Page 1

Technical Information

TI 389O/98/en/09.05

188839 09/05 00

Vibracon LVL-B1, LVL-B2

Level limit switch

Robust vibration limit switch for bulk solids,

also for dust incendive hazard areas

Application

Vibracon LVL-B* is a robust level limit

switch for silos with fine-grained or

coarse-grained, non-fluidised bulk solids.

The various designs means the device

has a wide range of applications.

Certificates are also available for use in

dust incendive hazard areas.

LVL-B1 compact design (250 mm

(10 in)) as vibrating rod for installation in

any direction

LVL-B2 vibrating rod with extension pipe

(500 mm/1000 mm/1500 mm/20 in/40 in/

60 in) for installation in any direction

Typical applications: cereals, coffee

beans, sugar, animal feed, rice,

detergents, dye powder, chalk, gypsum,

cement, sand, plastic granules.

Features

• No calibration: easy commissioning

(plug and play)

• Insensitive to build-up: maintenancefree operation

• No mechanically moving parts: no

wear, long operating life

• Sensor material 316L: hardly any

abrasion even with building materials

• F16 plastic housing with cover with

sight glass: switch status visible from

outside

• F18 aluminium housing also available

• Insensitive to external vibration and

flow noises

• Also available with explosion

protection ATEX II 1/3 D, FM or

CSA approval

Page 2

Table of contents

Vibracon LVL-B1, LVL-B2

Function and system design. . . . . . . . . . . . . 3

Measuring principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cable specifications. . . . . . . . . . . . . . . . . . . . 4

Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measured variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring range (application) . . . . . . . . . . . . . . . . . . . . . 4

Input signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Measuring frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Galvanic isolation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Switch behaviour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power-on behaviour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fail-safe mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Switching delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ex specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electronic insert FEM 22 (E5) . . . . . . . . . . . . 5

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connectable load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electronic insert FEM 24 (WA) . . . . . . . . . . . 6

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Output signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Signal on alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connectable load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operating conditions. . . . . . . . . . . . . . . . . . . 7

Installation instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ambient temperature range . . . . . . . . . . . . . . . . . . . . . . . 7

Storage temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Climate class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Vibration resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . 7

Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Thermal shock resistance . . . . . . . . . . . . . . . . . . . . . . . . . 8

Limiting medium pressure range. . . . . . . . . . . . . . . . . . . . 8

State of aggregation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grain size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bulk density. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lateral load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mechanical construction . . . . . . . . . . . . . . . . 9

Design, dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Human interface . . . . . . . . . . . . . . . . . . . . . . 11

Display elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating elements of electronic inserts. . . . . . . . . . . . . 11

Sediment detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Certificates and approvals. . . . . . . . . . . . . . 12

CE mark, declaration of conformity. . . . . . . . . . . . . . . . . 12

Ex approval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Type of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Other standards and guidelines . . . . . . . . . . . . . . . . . . . 12

Ordering information . . . . . . . . . . . . . . . . . . 13

Product structure LVL-B1 . . . . . . . . . . . . . . . . . . . . . . . . 13

Product structure LVL-B2 . . . . . . . . . . . . . . . . . . . . . . . . 13

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 14

High pressure sliding sleeve . . . . . . . . . . . . . . . . . . . . . . 14

Sliding sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Supplementary documentation. . . . . . . . . . 15

Operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Safety informations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Directive conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Supplementary informations . . . . . . . . . . . . . . . . . . . . . . 15

Date of issue 09/29/05 188839

2

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 3

Vibracon LVL-B1, LVL-B2

Function and system design

Function and system design

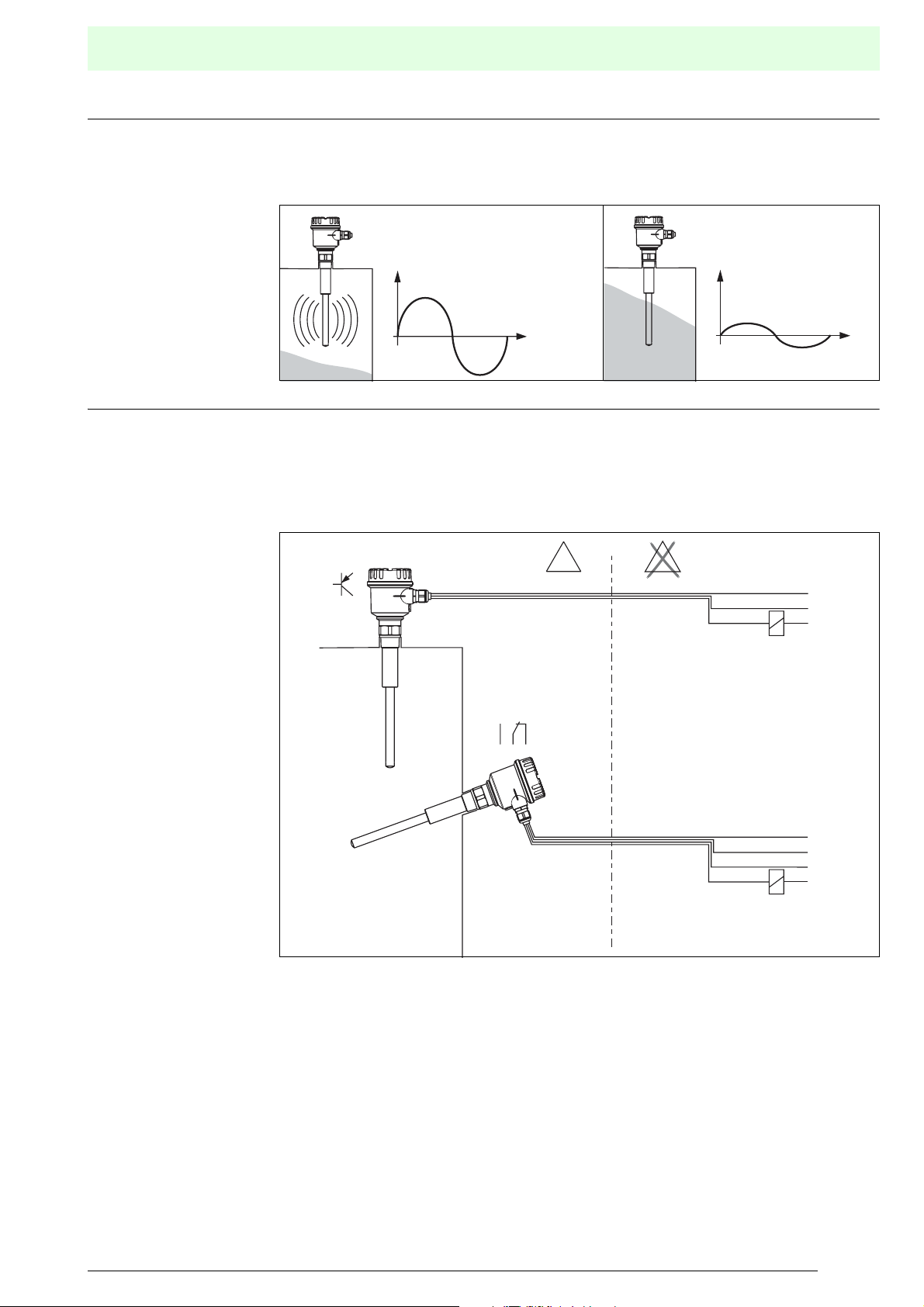

Measuring principle A piezoelectric drive excites the vibrating rod of Vibracon LVL-B1, LVL-B2 to its resonance

frequency. If medium covers the vibrating rod, the rod's vibrating amplitude changes (the vibration

is damped). Vibracon’s electronics compare the actual amplitude with a target value and indicates

whether the vibrating rod is vibrating freely or whether it is covered by medium.

A

t

A = amplitude

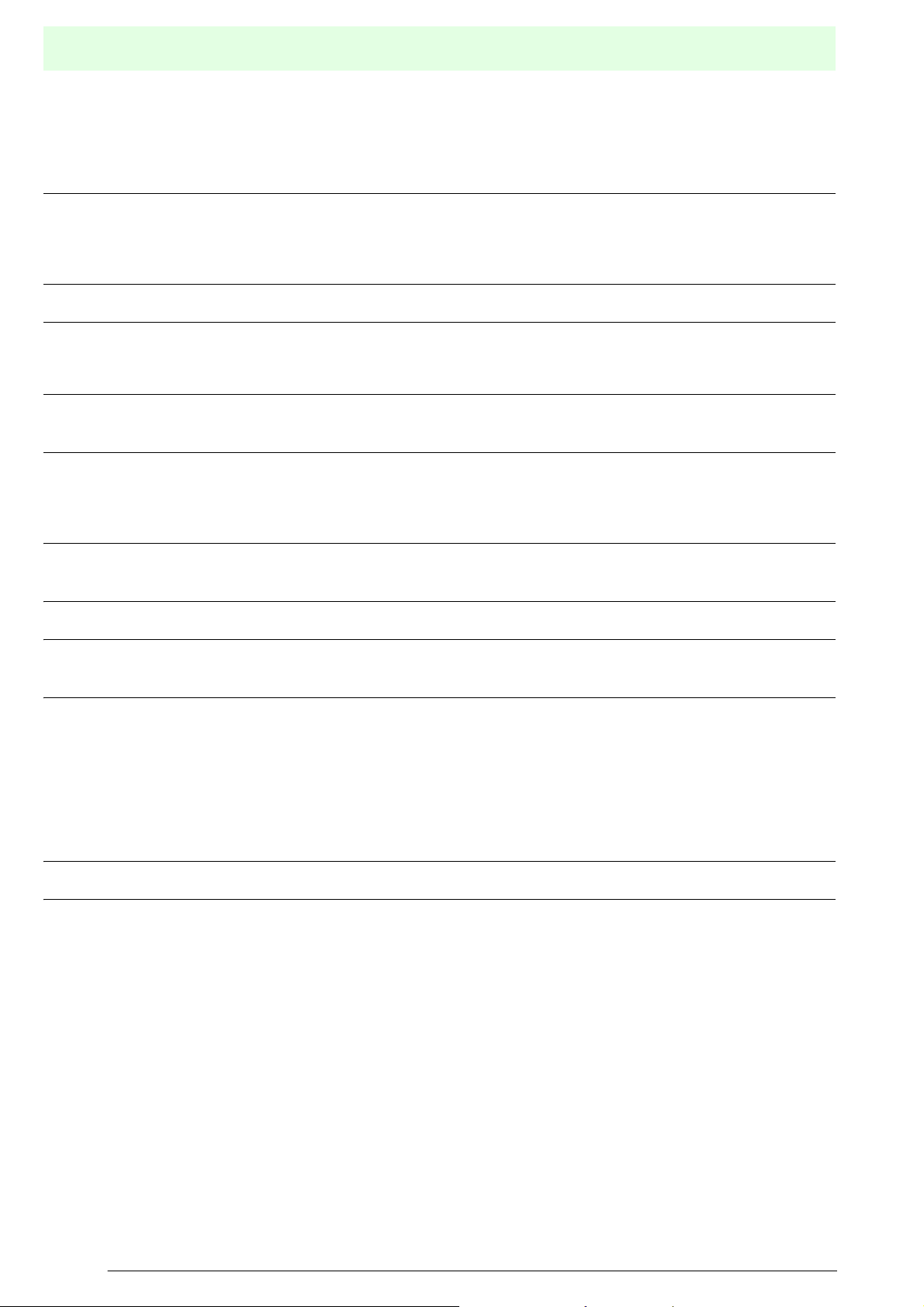

Measuring system Vibracon LVL-B* is a compact electronic switch.

Thus, the entire measuring system only consists of:

• Vibracon LVL-B1 or LVL-B2 with FEM 22 (E5) or FEM 24 (WA) electronic insert

• a supply point and

• the connected control systems, switching units, signalling systems (e. g. lamps, horns, PCS,

PLC, etc.)

X

E

A

t

E

X

…

+–

U –

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

U –

~

3

Page 4

Cable specifications

Cable specifications

Use a shielded cable in the event of strong electromagnetic radiation.

Immunity to temperature change of connec ti ng cable

The connecting cables must withstand the ambient temperature +15 K.

Cable entries M20 x 1,5 (cable gland); ½ NPT; G½

Input

Measured variable Level (according to the mounting location and the overall length)

Vibracon LVL-B1, LVL-B2

Measuring range

(application)

Input signal Probes covered

Measuring frequency 700 Hz ... 800 Hz

The measuring range depends on the mounting location of Vibracon LVL-B* and the length of the

pipe extension selected. The pipe extension is available in the following lengths:

500 mm, 1000 mm, 1500 mm, 20 in, 40 in, 60 in.

! small amplitude

Probe not covered

! large amplitude

Output

Galvanic isolation FEM 22 (E5): between sensor and power supply

FEM 24 (WA): between sensor, power supply and load

Switch behaviour binary

Power-on behaviour When switching on the power supply the output is set to "signal on alarm".

After a maximum of 3 s it switches to the correct output signal.

Fail-safe mode Minimum/maximum quiescent current safety can be switched at electronic insert.

Max. = maximum safety:

When the vibrating rod is covered, the output switches in the direction of the signal on alarm.

Used for overfill protection for example.

Min. = minimum safety:

When the vibrating rod becomes exposed, the output switches in the direction of the signal on

alarm.

Used for empty running protection for example.

Switching delay 0.5 s when the sensor is covered, 1 s when the sensor is exposed

Ex specifications FEM 22 (E5), FEM 24 (WA):

Explosion protection for explosive dust-air mixtures: Dust-Ex, DIP

4

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 09/29/05 188839

Page 5

Vibracon LVL-B1, LVL-B2

Electronic insert FEM 22 (E5)

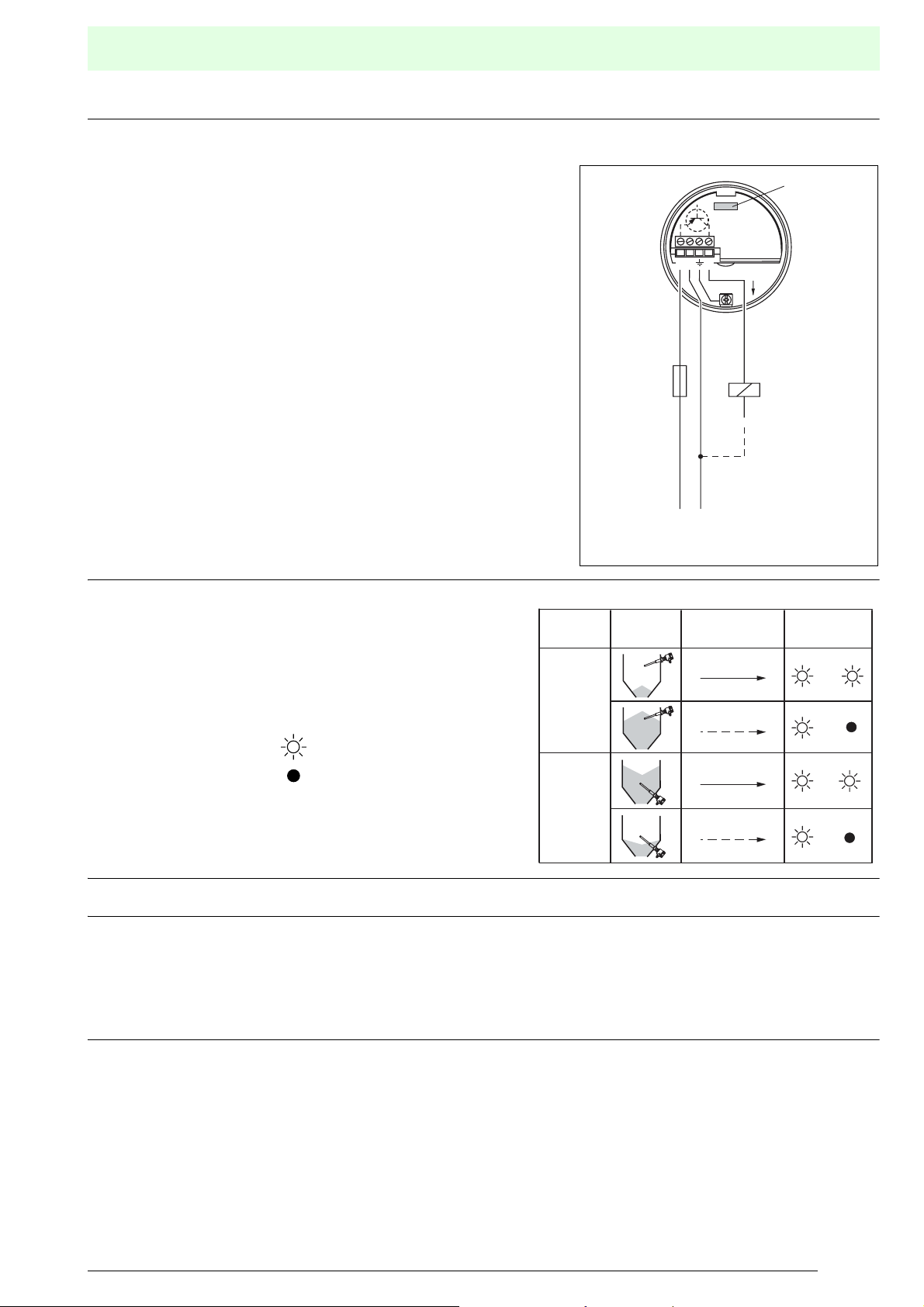

Electrical connection Three-wire direct current connection

Preferred in conjunction with

programmablelogic controllers (PLC),

DI modules as per EN 61131-2.

Positive signal at electronics switch output

(PNP); Output blocked at level limit.

Electronic insert FEM 22 (E5)

FEM 22 (E5)

13

F

0.5 A

2

(+)

R

e. g.

Relay

PLC

–

L+ L–

…

U – 10 V ... 45 V (DC)

Output signal

I

L

< 100 µA

= load current

(switched throuht)

= residual current

(blocked)

Safety

connection

Max.

Level Output signal LEDs

L+ +

1 3

< 100 µA

1 3

= lit

= not lit

Min.

L+ +

1 3

< 100 µA

1 3

Signal on alarm Output signal on power failure or in the event of device failure: < 100 µA

Connectable load • Load switched via transistor and separate PNP connection

• Load current: max. 45 V (cyclical overload and short-circuit protection),

continuous max. 350 mA

• Residual current: < 100 µA (for blocked transistor)

• Capacitive load: max. 0.5 µF for 45 V, max. 1.0 µF for 24 V

• Residual voltage: < 3 V (for transistor switched through)

green yellow

I

L

I

L

Power supply DC voltage 10 V … 45 V

Ripple max. 5 V, 0 Hz … 400 Hz

Current consumption max. 15 mA

Power consumption max. 0.68 W

Reverse polarity protection

Separation voltage: 2.2 kV

Overvoltage protection: overvoltage category III

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

5

Page 6

Electronic insert FEM 24 (WA)

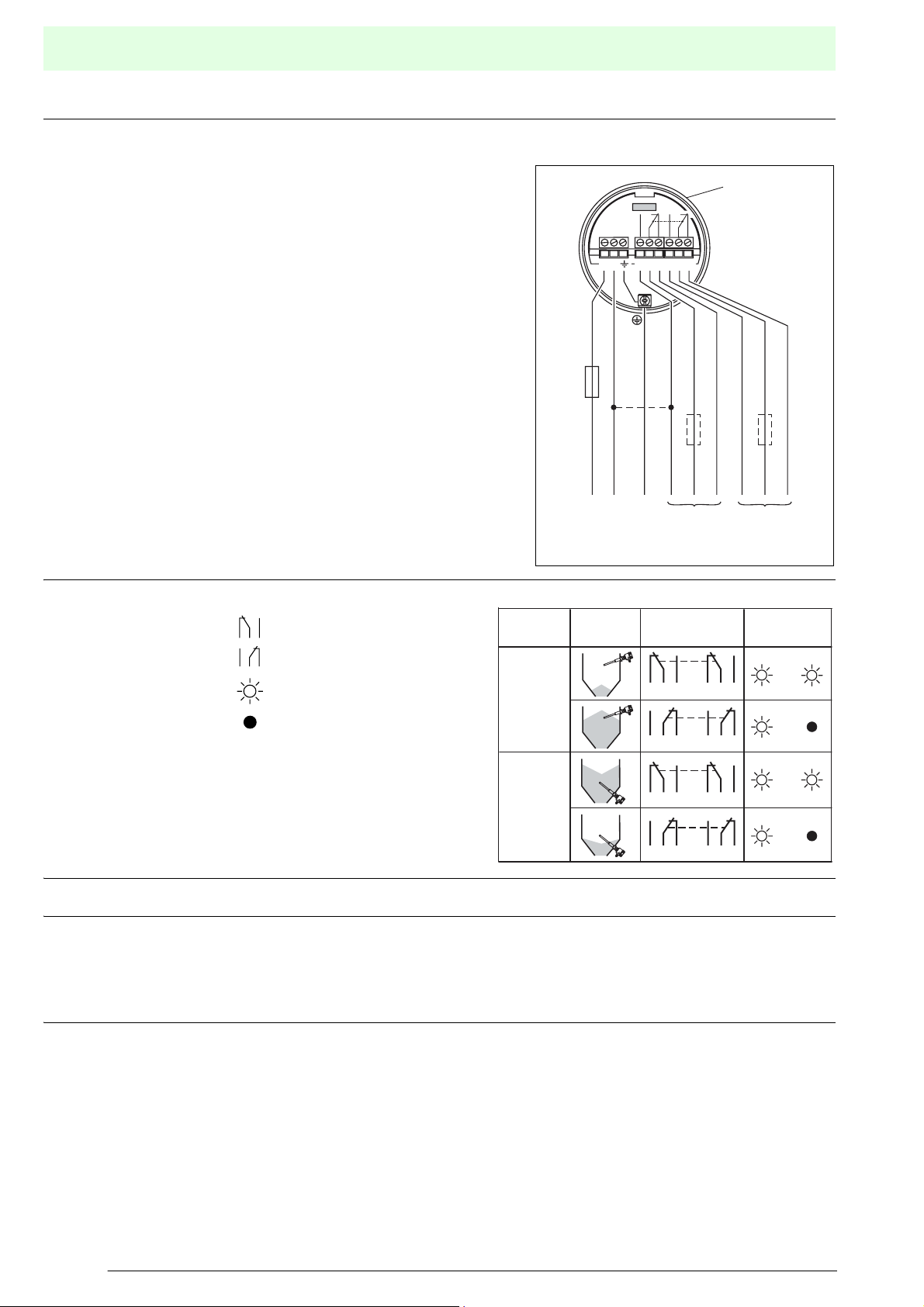

Electronic insert FEM 24 (WA)

Electrical connection Universal current connection with relay output

Power supply:

Please note the different voltage rangesfor AC

and DC.

Output:

When connecting a device withhigh inductance,

provide a spark arresterto protect the relay

contact.

A fine-wire fuse (depending on theload

connected) protects the relaycontact in the event

of a short-circuit.

Both relay contacts switch simultaneously.

DPDT (double pole double throw)

* When jumpered, therelay output works with

NPN logic.

** see below "Connectable load"

F

0.5 A

Vibracon LVL-B1, LVL-B2

FEM 24 (WA)

12 345 6 78

*

!

Note!

Please note the different voltage ranges for

direct and alternating current.

U ~ 19 V ... 253 V (AC)

Output signal

= relay energised

Safety

connection

= relay de-energised

= lit

Max.

= not lit

Min.

Signal on alarm Output signal in event of power failure: relay de-energised

NO

C

a

u

L1

NL–PE

L+

(Ground)

…

Level Output signal LEDs

**

U – 19 V ... 55 V (DC)

435 768

435 768

435 768

435 768

NC

r

…

NO

C

a

u

**

green yellow

NC

r

Connectable load • Loads switched via 2 floating change-over contacts.

• I~ max. 6 A, U~ max. 253 V; P~ max. 1500 VA, cos ϕ = 1, P~ max. 750 VA, cos ϕ > 0.7;

• I– max. 6 A to 30 V, I– max. 0.2 A to 125 V.

• The following applies when connecting a functional extra-low voltage circuit with double

insulation as per IEC 1010: sum of voltages of relay output and power supply max. 300 V

Power supply Alternating voltage 19 V… 253 V, 50/60 Hz or DC voltage 19 V … 55 V

Power consumption max. 1.3 W

Reverse polarity protection

Separation voltage: 2.2 kV

Overvoltage protection: overvoltage category III

6

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 09/29/05 188839

Page 7

Vibracon LVL-B1, LVL-B2

Operating conditions

Installation instructions Mounting location

e. g. storage or buffer container

Orientation

Operating conditions

*

**

Horizontal installation/vertical installation

* with protective cover (to be provided by customer)

** with protecting tube (to be provided by customer)

Environment

Ambient temperature

range

Storage temperature -40 °C ... 85 °C (233 K ... 358 K)

Climate class Climatic protection as per DIN IEC 68 part 2-38, fig. 2a

Degree of protection IP66/IP67, Nema 4x

Vibration resistance DIN 60068-2-27/IEC 68-2-27: shock 30 g, vibration 0.01 g

Electrical safety IEC 61010, CSA 1010.1-92, FM3600

Electromagnetic

compatibility

-40 °C ... 70 °C (233 K ... 343 K)

Interference emission to EN 61326, Electrical Equipment Class B

Interference immunity to EN 61326, annex A (Industrial)

2

/Hz

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

7

Page 8

Process

Vibracon LVL-B1, LVL-B2

Process

Environment Permitted ambient temperature T

container:

T

a

T

p

Thermal shock resistance max. 120 K

Limiting medium pressure

range

-1 bar ... 25 bar

Maximum working pressure (MWP)

25 bar

Burst pressure

100 bar

at housing depending on the medium temperature Tp in the

a

T

a

°C

70

50

0

150900–40

T

p

°C

–40

State of aggregation Solids

Grain size ≤ 25 mm

Bulk density ≥ 200 g/l, not fluidised

Lateral load

500

450

400

350

300

250

200

150

100

50

Maximum admissible lateral load F in N

0

300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

L

F

Overall length L in mm

100 mm = 3.94 in

Date of issue 09/29/05 188839

8

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 9

Vibracon LVL-B1, LVL-B2

Mechanical construction

Note!

!

Design, dimensions Compact version LVL-B1

All dimensions in mm! (100 mm = 3.94 in)

Mechanical construction

Ø85

21.5

372

225

151

Version with pipe extension LVL-B2

R1/1¼ NPT

max. 76

100

AF50AF41/AF1¾

R1½/1½ NPT

Ø29

Ø16

max. 60

21.5

159.5 + L

L = x

151

x = 500 mm;1000 mm;1500 mm; 20 in; 40 in; 60 in

max. 65

Ø80

105

AF50AF41/AF1¾

R1½/1½ NPTR1/1¼ NPT

Ø29

Ø16

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

9

Page 10

Mechanical construction

Vibracon LVL-B1, LVL-B2

Weight LVL-B1/LVL-B2 with F16 housing, FEM 24 (WA) and R1 thread:

compakt = approx. 1.0 kg

500 mm = approx. 1.3 kg

1000 mm = approx. 2.0 kg

1500 mm = approx. 2.6 kg

Material F16 housing: PTB-FR, cover with transparent glass made of PA12, EPDM cover seal

F18 housing: Aluminium EN-AC-AlSi10Mg, plastic coated

Cover seal: EPDM

Process connections:

• R1, R1½ (1.4435/316L, DIN 2999)

• 1¼ - 11½ NPT,1½ - 11½ NPT (1.4435/316L, ANSI B 1.20.1)

Sensor: 1.4435/316L

10

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 11

Vibracon LVL-B1, LVL-B2

Display elements

!

Human interface

Human interface

Note!

The switch settings in the following graphics are in the as-delivered state.

FEM 22 (E5)

Operating elements of

electronic inserts

One green LED: operation

One yellow LED: electronic switch closed

FEM 24 (WA)

One green LED: operation

One yellow LED: contact closed

(relay energised or fed with current)

MAX

MIN

U 10...45V DC

I m ax : 350 mA

-

L+L

12 3

~

U

–

19... 55V DC

19... 253V AC

L1 N

12

FEM22

DC PNP

MAX

MIN

1

3

MAX

MIN

35

4

345678

FEM24

347568

(Factory setting)

one switch for safety mode

MAX – overfill protection

MIN – dry running protection

one switch for bulk density/density setting

" 400 g/l (high bulk density)

# 200 g/l (low bulk density)

Sediment detection Detection of solids under water

HO

2

The system does not detect coverage by liquids

similar to water.

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

11

Page 12

Certificates and approvals

Certificates and approvals

Vibracon LVL-B1, LVL-B2

CE mark, declaration of

conformity

Ex approval ATEX approval in preparation

Type of protection See "Ordering information" as of page 13 and "Supplementary documentation" on page 15.

Other standards and

guidelines

The instrument is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate.

The instrument complies with the applicable standards and regulations as listed in the EC

declaration of conformity and thus complies with the statutory requirements of the EG directives.

Pepperl+Fuchs confirms the successful testing of the instrument by affixing to it the CE mark.

Your Pepperl+Fuchs sales centre can provide you with information on the Ex versions which can

currently be delivered.

All explosion protection data are given in a separate documentation (see "Supplementary

documentation") which is available upon request.

Other standards and guidelines that were taken into consideration in designing and developing

Vibracon LVL-B1, LVL-B2:

• Low Voltage Directive (73/23/EEC)

• DIN EN 61010 part 1, 2001

Protection Measures for Electrical Equipment for Measurement, Control, Regulation and

Laboratory Procedures

Part 1: general requirements

• EN 61326

Electrical Equipment for Measurement, Control and Laboratory Use

EMC requirements

12

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 13

Vibracon LVL-B1, LVL-B2

Ordering information

Product structure LVL-B1

LVL–B1– – –

Electrical output

B3 FEM 20 B, AS-interface-Bus

E5 FEM 22, PNP 3-wire, 10 V DC ... 45 V DC

WA FEM 24, relay, DPDT, 19 V AC ... 253 V AC, 19 V DC ... 55 V DC

Housing, cable entry

A6 aluminium housing F18, IP66/IP67, Nema 4x, cable gland M20

A7 aluminium housing F18, IP66/IP67, Nema 4x, ¾ NPT

A8 aluminium housing F18, IP66/IP67, Nema 4x, entry G½A

C polyester housing F16, IP66/IP67, Nema 4x, cable gland M20

Q polyester housing F16, IP66/IP67, Nema 4x, ½ NPT

Process connection

N3 thread 1¼ NPT, ANSI, 1.4435/316L

N5 thread 1½ NPT, ANSI, 1.4435/316L

R3 thread R1, DIN 2999, 1.4435/316L

R5 thread R1½, DIN 2999, 1.4435/316L

Design

B1 compact design

XX special version

P polyester housing F16, IP66/IP67, Nema 4x, entry G½A

Certificates

NA version for non-hazardous areas

EX ¬ II 1/3 D

FS FM, DIP + CSA DIP, CI. II, III, Div. 1 + 2, Gr. E–G

CG CSA, General Purpose

Optional equipment

A with optional equipment

Ordering information

Product structure LVL-B2

LVL–B2– –

Electrical output

B3 FEM 20 B, AS-interface-Bus

E5 FEM 22, PNP 3-wire, 10 V DC ... 45 V DC

WA FEM 24, relay, DPDT, 19 V AC ... 253 V AC, 19 V DC ... 55 V DC

Housing, cable entry

A6 aluminium housing F18, IP66/IP67, Nema 4x, cable gland M20

A7 aluminium housing F18, IP66/IP67, Nema 4x, ¾ NPT

A8 aluminium housing F18, IP66/IP67, Nema 4x, entry G½A

C polyester housing F16, IP66/IP67, Nema 4x, cable gland M20

Q polyester housing F16, IP66/IP67, Nema 4x, ½ NPT

P polyester housing F16, IP66/IP67, Nema 4x, entry G½A

Sensor length

2 500 mm

3 1000 mm

4 1.500 mm

6 20 in

7 40 in

8 60 in

Process connection

N3 thread 1¼ NPT, ANSI, 1.4435/316L

N5 thread 1½ NPT, ANSI, 1.4435/316L

R3 thread R1, DIN 2999, 1.4435/316L

R5 thread R1½, DIN 2999, 1.4435/316L

Design

B2 extended design (500 mm/20 in ... 1.500 mm/60 in)

XX special version

Certificates

NA version for non-hazardous areas

EX ¬ II 1/3 D

FS FM, DIP + CSA DIP, CI. II, III, Div. 1 + 2, Gr. E–G

CG CSA, General Purpose

Optional equipment

A with optional equipment

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

13

Page 14

Accessories

Vibracon LVL-B1, LVL-B2

Accessories

High pressure sliding

sleeve

Sliding sleeve

!

!

for pressurised container

• R1½, DIN 2999

ordering code: LVL-Z200

• 1½-11½ NPT, ANSI B 1.20.1

ordering code: LVL-Z201

Note!

Suitable for multiple switch-point configurations!

for unpressurised container, IP65

• R1½, DIN 2999

ordering code: LVL-Z202

• 1½-11½ NPT, ANSI B 1.20.1

ordering code: LVL-Z203

Note!

Only suitable for one-time switch-point

configuration!

~70

21.5

21

10

57.5

24.5

Ø70

R1½

1½-11½ NPT

G1¼

R1½

1½-11½ NPT

M6 x 25/

AF5

AF60

25

22

MWP = 25 bar

(360 psi)

= max. 150 °C

T

a

(max. 300 °F)

AF50

M6 (3x)

AF50

MWP = 0 bar

(0 psi)

= max. 150 °C

T

a

(max. 300 °F)

Spare parts • FEM 22 (E5) electronic insert

• FEM 24 (WA) electronic insert

• Cover for polyester housing (F16), transparent plastic with seal

• Cover for aluminium housing (F18), aluminium with seal

• Cover for aluminium housing (F18), aluminium with glass insert and seal (not for EEx d)

14

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 09/29/05 188839

Page 15

Vibracon LVL-B1, LVL-B2

Supplementary documentation

Operating instructions KA 227O

Safety informations SI 300O-A (ATEX approval in preparation)

Directive conformity Directive conformity 89/336/EC (EMC)

• Emitted interference to EN 61326, class B equipment

• Interference immunity to EN 61326, annex A (industrial sector) and NAMUR EMC

recommendation (NE 21)

Directive 94/9/EC (ATEX)

Directive 73/23/EC (Low Voltage Directive) EN 61010-1

Supplementary documentation

Supplementary

informations

EC-Type Examination Certificate, Statement of Conformity, Declaration of Conformity and

instructions have to be observed. For information see www.pepperl-fuchs.com.

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

15

Page 16

Notes

Vibracon LVL-B1, LVL-B2

16

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 17

Vibracon LVL-B1, LVL-B2

Notes

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

17

Page 18

Notes

Vibracon LVL-B1, LVL-B2

18

Date of issue 09/29/05 188839

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 19

With regard to the supply of products, the current issue of the following document is applicable: The General Terms of

Delivery for Products and Services of the Electrical Industry, published by the Central Association of the

"Elektrotechnik und Elektroindustrie (ZVEI) e.V." including the supplementary clause: "Erweiterter Eigentumsvorbehalt".

We at Pepperl+Fuchs recognize a duty to make a contribution to the future,

For this reason, this printed matter is produced on paper bleached without the use of chlorine.

Page 20

PROCESS AUTOMATION

SIGNALS FOR THE WORLD OF AUTOMATION

For half a century Pepperl+Fuchs has continually provided new impetus to the world of automation. We develop, manufacture and market electronic sensors and interface modules through our worldwide network. Our global presence and

highly flexible production and service organisations enable us to offer you complete individual solutions – right where you

need us! We know what we’re talking about – because today Pepperl+Fuchs is the company with the largest selection of

industrial sensors technology in the World – serving a very broad spectrum of applications. Our signals move the World.

Twinsburg

Mannheim

Singapore

www.pepperl-fuchs.com

Worldwide Headquarters

Pepperl+Fuchs GmbH · Königsberger Allee 87

68307 Mannheim · Germany

Tel. +49 621 776-0 · Fax +49 621 776-1000

e-mail: pa-info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc. · 1600 Enterprise Parkway

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555 · Fax +1 330 4254607

e-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd. · P+F Building

18 Ayer Rajah Crescent · Singapore 139942

Company Registration No. 199003130E

Tel. +65 67799091 · Fax +65 68731637

e-mail: sales@sg.pepperl-fuchs.com

Subject to reasonable modifications due to technical advances • Copyright PEPPERL+FUCHS • Printed in Germany • Part. No.No. 30360 04/04 10

SIGNALS FOR THE WORLD OF AUTOMATION

TI 389O/98/en/09.05

FM7.0

188839 09/05 00

Loading...

Loading...