Page 1

VBA-4E3A-G20ZEL/M1L-P2

AS-Interface

Motor Control Module

FACTORY AUTOMATION

MANUAL

Page 2

1 Introduction ................................................................................. 4

2 Declaration of Conformity .......................................................... 5

3 Safety ................................................................................................. 6

3.1

Symbols Relevant to Safety ................................................................. 6

3.2

Intended Use .......................................................................................... 6

3.3

General Safety Information ................................................................... 6

4 Product Description .................................................................... 7

4.1

Use and Application.............................................................................. 7

4.2

Housing .................................................................................................. 8

4.3

Indicators and Operating Controls ...................................................... 9

4.4

Interfaces and Connections ............................................................... 11

5 Installation ................................................................................. 13

5.1

Storage and Transport .............................................................................. 13

5.2

Unpacking ............................................................................................ 13

5.3

Connecting the AS-Interface and Auxiliary Power Flat Cable ........ 13

5.4

Connecting Motors and Sensors ....................................................... 16

6 Commissioning ......................................................................... 17

6.1

AS-Interface Communication ............................................................. 17

6.2

Configuration of the Start/Stop Ramps ............................................. 19

7 Troubleshooting .............................................................................22

3

VBA-4E3A-G20-ZEL/M1L-P2

Page 3

VBA-4E3A-G20-ZEL/M1L-P2

Introduction

1 Introduction

Congratulations

You have chosen a device manufactured by Pepperl+Fuchs. Pepperl+Fuchs develops,

produces and distributes electronic sensors and interface modules for the market of

automation technology on a worldwide scale.

Please read the operating instructions carefully before installing this device and putting it into

operation. The instructions and notes contained in this document will guide you step by step

through the installation and commissioning procedures to ensure trouble-free use of this

product. By doing so, you:

■

Guarantee safe operation of thedevice

■

Can utilize the entire range of device functions

■

Avoid faulty operation and associated faults

■

Reduce costs associated with downtime and incidental repairs

■

Increase the effectiveness and operating efficiency of your plant.

Store these instructions somewhere safe in order to have them available for future work on the

device.

After opening the packaging, please ensure that the device is intact and that the package is

complete.

Symbols used

The following symbols are used in this manual:

Note!

This symbol draws your attention to important information.

Handling instructions

You will find handling instructions beside this symbol

4

Page 4

VBA-4E3A-G20-ZEL/M1L-P2

Declaration of Conformity

2 Declaration of Conformity

All products were developed and manufactured under observance of the applicable European

standards and guidelines.

Note!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, 68307 Mannheim, has a certified quality

assurance system that conforms to ISO 9001.

ISO9001

5

Page 5

VBA-4E3A-G20-ZEL/M1L-P2

Safety

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

3

Safety

3.1

Symbols Relevant to Safety

3.2

Intended Use

The AS-Interface motor control module is used to control one or two DC roller Rulmeca RDR

BL3 motors. The motor control module has two inputs for connecting three-wire sensors.

Read through these instructions thoroughly. Familiarize yourself with the device before

installing, mounting, or operating.

Always operate the device as described in these instructions to ensure that the device and

connected systems function correctly. The protection of operating personnel and plant is only

guaranteed if the device is operated in accordance with its intended use.

3.3

General Safety Information

Make sure that the flat cables engage completely in the flat cable guide, to ensure a complete

seal and secure contact.

During operation, make sure that connectors are not disconnected or inserted, and the flat

cable guide is not opened. This could inadvertently start motors.

Only instructed specialist staff may operate the device in accordance with the operating

manual.

User modification and or repair are dangerous and will void the warranty and exclude the

manufacturer from any liability. If serious faults occur, stop using the device. Secure the device

against inadvertent operation. In the event of repairs, return the device to your local

Pepperl+Fuchs representative or salesoffice.

The connection of the device and maintenance work when live may only be carried out by a

qualified electrical specialist.

The operating company bears responsibility for observing locally applicable safety regulations.

Store the not used device in the original packaging. This offers the device optimal protection

against impact and moisture.

Ensure that the ambient conditions comply with regulations.

Note!

Disposal

Electronic waste is hazardous waste. When disposing of the equipment, observe the current

statutory requirements in the respective country of use, as well as local regulations.

6

Page 6

VBA-4E3A-G20-ZEL/M1L-P2

Product Description

4

Product Description

4.1

Use and Application

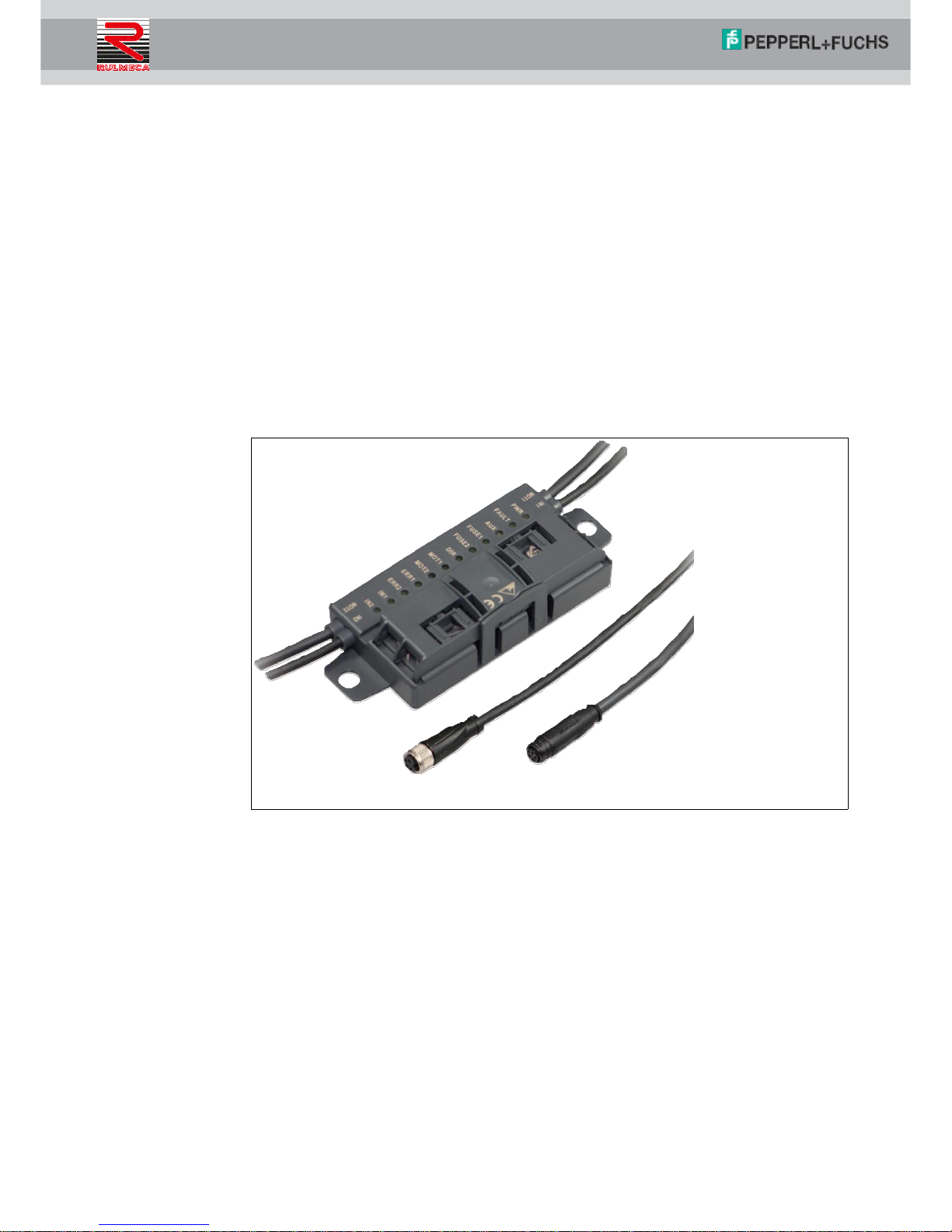

The VBA-4E3A-G20-ZEL/M1L-P2 motor control module is an AS-Interface connection module

for controlling one or two DC roller motors. The module is optimized for type Rulmeca RDR

BL3 motors.

To record statuses in the field environment, the module has two inputs for three-wire sensors

with positive-switching output (PNP) or for mechanical contacts. The input characteristic of the

inputs corresponds to type 1 according to EN 61131-2.

The motors and the sensors are supplied with power via external auxiliary power. This auxiliary

power is supplied to the AS-Interface flat cable of the motor control module via a second flat

cable.

■

The permissible auxiliary power is 18 V ...... 30 V.

■

The sensor power supply may be loaded, in total, with 500 mA.

■

For each motor, a maximum current load of 5 A is permitted.

Figure 4.1 VBA-4E3A-G20-ZEL/M1L-P2 motor control module

7

Page 7

VBA-4E3A-G20-ZEL/M1L-P2

Product Description

Essential function and application characteristics of the motor control module are:

■

Compact housing for direct mounting in support profiles or cable ducts

■

Connection of the motors/sensors via cable outputs with M8 connectors

■

Insulation piercing technology with gold-plated contact pins for contacting the ASInterface flat cable

■

Function displays for the bus, external auxiliary power, status information, inputs, and

outputs

■

Communication monitoring

■

Configurable start/stop ramps for motorcontrol

■

Supply of the connected components from the external auxiliary power

4.2

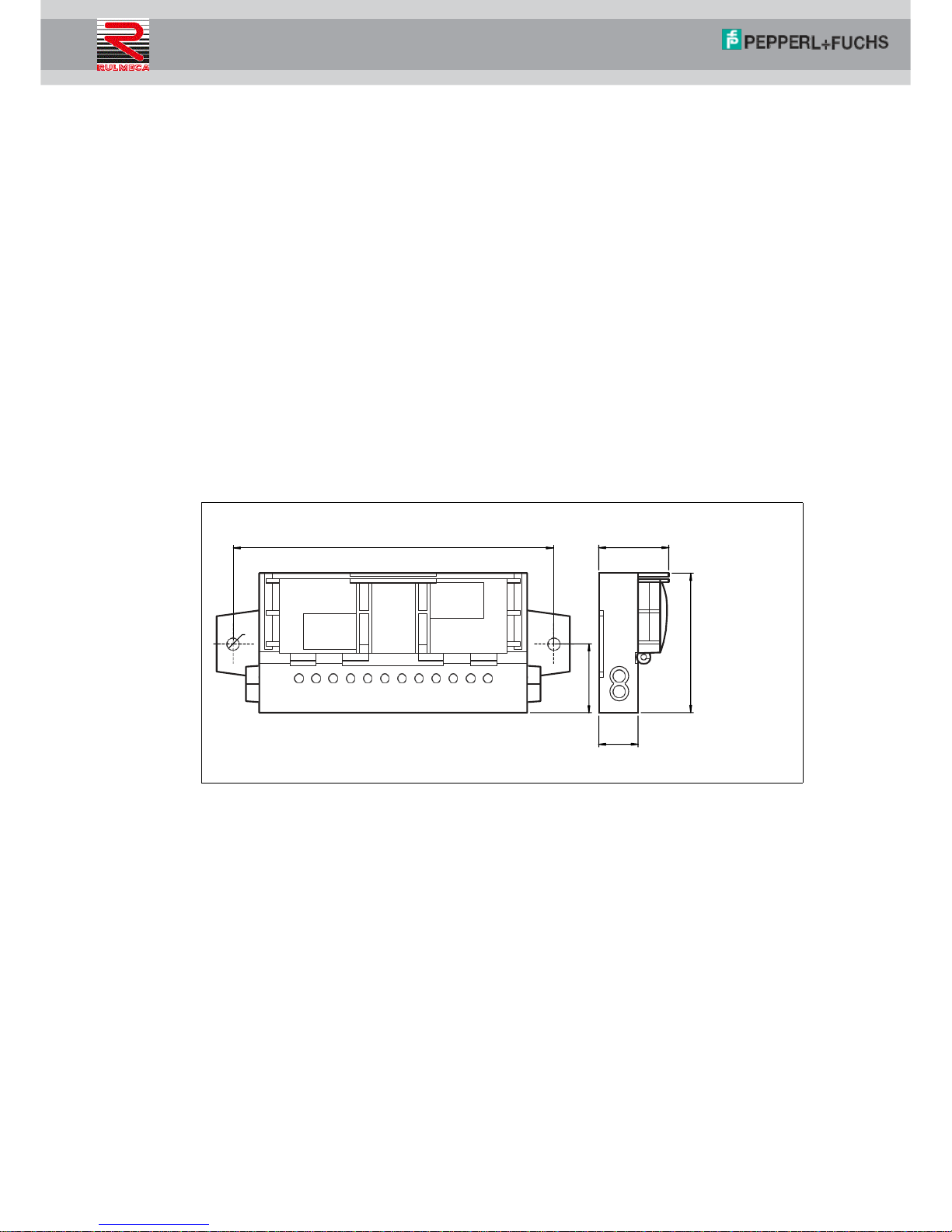

Housing

The housing is made entirely of plastic, with the exception of the hinge pins for the hinged cable

guide.

The main components are

■

A mounting base with electronics encapsulated in casting resin

■

A folding guide cage as a cable guide for the AS-Interface flat cable.

Figure 4.2 Housing dimensions

8

15

Ø 8

27.5

120

27.5

54

Page 8

VBA-4E3A-G20-ZEL/M1L-P2

Product Description

4.3

Indicators and Operating Controls

Figure 4.3 Status indications on the motor controlmodule.

The operating status of the motor control module is displayed via 12 LEDs.

Note!

Additional Flashing Codes during Module Configuration

The following status information relates only to the normal mode of the motor control module. If

you set the motor control module to configuration mode for parameterization, this is indicated

by multiple LEDs flashing. Details can be found in the "Commissioning" chapter.

Status Indication for Start/Stop Ramps

Once the AUX external auxiliary power has been switched on, the motor control module first

shows the number of the stored start/stop ramp. For ramps 1 to 7, the ERR2, IN1, and IN2

LEDs indicate a numerical value in binary code by short flashing. ERR2 LED is the highest

value bit. The LEDs flash five times for 50 ms each time.

If no start/stop ramp is stored, the six MOT1 ... IN2 LEDs flash.

For more information on the start/stop ramps, see "Configuration of Start/Stop Ramps" in the

"Commissioning" chapter.

Start/Stop Ramp Display

Ramp no.

LED MOT1

LED MOT2

LED ERR1

LED ERR2

IN1 LED

IN2 LED

0 Flashes

Flashes

Flashes

Flashes

Flashes

Flashes

1 Off

Off

Off

Off

Off

Flashes

2 Off

Off

Off

Off

Flashes

Off

3 Off

Off

Off

Off

Flashes

Flashes

4 Off

Off

Off

Flashes

Off

Off 5

Off

Off

Off

Flashes

Off

Flashes

6 Off

Off

Off

Flashes

Flashes

Off

7 Off

Off

Off

Flashes

Flashes

Flashes

9

MOT2

MOT1

IN2

IN1

AUX BLACK ASI YELLOW

PWR

FAULT

AUX

FUSE1

FUSE2

DIR

MOT1

MOT2

ERR1

ERR2

IN1

IN2

Page 9

VBA-4E3A-G20-ZEL/M1L-P2

Product Description

Status Indications for AS-Interface and Power Supply

The PWR LED and the FAULT LED show the AS-Interface operating status. Various error

statuses are displayed as a collective error message "Peripheral fault."

Display of the AS-Interface Operating Statuses

LED PWR

Green

LED FAULT

Red Status

On

Off

AS-Interface power supply is OK

Flashes

On

Address = 0

On

On

AS-Interface communication error

Flashes

Flashes

Peripheral fault, collective error message for:

■

AUX external auxiliary power is missing or is inverted

■

Overload of the sensor supply (IN+, IN-)

■

Overload of the speed signal SPEED

Off

Off

AS-Interface voltage missing

The AUX LED shows the status of the AUX external auxiliary power.

Display of the AUX External Auxiliary Power

AUX LED

Red/green

Status

Green on

AUX external auxiliary power is OK

Red on

AUX external auxiliary power is inverted

Off

AUX external auxiliary power voltage is missing

Status Indications for Motor Fuses

The FUSE1 LED for motor 1 and the FUSE2 LED for motor 2 show the status of the power

supplied to the motors.

Motor Fuse Indicator

LED FUSE1

LED FUSE2

Green

Status

On

Power supply for motor is OK

Off

Power supply for motor is missing:

■

Fuse is faulty or

■

AUX external auxiliary power is not connected

Note!

Motor Fuses Are Safety Fuses

Fuses with a 5 A rated current act as protection against short circuits. Each motor is

safeguarded with a fuse. The fuses are not interchangeable. If a fuse is faulty, the module must

be replaced.

10

Page 10

VBA-4E3A-G20-ZEL/M1L-P2

Product Description

Status Indications for Motors MOT1, MOT2

The MOT1, MOT2, ERR 1, ERR2, and DIR LEDs display information about the operating

statuses of the respective motor.

Motor Activity Indicators

LED MOT1

LED MOT2

Yellow

Status

On

Motor is in operation

Off

Motor is off

Motor Fault Indicators

LED ERR1

LED ERR2

Yellow

Status

On

Motor fault is present:

■

Fault output of the motor is active or

■

No motor is connected or

■

Fuse is faulty

Off

No motor fault

Motor Direction of Rotation Indicator

LED DIR

Yellow

Status

On

Direction of rotation to the right (in accordance with RDR BL3,)

Off

Direction of rotation to the left (in accordance with RDR BL3,)

Status Indications for IN1, IN2 Sensors

The IN1 LED for input 1 and IN2 LED for input 2 show the switching statuses of the inputs.

Display of the Inputs

IN1 LED

IN2 LED

Yellow

Status

On

Input is set (high)

Off

Input is not set (low)

4.4

Interfaces and Connections

Flat Cable Specification

The AS-Interface motor control module is compatible with the AS-Interface standard cable in

accordance with IEC 62026-2.

11

Page 11

VBA-4E3A-G20-ZEL/M1L-P2

Product Description

The following AS-Interface cable types are available with UL Recognized approval:

AS-Interface Cable Types with UL Approval

Pepperl+Fuchs

Designation

Color

Sheathing material/

wire insulation

Cross-section

UL "Cable Style"

Approval

VAZ-FK-R-YE

Yellow

TPE/TPE

2x 1.5 mm

2103

VAZ-FK-R-BK

Black

TPE/TPE

2x 1.5 mm

2103

VAZ-FK-PUR-YE

Yellow

PUR(TMPU)/TPM

2x 1.5 mm

20549

VAZ-FK-PUR-BK

Black

PUR(TMPU)/TPM

2x 1.5 mm

20549

Input/Output Connections

The sensors and motors are connected to the motor control module via cables with round M8

connectors:

■

Sensors: socket, four-pin

■

Motors: socket, five-pin

The cable length is 1m.

Motor Supply from Auxiliary Power

The motors are supplied with power directly from the AUX external auxiliary power and this

cannot be switched. The voltage is always on contacts 1 and 3 of the five-pin M8 connector.

Connector Assignment

Connection for

Connectors

Plug type/plug assignment

Sensor

4

2

Input: LF004-GS1-A in accordance with

IEC/EN 61076-2-104

M8, 4-pin, socket, cap nut, coding A

Matching female connector: LM004-Gx1-A

or similar

1: IN+ sensor supply

2: Not used

3: IN- sensor supply

4: IN input

3 1

Motor

4

2

Motor: NF005-SS1-B in accordance with

IEC/EN 61076-2-104

M8, 5-pin, socket, snap lock, coding B

Matching female connector: NM005-Sx1-B

or similar

1: MOT+ motor supply

2: DIR direction of rotation

3: MOT- (=AUX-) motor supply

4: ERROR motor fault

5: SPEED velocity signal

3 1

5

12

Page 12

VBA-4E3A-G20-ZEL/M1L-P2

Installation

5

Installation

5.1

Storage and Transport

For storage and transport purposes, package the unit using shockproof packaging material

and protect it against moisture. The best method of protection is to package the unit using the

original packaging. Furthermore, ensure that the ambient conditions are within allowable range.

5.2

Unpacking

Check the product for damage while unpacking. In the event of damage to the product, inform

the post office or parcel service and notify the supplier.

Retain the original packaging in case the device must be stored or shipped again at a later

date.

Should you have any questions, please direct them to Pepperl+Fuchs.

5.3

Connecting the AS-Interface and Auxiliary Power Flat Cable

The motor control module is connected to the AS-Interface network and the AUX auxiliary

power via the AS-Interface flat cable. The yellow flat cable is for communication and the black

flat cable is for the AUX auxiliary power. The permissible auxiliary power is 18 V ... 30 V.

Contact between the motor control module and flat cables is established via two metal

mandrels and using insulation piercing technology. The flat cables are routed through a hinged

cable guide. When closed, the cable guide is locked using a locking bracket and can be

opened again without the needsfor tools.

The profiled flat cables have a narrow upper side (with a visibly offset profile edge) and a wide

under side (profile edge not visible). The cable guide allows the flat cables to be inserted on

both sides, for flexible connection of flat cables already laid in cable ducts. However, you must

make sure that the profile edge always points to the motor control module. Mechanical reverse

polarity protection prevents complete closure of the cable guide if the flat cable is inserted

incorrectly.

13

Caution!

If one is inserted incorrectly, the motor control module will not work.

If the flat cable is inserted in the cable guide in the wrong direction, the voltage is inverted. The

motor control module will not work. However, internal electrical reverse polarity protection

protects it against breakage.

Page 13

VBA-4E3A-G20-ZEL/M1L-P2

Installation

4 3 5 2

AUX

YELLOW

BLACK

1

Connecting Flat Cables on the Narrow Side

The profile edge is visible from above.

1.

Open the cable guide. To do this, push the locking bracket (1) slightly to one side.

2.

Insert the black AUX flat cable with the profile edge (4) to the motor control module into the

lower guide (see the module tag "Black AUX").

3.

Insert the yellow AS-Interface flat cable with the profile edge (3) to the motor control module

into the upper guide (see the module tag "YELLOW").

4.

Make sure that the profile edges of both flat cables are under the respective reverse polarity

protection (2, 5).

5.

Close the cable guide. It must engage securely in the locking bracket (1).

The metal mandrels contact the strands in the flat cables.

Figure 5.1 Connecting Flat Cables on the Narrow Side

14

Page 14

VBA-4E3A-G20-ZEL/M1L-P2

Installation

Connecting Flat Cables on the Wide Side

The profile edge is not visible from above. For orientation purposes in the figure below, the

edge is shown as a hidden edge drawn with a dotted line.

1.

Open the cable guide. To do this, push the locking bracket (1) slightly to one side.

2.

Insert the black AUX flat cable with the profile edge (3) to the motor control module into the

lower guide (see the module tag "Black AUX").

3.

Insert the yellow AS-Interface flat cable with the profile edge (2) to the motor control module

into the upper guide (see the module tag "YELLOW").

4.

Close the cable guide. It must engage securely in the locking bracket (1).

The profile edges (2, 3) of both flat cables are above the two reverse polarity protections.

The metal mandrels contact the strands in the flat cables.

Figure 5.2 Connecting flat cables on the wide side (profile edge as dotted line)

15

2 3

AUX

YELLOW

BLACK

1

Page 15

VBA-4E3A-G20-ZEL/M1L-P2

Installation

Flat Cable Inserted Incorrectly

The figure below shows an incorrectly inserted flat cable. The profile edge (2) does not point to

the motor control module; the flat cable is therefore inserted with reverse polarity. The flat cable

is located on the reverse polarity protection (1) with a curvature, which means that the cable

guide cannot be closed completely (mechanical reverse polarity protection).

Figure 5.3 Flat cable inserted incorrectly (profile edge as dotted line)

5.4

Connecting Motors and Sensors

Figure 5.4 Connection wiring diagram for motors and sensors

16

1

2

AUX+

AUX-

AUX

5

MOT

1 3

M

4 2

MOT1 & MOT2

MOT+

DIR

ERROR

SPEED

MOT-

1

2

4

5

3 ERR

FAULT

FUSE

DIR

PWR

IN

IN-

(n.c.)

3

2

AS-Interface -

2

1

4

3

IN1 & IN2

1

IN+

4

IN

AS-Interface +

Page 16

VBA-4E3A-G20-ZEL/M1L-P2

Commissioning

6

Commissioning

6.1

AS-Interface Communication

Assigning the AS-Interface Data Bits

Four data bits are available for communication to take place between the motor control module

and the master. Three data bits are available for controlling the motors.

The following designations apply below:

■

DI0...DI3 for AS-Interface input data (motor control module to master)

■

DO0...DO2 for AS-Interface output data (master to motor control module)

DI0...DI03 Motor Control Module to Master

AS-Interface data bit

Input DI

DI0

Fault at output MOT1

DI1

Fault at output MOT2

DI2

Switching status input IN1

DI3

Switching status input IN2

DO0...DO2 Master to Motor Control Module

AS-Interface data bit

Output DO

DO0

Start/stop motor 1

DO1

Start/stop motor 2

DO2

Direction of rotation of motor 1 and motor 2

AS-Interface Communication Monitoring

The motor control module has a watchdog function. If there has been no communication with

the master for more than 40 ms, the motor control module sets the output data DO0...DO2 to

logical 0.

Starting/Stopping Motors (D00, D01)

You can start or stop the motors separately via the DO0 and DO1 bits. To start motors, you must

set the corresponding data bit to logical 1. Via the joint SPEED control signal, the motor control

module actuates the respective motor switched on with an analog voltage value. The SPEED

control signal is released only when DO0 or DO1 data bit is set for the relevant output. The

analog voltage value corresponds to the set speed.

DO0, DO1 Data Bits

Data bit

Status

Function

LED MOT1/2

DO0

1 Start motor 1 (SPEED > 1.5 V)

MOT1: on

0 Stop motor 1 (SPEED < 1.5 V)

MOT1: off

DO1

1 Start motor 2 (SPEED > 1.5 V)

MOT2: on

0 Stop motor 2 (SPEED < 1.5 V)

MOT2: off

Switching the Motor Direction of Rotation (DO2)

You can switch the direction of rotation of the motors using the DIR control signal. The direction

of rotation signal is valid for both motors together. For control purposes, you must parameterize

the DO2 data bit accordingly.

Logical 0, according to RDR BL3, corresponds to direction of rotation to the left. The motor

control module switches the DIR control signal to high impedance.

17

Page 17

VBA-4E3A-G20-ZEL/M1L-P2

Commissioning

Logical 1, according to RDR BL3, corresponds to direction of rotation to the right. The motor

control module switches the DIR control signal to AUX level.

DO2 Data Bit

Data bit

Status

Function

DIR direction of rotation signal

LED DIR

DO2

0 Direction of rotation left

High impedance, approx. 0 V

Off

1 Direction of rotation right

(U

AUX

- 1) V

At idle speed, Ri=5.6 k

On

Adjusting the Motor Speed (P0...P2)

You can adjust the speed for both motors simultaneously only via the P0...P2 parameter bits. To

do this, you must parameterize one of eight predefined speed values. The speed values

correspond to analog voltagevalues.

If the master does not change the parameter bits when the AS-Interface network is switched

on, the eighth speed value (7.26 V) is set per default on the motor control module.

The motor control module issues the set control voltage to the motors via the SPEED control

signal as soon as the motors are switched on via DO0 and DO1 data bits (logical 1). The

control voltage is readjusted by the motor control module and is therefore independent of the

load within certain limits. If the control limits are exceeded due to an excessive load, the motor

control module issues a peripheral fault.

Parameter Bits P0...P2

P2 P1 P0

DO0 (MOT1)

or DO1 (MOT2)

Speed signal SPEED

(Tolerance range)

LED MOT1

or MOT2

x x x 0 < 1.5 V

Off

0 0 0 1 3.96 V (3.92 V .... 4.00 V)

On

0 0 1 1 4.78 V (4.73 V .... 4.83 V)

On

0 1 0 1 5.61 V (5.55 V .... 5.67 V)

On

0 1 1 1 6.44 V (6.38 V .... 6.50 V)

On

1 0 0 1 8.50 V (8.42 V .... 8.59 V)

On 1 0 1 1

9.63 V (9.53 V .... 9.73 V)

On 1 1 0 1

10.00 V (9.90 V .... 10.10 V)

On

1 1 1 1

7.26 V (7.19 V .... 7.33 V)

Basic setting

On

Reporting a Motor Fault (DI0, DI1)

The motor control module records a motor fault via the ERROR status signal. The motor control

module reports faults to the master using DI0 (motor 1) and DI1 (motor 2) data bits. In the event

of a motor fault, the motor control module sets the respective DI0 or DI1 data bit to logical "1."

This status is set if no motor is connected or the motor is not supplied with power if a fuse in the

motor control module is defective.

18

Page 18

VBA-4E3A-G20-ZEL/M1L-P2

Commissioning

DI0, DI1 Data Bits

Data bit

Status

Motor error status

Motor error signal ERROR

LED ERR1/2

DI0 0

No fault in motor 1

U

ERROR

1.2 V, I

ERROR

40 A

ERR1: off

1

■

Fault in motor 1

■

Or motor 1 is not connected

■

Or fuse is defective

High impedance

ERR1: on

DI1 0

No fault in motor 2

U

ERROR

1.2 V, I

ERROR

40 A

ERR2: off

1

■

Fault in motor 2

■

Or motor 2 is not connected

■

Or fuse is defective

High impedance

ERR2: on

Status of the Sensor Inputs (DI2, DI3)

The motor control module transfers the switching statuses of the IN1 and IN2 inputs to the

master using the DI2 (IN1) and DI3 (IN3) data bits.

There is a filter downstream of the inputs that suppresses pulses 2 ms.

DI2, DI3 Data Bits

Data bit

Status

Input switching status

LED IN1/2

DI2

0

Unattenuated, I

IN

0.5 mA

IN1: off

1

Attenuated, I

IN

2.0 mA

IN1: on

DI3

0

Unattenuated, I

IN

0.5 mA

IN2: off

1

Attenuated, I

IN

2.0 mA

IN2: on

6.2

Configuration of the Start/Stop Ramps

Overview

To control the acceleration and to stop the motors, you can set one of eight defined start/stop

ramps for the speed signal SPEED. These ramps always apply to both motors simultaneously.

The ramp duration corresponds to the time from stopping to reaching the maximum speed or

from the maximum speed up to stopping. The inclines of the ramps are constant for each of the

eight ramps and independent of the set speed. The reference value for all ramps is the speed

signal SPEED = 10 V. For a lower parameterized speed, the ramp duration is proportionally

shorter.

Predefined Start/Stop Ramps

Ramp no.

Ramp duration

0 No ramp (default setting)

1 50 ms

2 100 ms

3 200 ms

4 300 ms

5 500 ms

6 1000 ms

7 1500 ms

19

Page 19

VBA-4E3A-G20-ZEL/M1L-P2

Commissioning

The ramp is not effective if the direction of rotation signal is switched when the motor is active.

In this case, the direction of rotation is reversed immediately.

Note!

Default Setting on Delivery

On delivery, ramp no. 0 (no ramp) is the default setting.

Configuring Start/Stop Ramps

To adjust a start/stop ramp, you must change the motor control module to configuration mode.

The motor control module stores a new ramp set in the internal nonvolatile memory. This ramp

is activated automatically every time the motor is switched on. You can reconfigure a ramp as

often as required.

A prerequisite for configuration is that the flat cables for the AS-Interface and AUX are

connected. Communication must already be taking place between the master and motor

control module.

Note!

Configuration Mode Display via LEDs

If the motor control module is in configuration mode, the MOT1, MOT2, ERR1, ERR2, IN1, IN2

LEDs flash simultaneously with a frequency of approx. 2 Hz.

The configuration sequence consists of nine steps. Defined data and parameter values are

transmitted between the master and the motor control module via the DO0...DO2, DI0 ... DI3

data bits andthe P0 .. P2 parameter bits. The master must keep the data and parameter bits

constant for at least 10 ms for each step. Longer intervals are possible as long as a period of

10 s is not exceeded for steps one to six.

The configuration of a new start/stop ramp runs in the following phases:

■

In steps one to six, the master sends parameter values to the motor control module to

activate configuration mode (max. 10 s). DO0.. DO2 must have the value "4" in each step.

■

If the parameter sequence was correct, the motor control module responds to the master

via DI0.. DI2 on the last parameter value with "C

hex

." This response indicates that

configuration mode is activated. The six MOT1 ..IN1 LEDs flash.

■

In step seven, the master sends the selected ramp no. to the motor control module via

DO0 ..DO2.

■

In step eight, the master sends the parameter value "4" to the motor control module via

P0 .. P2. The motor control module stores the ramp number in the nonvolatile memory. It

responds to the master with "A

Hex

" via DI0 ..DI2.

■

In step nine, the master exits configuration mode. The master sends data value "4" via

DO0...DO2 and data value "7" via P0.. P2. The motor control module switches to normal

mode. The six MOT1 ..IN1 LEDs stop flashing.

Note!

Sequence for Command Transmission

For each step, you generally send the data value via DO0.. D02 first and then the parameter

value P0.. P2. The following table shows the contexts of communication between the master

and motor control module. The value "x" represents any of the values in the table.

20

Page 20

VBA-4E3A-G20-ZEL/M1L-P2

Commissioning

Sequence for Configuring a Start/Stop Ramp

Send the following data values and parameter values to the motor control module:

1.

In accordance with steps one to six, for each step send the data value "4" via DO0...DO2 and

then via P0...P2, a value of the parameter string 3,1,6,3,1,6 one after the other.

2.

If configuration mode is active, send the required ramp number via DO0...DO2 and the

parameter value "6" via P0...P2 as step seven.

3.

As step eight, send the ramp number again via DO0...DO2 and parameter value "4" via

P0...P2.

4.

As step nine, send data value "0" via DO0...DO2 and parameter value "7" via P0...P2.

The motor control module has stored the new start/stop ramp and switched back to

normal mode.

Contexts of Module Communication

Step

DO0...DO2

P0...P2

DI0 .. DI3

Comment

4

x x Motor control module in normal mode

1 4 3 x Start activation sequence for configuration mode

2 4 1 x

3 4 6 x

4 4 3 x

5 4 1 x

6 4 6

C

hex

End activation sequence for configuration mode.

Motor control module responds with C

hex

if

configuration mode is OK.

7 Ramp no.

6

C

hex

Transfer of the ramp number to the motor control

module

8 Ramp no.

4

A

hex

The ramp is stored

9 0 7 x Motor control module switches back to normal mode

Troubleshooting during Configuration

The following table describes the behavior of the motor control module if a fault occurs during

the nine-step configuration process.

Fault Scenarios

Step

Possible fault

Motor control module reaction

1 to 6

■

Incorrect data or parameter values or

■

steps 1 to 6 take longer than 10 s

Motor control module remains in normal mode

7 or 8

Incorrect data or parameter values

■

Motor control module responds with "E

hex

"

via DI0 ... DI3 and remains in configuration

mode.

■

The motor control module switches to

normal mode only when the master sends

"0" via DO0 ... DO2 and "7" via P0 ... P2.

■

If "0" or "7" has already been set by the

master in one of these steps, the motor

control module switches to normal mode

immediately without sending a response.

The stored ramp is not changed.

21

Page 21

VBA-4E3A-G20-ZEL/M1L-P2

Troubleshooting

7

Troubleshooting

Fault Information and Remedy

Fault

LED display

Possible cause

Remedy

No data

communication

withAS-Interface

master

PWR off

AS-Interface voltage is missing or

has reverse polarity

Check AS-Interface wiring

PWR flashes and

FAULT on

Module address is 0

Program module address

PWR on and

AS-Interface Master is not

switched on (offline) or

There is duplicate addressing

Switch on the AS-Interface master

FAULT on

or

Check the addresses of all modules

on the AS-Interface segment

Motors will not

start

AUX off

AUX external power supply is

missing

Check AUX voltage and AUX flat

cable

AUX red on

AUX external power supply is

inverted

Correct the polarity of the AUX flat

cable in the cable guide

AUX green on and

FUSE1 (motor 1)

and/or FUSE2

(motor 2) off

Motor fuse is faulty due to

overloading of the motor supply

Replace the motor control module

(cannot be repaired) and remove

the cause of the overload before

starting the motor again

Note: Fault information via ASInterface via DI0 (motor 1) data bit

and/or DI1 (motor 2) data bit and

ERR1 LED on and/or ERR2 LED on

PWR and FAULT

flash alternately

Peripheral fault "Overload speed

signal SPEED":

Motor or motor cable or motor

control module is faulty

Replace motor or motor control

module

FUSE1 (motor 1)

on and/or FUSE2

(motor 2) on and

ERR1 (motor 1) on

and/or ERR2

(motor 2) on

Motor fault: motor is blocked or

faulty

Remove the motor blockage or

replace the motor

Note: Fault information via ASInterface via DI0 (motor 1) data bit

and/or DI1 (motor 2) data bit

Sensors or IN1,

IN2 inputs not

working

AUX off

AUX external power supply is

missing

Check AUX voltage and AUX flat

cable

AUX red on

AUX external power supply is

inverted

Correct the polarity of the AUX flat

cable in the cable guide

PWR and FAULT

flash alternately

Periphery fault: overload on

sensor supply

Check the sensors and eliminate

the overload

22

Page 22

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Loading...

Loading...