Page 1

3.0

Spec.

MANUAL

VBG-EN-K30-DMD-S16

EtherNet/IP Gateway with

integrated Safety Monitor

FACTORY AUTOMATION

Page 2

VBG-EN-K30-DMD-S16

With regard to the supply of products, the current issue of the following document is applicable: The General Terms of Delivery for Products and Services of the Electrical Industry,

published by the Central Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the supplementary

clause: "Expanded reservation of proprietorship"

Page 3

AS-Interface

Table of contents

Table of contents

Conformity Statement

1 Symbol catalog .....................................................................................9

1.1 Abbreviations................................................................................................... 9

2 General ................................................................................................10

2.1 Product information....................................................................................... 10

2.2 Brief description ............................................................................................ 11

3 Safety...................................................................................................12

3.1 Safety standard.............................................................................................. 12

3.2 Intended use................................................................................................... 12

3.2.1 Conditions of use..........................................................................................................12

3.2.2 Residual risks (EN 292-1) ............................................................................................. 12

3.3 Areas of application....................................................................................... 12

3.4 Organizational requirements ........................................................................ 13

3.4.1 Documentation ..............................................................................................................13

3.4.2 Traceability of the devices ........................................................................................... 13

3.4.3 Safety regulations .........................................................................................................13

3.4.4 Qualified personnel....................................................................................................... 14

3.4.5 Repair ............................................................................................................................. 14

3.4.6 Disposal ......................................................................................................................... 14

4 Spezifications .....................................................................................15

4.1 Technical data................................................................................................ 15

4.1.1 Data sheet VBG-EN-K30-DMD-S16 .............................................................................. 15

4.2 Safety-relevant characteristic data .............................................................. 17

4.3 System reaction times – example calculations........................................... 18

4.4 Scope of delivery ........................................................................................... 21

5 Installation...........................................................................................22

5.1 Dimensions..................................................................................................... 22

5.2 Connections ................................................................................................... 22

5.3 Installing in the control cabinet.................................................................... 23

5.4 Removing........................................................................................................ 23

5.5 Electrical Connection .................................................................................... 24

5.6 Commissioning.............................................................................................. 25

5.6.1 Switching to advanced display mode ......................................................................... 25

5.6.2 Setting of ethernet properties...................................................................................... 25

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

3

Page 4

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Table of contents

5.6.3 Connecting AS-i Slaves ................................................................................................ 26

5.7 Quick setup..................................................................................................... 27

5.8 Error tracing....................................................................................................28

5.8.1 Faulty slaves .................................................................................................................. 28

5.8.2 Error display (last error) ...............................................................................................28

5.8.3 Addressing.....................................................................................................................29

5.8.3.1 Assigning address 6 to slave currently at address 2 ....................................................29

5.8.4 Replacing a defective AS-i Safety Slave .....................................................................30

5.8.5 Replacing the chip card ................................................................................................ 31

5.8.6 Local parameter setting of safe AS-i/Gateways and Monitors .................................. 32

5.9 Safe configuration using ASIMON 3 G2 ...................................................... 34

6 Maintenance ....................................................................................... 36

6.1 Checking for safe turn-off .............................................................................36

7 Electrical connection ......................................................................... 37

7.1 Overview of terminals, indicators and operating elements .......................37

7.1.1 VBG-EN-K30-DMD-S16 ..................................................................................................37

7.2 AS-i bus connection.......................................................................................38

7.3 Information about the device types.............................................................. 38

7.4 AS-i and power supply terminal assignments............................................. 38

7.4.1 Electrical connection VBG-EN-K30-DMD-S16............................................................. 39

7.5 Diagnostics interface.....................................................................................40

7.5.1 Diagnostics port RS 232 ............................................................................................... 40

7.6 Chip card......................................................................................................... 40

7.7 EtherNet/IP interface......................................................................................40

7.8 Release circuits..............................................................................................41

7.8.1 Wiring overview of Safety Monitor............................................................................... 41

7.9 Indicators and operating elements............................................................... 42

7.9.1 LED indicators – master ............................................................................................... 42

7.9.2 LED indicators - monitor ............................................................................................... 43

7.9.3 Buttons ...........................................................................................................................44

8 Function and startup of the Safety Monitor..................................... 45

8.1 Powering up the device ................................................................................. 45

8.2 Configuration of the safety functions ..........................................................45

8.2.1 Description of configuration using ASIMON 3 G2 software......................................46

8.2.2 Description of configuration using chip card with master configuration ................47

8.2.3 Configuration using a chip card with complete configuration..................................47

8.3 Safety-relevant documentation of the application ......................................48

8.4 Diagnostic data............................................................................................... 48

8.4.1 Switch-off history ..........................................................................................................49

8.5 Password protection...................................................................................... 49

8.5.1 Procedure for configuring and teaching code sequences........................................ 49

8.5.2 Function of the ESC/Service key ................................................................................. 50

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

4

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 5

AS-Interface

Table of contents

8.6 Safe coupling slaves on the AS-i circuits.................................................... 51

8.7 Chip card ........................................................................................................ 51

8.7.1 Unsafe data .................................................................................................................... 51

8.7.1.1 Card unformatted .........................................................................................................51

8.7.1.2 Data not compatible ..................................................................................................... 52

8.7.1.3 Card empty................................................................................................................... 52

8.7.1.4 Data compatible ........................................................................................................... 52

8.7.1.5 Data in the device and on the chip card identical......................................................... 52

8.7.1.6 Data in the device and on the chip card not identical................................................... 52

8.7.2 Safe data ........................................................................................................................ 53

8.7.2.1 Data incompatible ........................................................................................................53

8.7.2.2 Data compatible ........................................................................................................... 54

8.7.2.3 Complete configuration ................................................................................................ 54

8.7.2.4 Data on the chip card and in the device are identical .................................................. 54

8.7.2.5 Data not identical ......................................................................................................... 55

8.7.2.6 Operating the chip card from the menu........................................................................ 55

8.7.3 Working with multiple memory banks ........................................................................ 55

9 Operation in advanced display mode...............................................57

9.1 Overview......................................................................................................... 57

9.2 Navigating through the advanced display mode ........................................ 61

9.3 ETHERNET/IP (main menu)........................................................................... 62

9.3.1 TCP/IP Object ................................................................................................................ 62

9.3.1.1 IF STATUS................................................................................................................... 62

9.3.1.2 IF CAPABILITY ............................................................................................................63

9.3.1.3 IF CONTROL ...............................................................................................................63

9.3.1.4 PATH TO LINK OBJECT ............................................................................................. 64

9.3.1.5 TCP/IP CONFIG........................................................................................................... 64

9.3.2 ETHERNET OBJECT ..................................................................................................... 65

9.4 QUICK SETUP ................................................................................................ 66

9.5 AS-I SAFETY................................................................................................... 67

9.5.1 TEACH CODES .............................................................................................................. 68

9.5.1.1 TEACH CODES – COMPLETE ................................................................................... 68

9.5.1.2 SINGLE SLAVE ........................................................................................................... 70

9.5.1.3 COUPLING SLAVE ...................................................................................................... 71

9.5.1.4 INPUT CODE SEQ. ..................................................................................................... 72

9.5.2 SAFE OUTPUT CH (channels for the release circuits) .............................................. 72

9.5.3 SAFE COUPLING (optional menu)............................................................................... 73

9.5.4 START/STOP (changing the Monitor mode) ............................................................... 73

9.5.5 CLEAR SAFE CFG (delete safe configuration)........................................................... 74

9.5.6 PIN (changing the PIN) ................................................................................................. 74

9.5.7 SAFE CHIPCARD........................................................................................................... 75

9.5.7.1 VIEW BANK X CONFIG (view active bank)................................................................. 76

9.5.7.2 CARD –>MONITOR (copy card data to the Monitor)................................................... 77

9.5.7.3 MONITOR –>CARD (copy Monitor data to the chip card) ........................................... 78

9.5.7.4 CLEAR CODES (delete code sequences) ................................................................... 80

9.5.7.5 CLEAR SAFE CARD.................................................................................................... 81

9.5.8 PROTECT (protect safe configuration) ....................................................................... 82

9.5.9 SAFETY SUBST VAL (Substitute values for input data from safe slaves) .............. 82

9.6 DIAGNOSTICS................................................................................................ 83

9.6.1 AS-I CIRCUIT (Selecting the AS-i circuit).................................................................... 84

9.6.2 SAFETY SLAVES (safety oriented slaves).................................................................. 84

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

5

Page 6

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Table of contents

9.6.3 INT MON (internal monitor)........................................................................................... 85

9.6.3.1 DIAGNOSTICS (Diagnostics for the internal monitor).................................................. 85

9.6.3.2 LAST DIAGNOSIS (Last diagnostics for the int. monitor).............................................86

9.6.3.3 MONITOR CONFIG (configuration of the int. monitor)................................................. 88

9.6.4 EXT SAFETY MON (external monitor) .........................................................................88

9.6.4.1 DIAGNOSE (Diagnosis for the external monitor)..........................................................89

9.6.4.2 LAST DIAGNOSIS (Last diagnostics for the external monitor).....................................90

9.6.4.3 ACTUAL CONFIG (Configuration for the external monitor)..........................................91

9.6.5 FAULT DETECTOR ........................................................................................................ 92

9.6.6 DELTA LIST ....................................................................................................................93

9.6.7 LCS (History of the slaves which have triggered a configuration error).................. 93

9.6.8 ERROR COUNTERS ......................................................................................................94

9.6.9 LPF (List of Peripheral Faults) .....................................................................................95

9.6.10 FLAGS ............................................................................................................................ 95

9.6.11 ACTUAL CONFIG (actual slave configuration)........................................................... 97

9.6.12 AS-I MASTER (Info) .......................................................................................................98

9.7 SLAVE ADR TOOL..........................................................................................99

9.8 TEST (Test tools for slaves)........................................................................100

9.8.1 AS-I CIRCUIT (Selecting the AS-i circuit)..................................................................100

9.8.2 SLAVE TEST TOOL ..................................................................................................... 101

9.8.3 BINARY INPUTS...........................................................................................................102

9.8.4 BINARY OUTPUTS.......................................................................................................102

9.8.5 ANALOG INPUTS.........................................................................................................102

9.8.6 ANALOG OUTPUTS.....................................................................................................103

9.8.7 PARAMETER ................................................................................................................104

9.9 SETUP (configuration of the AS-i network) ............................................... 104

9.9.1 AS-I CIRCUIT ................................................................................................................105

9.9.2 OPERATION MODE .....................................................................................................105

9.9.3 STORE ACTUAL (store currently detected configuration) ...................................... 105

9.9.4 FORCE OFFLINE (Switch AS-i Master to offline operation) .................................... 106

9.9.5 AUTO ADDR ENABLE (enable automatic address).................................................. 106

9.9.6 AS-I ADDRESS (AS-i address assistant) ...................................................................107

9.9.7 AS-I CONTROL (Optional)........................................................................................... 107

9.9.7.1 CONTROL INFO (Status of the control program).......................................................108

9.9.7.2 CONTROL RUN (start or stop the control program)...................................................108

9.9.7.3 CONTROL FLAGS (control program flag memory).................................................... 109

9.9.8 LOS (list of offline slaves) ..........................................................................................109

9.9.9 CHIPCARD....................................................................................................................110

9.9.10 Language (menu language)........................................................................................110

9.9.11 FACTORY RESET (factory default settings) .............................................................110

9.10 DISPLAY CONTRAST (set display contrast).............................................. 111

10 Advanced Diagnostics for AS-i Masters ........................................ 112

10.1 List of corrupted AS-i Slaves (LCS)............................................................ 112

10.2 Protocol analysis: Counters for corrupted data telegrams......................112

10.3 Offline Phase for Configuration Errors ......................................................113

10.4 Functions of the AS-i Fault Detector .......................................................... 113

10.4.1 Duplicate address detection ....................................................................................... 113

10.4.2 Earth/Ground Fault Detector ......................................................................................114

10.4.3 Noise Detector .............................................................................................................114

10.4.4 Over-voltage Detector ................................................................................................. 114

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

6

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 7

AS-Interface

Table of contents

11 EtherNet/IP interface ........................................................................115

11.1 Objekt modelling .......................................................................................... 115

11.1.1 Identity object .............................................................................................................. 116

11.1.2 Assembly Object ......................................................................................................... 117

11.1.3 AS-i Master Object ...................................................................................................... 120

11.1.4 AS-i slave Object ......................................................................................................... 122

11.1.5 I/O Data Object ............................................................................................................ 123

11.1.6 Advanced Diagnostics Object ................................................................................... 127

11.1.7 Short Command Interface Object.............................................................................. 128

11.1.8 Long Command Interface Object............................................................................... 128

11.1.9 Safety Control Status Internal Monitor ..................................................................... 128

11.1.10 Safety Control Status External Monitor .................................................................... 130

12 Appendix: the first commissioning with CompactLogix ..............132

12.1 Working with sample files ........................................................................... 135

13 Data Transfer using CIP Messages in RSLogix5000..................... 136

13.1 MSG instruction and Message Type Tag ................................................... 136

13.2 Example 1: read LAS ................................................................................... 138

13.3 Example 2: read/write 16-bit (analog) data ................................................ 139

14 System startup using AS-i Control Tools.......................................140

15 Configuration with Windows Software ASIMON 3 G2...................143

16 Status indication, faults and fault elimination ...............................144

16.1 Spontaneous display of faults from the safety unit ................................. 144

16.2 Replacing a defective safety-configured AS-i slave ................................. 145

16.3 Replacing a defective AS-i Safety Monitor ................................................ 146

16.4 Forget the password? What do I do now? ................................................ 146

17 Glossary ............................................................................................148

18 Appendix: example of a bidirectional safety coupling.................. 151

19 Reference List...................................................................................153

19.1 Manual: “ASIMON 3 G2 Configuration Software“ ..................................... 153

19.2 Sources......................................................................................................... 153

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

7

Page 8

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Conformity Statement

Conformity Statement

The AS-i 3.0 EtherNet/IP Gateways with integrated Safety Monitor have

been developed and produced in accordance with the applicable european standards and directives. The conformity statement according to the

EC EMC-, low voltage, and -maschinery directive can be sent to by

request.

Additional information can be found in the Pepperl+Fuchs GmbH basic

catalogue or in the online catalogue in internet.

Subject to technical modifications.

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

8

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 9

1. Symbol catalog

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total malfunctioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or result in material damages and destruction.

1.1 Abbreviations

AS-Interface

Symbol catalog

AS-i

AOPD

CRC

I/O

EDM

EMC

ESD

PELV

PFD

PLC

SaW

AS-interface (actuator sensor interface)

Active opto-electronic protective device

Cyclic redundancy check

Input/output

External device monitoring

Electromagnetic compliance

Electrostatic discharge

Protective extra-low voltage

Probability of failure on demand

Programmable logic control

Safety at Work, safety technic

Information!

Additional information can be found in section <Glossary>.

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

9

Page 10

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

2. General

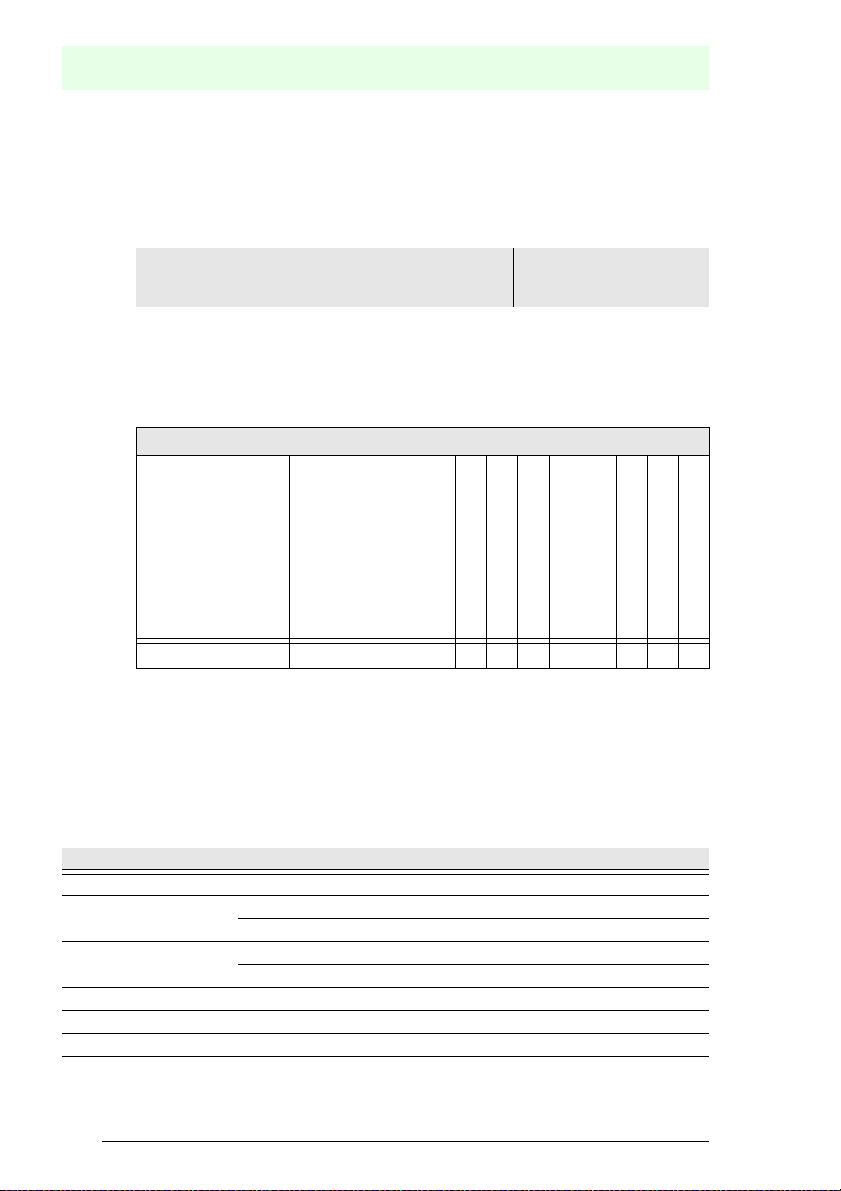

2.1 Product information

This system manual applies to the following Pepperl+Fuchs GmbH equipment:

General

AS-i 3.0 EtherNet/IP Gateway, 2 Master with duplicate

VBG-EN-K30-DMD-S16

address' recognition and AS-i inspector, integrated

Safety Monitor (16 release circuits)

Tab. 2-1.

The AS-i/Gateway with integrated Safety Monitor combines two devices in one

housing: an

AS-i 3.0 EtherNet/IP Gateway and a Safety Monitor for 2 AS-i circuits.

The safety unit provides 4 inputs which can be defined as either EDM or as

START inputs.

Functions of the device

–

2 master

Relais circuits

AS-i

Master, power supply

Diagnostic interface

Semiconductor outputs

SaW outputs

VBG-EN-K30-DMD-S16 16 2 2 RS 232 2 16 2

Tab. 2-2.

The EtherNet/IP Gateway serves to connect AS-i systems to the superordinate

EtherNet/IP controller.

All possibilities offered by AS-i can be used via EtherNet/IP.

Commissioning, debugging and setting up of the AS-i parameters can be accom-

plished with the use of push-buttons, the display and the LEDs, but it can also be

handled via Ethernet TCP/IP or via the diagnostic interface.

Safety relays

Caption

2 master: The device is a double master

Relais circuits: number of release circuits

16: safety unit generates 16 independent switching signals

AS-i: number of AS-i circuits

2: safety unit functions with two equal AS-i circuits

Master, power supply: 2: The unit contains two AS-i Masters.

Diagnostic interface: type of the diagnostic port

Semiconductor outputs: number of semiconductor outputs

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

10

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Tab. 2-3.

Issue date: 17.4.2009

Page 11

Caption

SaW outputs: number of SaW outputs

Safety relays: number of safety relays

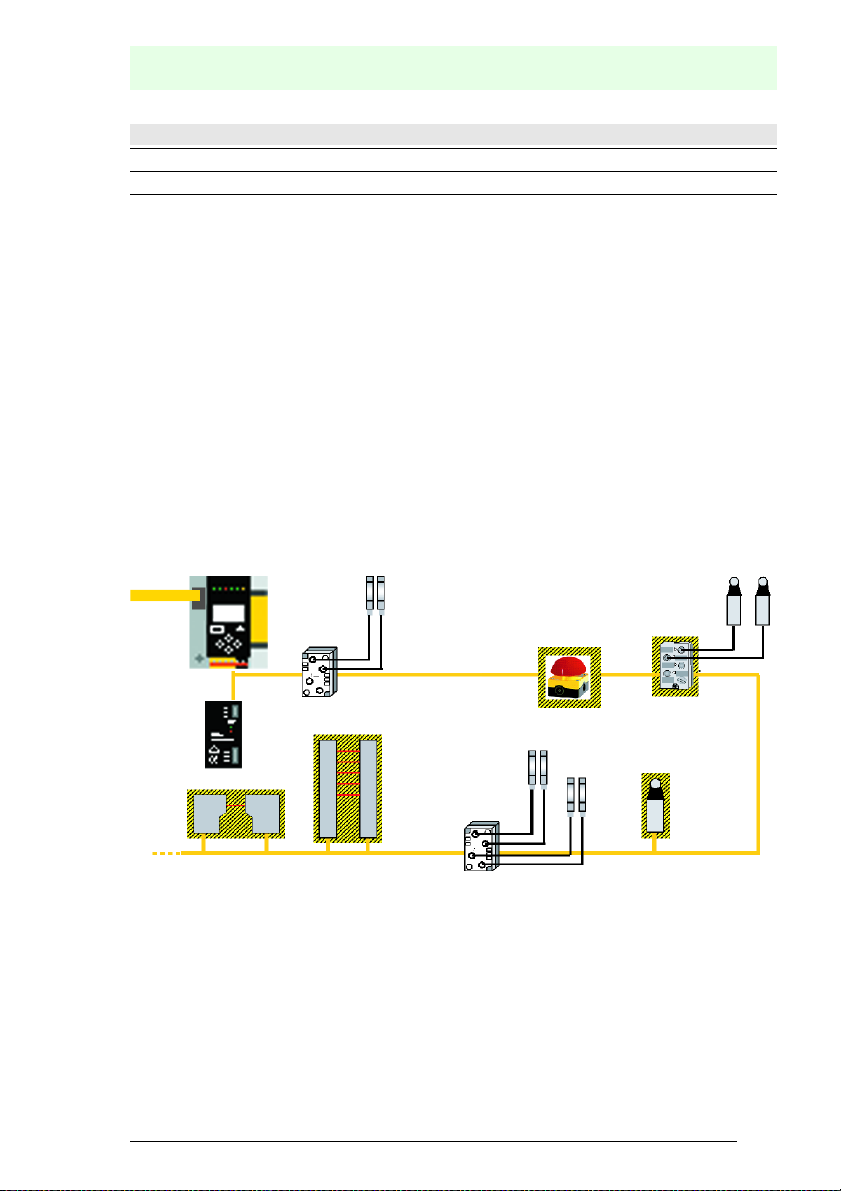

2.2 Brief description

The actuator-sensor interface (AS-i) has established itself as a system for networking primarily binary sensors and actuators at the lowest level of the automation hierarchy. The high number of installed systems, the ease of use and the reliable operating behaviour also make the AS-i interesting in the area of machine

safety.

The safety AS-i system is intended for safety applications up to Category 4/

SIL 3. Mixed operation of standard components and safe components is possible.

The AS-i/Gateways with integrated Safety Monitor monitors within an AS-i system

the safe slaves which have been assigned according to the configuration specified by the user with the configuration software. In the event of a stop request or a

defect, the AS-i/Gateways with integrated Safety Monitor switches off the system

in protective operation mode with a maximum reaction time of 40 ms.

AS-i/Gateway with integrated Safety Monitor

Standard

module

Safety emergency

shutdown switches

AS-Interface

Safety

module

General

Tab. 2-3.

AS-i power

supply unit

Protective photoelectric

sensor

Fig. 2-1. Safe and standard components in an AS-i network

Protective photoelectric

light barrier

Standard

module

Safety position

switch

Multiple AS-i Safety Monitors can be used within an AS-i system. In this way, a

safe slave can be monitored by multiple AS-i Safety Monitors.

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

11

Page 12

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

3. Safety

3.1 Safety standard

The AS-I Safety Monitor has been developed, manufactured, tested and submitted for type testing in accordance with the safety standards prevailing at the time

of testing. The safety requirements per Category 4 in accordance with EN 954-1,

SIL3 in accordance with EN 61 508 and Performance Level “e” in accordance

with EN ISO 13 849-1 are met by all devices.

Information!

A detailed listing of the values for probability of failure (PFD values) can be found in

section <Safety-relevant characteristic data>.

Following a risk analysis you can sue the AS-I Safety Monitor in accordance with

its safety category as a shut-down protection device for protecting hazardous areas.

3.2 Intended use

3.2.1 Conditions of use

The AS-I Safety Monitor has been developed as a shut-down protection device

for protecting hazardous areas on powered equipment.

Attention!

Protection of operating personnel and equipment is not provided is the device is

not used in accordance with its intended use.

Safety

Attention!

Manipulation of and changes to the devices other than expressly described in this

Manual are not permitted.

3.2.2 Residual risks (EN 292-1)

The circuits suggested in this Manual have been tested and verified with the

greatest care. The prevailing standards and regulations are met when using the

components and wiring shown. Residual risks remain if:

• There are any deviations from the suggested wiring concept which may result

in the connected safety-relevant assemblies or protective devices not being

incorporated or only insufficiently incorporated into the safety circuit.

• The operator does not follow the prevailing safety regulations for operation,

setting and maintenance of the machine. Machine inspection and maintenance intervals must be strictly observed.

3.3 Areas of application

The AS-I Safety Monitor, when properly used, enables the operation of sensorcontrolled personal protection equipment and additional safety components.

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

12

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 13

AS-Interface

Safety

The device also assumes the mandatory E-STOP function (Stop Category 0 or 1)

for all non-manually operated machines, dynamic monitoring of the restart function and the protection monitoring function.

Examples for use of the AS-I Safety Monitor:

The device is used economically in machines and equipment in which the standard AS-I bus is the local bus. Using the Safety Monitor as a bus component allows already existing AS-I bus configurations to be easily expanded, and safety

components having the corresponding AS-i Safety at Work interface can be inserted without difficulty. If there is no AS-I Safety at Work interface on the safety

component, so-called coupling modules can be used to establish the connection.

Existing AS-I masters and AS-I power supplies can be used as well.

There are no industry-specific restrictions. Some of the key applications are listed

below:

• Machine tools

• Expanded machining centers with multiple control elements and safety sensors for wood and metal processing

• Printing and paper processing machines, trimming machines

• Packaging machinery, both stand-alone and as systems

• Food and beverage machinery

• Workpiece and bulk material conveying systems

• Rubber and plastics industry processing machinery

• Automatic assembly and handling equipment.

3.4 Organizational requirements

3.4.1 Documentation

All the specifications in this System Manual, in particular the sections “Safety Instructions” and “Commissioning”, must be strictly observed.

All the safety instructions in the manual “ASIMON 3 G2 Configuration Software”

must be strictly observed.

Please note the safety rules when configuring the safety functions, see section

<Configuration of the safety functions>. Checking of the release code and testing

the system must be documented in writing and is part of the system documentation.

Keep this System Manual in a safe location where it can be readily accessed. It

should always be available.

3.4.2 Traceability of the devices

The ordering party is responsible for ensuring traceability of the devices by serial

number!

3.4.3 Safety regulations

Observe the locally prevailing legal regulations and requirements of the trade associations.

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

13

Page 14

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

3.4.4 Qualified personnel

Installation, commissioning and maintenance of the devices are to be performed

only by qualified specialists.

Electrical work is to be performed only by electrical technicians.

Setting and changing the device configuration via PC and ASIMON 3 G2 configu-

ration software are to be performed only by an authorized safety representative.

The password for changing a device configuration must be kept under lock and

key by the safety representative.

3.4.5 Repair

Repairs, in particular opening of the housing, are to be performed only by the

manufacturer or by an authorized representative of the manufacturer.

3.4.6 Disposal

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances when

disposing this product!

The device does not contain batteries that need to be removed before disposing it.

Safety

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

14

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 15

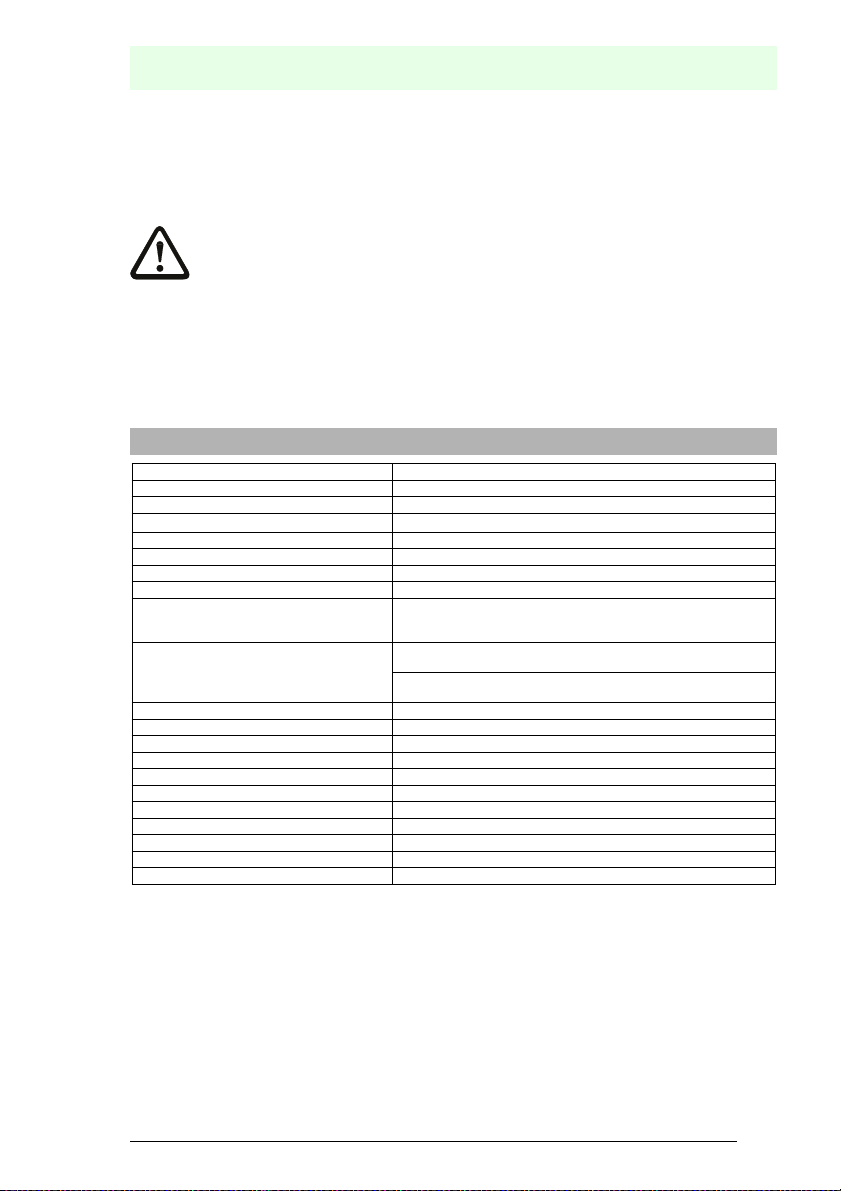

4. Spezifications

4.1 Technical data

Attention!

The AS-I power supply for the AS-I components must have isolation per IEC 60

742 and be able to handle momentary power interruptions of up to 20 ms. The

power supply for the 24 V supply must also have isolation per IEC 60 742 and be

able to handle momentary power interruptions of up to 20 ms. The maximum output voltage of the power supply must also be less than 42 V in case of a fault.

4.1.1 Data sheet VBG-EN-K30-DMD-S16

VBG-EN-K30-DMD-S16

Ethernet/IP interface RJ-45

Baud rates 10/100 MBaud

Serial interface RS 232

AS-i cycle time 150 Ps

Safety monitor

Release circuit 4-cha nnel

Start delay < 10 s

Respond delay < 40 ms

Inputs:

4 x EDM/Start

Output:

4 x output switching elements

Card slot chip card for storage of configuration data

Displays

LCD indication of slave addresses and error messages

LED power power on

LED net Ethernet/IP master recognized

LED config error configuration error

LED U AS-i AS-i voltage OK

LED AS-i active AS-i normal operation active

LED prg enable automatic addresses programming enabled

LED prj mode configuration mode active

LED AUX auxiliary power

(number of slaves + 2)

*

EDM: inputs of external device monitoring circuits

start: start inputs

switching current statical 4 mA at 24 V, dynamic 30 mA at 24 V (T=100 µs)

relay outputs (output circuits 1 and 2)

max. contact load: 3 A AC-15 at 30 V, 3 A DC-13 at 30 V

semiconductor outputs (output circuits 3 and 4)

max. contact load: 0,5 A DC-13 at 30 V

AS-Interface

Spezifications

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

15

Page 16

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Spezifications

VBG-EN-K30-DMD-S16

4 x LED EDM/Start state of input of ext. device monitoring circuit

4 x LED output circuit state of output circuit

Electrical data

Operating current master power supply, approx. 300 mA out of AS-i network 1,

Operating voltage AS-i voltage 30 V DC

Voltage of insulation t 500 V

Standards EN 61 000-6-2, EN 61 000-6-4

Housing AS-i master housing in stainless steel

Ambient operating temperature 0°C … +55°C

Storage temperature -25°C … +85°C

Dimensions (L / W / H in mm) 120 / 100 / 96

Protection category IEC 60 529 IP20

Tolerable loading referring to impacts and vibrations according to EN 61 131-2

Weight 800 g

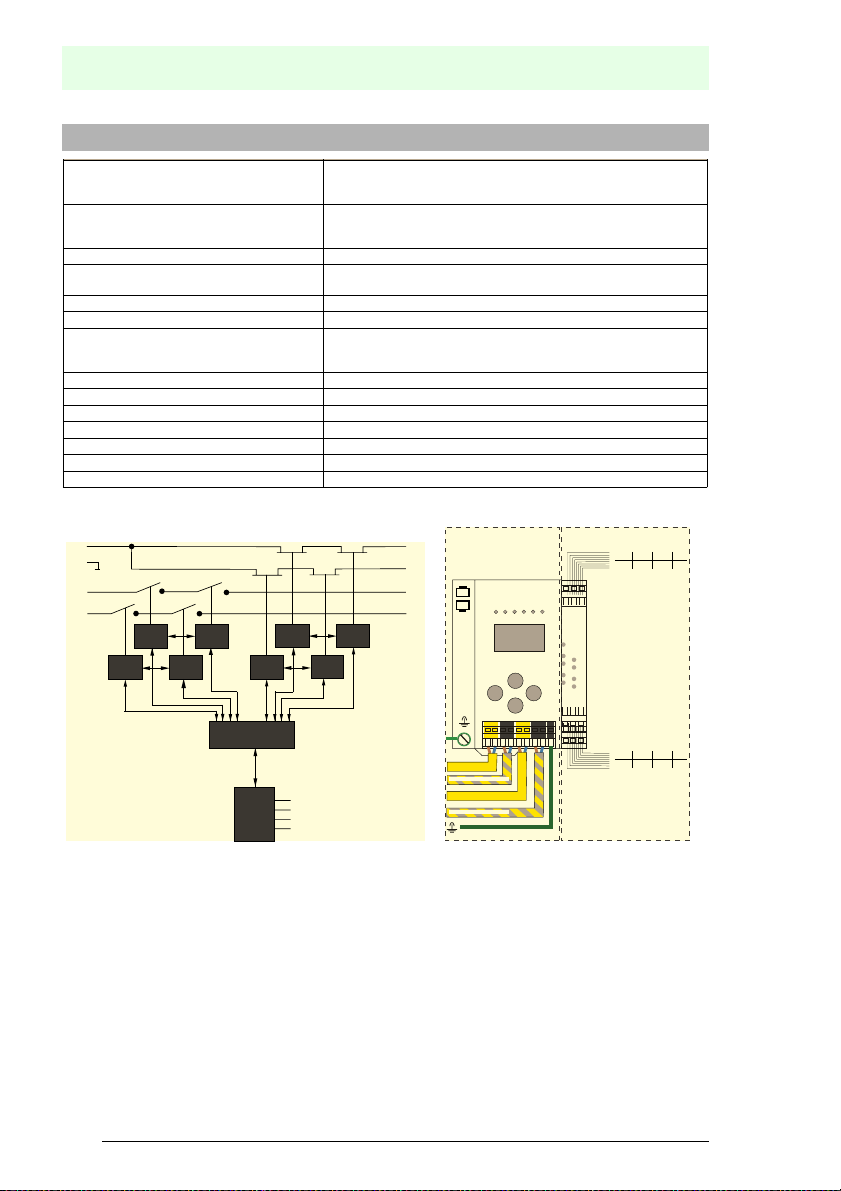

Safety Monitor block diagram: Connections: Gateway + Safety Monitor

LED off: open

LED on: closed

LED off: open

LED on: closed

approx. 70 mA out of AS-i network 2

EN 62 061, SIL3, IEC 61 508, SIL3

EN 13 849, performance level e

24 V

0 V

1.13 1.14

2.13

16

Freigabe

(Release)

Freigabe

(Release)

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Freigabe

(Release)

Freigabe

(Release)

Freigabe

(Release)

Sicherheitsmonitor

(Safety Monitor)

Eingänge

(Inputs)

Freigabe

(Release)

Freigabe

(Release)

Freigabe

(Release)

1.Y1 (EDM 1 / Start 1)

2.Y1 (EDM 2 / Start 2)

1.Y2 (EDM 3 / Start 3)

2.Y2 (EDM 4 / Start 4)

3.14

4.14

2.14

Ethernet/IP

+ASI 1–

ASI 1 +PWR- (max. 8A)

+ ASI 2 –

ASI 2 +PWR- (max. 8A)

+

+-+-+

output switching elements

-

-

+

output switching elements

1.13

0 V

+

2.Y2

2.Y1

EDM/START inputs

1.Y1

+

+

4.14

1.14

3.14

EDM/START inputs

2.13+24 V

1.Y2

2.14

Issue date: 17.4.2009

Page 17

AS-Interface

Spezifications

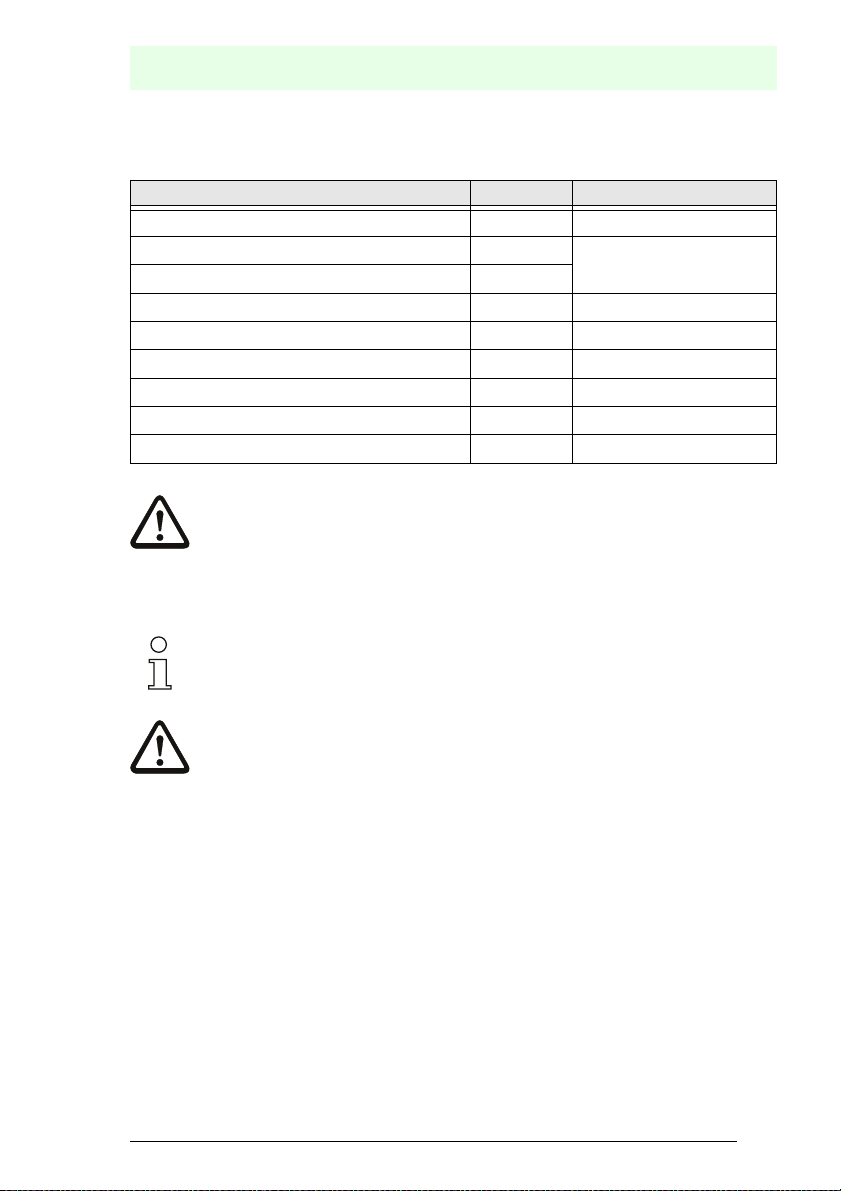

4.2 Safety-relevant characteristic data

Characteristic data Value Standard

Safety category 4 EN 954-1

Safety category 4 EN 13849-1:2006/PLe Cat 4

Performance Level (PL) e

Safety Integrated Level (SIL) 3 IEC 61508

Lifespan (TM) in years 20 EN 13849-1:2006/PLe Cat 4

Maximum switch-on time in months 12 IEC 61508

PFD

PFH

(probability of a dangerous failure per hour) < 5,36 x 10

D

Max. system reaction time in milliseconds

< 9,25 x 10

40 IEC 61508

-6

IEC 61508, EN 62061

-9

IEC 61508, EN 62061

Tab. 4-4.

Attention!

In addition to the system reaction time of max. 40 ms, the reaction times of the safe ASinterface sensor slave, of the sensor being used for monitoring, of the safe AS-interface

actuator slave and of the actuator used for this purpose must still be added. Please note

that additional reaction times may likewise arise through the configuration of the safety

monitor.

Notice!

Refer to the technical data for the slaves as well as to that for the sensors and actuators

for the reaction times to be added.

Attention!

The system reaction times of the daisy-chained AS-interface components are added up.

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

17

Page 18

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

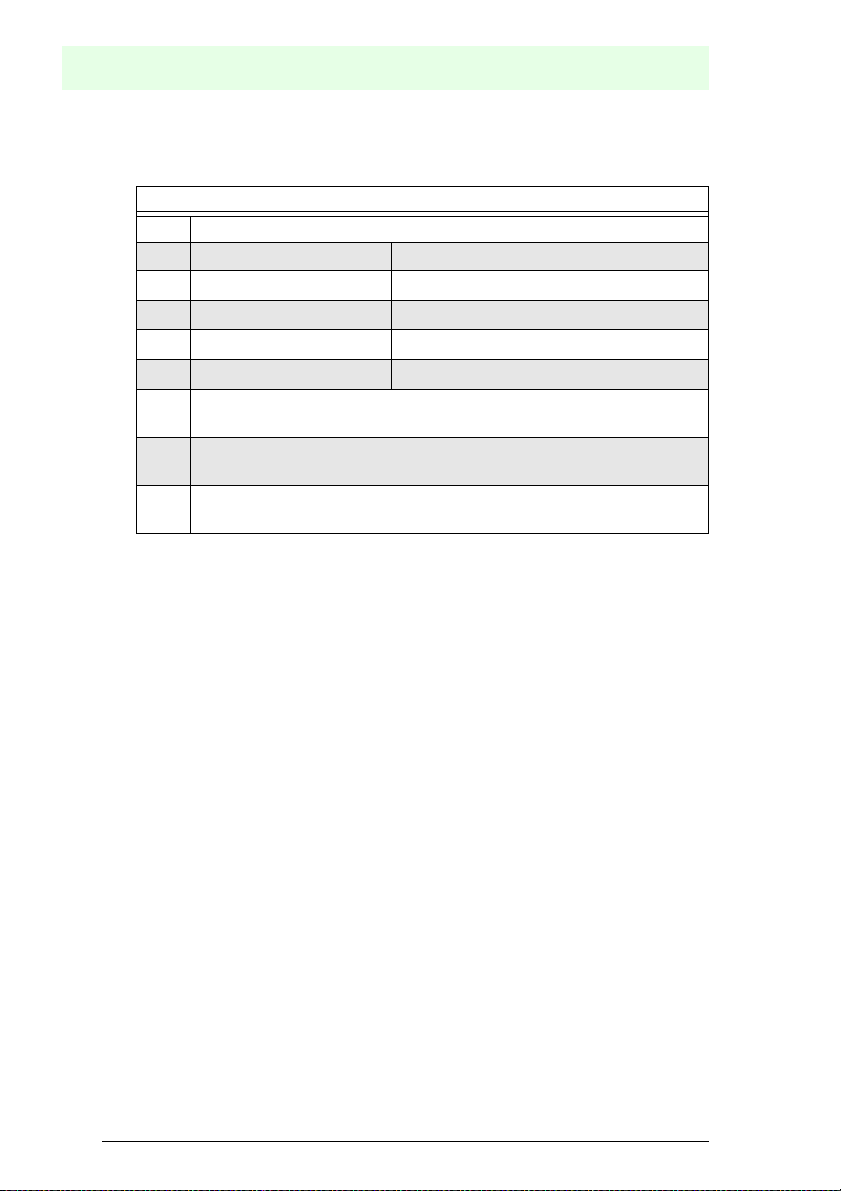

4.3 System reaction times – example calculations

System components:

AS-i network 1

ASI1

AS-i network 2

ASI2

Safe sensor slave (EMERGENCY-OFF switch: t

S1-1

Safe sensor slave (safety light barrier: t

S1-2

Safe sensor slave (EMERGENCY-OFF switch: t

S2-1

Safe actuator slave (motor starter: t

A2-1

SM1-1 Safety monitor with 16 relais circuits and one safe AS-i output in AS-i

network 1

SM1-2 Safety monitor with 2 relais circuits and one safe AS-i output in AS-i

network 1

SM2-1

Safety monitor with 16 relais circuits and one safe AS-i output in AS-i

network 2

RA2-1

= 18 ms)

RS1-2

= 50ms)

Spezifications

= 100 ms)

RS1-1

= 100ms)

RS2-1

Tab. 4-5.

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

18

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 19

AS-Interface

Spezifications

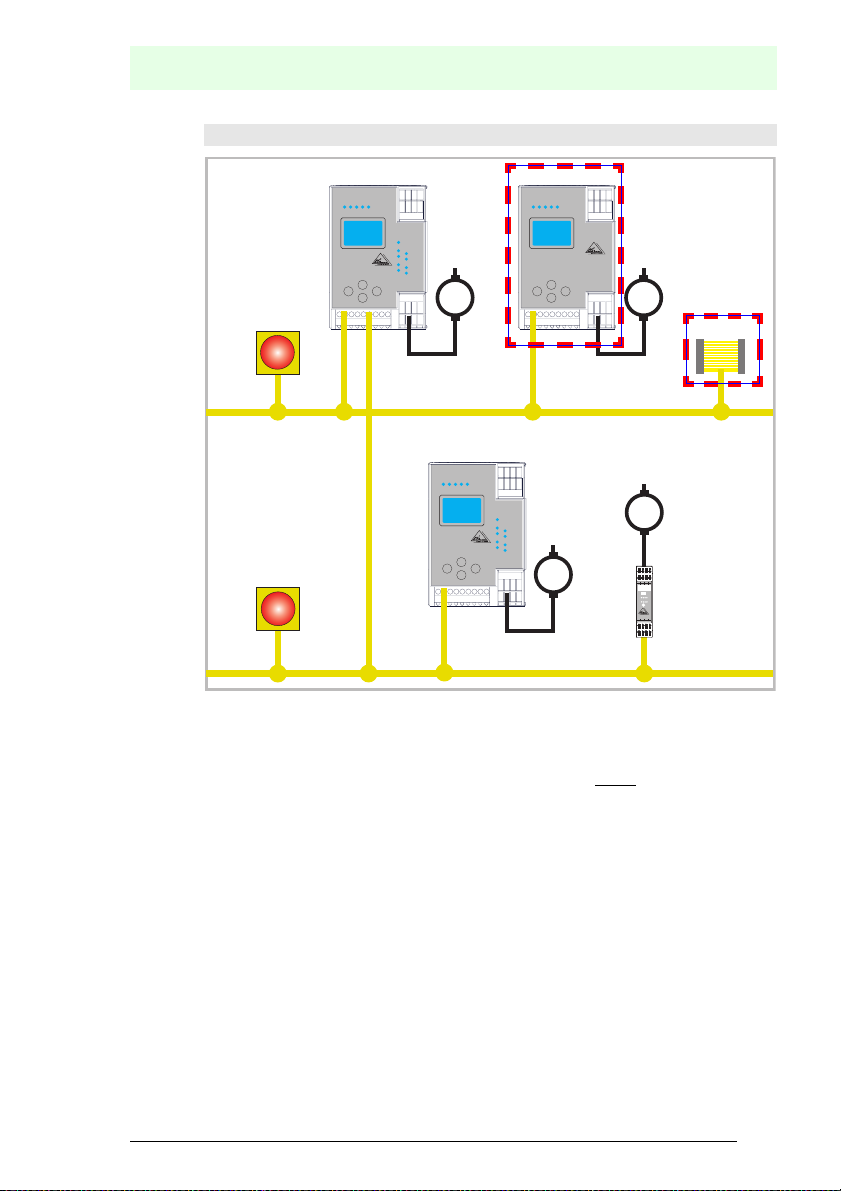

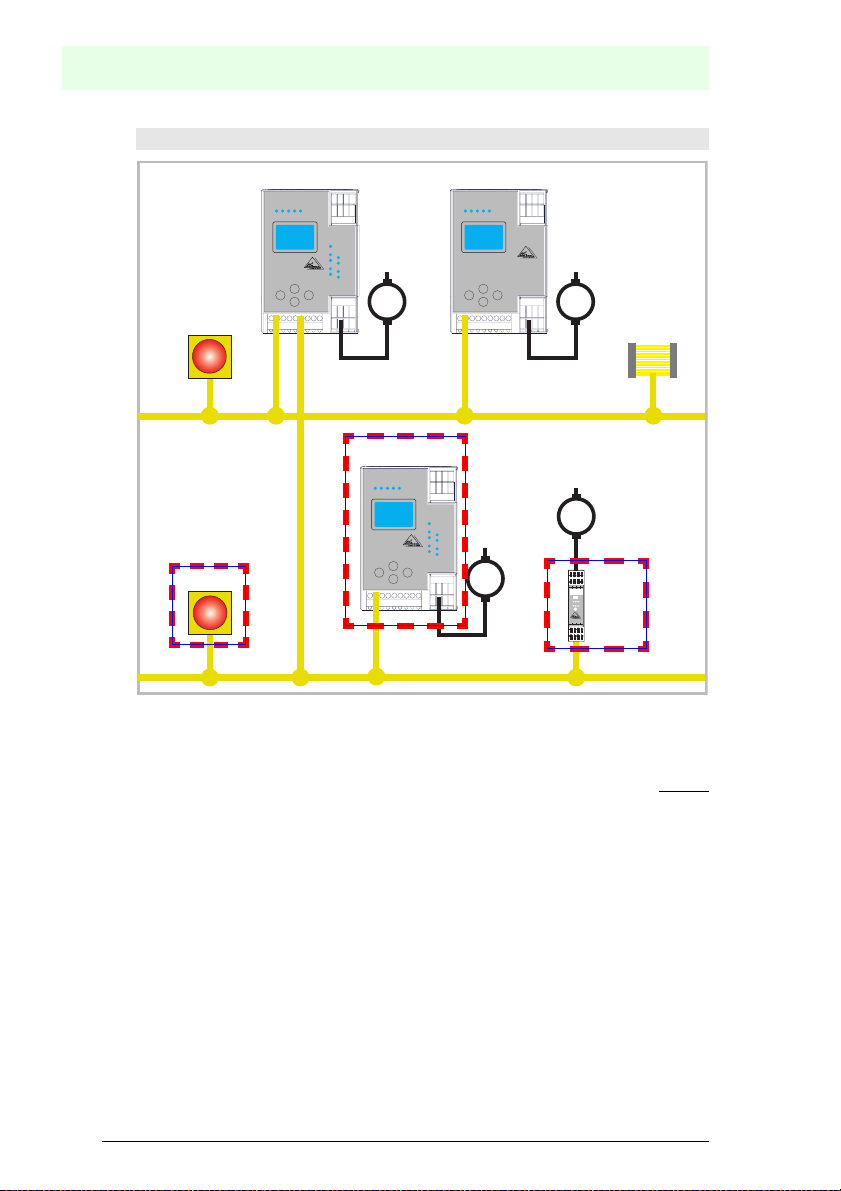

System configuration - example 1: Calculation of the system reaction time

SM1-1

AS-i Safety Monitor

M

S1-1

SM1-2

AS-i Safety Monitor

M

S1-2

AS-i 1

SM2-1

M

AS-i Safety Monitor

S2-1

M

AS-i 2

Upon activation of safety light barrier S1-2, the relay safety output of safety monitor SM1-2 is controlled.

Calculation of the AS-i relevant system reaction time:

t

System total a)

= t

R S1-2

+ t

= 18ms + 40ms = 58ms

R System

I–

I1

Run

Prg

1.13

ASI+

I+

I+

I+

I2

1.Y1

1.Y2

Prg

1

I

I2

1.Y2

1.Y1

Alarm

Pwr

Fault

Out

1.14

1.23

1.24

ASI–

nc

nc

A2-1

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

19

Page 20

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Spezifications

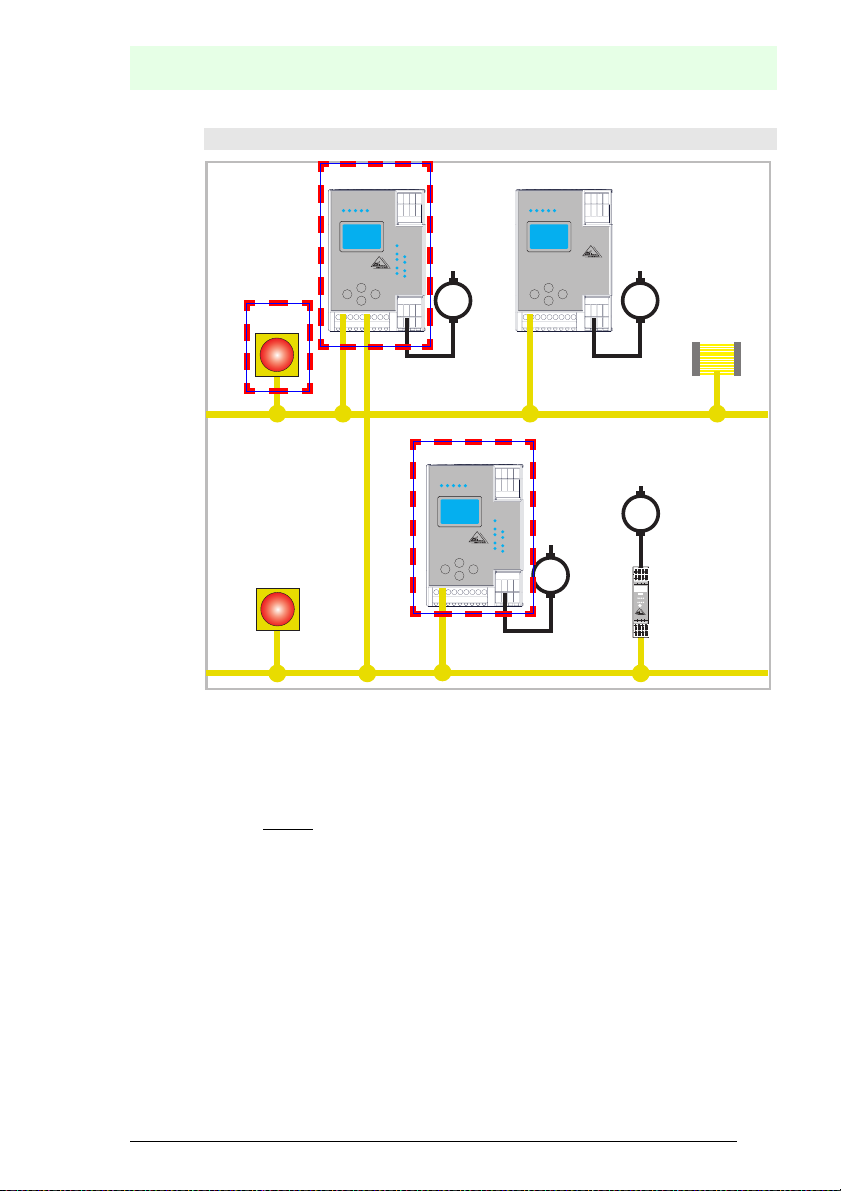

System configuration - example 2: Calculation of the system reaction time

SM1-1

AS-i Safety Monitor

M

S1-1

SM1-2

AS-i Safety Monitor

M

S1-2

AS-i 1

SM2-1

M

AS-i Safety Monitor

S2-1

M

AS-i 2

Upon locking of the EMERGENCY-OFF switch S2-1, the motor starter is controlled via the safe AS-interface output of safety monitor SM2-1.

Calculation of the AS-interface-relevant system reaction time:

t

System total b)

= t

R S2-1

+ t

R System

+ t

= 100ms + 40ms + 50ms = 190ms

R A2-1

I+

I–

I2

I1

Run

1

I

Pwr

Prg

1.14

1.13

ASI–

ASI+

I+

I+

1.Y2

1.Y1

Prg

I2

1.Y2

1.Y1

Alarm

Fault

Out

1.24

1.23

nc

nc

A2-1

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

20

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 21

AS-Interface

Spezifications

System configuration - example 3: Calculation of the system reaction time

SM1-1

AS-i Safety Monitor

M

S1-1

SM1-2

AS-i Safety Monitor

M

S1-2

AS-i 1

SM2-1

M

AS-i Safety Monitor

S2-1

M

AS-i 2

Upon locking of the EMERGENCY-OFF switch S1-1, the relay output of safety

monitor SM2-1 is controlled via the coupling of the safe AS-interface output of

safety monitor SM1-1.

Calculation of the AS-i relevant system reaction time:

t

System total c)

= t

R S1-1

+ t

R System ASI1

+ t

R System ASI2

40ms = 180ms

I–

I+

I+

I+

I1

I2

1.Y1

1.Y2

A2-1

Run

Prg

1

I

I2

1.Y2

1.Y1

Alarm

Pwr

Fault

Out

Prg

1.13

1.14

1.23

1.24

ASI+

ASI–

nc

nc

= 100ms + 40ms +

4.4 Scope of delivery

The basic unit consists of:

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor.

The following accessories are available:

Software CD with

®

• ASIMON 3 G2 communication software for Microsoft

2000/XP/Vista

®

Windows Me/NT/

• System manual in PDF format (Adobe® Acrobat Reader® Version 5.x or

newer is required for viewing the files)

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

21

Page 22

5. Installation

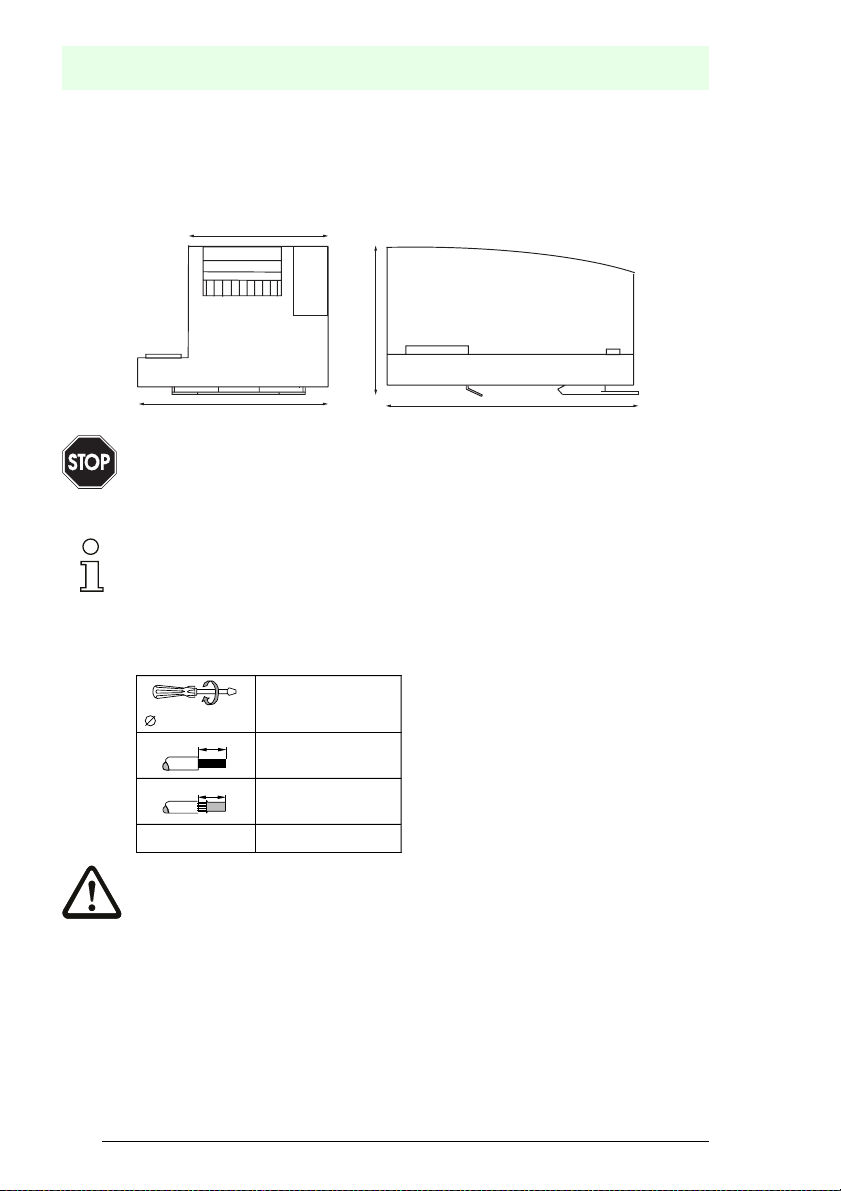

5.1 Dimensions

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Installation

78

96

Warning!

Cover the top of the gateway when doing any drilling work above the unit. No particles,

especially metal chips, should be allowed to enter the housing, since this could cause a

short circuit.

Information!

Please refer to installation instruction for this device for detailed mounting information.

5.2 Connections

5 ... 6 mm / PZ2

10

10

AWG 2 x 24 ...12

Attention!

The AS-I power supply for the AS-I components must have isolation per IEC 60 742

and be able to handle momentary power interruptions of up to 20 ms. The power supply for the 24 V supply must also have isolation per IEC 60 742 and be able to handle

momentary power interruptions of up to 20 ms. The maximum output voltage of the

power supply must also be less than 42 V in case of a fault.

110

2 x (0,5 .... 1,5) mm

2 x (0,5 ..

0,8 Nm

7 LB.IN

.. 1,5) mm

120

2

2

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

22

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 23

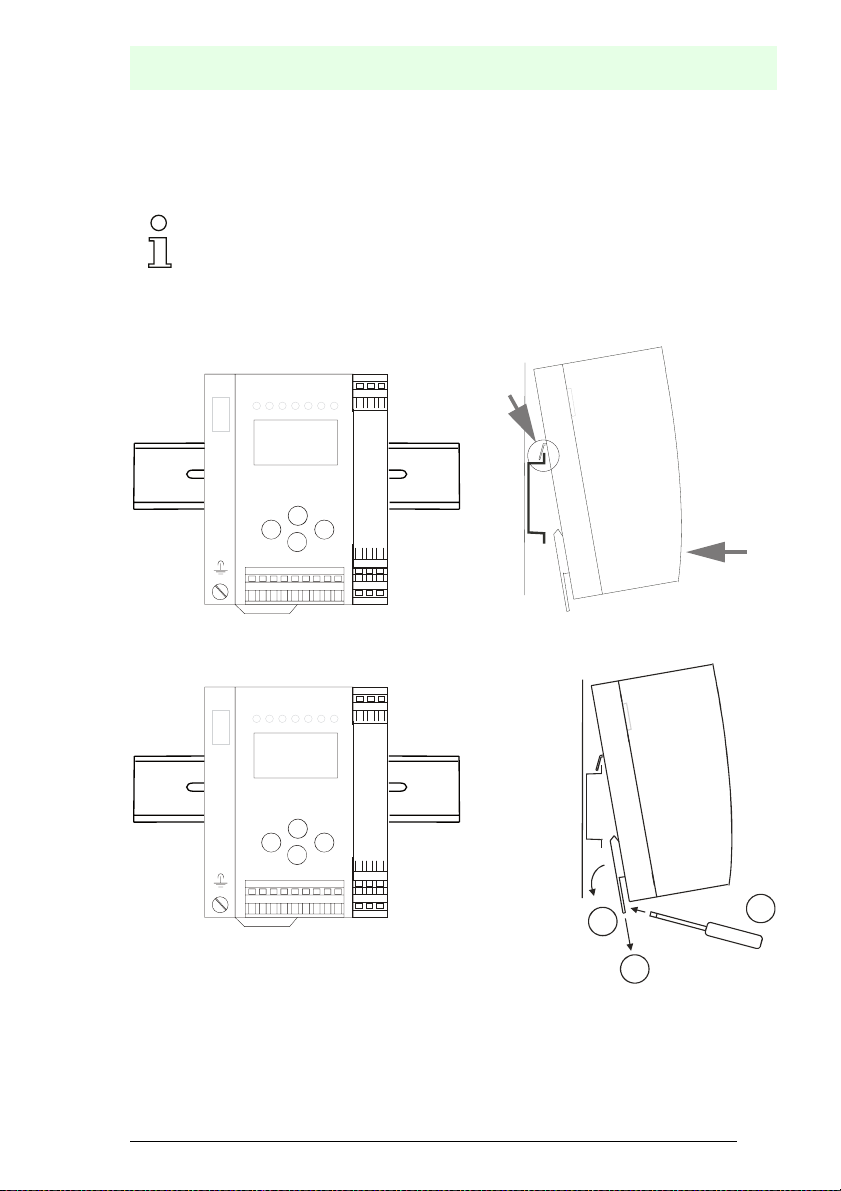

5.3 Installing in the control cabinet

The AS-I/Gateway is installed in the control cabinet on 35mm DIN rails per DIN

EN 50 022.

Information!

The enclosure of the AS-I/Gateway is made of stainless steel. The unit is also suitable for exposed wall mounting.

To install, place the unit on the upper edge of the DIN rail and then snap in the

lower edge.

-

-

+-+

+

AS-Interface

Installation

[1]

[2]

5.4 Removing

-

-

+-+

+

3

2

To remove, press the holding clamps [2] down using a screwdriver [1], press the

unit firmly against the upper rail guide and lift out.

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

1

23

Page 24

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

5.5 Electrical Connection

Information!

Electrical connections are described in section <Electrical connection>.

Information!

See also section <Operation in advanced display mode> for further information.

Installation

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

24

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 25

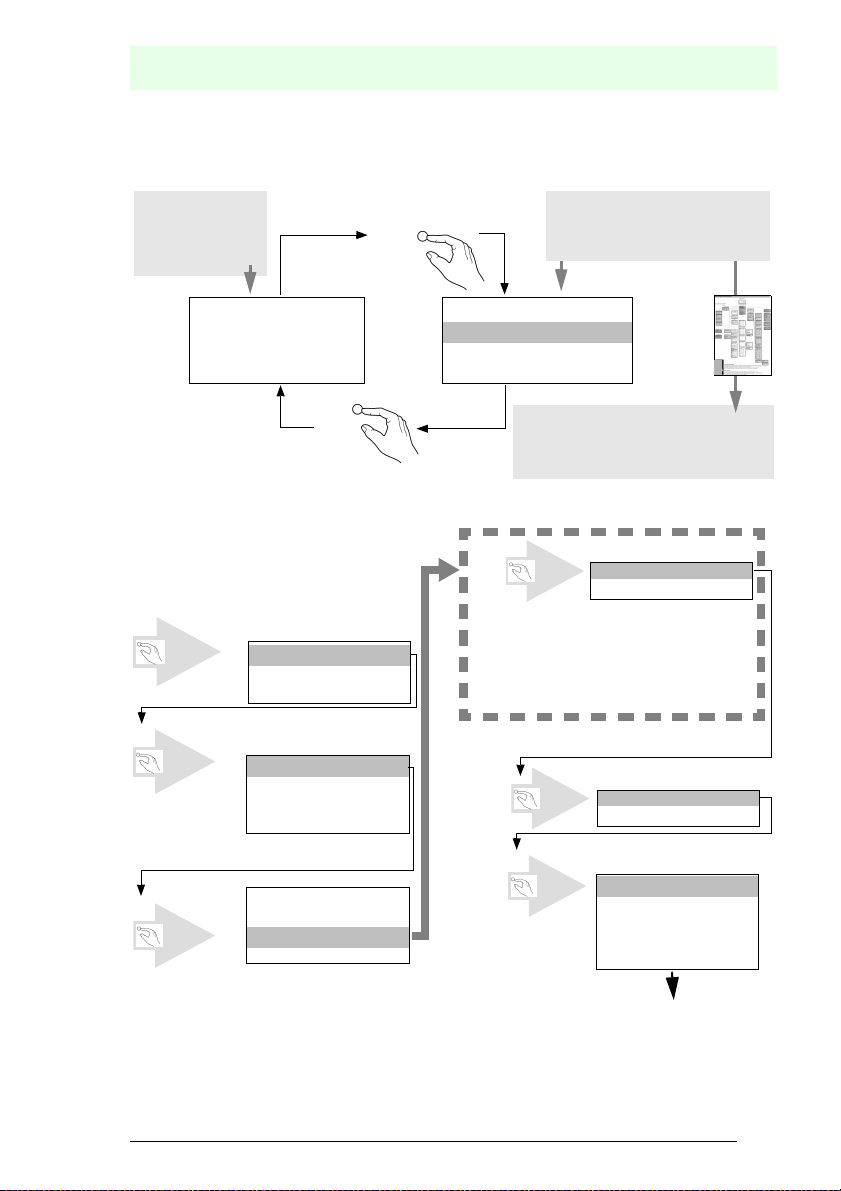

5.6 Commissioning

5.6.1

classical display

Switching to advanced display mode

AS-Interface

Installation

advanced display mode

OK

LCD

1.12A

UNKNOWN SLAVE

ESC

5.6.2 Setting of ethernet properties

LCD

OK

OK

TCP/IP OBJECT

ETHERNET OBJECT

IF STATUS

IF CAPABILITY

IF CONTROL

...

IF STATUS

IF CAPABILITY

IF CONTROL

...

ETHERNET/IP

QUICK SETUP

SETUP

DIAGNOSIS

menu structure see additional page

OK

When using DHCP, no adjustment is necessary

OK

1xESC

LCD

USE DHCP

USE STORED VAL.

IF STATUS

IF CAPABILITY

IF CONTROL

PATH TO LINK OBJ .

TCP/IP CONFIG

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

25

Page 26

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

5

S

5

e

U

R

Installation

IF STATUS

IF CAPABILITY

IF CONTROL

PATH TO LINK OBJ.

TCP/IP CONFIG

IP ADDRESS

192. 168. 42. 149

NET MASK

255. 255. 255. 0

GATEWAY

0 . 0 . 0

IP ADDRESS

192.168.42.149

↓

OK

OK

(

ESC

5.6.3 Connecting AS-i Slaves

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i

...

NET MASK

255. 255. 255. 0

GATEWAY

0 . 0 . 0

AS-i Master

AS-i

OK

(

ESC

OK

(

2xESC

Restart the gateway to assume your chang

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i Master

1. 1

0.5s

NET MASK

255. 255. 25

IP ADDRES

192.168.42.1

NET MASK

255. 255. 25

GATEWAY

0 . 0 . 0

GATEWAY

0 . 0 . 0 . 0

ETHERNET/I

QUICK SET

SLAVE ADD

LCD

AS-i

AS-i

Slave 1

AS-i

Slave 5

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

26

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

1. 41

SEARCHING SLAVES

LCD

Slave 1

AS-i

Slave 5

1. 5

0.5s

Issue date: 17.4.2009

Page 27

5.7 Quick setup

AS-Interface

Installation

config error

1. 5

1xOK

ETHERNET

QUICK SETUP

SETUP

IO + PARAM. TEST

OK

WARNING:

OUTPUTS MAY BE

RESET

OK

LCD

STORE AS-I

CONFIGURATION

OK

STORE +PRJ MODE

↓

2x ESC

LCD

LCD

LCD

.

CONFIGURATION OK

LCD

HOST ERROR

NO CONNECTION

LCD

OK

↓

LCD

STORE AS-I

CONFIGURATION

STORE +RUN

STORE +PRJ MODE

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

27

Page 28

5.8 Error tracing

5.8.1 Faulty slaves

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Installation

1.1

AS-i Master

MISSING SLAVE

LCD

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

5.8.2 Error display (last error)

power

net

config error

U AS-i

AS-i active

prg enable

prj mode

AS-i

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

AS-i Master

power

net

Config error

U AS-i

AS-i active

prg enable

prj mode

AS-Interface

AS-i

Slave 1

AS-i

Slave 5

AS-i

Slave 24

2s

1.24

MISSING SLAVE

2s

AS-i Master

set/↓

LCD

LCD

Host error

no connection

1: ON 2: OFF

24

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

28

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 29

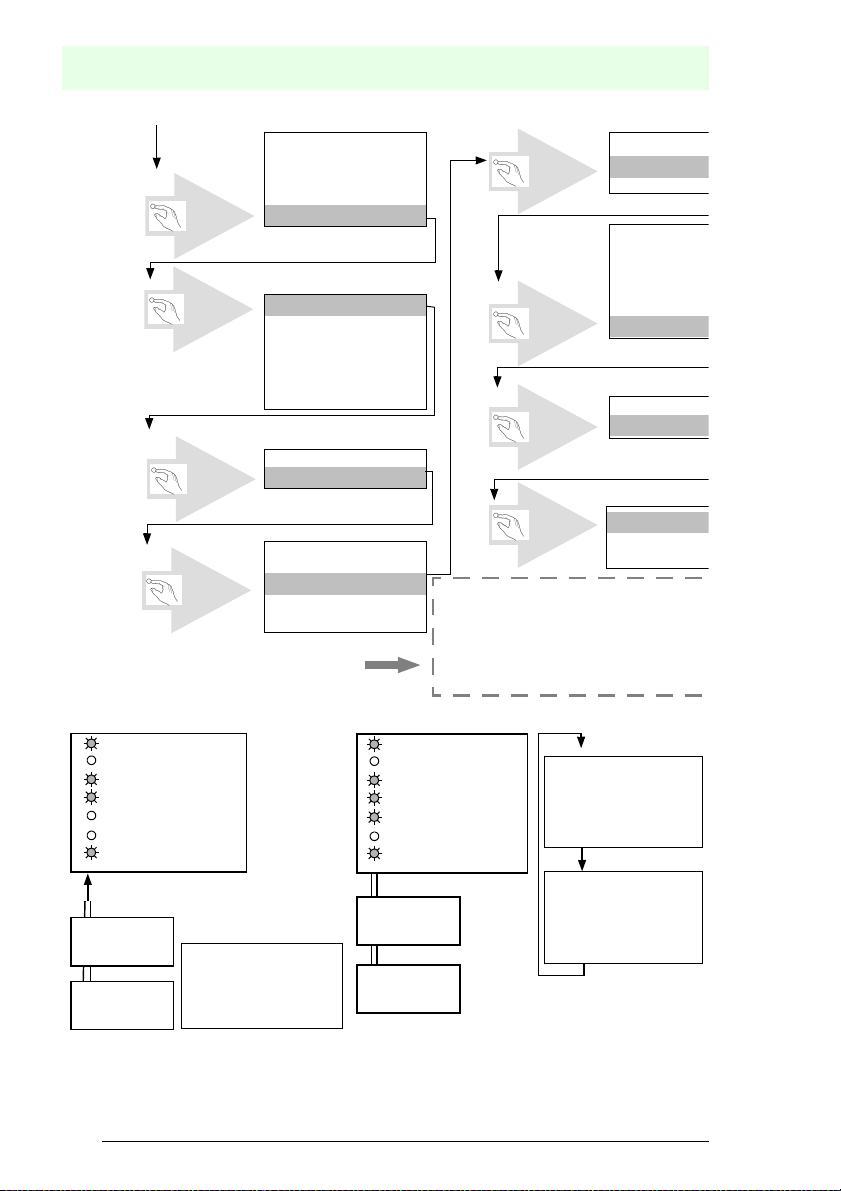

5.8.3 Addressing

5.8.3.1 Assigning address 6 to slave currently at address 2

AS-Interface

Installation

LCD

1. 41

SEARCHING SLAVE

OK

2x

↓

ETHERNET

QUICK SETUP

SLAVE ADR TOOL

SLAVE TEST TOOL

OK

LCD

SLAVE ADR TOOL

CONNECT NEW SLAVE

OLD ADDRESS

NEW ADDRESS

Master Slave

Modul anschließen/Connect

module/Raccordez module/

Collegare modulo/Conecte modulo

LCD

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 3

PRG

1x

↓

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 6

PRG

1x

↓

SLAVE ADR TOOL

OLD ADDRESS 2

NEW ADDRESS 6

PRG

OK

SLAVE ADR TOOL

OK

2 x ESC

1. 6

UNKNOWN SLAVE

3 x OK

LCD

LCD

LCD

LCD

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

29

Page 30

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Installation

For additional information see manual, section <Operation in advanced display

mode>.

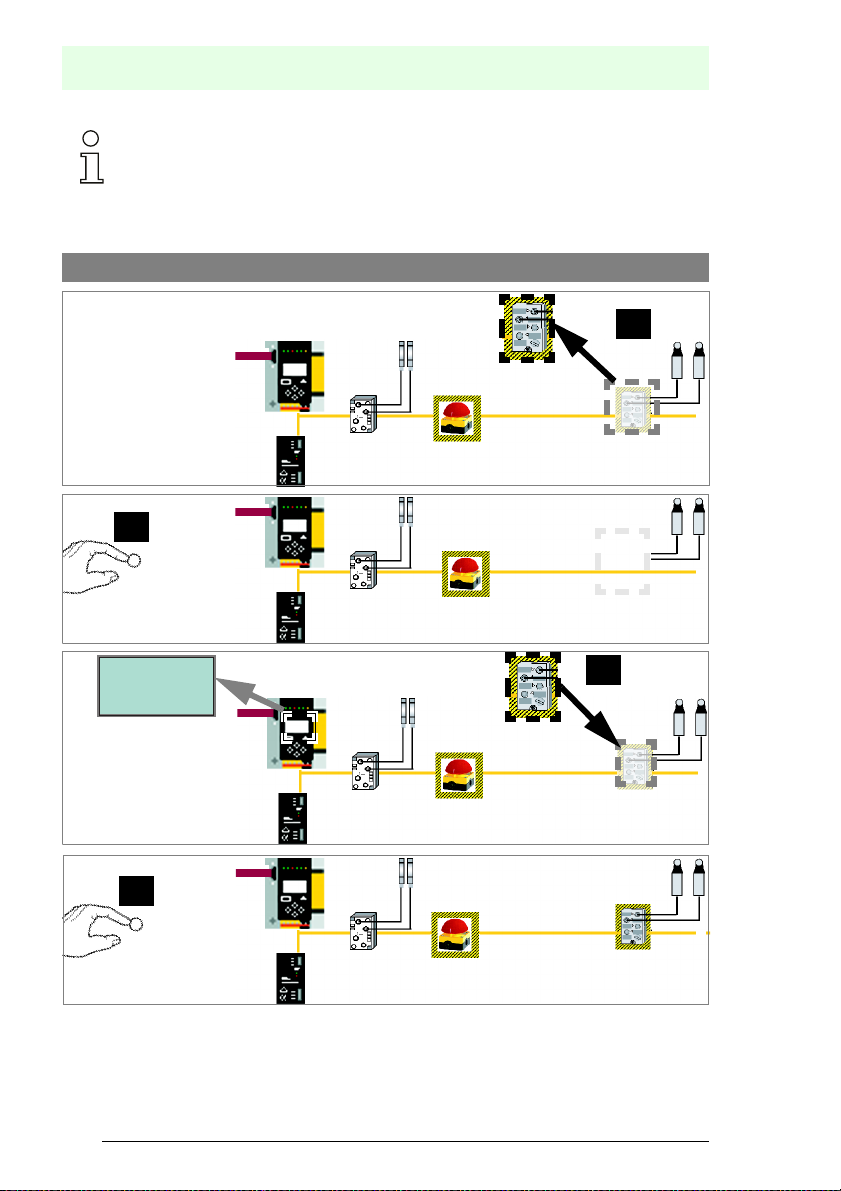

5.8.4 Replacing a defective AS-i Safety Slave

The new slave must be able to send teaching codes and must have the same address as the old one. Only one

missing slave is allowed!

[1]

[2]

ESC/Service

(3 seconds)

CONNECT

NEW SLAVE 17

THEN PRESS

SERVICE

[3]

[4]

ESC/Service

(3 seconds)

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

30

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 31

5.8.5 Replacing the chip card

Always turn off power before inserting or removing the card!

[1]

AS-Interface

Installation

[2]

[3]

[6] [7]

neu/new/neuve/

[8]

[4] [5]

alt/old/ancien/

vecchia/anciano

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

31

Page 32

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

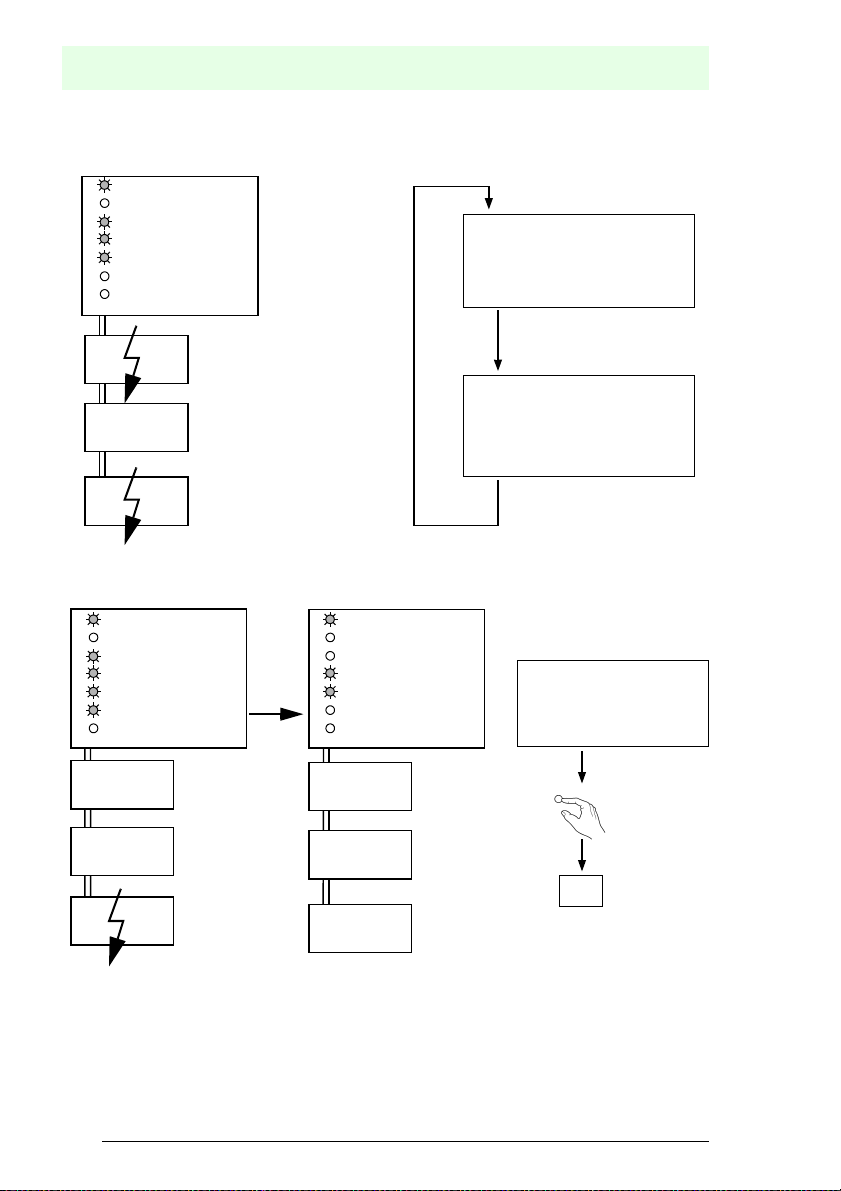

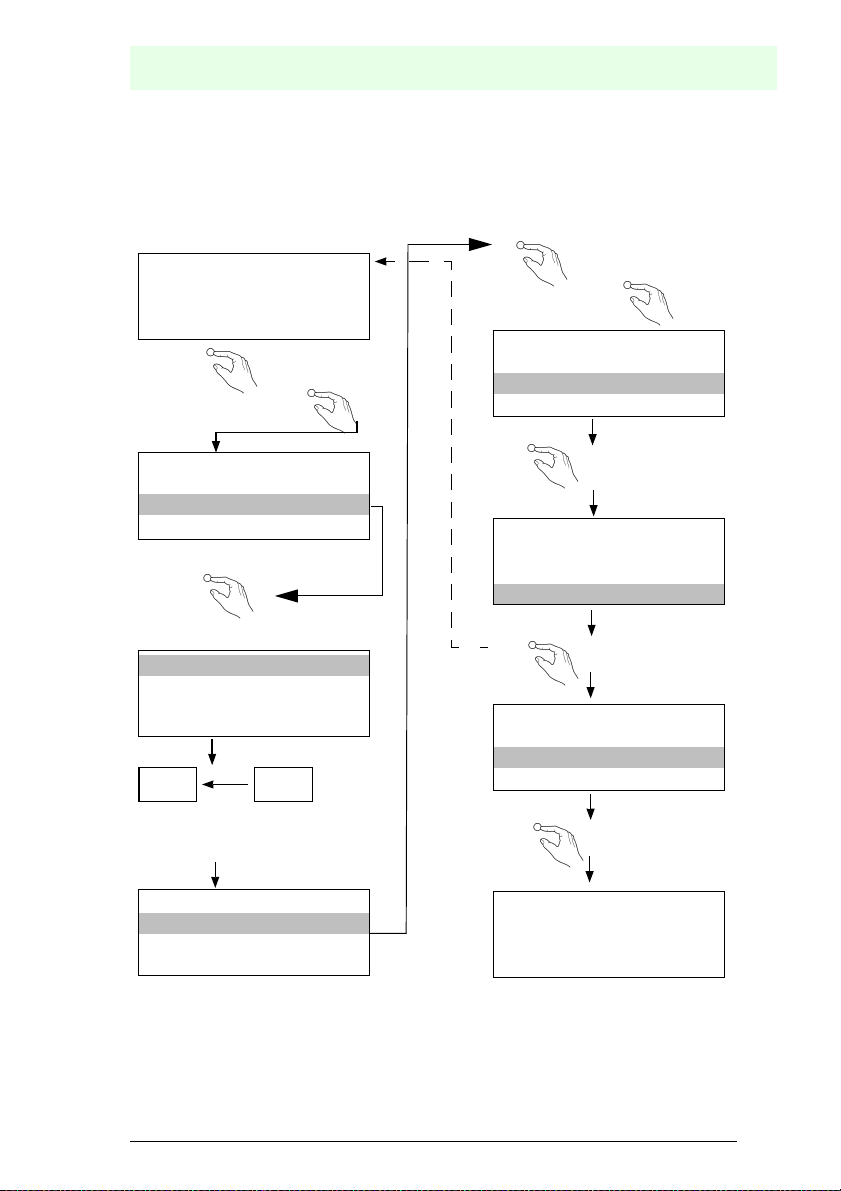

5.8.6 Local parameter setting of safe AS-i/Gateways and Monitors

CHIPCARD AND

DATA

DIFFERENT

CARD->MASTER

MASTER->CARD

CONTINUE

Daten kopieren

Keine Aktion erforderlich

CHIPCARD FOUND

DATA WILL

BE SYNCHRONIZED

Keine Aktion erforderlich

KARTE->MASTER oder

MASTER->KARTE

/No action required/

/Aucune action requise/

/No action required/

/Aucune action requise/

Unsichere Daten / Non-safe data/

Données non-sécurisées/

Dati non sicuri / Datos no seguros/

Geräte+Chipdaten ungleich

(Werkskonfiguration geändert)

/Device+card data not equal

(Factory configuartion changed)

Fehlermeldung:

/Error message/

Geräte+Chipdaten gleich

/Device data+card data equal/

Keine Meldung

Karte leer + formatiert

/Card empty + formatted/

Daten werden synchronisiert:

/No message/

/Data being synchronized/

Installation

Copy data CARD->MASTER

or MASTER->CARD

Copier données Carte->Maître ou

Maître-Carte

Copiare dati Chipcard->Master o

copiare dati Master->Chipcard

Copiar dates Chip->Maestro o

/Nessuna azione richiesta/

/Ninguna deción requrida/

/Nessuna azione richiesta/

/Ninguna deción requrida/

Maestro ->Chip

konfiguration)

DATA FROM

(Werks

Daten kompatibel

/Data compatible (factory

configuration)/

Daten nicht kompatibel

/Data not compatible/

Karte nicht formatiert

/Card not formatted/

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

32

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

CHIPCARD TAKEN

Daten werden übernommen:

/Data being acepted/

CHIPCARD NOT

COMPATIBLE

Fehlermeldung:

/Error message/

NEW CHIPCARD

WILL BE FORMATTED

DATA WILL BE

Karte wird formatiert:

SYNCHRONIZED

/Formatting card /

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

Karte löschen

/Clear the card/

/Supprimer carte/

/Cancellare chipcard/

/Borrar chip/

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

Issue date: 17.4.2009

Page 33

Stamm-/Vollständige

Konfiguartion auf der Chipkarte

enthalten

/Master configuration or

complete configuration on the

card

Sichere Daten / Safe data/

Données sécurisées/

Dati sicuri / Datos seguros

Stamm-/Vollständige

Konfiguartion auf der Chipkarte

/Master configuration or

complete configuration on the

Gerät enthält keine validierte

Konfiguration

/No validated configuration in

Gerät enthält validierte

Konfiguration, Daten ungleich

/There is a validated

configuration on the card, data

not equal

card

Gerät enthält validierte

Konfiguration

/There is a validated

configuration on the card

the device/

Stamm-/Vollständige

Konfiguartion auf der Chipkarte

/Master configuration or

complete configuration on the

card

ERROR.

CHIPCARD AND

SAFETY DATA

COPY BANK A TO

MONITOR

...

RELEASE CODE:

DIFFERENT.

1BDF

Beide Konfigurationen ungleich/

Both configurations not equal

Fehlermeldung:

/Error message/

Beide Konfigurationen gleich/

Both configurations identical

Keine Meldung

/No message/

Datenfreigabe per

Release-Code notwendig:

/Data release via release code

required/

DELETE CHIPCARD

OR SAFETY DATA

Daten löschen

/Clear data/

/Supprimer données /

/Cancellare dati

Keine Aktion erforderlich

/No action required/

/Aucune action requise/

---------------

TYPE CODE

1BDF OK

Konfiguration per

Release-Code freigeben

/Validate the configuration

AS-Interface

Installation

/Borrar datos

/Nessuna azione richiesta/

/Ninguna deción requrida/

via release code/

/Respecter les indications

de sécurité exposées dans

le manuel ASIMON

/Osservare le istruzioni di

sicurezza riportate nel

manuale ASIMON

/Habilitar la configuratión

con el código de liberatión/

CHIPCARD FOUND

SAFETY DATA WILL

Validierte Konfiguration im

Gerät, Chipkarte leer

/Validated configuration

in the device, chip card empty/

Keine validierte Konfiguration im

Gerät + Chipkarte

/No validated configuration in

the device + chip card/

Sichere Daten auf der

Chipkarte nicht kompatibel

zum Gerät

/Safe data on the chip card

not compatible to the device/

BE SYNCHRONIZED

Daten werden synchronisiert:

/Data being synchronized/

CHIPCARD FOUND

SAFETY DATA WILL

Daten werden synchronisiert:

/Data being synchronized/

CHIPCARD NOT

COMPATIBLE

Fehlermeldung:

/Error message/

Keine Aktion erforderlich

BE SYNCHRONIZED

Keine Aktion erforderlich

Karte löschen

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

/No action required/

/Aucune action requise/

/Nessuna azione richiesta/

/Ninguna deción requrida/

/Clear the card/

/Supprimer carte/

/Cancellare chipcard/

/Borrar chip/

For further information see manual, section <Chip card>

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

33

Page 34

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

Installation

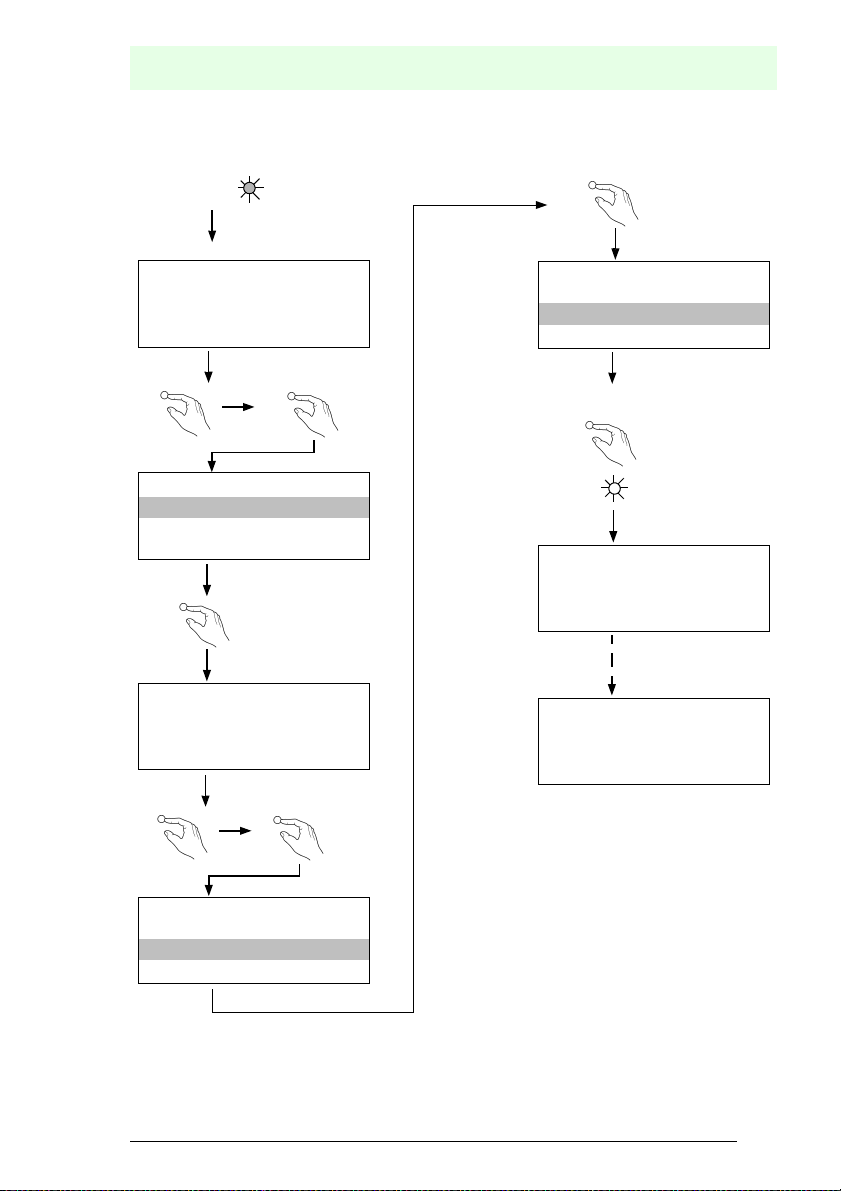

5.9 Safe configuration using ASIMON 3 G2

ASIMON 3 G2

Software

Start

Before commissioning the safety unit, put the gateway into operation!

ASIMON 3 G2 Software

Change the preset password during the first use of the device (Monitor/change password)!

ASIMON 3 G2 Software

Create the desired configuration.

ASIMON 3 G2 Software

Download the configuration with MONITOR / PC-> MONITOR into the device. Enter the password for

this purpose.

ASIMON 3 G2 Software

You can acknowledge the request TEACH CODE SEQUENCES? selecting "Yes", or you can do it later

via display selecting "No".

ASIMON 3 G2 Software

Check the configuration log (respect instructions in <chap. 5.8> of the ASIMON manual!).

ASIMON 3 G2 Software

Validate the configuration with MONITOR –> VALIDATION.

ASIMON 3 G2 Software

Start the monitor with MONITOR–> START.

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

34

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 35

ASIMON 3 G2 Software

☺Press OK for Menu

Output Circuit

1:ON 2:OFF

If you have assigned the safety monitor its own address in the software

ASIMON 3 G2, adjust the configuration in the AS-i master (Quick Setup)! This is also

valid when using simulated slaves.

Please consider notes on safety in the software manual ASIMON 3 G2!

☺ Press OK for Menu

Output Circuit

1:ON 2:ON

3:ON 4:ON

The device is in the protected mode now.

AS-Interface

Installation

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

35

Page 36

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

6. Maintenance

6.1 Checking for safe turn-off

The safety representative is responsible for checking flawless function of the AS-i

Safety Monitor within the safety system.

Safe turn-off when an associated safe sensor or switch is triggered must be

checked at least once a year.

Attention!

To do this, actuate each safe AS-i slave and observe the switching behavior of

the output circuits of the AS-i Safety Monitor.

Attention!

Note the maximum turn-on duration and the overall turn-on operating duration.

These values depend on the PFD value selected (see section <Safety-relevant

characteristic data>).

When the maximum turn-on duration is reached (three, six or twelve months),

check the complete safety system and its proper function.

When the total operating time (20 years) has been reached, the device must be

returned to the manufacturer to check for proper function.

Maintenance

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

36

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 37

7. Electrical connection

7.1 Overview of terminals, indicators and operating elements

7.1.1 VBG-EN-K30-DMD-S16

AS-Interface

Electrical connection

[1]

[6]

[2]

[3]

[1]

[4]

[5]

-

-

+-+

+

[6]

[7]

[8]

Legend:

[1] LEDs

[2] EtherNet/IP interface

[3] LC display

[4] Buttons

[5] Terminals: Supply voltage and AS-i circuit

[6] Terminals: Safety monitor

[7] Chip card slot

[8] RS 232 diagnostics port

1

5 ... 6 mm / PZ2

10

2 x (0,5 .... 1,5) mm

10

2 x (0,5 ..

AWG 2 x 24 ...12

0,8 Nm

7 LB.IN

.. 1,5) mm

2

2

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

1. Only together with ASIMON 3 G2 Software or AS-i Control Tools

37

Page 38

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

7.2 AS-i bus connection

Blue

AS-i-

Brown

AS-i+

Blau

AS-i-

Electrical connection

Braun

AS-i+

Yellow ASi ribbon cable

2-conductor AS-i round cable

(Recommended: flexible power cable

H05VV-F2x1,5 per DIN VDE 0281)

Information!

Electrical work is to be performed only by electrical technicians.

7.3 Information about the device types

Information!

A listing of the individual devices and their features can be found in section <Product

information>.

7.4 AS-i and power supply terminal assignments

Information!

The cable indicated by hatching must not have slaves or repeaters connected to

it.

The yellow cable must not have AS-i power suppliers or additional masters connected to it.

Information!

The function ground can be connected either to the grounding screw or to the terminal.

The function ground should be made with as short a cable as possible to ensure good

EMC characteristics.

Therefore function grounding using the grounding screw is preferred.

Attention!

The AS-I power supply for the AS-I components must have isolation per IEC 60

742 and be able to handle momentary power interruptions of up to 20 ms. The

power supply for the 24 V supply must also have isolation per IEC 60 742 and be

able to handle momentary power interruptions of up to 20 ms. The maximum output voltage of the power supply must also be less than 42 V in case of a fault.

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

38

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 39

7.4.1 Electrical connection VBG-EN-K30-DMD-S16

Gateway Safety Monitor

M4

5 mm max!

Function ground

-

+ASI 1–

ASI 1 +PWR– (max. 8A)

+ASI 2–

+

ASI 2 +PWR– (max. 8A)

-

+-+

+

Terminal Signal / Description

+ASI 1– Connection to AS-i Circuit 1

+ASI 2– Connection to AS-i Circuit 2

ASI 1 +PWR– Supply voltage for AS-i Circuit 1 (max. 8 A)

ASI 2 +PWR– Supply voltage for AS-i Circuit 2 (max. 8 A)

FG Function ground

Information!

AS-i Circuits 1 and 2 are powered by separate power supplies.

AS-Interface

Electrical connection

Information!

For additional information, please refer to the section <AS-i and power supply terminal

assignments>.

Issue date: 17.4.2009

Subject to reasonable modifications due to technical advances. © Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

39

Page 40

AS-i 3.0 EtherNet/IP Gateway with integrated Safety Monitor

7.5 Diagnostics interface

The service and diagnostics interface (in conjunction with AS-i Control Tools or

ASIMON 3 G2 software) is used for communication between the PC and the unit.

7.5.1 Diagnostics port RS 232

The service and diagnostics interface is configured as a mini DIN-6 female and it

is placed on the front plate, on the left hand side.

7.6 Chip card

The configuration is stored in a fixed installed EEPROM and can be overwritten

by the chip card. The chip card does not have to be inserted in operation.

Warning!

Power must always be turned off when removing or inserting the chip card!

Electrical connection

7.7 EtherNet/IP interface

A

B

The EtherNet/IP interface consists of two RJ-45 sockets. It is placed on the left

housing side (see section <Overview of terminals, indicators and operating elements>). The RJ-45 socket is based on the MDI (none auto-crossover) and supports 10 Base T or 100 Base TX networks according to the IEEE 802.3

Subject to reasonable mod ifications due to technical advances. © Pepperl+Fuchs, Printe d in Germany

40

Pepperl+Fuchs Group · Tel.: Germany (6 21) 7 76-0 · USA (3 30) 4 25 35 55 · Singapore 7 79 90 91 Internet http://www.pepperl-fuchs.com

Issue date: 17.4.2009

Page 41

7.8 Release circuits

7.8.1 Wiring overview of Safety Monitor

1.13

2.13+24 V

0 V

+

2.Y2

2.Y1

Aux

1.Y1

1.Y2

2.Y1

2.Y2

K1

K2

K3

K4

1.Y2

1.Y1

2.14+4.14+1.14

3.14

1.Y1 (EDM 1/Start 1), 2.Y1 (EDM 2/Start 2), 1.Y2 (EDM 3/Start 3),

2.Y2 (EDM 4/Start 4)

The safety unit provides 4 inputs. The EDM & START inputs can be defined freely.

The inputs may not be connected to other potentials, but rather only directly or

through potential-free switches to + (for EDM/START).

Switching current static 4 mA at 24 V, dynamic 30 mA at 24 V (T=100 µs).

3.14, 4.14

AS-Interface

Electrical connection

Semiconductor outputs. Max. contact load: 0.5 A DC-13 at 30 V.

1.14, 2.14; 1.13, 2.13

Potential-free relay contacts. Safety relay with one contact set for read-back. Max.

contact load: 3 A AC-15 at 30 V, 3 A DC-13 at 30 V.

0V, 24V

Semiconductor outputs are powered by separate 24 V DC.

+ (for EDM/Start)