Pepperl+Fuchs VDM18-100/20/122/151, VDM18-100/20/88/122/151, VDM18-300/20/122/151, VDM18-300/20/88/122/151, VDM18-300/21/122/151 User Manual

Page 1

FACTORY AUTOMATION

HANDBUCH / MANUAL / MANUEL

VDM18-100/20/122/151

VDM18-100/20/88/122/151

VDM18-300/20/122/151

VDM18-300/20/88/122/151

VDM18-300/21/122/151

Page 2

Copyright (Deutsch)

Die Wiedergabe bzw. der Nachdruck dieses Dokuments, sowie die entsprechende Speicherung in Datenbanken

und Abrufsystemen bzw. die Veröffentlichung, in jeglicher Form, auch auszugsweise, oder die Nachahmung

der Abbildungen, Zeichnungen und Gestaltung ist nur auf Grundlage einer vorherigen, in schriftlicher Form vorliegenden Genehmigung seitens Pepperl+Fuchs GmbH, zulässig.

Für Druckfehler und Irrtümer, die bei der Erstellung der Betriebsanleitung unterlaufen sind, ist jede Haftung

ausgeschlossen. Liefermöglichkeiten und technische Änderungen vorbehalten.

Erstveröffentlichung August 2004.

Copyright (Englisch)

No part of this document may be reproduced, published or stored in information retrieval systems or data bases

in any manner whatsoever, nor may illustrations, drawings and the layout be copied without prior written permission from Pepperl+Fuchs GmbH.

We accept no responsibility for printing errors and mistakes which occurred in drafting this manual. Subject to

delivery and technical alterations.

First publication August 2004

Copyright (Français)

Toute reproduction de ce document, ainsi que son enregistrement dans une base ou système de données ou

sa publication, sous quelque forme que ce soit, même par extraits, ainsi que la contrefaçon des dessins et de la

mise en page ne sont pas permises sans l’autorisation explicite et écrite de Pepperl+Fuchs GmbH.

Nous déclinons toute responsabilité concernent les fautes éventuelles d’impression et autres erreurs qui

auraient pu intervenir lors du montage de cette brochure. Sous réserve de modifi cations techniques et de

disponibilité pour livraison.

Première publication Août 2004

Page 3

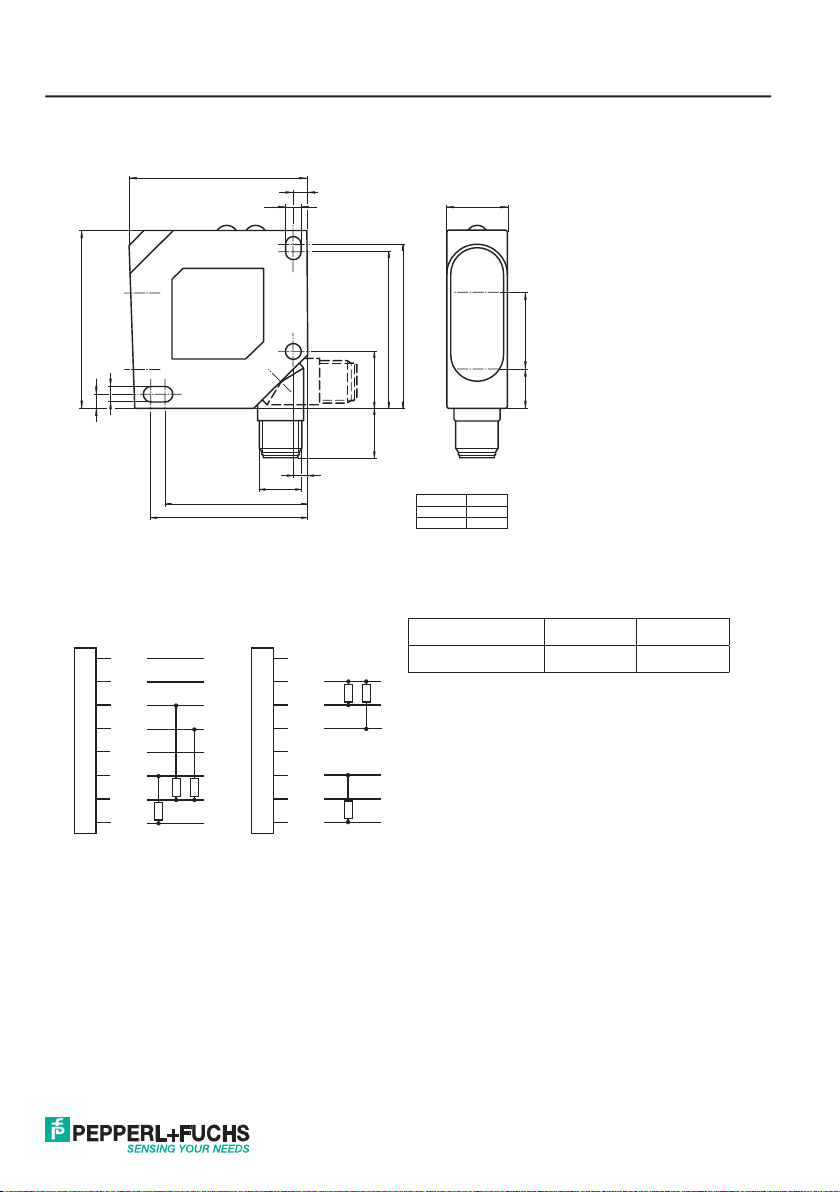

Maßzeichnung / Dimensional drawing / Plan coté

50

50

4.3

4

40

44

4.3

M12 x 1

4

4

Abb. 1 / Illustr. 1 / Fig. 1

Anschluss / Wiring / Raccordement

Option /20 - 2 x PNP Option /21 - 2 x NPN

n.c.

1

2

+UB

Q1

3

Q2

4

n.c.

5

Analog +

6

0 V

7

Analog -

8

n.c.

1

2

+UB

Q1

3

Q2

4

n.c.

5

Analog +

6

0 V

7

Analog -

8

17

Receiver

18

13.5

46

44

Version X (mm)

VDM18-100 18.4

VDM18-300 21.5

X11

Emitter

Typ / Type / Ref. Pin 1 Pin 5

VDM18 .../88 RS485 Y/A RS485 Z/B

Abb. 2 / Illustr. 2 / Fig. 2

3

Page 4

Inhalt / Content / Contenu

Deutsch ................................................................................................................... 5

English ................................................................................................................... 26

Français ................................................................................................................. 47

4

Page 5

Mounting and

operating instructions

Content

Signs and Symbols ......................................................................................................................................26

Safety information .......................................................................................................................................26

Appropriate use ...........................................................................................................................................27

Performance characteristics ........................................................................................................................27

Mode of function ..........................................................................................................................................27

Mounting ......................................................................................................................................................28

Electrical installation ...................................................................................................................................29

Instructions of use .......................................................................................................................................30

General use .................................................................................................................................................30

Settings........................................................................................................................................................32

Functions .....................................................................................................................................................32

Reset ...........................................................................................................................................................34

Unlocking keys ............................................................................................................................................34

Averaging ....................................................................................................................................................35

Automatic zero mode...................................................................................................................................35

Automatic centre mode................................................................................................................................36

Maximum hold mode ...................................................................................................................................36

Difference hold mode ..................................................................................................................................37

Measured value hold mode .........................................................................................................................37

Differential measurement mode ..................................................................................................................38

Transmission protocol .................................................................................................................................40

Bus commands ............................................................................................................................................41

Explanations on bus commands..................................................................................................................42

Optical data (typ.) ........................................................................................................................................43

Electrical data (typ.), ....................................................................................................................................43

Mechanical data ..........................................................................................................................................43

Order information.........................................................................................................................................44

26

Date of issue: 08/08/2011 Partnummer: 194551

Page 6

Mounting and

operating instructions

Signs and Symbols

Warning

This symbol signals passages in the manual which must be observed at all times. Non-compliance can

cause injuries or material damage.

Warning Laser

This symbol appears in front of warning passages concerning the danger of laser beams.

Information

This symbol signals passages with useful information.

Safety information

It is essential that this manual, and the safety information in particular, is read, thoroughly understood and observed before setting the VDM18 sensor into operation.

The VDM18 sensor may only be connected, mounted and adjusted by qualifi ed personnel.

Interventions and alterations to the device are not permissible!

The VDM18 sensor is not a safety component as described by EU machine directives and must

never be used in applications where human safety is at risk.

The VDM18 sensor complies with laser protection class 2 according to DIN EN 60825-1, status

2008-05. The technical requirements comply with EN 60947-5-2, 2000 edition.

Never look into the path of the laser. Do not suppress the refl ex to close the eyelids.

Gazing into the beam path for longer periods can damage the retina of the eye.

When mounting the sensor, ensure if possible that the beam path is sealed off at the end. The

laser must not be directed at people (head height). When aligning VDM18, ensure that there are

no refl ections on refl ective surfaces.

Should the safety label on the VDM18 sensor be partly covered due to its installation position,

other safety labels are to be positioned on visible parts of the sensor. When applying the new

safety label, make sure that you cannot look into the laser beam whilst reading it.

Date of issue: 08/08/2011 Partnummer: 194551

27

Page 7

Mounting and

operating instructions

Appropriate use

The VDM18 sensor is not authorised for use in protecting human safety on machines and during

technical applications.

The VDM18 is an optical sensor and measures distances without contact. When combined with another VDM18

sensor, the thickness of objects can also be measured.

Performance characteristics

• Operating range VDM18-100: 30 – 100 mm

• Operating range VDM18-300: 80 – 300 mm

• 2 digital outputs

• Analogue output 4-20 mA

• Compact design 50 x 50 x 17 mm

• High resolution (0.1 % of measuring range)

• Option /88 with serial bus interface (RS 485 half-duplex)

• “Teach-in” settings also possible per software

• Wide functional range

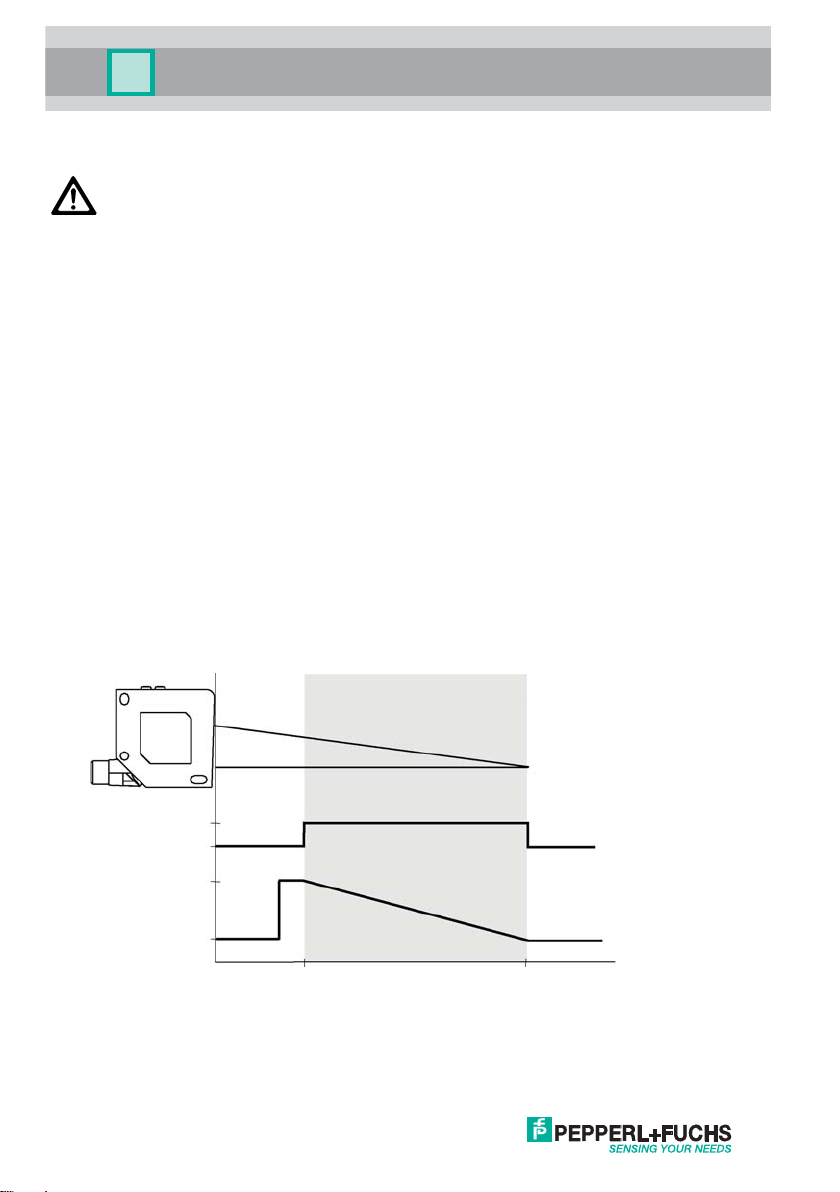

Mode of function

The VDM18 sensor measures according to the principle of triangulation. The distance between the object and sensor

is determined on the basis of the position of the light spot on the detector.

Operating range (Factory setting)

On

Off

20 mA

4 mA

Illustr. 3

28

OK LED (green)

(Good Target)

Analogue

output

(invertible)

VDM18-100 ...

VDM18-300 ...

30 mm

80 mm

100 mm

300 mm

Date of issue: 08/08/2011 Partnummer: 194551

Page 8

Mounting and

operating instructions

Light spot representation

VDM18-100 VDM18-300

C (mm)

D (mm)

E (mm)

1.5 x 3 1.5 x 3.5

1.5 x 3.25 2 x 4.5

B

D

30A (mm) 80

100B (mm) 300

29.4 32.5

Illustr. 4

Receiver

Emitter

A

11

E

8.5

C

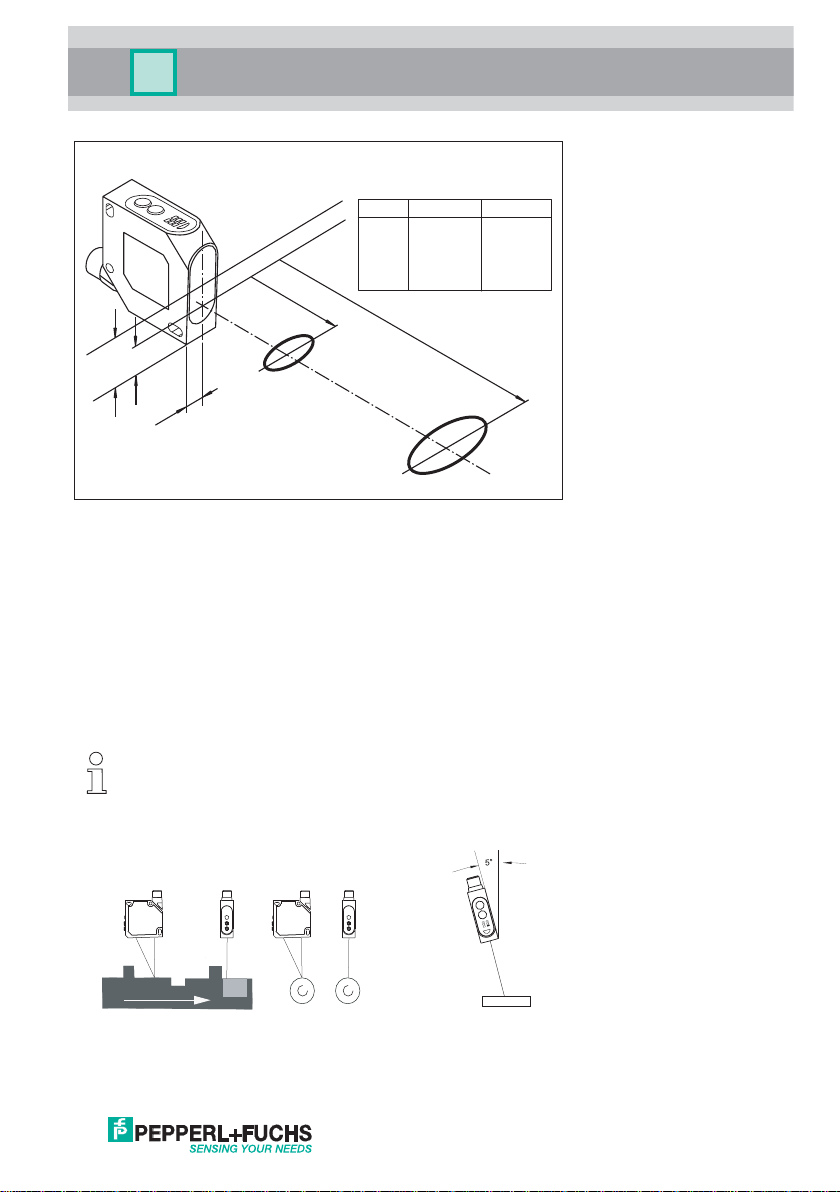

Mounting

Sensor alignment

Position VDM18 in a way that the distance to the object is within the working range of the sensor.

Screw the VDM18 sensor to the mounting bracket, e.g. type OMH-VDM18 (not included in delivery) or a suitable

device. Only use the holes provided in the housing (see dimensioned drawing) for this purpose.

If steps, moving or striped objects are to be detected, the front panel of the sensor should be mounted at a right

angle to the direction of movement or stripes (Illustr. 5 + 6).

With very refl ective objects, the sensor must be mounted at an angle of approx. 5° (Illustr. 7).

To optimise measurements, the VDM18 sensor is to be given constructive protection from vibrations.

The VDM18 sensor is now mounted.

Z

Illustr. 5 Linear movement

Date of issue: 08/08/2011 Partnummer: 194551

Z

Illustr. 6 Rotating movement

Illustr. 7 Refl ective object

29

Page 9

Mounting and

operating instructions

Electrical installation

Warning: Pin 1 and pin 5 must not be connected to operational voltage as this will destroy the

VDM18 sensor.

Turn the sensor connector plug according to the installation position (Illustr. 1) so that the connection cable can be

freely connected without being bent.

Insert the socket of the connection cable into the VDM18 connector and screw tight

For example, secure the connection cable from sliding with a cable tie .

Connect VDM18 as shown in Illustr. 8

Option /20 - 2 x PNP Option /21 - 2 x NPN

n.c.

1

2

+UB

Q1

3

Q2

4

n.c.

5

Analog +

6

0 V

7

Analog -

8

n.c.

1

2

+UB

Q1

3

Q2

4

n.c.

5

Analog +

6

0 V

7

Analog -

8

Illustr. 8 Connection diagram

Connection Colour Use Comments

1 (WH) White RS485 Y/A /88 option only

2 (BN) Brown + U

B

3 (GN) Green As signal output Q1 or input with optional input functions (see

“Settings” page 32)

4 (YE) Yellow As signal output Q2 or switching function “good target” (detec-

table object in measuring range)

5 (GY) Grey RS 485 Z/B /88 option only

6 (PK) Pink Q

7 (BU) Blue - U

A + analogue measurement

B

8 (RD) Red QA - analogue mass

Type Pin 1 Pin 5

VDM18 .../88 RS485 Y/A RS485 Z/B

Q1

Q2 or good target

Once power supply has been connected, the VDM18 is ready for operation after a short stand-by delay

(< 300 ms).

For maximum precision, please allow for a heating period (approx. 5 minutes).

30

Date of issue: 08/08/2011 Partnummer: 194551

Page 10

Mounting and

operating instructions

Instructions of use

Control panel

The VDM18 has various modes and is confi gured using the S and T buttons.

Button

S

Set button: Change / confi rm a setting or set a switching point

T

Toggle button: Select a function (proceed to the next function)

The selected settings and signal condition are indicated by LEDs.

S

T

ZA

LED Colour Use/Description

BA Green Power supply indicator

Q2

ZA Red Status indicator

1 Yellow Q1 input/output

Q

2 Yellow Q2 input/output

Q

H Green Q

OK Green Good target (object detected and in measuring range)

T Green Pulse stretching function is active

Z Green Q

On: ready (run mode)

Flashing: setting mode is active

Function activated/not activated, or confi rmation signal

1 trigger input or Q1 enable input function active

1 automatic centre or Q1 automatic zero function is active

1, Q2, H, OK, T and Z

BA

Q1

H OK

T Z

Illustr. 9

The table of functions on page 32 explains the further signifi cance of the LEDs: Q

General use

The following four steps are used to confi gure the VDM18 sensor:

1. Activate setting mode

Press the S and T buttons simultaneously for 3 seconds

After this period, the power supply indicator BA fl ashes

set VDM18, see Illustr. 9. The LEDs show the status of function no. 1 (page 32)

When all the LEDs start immediately fl ashing

Unlock VDM18, see paragraph “Unlocking keys” on page 34

2. Select functions (see page 32)

Press the T button to select the next function in the function table.

The function number is indicated by a clear LED pattern and the function status is indicated by the status indicator ZA

(LED on = active, LED off = not active).

The sensor only switches to the next function when the T button is released.

Date of issue: 08/08/2011 Partnummer: 194551

31

Page 11

Mounting and

operating instructions

If no change occurs:

Press T button for longer

The fi rst function follows the last available function.

If the wrong function is selected by mistake, it is not possible to jump directly back to the previous function number.

Press the T button several times until the required function reappears.

Or deactivate setting mode (see point 4) and repeat procedure from step 1.

3. Setting the function status

Press the S button to alter the status of a particular function. The status indicator alters according to the table of

functions. Settings are immediately effective but must still be saved as described in point 4.

Should the status indicator not alter or not light up whilst S is pressed

Check the position of the VDM18 sensor in relation to the measuring range and adapt if necessary

To reset the setting, press the S button once again (is not valid when transferring measured value as switching point!)

4. Deactivate setting mode

First press the T button and then simultaneously press the S button. All settings are then saved. Once the S button is

released, the sensor is in run mode. The BA power supply indicator is permanently alight.

Should the power supply fail during the setting procedure, all settings are lost.

32

Date of issue: 08/08/2011 Partnummer: 194551

Page 12

Mounting and

operating instructions

Settings

The VDM18 sensor can be confi gured as follows with functions 1 to 26 in setting mode (teach-in).

Button

S

Set button: Change / confi rm a setting or set a switching point

T

Toggle button: Select a function (proceed to the next function)

Functions

No. LED Muster Description “ZA” status indicator Factory setting

1

Select Q1 output mode. On = Q1 is a signal output

Off = Q1 is not a signal output

On

2

3 Scanning zone: Transfer of current meas.

4

5

6

7

8

9

10

Transfer of current meas. value as 1st

switching point of Q1. signal output.

value as 2nd switching point of Q1 signal

output. Q1 must be signal output (see

function no 1).

N.C./N.O. change-over of switching

functions for Q1.

Q2 output mode. On = Q2 is a signal output

Transfer of current meas. value as 1st

switching point of Q2 signal output.

Q2 must be signal output (see function

no 5)

Scanning zone: Transfer of current meas.

value as 2nd switching point of Q2 signal

output. Q2 must be signal output (see

function no 5).

N.C./N.O. change-over of switching

functions for Q2.

Pulse stretching of Q1 and Q2 by 50 ms. On = Pulse stretching on

Q2 signal output shows status “good

target”. Switching signal can be inverted

with function no 8.

On* = Measured value valid

Off* = Measured value invalid

On = Measured value valid

Off = Measured value invalid

On = N.C.

Off = N.O.

Off = Q2 displays good target

On* = Measured value valid

Off *= Measured value invalid

On = Measured value valid

Off = Measured value invalid

On = N.C.

Off = N.O.

Off = Pulse stretching off

On = Object within...

Off = Object outside...

...measuring range

Half measuring

range

Off

N.O.

Off

Good Target

Off

N.O.

Off

On

* as long as the S button is pressed

Date of issue: 08/08/2011 Partnummer: 194551

33

Page 13

Mounting and

operating instructions

No. LED Muster Description “ZA” status indicator Factory setting

11

12

13

14

15

16

17 Set analogue output 100% (20 mA): When

Q1 trigger input mode:

With rising edge on Q1, measured value is

held until the next trigger occurs.

Q1 enable input mode:

Used to switch laser beam on and off.

Laser beam is on when Q1 = +UB. If Q1

= - UB, the laser beam is switched off.

Last measured value remains. When reactivated, the response time is prolonged

according to the set mean value.

Switches off averaging:

The fi rst measured value is taken into

account (page 35).

Switches on 4 ms averaging:

the fi rst 10 meas. values are taken into

account (page 35).

Switches on 40 ms averaging:

all (max. 100) meas. values are taken into

account (page 35).

Set analogue output 0% (4 mA):

When S button is activated, the current

meas. value corresponds with 0% value of

the analogue output.

S button is activated, the current meas.

value corresponds with 100% value of the

analogue output.

On = Q1 is a trigger input

Off = Q1 is not a trigger input

On = active

Off = not active

On = Averaging off On

On = active

Off = not active

On = active

Off = not active

On* = Object within…

Off* = Object outside...

...measuring range

On* = Object within…

Off* = Object outside...

...measuring range

Off

Off

Off

Off

0% = 4 mA = end

of meas. range

100% = 20 mA

= start of meas.

range

18

19

* as long as the S button is pressed

34

Q1 automatic zero mode:

For characteristic curve displacement. If

Q1 = +UB, the current measuring signal

is set to the analogue value 0 % = 4 mA.

The incline of the characteristic curve is

maintained. If exceeded, the characteristic curve ends at the start or end of the

measuring range.

Q1 automatic centre mode: displacement

of centre of characteristic curve. If Q1 =

+UB, the current measuring signal is set to

the analogue value

50 % = 12 mA. The incline of the characteristic curve is maintained. If exceeded,

the characteristic curve ends at the start

or end of the measuring range.

On = Automatic zero active

Off = Autommatic zero not active

On = Automatic centre active

Off = Automatic centre not

active

Not active

Not active

Date of issue: 08/08/2011 Partnummer: 194551

Page 14

Mounting and

operating instructions

No. LED Muster Description “ZA” status indicator Factory setting

20

21

22

Q1 maximum hold mode:

Provided

1 = +UB, the max. recorded measured

Q

value is stored.

If Q1 = -UB, the determined value is transmitted at the analogue output. A minimum

hold can be set by inverting the analogue

characteristic curve (analogue 100% point

< analogue

0 % point).

Q1 difference hold mode:

Provided Q1 = +UB, the difference

between the measured values is saved.

When Q1 = -UB, the determined value is

transmitted at the analogue output.

Activate factory settings:

When the S button is pressed, the factory

setting is activated.

On = Maximum hold active

Off = Maximum hold not active

On = Difference hold active

Off = Difference hold not active

ZA lights up as long as the S button

is pressed

Not active

Not active

Not active

23

24 Meas. value hold mode:

25

26

Locking keys:

If function is activated locking becomes

active once the setting mode has been

quit. Cancel locking with RESET or the

unlocking function (see “Unlocking keys”)

If no object is in the measuring range

(good target = off), the last meas. value is

held at the analogue output.

Differential measurement mode master:

Activate/deactivate (option /88 only)

Description see differential measurement

mode (page 38).

Differential measurement mode slave:

Activate/deactivate (option /88 only)

Description see differential measurement

mode (page 38).

Reset

When switching on the sensor (power on), keep the S button pressed (approx. 10 seconds) until the

LED lights stop fl ashing and are permanently on. The BA power supply indicator is green. When the

S button is released, a Reset is carried out which returns the VDM18 to delivery status where factory

settings are active.

(See table of functions page 32-34).

Unlocking keys

When switching on the sensor (power on), keep the T button pressed (approx. 10 seconds) until the

LED lights stop fl ashing and are permanently on. The ZA status indicator is red. When the T button is

released, the setting mode is unlocked.

On = Locking is active

Off = Locking is not active

On = Meas. value hold is active

Off = Meas. value hold is

not active

On = Differential measurement

mode - master is active

Off = Differential measurement

mode - master is not active

On = Differential measurement

mode - slave is active

Off = Differential measurement

mode - slave is not active

Not active

Not active

Not active

Not active

Date of issue: 08/08/2011 Partnummer: 194551

35

Page 15

Mounting and

operating instructions

Averaging

The measuring result (output signal) is smoothed by averaging. The measured values are read continuously into a

memory and the arithmetical mean is formed. Functions 14 and 15 (page 33) determine the number of measurements (10 or 100) to be used for averaging.

With a scanning rate of 0.4 ms per measurement, the response time lies between 0.4 ms (without averaging) and 40

ms.

Example of use: When measuring rough surfaces, it is possible to counter-balance fl uctuations in measured values.

Measuring object

Response time

I(mA)

Direction of movement

0.4 ms = measured value (no average)

4 ms = averaging with 10 measured values

40 ms = averaging with 100 measured values

Response time t(s)

Illustr. 10 Output characteristics in relation to arithmetical mean

Automatic zero mode

The output characteristic curve 4 – 20 mA is displaced with this function. When the automatic zero mode is activated

and Q1 = +UB, the current measured value is equated with the output value of 0% = 4 mA. The incline of the characteristic curve is maintained and the minimum and maximum values of the characteristic curve are limited by the

measuring range.

The distance to the object must be within the measuring range.

100% (20 mA)

50% (12 mA)

0% (4 mA)

Q1

Illustr. 11

+UB

-UB

Analogue signal

t(s)

100% (20 mA)

0% (4 mA)

Illustr. 12

80

150 300

Factory setting

Autom. zero at 150 mm

mm

36

Date of issue: 08/08/2011 Partnummer: 194551

Page 16

Mounting and

operating instructions

Automatic centre mode

The output characteristic curve 4 – 20 mA is displaced with this function. When the automatic centre function is

activated and Q1 = +UB, the current measured value is equated with the output value of 50% = 12 mA. The incline of

the characteristic curve is maintained and the minimum and maximum values of the characteristic curve are limited

by the measuring range.

The distance to the object must be within the measuring range.

0% (4 mA)

+UB

Q1

Analogue signal

-UB

100% (20 mA)

50% (12 mA)

0% (4 mA)

t(s)

100% (20 mA)

50% (12 mA)

Illustr. 13 Illustr. 14

120

80

Autom. centre at 120 mm

190

300

mm

Maximum hold mode

When maximum hold mode is activated and Q1 = +UB, this function detects the maximum value of the measuring

signal and stores it.

If Q1 = -UB, the last maximum value is transmitted at the analogue output.

Example of use: determining the maximum value of a shaft

The minimum value can be determined by inverting the analogue output characteristic (see function no. 16 and 17).

100% (20 mA)

0% (4 mA)

Analogue value

100% (20 mA)

0% (4 mA)

Analogue output

+UB

Q1

-UB

Illustr. 15

Date of issue: 08/08/2011 Partnummer: 194551

14 mA

1

AABB

2

1

1

8 mA

2

2

Q1 = +UB = Sample. Collect measured values

A

B

Q1 = -UB = Display. Last maximum of analogue signal at

analogue output

37

Page 17

Mounting and

operating instructions

Difference hold mode

When the difference hold function is activated and Q1 = +UB, this function detects the difference between the minimum and maximum value of the measuring signal and stores it.

1 = -UB, the last differential value is transmitted at the analogue output.

If Q

Example of use: Checking the contents of open containers or packages.

100% (20 mA)

Analogue valueAnalogue output

0% (4 mA)

100% (20 mA)

0% (4 mA)

Q1

Illustr. 16

15500149

1

1

+UB

-UB

AB

2

BB

A

1

2

2

A

B

12 mA

2 mA

Q1 = +UB = Sample. Collect measured values

Q1 = -UB = Display. Last maximum of analogue signal at

analogue output

Measured value hold mode

When this function is activated, the last valid measured value is saved.

When no object is in the measuring range, the last valid measured value is transmitted at the analogue output. The

current value is only displayed again when an object is within the measuring range (OK LED = on).

Example of use: Maintain position of tool during change-over of work piece when machining.

Behaviour of analogue output with and without measured value hold.

Start of measuring range

End of measuring range

100% (20 mA)

0% (4 mA)

100% (20 mA)

0% (4 mA)

Good Target Q2

Illustr. 17

38

With measured value hold

Without measured value hold

ON

OFF

Date of issue: 08/08/2011 Partnummer: 194551

Page 18

Mounting and

operating instructions

Differential measurement mode

Differential measurement can only be used with /88 option of VDM18.

Simultaneous connection to SPC control or a PC via the RS 485 interface is not possible with

differential measurement.

With this measuring procedure, two VDM18.../88 sensors are connected to one another. The measuring ranges can

overlap (1), be directly adjacent (2) or apart (3) (Illustr. 18).

To achieve optimum use of the measuring range, the measuring object should if possible be aligned in the centre of

the measuring range.

1

2

3

Illustr. 18

Measuring range

The following steps must be carried out for differential measurement:

1. Mount both VDM18.../88 sensors.

2. Connect sensors according to the electrical connection diagram

Master Slave

Illustr. 19

1

2

3

4

5

6

7

8

RS485Y/A

+UB

Q1

Q2

RS485Z/B

Analog +

0 V

Analog -

RS485Y/A

+UB

Q1

Q2

RS485Z/B

Analog +

0 V

Analog -

1

2

3

4

5

6

7

8

3. One of the sensors must be confi gured as a slave. Activate function 26 (see “Settings”, page 32)

Date of issue: 08/08/2011 Partnummer: 194551

39

Page 19

Mounting and

operating instructions

4. Insert reference object of known width in measuring range.

Warning: LED “OK” (Good target) must light up on both sensors.

5. Confi gure the second VDM18.../88 sensor as the master. Activate function no. 25 (page 34).

Warning: The sensor can only be confi gured as a master when the object is inside the measuring range of both

sensors (see point 4).

6. The analogue value on the master corresponds with the measured reference width and the 50% value (autom.

centre function) of 12 mA. All function settings on the master are based on the difference in thickness.

7. Feed objects into the measuring range to start measurement.

8. The measured value provides the difference to the reference width and is at the analogue output of the master.

The analogue output of the slave supplies the distance to the object.

We recommend resetting sensors to factory setting (function 22, page 34) before confi guration of

sensors as master or slave.

In differential measurement mode, resolution and linearity must be multiplied by 2, because 2

sensors are used.

40

Date of issue: 08/08/2011 Partnummer: 194551

Page 20

Mounting and

operating instructions

Sensor confi guration with the VDMConfi g software

The operating software “VDMConfi g” is available to facilitate programming of versions /88 Its simulation mode

indicates the correct bus commands for the respective case.

For more information see our homepage: www.pepperl-fuchs.com and the order information on page 44.

Transmission protocol

Transmission frame

The bus-compatible RS 485 interface of VDM18.../88 operates in half-duplex mode (1 Stopbit, no parity).

As a rule, the VDM18.../88 sensor is a slave and only sends data when addressed by a higher ranking control system

(master) except difference measuring.

A baudrate of 38,4 KBaud and the following protocol must be observed for data transmission:

• 7 data bits + 1 address bit (MSB) MSB 6.....1 LSB

address bit 7 data / address bits

Procedure:

When the address bit has been set, the VDM18.../88 sensor compares the bus address with its own. If they match,

the VDM18.../88 sensor interprets all further data and sends an appropriate feedback signal.

The structure of the transmission frame is as follows:

1st byte 2nd byte 3rd byte ... Last byte

Request from master:

Address of slave Length Command Parameter(s) Checksum

Answer from slave:

Address of slave Length Command Parameter(s) Checksum

Length = Number of characters incl. checksum and address byte

Command = See table of bus commands on page 41

Parameters = Parameter byte 0 to n, depending on command. The slave sends the requested data

Checksum = Exclusive OR of all characters sent incl. address byte

Slave answers:

Address of slave 4 N*

Address of slave 4 Y*

Address of slave 4 + n Y 1

1

is sent when an error regarding checksum, frame length or parameter / command occurs.

*

*2 is sent when the command has been carried out.

Date of issue: 08/08/2011 Partnummer: 194551

in this range.

1

2

Checksum

Checksum

st

parameter, 2nd parameter,

3rd parameter, …, n parameter

Checksum

41

Page 21

Mounting and

operating instructions

Bus commands

Command

(ASCII)

131Signal output Q

232Signal output Q

G47Good Target

T54Q

E45Q

B42Averaging

N4ECharacteristic curve 0% point See 1) page 42

H48Characteristic curve 100% point See 1) page 42

Z5AQ

C43Q

X58Maximum search

M4DMinimum search

D44Difference search

W57Factory setting

V56Key lock

S53Store EEPROM

Q51

A41Distance measuring values See 3) page 42

I49Operating measuring values See 3) page 42

F46Fast measured value output See 4) page 42

L4GChange slave address See 2) page 42

?3FRead sensor setting See 5) page 42

42

Description

Hex

of command

1 is trigger input

1 is enable input

1 is automatic zero

1 is automatic centre

1 input software confi rmation

Q

explanation

Master parameters

th

byte and following) hex

(5

1 High byte switching point 1 see 1) page 42

2 Low byte switching point 1 see 1) page 42

1

2

3

4 High byte switching point 2 see 1) page 42

5

1 High byte switching point 1 see 1) page 42

2 Low byte switching point 1 see 1) page 42

3 Confi guration:

4 High byte switching point 2 see 1) page 42

5 Low byte switching point 2

D0 = 1 = 0.4 ms (averaging off)

D1 = 1 = 4 ms (10 measured values)

D2 = 1 = 40 ms (100 measured values)

Settings see 2) page 42

D0 = 0 not active

D0 = 1 active

Settings see 2) page 42

D0 = 0 Q1 = off

D0 = 1 Q2 = on

Confi guration:

D0: 1 = N.O., 0 = N.C

D1: 1= pulse stretching

0 = off, see 2) page 42

Low byte switching point 2

is sent for high and low byte 00, if there is no second

switching point, see 1) page 42

D0: 1 = N.O., 0 = N.C

D1: 1= pulse stretching

0 = off, see 2) page 42

is sent for high and low byte 00, if there is no second

switching point, see 1) page 42

Date of issue: 08/08/2011 Partnummer: 194551

Page 22

Mounting and

operating instructions

Explanations on bus commands

1)

Highbyte Lowbyte

0 0 D11 D10 D9 D8 D7 D6

D0 - D11 = distance value 0 - 4095 (according to the set measuring range)

2)

Byte

0 D6D5D4D3D2D1D0

3)

Highbyte Lowbyte

0 GT D11 D10 D9 D8 D7 D6

D0 - D11 = distance value (0 - 4095) Q1 = status of Q1

GT = Good Target

4)

Highbyte Lowbyte

0 1 D11 D10 D9 D8 D7 D6

D0 - D11 = distance value (0 - 4095)

Bit6 = 1: High byte

Bit6 = 0: Low byte

5)

After input of “?”, the sensor setting is transmitted as follows:

1 Function 1

2 Function 1

3 Function 2

4 Function 2

5 Function 3

6 Function 3

7 Characteristic curve 0% High byte See 1)

8 Characteristic curve 0% Low byte See 1)

9 Characteristic curve 100% High byte See 1)

10 Characteristic curve 100% Low byte See 1)

11 Switching threshold Q

12 Switching threshold Q

13 Scanning zone Q1 High byte See 1)

14 Scanning zone Q

15 Switching threshold Q

16 Switching threshold Q2 Low byte See 1)

17 Scanning zone Q2 High byte See 1)

18 Scanning zone Q2 Low byte See 1)

High byte

Low byte

High byte

Low byte

High byte

Low byte

1 High byte See 1)

1 Low byte See 1)

1 Low byte See 1)

2 High byte See 1)

0 0 D5 D4 D3 D2 D1 D0

0 Q1D5D4D3D2D1D0

0 0 D5 D4 D3 D2 D1 D0

D8: trigger input

D9:Q1 is enable input

D10: X

D11: Maximum hold

D12: Difference hold

D13: Q1 is software input

D14: fast meas. value output

D0: Q1 is signal output

D1: Q1 is scanning zone

D2: Q1 is signal output inversion (1 = N.C.)

D3: Q1 is signal output pulse stretching

D4: Minimum hold

D5: Autom. zero

D6: Autom. centre

D8 ... D14: Identifi cation of variants

D0: Q1 is signal output

D1: Q1 is scanning zone

D2: Q1 is signal output inversion (1 = N.C.)

D3: Q1 is signal output pulse stretching

D4: Q2 is good target output

D5 ... D6: X

D8: Measured value hold

D9, D10: X

D11: Key lock

D12 ... D14: X

D0: Mean value 0.4 ms

D1: Mean value 4 ms

D2: Mean value 40 ms

D3 ... D6: X

Date of issue: 08/08/2011 Partnummer: 194551

43

Page 23

Mounting and

operating instructions

Optical data (typ.)

Operating range VDM18-100 30 ... 100 mm

Measuring range VDM18-100 70 mm

Operating range VDM18-300 80 ... 300 mm

Measuring range VDM18-300 220 mm

Resolution*

Light used Pulsed laser light, red 650 nm, MTBF>50,000h *

Size of light spot See Illustr. 4 page 28

Ambient light Constant light 5000 lux as per EN 60947-5-2

Laser protection class 2 (EN 60825/1)

1

<0.1% of measuring range

2

Electrical data (typ.),

Operating voltage UB 18-30 V DC *

Power consumption (no load) ≤ 40 mA at 24 V DC

Signal outputs Q

Output current Q

Switching frequency Q

Response time Q

Maximum capacitive load Q

Pulse stretching Q

Analogue output Q

1, Q2 ≤ 100 mA

1, Q2 ≤ 1 kHz

1, Q2, QA 0.4 ms (when averaging = off) / 4 ms / 40 ms

1, Q2 < 100 nF

1, Q2 50 ms (when activated)

A 4-20 mA*

1/Q2 (PNP or NPN, N.O. / N.C. selectable)

Interface RS485 (/88 option only)

Non-Linearity <0.25% of measuring range

Temperature drift < 0.02% / °C

Protective circuits Reverse battery protection, short circuit protection (not RS 485)

VDE protection class *

5

Stand-by delay ≤ 300 ms

3

4

Mechanical data

Housing material ABS, shock-resistant

Front screen PMMA

Protection IP 67*

Ambient temperature range -10 to +60 °C

Storage temperature range -20 to +80 °C

Connection M12 connector, 8-pin

Weight approx. 43 g

*1 smallest, measurable difference

*2 at ambient temperature : +40 °C

*3 limit values

*4 recommended burden < 500 Ohm (apparent ohmic resistance )

*5 rating 50V DC

*6 with attached connector

6

44

Date of issue: 08/08/2011 Partnummer: 194551

Page 24

Mounting and

operating instructions

Order information

Sensor type Description

VDM18-100/20/122/151 Distance sensor, 30 to 100 mm, Resolution 0.1% of measuring range,

VDM18-100/20/88/122/151 Distance sensor, 30 to 100 mm, Resolution 0.1% of measuring range,

VDM18-300/20/122/151 Distance sensor, 80 to 300 mm, Resolution 0.1% of measuring range,

VDM18-300/20/88/122/151 Distance sensor, 80 to 300 mm, Resolution 0.1% of measuring range,

VDM18-300/21/122/151 Distance sensor, 80 to 300 mm, Resolution 0.1% of measuring range,

Accessories (not included in standard delivery)

Accessory Description

V17-G-5M-PUR Connection cable M12, 8-pin, 5 m in length, straight, PUR

V17-G-2M-PUR Connection cable M12, 8-pin, 2 m in length, straight, PUR

OMH-VDM18-01 Recommended mounting bracket

OMH-VDM18-02 Recommended mounting bracket

VDMConfi g Software

Interface Cable RS232-RS485 Interface converter RS 485/422 to RS 232

Interface Cable RS232-USB Interface cable incl. CD-ROM USB-RS 232

2 x PNP, N.O/N.C., 4 to 20 mA, M12 8-pin connector

2 x PNP, N.O/N.C., 4 to 20 mA, RS485,M12 8-pin connector

2 x PNP, N.O/N.C., 4 to 20 mA, M12 8-pin connector

2 x PNP, N.O/N.C., 4 to 20 mA, RS485, M12 8-pin connector

2 x NPN, N.O/N.C., 4 to 20 mA, M12 8-pin connector

To operate the VDM18 sensor on a PC, the PC must be equipped with a RS 485 interface. If this is

not the case the existing interface (RS 232, USB, etc.) can be used with a adaptor.

If your PC has a RS 232 interface, we recommand to use the RS 232 converter Interface Cable

RS232-RS485.

If your PC has only a USB interface, you will need in adition the interface cable RS232-USB.

*See article number in accessories list above

Data sheets, instruction manuals and software can be downloaded from www.pepperl-fuchs.com

Date of issue: 08/08/2011 Partnummer: 194551

45

Page 25

Mounting and

operating instructions

RS485 / RS422 <-> RS232 - Converter Setup

46

Date of issue: 08/08/2011 Partnummer: 194551

Page 26

DOCT-1314A 194551

08/2011

Loading...

Loading...