Pepperl+Fuchs VBG-PN-K30-DMD-S16-EV, VBG-PN-K30-DMD-S16, VBG-PN-K30-D-S16, VBG-PNS-K30-DMD User Manual

Page 1

MANUAL

AS-I 3.0 PROFINET

ATEWAY WITH INTEGR.

G

AFETY MONITOR

S

FACTORY AUTOMATION

Page 2

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the

Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie

(ZVEI) e.V.) in its most recent version as well as the supplementary clause: "Expanded reservation

of proprietorship"

Page 3

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Table of contents

Table of contents

1 Introduction...........................................................................................8

2 Declaration of conformity ....................................................................9

2.1 Declaration of conformity................................................................................ 9

3 Safety...................................................................................................10

3.1 Symbols relevant to safety............................................................................ 10

3.2 General notes on safety ................................................................................10

3.3 Disposal .......................................................................................................... 10

4 General ................................................................................................11

4.1 Product information....................................................................................... 11

4.1.1 AS-i 3.0 PROFINET Gateway with integr. Safety Monitor ..........................................11

4.1.2 AS-i 3.0 Gateway PROFINET via PROFIsafe ............................................................... 12

4.2 New Generation of AS-i Gateways with ethernet diagnostics interface ... 13

4.3 Brief description............................................................................................. 14

5 Specifications - AS-i/PROFINET Gateways......................................16

5.1 Technical data ................................................................................................ 16

5.2 Safety-relevant characteristic data............................................................... 17

5.2.1 Overview of parameter for determining the failure rates ........................................... 18

5.3 Reaction times................................................................................................ 19

5.3.1 Sensor -> local relay output..........................................................................................19

5.3.2 Sensor -> local electronic output ................................................................................. 19

5.3.3 Sensor -> AS-i relay output........................................................................................... 20

5.3.4 Sensor -> AS-i electronic output .................................................................................. 20

5.3.5 System reaction times – example calculations ..........................................................21

5.4 Scope of delivery ........................................................................................... 24

6 Specifications - AS-i/PROFIsafe Gateway........................................25

6.1 Technical data ................................................................................................ 25

6.2 Safety-relevant characteristic data............................................................... 26

6.3 Reaction times................................................................................................ 27

6.3.1 Ethernet (PROFIsafe) -> local relay output.................................................................. 27

6.3.2 Ethernet (PROFIsafe) -> local electronic output ......................................................... 27

6.3.3 Ethernet (PROFIsafe) -> AS-i relay output................................................................... 28

6.3.4 Ethernet (PROFIsafe) -> AS-i electronic output ..........................................................28

27.9.2013

3

Page 4

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Table of contents

7 Installation...........................................................................................29

7.1 Dimensions .................................................................................................... 29

7.2 Connections................................................................................................... 29

7.3 Installing in the control cabinet.................................................................... 30

7.4 Removing ....................................................................................................... 30

7.5 Commissioning.............................................................................................. 31

7.5.1 Switching to advanced display mode .......................................................................... 31

7.5.2 Setting the PROFINET properties ................................................................................31

7.5.3 Setting the PROFIsafe address .................................................................................... 32

7.5.4 Connecting AS-i Slaves ................................................................................................ 33

7.5.5 Quick setup .................................................................................................................... 34

7.5.6 Error tracing ...................................................................................................................35

7.5.6.1 Faulty slaves.................................................................................................................35

7.5.6.2 Error display (last error) ................................................................................................35

7.6 Addressing..................................................................................................... 36

7.6.1 Assigning address 15 to slave currently at address 2............................................... 36

7.7 Local parameter setting of safe AS-i Gateways and Monitors .................. 37

7.8 Replacing a defective safety-related AS-i slave ......................................... 39

7.9 Replacing the chip card ................................................................................ 40

7.10 Replacing a defective device........................................................................ 40

7.10.1 Teaching the group manager after replacing a device ..............................................43

7.11 Replacing the monitor................................................................................... 44

7.12 Safe configuration using ASIMON 3 G2 ..................................................... 47

8 Maintenance ........................................................................................49

8.1 Checking for safe turn-off............................................................................. 49

9 Electrical connection..........................................................................50

9.1 Overview of terminals, indicators and operating elements....................... 50

9.1.1 VBG-PN-K30-D-S16, VBG-PN-K30-DMD-S16, VBG-PNS-K30-DMD, VBG-PN-K30DMD-S16-EV50

9.2 AS-i bus connection...................................................................................... 51

9.3 Information about the device types ............................................................. 51

9.4 AS-i and power supply terminal assignments ............................................ 51

9.4.1 Electrical connection VBG-PN-K30-D-S16 .................................................................52

9.4.2 Electrical connection VBG-PN-K30-DMD-S16-EV .......................................................53

9.4.3 Electrical connection VBG-PN-K30-DMD-S16, VBG-PNS-K30-DMD ........................ 54

9.5 Diagnostics interface .................................................................................... 55

9.5.1 Diagnostics port RS 232 ...............................................................................................55

9.6 PROFINET interface...................................................................................... 55

9.7 Safe coupling via Ethernet ............................ (VBG-PN-K30-DMD-S16-EV)56

9.8 Chip card ........................................................................................................ 56

4

27.9.2013

Page 5

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Table of contents

9.9 Release circuits.............................................................................................. 57

9.9.1 Wiring overview - safety unit ........................................................................................57

9.10 Indicators and operating elements............................................................... 58

9.10.1 LED indicators – master................................................................................................ 58

9.10.2 LED indicators - safety unit .......................................................................................... 59

9.10.3 Buttons ........................................................................................................................... 60

10 Function and startup of the Safety Monitor .....................................61

10.1 Powering up the device ................................................................................. 61

10.2 Configuration of the safety functions .......................................................... 61

10.2.1 Description of configuration using ASIMON 3 G2 software ...................................... 62

10.2.2 Description of configuration using chip card with master configuration ................63

10.2.3 Configuration using a chip card with complete configuration.................................. 63

10.3 Safety-relevant documentation of the application ...................................... 64

10.4 Diagnostic data .............................................................................................. 64

10.4.1 Diagnostics of release circuits 1-4 via the binary data ............................................. 65

10.5 Switch-off history........................................................................................... 65

10.5.1 Diagnostic values in the IDI ..........................................................................................66

10.6 Password protection...................................................................................... 67

10.6.1 Procedure for configuring and teaching code sequences ........................................ 68

10.6.2 Function of the ESC/Service key..................................................................................69

10.7 Safe coupling slaves on the AS-i circuits .................................................... 69

10.8 Chip card......................................................................................................... 69

10.8.1 Unsafe data ....................................................................................................................69

10.8.1.1 Card unformatted ..........................................................................................................69

10.8.1.2 Data not compatible ......................................................................................................70

10.8.1.3 Card empty ................................................................................................................... 70

10.8.1.4 Data compatible ............................................................................................................70

10.8.1.5 Data in the device and on the chip card identical .........................................................70

10.8.1.6 Data in the device and on the chip card not identical ...................................................70

10.8.2 Safe data .........................................................................................................................71

10.8.2.1 Data incompatible ......................................................................................................... 71

10.8.2.2 Data compatible ............................................................................................................71

10.8.2.3 Complete configuration.................................................................................................72

10.8.2.4 Data on the chip card and in the device are identical ...................................................72

10.8.2.5 Data not identical ..........................................................................................................72

10.8.2.6 Operating the chip card from the menu ........................................................................73

10.8.3 Working with multiple memory banks ......................................................................... 73

11 Operation in advanced display mode ...............................................75

12 Advanced Diagnostics for AS-i Masters...........................................76

12.1 List of corrupted AS-i Slaves (LCS) ............................................................. 76

12.2 Protocol analysis: Counters for corrupted data telegrams ....................... 76

12.3 Offline Phase for Configuration Errors ........................................................ 77

12.4 Functions of the AS-i Fault Detector ............................................................ 77

12.4.1 Duplicate address detection .........................................................................................77

12.4.2 Earth/Ground Fault Detector ........................................................................................ 78

27.9.2013

5

Page 6

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Table of contents

12.4.3 Noise Detector ............................................................................................................... 78

12.4.4 Over-voltage Detector ................................................................................................... 78

12.5 Functions of the new generation of AS-i Gateways ................................... 79

12.5.1 C-programmable Gateways ..........................................................................................79

12.5.2 Interchangeable memory card......................................................................................79

12.5.3 Earth fault monitor......................................................................................................... 79

12.5.4 Current can be read directly on the unit......................................................................80

12.5.5 Self-resetting fuses ....................................................................................................... 81

12.5.6 AS-i Power24V capable ................................................................................................. 81

12.5.7 Ethernet diagnostics interface with web server .........................................................82

12.5.8 Transitionless operating mode changes ..................................................................... 82

13 Configuration of AS-i/PROFINET Gateways.....................................83

13.1 Projecting PROFINET network ..................................................................... 83

13.2 Logical slots................................................................................................... 83

13.2.1 Options ........................................................................................................................... 83

13.2.2 32 bytes digital AS-i I/O data (A and B slaves) ...........................................................86

13.2.3 16 bytes digital AS-i I/O data (A slaves only)..............................................................88

13.2.4 16 bytes digital AS-i I/O data (B slaves only)..............................................................88

13.2.5 4 words analog AS-i input data .................................................................................... 89

13.2.6 4 Words analog AS-i output data .................................................................................91

13.2.7 36 bytes command interface ........................................................................................ 92

13.2.8 34 bytes command interface ........................................................................................ 93

13.2.9 12 byte command interface .......................................................................................... 94

13.3 Executing of command interface commands ............................................. 94

13.4 PROFINET diagnostics.................................................................................. 95

13.4.1 Channel error codes ...................................................................................................... 95

13.4.2 Manufacturer specific diagnostic................................................................................. 96

13.4.3 Safety Control/Status .................................................................................................... 99

13.4.3.1 Diagnostics in the cyclic channel (10 Byte SafeLink.Diag.) ........................................101

13.5 Device-specific parameters ........................................................................ 102

13.6 Media Redundancy Protocol MRP ............................................................. 103

14 System startup using AS-i Control Tools.......................................104

15 Configuration with Windows Software ASIMON 3 G2 ...................107

16 Status indication, faults and fault elimination ...............................108

16.1 Spontaneous display of faults from the safety unit ................................. 108

16.2 Replacing a defective safety-configured AS-i slave................................. 109

16.3 Replacing a defective AS-i Safety Monitor ................................................ 110

16.4 Forget the password? What do I do now? ................................................ 110

17 Safe Link............................................................................................112

17.1 General introduction .................................................................................. 112

17.2 Configuration ............................................................................................... 113

17.2.1 Configuration using ASIMON ..................................................................................... 114

6

27.9.2013

Page 7

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Table of contents

17.3 Diagnostics .................................................................................................. 115

18 Glossary ............................................................................................117

19 Appendix, Examples.........................................................................120

19.1 Startup on a Siemens NC control ............................................................... 120

19.1.1 Setting in the S7 configuration...................................................................................120

19.1.2 Setting in the NC control .............................................................................................121

19.1.3 Setting “PROFISAFE_IN_ADDRESS“ ........................................................................121

19.1.4 Setting “PROFISAFE_OUT_ADDRESS“ ....................................................................121

19.1.5 Setting “PROFISAFE_IN_ASSIGN“ ............................................................................121

19.1.6 Setting “PROFISAFE_OUT_ASSIGN" ........................................................................ 122

19.1.7 Setting “PROFISAFE_IN_FILTER" .............................................................................122

19.1.8 Setting “PROFISAFE_OUT_FILTER" .........................................................................122

19.2 Safety diagnostics in the input data image (IDI) ....................................... 123

19.2.1 Representation of the diagnostic information ..........................................................123

19.2.2 Other representation variants .................................................................................... 124

19.2.3 Changing the default setting ......................................................................................124

20 Reference List...................................................................................127

20.1 Manual: “ASIMON 3 G2 Configuration Software“ .....................................127

20.2 Sources ......................................................................................................... 127

21 Codes indicated by the display.......................................................128

27.9.2013

7

Page 8

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Introduction

1. Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops, produces and distributes electronic sensors and interface modules for the

market of automation technology on a worldwide scale.

Before installing this equipment and put into operation, read this manual carefully.

This manual containes instructions and notes to help you through the installation

and commissioning step by step. This makes sure bring such a trouble-free use of

this product. This is for your benefit, since this:

• ensures the safe operation of the device

• helps you to exploit the full functionality of the device

• avoids errors and related malfunctions

• avoids costs by disruptions and any repairs

• increases the effectiveness and efficiency of your plant

Keep this manual at hand for subsequent operations on the device.

After opening the packaging please check the integrity of the device and the

number of pieces of supplied.

Symbols used

The following symbols are used in this manual:

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damages and destruction.

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

27.9.2013

8

Page 9

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Declaration of conformity

2. Declaration of conformity

2.1 Declaration of conformity

This product was developed and manufactured under observance of the applicable European standards and guidelines.

Information!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

27.9.2013

9

Page 10

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Safety

3. Safety

3.1 Symbols relevant to safety

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damages and destruction.

3.2 General notes on safety

Only instructed specialist staff may operate the device in accordance with the operating manual.

User modification and or repair are dangerous and will void the warranty and exclude the manufacturer from any liability. If serious faults occur, stop using the device. Secure the device against inadvertent operation. In the event of repairs, return the device to your local Pepperl+Fuchs representative or sales office.

The connection of the device and maintenance work when live may only be carried out by a qualified electrical specialist.

The operating company bears responsibility for observing locally applicable safety regulations.

Store the not used device in the original packaging. This offers the device optimal

protection against impact and moisture.

Ensure that the ambient conditions comply with regulations.

3.3 Disposal

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances when

disposing this product!

The device does not contain batteries that need to be removed before disposing it.

10

27.9.2013

Page 11

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

General

4. General

4.1 Product information

This system manual applies to the following Pepperl+Fuchs equipment:

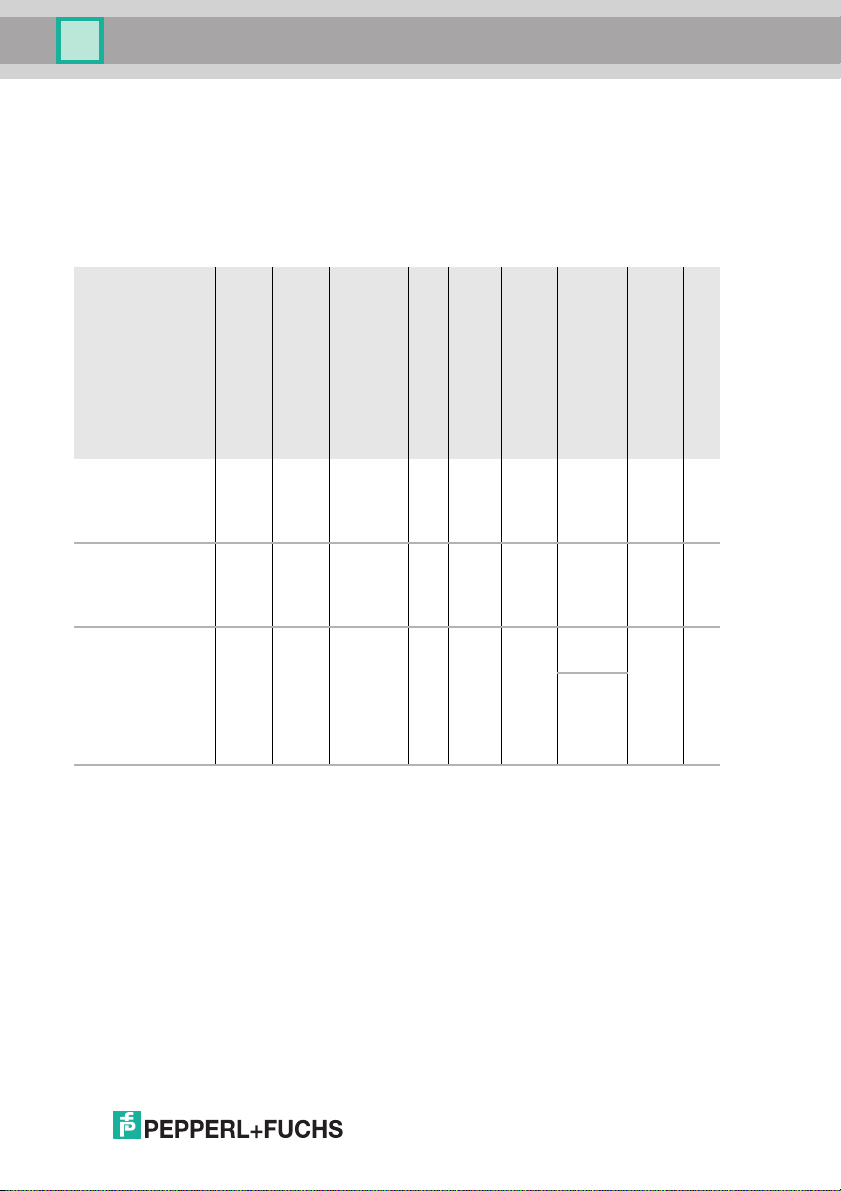

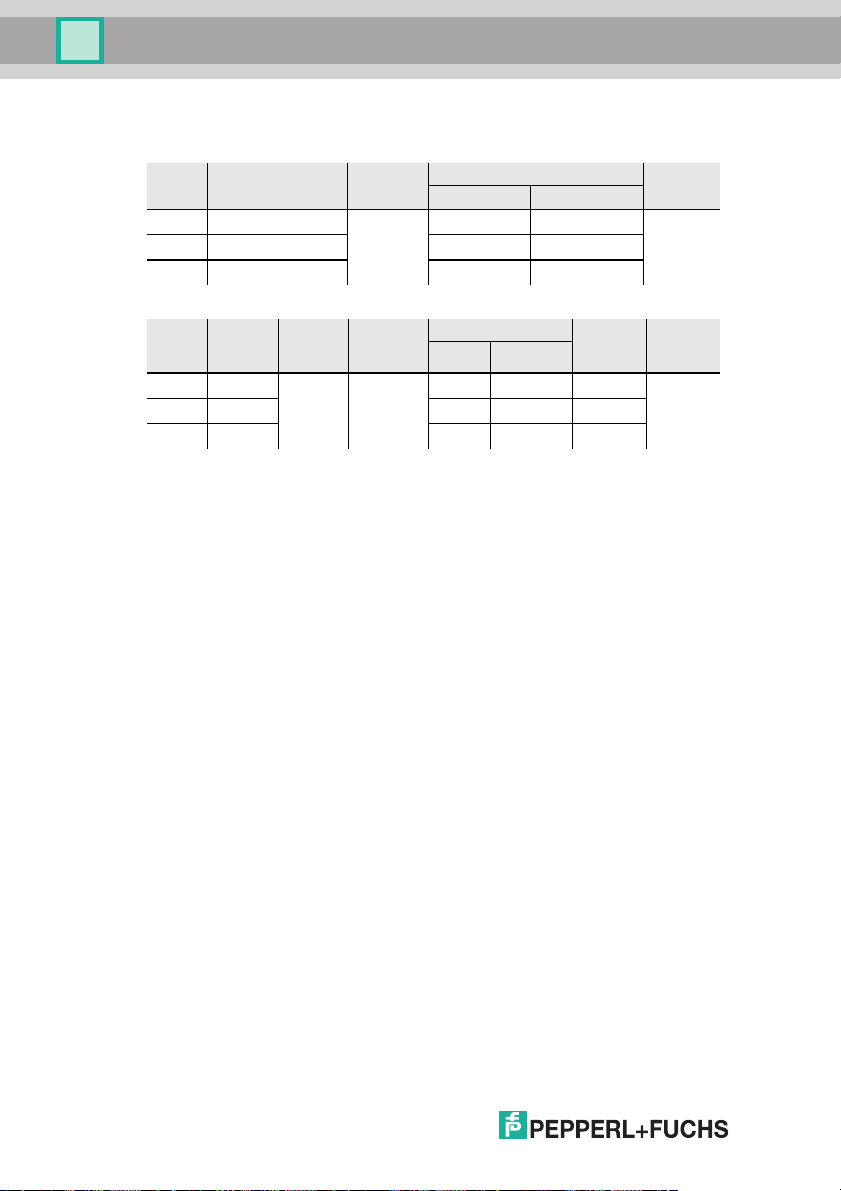

4.1.1 AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Article No.

VBG-PN-K30-DMD-S16

VBG-PN-K30-D-S16

VBG-PN-K30-DMD-S16EV

1. power supply, 1 gateway for 2 AS-i networks, inexpensive power supplies:

- "yes, max. 4A/AS-i network":

Cost-effective power for 2 AS-i networks with 1 power supply (optionally supply of multiple Single Gateways by 1

power supply).

- "no, max. 8A/AS-i network, redundant supply":

1 power supply per AS-i network. Gateway is powered in normal operation from one of the two AS-i power supplies.

Should one AS-i power supply fail, switching to the other AS-i power supply allows all the diagnostics functions to

be maintained and the unaffected AS-i network continues to operate.

"no, max. 8A/AS-i network":

1 power supply per AS-i network

2. Ethernet fieldbus + RS 232:

Access to AS-i master and safety monitor via Pepperl+Fuchs proprietary software over Ethernet fieldbus interface

or RS 232 interface and adapter cable.

3. AS-i Power24V capable:

- VBG-PN-K30-DMD-S16-EV device can be operated directly on a 24V (PELV) power supply

- with integrated data coupling coils and adjustable self-resetting fuses for safe use also of powerful 24V power supplies.

27.09.2013

Type

Safety,

PROFINET

Safety,

PROFINET

Safety,

PROFINET

Inputs safety, expandable to

max.

62 x

2 channels

max.

62 x

2 channels

max.

62 x 2

channels,

max.

1922

in max.

configuration

Outputs Safety, SIL 3, cat. 4

Safety outputs,

independent according to SIL 3,

Safety communication

Number of AS-i networks,

number of AS-i Master

1 power supply,

4 release

circuits;

2 x relay,

2 x fast

electronic

safe outputs

4 release

circuits;

2 x relay,

2 x fast

electronic

safe outputs

4 release

circuits;

2 x relay,

2 x fast

electronic

safe outputs

Tab. 4-1. Funcion range "AS-i 3.0 PROFINE T Gateway with integr. Safety Monitor"

max.

16

max.

16

max.

32,

max.

992 in

max.

configuration

-

-

Safe

Link

2 AS-i

networks, 2

AS-i

Masters

2 AS-i

networks, 1

AS-i

Master

2 AS-i

networks, 2

AS-i

Masters

1 gateway for 2 AS-i networks1Diagnostic and

no, max.

8A/AS-i

network,

redundant

supply

no, max.

8A/AS-i

network,

redundant

supply

no, max.

4A/AS-i

Kreis

Power24V

Ethernet

fieldbus

+ RS 232

Ethernet

fieldbus

+ RS 232

Ethernet

fieldbus

+ RS 232

3

configuration interface2Programming in C

no

no

optional

11

Page 12

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

General

The AS-i 3.0 PROFINET Gateway with integr. Safety Monitor combines two devices in one housing: an AS-i/PROFINET Gateway and a Safety Monitor for 2 ASi circuits.

The safety unit provides 4 inputs which can be defined as either EDM or as

START inputs.

AS-i/PROFINET-Gateways serve to connect AS-i systems to the superordinate

PROFINET controller. It acts as a master for AS-i and as a slave on field bus level.

Commissioning, debugging and setting up of the AS-i parameters can be accomplished with the use of the display, but it can also be handled via the diagnostic interface and the field bus.

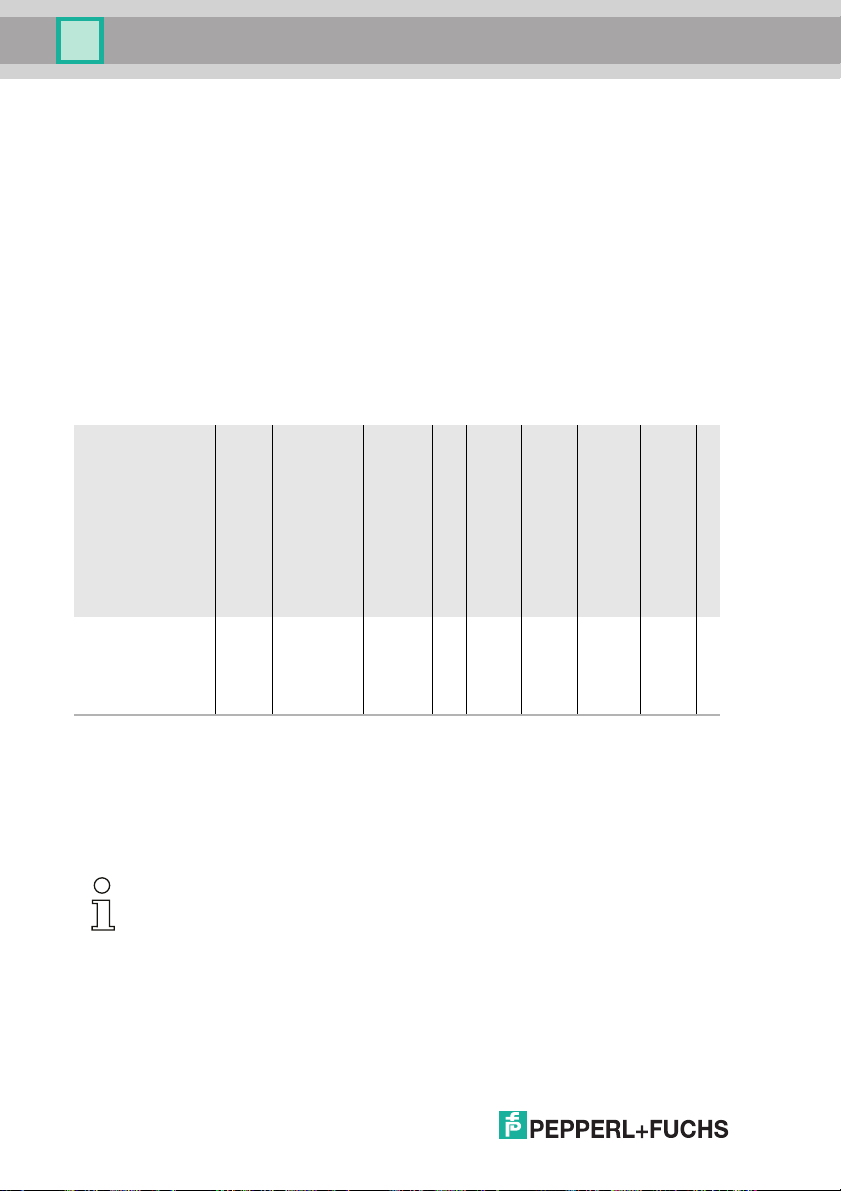

4.1.2 AS-i 3.0 Gateway PROFINET via PROFIsafe

VBG-PNS-K30-DMD

12

Article No.

PROFIsafe,

PROFINET

Type

max.

62 x

2 channels

Inputs safety, expandable to

Outputs Safety, SIL 3, cat. 4

Safety outputs,

independent according to SIL 3,

Safety communication

Number of AS-i networks,

number of AS-i Master

1 power supply,

4 release

circuits;

2 x relay,

2 x fast

electronic

safe outputs

max.

16

Tab. 4-2. Funcion range "AS-i 3.0 Gateway PROF INET via PROFIsafe"

PROFI

safe

(F-CPU)

2 AS-i

networks,

2AS-i

Masters

1 gateway for 2 AS-i networks

no, max.

8A/AS-i

network,

redundant supply

Diagnostic and

configuration interface

RS 232 +

Ethernet

no

The AS-i 3.0 Gateway PROFINET via PROFIsafe is a combination of an AS-i/

PROFINET Gateway with a PROFIsafe F-device. It is used for transmitting of

safety related data to/from SaW slaves via the standard field bus PROFINET.

The gateway supports 64 release circuits. The integrated safety unit provides 4

non-safety inputs. PROFIsafe transfers input status data to F-Host.

Information!

PROFIsafe is a certified acc. to IEC 61508 profile for PROFIBUS and PROFINET. With

SIL 3 (Safety Integrity Level) or category 4 acc. to EN 954-1 fulfills PROFIsafe the

highest safety requirements for the process- and manufacturing industry. Both safety

related and standard communication are possible via one and the same cable.

AS-i/PROFINET-Gateways serve to connect AS-i systems to the superordinate

PROFINET controller. It acts as a master for AS-i and as a slave on field bus level.

Programming in C

27.09.2013

Page 13

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

General

Commissioning, debugging and setting up of the AS-i parameters can be accomplished with the use of the display, but it can also be handled via the diagnostic interface and the field bus.

4.2 New Generation of AS-i Gateways with ethernet diagnostics interface

The plus points of the new Gateway generation at a glance:

• Gateways now programmable in C

• Ethernet diagnostics interface for remote diagnostics

• Integrated web server: diagnostics for the Gateways and the AS-i circuits

over Ethernet possible with no additional software

• GSD configuration files already stored in the web server

• Earth fault monitor distinguishes between AS-i cable and sensor cable

• Current from both AS-i circuits in the "1 Gateway, 1 power supply for 2 AS-i

circuits" version can now be read directly on the unit

• Self-resetting fuses in the "1 Gateway, 1 power supply for 2 AS-i circuits" version

• Device temperature display

• AS-i Power24V capable

• Interfaces for virtually every bus system and Ethernet solution

Information!

See also section <Functions of the new generation of AS-i Gateways> for further information.

27.09.2013

13

Page 14

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

General

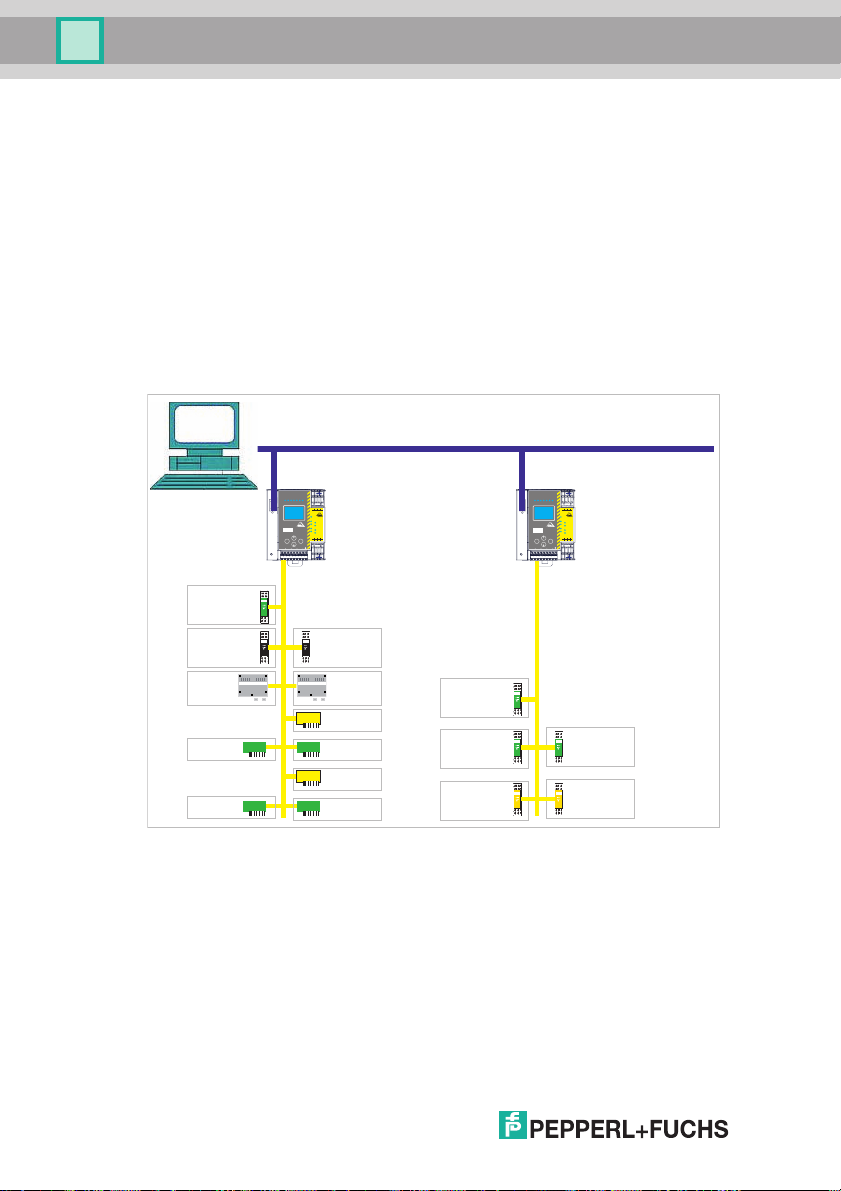

4.3 Brief description

The actuator-sensor interface (AS-i) has established itself as a system for networking primarily binary sensors and actuators at the lowest level of the automation hierarchy. The high number of installed systems, the ease of use and the reliable operating behaviour also make the AS-i interesting in the area of machine

safety.

The safety AS-i system is intended for safety applications up to Category 4/SIL 3.

Mixed operation of standard components and safe components is possible.

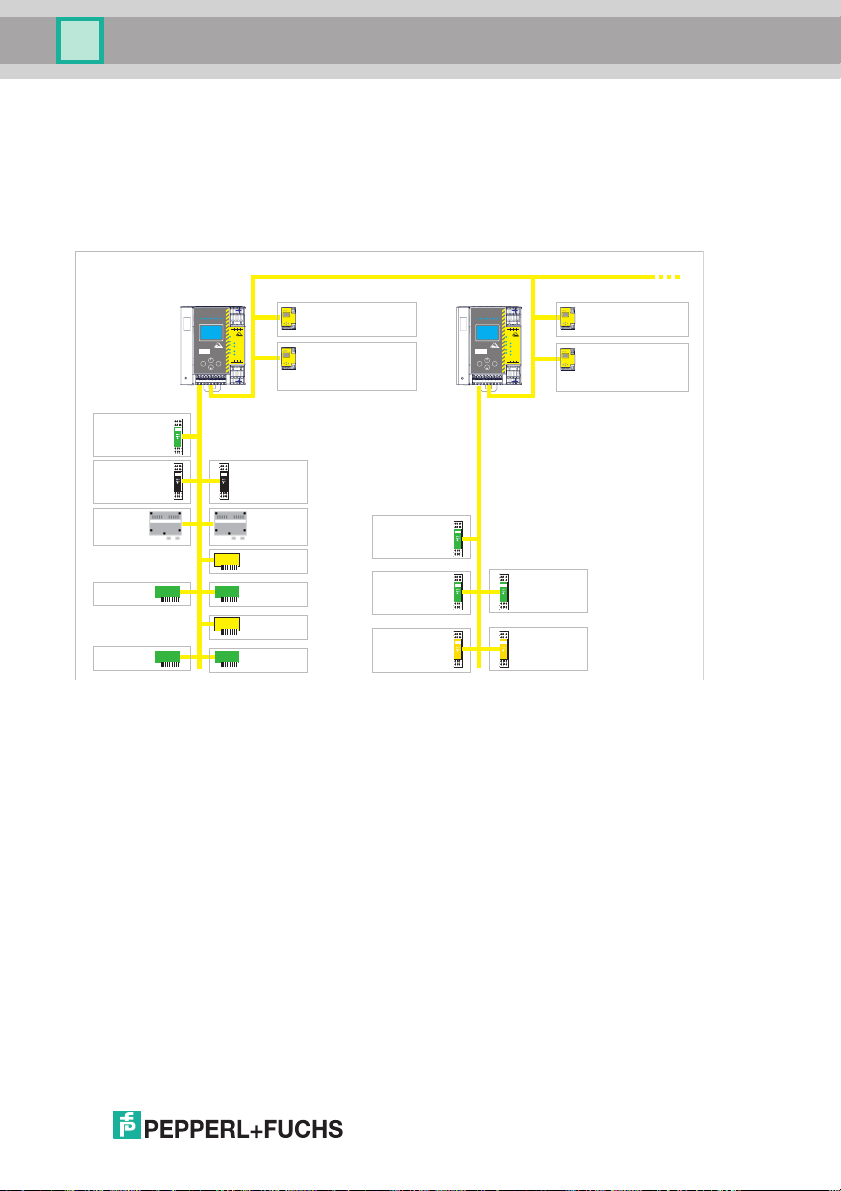

AS-i 3.0 Gateway PROFINET via PROFIsafe

The safety unit monitors within an AS-i system the safe slaves which have been

assigned according to the configuration specified by the user with the configuration software. This safety information is transmitted to PROFIsafe.

SPS

1.13

2.13+24 V

0 V

+

2.Y2

2.Y1

Aux

AS-i Safety

Integrated

1.Y1

1.Y2

2.Y1

2.Y2

K1

K2

K3

K4

1.Y2

1.Y1

+

Mode

2.14

3.14

4.14+1.14

ESC

OK

Service

Set

ASI

+PWR+ASI

+ASI 1

1

2

+ASI

Safety In

Adr. 1

Analog In

Adr. 3

Analog In

Adr. 10

OEM 3O

Adr. 22A

OEM 4I/4O

Adr. 26

Abb. 4-1. Safe and standard components in an AS-i network

Analog In

Adr. 4

Analog In

Adr. 11

OEM Safety

Adr. 21

OEM 3O

Adr. 23A

OEM Safety

Adr. 24

OEM 2I/2O

Adr. 27

Safety In

Adr. 6

Safety In

Adr. 12

Safety Out

Adr. 4/7B

2.13+24 V

0 V+1.13

2.Y2

2.Y1

Aux

AS-i Safety

Integrated

1.Y1

1.Y2

2.Y1

2.Y2

K1

K2

K3

K4

1.Y2

1.Y1

Mode

2.14+4.14+1.14

3.14

ESC

OK

Service

Set

ASI

+PWR+ASI

+ASI 1

1

2

+ASI

Safety In

Adr. 13

Safety Out

Adr. 2/7A

14

27.09.2013

Page 15

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

General

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

The AS-i/PROFINET Gateway monitors within an AS-i system the safe slaves

which have been assigned according to the configuration specified by the user

with the configuration software. In the event of a stop request or a defect, the ASi/PROFINET Gateway switches off the system in protective operation mode with a

maximum reaction time of 40 ms.

AS-i coupling circuit

Analog In

Adr. 10

OEM 3O

Adr. 22A

OEM 4I/4O

Adr. 26

Safety In

Adr. 1

Analog In

Adr. 3

coupling slave Adr. 1

Analog In

Adr. 11

OEM Safety

Adr. 21

OEM 3O

Adr. 23A

OEM Safety

Adr. 24

OEM 2I/2O

Adr. 27

lightgrids 1

coupling slave Adr. 2

emergency-stop

circuit 1

Safety In

Adr. 6

Safety In

Adr. 12

Safety Out

Adr. 4/7B

1.13

2.13+24 V

0 V

+

2.Y2

2.Y1

Aux

AS-i Safety

Integrated

1.Y1

1.Y2

2.Y1

2.Y2

K1

K2

K3

K4

1.Y2

1.Y1

+

Mode

2.14

3.14

4.14+1.14

ESC

OK

Service

Set

Safety In

Adr. 13

Safety Out

Adr. 2/7A

1.13

2.13+24 V

0 V

+

2.Y2

2.Y1

Aux

AS-i Safety

Integrated

1.Y1

1.Y2

2.Y1

2.Y2

K1

K2

K3

K4

1.Y2

1.Y1

+

Mode

2.14

3.14

4.14+1.14

ESC

OK

Service

Set

Analog In

Adr. 4

coupling slave Adr. 6

silent running

coupling slave Adr. 7

emergency-stop

circuit 2

Abb. 4-2. Safe and standard components in an AS-i network

Multiple AS-i Safety Monitors can be used within an AS-i system. In this way, a

safe slave can be monitored by multiple AS-i Safety Monitors.

27.09.2013

15

Page 16

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

5. Specifications - AS-i/PROFINET Gateways

5.1 Technical data

The technical data are placed in the data sheet. Please view the current version

on the web page: http://www.pepperl-fuchs.com.

Attention!

The AS-I power supply for the AS-I components must have isolation per IEC 60 742

and be able to handle momentary power interruptions of up to 20 ms. The power supply for the 24 V supply must also have isolation per IEC 60 742 and be able to handle

momentary power interruptions of up to 20 ms. The maximum output voltage of the

power supply must also be less than 42 V in case of a fault.

16

27.9.2013

Page 17

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

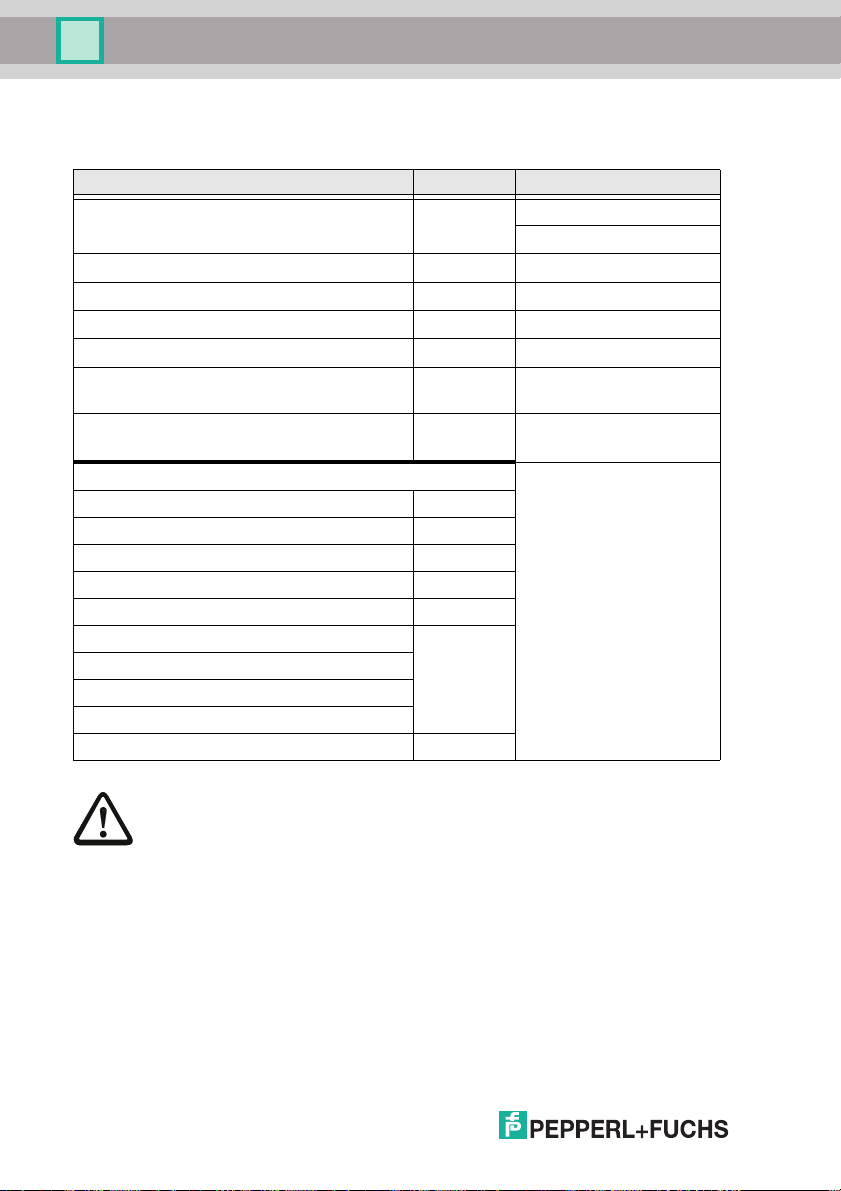

5.2 Safety-relevant characteristic data

Characteristic data Value Standard

Safety category 4 EN 954-1

Safety category 4 EN ISO 13849-1: 2008

Performance Level (PL) e

Safety Integrity Level (SIL) 3 EN 61508: 2001

Lifespan (TM) in years 20 EN ISO 13849-1: 2008

Maximum switch-on time in months 12 EN 61508: 2001

Max. system reaction time in milliseconds

Attention!

In addition to the system reaction time of max. 40 ms, the reaction times of the safe ASinterface sensor slave, of the sensor being used for monitoring, of the safe AS-interface

actuator slave and of the actuator used for this purpose must still be added. Please note

that additional reaction times may likewise arise through the configuration of the safety

monitor.

Notice!

Refer to the technical data for the slaves as well as to that for the sensors and actuators

for the reaction times to be added.

40 EN 61508: 2001

Tab. 5-3.

Attention!

The system reaction times of the daisy-chained AS-interface components are added up.

27.9.2013

17

Page 18

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

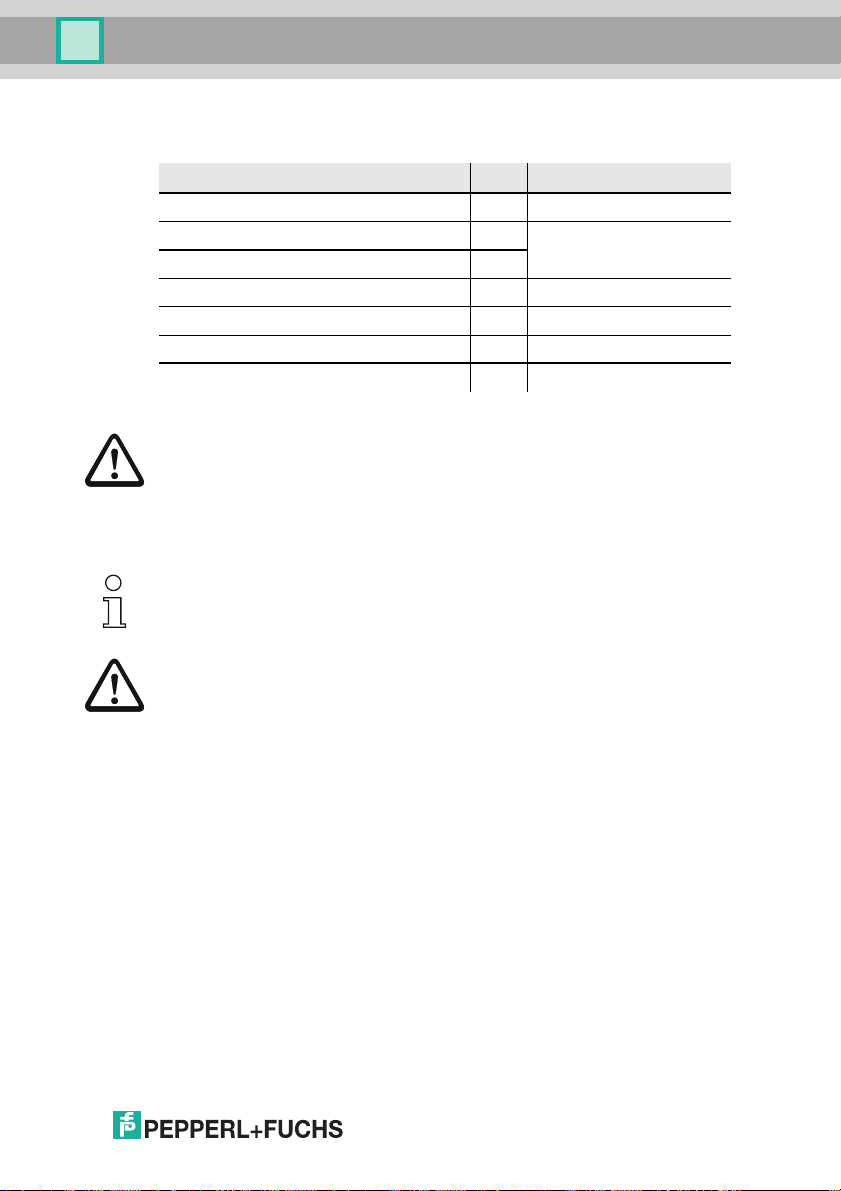

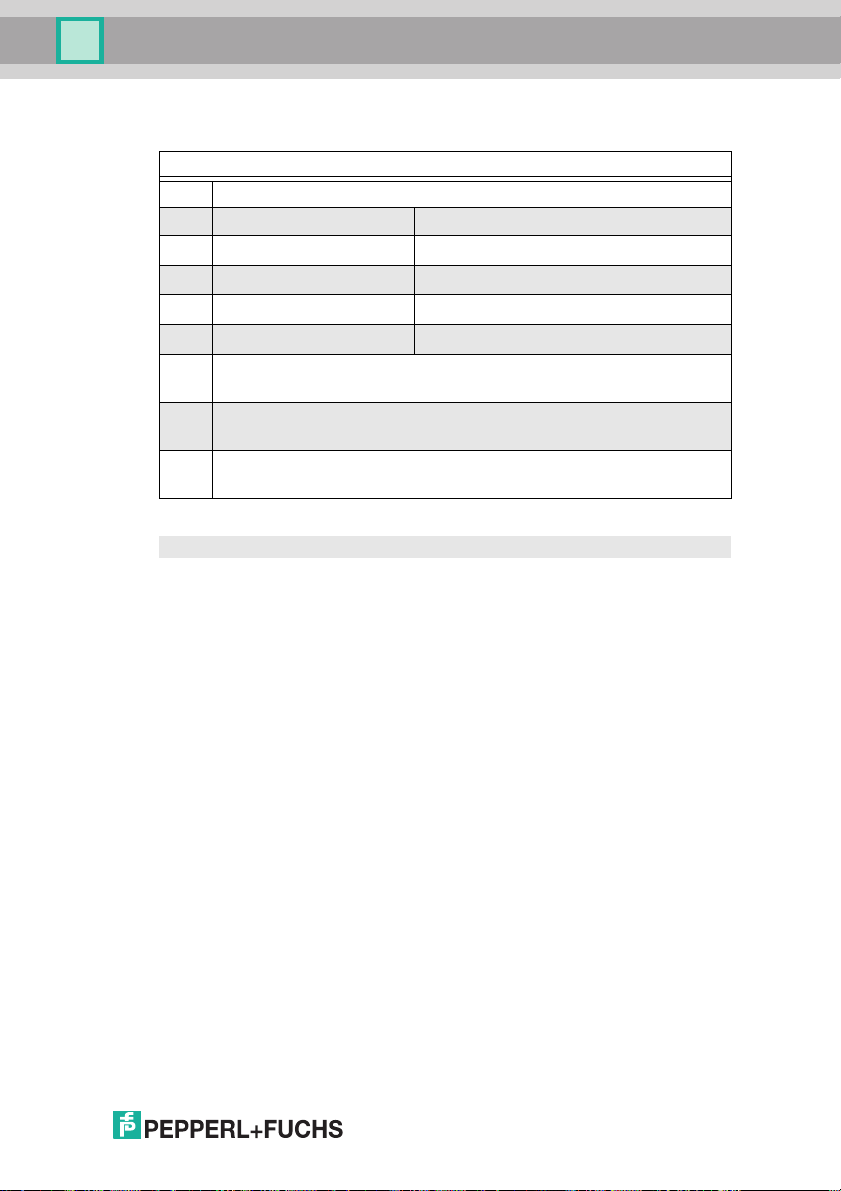

5.2.1 Overview of parameter for determining the failure rates

nop/y switching intervals

t

[s]

cycle

B10d

value

electromechanics Standard

MTTFd [years] PFH [1/h]

105.120 300 2.500.000 237,82

52.560 600 475,65

8.760 3600 2853,88

nop/y switching

intervals

t

cycle

105.120 300 2.500.000

B10d

value

electronics

PFH

-09

4,76 E

electromechanics PFH

MTTFdPFH

237,82

52.560 600 475,65

8.760 3600 2853,88

-9

9,908 x 10

-9

4,853 x 10

-10

9,054 x 10

total

1,12 x 10-81,6 x 10

5,09 x 10-99,85 x 10

-10

7,82 x 10

5,54 x 10

-8

-9

-9

EN ISO

13849-1

Tab. 5-4.

Standard

EN 62061

EN 61508

Tab. 5-5.

18

27.9.2013

Page 19

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

5.3 Reaction times

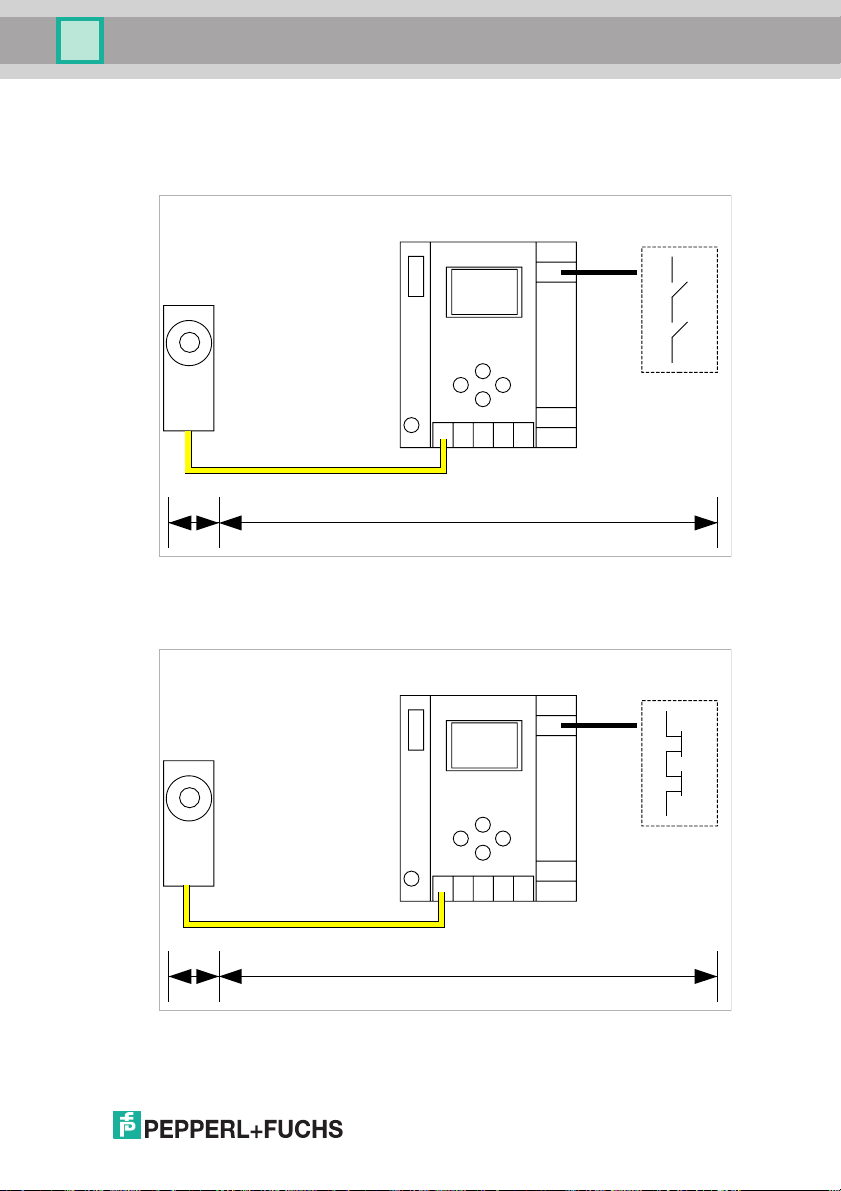

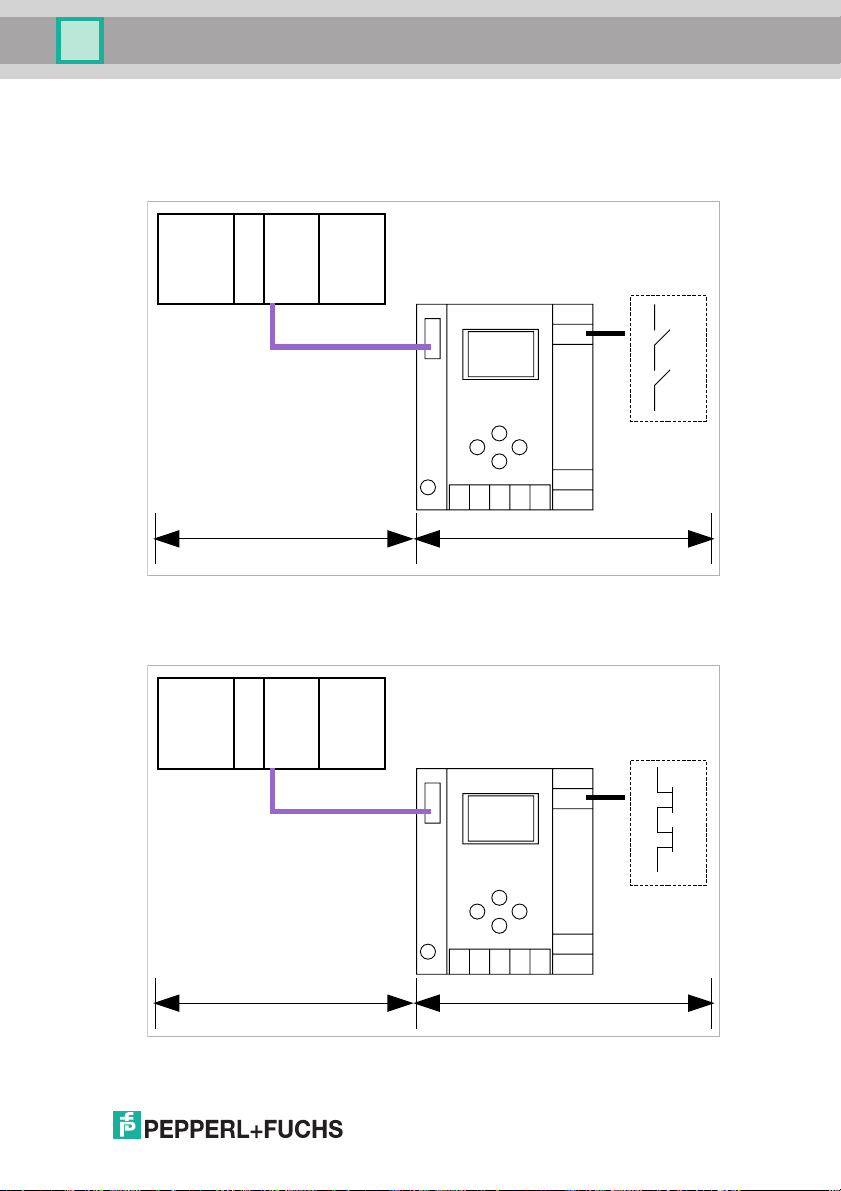

5.3.1 Sensor -> local relay output

Sensor

t

t

s

ts = maximal reaction time of the sensor (see data sheet)

t

= maximal system reaction time

react

react

= 40ms

1.13

2.13

1.14

2.14

5.3.2 Sensor -> local electronic output

Sensor

t

s

ts = maximal reaction time of the sensor (see data sheet)

t

= maximal system reaction time

react

27.9.2013

t

react

24V

3.14

4.14

= 30ms

19

Page 20

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

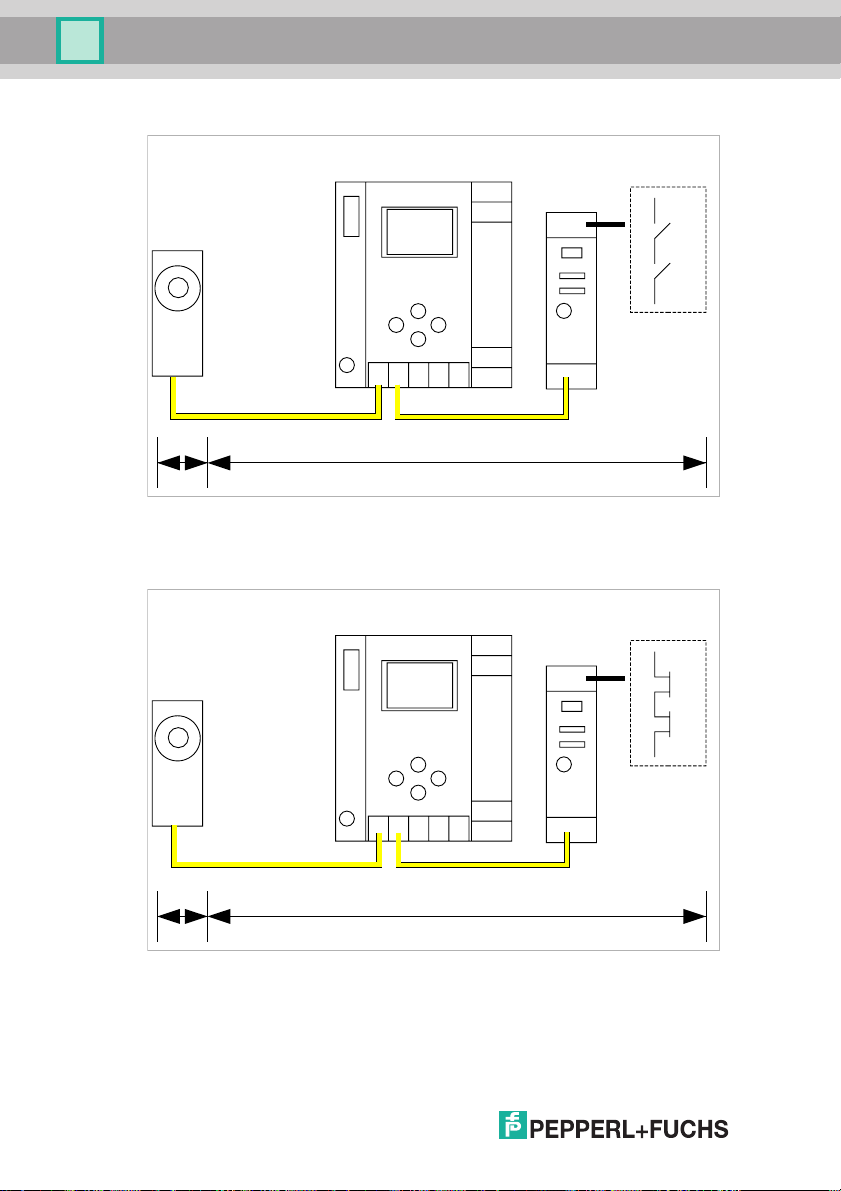

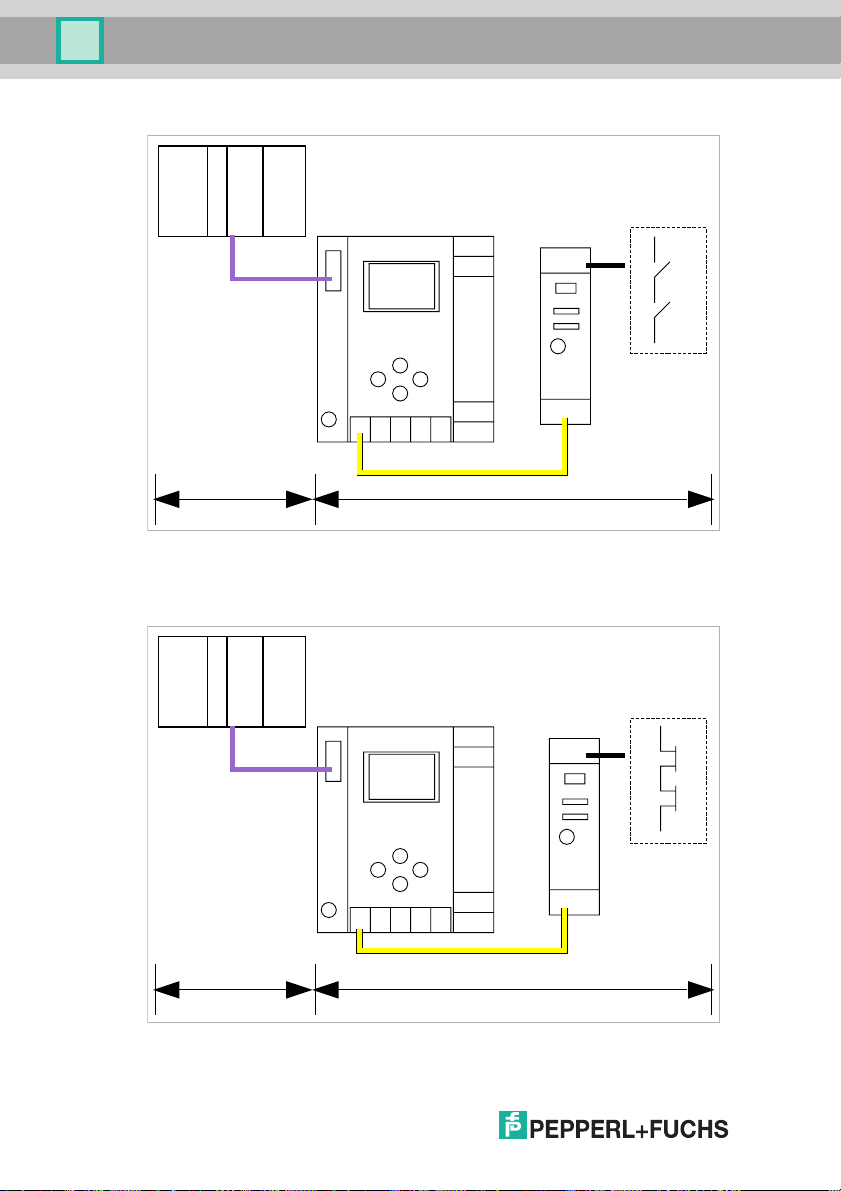

5.3.3 Sensor -> AS-i relay output

1.13

1.14

1.23

1.24

Sensor

t

s

ts = maximal reaction time of the sensor (see data sheet)

t

= maximal system reaction time

react

5.3.4 Sensor -> AS-i electronic output

Sensor

t

s

ts = maximal reaction time of the sensor (see data sheet)

t

= maximal system reaction time

react

t

react

t

react

Relay output

= 85ms

24V

1.14

2.14

Electronic output

= 85ms

20

27.9.2013

Page 21

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

5.3.5 System reaction times – example calculations

System components:

AS-i network 1

ASI1

AS-i network 2

ASI2

Safe sensor slave (EMERGENCY-OFF switch: t

S1-1

Safe sensor slave (safety light barrier: t

S1-2

Safe sensor slave (EMERGENCY-OFF switch: t

S2-1

Safe actuator slave (motor starter: t

A2-1

SM1-1 Safety monitor with 16 relais circuits and one safe AS-i output in AS-i

network 1

SM1-2 Safety monitor with 2 relais circuits and one safe AS-i output in AS-i

network 1

SM2-1

Safety monitor with 16 relais circuits and one safe AS-i output in AS-i

network 2

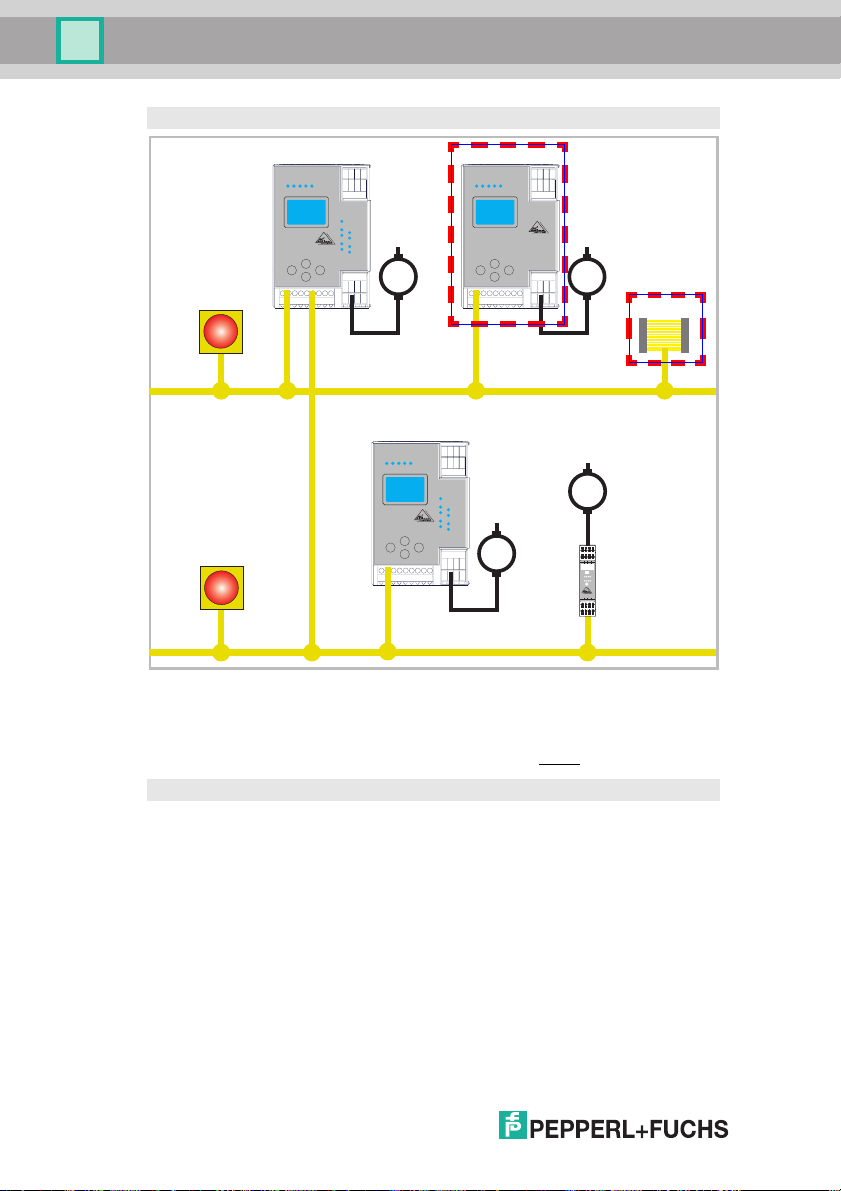

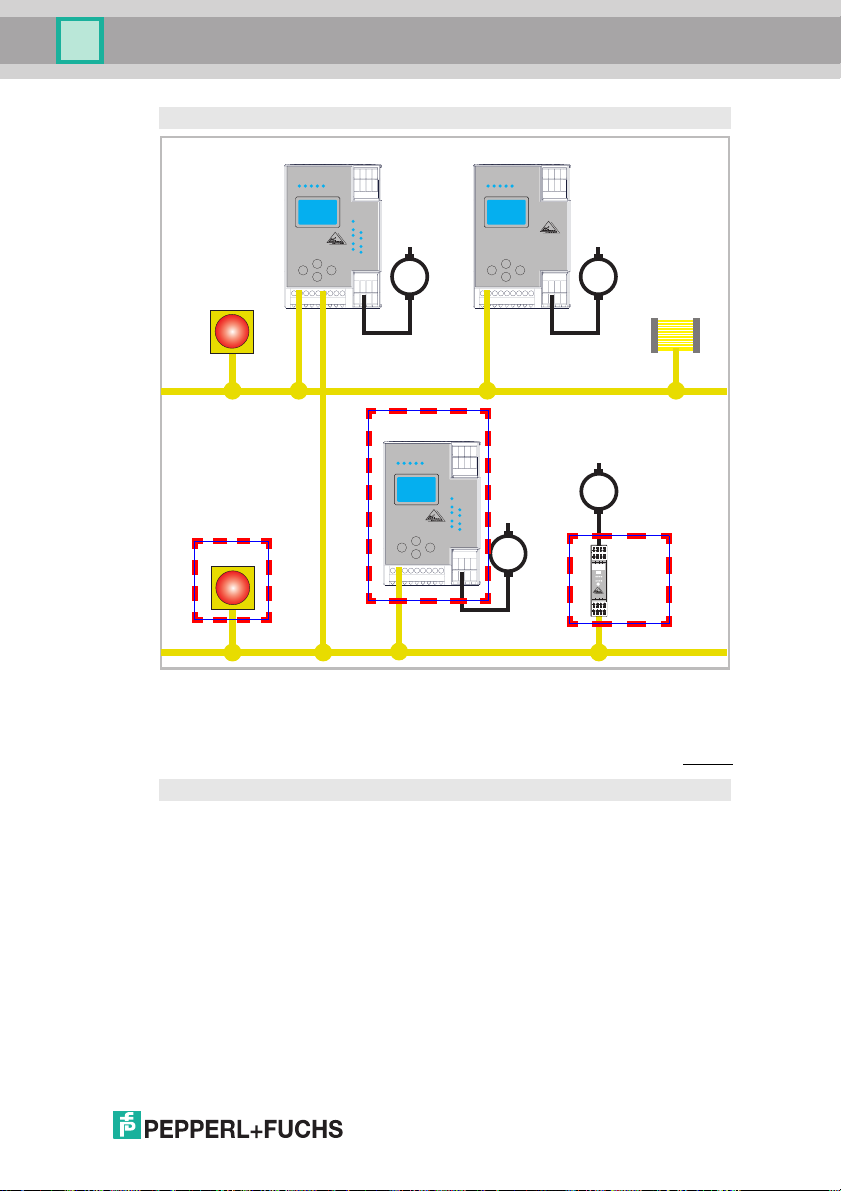

System configuration - example 1: Calculation of the system reaction time

RA2-1

= 18 ms)

RS1-2

= 50ms)

RS1-1

RS2-1

= 100 ms)

= 100ms)

Tab. 5-6.

27.9.2013

21

Page 22

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

System configuration - example 1: Calculation of the system reaction time

SM1-1

AS-i Safety Monitor

M

S1-1

SM1-2

AS-i Safety Monitor

M

S1-2

AS-i 1

SM2-1

M

AS-i Safety Monitor

S2-1

M

AS-i 2

Upon activation of safety light barrier S1-2, the relay safety output of safety monitor SM1-2 is controlled.

Calculation of the AS-i relevant system reaction time:

t

System total a)

= t

R S1-2

+ t

= 18ms + 40ms = 58ms

R System

System configuration - example 2: Calculation of the system reaction time

I–

I+

I1

I2

Run

1

I

Pwr

Prg

1.13

1.14

ASI+

ASI–

I+

I+

1.Y1

1.Y2

Prg

I2

1.Y2

1.Y1

Alarm

Fault

Out

1.23

1.24

nc

nc

A2-1

22

27.9.2013

Page 23

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

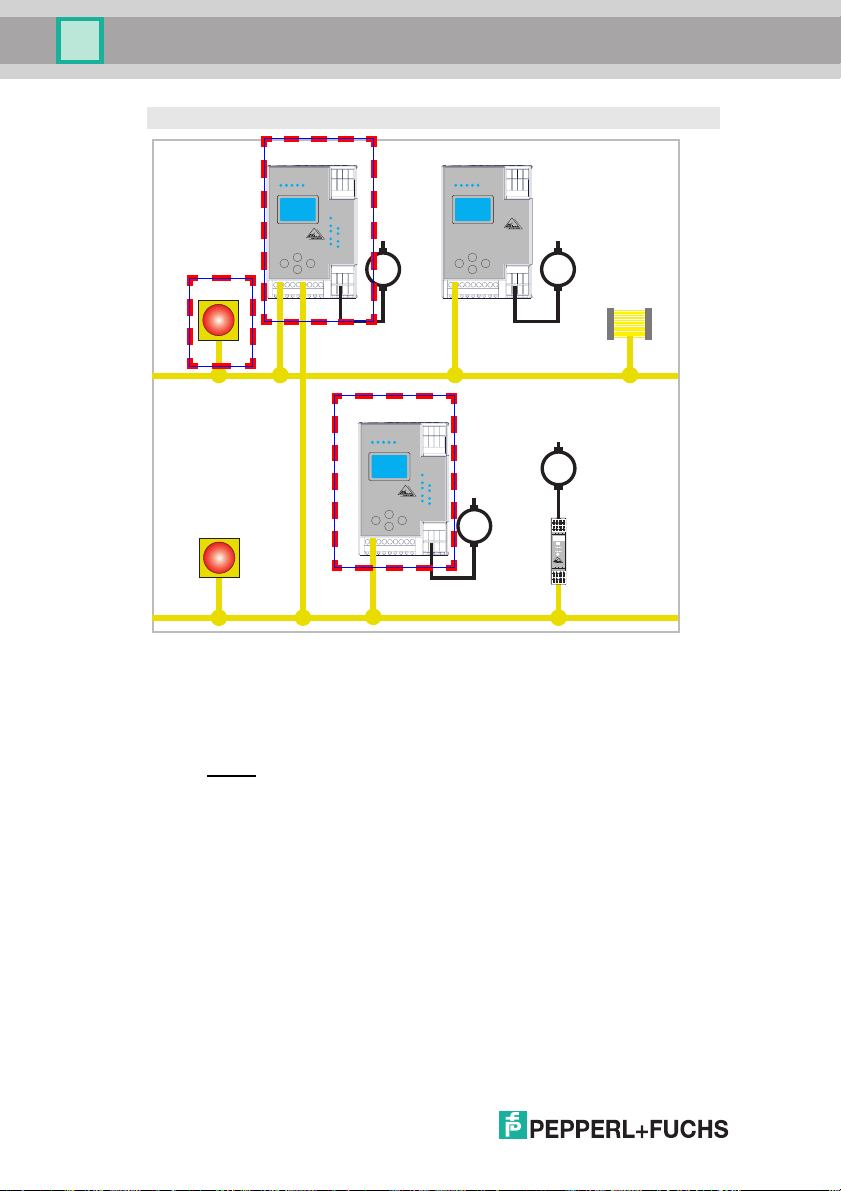

System configuration - example 2: Calculation of the system reaction time

SM1-1

AS-i Safety Monitor

M

S1-1

SM1-2

AS-i Safety Monitor

M

S1-2

AS-i 1

SM2-1

M

AS-i Safety Monitor

S2-1

M

AS-i 2

Upon locking of the EMERGENCY-OFF switch S2-1, the motor starter is controlled via the safe AS-interface output of safety monitor SM2-1.

Calculation of the AS-interface-relevant system reaction time:

t

System total b)

= t

R S2-1

+ t

R System

+ t

= 100ms + 40ms + 50ms = 190ms

R A2-1

System configuration - example 3: Calculation of the system reaction time

I–

I1

Run

Prg

1.13

ASI+

I+

I+

I+

I2

1.Y1

1.Y2

Prg

1

I

I2

1.Y2

1.Y1

Alarm

Pwr

Fault

Out

1.14

1.23

1.24

ASI–

nc

nc

A2-1

27.9.2013

23

Page 24

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFINET Gateways

System configuration - example 3: Calculation of the system reaction time

SM1-1

AS-i Safety Monitor

M

S1-1

SM1-2

AS-i Safety Monitor

M

S1-2

AS-i 1

SM2-1

M

AS-i Safety Monitor

S2-1

M

AS-i 2

Upon locking of the EMERGENCY-OFF switch S1-1, the relay output of safety

monitor SM2-1 is controlled via the coupling of the safe AS-interface output of

safety monitor SM1-1.

Calculation of the AS-i relevant system reaction time:

t

System total c)

= t

R S1-1

+ t

R System ASI1

+ t

R System ASI2

40ms = 180ms

I+

I+

I+

I–

1.Y2

1.Y1

I2

I1

A2-1

Run

Prg

1

I

I2

1.Y2

1.Y1

Alarm

Pwr

Fault

Out

Prg

1.24

1.23

1.14

1.13

nc

nc

ASI–

ASI+

= 100ms + 40ms +

5.4 Scope of delivery

The basic unit consists of:

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor.

The following accessories are available:

Software CD with

• ASIMON 3 G2 communication software for Microsoft

Windows 7/Windows 8

• System manual in PDF format (Adobe® Reader® Version 7.x or newer is

required for viewing the files)

24

®

Windows XP/Vista/

®

27.9.2013

Page 25

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFIsafe Gateway

6. Specifications - AS-i/PROFIsafe Gateway

6.1 Technical data

The technical data are placed in the data sheet. Please view the current version

on the web page: http://www.pepperl-fuchs.com.

Attention!

The AS-I power supply for the AS-I components must have isolation per IEC 60 742

and be able to handle momentary power interruptions of up to 20 ms. The power supply for the 24 V supply must also have isolation per IEC 60 742 and be able to handle

momentary power interruptions of up to 20 ms. The maximum output voltage of the

power supply must also be less than 42 V in case of a fault.

27.9.2013

25

Page 26

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFIsafe Gateway

6.2 Safety-relevant characteristic data

Characteristic data Value Standard

Safety category 4 EN 954-1

EN ISO 13849-1: 2008

Performance Level (PL) e EN ISO 13849-1: 2008

Safety Integrity Level (SIL) 3 IEC 61508: 2001

Lifespan (TM) in years 20 EN ISO 13849-1: 2008

Maximum switch-on time in months 12 IEC 61508: 2001

PFD

PFH

D

(probability of a dangerous failure per hour)

Max. system reaction time in milliseconds

PROFIsafe → local relay output 15

PROFIsafe → local electronic output 5

PROFIsafe → AS-i relay output 60

PROFIsafe → AS-i electronic output 50

AS-i → PROFIsafe 30

PROFINET → local output 40

PROFINET → AS-i

AS-i → local output

AS-i → AS-i

AS-i → PROFINET 50

Attention!

In addition to the system reaction time in the gateway, eventually reaction times of

other daisy-chained safe AS-i and PROFIsafe componentshave to be added too.

Please note that additional reaction times may likewise arise through the configuration

of the safety unit.

< 9,25 x 10

< 5,36 x 10

-6

IEC 61508: 2001,

EN 62061: 2005

-9

IEC 61508: 2001,

EN 62061: 2005

IEC 61508: 2001

Tab. 6-7.

26

27.9.2013

Page 27

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFIsafe Gateway

6.3 Reaction times

6.3.1 Ethernet (PROFIsafe) -> local relay output

1.13

2.13

1.14

2.14

t

ethernet

t

= reaction time PROFIsafe type 150ms

ethernet

t

= maximal system reaction time

react

6.3.2 Ethernet (PROFIsafe) -> local electronic output

t

ethernet

t

= reaction time PROFIsafe type 150ms

ethernet

t

= maximal system reaction time

27.9.2013

react

t

= 15ms

react

24V

1.14

2.14

t

= 5ms

react

27

Page 28

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Specifications - AS-i/PROFIsafe Gateway

6.3.3 Ethernet (PROFIsafe) -> AS-i relay output

1.13

1.14

1.23

1.24

Relay output

t

ethernet

t

= reaction time PROFIsafe type 150ms

ethernet

t

= maximal system reaction time

react

6.3.4 Ethernet (PROFIsafe) -> AS-i electronic output

t

react

t

ethernet

t

= reaction time PROFIsafe type 150ms

ethernet

t

= maximal system reaction time

react

t

react

= 60ms

24V

1.14

2.14

Electronic output

= 50ms

27.9.2013

28

Page 29

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7. Installation

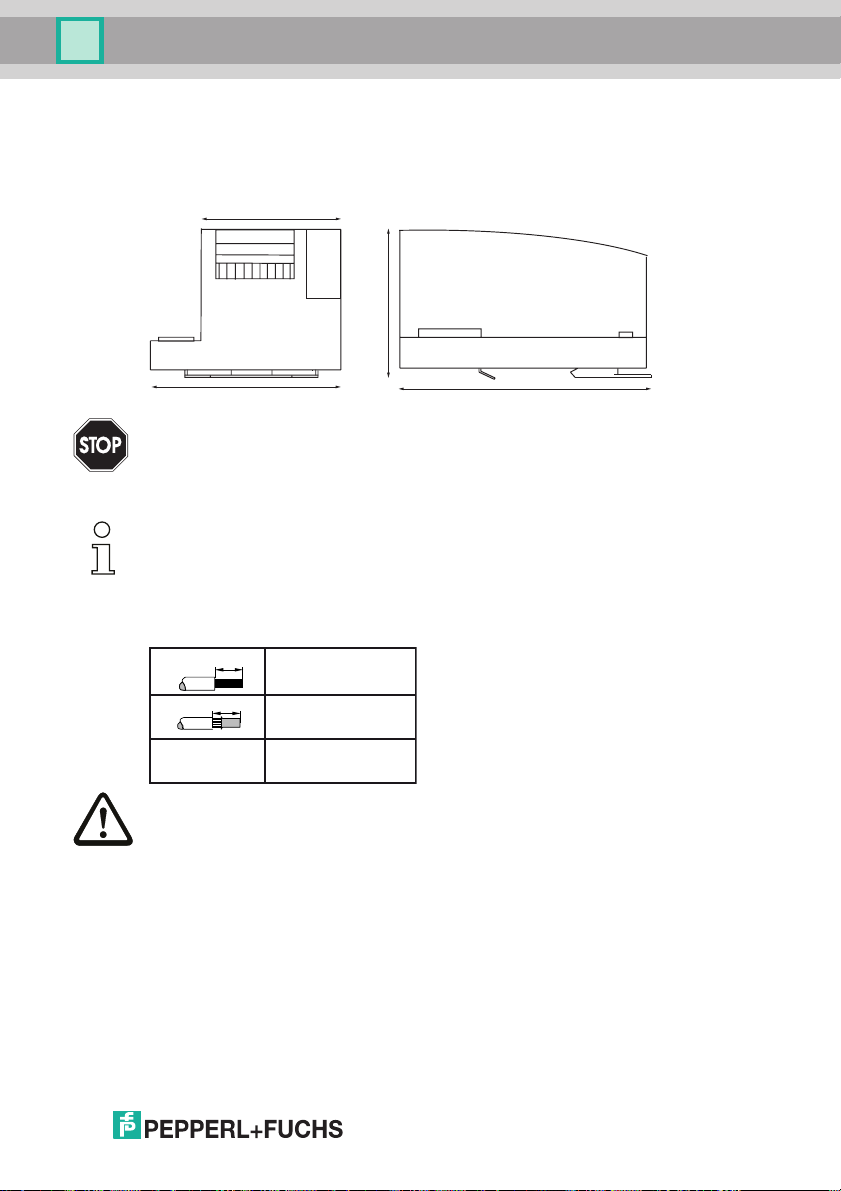

7.1 Dimensions

80

96

Warning!

Cover the top of the gateway when doing any drilling work above the unit. No particles,

especially metal chips, should be allowed to enter the housing, since this could cause a

short circuit.

Information!

Please refer to installation instruction for this device for detailed mounting information.

7.2 Connections

10

10

AWG 24 ... 12

Attention!

The power supply for the AS-I components must have isolation per IEC 60 742 and be

able to handle momentary power interruptions of up to 20 ms. The power supply for

the 24 V supply must also have isolation per IEC 60 742 and be able to handle

momentary power interruptions of up to 20 ms. The maximum output voltage of the

power supply must also be less than 42 V in case of a fault.

110

0,2 ... 2,5 mm

0,2 ... 2,5 mm

120

2

2

27.9.2013

29

Page 30

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

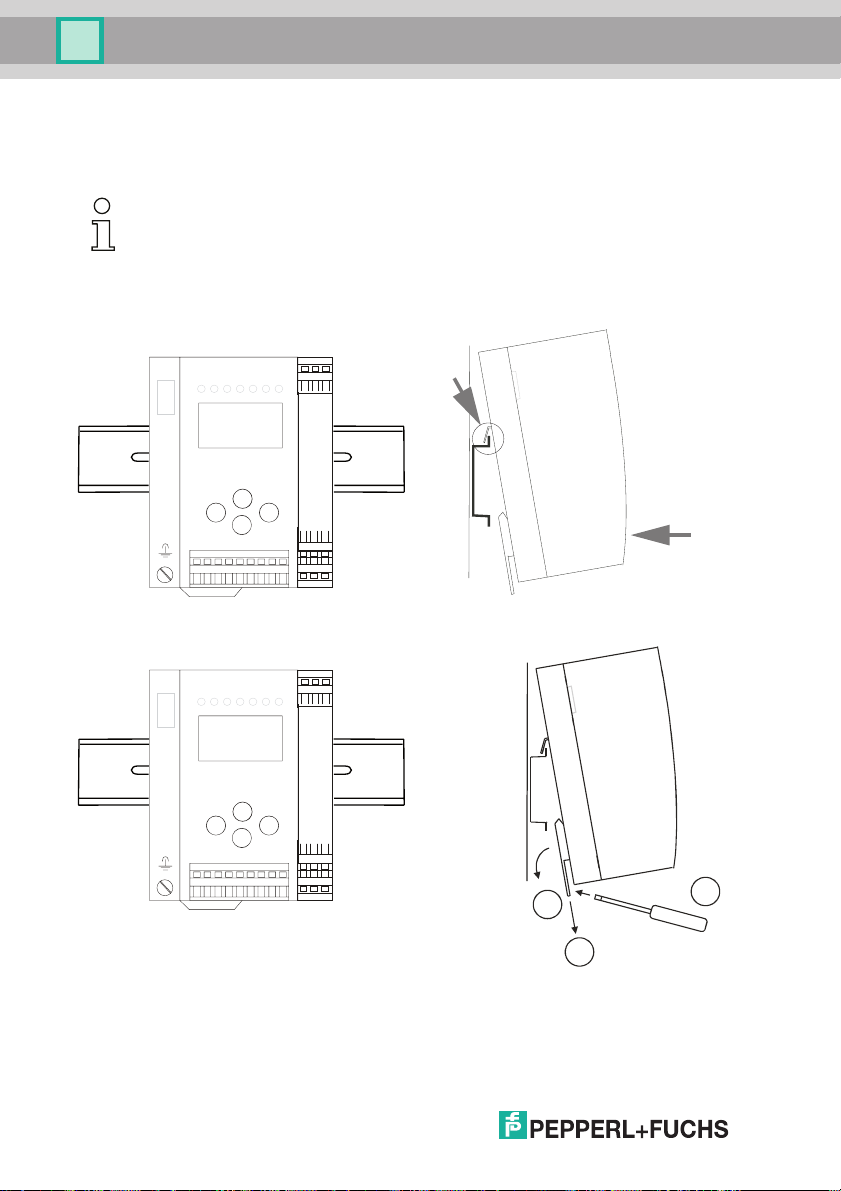

7.3 Installing in the control cabinet

The AS-I/Gateway is installed in the control cabinet on 35mm DIN rails per DIN

EN 50 022.

Information!

The enclosure of the AS-I/Gateway is made of stainless steel. The unit is also suitable for exposed wall mounting.

To install, place the unit on the upper edge of the DIN rail and then snap in the

lower edge.

[1]

-

-

+-+

+

[2]

7.4 Removing

To remove, press the holding clamps [2] down using a screwdriver [1], press the

unit firmly against the upper rail guide and lift out.

30

-

-

+-+

+

3

1

2

27.9.2013

Page 31

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.5 Commissioning

7.5.1

classical display

Switching to advanced display mode

advanced display mode

OK

LCD

1.12A

UNKNOWN SLAVE

ESC/Service

7.5.2 Setting the PROFINET properties

PROFINET

QUICK SETUP

AS-I SAFETY

DIAGNOSIS

LCD

(OK

(OK oder/or/ou/o/o

PROFINET

TCP/IP

ETHERNET

TCP/IP

ACTUAL VALUES

CONFIGURATION

Restart the Gateway for changes to become effective

LCD

menu structure see additional page

CONFIGURATION

STATIC

IP ADDRESS

192.168.42.53

NETMASK

255.255.255.0

GATEWAY

192.168.42.53

CONFIGURATION

PROFINET ONLY

27.9.2013

31

Page 32

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

(OK

(OK

(OK

PROFINET

TCP/IP

ETHERNET

ETHERNET:

PORT 1 MODE:

100BASE-TX FDX

PORT 2 MODE:

NO CONNECTION

MAC ID DEVICE:

00-16-77-10 AF-8C

MAC ID PORT 1:

00-16-77-10 AF-8D

MAC ID PORT 2:

00-16-77-10 AF-8E

PROFINET

TCP/IP

ETHERNET

PROFINET

QUICK SETUP

DIAGNOSIS

SLAVE ADDR TOOL

oder/or/ou/o/o

OK

ESC

100BASE-TX FDX

100BASE-TX HDX

10BASE-T FDX

10BASE-T HDX

NO CONNECTION

TCP/IP

ACTUAL VALUES

CONFIGURATION

ACTUAL VALUES:

IP ADDRESS

192.168.42.53

NETMASK

255.255.255.0

GATEWAY

192.168.42.53

SOURCE

STATIC CONFIG

7.5.3 Setting the PROFIsafe address

Information!

Available only with AS-i PROFIsafe Gateways.

32

27.9.2013

Page 33

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

PROFINET

QUICK SETUP

SAFETY

...

↓

PROFINET

QUICK SETUP

SAFETY

...

OK

↓

ASI SAFETY

SAFE OUTPUT CH

PROFISAFE

START/STOP

...

7.5.4 Connecting AS-i Slaves

AS-i

Power

PROFINET

Config error

U AS-i

AS-i active

prg enable

prj mode

AS-i Master

AS-i

Power

PROFINET

Config error

U AS-i

AS-i active

prg enable

prj mode

PROFISAFE ADDR.

Status

OK

PROFISAFE ADDR.

06

↓

OK

↓

PROFISAFE ADDR.

17

LCD

1. 1

AS-i Master

0.5s

AS-i

AS-i

Slave 1

AS-i

Slave 5

27.9.2013

1. 41

SEARCHING SLAVES

LCD

Slave 1

AS-i

Slave 5

1. 5

0.5s

33

Page 34

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.5.5 Quick setup

config error

OK

1. 5

1xOK

PROFINET

QUICK SETUP

ASI SAFETY

DIAGNOSIS

OK

WARNING:

OUTPUTS MAY BE

RESET

OK

LCD

STORE AS-I

CONFIGURATION

OK

STORE +PRJ MODE

↓

config error

LCD

CONFIGURATION OK

10s

Host error

no connection

1: ON 2: OFF

LCD

LCD

LCD

LCD

↓

STORE AS-I

CONFIGURATION

STORE +RUN

STORE +PRJ MODE

34

LCD

27.9.2013

Page 35

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.5.6 Error tracing

7.5.6.1 Faulty slaves

Power

PROFINET

Config error

U AS-i

AS-i

AS-i active

prg enable

prj mode

AS-i Master

1.1

MISSING SLAVE

LCD

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

7.5.6.2 Error display (last error)

Power

PROFINET

Config error

U AS-i

AS-i active

prg enable

prj mode

AS-i

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

AS-i Master

Power

PROFINET

Config error

U AS-i

AS-i active

prg enable

prj mode

AS-Interface

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

2s

1.24

MISSING SLAVE

2s

AS-i Master

set/↓

LCD

LCD

PROFINET error

No connection

1: ON 2: OFF

24

27.9.2013

35

Page 36

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.6 Addressing

7.6.1 Assigning address 15 to slave currently at address 2

1. 41

SEARCHING SLAVE

OK

↓

LCD

4x

OK

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 0

PRG

6x

OK

1x

↓

QUICK SETUP

AS-I SAFETY

DIAGNOSIS

SLAVE ADDR TOOL

OK

AS-I CIRCUIT 1

AS-I CIRCUIT 2

OK

SLAVE ADR TOOL

CONNECT NEW SLAVE

OLD ADDRESS

NEW ADDRESS

OK

Master Slave

Connect module

Hinweis!

Weitere Informationen finden Sie im Kap. <Bedienung im erweiterten Anzeigemodus>.

2 x ESC

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 15

PRG

↓

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 15

PRG

OK

SLAVE ADR TOOL

CONNECT NEW SLAVE

OLD ADDRESS

NEW ADDRESS

1. 15

UNKNOWN SLAVE

36

27.9.2013

Page 37

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.7 Local parameter setting of safe AS-i Gateways and Monitors

CHIPCARD AND

DATA

DIFFERENT

CARD->MASTER

MASTER->CARD

CONTINUE

Daten kopieren

Keine Aktion erforderlich

CHIPCARD FOUND

DATA WILL

BE SYNCHRONIZED

Keine Aktion erforderlich

Master->Karte

Karte->Master oder

/No action required/

/Aucune action requise/

/No action required/

/Aucune action requise/

Unsichere Daten / Non-safe data/

Données non-sécurisées/

Dati non sicuri / Datos no seguros/

Geräte+Chipdaten ungleich

(Werkskonfiguration geändert)

/Device+card data not equal

(Factory configuartion changed)

Fehlermeldung:

/Error message/

Geräte+Chipdaten gleich

/Device data+card data equal/

Keine Meldung

Karte leer + formatiert

/Card empty + formatted/

Daten werden synchronisiert:

/No message/

/Data being synchronized/

/Copy data Card->Master

or Master->Card/

/Copier données Carte->Maître ou

Maître-Carte/

/Copiare dati Chipcard->Master o

copiare dati Master->Chipcard/

/Copiar datos TarjetaChip->Maestro

o Maestro ->TarjetaChip/

/Nessuna azione richiesta/

/Ninguna acción requrida/

/Nessuna azione richiesta/

/Ninguna acción requrida/

konfiguration)

en kompatibel

(Werks

Dat

/Data compatible (factory

Daten nicht kompatibel

/Data not compatible/

/

Card not formatted

Karte nicht formatiert

/

27.9.2013

DATA FROM

Daten werden übernommen:

/Data being acepted/

configuration)/

CHIPCARD NOT

COMPATIBLE

Fehlermeldung:

/Error message/

NEW CHIPCARD

WILL BE FORMATTED

Karte wird formatiert:

/Formatting card /

CHIPCARD TAKEN

DATA WILL BE

SYNCHRONIZED

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna acción requrida/

Karte löschen

/Clear the card/

/Supprimer carte/

/Cancellare chipcard/

/Borrar tarjeta chip/

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna acción requrida/

37

Page 38

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

ERROR.

CHIPCARD AND

SAFETY DATA

DIFFERENT.

DELETE CHIPCARD

Stamm-/Vollständige

Konfiguartion auf der Chipkarte

enthalten

/Master configuration or

complete configuration on the

card

Sichere Daten / Safe data/

Données sécurisées/

Dati sicuri / Datos seguros

Stamm-/Vollständige

Konfiguartion auf der Chipkarte

/Master configuration or

complete configuration on the

Gerät enthält keine validierte

Konfiguration

/No validated configuration in

Gerät enthält validierte

Konfiguration, Daten ungleich

/There is a validated

configuration on the card, data

not equal

card

Gerät enthält validierte

Konfiguration

/There is a validated

configuration on the card

the device/

Stamm-/Vollständige

Konfiguartion auf der Chipkarte

/Master configuration or

complete configuration on the

card

Beide Konfigurationen ungleich/

Both configurations not equal

Fehlermeldung:

/Error message/

Beide Konfigurationen gleich/

Both configurations identical

Keine Meldung

/No message/

COPY BANK A TO

Datenfreigabe per

MONITOR

Release-Code notwendig:

/Data release via release code

required/

OR SAFETY DATA

...

RELEASE CODE:

1BDF

---------------

TYPE CODE

1BDF OK

Daten löschen

/Clear data/

/Supprimer données /

/Cancellare dati

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

Konfiguration per

Release-Code freigeben

/Validate the configuration

via release code/

/Borrar datos

/Ninguna acción requrida/

/Respecter les indications

de sécurité exposées

dans le manuel ASIMON

/Osservare le istruzioni di

sicurezza riportate nel

manuale ASIMON

/Habilitar la configuración

vía código de liberación/

38

CHIPCARD FOUND

SAFETY DATA WILL

Validierte Konfiguration im

Gerät, Chipkarte leer

/Validated configuration

in the device, chip card empty/

Keine validierte Konfiguration im

Gerät + Chipkarte

/No validated configuration in

the device + chip card/

Sichere Daten auf der

Chipkarte nicht kompatibel

zum Gerät

/Safe data on the chip card

not compatible to the device/

BE SYNCHRONIZED

Daten werden synchronisiert:

/Data being synchronized/

CHIPCARD FOUND

SAFETY DATA WILL

BE SYNCHRONIZED

Daten werden synchronisiert:

/Data being synchronized/

CHIPCARD NOT

COMPATIBLE

Fehlermeldung:

/Error message/

For further information see manual, section <Chip card>

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna acción requrida/

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna acción requrida/

Karte löschen

/Clear the card/

/Supprimer carte/

/Cancellare chipcard/

/Borrar chip/

27.9.2013

Page 39

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.8 Replacing a defective safety-related AS-i slave

The new slave must be able to send code sequences and must have the same

address as the old one. The addressing of the new slave is carried out automatically

by default for all Pepperl+Fuchs AS-i Masters. Only one missing slave is allowed!

[2]

ESC/Service

(3 seconds)

[1]

27.9.2013

CONNECT

NEW SLAVE 17

THEN PRESS

SERVICE

[4]

ESC/Service

(3 seconds)

[3]

39

Page 40

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.9 Replacing the chip card

Always turn off power before inserting or removing the card!

[1]

[2]

old

[3]

7.10 Replacing a defective device

If Safe Link is used, it is necessary to teach the group manager after replacing a

defective device (see next section)!

40

new

27.9.2013

Page 41

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

[1]

[2]

old

new

[3]

27.9.2013

41

Page 42

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

☺

Installation

|COPY BANK A |

|COPY BANK A |

|TO MONITOR |

|TO MONITOR |

|MASTER |

|MASTER |

|CONFIGURATION

|CONFIGURATION

↓ |

↓ |

↓

...

|RELEASE CODE |

|FFFF |

|----------------|

|TYPE CODE ? |

| |

|RELEASE CODE |

|FFFF |

|----------------|

|TYPE CODE ? |

|0000 OK|

|RELEASE CODE |

|FFFF |

↓

|----------------|

|TYPE CODE |

OK

|0000 OK|

42

|START MONITOR |

| |

| |

|

|OK

Press OK for Menu

Output Circuit

1:ON 2:ON

3:ON 4:ON

↓

OK

OK

27.9.2013

Page 43

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

☺

Installation

7.10.1 Teaching the group manager after replacing a device

|QUICK SETUP |

|SAFETY |

|DIAGNOSIS |

|SLAVE ADR TOOL |

|AS-SAFETY |

|SAFE OUTPUT CH |

|START/STOP |

|CLEAR SAFE CFG |

|PIN |

|PROTECT |

|SWITCH CYCLES |

|CROSS COMM. |

|INTERFACE |

|NODE STATUS |

|NODE OVERVIEW |

|TEACH IN |

|WARNING |

|SAFE CROSS COMM.|

|WILL BE STOPPED |

|NUMBER OF |

|REPLACED NODES |

|1 |

|OK |

↓

OK

↓

OK

↓

OK

OK

↓

OK

|WARNING |

|SAFE CROSS COMM.|

OK

|WILL BE STARTED |

PRESS OK FOR MENU

OUTPUT CIRCUIT

esc

1:ON 2:ON

3:ON 4:ON

27.9.2013

43

Page 44

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

7.11 Replacing the monitor

"1"+

"1"

Monitor

AS-i 1 AS-i 2

[1]

Monitor

"2"

"2"+

"2"

Monitor

AS-i 1 AS-i 2

[2]

"1"+

Monitor

"1"

Monitor

+ "2"

"1""2"

Monitor

+ "2"

+ "1"

44

"1"+

"2"

Monitor

AS-i 1 AS-i 2

Monitor

+ "2"

"1"

27.9.2013

Page 45

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

☺

Installation

Safety configuration + AS-i configuration different!

+ "1"

"2"

Monitor

|Error:

|Chip Card and |

ESC

|Safety Data |

|Different. |

|Delete Chip |

|Card or Safety |

|Data |

|Chipcard and |

|AS-i Data |

↓

|Different |

|Chipcard->Master

|Master->Chipcard

|Continue

|

|

OK

ESC

Press OK for Menu

Output Circuit

OK

1:OFF 2:OFF

3:OFF 4:OFF

|QUICK SETUP |

|SAFETY |

|DIAGNOSIS

|

|SLAVE ADR TOOL |

↓

OK↓OK

|TEST |

|SAFE CHIPCARD |

|ACTIVE: BANK A |

↓

|VIEW |

|CARD -> MONITOR |

OK

|MONITOR -> CARD |

|CLEAR CODES

|

|LCD CONTRAST |

27.9.2013

45

Page 46

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

☺

Installation

|ENTER PIN |

|0000 |

| |

|

|OK

|SELECT BANK |

|

|A

| |

|OK |

|STOP MONITOR |

| |

| |

|

|OK

|COPY BANK A to |

|MONITOR |

|RELEASE DATE: |

|2006/06/17 18:43 |

|BY: |

|ROLF BECKER |

|CONFIG NAME: |

|TEST SOFTWARE |

|INSTALLATION |

|INSTRUCTION V1.00 |

|RELEASE CODE: |

|1BDF |

|-------------------|

|TYPE CODE |

|1BDF OK |

|START MONITOR |

| |

| |

|

|OK

↓

OK

↓

OK

↓

OK

OK↓OK

↓

OK

ESC

46

Press OK for Menu

Output Circuit

1:ON 2:ON

3:ON 4:ON

OK

27.9.2013

Page 47

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

Safety configuration + AS-i configuration identic!

AS-i 1 AS-i 2

7.12 Safe configuration using ASIMON 3 G2

ASIMON 3 G2

Software

Start

Before commissioning the safety unit, put the gateway into operation!

ASIMON 3 G2 Software

Change the preset password during the first use of the device (Monitor/change password)!

ASIMON 3 G2 Software

Create the desired configuration.

ASIMON 3 G2 Software

Download the configuration with MONITOR / PC-> MONITOR into the device. Enter the password for

this purpose.

27.9.2013

47

Page 48

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Installation

ASIMON 3 G2 Software

You can acknowledge the request TEACH CODE SEQUENCES? selecting "Yes", or you can do it later

via display selecting "No".

ASIMON 3 G2 Software

Check the configuration log (respect instructions in <chap. 5.8> of the ASIMON manual!).

ASIMON 3 G2 Software

Validate the configuration with MONITOR –> VALIDATION.

ASIMON 3 G2 Software

Start the monitor with MONITOR–> START.

☺ PRESS OK FOR MENU

OUTPUT CIRCUIT

☺Press OK for Menu

Output Circuit

1:ON 2:OFF

1:ON 2:ON

3:ON 4:ON

The device is in the protected mode now.

48

If you have assigned the safety monitor its own address in the software

ASIMON 3 G2, adjust the configuration in the AS-i master (Quick Setup)! This is also

valid when using simulated slaves. /

Please consider notes on safety in the software manual ASIMON 3 G2!

27.9.2013

Page 49

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Maintenance

8. Maintenance

8.1 Checking for safe turn-off

The safety representative is responsible for checking flawless function of the AS-i

Safety Monitor within the safety system.

Safe turn-off when an associated safe sensor or switch is triggered must be

checked at least once a year.

Attention!

To do this, actuate each safe AS-i slave and observe the switching behavior of

the output circuits of the AS-i Safety Monitor.

Attention!

Note the maximum turn-on duration and the overall turn-on operating duration.

These values depend on the PFD value selected (see section <Safety-relevant

characteristic data>).

When the maximum turn-on duration is reached (three, six or twelve months),

check the complete safety system and its proper function.

When the total operating time (20 years) has been reached, the device must be

returned to the manufacturer to check for proper function.

27.9.2013

49

Page 50

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Electrical connection

9. Electrical connection

9.1 Overview of terminals, indicators and operating elements

9.1.1 VBG-PN-K30-D-S16, VBG-PN-K30-DMD-S16, VBG-PNS-K30-DMD, VBG-PNK30-DMD-S16-EV

[1]

[6]

[2]

[3]

[1]

[4]

[5]

-

-

+-+

+

[6]

[7]

[8]

Legend:

[1] LEDs

[2] PROFINET interface

[3] LC display

[4] Buttons

[5] Terminals: Supply voltage and AS-i circuit

[6] Terminals: Safety unit

[7] Chip card slot

[8] RS 232 diagnostics port

1

10

0,2 ... 2,5 mm

10

0,2 ... 2,5 mm

AWG 24 ... 12

2

2

50

1. Only together with ASIMON 3 G2 Software or AS-i Control Tools

27.9.2013

Page 51

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Electrical connection

9.2 AS-i bus connection

Blue

AS-i-

Brown

AS-i+

Blue

AS-i-

Brown

AS-i+

Yellow ASi ribbon cable

2-conductor AS-i round cable

(Recommended: flexible power cable

H05VV-F2x1,5 per DIN VDE 0281)

Information!

Electrical work is to be performed only by electrical technicians.

9.3 Information about the device types

Information!

A listing of the individual devices and their features can be found in section <Product

information>.

9.4 AS-i and power supply terminal assignments

Information!

The cable indicated by grey must not have slaves or repeaters connected to it.

The yellow cable must not have AS-i power suppliers or additional masters connected

to it.

Information!

The function ground can be connected either to the grounding screw or to the terminal.

The function ground should be made with as short a cable as possible to ensure good

EMC characteristics.

Therefore function grounding using the grounding screw is preferred.

Attention!

The AS-I power supply for the AS-I components must have isolation per IEC 60 742

and be able to handle momentary power interruptions of up to 20 ms. The power supply for the 24 V supply must also have isolation per IEC 60 742 and be able to handle

momentary power interruptions of up to 20 ms. The maximum output voltage of the

power supply must also be less than 42 V in case of a fault.

+AS-i 2– (Connection to 2nd AS-i Circuit)

More information about the additional slave circuit can be found in section <Safe coupling slaves on the AS-i circuits>.

27.9.2013

51

Page 52

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Electrical connection

9.4.1 Electrical connection VBG-PN-K30-D-S16

M4

5 mm max!

Function ground

Gateway Safety Unit

+ASI 1

-

+-+

+ASI 1–

+ASI 1–

ASI 1 +PWR– (max. 8A)

+

+ASI 2– / 24V, 0V

ASI 1

+ASI 2-

+PWR-+ASI 1

24V 0V

-

-

+

+

Terminal Signal / Description

+ASI 1–

ASI 1 +PWR–

+ASI 2 – / 24 V, 0 V

FG

Connection to AS-i Circuit 1

Supply voltage for AS-i Circuit 1 (max. 8 A)

Connection to AS-i Circuit 2; 24 V supply optional

Function ground

Information!

For additional information, please refer to the section <AS-i and power supply terminal

assignments>.

52

27.9.2013

Page 53

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Electrical connection

9.4.2 Electrical connection VBG-PN-K30-DMD-S16-EV

Gateway Safety Unit

M4

5 mm max!

Function ground

+ASI 1–

+ASI 1–

+ASI 2–

+

ASI +PWR– (max. 8A) / 24V, 0V

+ASI PWR-

+ASI

+ASI 1

1

2

+ASI

24V 0V

-

-

-

+-+

+

+

Terminal Signal / Description

+ASI 1–

+AS-i 2–

ASI +PWR– /

24 V, 0 V

FG

1. The gateway is AS-i Power24V capable and can be operated directly on a 24V (PELV) power supply.

Connection to AS-i Circuit 1

Connection to AS-i Circuit 2

Supply voltage for AS-i Circuits (max. 8 A) /

Power 241 supply optional

Function ground

Information!

AS-i Circuit 1 and 2 are both powered from a

Pepperl+Fuchs GmbH power supply!

No other power supplies are approved!

Attention!

Earth fault detector sensor without function when using AS-i Power24!

Information!

For additional information, please refer to the sections: <AS-i and power supply terminal assignments> and <AS-i Power24V capable>.

27.9.2013

53

Page 54

AS-i 3.0 PROFINET Gateway with integr. Safety Monitor

Electrical connection

9.4.3 Electrical connection VBG-PN-K30-DMD-S16, VBG-PNS-K30-DMD

Gateway Safety Unit

M4

5 mm max!

-

-

+-+

+

Function ground

+ASI 1–

ASI 1 +PWR– (max. 8A)

+ASI 2–

+

ASI 2 +PWR– (max. 8A)

Terminal Signal / Description

+ASI 1–

+ASI 2–

ASI 1 +PWR–

ASI 2 +PWR–

FG

Connection to AS-i Circuit 1

Connection to AS-i Circuit 2

Supply voltage for AS-i Circuit 1 (max. 8 A)

Supply voltage for AS-i Circuit 2 (max. 8 A)

Function ground

Information!

AS-i Circuits 1 and 2 are powered by separate power supplies.

Information!