info@in.pepperl-fuchs.com.

Asia-Pacific

Australia, Singapore, China, Thailand, ... +65-6779-9091

sales@sg.pepperl-fuchs.com

Japan +81-45-939 7802

sales@jp.pepperl-fuchs.com

Page 27

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

www.pepperl-fuchs.com

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

For the Pepperl+Fuchs representative

closest to you check www.pepperl-fuchs.com/pfcontact

PROCESS AUTOMATION –

PROTECTING YOUR PROCESS

219365 / TDOCT-1800_ENG

06/2006

Loading...

Loading...