Page 1

MANUAL

AS-I 3.0 ETHERNET/IP+

ODBUS TCP GATEWAY

M

FACTORY AUTOMATION

Page 2

AS-i 3.0 EtherNet/IP+ Modbus TCP Gateway

With regard to the supply of products, the current issue of the follo w ing document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the Central

Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in

its most recent version as well as the supplementary clause: "Expa nded reservation of proprietor ship".

Page 3

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Table of contents

Table of contents

AS-i 3.0 EtherNet/IP+ Modbus TCP Gateway

Table of contents

1 Introduction...........................................................................................7

2 Declaration of conformity....................................................................8

2.1 Declaration of conformity................................................................................8

3 Safety.....................................................................................................9

3.1 Intended use..................................................................................................... 9

3.2 General safety information..............................................................................9

3.2.1 Disposal............................................................................................................................9

4 General ................................................................................................10

4.1 Product information....................................................................................... 10

4.2 New Generation of AS-i Gateways with ethernet diagnostics interface... 11

4.3 AS-i specification 3.0.....................................................................................11

5 Specifications .....................................................................................12

5.1 Technical data................................................................................................12

6 Installation...........................................................................................13

6.1 Dimensions.....................................................................................................13

6.2 Connections ...................................................................................................13

6.3 Installing in the control cabinet.................................................................... 14

6.4 Removing........................................................................................................14

6.5 Commissioning..............................................................................................15

6.5.1 Switching to advanced display mode..........................................................................15

6.5.2 Select Modbus TCP .......................................................................................................15

6.5.2.1 Displaying of Ethernet properties..................................................................................16

6.5.2.2 Setting of Ethernet properties .......................................................................................16

6.5.2.3 Setting of watchdog time................ .. ... ............................... ... ............................... ... ......17

6.5.3 Select EtherNet/IP .........................................................................................................17

6.5.3.1 Select command interface mode ..................................................................................18

6.5.3.2 Setting of EtherNet/IP properties..................................................................................18

6.5.4 Connecting AS-i Slaves .............................. ............................... ... ... .............................19

6.6 Quick setup.....................................................................................................20

6.7 Error tracing ................................................................................................... 21

26.9.2013

3

Page 4

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Table of contents

6.7.1 Faulty slaves ...................... ... .. ................................ ............................... ........................21

6.7.2 Error display (last error)................................................................................................21

6.7.3 Replacing the chip card ................................................................................................22

6.7.4 Local parameter setting of AS-i/Gateways........ ... ............................... ... .. ...................23

7 Electrical connection..........................................................................24

7.1 Overview of terminals, indicators and operating elements....................... 24

7.1.1 VBG-ENX-K20-D, VBG-ENX-K20-DMD, VB G- E NX- K2 0 -DM D- EV..................... ... .. ...... 2 4

7.2 AS-i bus connection...................................................................................... 25

7.3 Information about the device types............................................................. 25

7.4 AS-i and power supply terminal assignments............................................ 25

7.4.1 Electrical connection VBG-ENX-K20-D........................................................................26

7.4.2 Electrical connection VBG-ENX-K20-DMD..................................................................27

7.4.3 Electrical connection VBG-ENX-K20-DMD-EV............................................................28

7.5 Ethernet interface.......................................................................................... 29

7.6 Diagnostics interface .................................................................................... 29

7.6.1 Diagnostics port RS 232 ........................................ .. ... ............................... ... ................29

7.7 Chip card........................................................................................................ 29

7.8 Indicators and operating elements.............................................................. 30

7.8.1 LED indicators – master...................................... ... ............................... ... .....................30

7.8.2 Buttons...........................................................................................................................31

8 Operation in advanced display mode...............................................32

9 Advanced Diagnostics for AS-i Masters...........................................33

9.1 List of corrupted AS-i Slaves (LCS)............................................................. 33

9.2 Protocol analysis: Counters for corrupted data telegrams....................... 33

9.3 Offline Phase for Configuration Errors........................................................ 34

9.4 Functions of the AS-i Fault Detector ........................................................... 34

9.4.1 Duplicate address detection.................. ... .. ... ............................... ... ... .. ........................34

9.4.2 Earth/Ground Fault Detector ........................................................................................35

9.4.3 Noise Detector ........ ... ... ............................... ... .. ................................ ... .. ... .....................35

9.4.4 Over-voltage Detector ............... .. ... ... ............................... ... ............................... ... .. ...... 3 5

9.5 Functions of the new generation of AS-i Gateways................................... 36

9.5.1 C-programmable Gateways ..........................................................................................36

9.5.2 Interchangeable memory card .. .. ................................ ... ............................... ... .............36

9.5.3 Earth fault monitor.........................................................................................................36

9.5.4 Current can be read directly on the unit......................................................................37

9.5.5 Self-resetting fuses ................................... .. ... ............................... ... ... ..........................38

9.5.6 AS-i Power24V capable.................................................................................................38

9.5.7 Ethernet diagnostics interface with web ser ver .. .. ... ... ............................... ... .. ... ........39

9.5.8 Transitionless operating mode changes.....................................................................39

10 EtherNet/IP interface.............................................. .............................40

10.1 Identity object ................................................................................................ 41

10.2 Device Level Ring Object.............................................................................. 42

4

26.9.2013

Page 5

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Table of contents

10.3 Quality of Service Object...............................................................................43

10.4 Assembly Object............................................................................................45

10.5 AS-i Master Object .........................................................................................48

10.6 AS-i slave Object............................................................................................ 51

10.7 I/O Data Object ............................................................................................... 52

10.8 Advanced Diagnostics Object ...................................................................... 55

10.9 Short Command Interface Object ................................................................. 56

10.10 Long Command Interface Object..................................................................56

10.11 Safety Control/Status.....................................................................................57

10.11.1 External Monitor ............................... ................................ .. ... ............................... ... ......57

10.11.1.1 Safety Control Status external Monitor ......... ... ... .. ................................ .. ......................57

11 The Modbus Address Table...................................................... .........59

11.1 Safety Control/Status.... .................................................................................71

11.1.1 External monitor, AS-i circuit 1/2 .................................................................................71

11.2 AS-i circuit 1 data........................................................................................... 73

11.2.1 Permanent configuration data......................................................................................73

11.2.2 Enhanced diagnostic................ ... .................................. ................................................73

11.2.3 Function invocation........................ .. ... .................................. ... .. ...................................74

11.3 AS-i circuit 1 analog data ..............................................................................75

11.3.1 16 bit output data of AS-i slaves according to slave profile 7.3 or 7.4.....................75

11.3.2 16 bit input data of AS-i slaves according to slave profile 7.3 or 7.4 .......................75

11.4 AS-i circuit 2 data........................................................................................... 76

11.4.1 Process data and actual configuration data ...............................................................76

11.4.2 Permanent configuration data......................................................................................76

11.4.3 Enhanced diagnostic................ ... .................................. ................................................76

11.4.4 Function invocation........................ .. ... .................................. ... .. ...................................77

11.5 AS-i circuit 2 analog data ..............................................................................78

11.5.1 16 bit output data of AS-i slaves according to slave profile 7.3 or 7.4.....................78

11.5.2 16 bit input data of as-i slaves according to slave profile 7.3 or 7.4 ........................78

11.6 Modbus watchdog..........................................................................................78

12 Operation via Ethernet IP (Modbus/TCP).........................................79

12.1 Message Structure.........................................................................................79

12.2 Ethernet TCP/IP functions............................................................................. 80

12.2.1 Function 3 (3hex): "Read multiple registers"..............................................................80

12.2.2 Function 16 (10hex): "Write multiple registers" ............ .. ... ... .. ... ................................80

12.2.3 Function 23 (17hex): "Read/Write multiple registers"................................................81

12.2.4 Exception codes............................................................................................................81

13 Data Transfer using CIP Messages in RSLogix5000.......................84

13.1 MSG instruction and Message Type Tag ..................................................... 84

13.2 Example 1: read LAS ..................................................................................... 86

13.3 Example 2: read/write 16-bit (analog) data ..................................................87

26.9.2013

5

Page 6

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Table of contents

14 System startup using AS-i Control Tools.........................................88

15 Appendix, Examples...........................................................................91

15.1 Commissioning with RSLogix5000 V20 or higher ...................................... 91

15.2 The first commissioning with CompactLogix ........................................... 101

15.2.1 Working with sample files...........................................................................................105

16 Codes indicated by the display.......................................................106

17 Glossary.............................................................................................108

18 Reference List...................................................................................113

18.1 Manual: “AS-i 3.0 Command Interface“..................................................... 113

26.9.2013

6

Page 7

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Introduction

1. Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops, produces and distributes electronic sensors and interface modules for the

market of automation technology on a worldwide scale.

Before installing this equipment and put into operation, read this manual carefully.

This manual containes instructions and notes to help you through the installation

and commissioning step by step. This makes sure bring such a trouble-free use of

this product. This is for your benefit, since this:

• ensures the safe operation of the device

• helps you to exploit the full functionality of the device

• avoids errors and related malfunctions

• avoids costs by disruptions and any repairs

• increases the effectiveness and efficiency of your plant

Keep this manual at hand for subsequent operations on the device.

After opening the packaging please check the integrity of the device and the

number of pieces of supplied.

Symbols used

The following symbols are used in this manual:

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peri pheral syst ems, or pl ant, potent ial ly lead ing t o total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or resu lt in material damages and destruction.

Contact

If you have any questions about the device, its functions, or accessories, please

contact us at:

Pepperl+Fuchs GmbH

Lilienthalstraße 200

68307 Mannheim

Telephone: +49 621 776-4411

Fax: +49 621 776-274411

E-Mail: fa-info@pepperl-fuchs.com

26.9.2013

7

Page 8

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Declaration of conformity

2. Declaration of conformity

2.1 Declaration of conformity

This product was developed and manufactured under observance of the applicable European standards and guidelines.

Information!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a

certified quality assurance system that conforms to ISO 9001.

26.9.2013

8

Page 9

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Safety

3. Safety

3.1 Intended use

Warning!

This symbol warns of a possible danger. The protection of operating personnel and the

system against possible dang er is not guaranteed if the control inte rface unit is not

operated in accordance to its intended use.

3.2 General safety information

Warning!

Safety and correct functioning of the device cannot be guaranteed if any operation

other than described in t his ope ra tio n ma nual i s per f or med . Con ne ct ing th e e qu ipmen t

and conducting any maintenance wor k und er power must e xclusi vely be perf ormed by

appropriately qualified perso nnel. In case a failure cannot be elim inated, the device

must be taken out of operation an d inadvertently operation must be prevented. Repair

work must be performed by the ma nufacturer only. Additions or modifi cations to the

equipment are not permitted and will void the warranty.

Information!

The operator is responsible for the observation of local safety standards.

3.2.1 Disposal

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances wh en

disposing this product!

The device does not contain batteries that need to be removed before disposing it.

26.9.2013

9

Page 10

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

General

4. General

4.1 Product information

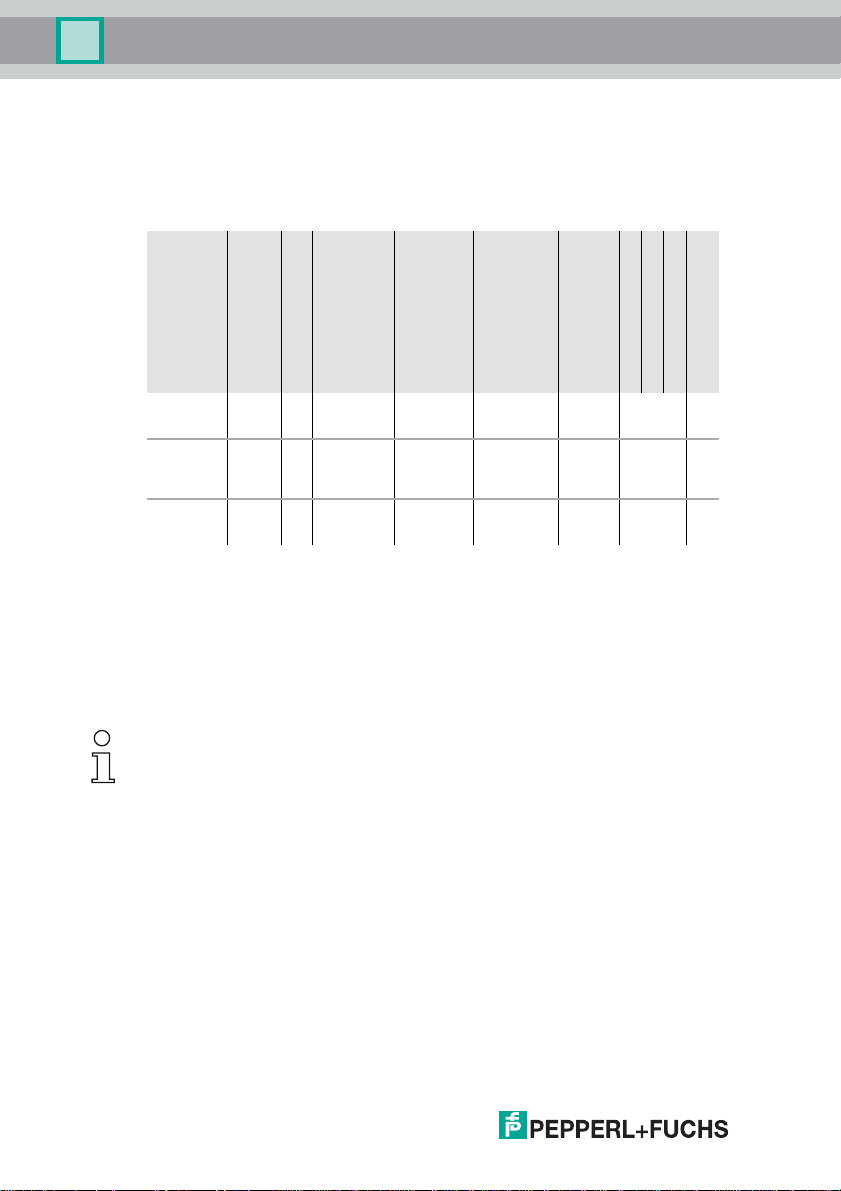

This system manual applies to the following Pepperl+Fuchs GmbH equipment:

1

Artikel Nr.

VBG-ENXK20-DMD-EV

VBG-ENXK20-DMD

VBG-ENXK20-D

1. AS-i Power24V capable.

Art

Schutzart

Schnittstelle, Feldbus

Gateway IP20

Gateway IP20

Gateway IP20

The devices can be operated directly on a 24V (PELV) power supply. The gateway VBG-ENX-K20DMD-EV is optimized with integrated data coupling coils and adjustable self-resetting fuses for

safe use also of powerful 24V power supplies. The gateways VBG-ENX-K20-D and VBG-ENXK20-DMD need to add in Power24V-operation a power supply decoupling unit.

EtherNet/IP +

ModbusTCP

EtherNet/IP +

ModbusTCP

EtherNet/IP +

ModbusTCP

Anzahl AS-i Kreise,

Anzahl der AS-i Master

2 AS-i networks, 2 AS-i

Masters

2 AS-i networks, 2 AS-i

Masters

2 AS-i networks, 2 AS-i

Masters

1 Netzteil, 1 Gateway

für 2 AS-i Kreise,

günstige Netzteile

yes, max. 4A/

AS-i network

no, max. 8A/

AS-i network,

redundant

supply

no, max. 8A/

AS-i network

Diagnose- und

Konfigurationsschnittstelle

Ethernet

Feldbus +

RS 232

Ethernet

Feldbus +

RS 232

Ethernet

Feldbus +

RS 232

Doppeladresserkennung

yes

yes

yes

AS-i Wächter

AS-i Power24V

optio

nal

optio

nal

optio

nal

Tab. 4-1.

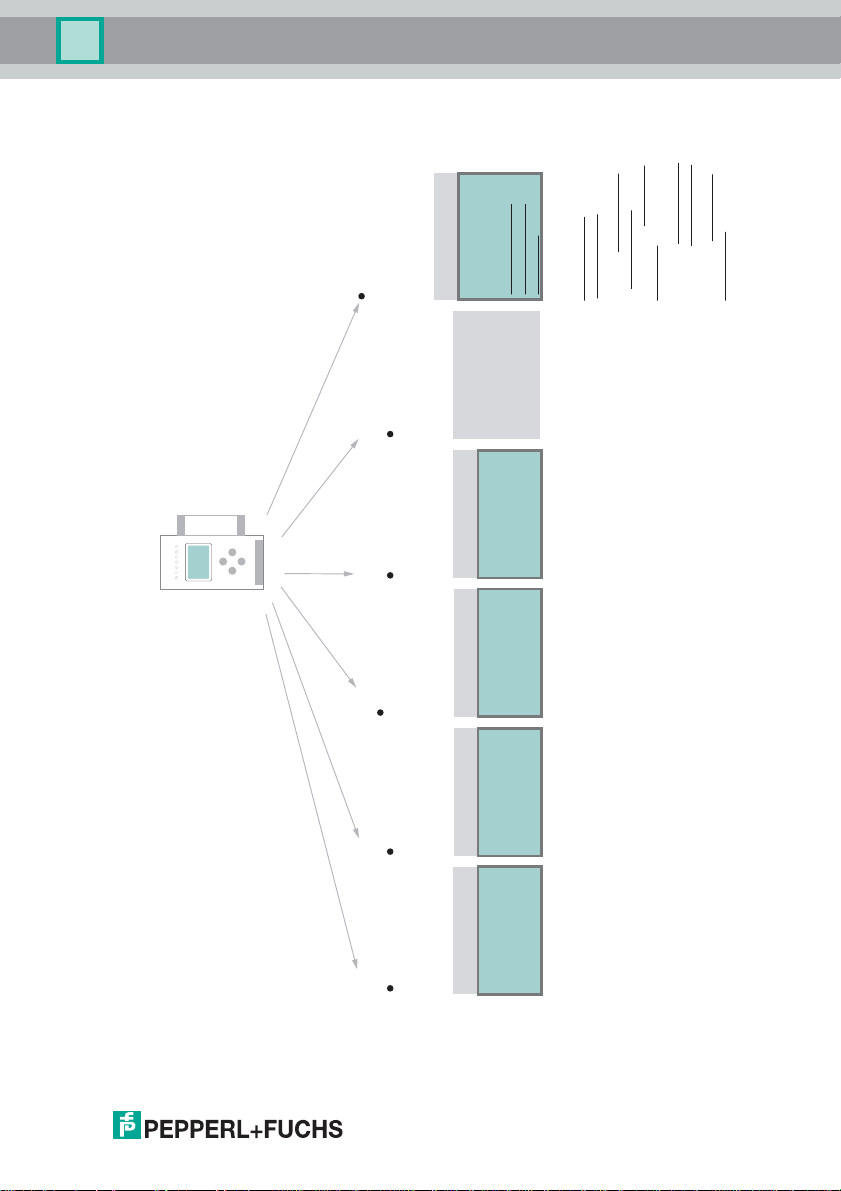

The AS-i 3.0 EtherNet/IP+Modbus TCP Gateway serves to connect AS-i systems

to the superordinate Ethernet controller.

Information!

The device uses one of two protokols: EtherNet/IP or Modbus TCP. The selection

takes place in the menu (see chap. <Installati on > ).

Programmierung in C

10

26.9.2013

Page 11

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

General

4.2 New Generati on of AS-i Gateways with ethernet diagnostics interface The plus points of the new Gateway generation at a glance:

• Gateways now programmable in C

• Ethernet diagnostics interface for remote diagnostics

• Integrated web server: diagnostics for the Gateways and the AS-i circuits

over Ethernet possible with no additional software

• GSD configuration files already stored in the web server

• Earth fault monitor distinguishes between AS-i cable and sensor cable

• Current from both AS-i circuits in the "1 Gateway, 1 power supply for 2 AS-i

circuits" version can now be read directly on the unit

• Self-resetting fuses in the "1 Gateway, 1 power supply for 2 AS-i circuits" ver-

sion

• Device temperature display

• AS-i Power24V capable

• Interfaces for virtually every bus system and Ethernet solution

Information!

See also section <Functions of the new generation of AS-i Gateways> for further information.

4.3 AS-i specification 3.0

The AS-i 3.0 devices already fulfil the AS-i specification 3.0.

The previous specifications (2.1 and 2.0) are supported as well.

Advanced Diagnostics

Diagnostics, which go far beyond the standard diagnostics facilitate the simple

detection of the occasionally occurring configuration errors and further irritations

towards the AS-i communication. So in case of an error the down time of machines can be minimized or you can initiate preventive maintenance.

Commissioning and monitoring

Commissioning, debugging and setting up of the AS-i parameters can also be accomplished with the use of push-buttons on the frontside of the gateway, the display and the LEDs. It is also possible to do the configuration with the software

"AS-i Control Tools".

26.9.2013

11

Page 12

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Specifications

5. Specifications

5.1 Technical data

The technical data are placed in the data sheet. Please view the current version

on the web page: http://www.pepperl-fuchs.de.

12

26.9.2013

Page 13

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

6. Installation

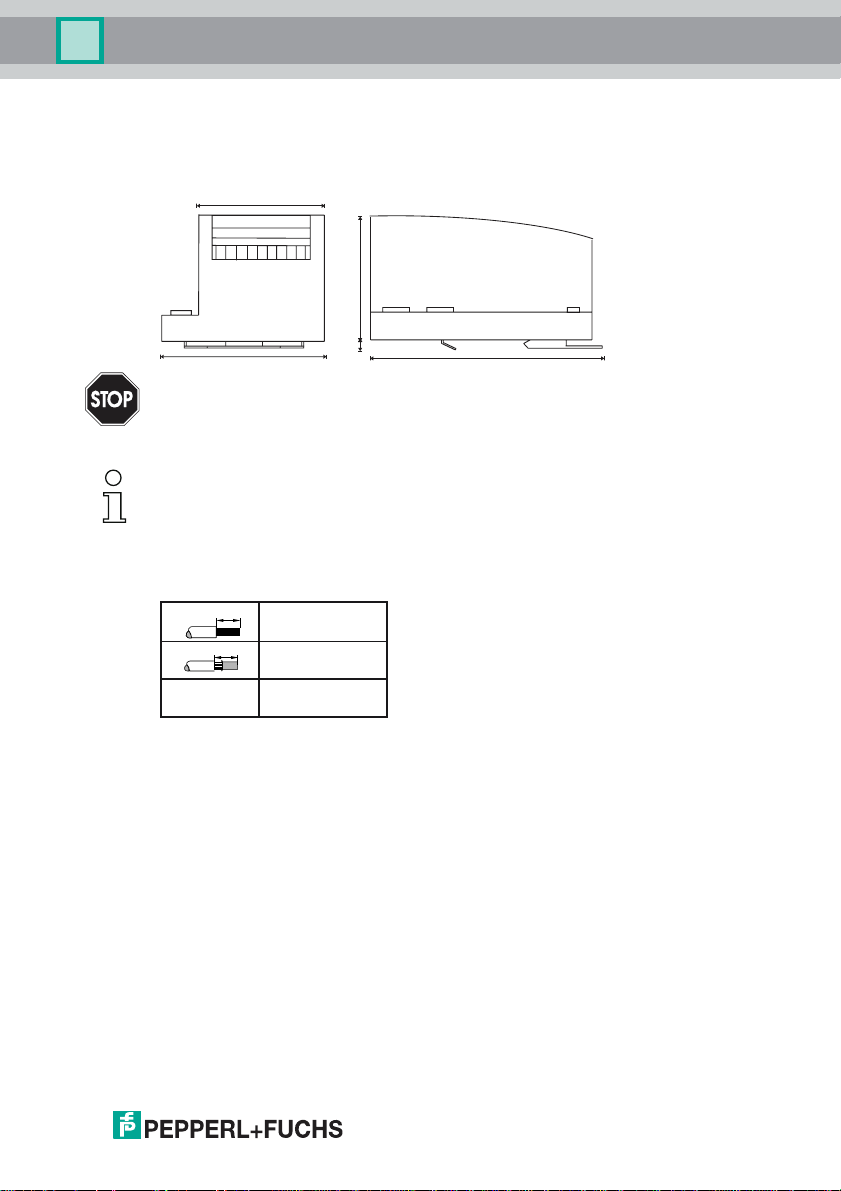

6.1 Dimensions

55

75

Warning!

85

Cover the top of the gateway w h en do ing any drilling work above the un it . N o p articles,

especially metal chips, should be allowed to enter the housing, since this could cause a

short circuit.

Information!

Please refer to installation instruction for this device for detailed mounting information.

6.2 Connections

10

10

AWG 24 ... 12

0,2 ... 2,5 mm

0,2 ... 2,5 mm

7

120

2

2

26.9.2013

13

Page 14

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

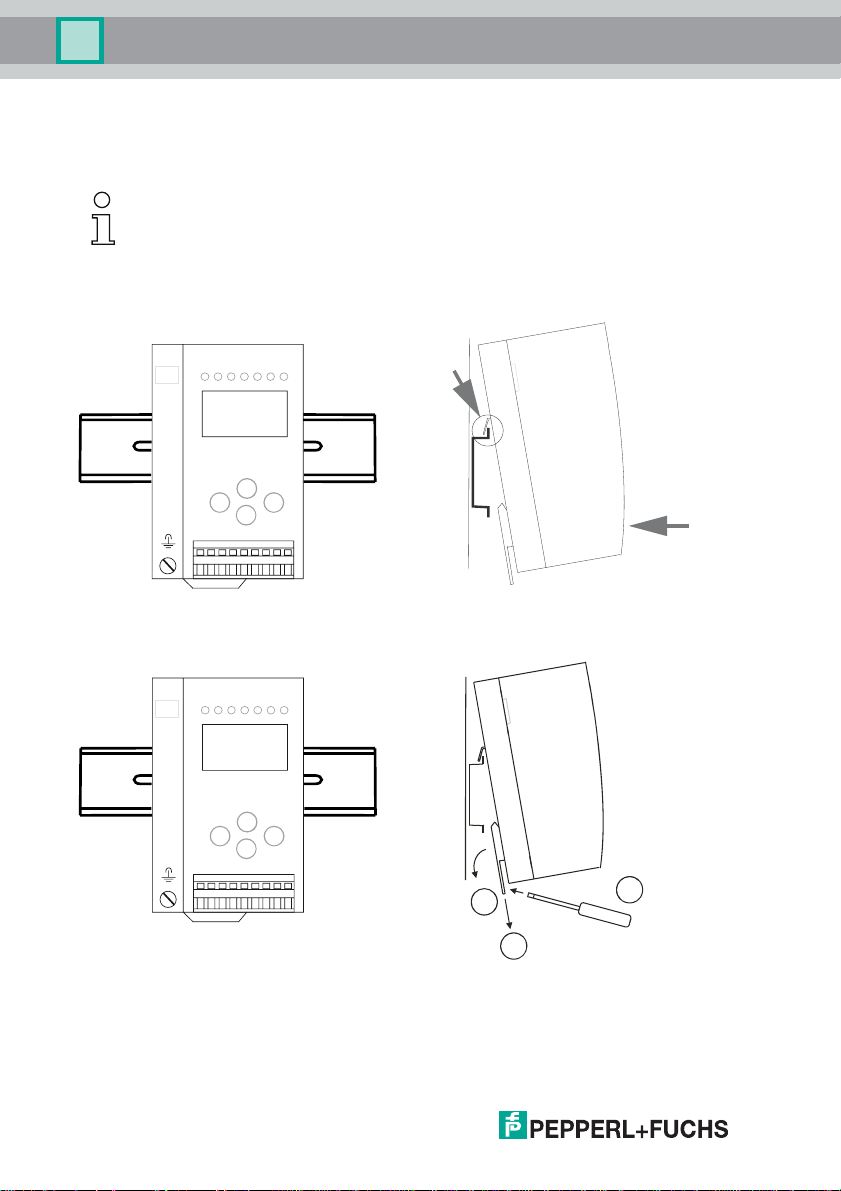

6.3 Installing in the control cabinet

The AS-i/Gateway is installed in the control cabinet on 35mm DIN rails per DIN

EN 50 022.

Information!

The enclosure of the AS-i/Gateway is made of stainless steel. The unit is also suitable

for exposed wall mounting.

To install, place the unit on the upper edge of the DIN rail and then snap in the

lower edge.

-

-

+-+

+

[1]

[2]

6.4 Removing

To remove, press the holding clamps [2] down using a screwdriver [1], press the

unit firmly against the upper rail guide and lift out.

14

-

-

+-+

+

3

1

2

26.9.2013

Page 15

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

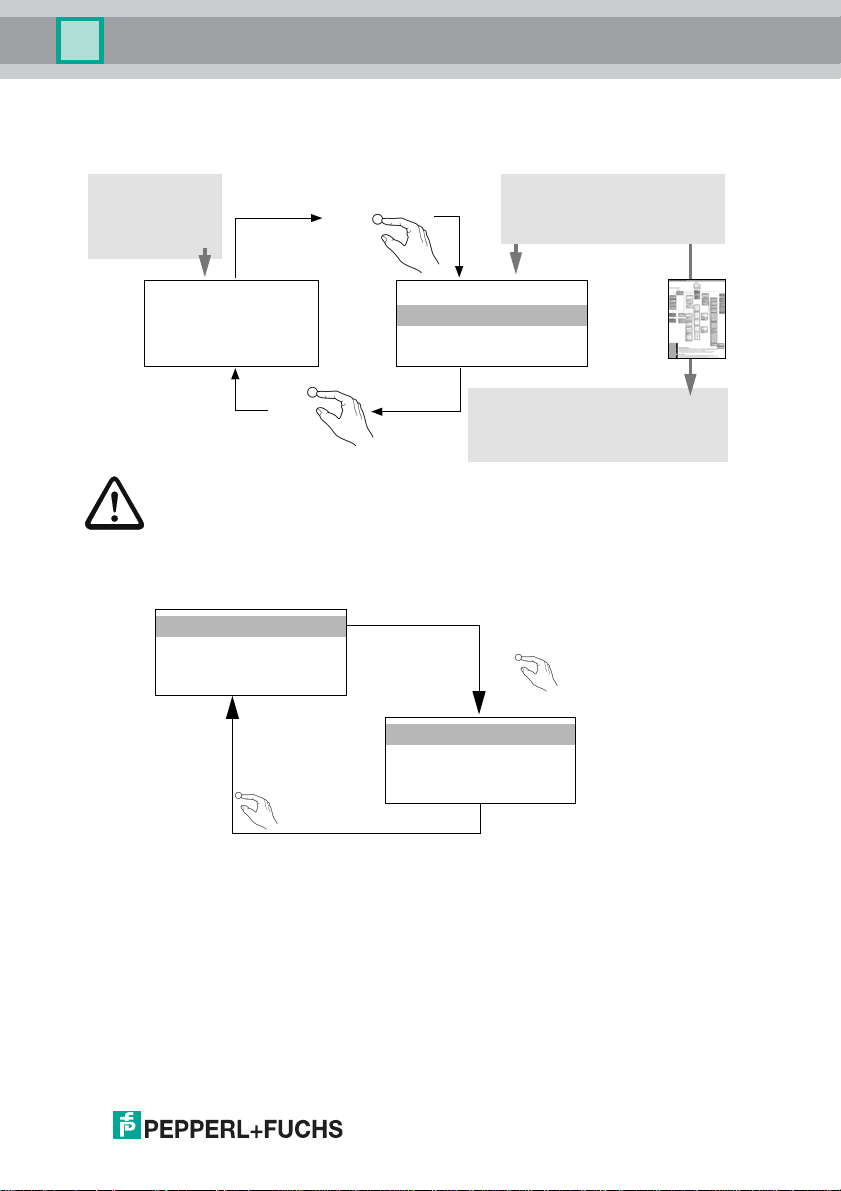

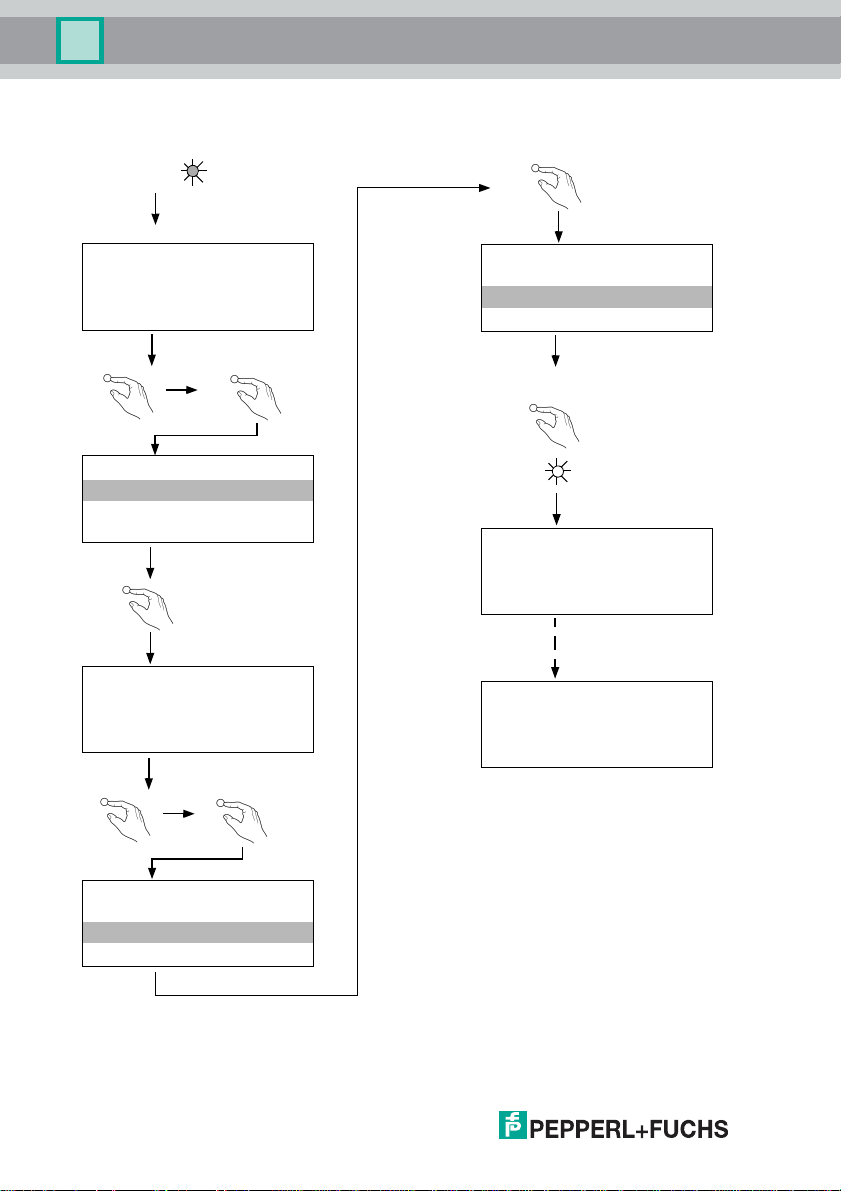

6.5 Commissioning

6.5.1

classical display

Switching to advanced display mode

OK

advanced display mode

1.12A

UNKNOWN SLAVE

ESC

The device handels multiple protocols! Please select one of them during the initial

operation.

6.5.2 Select Modbus TCP

ETHERNET

QUICK SETUP

SLAVE ADR. TOOL

SLAVE TEST TOOL

ESC

LCD

ETHERNET

QUICK SETUP

SLAVE ADR TOOL

SLAVE TEST TOOL

menu structure see additional page

OK

MODBUS TCP X

ETHERNET/IP

LCD

26.9.2013

15

Page 16

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

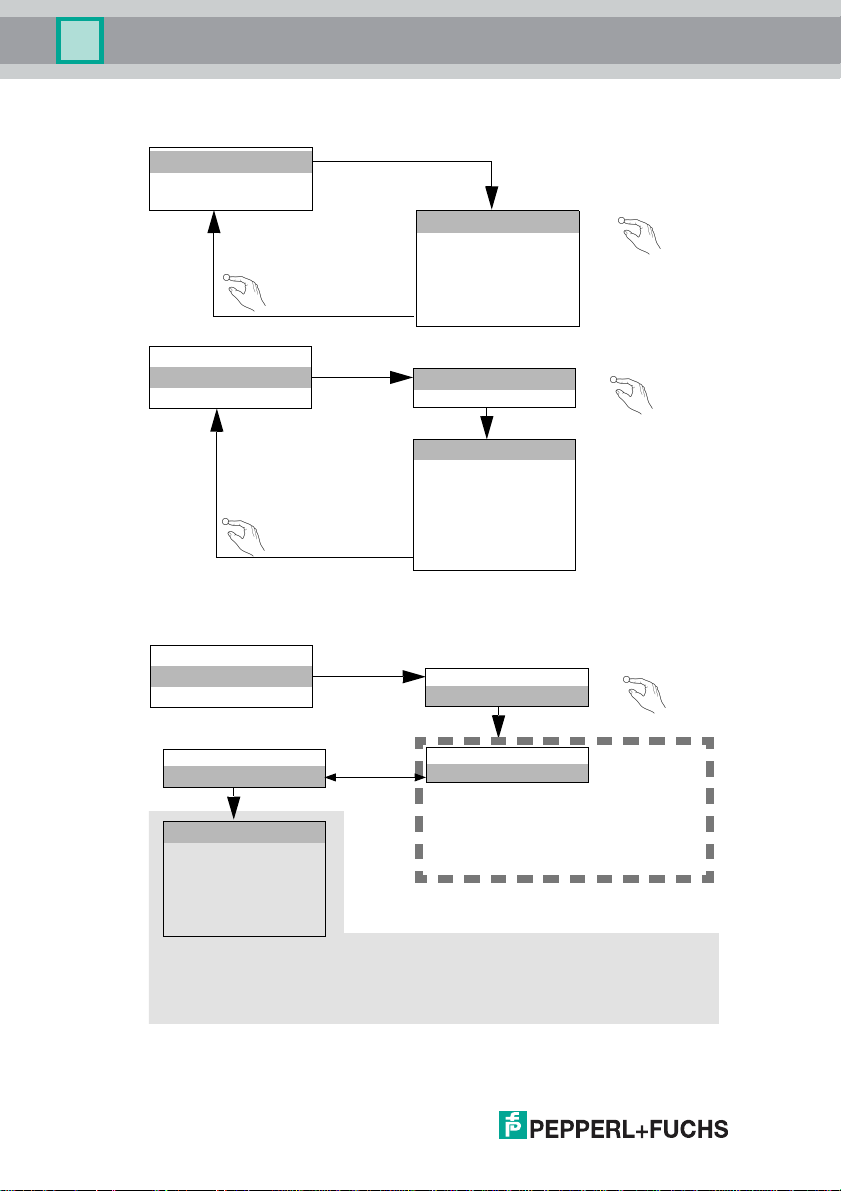

6.5.2.1 Displaying of Ethernet properties

ETHERNET

TCP/IP

MODBUS

ESC

ETHERNET

TCP/IP

MODBUS

ESC

6.5.2.2 Setting of Ethernet properties

ETHERNET

LINK:

100 BASE-TX FDX

MAC ID:

00-16-77-002E-C3

ACTUAL VALUES

CONFIGURATION

ACTUAL VALUES

IP ADDRESS

192. 168. 000.254

NET MASK

255. 255. 255. 0

GATEW AY

0 .0 .0 .0

OK

OK

16

ETHERNET

TCP/IP

MODBUS

CONFIGURATION

STATIC

ACTUAL VALUES

CONFIGURATION

CONFIGURATION

DYNAMIC

When using DHCP, no adjustment is necessary

IP ADDRESS

192. 168. 42. 149

NET MASK

255. 255. 255. 0

GATEWAY

0 . 0 . 0. 0

If you do not have DHCP client access, please contact your network administrator. /

OK

26.9.2013

Page 17

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

6.5.2.3 Setting of watchdog time

ETHERNET

TCP/IP

MODBUS

WATCHDOG TIME

200

ESC

in 10ms steps

000 = disable

"

6.5.3 Select EtherNet/IP

ETHERNET

QUICK SETUP

SLAVE ADR. TOOL

SLAVE TEST TOOL

MODBUS TCP X

ETHERNET/IP

CHANGES TAKE

EFFECT ON NEXT

POWER ON

Restart the gateway to assume your changes

OK

OK

!

MODBUS TCP

ETHERNET/IP X

ETHERNET/IP

NOT ACTIVE

ACTIVATE IT?

YES

NO

↓

OK

↓

OK

26.9.2013

17

Page 18

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

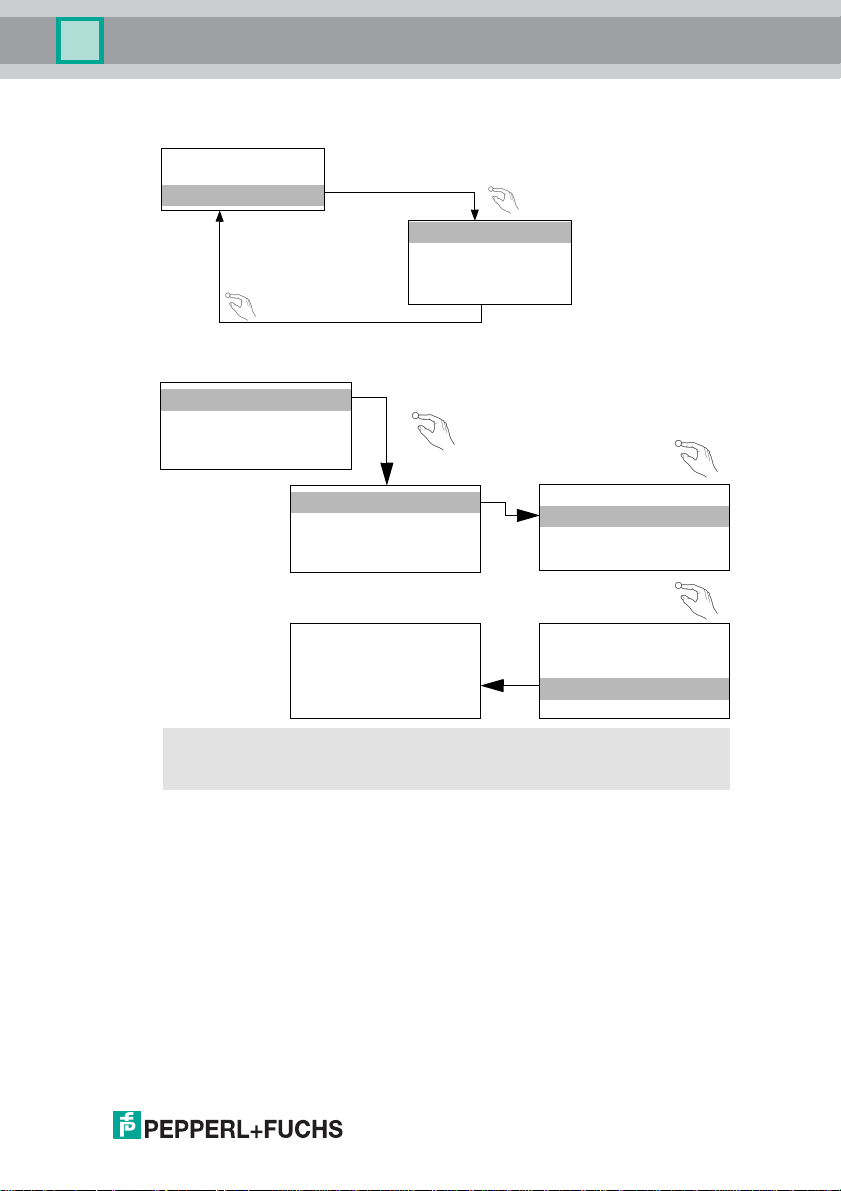

6.5.3.1 Select command interface mode

MODBUS TCP

ETHERNET/IP X

OK

TCP OBJECT

↓

ETHERNET OBJECT

OK

MAILBOX MODE

ESC

MAILBOX MODE

38 BYTE

OK

6.5.3.2 Setting of EtherNet/IP properties

TCP/IP OBJECT

ETHERNET OBJECT

IF STATUS

IF CAPABILITY

IF CONTROL

...

If you do not have DHCP client access, please contact your network administrator. /

OK

↓

MAILBOX MODE

38 Byte:

Enchanced mailbox length for current device revision

36 Byte:

Compatibility mode for older devices

MAILBOX MODE

36 BYTE

USE DHCP

When using DHCP, no adjustment is necessary

OK

18

TCP/IP OBJECT

ETHERNET OBJECT

IF STATUS

IF CAPABILITY

IF CONTROL

PATH TO LINK OBJ.

TCP/IP CONFIG

Restart the gateway to as sume your changes

↓

OK

IP ADDRESS

192. 168. 42. 149

NET MASK

255. 255. 255. 0

GATEWAY

0 . 0 . 0. 0

26.9.2013

Page 19

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

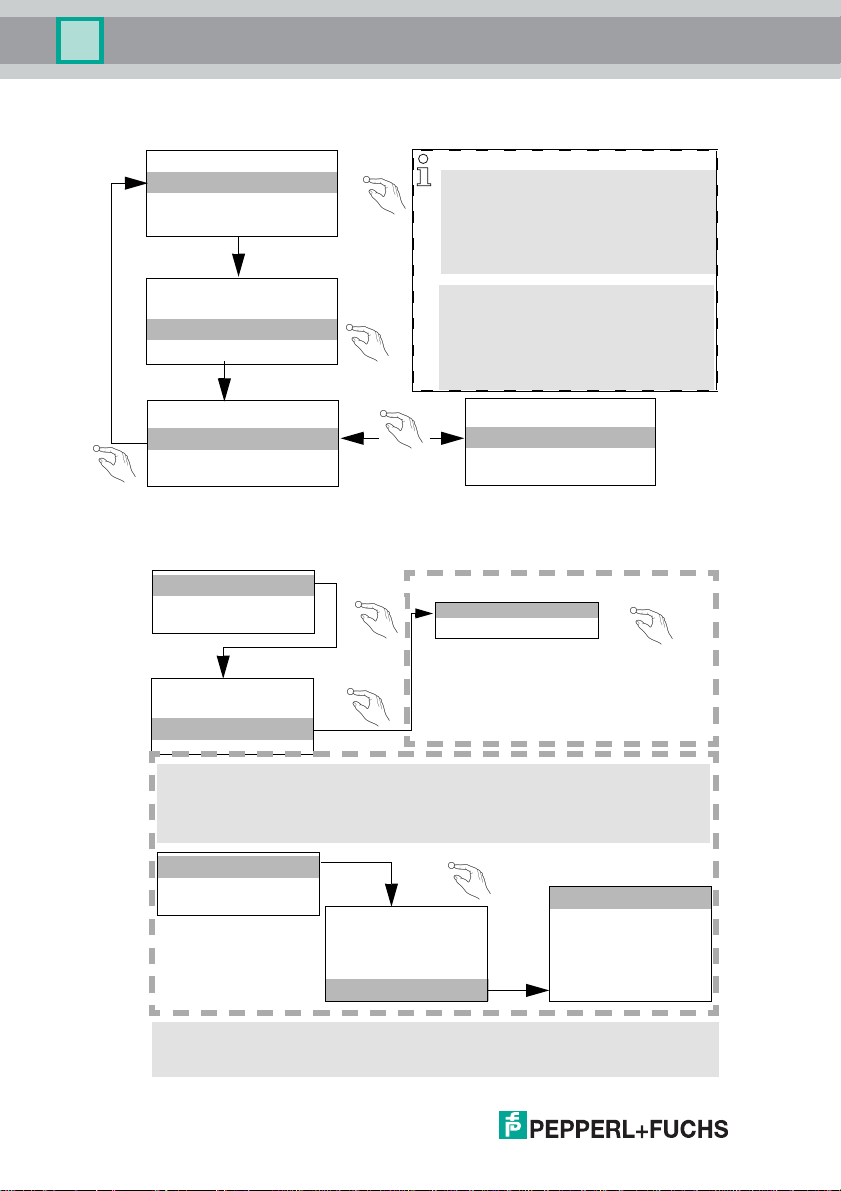

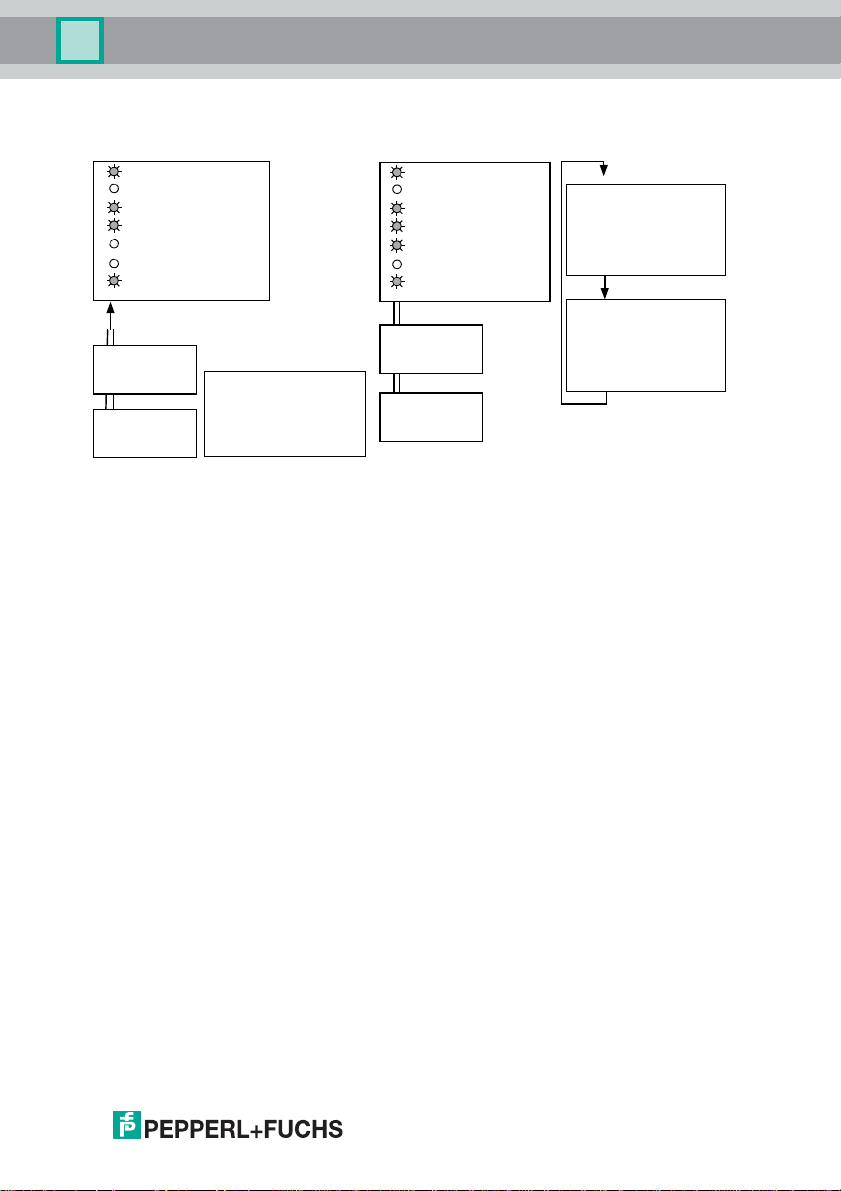

6.5.4 Connecting AS-i Slaves

AS-i

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i Master

AS-i

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i Master

LCD

1. 1

0.5s

AS-i

Slave 1

AS-i

Slave 5

LCD

1. 41

SEARCHING SLAVES

AS-i

Slave 1

AS-i

Slave 5

1. 5

0.5s

26.9.2013

19

Page 20

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

6.6 Q uick setup

config error

1. 5

1xOK

ETHERNET

QUICK SETUP

SETUP

IO + PARAM. TEST

OK

WARNING:

OUTPUTS MAY BE

RESET

OK

LCD

STORE AS-I

CONFIGURATION

OK

STORE +PRJ MODE

↓

2x ESC

LCD

LCD

LCD

.

CONFIGURATION OK

LCD

HOST ERROR

NO CONNECTION

LCD

OK

STORE AS-I

CONFIGURATION

STORE +RUN

STORE +PRJ MODE

20

↓

LCD

26.9.2013

Page 21

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

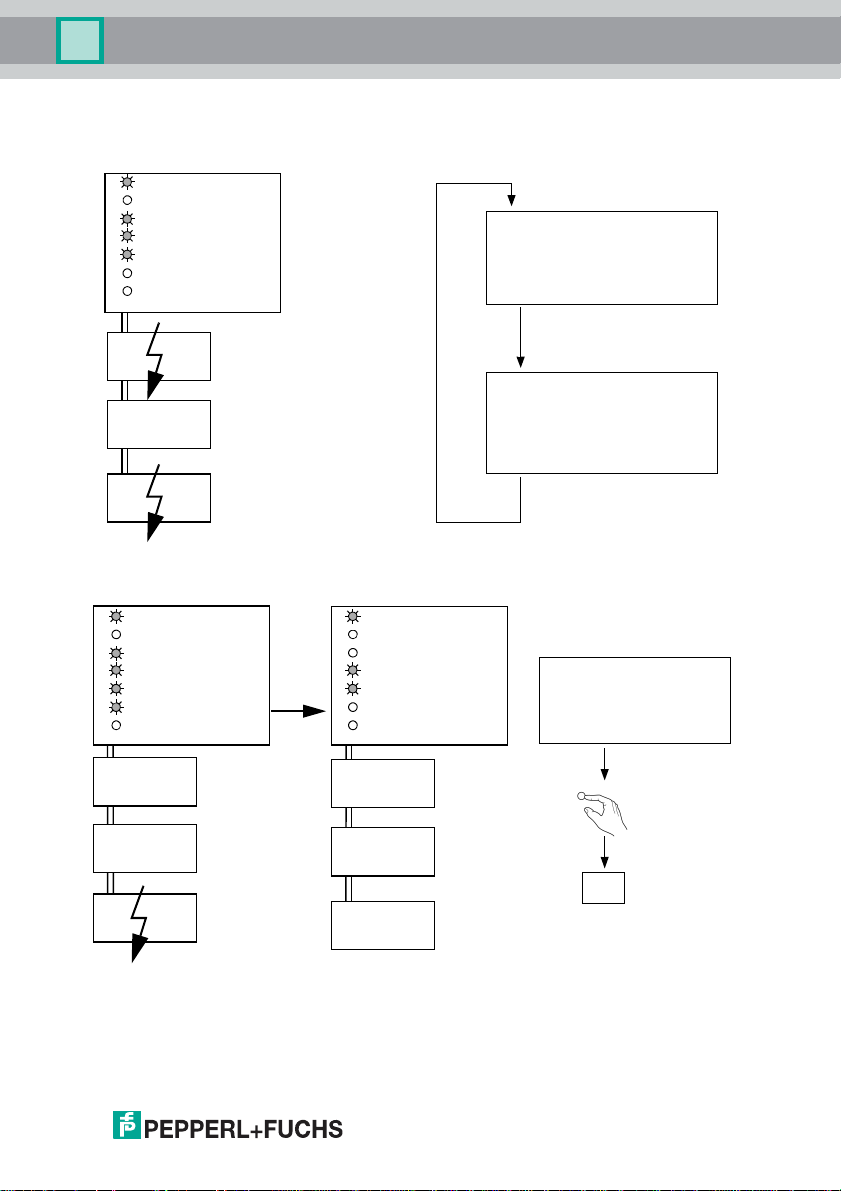

6.7 Error tracing

6.7.1 Faulty slaves

power

net

config error

U AS-i

AS-i active

prg enable

AS-i

prj mode

AS-i Master

LCD

1.1

MISSING SLAVE

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

6.7.2 Error display (last error)

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

AS-i Master

power

net

Config error

U AS-i

AS-i active

prg enable

prj mode

AS-Interface

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

2s

LCD

1.24

MISSING SLAVE

2s

LCD

Host error

no connection

AS-i Master

set/↓

24

26.9.2013

21

Page 22

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

6.7.3 Replacing the chip card

Always turn off power before inserting or removing the card!

[1]

[2]

22

[3]

old

new

26.9.2013

Page 23

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Installation

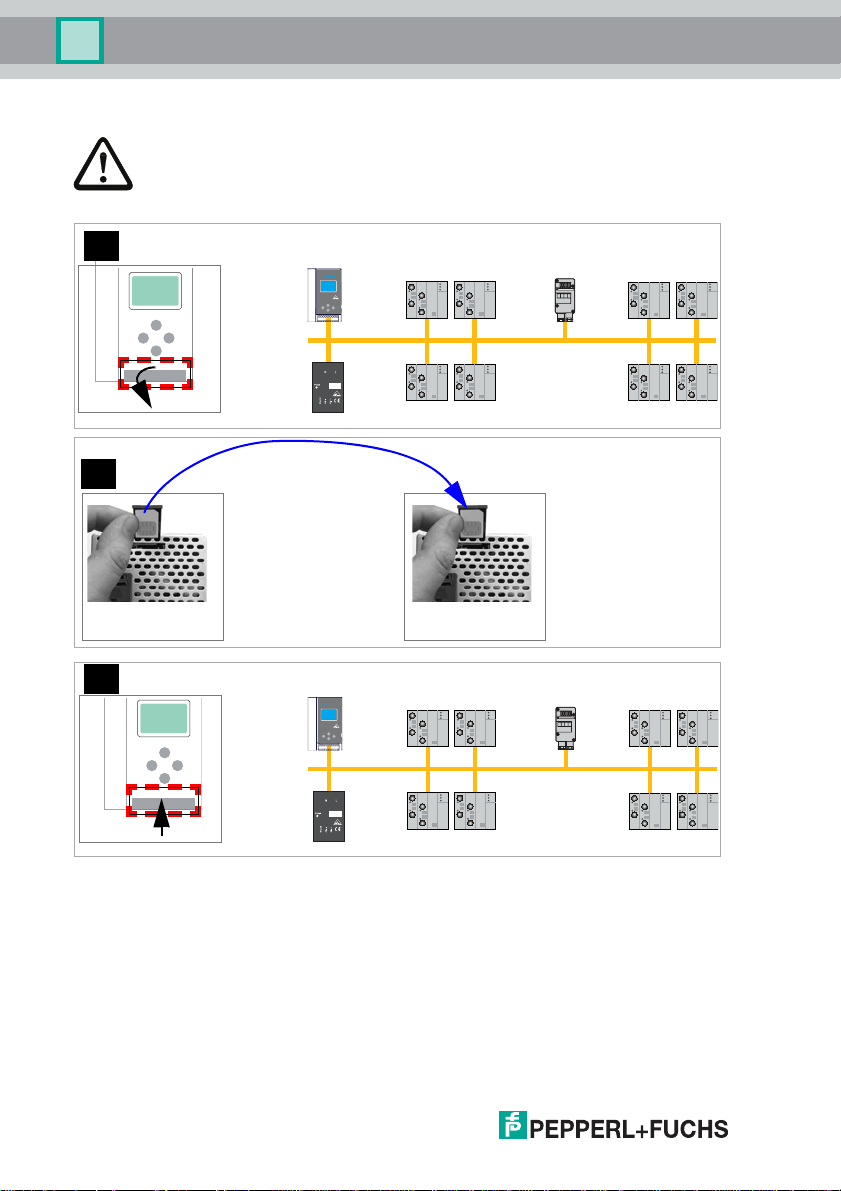

6.7.4 Local parameter setting of AS-i/Gateways

Geräte+Chipdaten ungleich

(Werkskonfiguration geändert)

/Device+card data not equal

(Factory configuartion changed)

Fehlermeldung:

/Error message/

Geräte+Chipdaten gleich

/Device data+card data equal/

Karte leer + formatiert

/Card empty + formatted/

CHIPCARD AND

DATA

DIFFERENT

CARD->MASTER

MASTER->CARD

CONTINUE

Keine Meldung

/No message/

CHIPCARD FOUND

DATA WILL

BE SYNCHRONIZED

Daten werden synchronisiert:

/Data being synchronized/

MASTER->KARTE

Copy data CARD->MASTER

or MASTER->CARD

Daten kopieren

KARTE->MASTER oder

Keine Aktion erforderlich

/No action required/

Keine Aktion erforderlich

/No action required/

Copier données Carte->Maître ou

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

Maître-Carte

Copiare dati Chipcard->Master o

copiare dati Master->Chipcard

Copiar dates Chip->Maestro o

Maestro ->Chip

konfiguration)

DATA FROM

(Werks

/Data compatible (factory

configuration)/

Daten kompatibel

Daten nicht kompatibel

/Data not compatible/

Karte nicht formatiert

/Card not formatted/

26.9.2013

CHIPCARD TAKEN

Daten werden übernommen:

/Data being acepted/

CHIPCARD NOT

COMPATIBLE

Fehlermeldung:

/Error message/

NEW CHIPCARD

WILL BE FORMATTED

DATA WILL BE

/Formatting card /

SYNCHRONIZED

Karte wird formatiert:

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

Karte löschen

/Clear the card/

/Supprimer carte/

/Cancellare chipcard/

/Borrar chip/

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

23

Page 24

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

7. Electrical connection

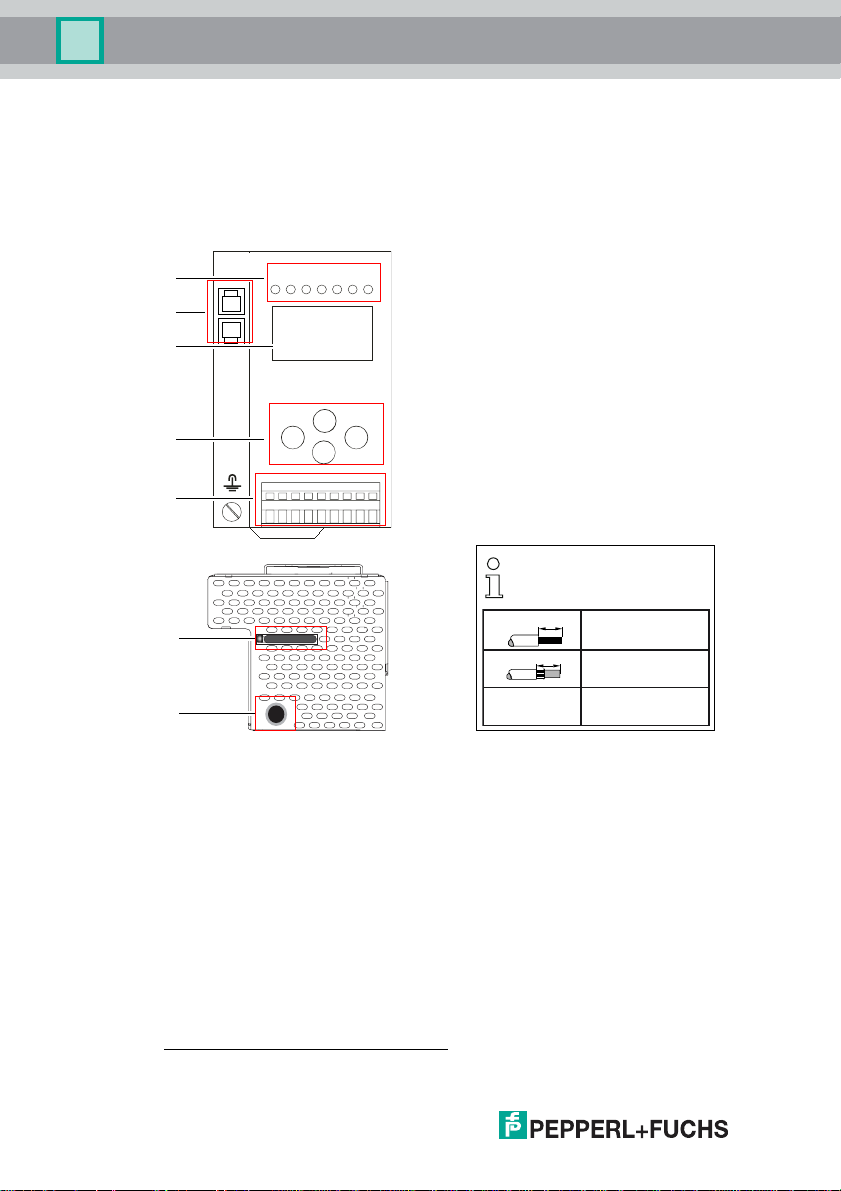

7.1 Overview of terminals, indicators and operating elements

7.1.1 VBG-ENX-K20-D, VBG-ENX-K20-DMD, VBG-ENX-K20-DMD-EV

[1]

[2]

[3]

[4]

[5]

-

+-+

-

+

[6]

[7]

Legend:

[1] LEDs

[2] Ethernet interface

[3] LC display

[4] Buttons

[5] Terminals: Supply voltage and AS-i circuit

[6] Chip card

[7] RS232 diagnostics port

1. Only together with AS-i Control Tools

1

10

0,2 ... 2,5 mm

10

0,2 ... 2,5 mm

AWG 24 ... 12

2

2

26.9.2013

24

Page 25

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

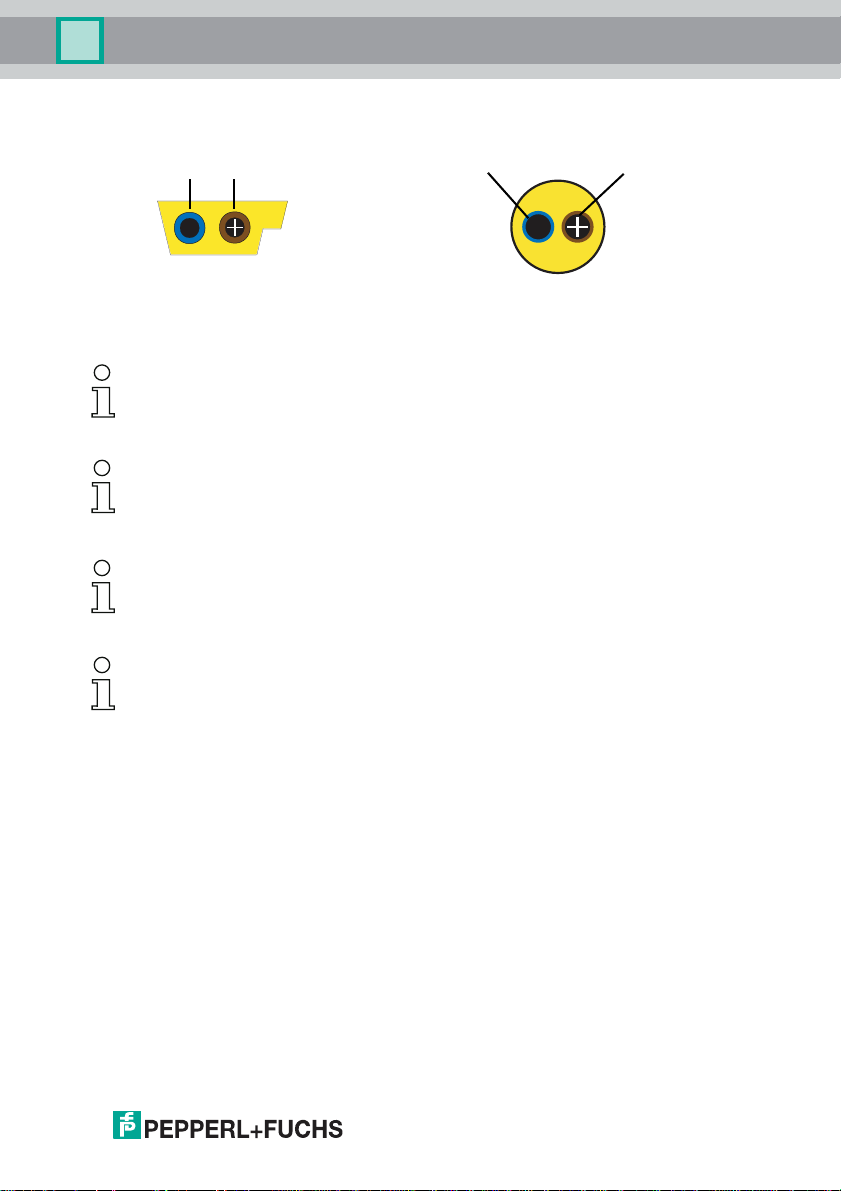

7.2 AS-i bus connection

Blue

AS-i-

Brown

AS-i+

Blue

AS-i-

Brown

AS-i+

Yellow ASi ribbon cable

2-conductor AS-i round cable

(Recommended: flexible power cable

H05VV-F2x1,5 per DIN VDE 0281)

Information!

Electrical work is to be performed only by electrical technicians.

7.3 Information about the device types

Information!

A listing of the individual device s and their features can be found in section <Produ ct

information>.

7.4 AS-i and power supply terminal assignments

Information!

The cable indicated by grey must not have slaves or repeaters connected to it.

The yellow cable must not have AS-i po wer supp liers or additional masters co nnecte d

to it.

Information!

The function ground can be connected either to the grounding screw or to the terminal.

The function ground shoul d be made with as s hort a cable a s pos sible to e nsure g ood

EMC characteristics.

Therefore function grounding using the grounding screw is preferred.

26.9.2013

25

Page 26

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

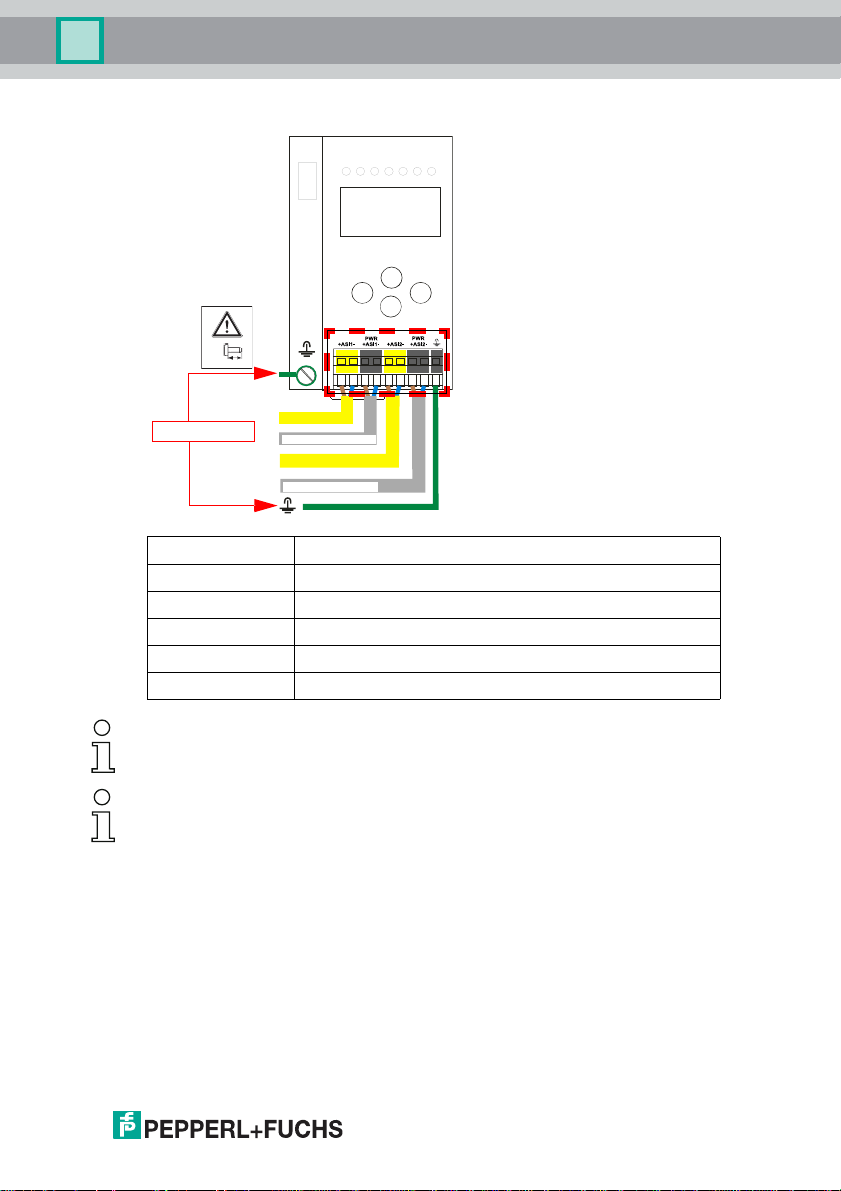

7.4.1 Electrical connection VBG-ENX-K20-D

ASI

+ASI-+ASI

-

-

+PWR

M4

5 mm max!

NC NC

-

-

+-+

+

Function ground

+ASI –

+ASI –

ASI +PWR– (max. 8A)

Terminal Signal / Description

+AS-i–

ASI +PWR–

FE

Connection to AS-i Circuit

Supply voltage for AS-i Circuit (max. 8 A)

Function ground

Information!

For additional information, plea se refer to the sect ion <AS -i and powe r supply t ermin al

assignments>.

26

26.9.2013

Page 27

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

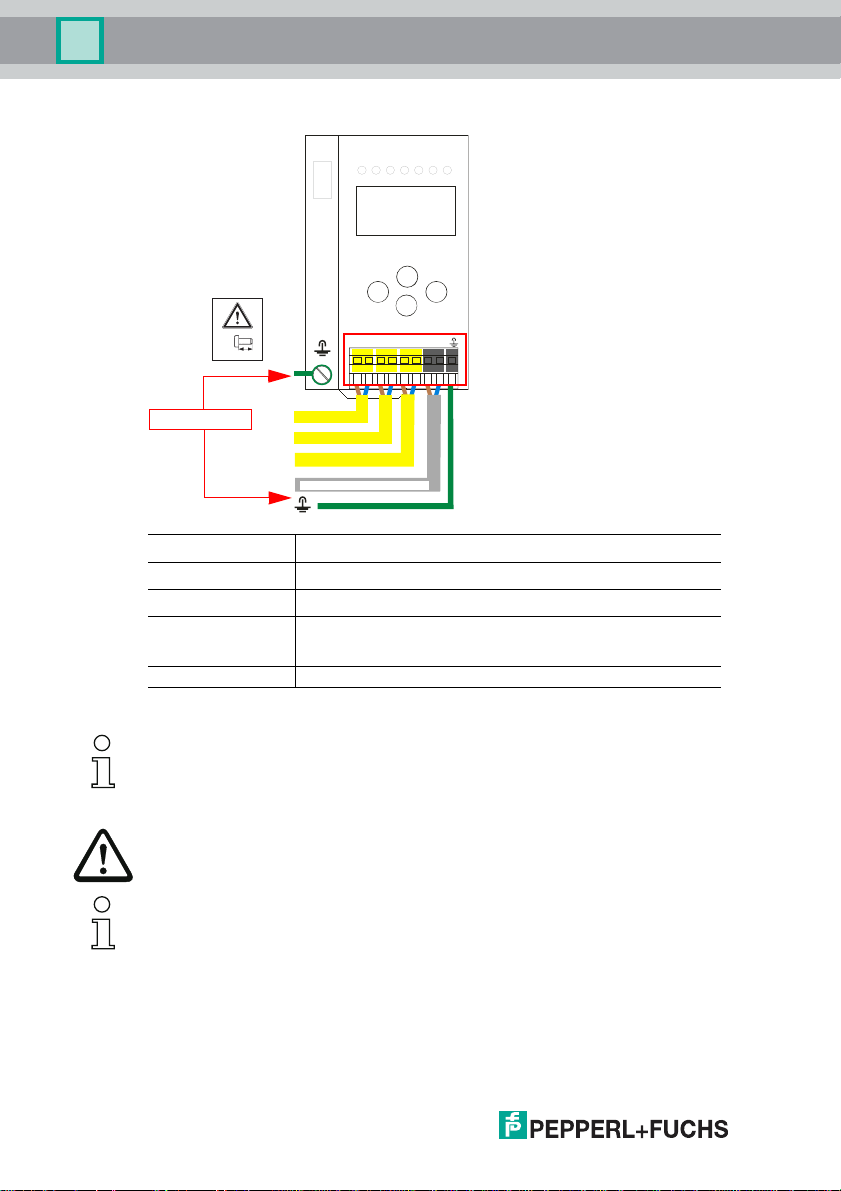

7.4.2 Electrical connection VBG-ENX-K20-DMD

M4

5 mm max!

-

-

+-+

+

Function ground

+ASI 1–

ASI 1 +PWR– (max. 8A)

+ASI 2–

+

ASI 2 +PWR– (max. 8A)

Terminal Signal / Description

+ASI 1–

+ASI 2–

ASI 1 +PWR–

ASI 2 +PWR–

FE

Connection to AS-i circuit1

Connection to AS-i circuit2

Supply voltage for AS-i circui t 1 (max. 8 A)

Supply voltage for AS-i circui t 2 (max. 8 A)

Function ground

Information!

AS-i circuits 1 and 2 are powered by separate power supplies.

Information!

For additional information, plea se refer to the sect ion <AS -i and powe r supply t ermin al

assignments>.

26.9.2013

27

Page 28

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

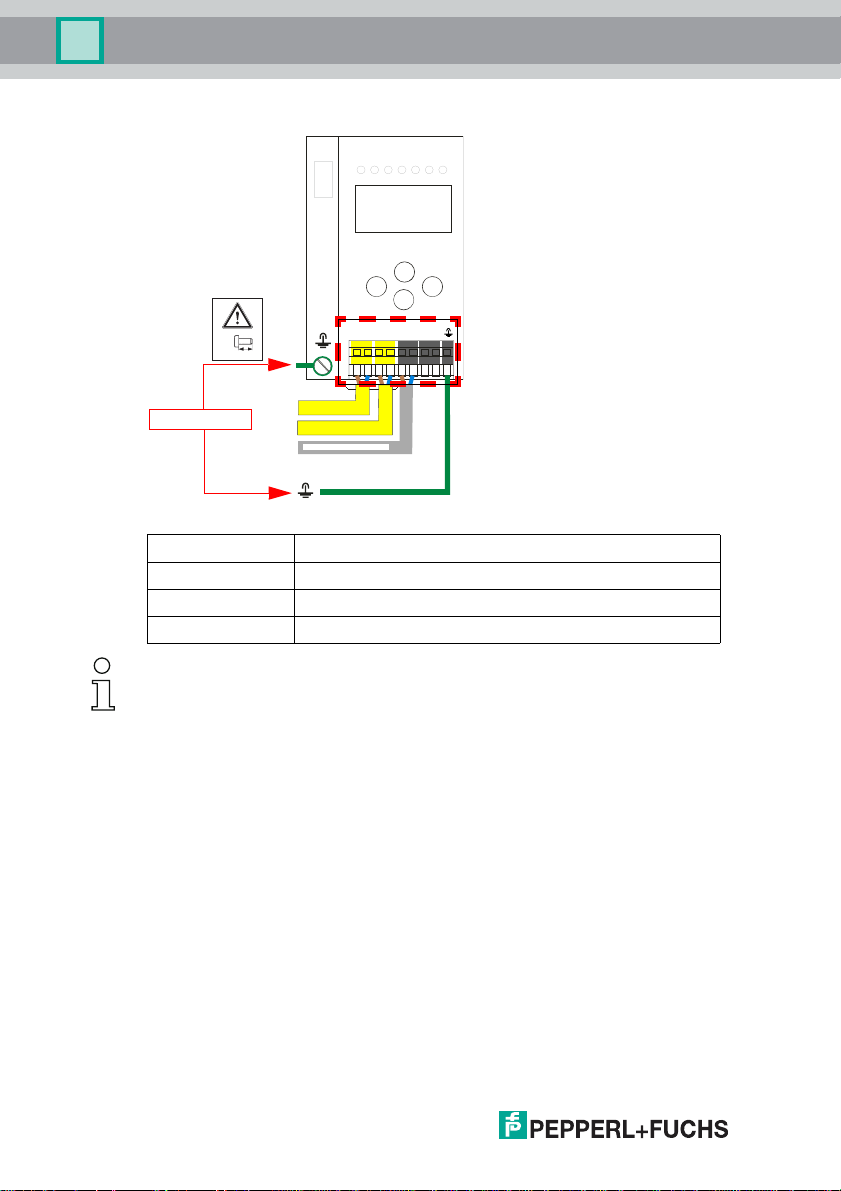

7.4.3 Electrical connection VBG-ENX-K20-DMD-EV

M4

5 mm max!

Function ground

+ASI1- +ASI1- +ASI2-

+ASI 1–

+ASI

1–

2–

+ASI

+

ASI +PWR– (max. 4A) / 24V, 0V

+ASI PWR 24V 0V

-

-

-

+

+-+

+

Terminal Signal / Description

+ASI 1–

+ASI 2–

ASI +PWR– /

24 V, 0 V

Connection to AS-i circuit1

Connection to AS-i circuit2

Supply voltage for AS-i circuits (max. 4 A) /

AS-i Power241 supply optional

FE Function ground

1. The gateway is AS-i Power24V capable and can be operated directly on a 24V (PELV) power supply.

28

Information!

AS-i Circuit 1 and 2 are both powered from a

Bihl+Wiedemann GmbH power sup-

ply!

No other power supplies are approved!

Attention!

Earth fault detector sensor without function when using AS-i Power24!

Information!

For additional information, please refer to the sections: <AS-i and power supply terminal assignments> and <AS-i Power24V capable>.

26.9.2013

Page 29

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

7.5 Ethernet interface

A

B

The ethernet interface consists of two RJ-45 sockets. It is placed on the left housing side (see section <Overview of terminals, indicators and operating elements>). The ethernet interface is driven according to the IEEE 802.3

7.6 Dia gno stics interface

The service and diagnostics interface (in conjunction with AS-i Control Tools

software) is used for communication between the PC and the unit.

7.6.1 Diagnostics port RS 232

The service and diagnostics interface is configured as a mini DIN-6 female and it

is placed at the top of the housing (see section <Overview of terminals, indicators

and operating elements>).

7.7 Chip card

The configuration is stored in a fixed installed EEPROM and can be overwritten

by the chip card. The chip card does not have to be inserted in operation.

Warning!

Power must always be turned off when removing or inserting the chip card!

26.9.2013

29

Page 30

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

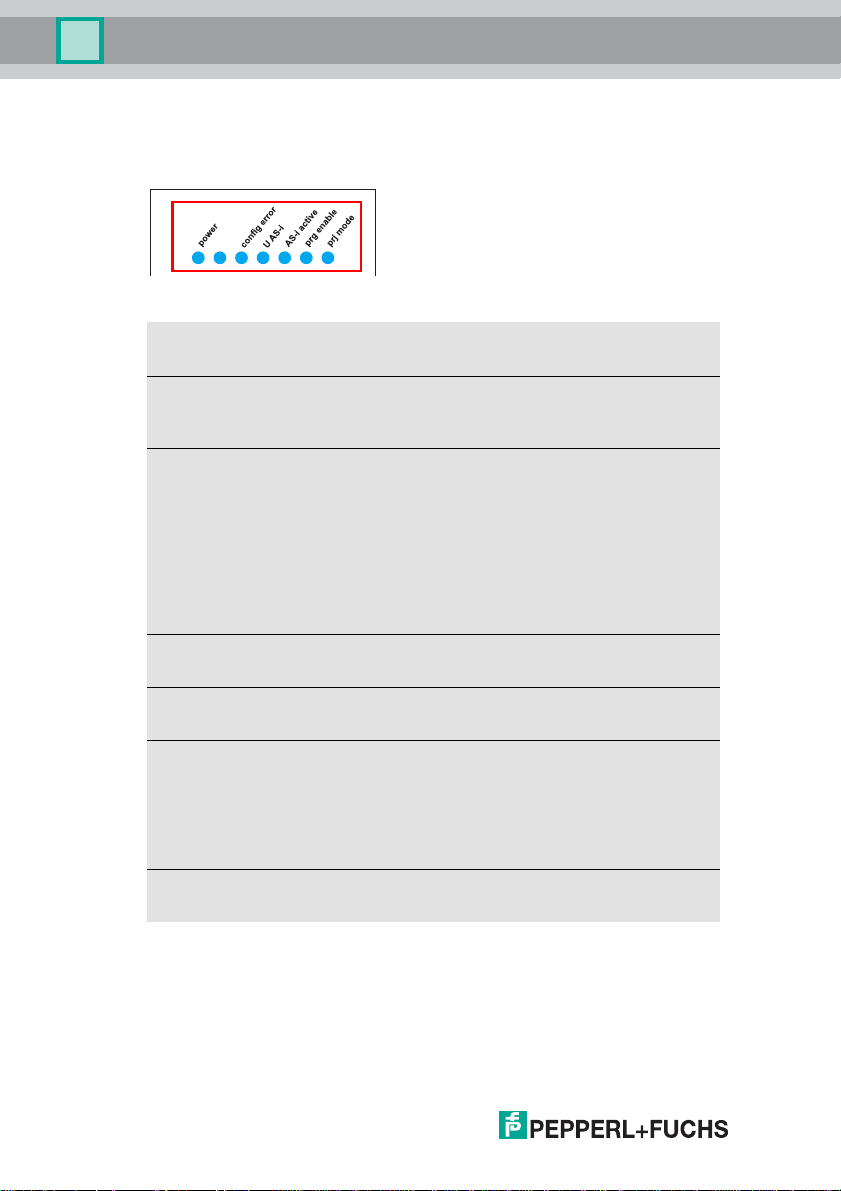

7.8 Indicators and operating elements

7.8.1 LED indicators – master

net

The LED’s on the front panel of the device indicate:

Power

The master is receiving sufficient power.

net (the bi-color LED indicates the state of the ethernet port)

LED red: no valid ENIP- or CIP connection.

LED green: at least one ENIP- or CIP connection present

config error

Configuration error.

At least one configured slave is missing, or at least one detected slave is not configured, or for at least one configured and detected slave the actual configuration data

does not match the nominal configuration data, or the master is in the startup process.

This LED flashes if a peripheral fault has been detected for at least one AS-i slave

on the AS-i network. If there a re con figurat ion erro rs as w ell as pe ripher y faults , only

the configuration error is displayed.

U AS-i

The AS-i network is sufficiently powered.

AS-i active

Normal operation is active

prg enable

Automatic single node replacem ent is enabled.

Exactly one slave is missing in the protected operating mode. The slave can be

replaced by another slave of the same type with address zero. The master automatically addresses the new slave to the faulty address and thus corrects the configuration error

prj mode

The AS-i master is in configuration mode.

30

26.9.2013

Page 31

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Electrical connection

7.8.2 Buttons

The buttons are used for the following:

Mode/⇑

Switching between configuration mode and protected operating mode, and saving

the current AS-i configurati on as the nominal configuration.

Set/⇓

Selecting the address of and assigning an address to a slave.

OK, ESC

Changing to the advanced display mo de.

For additional information see section <Operation in advanced display mode>.

26.9.2013

31

Page 32

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Operation in advanced display mode

8. Operation in advanced display mode

Information!

You will find a description of the display menu in the separate document

"Display_Menue".

32

26.9.2013

Page 33

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

9. Advanced Diagnostics for AS-i Masters

The advanced AS-i diagnostics is intended to localize occasionally occurring configuration errors and to determine the quality of data transmission on AS-i without

using additional diagnostics tools.

AS-i Control Tools, a MS-Windows software designed to simplify AS-i installation

and used to program AS-i Control, enables operation of the advanced diagnostics

functions (LCS, error counters, and LOS).

9.1 List of corrupted AS-i Slaves (LCS)

The LCS contains the information from the Delta list. In addition to the list of configured slaves (LPS), the list of detected slaves (LDS), and the list of activated

slaves (LAS), the AS-i master creates a fourth list, the list of corrupted slaves

(LCS) containing advanced diagnostics data used to diagnose the causes for intermittently occurring configuration errors on AS-i. This list contains entries for all

AS-i slaves that were responsible for at least one intermittent configuration error

since the list was last read or since the AS-i master was turned on. Furthermore,

intermittent AS-i power failures are listed in the LCS at the position of AS-i slave

with address 0.

Information!

Whenever the LCS is read it is deleted from memory.

Information!

The last intermittent configuration error can also be displaye d on the AS-i master:

Pressing the "Set" button on the AS-i master initiates the display of the AS-i slave

responsible for the last i ntermi ttent con figur ation err or. If a i ntermi ttent AS -i power failure occurred, the display show s 39 after pressing the "Set" button.

This function is only available if the device is in normal ope rating mod e of the prote cted

mode (display empty) or in the off- line phase (Display: "40").

9.2 Protocol analysis: Counters for corrupted data telegrams

The AS-i master with advanced diagnostics provides a counter for telegram repetitions for each AS-i slave. The counter counts up every time a corrupted data telegram has been found, making it possible to determine the quality of the transmission if only a few telegrams are corrupt and the AS-i slave never caused a

configuration error.

Information!

The counter values are read vi a the host inter face and will be de leted after th ey were

read.

The highest possible counter v alue is 254. 255 indicates a counter overflow.

Displaying the protocol analysis is possible through the AS-i Control Tools software by using the command "Master | AS-i Diagnostics".

26.9.2013

33

Page 34

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

9.3 Offline Phase for Configuration Errors

The AS-i masters with advanced diagnostics offer the possibility to set themselves into the offline phase when a configuration error occurs and thus are able

to transition the AS-i network into a safe operational state. This ensures a quick

reaction to a configuration error and the host can be relieved from this task. If any

problems occur on the AS-i network, the AS-i masters can independently switch

the AS-interface into a safe state.

There are two different ways to parameterize the AS-i master for this feature:

• Any configuration error occurring on AS-i switches the master from regular

operation in protected mode into the offline phase.

• o . A list with the addresses of slaves that can potential initiate the off-line

phase is defined (list of offline slaves LOS).

The user can decide how the system should react to a configuration error on

AS-i. Thus, the AS-i master can be set to the offline phase for critical AS-i slaves,

whereas for less critical slaves only the error message is sent to the host, but ASi is still running.

Like the advanced diagnostics, the parameterization "offline phase on configuration error" is also supported by "AS-i-Control-Tools"

(Command | Characteristics | Offline because of configuration error).

There are two options to reset the error message "OFFLINE BY LOS:

1. Deleting the complete LOS list on the affected AS-i network ("CLEAR ALL").

2. Power reset on the affected AS-i network.

Attention!

If a power reset occurs on the AS-i network 1 the complete double gateway will

be shut down.

9.4 Functions of the AS-i Fault Detector

9.4.1 Duplicate address detection

If two slaves on an AS-i network have the same address, a duplicate address exists. Since the master cannot communicate individually with these slaves any

longer, this is considered an error. Because the two slave replies interfere, it is impossible for the master to recognize the slave responses. This results in extremely unstable network behavior.

The duplicate address detection function is used to safely recognize a duplicate

address and to display it on the screen and in AS-i Control Tools.

A duplicate address causes a configuration error and is displayed on the screen.

Information!

Duplicate addresses can be recogn ize d onl y on an AS -i seg men t dir ec tly c onn ec ted t o

the master.

34

26.9.2013

Page 35

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

9.4.2 Earth/Ground Fault Detector

An Earth/Ground Fault exists when the voltage

=0,5 U

U

GND

10% U

This error substantially limits the noise immunity of the AS-i communication.

Ground faults are indicated on the master´s display as well as in AS-i Control

Tools.

Information!

To recognize ground faults the master must be grounded with its machine ground connection.

Information!

A ground fault in one of the two networks of a double master in a version 1 power supply for two AS-i networks causes a ground fault in the other network as well because of

the the existing galvanic connection.

9.4.3 Noise Detector

The noise detector detects AC voltages on AS-i, that are not initiated by an AS-i

master or AS-i slaves. These interference voltages can cause telegram disturbances.

A frequent cause are insufficiently shielded frequency inverters or improperly

routed cables.

Noises is indicated on the master´s display as well as in AS-i Control Tools.

.) is outside of the following range:

AS-i

≤ U

GND

≤ 90% U

AS-i

AS-i

U

(Nominal value of

GND

9.4.4 Over-voltage Detector

Over-voltages are present if the conductors of an AS-i network that normally are

routed electrically symmetrical with respect to machine ground, are strongly electrically raised. A cause can for example be startup procedures of large consumers.

However, over-voltages do generally not interfere with the AS-i communication,

but can under certain circumstances cause incorrect sensor signals.

Over-voltages are indicated on the master´s display as well as in the AS-i Control

Tools.

26.9.2013

35

Page 36

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

9.5 Functions of the new generation of AS-i Gateways

The new generation scores with further optimized diagnostics, several additional

functions and even greater operating convenience.

Information!

A listing of the individual devices and their features can be found in section

Generation of AS-i Gateways with ethernet diagnostics interface>.

9.5.1 C-programmable Gateways

Main menu || SETUP || AS-I CONTROL || CONTROL FLAGS ||

The devices programmed in C are able themselves to take over a great number of

control tasks. In smaller systems the user will even be able to do without a PLC

altogether: if desired the C program can function as a full mini-PLC. In more complex applications the C-programmable Gateways make the work of the PLC easier - for example by pre-processing special functions.

Control Info

Control Run

Control Flags

Control Flags

0:00 00 00 00

4:00 00 00 00

8:00 00 00 00

<New

"

9.5.2 Interchangeable memory card

Main menu || SETUP || CHIPCARD || AS-I CHIPCARD ||

Interchangeable memory card: redundant memory for C program and device configuration.

Chipcard

AS-i Chipcard

Format Chipcard

9.5.3 Earth fault monitor

Main menu || DIAGNOSE || ASI WATCHDOG ||

The new earth fault monitor allows the service technician to detect whether an

earth fault has occurred directly on AS-i

1.

Earth fault

36

26.9.2013

Page 37

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

or on a sensor line.

1.

Earth fault sen.

The menu EFLT Ratio shows the asymmetry of the AS-i network, referenced to

ground (see sketch).

100%

0%

100%

%

%

AS-i +

AS-i -

EFLT Ratio: #

AS-i+ 2%

AS-i DC Voltage: 1

31,3V

$

EFLT Ratio: #

AS-i+ 100%

AS-i DC Voltage: 2

31,5V

9.5.4 Current can be read directly on the unit

Now the devices display both the maximum current and the current actually

present in the respective AS-i circuit. Heavy consumers or a strong overload in an

AS-i circuit are then easy to detect. Plus you can set the maximum cu rrent in the

AS-i circuit on these devices. This ensures line protection even when using large

24V power supplies.

AS-i power

Reset

Maximal: 2

1,3A

26.9.2013

"

37

Page 38

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

Maximal: #

1,3A

current: 2

0,3A "

Current: #

0,3A

Current limiting 2

3,2A "

9.5.5 Self-resetting fuses

Main menu || SETUP || CURRENT LIMIT ||

Thanks to self-resetting fuses in the "1 Gateway, 1 power supply for 2 AS-i circuits" Gateway version, when there is a short circuit in one of the two AS-i circuits

the other circuit and the Gateway remain operational - the host controller keeps

receiving diagnostic information from AS-i, which also provides meaningful assistance towards rapid troubleshooting.

The fuse resets itself periodically to check if the error is solved. The measured

current value is available as diagnostic information at the field on the display and

at the control level.

9.5.6 AS-i Power24V capable

Main menu || SETUP || ASI POWER ||

Gateways for AS-i Power24V have been developed especially for use in small

systems. They don‘t need any special AS-i power supply. With a standard 24V

power supply a 50 m line lenght and with an AS-i power supply min. 100 m line

lenght can be realised.

38

Current limiting

3,2A

2

AS-i Power

24V geerdet

change

26.9.2013

Page 39

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

Advanced Diagnostics for AS-i Masters

AS-i Power

AS-i PWR Supply

change

9.5.7 Ethernet diagnostics interface with web server

These devices allow diagnostics for both the Gateway and the AS-i networks (including Safety technology) over Ethernet without additional software. AS-i network can be thus a part of a remote maintenance concept. Morover the configuration file are stored on the web server and so they are always within reach.

9.5.8 Transitionless operating mode changes

Main menu || SETUP || MODE CHANGE ||

These devices are able to change the operating mode from projecting mod e to

the protected operating mode without having to first go to the "offline phase".

This means the Slave outputs are not cleared and the safe Slaves not turned off.

Activation and deactivation is set using the Ethernet start parameterization.

This function must be explicitly activated; the default setting is “Deactivated.”

The setting for activated and deactivated is saved, which means that it remains

set after a "power cycle".

Mode Change

Offline Phase

yes

change

26.9.2013

39

Page 40

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10. EtherNet/IP interface

Objekt modelling

The attributes of bus participants are mapped into objects in the CIP family (DeviceNet, ControlNet and EtherNet/IP) bus systems.

In addition to for all EtherNet/IP devices common objects, there are other objects

in the AS-i gateways to access the data of the AS-i network:

• Identity

• Assembly

• AS-i master

• AS-i slave

• I/O data

• Advanced diagnostics

• Short command interface

• Long command interface

• Safety Control Status (external)

Class code Object name Number of instances

0x01 Identity 1

0x02 Message router 1

0x04 Assembly 24 (single master)

0x06 Connection manager 1

0x47 Device level ring 1

0x48 Quality of service 1

0x64 AS-i master 1 for each AS-i circuit

0x65 AS-i slave 64 for each AS-i circuit

0x66 E/A data 1 for each AS-i circuit

0x67 Advanced diagnos ics 1 for each AS-i circuit

0x68 Short command interface 1

0x69 Long command interface 1

0x6B Safety Control Status external Mo nitor 1 for each AS-i circuit

86 (double master)

Tab. 10-2.

40

26.9.2013

Page 41

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.1 Identity object

class code: 1 (0x01)

number of instanzes: 1

instance attributes

Attribute ID Access Rule Name Value

1 get vendor 5

2 get device type 12

3 get product code e. g.: "2386" (double master)

4 get revision 1.1

5 get status see overwiev listed below

6 get serial number unique number, 32-bit

7 get product name e. g.: "VBG-ENX-K20-D"

Common services

Service Code Class Instance Service name

0x05 no yes code 1

(class + instance)

0x10 yes yes get attributes all

0x0E yes yes get attributes all

e. g.: "2385" (single master)

Tab. 10-3.

Tab. 10-4.

26.9.2013

41

Page 42

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.2 Device Level Ring Object

Class Code: 71 (0x47)

number of instanzes: 1

instance attributes

Attribute ID Access Rule Name Value

1 (0x01) get network topo-

logy

2 (0x02) get network status 0 (normal), 1 (ring fault)

10 (0x0E) get active supervi-

sor address

12 (0x0C) get capability flags 1 (announce-based ring node)

Common Services

Service Code Class Instance Service Name

1 (0x01) yes yes get attributes all

14 (0x0E) yes yes get attribute single

0 (linear), 1 (ring)

byte 0-3: ip-adress,

byte 4-9: mac-adress

Tab. 10-5.

Tab. 10-6.

42

26.9.2013

Page 43

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.3 Quality of Service Object

Class Code: 72 (0x48)

number of instanzes: 1

instance attributes

Attribute ID Access Rule Name Value

1 (0x01) get/set 802.1q tag

enable

4 (0x04) get/set dscp urgent dscp after rfc 3168 for cip class 0/1

5 (0x05) get/set dscp scheduled dscp after rfc 3168 for cip class 0/1

6 (0x06) get/set dscp high dscp after rfc 3168 for cip class 0/1

7 (0x07) get/set dscp low dscp after rfc 3168 for cip class 0/1

8 (0x08) get/set dscp explicit dscp after rfc 3168 for cip class 3/

Common Services

0 (disabled), 1 (enabled)

urgent (default 55)

scheduled (default 47)

high (default 43)

low (default 31)

ucmm (default 27)

Tab. 10-7.

Service Code Class Instance Service Name

14 (0x0E) no yes get attributes single

16 (0x10) no yes get attribute single

Tab. 10-8.

Information!

The new settings take effect only after a device restart.

Information!

If “802.1Q Tag Enable“ is tu rn ed o n, the VL AN ID s et i n the de vi ce me nu “E th erne t“ - >

“EtherNet/IP“ -> “VLAN ID“ is used.

Information!

The integrated switch uses four internal priority queues.

Information!

The VLAN ID is only used if in the EtherNet/IP Quality of Service Object (0x48)

Attribute 1 (802.1Q Tag Enable) is se t to 1 (= ON), so th at Et hernet frames ar e sent in

accordance with IEEE 802.1Q.

26.9.2013

43

Page 44

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

Mapping of the SDCP and 802.1D priorities to the queues is as follows:

Switch queue DSCP 802.1D priority

4 (highest priority) 59 7

3 46, DSCP Urgent, DSCP Scheduled,

DSCP High

2 24, DSCP Low, DSCP Explicit 2,3

1 (lowest priority) other values 0,1

4, 5, 6

Tab. 10-9.

44

26.9.2013

Page 45

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.4 Assembly Object

class code 4 (0x04)

number of instances: 86

The Assembly Object bandles data from the application objects.

The Assembly Object Instances consist of (in case of a double master):

• A-slaves and/or single slaves from circuit 1

• single, A- and B-slaves (all slaves) from circuit 1

• A-slaves and/or single slaves from both circuits

• single, A- and B-slaves (all slaves) from both circuits

• No 16-bit data

• No command interface

• Short command interface

• Long command interface

• 16-bit data of slaves 29…31 from circuit 1 (or from both circuits) in the following format:

16-bit data of slaves 29 … 31

byte data item (attribute ID=3)

n Slave 31 ch1 high byte

n+1 Slave 31 ch1 low byte

n+2 Slave 31 ch2 high byte

n+3 Slave 31 ch2 low byte

n+4 Slave 31 ch3 high byte

n+5 Slave 31 ch3 low byte

n+6 Slave 31 ch4 high byte

n+7 Slave 31 ch4 low byte

n+8 Slave 30 ch1 high byte

n+9 Slave 30 ch1 low byte

n+10 Slave 30 ch2 high byte

n+11 Slave 30 ch2 low byte

n+12 Slave 30 ch3 high byte

n+13 Slave 30 ch3 low byte

n+14 Slave 30 ch4 high byte

n+15 Slave 30 ch4 low byte

n+16 Slave 29 ch1 high byte

n+17 Slave 29 ch1 low byte

n+18 Slave 29 ch2 high byte

n+19 Slave 29 ch2 low byte

26.9.2013

Tab. 10-10.

45

Page 46

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

16-bit data of slaves 29 … 31

n+20 Slave 29 ch3 high byte

n+21 Slave 29 ch3 low byte

n+22 Slave 29 ch4 high byte

n+23 Slave 29 ch4 low byte

Instances 100 (0x64)…135 (0x87) can only be read, while instances 136

(0x88) …171 (0xAB) can be read and written.

Information!

The are only instances 100 (0x64) … 105 (0x69) and 109 (0x6D) … 114 (0x72) in case

of a single master.

Tab. 10-10.

46

26.9.2013

Page 47

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

Assembly Instance Data Item

input output size

100 (0x64) 136 (0x88) 16

101 (0x65) 137 (0x89) 28 short

102 (0x66) 138 (0x8A) 54 long

103 (0x67) 139 (0x8B) 40

104 (0x68) 140 (0x8C) 52 short

105 (0x69) 141 (0x8D) 78 long

106 (0x6A) 142 (0x8E) 64

107 (0x6B) 143 (0x8F) 76 short

108 (0x6C) 144 (0x90) 102 long

109 (0x6D) 145 (0x91) 32

110 (0x6E) 146 (0x92) 44 short

111 (0x6F) 147 (0x 93) 70 long

112 (0x70) 148 (0x94) 56

113 (0x71) 149 (0x95) 68 short

114 (0x72) 150 (0x96) 94 long

115 (0x73) 151 (0x97) 80

116 (0x74) 152 (0x98) 92 short

117 (0x75) 153 (0x99) 118 long

118 (0x76) 154 (0x9A) 32

119 (0x77) 155 (0x9B) 44 short

120 (0x78) 156 (0x9C) 70 long

121 (0x79) 157 (0x9D) 56

122 (0x7A) 158 (0x9E) 68 short

123 (0x7B) 159 (0x9F) 94 long

124 (0x7C) 160 (0xA0) 80

125 (0x7D) 161 (0xA1) 92 short

126 (0x7E) 162 (0xA2) 118 long

127 (0x7F) 163 (0xA3) 64

128 (0x80) 164 (0xA4) 76 short

129 (0x81) 165 (0xA5) 102 long

130 (0x82) 166 (0xA6) 88

131 (0x83) 167 (0xA7) 100 short

132 (0x84) 168 (0xA8) 126 long

133 (0x85) 169 (0xA9) 112

134 (0x86) 170 (0xAA) 124 short

135 (0x87) 171 (0xAB) 150 long

digital analog command inter-

(byte)

AS-i circuit 1,

single- and A-slaves

AS-i circuit 1,

all slaves

AS-i circuit 1+2,

single- and A-slaves

AS-i circuit 1+2,

all slaves

AS-i circuit 1,

analog slaves 29 .. 31

AS-i circuit 1+2,

analog slaves 29 .. 31

AS-i circuit 1,

analog slaves 29 .. 31

AS-i circuit 1+2,

analog slaves 29 .. 31

AS-i circuit 1,

analog slaves 29 .. 31

AS-i circuit 1+2,

analog slaves 29 .. 31

AS-i circuit 1,

analog slaves 29 .. 31

AS-i circuit 1+2,

analog slaves 29 .. 31

face

Tab. 10-11.

26.9.2013

47

Page 48

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.5 AS-i Master Object

class code: 100 (0x64)

1 instance for each AS-i circuit

attribute

ID

100 (0x64) get ec-flags UINT (16-bit)

101 (0x65) get/set hi-flags USINT

102 (0x66) get/set operational mode BOOL

103 (0x67) get LDS (list of detected slaves) ULINT

104 (0x68) get/set LPS (list of projected slaves) ULINT

105 (0x69) get LAS (list of activated slaves) ULINT

106 (0x6A) get LPF (list of peripheral faults) ULINT

107 (0x6B) get/set Store_Actual_Configuration BOOL

108 (0x6C) get/set Store_Actual_Parameters BOOL

109 (0x6D) get/set Change_Slave_Adress UINT

110 (0x6E) get/set Lock push-buttons BOOL

EC-flags (16-bit)

2152142132122112102928272625242322212

DA NSE OV EF – – – Pok OR APF NA CA AAv AAs S0 Cok

access rule name devicenet data

type

default data

value

Tab. 10-12.

Tab. 10-13.

DA (double_address): AS-i duplicate address detection

0: no duplicate address

1: duplicate address

NSE (noise): AS-i noise detection

0: no noise

1: noise fault

OV (overvoltage): AS-i overvoltage detection

0: no overvoltage

1: overvoltage fault

EF (earth_fault): AS-i earth fault detection

0: no earth fault

1: earth fault

PoK (periphery_ok): Periphery is OK

0: Periphery is OK

1: Periphery is not OK

OR (offline_ready: The off-line phase is active

APF (ASi-power_fail): An AS-i power fail is occured

NA (normal_operation_active) : The normal operation mode is active

0: normal operation is active

1: normal operation is not active

0

26.9.2013

48

Page 49

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

CA (configuration_active): The configuration -mode is active

AAv (Auto_Address_Available): Automatic programming is possible

0: Auto-address is possible

1: Auto-address is not possible

AAs (Auto_Address_Assign): Automatic programming i s allowed

S0 (LDS.0): There is an AS-i slave with address ’0’

Cok (config_ok): Configuration error:

0: no error

1: error

Hi-flags (8-bit)

2

1

2

AAe OL DX

AAe: Auto_Address_Enable

OL: Off-line

DX: Data_Exchange_Active

Operational mode (8-bit):

1: configuration mode

0: protected mode

0

2

2

Tab. 10-14.

LDS, LAS, LPS, LPF (64-bit)

7

6

5

4

3

2

1

Byte

2

2

2

2

2

2

2

0

2

0 7A6A5A4A3A2A1A0A

……

7 31B 30B 29B 28B 27B 26B 25B 24B

Tab. 10-15.

LDS: list of dete ct ed slaves

LAS: list of activated slaves

LPS: list of activated slaves

LPF: list of peri ph eral faults

26.9.2013

49

Page 50

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

Store actual parameter/store actual configuration/lock push-buttons

True: proceed the action

Change slave address (16-bit)

7

6

5

4

3

2

Byte

2

2

2

2

2

0 – B source address

1 – B target address

Meaning of the bit B

B = 0: Single AS-i Slave or A-slave

B = 1: B-slave

1

2

2

2

0

Tab. 10-16.

50

26.9.2013

Page 51

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.6 AS-i slave Object

class code: 101 (0x65)

64 instances for each AS-i circuit, 1 for each AS-i slave

instance ID AS-i slave

1 (0x01) slave 0, circuit 1

2 (0x02) slave 1A, circuit 1

……

32 (0x20) slave 31A circuit 1

33 (0x21) empty, circuit 1

34 (0x22) slave 1B, circuit

……

64 (0x40) slave 31B, circuit 1

65 (0x41) slave 0, circuit 2

……

96 (0x60) slave 31A, circuit 2

97 (0x61) empty, circuit 2

……

98 (0x62) slave 1B, circuit 2

……

128 (0x80) slave 31B, circuit 2

Tab. 10-17.

attributeIDaccess

100 (0x64) get actual configuration UINT

101 (0x65) get/set permanent configuration UINT slave 0, 32: not read-/writea102 (0x66) get/set actual parameters USINT

103 (0x67) get/set permanent parameters USINT

104 (0x68) get/set xID1 USINT slave 0: writeable only,

actual configuration/permanent configuration (16-bit)

2152142132122112102928272625242322212

ID IO xID2 XID1

parameter xID1 (8-bit)

272625242322212

–data

26.9.2013

rule

name devicenet

data type

0

remark

ble

slave 0 - 32: readable

Tab. 10-18.

0

Tab. 10-19.

Tab. 10-20.

51

Page 52

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.7 I/O Data Object

class code: 102 (0x66)

Input and output data

1 instance for each AS-i circuit

Instance 1 equates to AS-i circuit 1

Instance 2 equates to AS-i circuit 2

attribute IDaccess rule name devicenet data typedefault data

100 get input data image, single and A-slaves ARRAY[16] of

101 get input data image, B-slaves ARRAY[16] of

102 get/set output data image single and A-slavesARRAY[16] of

103 get/set output data image, B-slaves ARRAY[16] of

104 get 16-bit input data slave 1 ARRAY[4] of INT

……… … …

134 get 16-bit input data slave 31 ARRAY[4] of INT

135 get/set 16-bit output data slave 1 ARRAY[4] of INT

……… … …

165 get/set 16-bit output data slave 31 ARRAY[4] of INT

value

USINT

USINT

USINT

USINT

Tab. 10-21.

52

26.9.2013

Page 53

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

Input and Output Data Image

Byte

7

2

F3 F2 F1 F0

0 flags slave 1/1A

1 slave 2/2A slave 3/3A

2 slave 4/4A slave 5/5A

3 slave 6/6A slave 7/7A

4 slave 8/8A slave 9/9A

5 slave 10/10A slave 11/11A

6 slave 12/12A slave 13/13A

7 slave 14/14A slave 15/15A

8 slave 16/16A slave 17/17A

9 slave 18/18A slave 19/19A

10 slave 20/20A slave 21/21A

11 slave 22/22A slave 23/23A

12 slave 24/24A slave 25/25A

13 slave 26/26A slave 27/27A

14 slave 28/28A slave 29/29A

15 slave 30/30A slave 31/31A

16 reserved slave 1B

17 slave 2B slave 3B

18 slave 4B slave 5B

19 slave 6B slave 7B

20 slave 8B slave 9B

21 slave 10B slave 11B

22 slave 12B slave 13B

23 slave 14B slave 15B

24 slave 16B slave 17B

25 slave 18B slave 19B

26 slave 20B slave 21B

27 slave 22B slave 23B

28 slave 24B slave 25B

29 slave 26B slave 27B

30 slave 28B slave 29B

31 slave 30B slave 31B

6

2

5

2

4

2

2

3

2

2

1

2

0

2

Tab. 10-22.

26.9.2013

53

Page 54

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

Flags

Input data Output data

F0 ConfigError Off-line

F1 APF LOS-master-bit

F2 PeripheryFault → ConfigurationMode

F3 ConfigurationActive → ProtectedMode

ConfigError: 0=ConfigOK 1=ConfigError

APF: 0=AS-i-Power OK 1=AS-i-Power Fail

PeripheryFault: 0=PeripheryOK 1=PeripheryFault

ConfigurationActive: 0=ProtectedOperationMode 1=ProjectingMode

Off-Line: 0=On-Line 1=Off-Line

LOS-master-bit 0=Off-Line by ConfigError

deactivated

16-bit data

Information!

A-slaves map the data on channels 1 and 2.

B-slaves map the data on channels 3 and 4.

1=Off-Line by ConfigError

activated.

Tab. 10-23.

54

In addition to the access via the command interfaces, the 16-bit data for or by the

slaves with 16-bit value can by exchanged cyclically (profile 7.3., S-7.4, S-6.0, S-

7.5, S-7.A.8, S-7.A.9, S-7.A.A). Competing writing access attemps on 16-bit output data will not be blocked by every other. If 16-bit output data for a particular

slave are being transmitted both cyclically and acyclically with the command interface, the acyclically transmitted values will be overwritten by the cyclically transmitted values.

Data of all channels of a slave can be transmitted in a reserved data area. Therefore accessing 16-bit data is as easy as accessing digital data.

16-bit value

Word 2152142132122112102928272625242322212

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

1 slave X, channel 1

2 slave X, channel 2

3 slave X, channel 3

4 slave X, channel 4

Tab. 10-24.

0

26.9.2013

Page 55

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.8 Advanced Diagnostics Object

class code: 103 (0x67)

1 instance for each AS-i circuit

Instance 1 equates to AS-i circuit 1

Instance 2 equates to AS-i circuit 2

attributeIDaccess

100 (0x64) Get/Set LOS (List of offline slaves) ULINT

101 (0x65) Get error counter A ARRAY[32] of USINT

102 (0x66) Get error counter B ARRAY[32] of USINT

rule

name devicenet

data type

Slave error counter:

single and A slaves

Index e rro r counter

1 slave 1/1A

2 slave 2/2A

3 slave 3/3A

……

31 slave 31/31A

B slaves

index error counter

1slave 1B

2slave 2B

3slave 3B

……

31 slave 31B

default

data value

Tab. 10-25.

Tab. 10-26.

Tab. 10-27.

26.9.2013

55

Page 56

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.9 Short Command Interface Object

class code: 104 (0x68)

1 instance

attributeIDaccess

100 (0x64) get/set content ARRAY[12] of USINT

rule

name devicenet

command [0]

toggle-bit and AS-i circuit [1]

data [2 … 11]

10.10 Long Command Interface Object

class code: 105 (0x69)

1 instance

attributeIDaccess

100 (0x64) get/set content ARRAY [38] of USINT

rule

name devicenet

command [0]

toggle-bit and AS-i circuit [1]

data [2 … 37]

For special details acc. the command interface commands see the separat manual "AS-i 3.0 Command Interface".

data type

data type

default

data value

default

data value

Tab. 10-28.

Tab. 10-29.

56

26.9.2013

Page 57

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

10.11 Safety Control/Status

10.11.1 External Monitor

10.11.1.1 Safety Control Status external Monitor

class code: 107 (0x6B)

1 instance per AS-i circuit

attributeIDaccess

100 (0x64) get slave 1: ARRAY [8] of USINT

……… … …

130 (0x82) get slave 31: ARRAY [8] of USINT

131 (0x83) get/set safety control slave1 USINT

……… … …

161 (0xA1) get/set safety control slave31 USINT

rule

name devicenet

safety status release circuit 1 [0]

safety status release circuit 2 [1]

…[2… 6]

safety status, release circuit8 [7]

safety status release circuit 1 [0]

safety status release circuit 2 [1]

…[2… 6]

safety status release circuit 8 [7]

data type

default

data value

Tab. 10-30.

Coding of states and colors see tab. <Coding of status bytes per OSSD>.

Safety control

Byte description

1 byte from the EtherNet/IP

bit 0: 1.Y1

bit 1: 1.Y2

bit 2: 2.Y1

bit 3: 2.Y2

bit 4 ... 7: reserved

Set (data write access)

The bits of the output byte s whic h hav e bee n set vi a t he host int erface are O Red wi th

the real and the homonymous hardware inputs of the device.

GET (data read access)

The information-bits of t he outputs 1.Y1, 1.Y 2, 1.Y2 and 2.Y2 which h ave been read

back only reflect the data bits set via the host interface.

26.9.2013

57

Page 58

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

EtherNet/IP interface

Coding of status bytes per OSSD

Bit [0 ... 3] State or. color

00

01

02

03

04

05

06

07

Bit [6] status or color

0 no device flashing yellow

1 at least one device flashing yellow

Bit [7] status or color

0 no device flashing red

1 at least one device flashing red

green permanent lighting

16

green flashing

16

yellow permanent lighting

16

yellow flashing

16

red permanent lighting

16

red flashing

16

grey or off

16

reserved

16

Tab. 10-31.

58

26.9.2013

Page 59

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

The Modbus Address Table

11. The Modbus Address Table

Cyclic data exchange similar to the Momentum Ethernet Adapter

AS-i circuit 1: Input Data Image IDI

4x

contact read access

reference

bit value

„bit“ 12345678910111213141516

1 1 - 16 F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 F13 F14 F15 F16

2 17 - 32 slave 0/0A slave 1/1A slave 2/2A slave 3/3A

3 33 - 48 slave 4/4A slave 5/5A slave 6/6A slave 7/7A

4 49 - 66 slave 8/8A slave 9/9A slave 10/10A slave 11/11A

5 65 - 80 slave 12/12A slave 13/13A slave 14/14A slave 15/15A

6 81 - 96 slave 16/16A slave 17/17A slave 18/18A slave 19/19A

7 97 - 112 slave 20/20A slave 21/21A slave 22/22A slave 23/23A

8 113 - 128 slave 24/24A slave 25/25A slave 26/26A slave 27/27A

9 129 - 144 slave 28/28A slave 29/29A slave 30/30A slave 31/31A

10 145 - 160 not used slave 1B slave 2B slave 3B

11 161 - 176 slave 4B slave 5B slave 6B slave 7B

12 177 - 192 slave 8B slave 9B slave 10B slave 11B

13 193 - 208 slave 12B slave 13B slave 14B slave 15B

14 209 - 224 slave 16B slave 17B slave 18B slave 19B

15 225 - 240 slave 20B slave 21B slave 22B slave 23B

16 241 - 256 slave 24B slave 25B slave 26B slave 27B

17 257 - 272 slave 28B slave 29B slave 30B slave 31B

F1 - F16: flags, see tab. <Reference 1>.

2152142132122112102928272625242322212

D0 D1 D2 D3 D0 D1 D2 D3 D0 D1 D2 D3 D0 D1 D2 D3

0

Tab. 11-32.

26.9.2013

59

Page 60

AS-i 3.0 EtherNet/IP+Modbus TCP Gateway

The Modbus Address Table

Cyclic data exchange similar to the Momentum Ethernet Adapter

AS-i circuit 2: Input Data Image IDI

4x

contact read access

reference

bit value

„Bit“ 12345678910111213141516

18 273 - 288F1F2F3F4F5F6F7F8F9F10F11F12F13F14F15F16

19 289 - 304 slave 0/0A slave 1/1A slave 2/2A slave 3/3A