Page 1

MANUAL

BARCODE SCANNER

VB8-305

FACTORY AUTOMATION

Page 2

VB8-305

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry, published by

the Central Association of the "Elektrotechnik und Elektroindustrie (ZVEI) e.V.

in their most recent version as well as the supplementary clause: "Extended reservation of title".

Part No. 193603

Date of issue 12/2005

Page 3

VB8-305

CONTENTS

1

1.1

1.2

2

2.1

2.1.1

2.1.2

2.2

2. 3

2. 4

3

3.1

3.2

INTRODUCTION .......................................................................................... 1

Status Indicators ........................................................................................... 2

Available Models........................................................................................... 3

INSTALLATION............................................................................................ 4

VB8-305-5 V DC CCD Scanner .................................................................... 4

Mechanical Installation.................................................................................. 4

Electrical Connections...................................................................................5

RS232 Interface............................................................................................ 6

WEDGE Interface ......................................................................................... 6

PEN Emulation Interface............................................................................... 7

Inputs ............................................................................................................ 7

Outputs .........................................................................................................8

External Beeper Connection......................................................................... 9

VB8- 305 (10 to 30 V DC) CCD Scanner ..................................................... 10

RS232 Interface........................................................................................... 11

Inputs ........................................................................................................... 12

Outputs ........................................................................................................13

External Beeper Connection........................................................................ 14

Positioning ................................................................................................... 16

DeviationMirror-VB8 Accessory................................................................... 17

SOFTWARE CONFIGURATION STRINGS ............................................... 20

Default Configuration .................................................................................. 20

VB8 Configuration....................................................................................... 22

Command Syntax .......................................................................................23

4

4.1

4.1.1 Handshaking...............................................................................................34

4.1.2 ACK/NACK from Host Protocol................................................................... 35

4.1.3 FIFO............................................................................................................ 35

Part No. 193603

4.1.4 RX Timeout................................................................................................. 35

4.2

4.2.1 Minimum Output Pulse................................................................................ 36

4.2.2 Overflow...................................................................................................... 36

4.2.3 Output and Idle Levels................................................................................ 37

4.2.4 Inter-Block Delay......................................................................................... 37

Date of issue 12/2005

REFERENCES ........................................................................................... 34

RS232 Parameters .....................................................................................34

Pen Parameters.......................................................................................... 36

iii

Page 4

VB8-305

4.3

Data Format................................................................................................ 38

4.3.1 Header/Terminator Selection...................................................................... 38

4.4

Power Save................................................................................................. 41

4.4.1 Sleep State .................................................................................................41

4.4.2 Enter Sleep Timeout ................................................................................... 41

4.4.3 Standby....................................................................................................... 41

4.5

Reading Parameters................................................................................... 41

4.5.1 Operating Modes ........................................................................................41

4.5.2 Reads per Cycle ......................................................................................... 43

4.6

Decoding Parameters ................................................................................. 43

4.6.1 Ink-Spread ..................................................................................................43

4.6.2 Overflow Control ......................................................................................... 43

4.6.3 Interdigit Control.......................................................................................... 43

5

A

B

TECHNICAL FEATURES ........................................................................... 44

Reading Diagrams ...................................................................................... 45

CODE IDENTIFIER TABLE........................................................................ 47

HEX/NUMERIC TABLE .............................................................................. 48

iv

Part No. 193603

Date of issue 12/2005

Page 5

VB8-305

Introduction

1 INTRODUCTION

The VB8 compact CCD reader is the perfect solution for many OEM applications.

It contains a built-in decoder

mix of technical characteristics it is perfect for integration into custom equipment,

setting a new standard in this product class.

This Reference Manual provides connection diagrams, default parameter listing,

complete application parameter settings, specific technical features and reading

diagrams.

Configuration for RS232 Interface User's

The easiest way to configure VB8 is by using the Configurations utility program

installed from the CD included with this manual. It provides a user-friendly graphic

interface that sends the command strings to the VB8 and Help On-Line to explain

configuration parameters.

This manual contains the complete set of command strings for VB8 configuration.

These strings must be sent via the RS232 interface using a terminal emulator such

as HyperTerminal, or with the WinHost Terminal. Configurations can also be sent as

batch files.

Refer to paragraph 3.2 for configuration procedures.

Configuration for Wedge Interface User's

For Wedge Interface User's, configuration can be accomplished either by reading the

Return to RS232 Interface

Interface, or by printing the command strings as a barcode label (or labels) and then

reading them with the VB8. The symbology must be Code 128 subset B.

Reference notes describing the operation of the more complex parameters are given

in chapter 4.

Part No. 193603

and multi-standard interface. Due to its well-balanced

barcode and then configuring through the RS232

Date of issue 12/2005

1

Page 6

VB8-305

Introduction

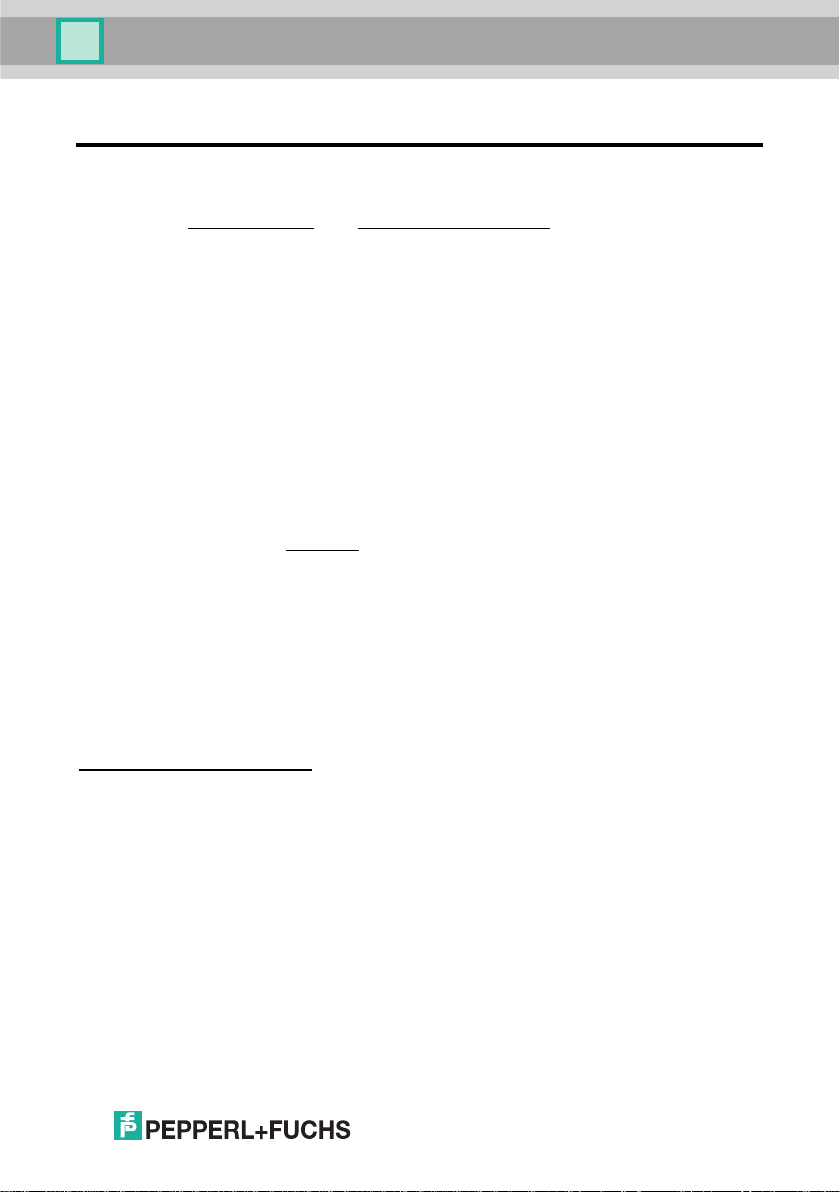

1.1 STATUS INDICATORS

The reader has two LED indicators signaling several operating conditions which are

described in the tables below.

Led2 Led1

VB8 Scanner

POWER ON / LED2 Meaning

ON Power supply ON

OFF

Power supply OFF

GOOD READ / LED1 Meaning

ON Good read (LED1 will remain ON until status changes)

OFF Miss read

POWER UP

DATA ENTRY

VB8 Scan Engine

Part No. 193603

2

Date of issue 12/2005

Page 7

VB8-305

Introduction

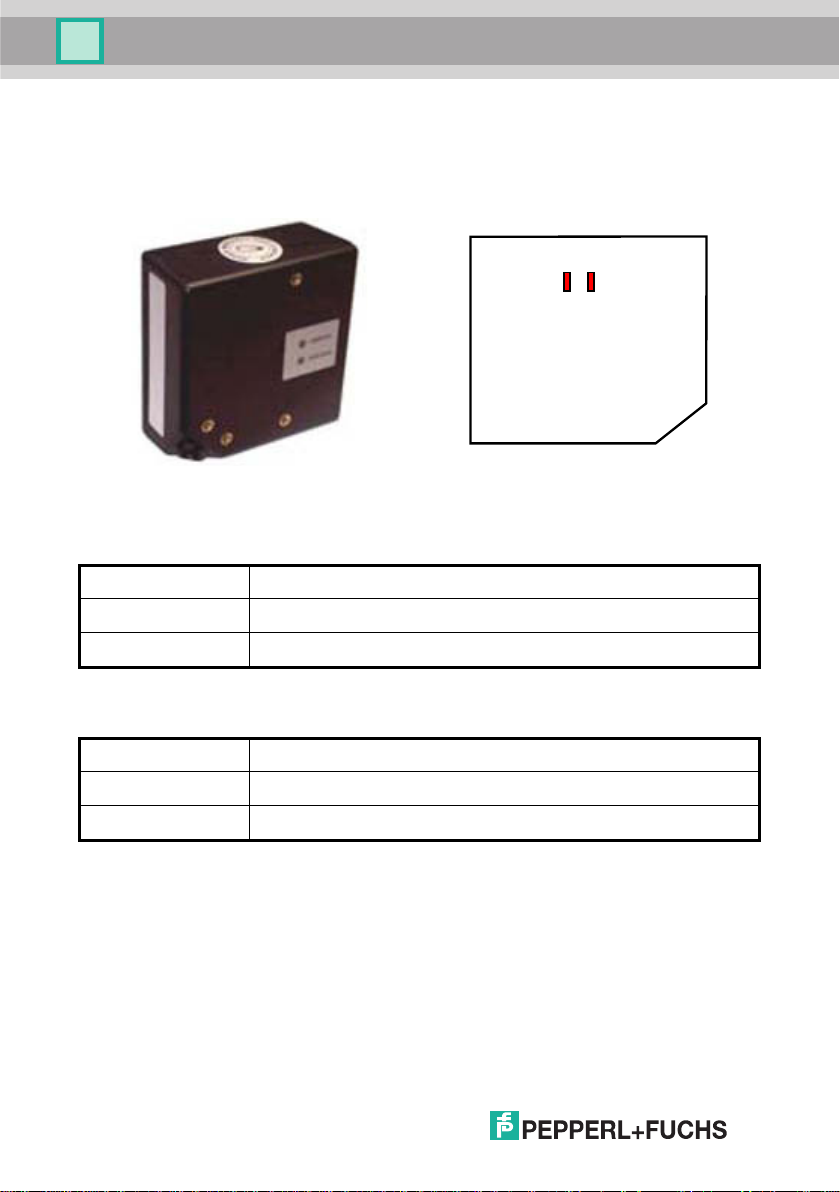

1.2 AVAILABLE MODELS

The VB8 reader is available in models that differ in regard to the following

characteristics:

• Barcode type

• Enclosure

The following models are therefore available:

Model1: VB8-305 = CCD Scanner for linear codes (10 to 30 V DC Power-supply)

•

•

Model2: VB8-305-5 V = CCD Scanner for linear codes (5 V DC Power-supply)

Part No. 193603

Date of issue 12/2005

3

Page 8

VB8-305

Installation

2 INSTALLATION

2.1

VB8 CCD SCANNER

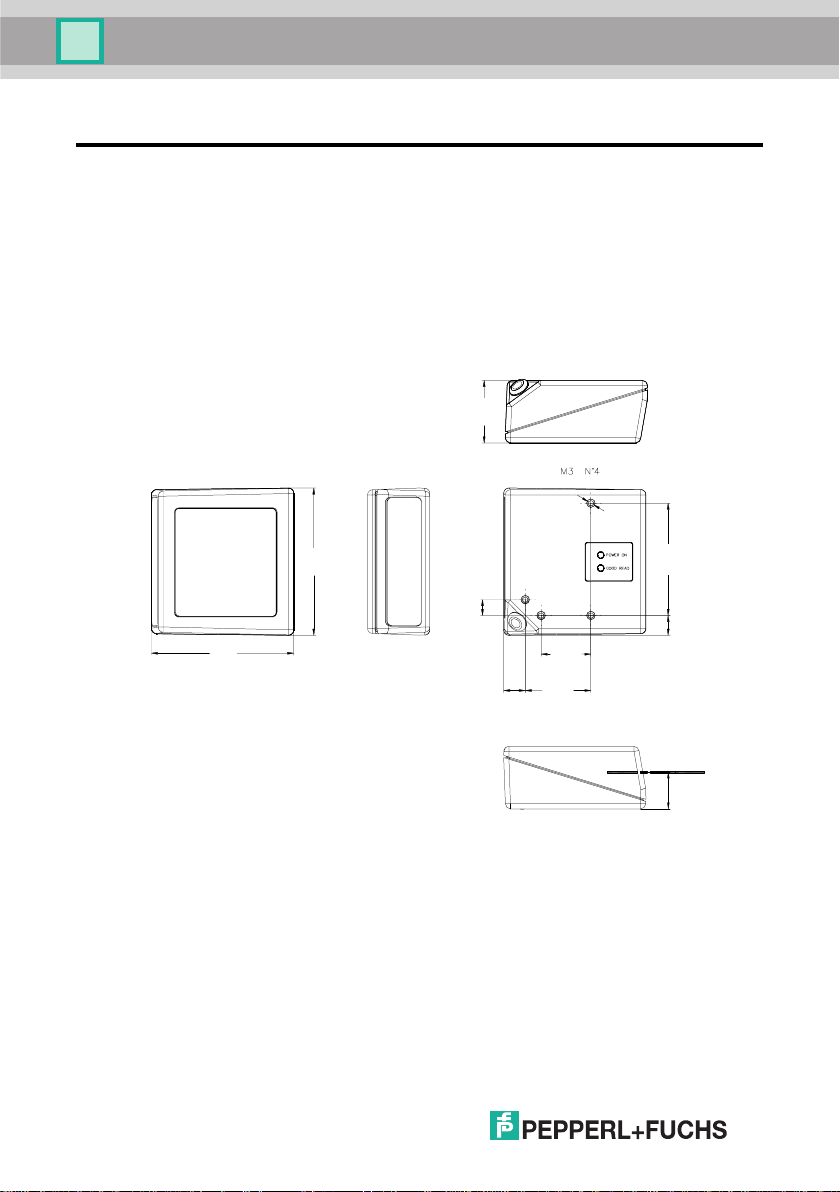

2.1.1 Mechanical Installation

The diagram below gives the overall dimensions of the reader and may be used for

its installation.

30.5

[1.20]

4

68.6

[2.70]

70.7

[2.78]

mm

[in.]

7.6

10.4

[0.41]

[0.30]

Figure 1 - Overall dimensions

[0.94]

31.6

[1.25]

54

[2.13]

24

9.5

[0.37]

Optical Axis

17.7

[0.70]

Part No. 193603

Date of issue 12/2005

Page 9

VB8-305

Installation

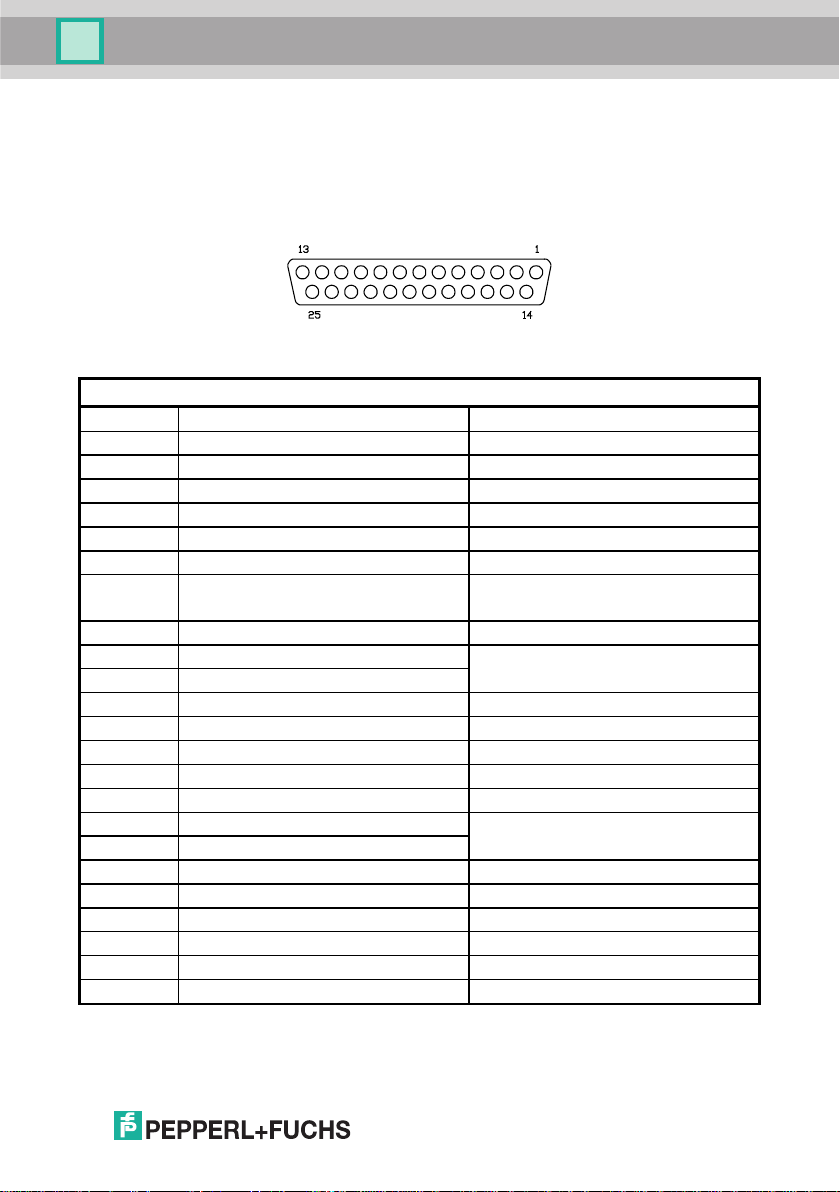

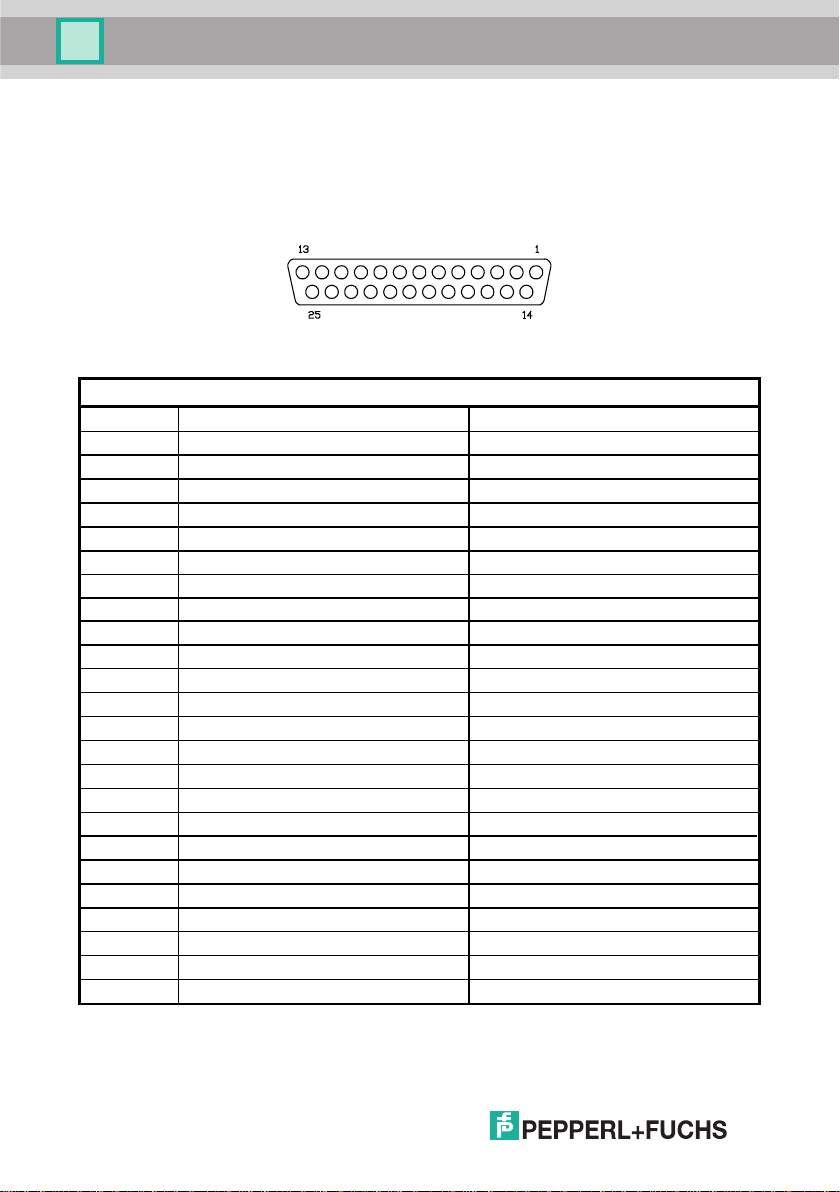

2.1.2 Electrical Connections VB8-305-5VDC

The VB8 Scanner is equipped with a 25-pin female D-Sub connector for connection

to the power supply and input/output signals. The details of the connector pins are

indicated in the following table:

Figure 2 - 25-pin female D-sub connector

25-pin Connector

1 Shield earth ground

2 TX transmit data

3 RX receive data

4 RTS request to send

5 CTS clear to send

6 nc not connected

7 SGND signal ground

8 EXT BEEPER beeper output signal

9 VCC+ +5 Vdc

10 nc not connected

11 OUT+

12 OUT13 VCC+ +5 Vdc

14 nc not connected

15 nc not connected

16 nc not connected

17 nc not connected

18 EXT TRIG+

19 EXT TRIG20 DATAIN_WAND

21 DATAOUT

22 OUT-

23 CLKIN

24 CLKOUT

25 GND power ground

see Figure 10

See Figures 6 to 9

Date of issue 12/2005 Part No. 193603

Table 1 - VB8 Scanner Pinout

5

Page 10

VB8-305

Installation

RS232 Interface

The VB8 Scanner can communicate with the Host using the RS232 signals

provided on the 25-pin connector. The pins are indicated in Table 1 and in the

following diagram:

It is always advisable to use shielded cables. The overall maximum cable length

must be less than 15 m (49.2 ft).

VB8 25-pin

2

TX

3

RX

4

RTS

CTS

5

7

SGND

Figure 3 - RS232 Interface connection to Host

Host

RXD

TXD

DCD

DTR

SGND

Earth

Ground

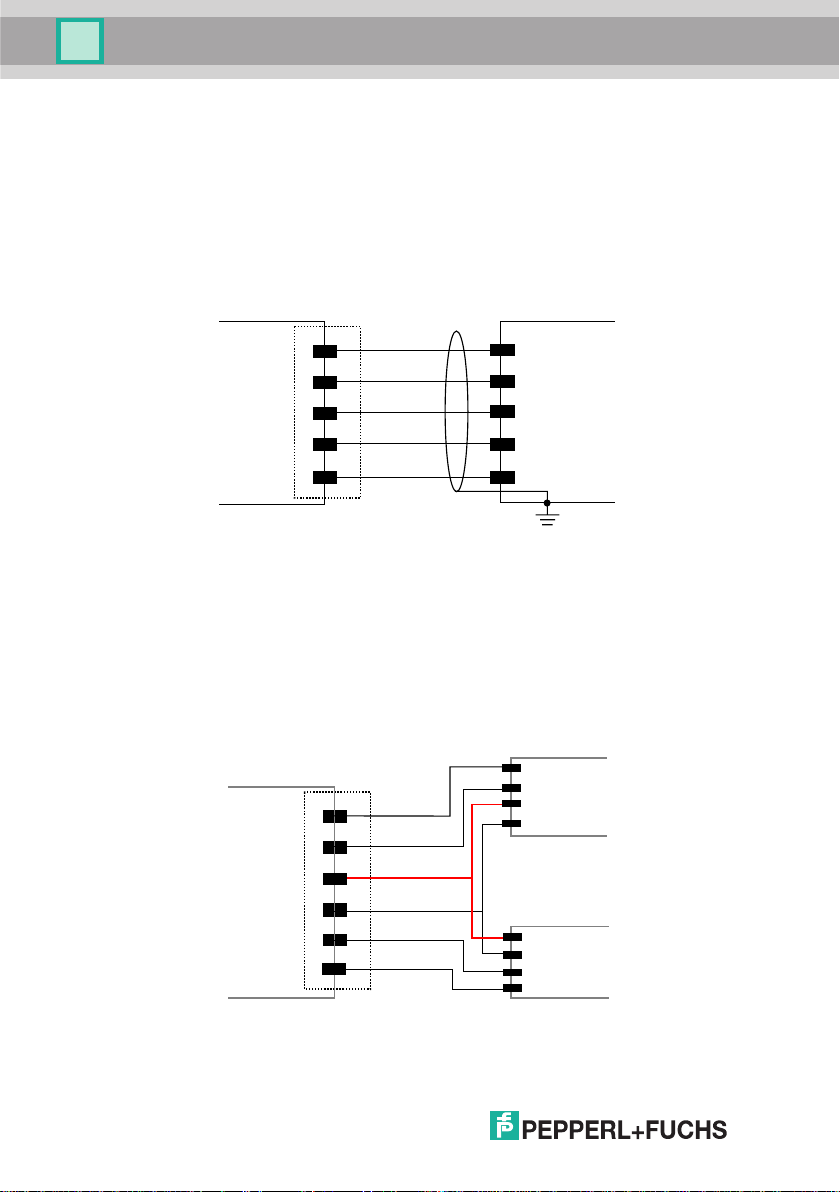

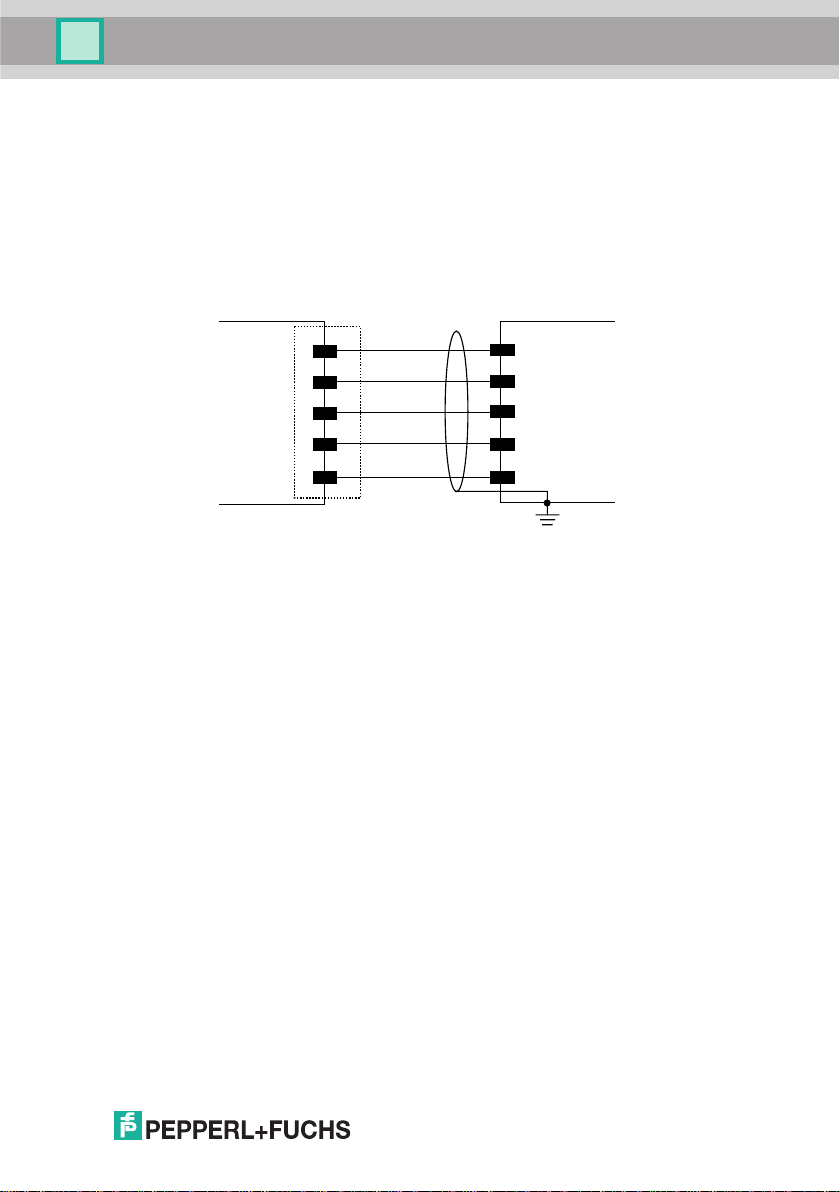

WEDGE Interface

The VB8 Scanner can communicate with the Host in a WEDGE Interface

(Keyboard Emulation) using the signals provided on the 25-pin connector. The pins

are indicated in Table 1 and in the following diagram:

VB8 25-pin

Figure 4 - Wedge Interface connection to Host (PC AT) and Keyboard

21

24

13

25

20

23

DATAOUT

CLKOUT

VCC+

GND

DATAIN

CLKIN

Host

DATA

CLK

VCC+

GND

Keyboard

VCC+

GND

DATA

CLK

Part No. 193603

Date of issue 12/2005

6

Page 11

VB8-305

Installation

PEN Emulation Interface

The VB8 Scanner can communicate with the Host in a PEN Emulation Interface

using the signals provided on the 25-pin connector. The pins are indicated in Table 1

and in the following diagram:

VB8 25-pin

WAND

4

VCC+

5

GND

25

Figure 5 - RS232 Interface connection to Host

Host

DATA

VCC+

GND

Earth

Ground

It is always advisable to use shielded cables.

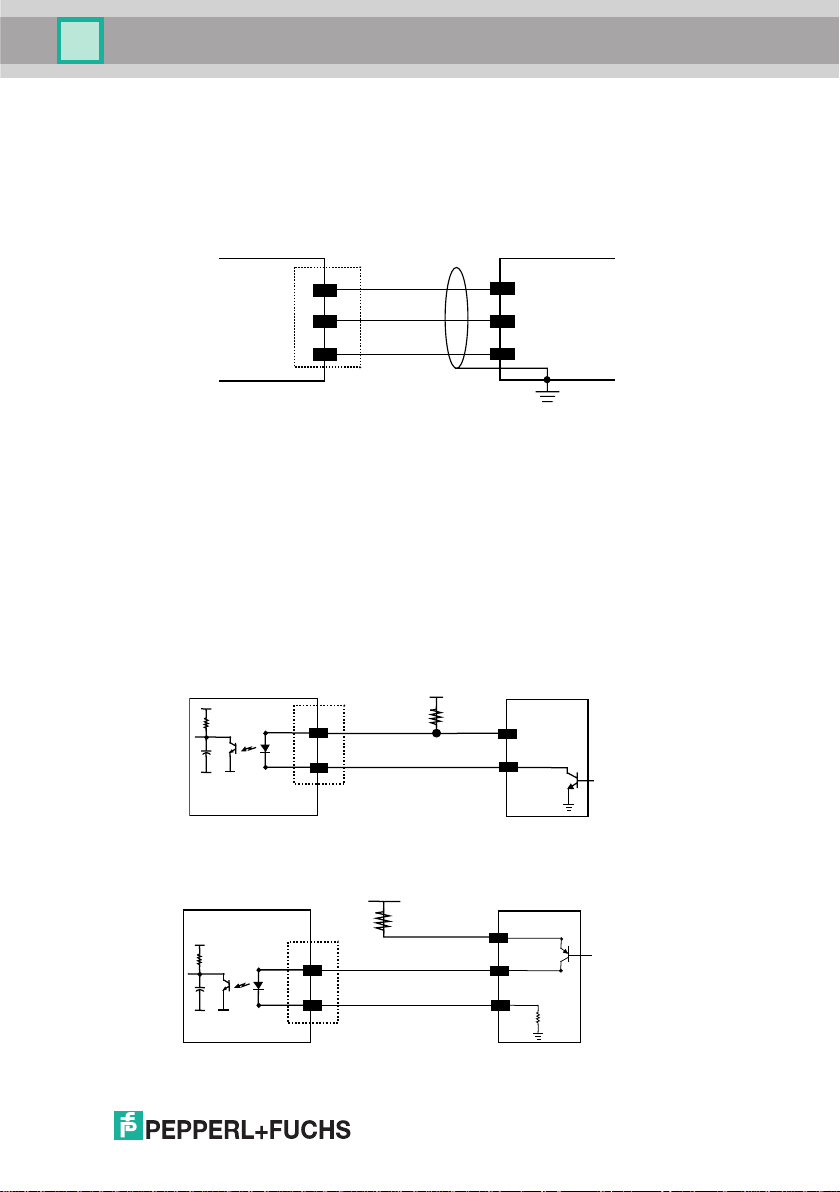

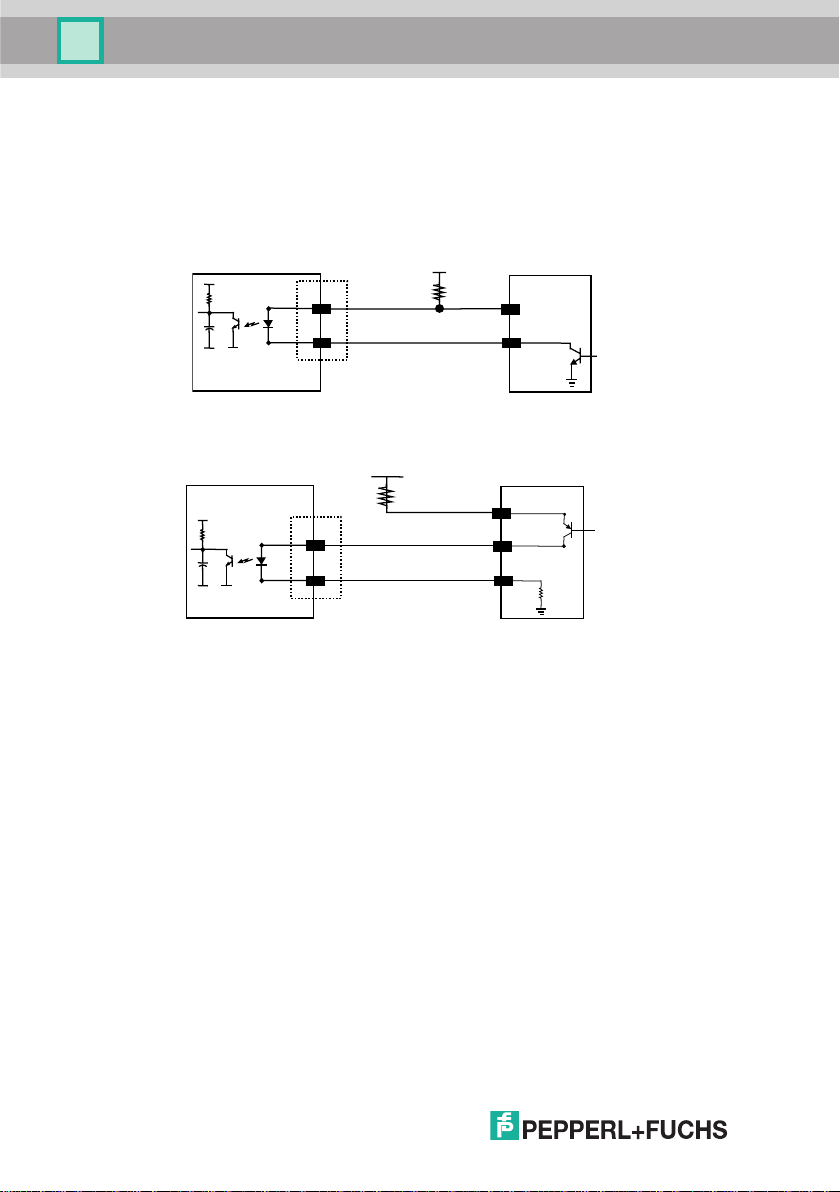

Inputs

There is an input available on the VB8 Scanner relative to the External Trigger.

The pins are indicated in Table 1. These inputs are optocoupled and can be driven

by both an NPN or PNP type command. The connections are indicated in the

following diagrams:

VB8

+ 5V

18

19

Vext

EXT TRIG+

EXT TRIG-

30 Vdc max.

EXTERNAL TRIGGER

V

Figure 6 - Input NPN command using external power

Vext

+ 5V

18

30 Vdc max.

EXT TRIG+

EXTERNAL TRIGGER

V

Signal

Signal

Date of issue 12/2005 Part No. 193603

19

EXT TRIG-

Ground

Figure 7 - Input PNP command using external power

7

Page 12

VB8-305

Installation

VB8

+ 5V

13

18

19

25

Vcc 5Vdc

EXT TRIG+

EXT TRIG-

GND

EXTERNAL TRIGGER

V

Ground

Signal

Figue 8 - Input NPN command using VB8 power

VB8

+ 5V

Vcc 5Vdc

13

18

EXT TRIG+

19

EXT TRIG-

25

GND

EXTERNAL TRIGGER

V

Signal

Ground

Figure 9 - Input PNP command using VB8 power

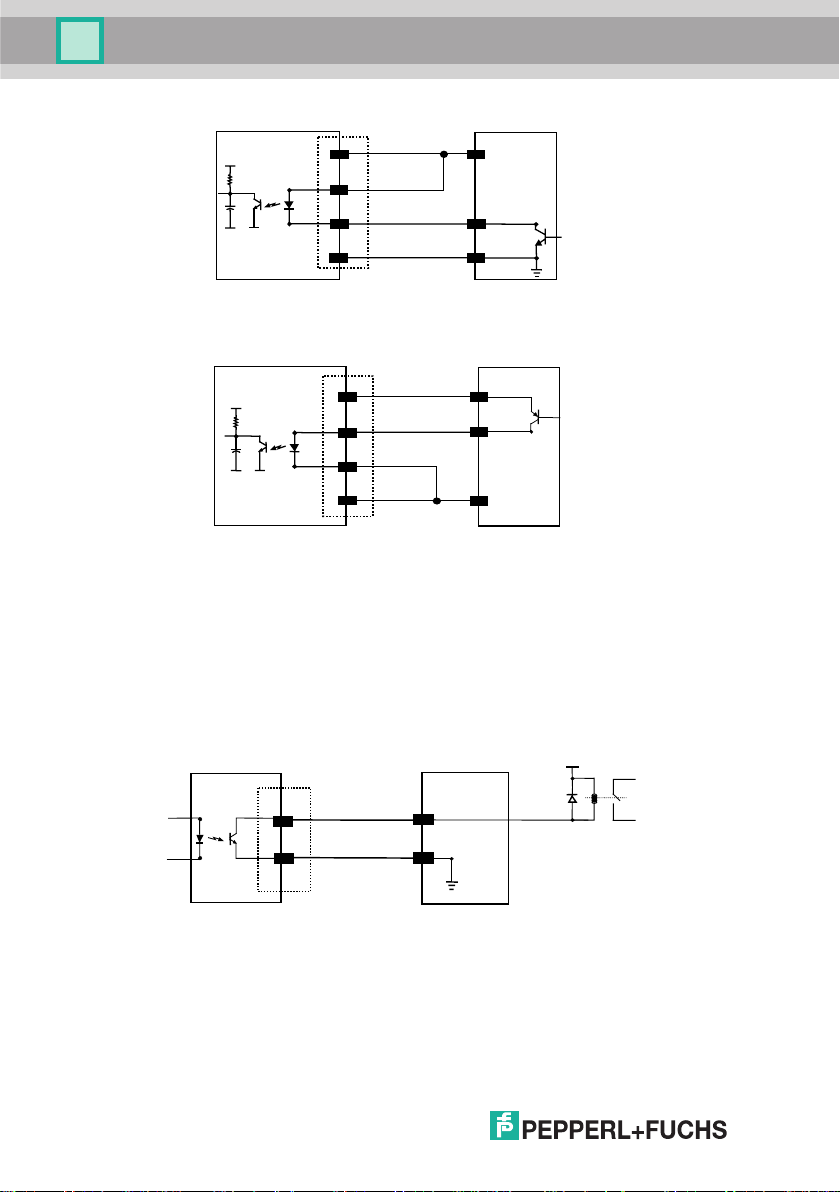

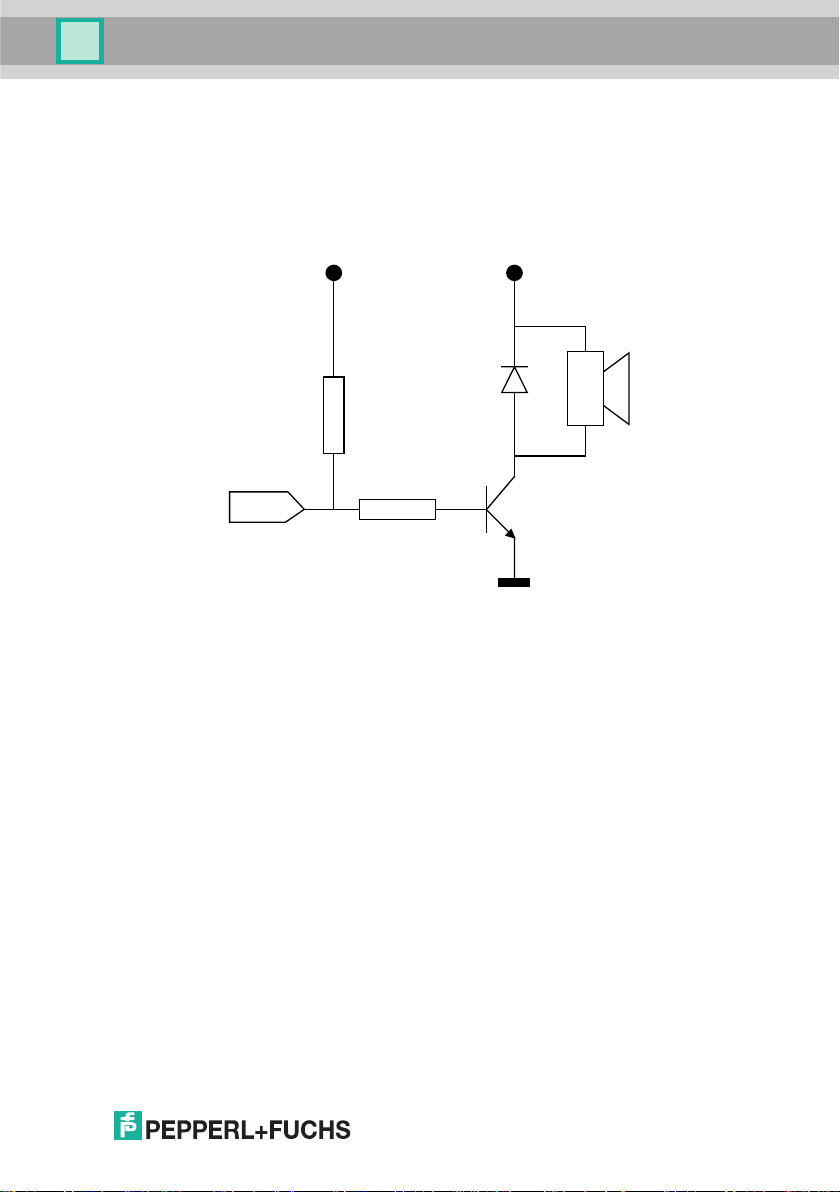

Outputs

There is an output available on the VB8 Scanner relative to the Good Read

event. The pins are indicated in Table 1. The connections are indicated in the

following diagram:

VB8

USER INTERFACE

Vext 40 Vdc max

8

11

OUT +

12

OUT -

Figure 10 - Output connection (Good Read). Example NPN

Part No. 193603

Date of issue 12/2005

Page 13

VB8-305

Installation

External Beeper Connection

A beeper output signal is provided on pin 8 so that an external piezoelectric buzzer

with internal oscillator can be connected for Good Read acoustic signaling. The

complete circuit to be built is shown in the schematic diagram below.

+5 Vdc (pin 13)+5 Vdc (pin 13)

+

BEEPER (pin 8)

D1 (1N4148)

R2 (10K)

Q1 (BC337)

R1 (1K)

GND (pin 25)

Figure 11 - VB8 Scanner Beeper Connection

BZ1 (see below)

The following list indicates several piezoelectric buzzers that can be used in the

circuitry above (part BZ1).

Manufacturer Type

MURATA PKB30SPC - 2001/3001

DIGISOUND F/TCW05

CITIZEN MEB-12C-5

BUJEON BS12-A

See chapter 3 for Beeper Control commands.

Date of issue 12/2005 Part No. 193603

9

Page 14

VB8-305

Installation

2.2 Electrical Connections VB8-305 (10 to 30 V DC)

The scanner cable is equipped with a 25-pin female D-sub connector for connection

with the power supply and input/output signals:

Figure 2 - 25-pin female D-sub connector

25-pin Connector

9, 13 VCC+ Power Supply Input Voltage +

25 GND

1 SHIELD

2, 21 TX

3, 20 RX

4 RTS

5 CTS

7

11 OUT +

10, 12, 22 OUT- Output -

18 EXT TRIG + External Trigger +

19 EXT TRIG - External Trigger -

6, 8, 14, 15, N.C.

16, 17, 23 N.C Not Connected

24 N.C. Not Connected

SGND Signal Ground

Power Supply Input Voltage -

Earth Ground

RS232 Transmit Data

RS232 Receive Data

RS232 Request To Send

RS232 Clear To Send

Output +

Not Connected

Part No. 193603

10

Table 1 - VB8 Scanner Pinout

Date of issue 12/2005

Page 15

VB8-305

Installation

RS232 Interface

The VB8 Scanner can communicate with the Host using the RS232 signals

provided on the 25-pin connector. The pins are indicated in Table 1 and in the

following diagram:

It is always advisable to use shielded cables. The overall maximum cable length

must be less than 15 m (49.2 ft).

VB8 25-pin

2

TX

3

RX

4

RTS

CTS

5

7

SGND

Figure 3 - RS232 Interface connection to Host

Host

RXD

TXD

DCD

DTR

SGND

Earth

Ground

Date of issue 12/2005 Part No. 193603

11

Page 16

VB8-305

Installation

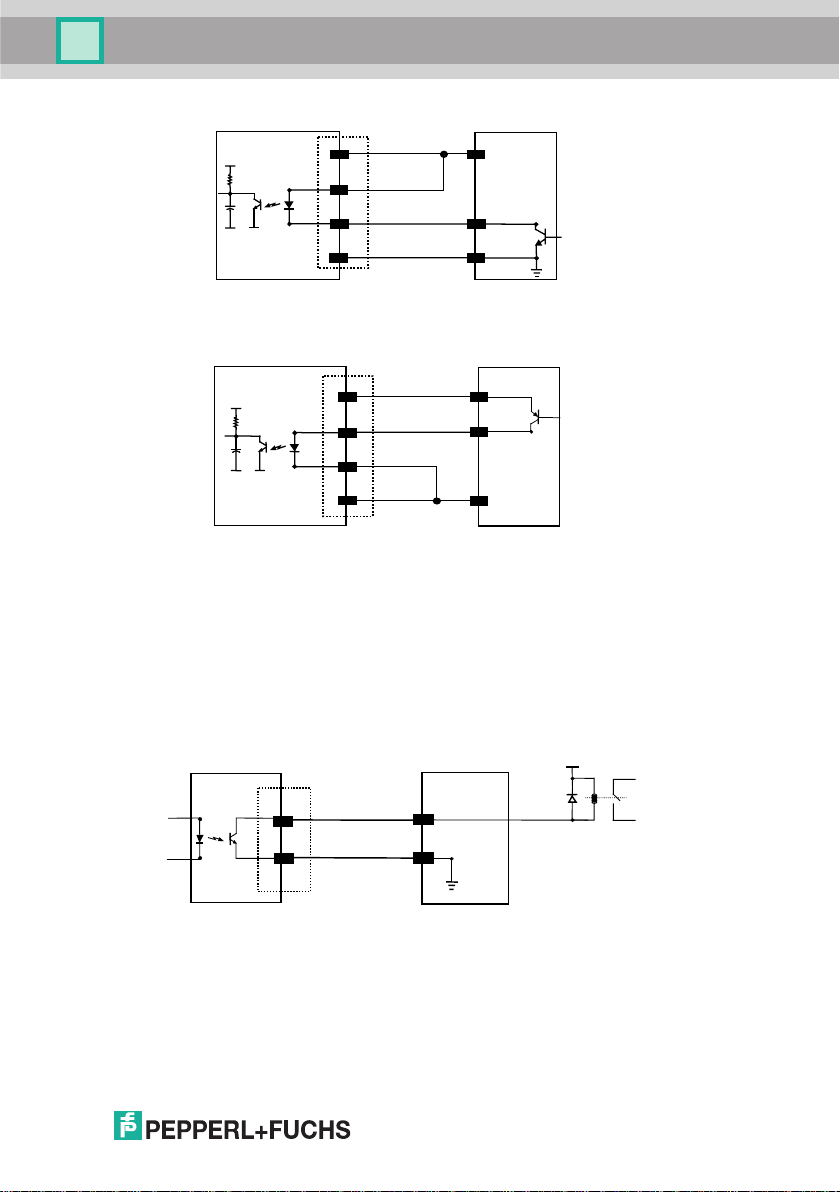

Inputs

There is an input available on the VB8 Scanner relative to the External Trigger.

The pins are indicated in Table 1. These inputs are optocoupled and can be driven

by both an NPN or PNP type command. The connections are indicated in the

following diagrams:

VB8

+ 5V

18

19

Vext

EXT TRIG+

EXT TRIG-

30 Vdc max.

EXTERNAL TRIGGER

V

Figure 6 - Input NPN command using external power

Vext

+ 5V

18

19

30 Vdc max.

EXT TRIG+

EXT TRIG-

EXTERNAL TRIGGER

V

Ground

Signal

Signal

12

Figure 7 - Input PNP command using external power

Part No. 193603

Date of issue 12/2005

Page 17

VB8-305

Installation

VB8

+ 5V

13

18

19

25

Vcc 5Vdc

EXT TRIG+

EXT TRIG-

GND

EXTERNAL TRIGGER

V

Ground

Signal

Figue 8 - Input NPN command using VB8 power

VB8

+ 5V

Vcc 5Vdc

13

18

EXT TRIG+

19

EXT TRIG-

25

GND

EXTERNAL TRIGGER

V

Signal

Ground

Figure 9 - Input PNP command using VB8 power

Outputs

There is an output available on the VB8 Scanner relative to the Good Read

event. The pins are indicated in Table 1. The connections are indicated in the

following diagram:

VB8

USER INTERFACE

Vext 40 Vdc max

Date of issue 12/2005 Part No. 193603

11

OUT +

12

OUT -

Figure 10 - Output connection (Good Read). Example NPN

13

Page 18

VB8-305

Installation

14

Part No. 193603

Date of issue 12/2005

Page 19

VB8-305

Installation

Date of issue 12/2005 Part No. 193603

15

Page 20

VB8-305

Installation

2.3 POSITIONING

The VB8 scanner is able to decode barcode labels at a variety of angles,

however significant angular distortion may degrade reading performance.

When mounting the VB8 take into consideration these three ideal label position

angles: Pitch 0°, Skew 10° to 30° and Tilt 0°. Follow the suggestions for the best

orientation:

The Pitch angle is represented by the value P in Figure 23. Position the reader in

order to minimize the Pitch angle.

Figure 23 - Pitch Angle

The Skew angle is represented by the value S in Figure 24. Position the reader to

assure at least 10° for the Skew angle. This avoids direct light reflection.

P

16

S

Figure 24 - Skew angle

Part No. 193603

Date of issue 12/2005

Page 21

VB8-305

Installation

The Tilt angle is represented by the value T in Figure 25. Position the reader in order

to minimize the Tilt angle.

T

Figure 25 - Tilt angle

2.4 DeviationMirror OMH-VB8 ACCESSORY

The OMH-VB8 is an 80° deflection mirror that is mounted directly to the VB8

Scanner or Scan Engine.

Figure 26 - OMH-VB8

The overall dimensions are provided in the figure below and can be used for its

mounting.

Part No. 193603

Date of issue 12/2005

17

Page 22

VB8-305

Installation

104

[4.10]

4.5

[0.18]

84.5

[3.33]

5

0

°

[0.28]

10

[0.39]

20

[0.79]

70

[2.76]

20

[0.79]

10

[0.39]

7

Figure 27 - DeviationMirror OMH-VB8 Overall Dimensions

To fix a VB8-xxx Scanner to the OMH-VB8, use the 4 M 2.5x5 mm screws

supplied with the DeviationMirror Kit. Refer to the figure below.

[0.94]

24

18

Part No. 193603

Figure 28 – Fixing VB8 Scanner to DeviationMirror OMH-VB8

Date of issue 12/2005

Page 23

VB8-305

Installation

The 80° deflection mirror assures that the minimum skew angle is maintained to

avoid direct light reflection which can degrade reading performance.

5

0

°

80°

10°

Figure 30 – Maintaining minimum skew angle

VB8

Code Surface

Date of issue 12/2005 Part No. 193603

19

Page 24

VB8-305

Software Configuration Strings

3 SOFTWARE CONFIGURATION STRINGS

3.1 DEFAULT CONFIGURATION

RS232 INTERFACE

9600 baud, parity disabled, 8 data bits, 1 stop bit, handshaking disabled,

ACK/NACK from Host disabled, 100 ms RX timeout, FIFO enabled, inter-character

delay disabled

WEDGE INTERFACE

USA keyboard, caps lock off, delays disabled, control character emulation =

ctrl+shift+key;

PEN Emulation INTERFACE

interpret mode, conversion to code 39 disabled, output level normal, idle level

normal, minimum output pulse 600 µs, overflow medium

DATA FORMAT

Code identifier disabled, field adjustment disabled, code length TX disabled,

character replacement disabled, header = STX, terminator = CR LF

POWER SAVE

270 read/sec, sleep disabled, standby disabled

READING PARAMETERS

On-Line mode

DECODING PARAMETERS

Ink spread enabled, overflow control enabled, interdigit control enabled, Puzzle

Solver™ disabled, decoding safety = 1 read

Date of issue 12/2005 Part No. 193603

20

Page 25

VB8-305

Software Configuration Strings

CODE SELECTION

enabled codes

• Interleaved 2 of 5

Check digit transmitted, variable length code; 4-99 characters

• EAN8/EAN13UPC A/UPC B without ADD ON

Check digit transmitted, no conversions

• Code 39

variable length code; 1-99 characters

• Code 128

Check digit not transmitted, variable length code; 1-99 characters

disabled codes

EAN 128, ISBT128,Code 93, Codabar, pharmaceutical codes,

Codablock-A, Codablock-F Standard and EAN, MSI, Plessey, Telepen,

Delta IBM, Code 11, Code 16K, Code 49

Date of issue 12/2005 Part No. 193603

21

Page 26

VB8-305

Software Configuration Strings

3.2 VB8 CONFIGURATION

VB8 is factory set for RS232 Interface applications. The easiest way to configure

VB8 is by using the Configuration utility program installed from the CD

included with this manual. Otherwise you can configure the scanner using this

manual as follows:

To use this manual for configuration:

1) Connect your VB8 to a PC RS232 port according to the information in

chapter 2. Set the PC serial port to the VB8 default RS232 communication

parameters.

2) Using a Terminal Emulation Program send the Restore Default string to the

reader using the syntax described on the next page.

3) Send all the necessary command strings according to your application's

requirements.

The WEDGE or PEN Emulation interface selections must be sent

last since they will cause the reader to no longer accept RS232

CAUTION

If working with the Wedge or Pen emulation interfaces, it is possible to return to the

RS232 connection by reading the code given below:

communications.

For WEDGE or PEN Emulation Users

Return to RS232 Interface

i$1k

i$1k

i$1k

22

Date of issue 12/2005 Part No. 193603

Page 27

VB8-305

Software Configuration Strings

Command Syntax

The command syntax is given below with an example:

Command(s)

The new setting will be definitive (stored in FLASH EPROM)

Example:

Multiple command programming sequence:

$+

BK0

AC410132CD7

Baud rate = 19200

Serial On-Line operating mode

Enter configuration environment

Each configuration parameter setting removes the condition previously active for that

parameter.

The device buffer can contain about 400 characters. If your

programming string goes over this value, you must split it into separate

groups and send each group after a delay of at least 3 seconds to give

NOTE

the reader time to empty the buffer and interpret the commands.

Date of issue 12/2005 Part No. 193603

<CR>$-$+

CR

$-

Carriage return character (0D Hex.)

Exit and save new configuration

Matrix 2/5 3 bars: no check digit,

variable length code from 1 to 32 characters

23

Page 28

VB8-305

Software Configuration Strings

SERIAL CONFIGURATION STRINGS

DESCRIPTION STRING

ENTER/EXIT CONFIGURATION COMMANDS

Enter Configuration

Exit and Save Configuration

Restore Default

Transmit Software Release (not for PEN emulation)

These commands do not require $-.

DESCRIPTION STRING

INTERFACE SELECTION

RS232

WEDGE for IBM AT

for IBM Terminals: 31xx, 32xx, 34xx, 37xx; make-break keyboard

for IBM Terminals: 31xx, 32xx, 34xx, 37xx; make-only keyboard

typewriter

Keyboard Type for IBM Terminals 31xx,

32xx, 34xx, 37xx

advanced

for IBM XT

for IBM Terminal 3153

for IBM PC Notebook

for IBM SURE1

for IBM AT - ALT mode

for IBM PC Notebook - ALT mode

for Wyse Terminal - ANSI Keyboard

for Wyse Terminal - PC Keyboard

for Wyse Terminal - ASCII Keyboard

for Wyse Terminal - VT220 style Keyboard

for Digital Terminals VT2xx/3xx/4xx

for Apple ADB Bus

PEN EMULATION

$+

$$+$*<CR>

$+$!<CR>

CP0

CP500

CP501

CP502

FK0

FK1

CP503

CP504

CP505

CP506

CP507

CP508

CP509

CP510

CP511

CP514

CP512

CP513

CP6

Date of issue 12/2005 Part No. 193603

24

Page 29

VB8-305

Software Configuration Strings

RS232

WEDGE

CD0

CD1

CD2

CD3

CD4

CD5

CD6

CD7

CD8

CC0

CC1

CC2

CA0

CA1

CA2

CB0

CB1

CE0

CE1

CE2

CE3

CF0

CF3

EC0

EC1

CK00 - CK99

CL00 - CL99

FJ7

FJ4

FJ2

FJ3

FJ1

FJ6

FJ5

FJ0

DESCRIPTION STRING

Baud rate 150

300

600

1200

2400

4800

9600

19200

38400

Parity none

even

odd

Data bits 7

8

9

Stop bits 1

2

Handshaking disable

RTS/CTS

XON/XOFF

RTS always On

ACK/NACK Protocol disable

enable

FIFO disable

enable

Inter-character delay (ms)

RX Timeout (100 ms)

DESCRIPTION STRING

Keyboard nationality Belgian

English

French

German

Italian

Spanish

Swedish

USA

Date of issue 12/2005 Part No. 193603

25

Page 30

VB8-305

Software Configuration Strings

DESCRIPTION STRING

WEDGE (continued)

Caps Lock caps Lock ON

caps Lock OFF

Num Lock Toggle Num Lock

Num Lock Unchanged

Delays

Inter-Character (ms)

Inter-Code (s)

Control Character Emulation

Ctrl + Shift + Key

Ctrl + Key

FE1

FE0

FL1

FL0

CK00 - CK99

FG00 - FG99

FO0

FO1

PEN

DESCRIPTION STRING

Operating mode

Minimum output pulse

interpret (does not require

transparent (does not require

200µs

400µs

600µs

800µs

1 ms

1.2 ms

Conversion to Code 39 disable conversion to Code 39

enable conversion to Code 39

Output level normal

inverted

Idle level normal

inverted

Overflow narrow overflow

medium overflow

wide overflow

Inter-Block delay (100 ms)

$+

or $-)

$+

or $-)

$]

$[

DG0

DG1

DG2

DG3

DG4

DG5

DA0

DA1

DD0

DD1

DE0

DE1

DH0

DH1

DH2

CK00-CK99

Date of issue 12/2005 Part No. 193603

26

Page 31

VB8-305

Software Configuration Strings

NOT FOR PEN EMULATION INTERFACES

DATA FORMAT

DESCRIPTION STRING

Code Identifier disable

DL standard

AIM standard

Custom

Custom Code Identifier

Headers no header

one character

two characters

three characters

four characters

five characters

six characters

seven characters

eight characters

Terminators no terminator

one character

two characters

three characters

four characters

five characters

six characters

seven characters

eight characters

EB0

EB1

EB2

EB3

EH

abc

EA00

EA01x

EA02xx

EA03

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx

xxxxxxxx

EA10

EA11x

xxx

xxxx

xxxxx

xxxxxx

xxxxxxx

xxxxxxxx

EA04

EA05

EA06

EA07

EA08

EA12xx

EA13

EA14

EA15

EA16

EA17

EA18

a = ASCII character.

b, c, x = HEX values representing an ASCII character.

a = ASCII character of the DL STANDARD Code Identifier from the table in

Appendix A.

00

b = Hex value of the first Custom Code Identifier character from

FF

= disable Code Identifier

= Hex value of the second Custom Code Identifier character from 00 to FE;

c

FF

= disable second character of Custom Code Identifier

x = Hex value from

00

to FE

to FE;

Date of issue 12/2005 Part No. 193603

27

Page 32

VB8-305

Software Configuration Strings

DATA FORMAT (continued)

DESCRIPTION STRING

Code Length Tx not transmitted

transmitted in variable-digit format

transmitted in fixed 4-digit format

Field Adjustment disable

right addition

left addition

right deletion

Field Adjustment Character

Character Replacement disable character replacement

first character replacement

second character replacement

third character replacement

a = ASCII character.

d = a number from the Hex/Numeric Table

e, f, g = HEX values representing an ASCII character

a = ASCII character of the DL STANDARD Code Identifier from the table in

Appendix A.

d = a number in the range

e = Hex value from

f = Hex value of the character to be replaced from

g

= Hex value of the new character to insert from 00 to FE

FF

= replace with no new character (remove character)

DESCRIPTION STRING

Read Rate 67 reads per sec.

135 reads per sec.

270 reads per sec.

Sleep State disable

enable

Enter Sleep Timeout (100 ms)

Standby enable

disable

NOT FOR PEN EMULATION INTERFACES

left deletion

01-32

from the Hex/Numeric Table

00

to FE

00

to FE

POWER SAVE

EE0

EE1

EE2

EF0

EFa0d

EFa1d

EFa2d

EFa3d

EGe

EO0

EO1

afg

EO2

afg

EO3

afg

BT0

BT1

BT2

BQ0

BQ1

BR00-BR99

BM0

BM1

Date of issue 12/2005 Part No. 193603

28

Page 33

VB8-305

Software Configuration Strings

DESCRIPTION STRING

READING PARAMETERS

Operating Modes serial on-line

See page 41 for details

on-line

automatic

test Mode disable

enable

Beeper Intensity very low intensity

low intensity

medium intensity

high intensity

Beeper Tone Tone 1

Tone 2

Tone 3

Tone 4

Beeper Type monotone

bitonal

Beeper Length long

short

BK0

BK1

BK3

#DStat0<CR>

#DStat1<CR>

BG0

BG1

BG2

BG3

BH0

BH1

BH2

BH3

BJ0

BJ1

BI0

BI1

DESCRIPTION STRING

DECODING PARAMETERS

Ink-Spread disable

enable

Overflow Control disable

enable

Interdigit Control disable

enable

Puzzle SolverTM disable

enable

Decoding Safety one read

two reads

three reads

four reads

CODE SELECTION

DESCRIPTION STRING

DISABLE ALL FAMILY CODES

EAN/UPC Disable EAN/UPC family

EAN 8/EAN 13/UPC A/UPC E without ADD ON

with ADD ON

with and without ADD ON

EAN 8/EAN 13 without ADD ON

with ADD ON 2 ONLY

with ADD ON 5 ONLY

with ADD ON 2 AND 5

Date of issue 12/2005 Part No. 193603

AX0

AX1

AW1

AW0

AV0

AV1

AU0

AU1

ED0

ED1

ED2

ED3

AZ0

AA0

AA1

AA5

AA8

AA3

AAK

AAL

AA6

29

Page 34

VB8-305

Software Configuration Strings

DESCRIPTION STRING

UPC A/UPC E without ADD ON

with ADD ON 2 ONLY

with ADD ON 5 ONLY

with ADD ON 2 AND 5

EAN 8 check digit transmission disable

enable

EAN 13 check digit transmission disable

enable

UPC A check digit transmission disable

enable

UPC E check digit transmission disable

enable

Conversions UPC E to UPC A

UPC E to EAN 13

UPC A to EAN 13

EAN 8 to EAN 13

Code 39 disable Code 39 family

Standard no check digit control

check digit control and transmission

check digit control without transmission

Full ASCII no check digit control

check digit control and transmission

check digit control without transmission

CIP 39

Code 32

code length

ISBN Conversion codes

CODE SELECTION (continued)

enable ISBN

enable ISSN

enable ISBN and ISSN

disable ISBN and ISSN

AA4

AAM

AAN

AA7

AAG0

AAG1

AAH0

AAH1

AAI0

AAI1

AAJ0

AAJ1

AAA

AAB

AAC

AAD

AP1

AP2

AP3

AP0

AB0

AB11

AB12

AB13

AB21

AB22

AB23

AB3

AB4

AB*

xxxx

xxxx = ASCII numbers that define the code length where:

• First 2 digits = minimum acceptable code length.

• Second 2 digits = maximum acceptable code length.

The minimum code length must always be less than or equal to the maximum.

The maximum code length for all codes is 99 characters.

Examples:

0132 = variable length from 1 to 32 digits in the code.

1010 = 10 digit code length only.

Date of issue 12/2005 Part No. 193603

30

Page 35

VB8-305

Software Configuration Strings

DESCRIPTION STRING

CODE SELECTION (continued)

2/5 disable Code 2/5 family

Interleaved 2/5 no check digit control

check digit control and transmission

check digit control without transmission

Normal 2/5 5 bars no check digit control

check digit control and transmission

check digit control without transmission

Industrial 2/5 (IATA) no check digit control

check digit control and transmission

check digit control without transmission

Matrix 2/5 3 bars no check digit control

check digit control and transmission

check digit control without transmission

CIP/HR

Codabar disable Codabar family

Standard no start/stop character equality control

nor transmission

no start/stop character equality control

but transmission

start/stop character equality control

but no transmission

start/stop character equality control

and transmission

ABC Codabar no start/stop character equality control

but transmission

Codabar ABC forced concatenation

code length

start/stop character case in transmission lower case

upper case

xxxx = ASCII numbers that define the code length where:

• First 2 digits = minimum acceptable code length.

• Second 2 digits = maximum acceptable code length.

The minimum code length must always be less than or equal to the maximum.

The maximum code length for all codes is 99 characters:

EXAMPLES:

0132 = variable length from 1 to 32 digits in the code.

1010 = 10 digit code length only.

Date of issue 12/2005 Part No. 193603

AC0

AC11

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

xxxx

AC5

AD0

xxxx

ADA0

ADA1

AC12

AC13

AC21

AC22

AC23

AC31

AC32

AC33

AC41

AC42

AC43

AD111

AD112

AD121

AD122

AD212

AD232

AD*

31

Page 36

VB8-305

Software Configuration Strings

DESCRIPTION STRING

CODE SELECTION (continued)

Code 128 disable Code 128 family

enable Code 128

control without transmission of check digit

enable EAN 128

control without transmission of check digit

add GS before Code disable

enable

ISBT 128 enable ISBT 128

enable all concatenations

disable all concatenations

Code 93 disable Code 93 family

enable Code 93

control without transmission of check digit

Codablock-A disable

enable

Codablock-F disable the family

enable Standard

enable EAN

MSI disable the family

no check

MOD10 no tx

MOD10 with tx

MOD11-MOD10 no tx

MOD11-MOD10 with tx

MOD10-MOD10 no tx

MOD10-MOD10 with tx

Plessey disable the family

Standard no check

Standard check - with tx

Standard check - no tx

Anker no check

Anker check - with tx

Anker check - no tx

Telepen disable the family

Numeric no check

Numeric check - with tx

Numeric check - no tx

Alpha no check

Alpha check - with tx

Alpha check - no tx

Delta IBM disable the family

no check

Type 1 check

Type 2 check

AI0

AI11

AI21

EQ0

EQ1

AI31

=&FNC3=<=>103d1

=&FNC3=<=>103d0

AK0

AK1

AO0

AO1

AN0

AN1

AN2

AE0

AE1

AE2

AE3

AE4

AE5

AE6

AE7

AF0

AF11

AF12

AF13

AF21

AF22

AF23

AL0

AL11

AL12

AL13

AL21

AL22

AL23

AH0

AH1

AH2

AH3

Date of issue 12/2005 Part No. 193603

32

Page 37

VB8-305

Software Configuration Strings

DESCRIPTION STRING

CODE SELECTION (continued)

Code 11 disable the family

no check

Type C with tx

Type C no tx

Type K with tx

Type K no tx

Type C and K with tx

Type C and K no tx

Code 16K disable

enable

Code 49 disable

enable

PDF417 disable

enable

AG0

AG1

AG21

AG22

AG31

AG32

AG41

AG42

AJ0

AJ1

AM0

AM1

AR0

AR1

Date of issue 12/2005 Part No. 193603

33

Page 38

y

y

y

VB8-305

Preferences

4 REFERENCES

4.1 RS232 PARAMETERS

4.1.1 Handshaking

Hardware handshaking: (RTS/CTS)

The RTS line is activated by the decoder before transmitting a character.

Transmission is possible only if the CTS line (controlled by the Host) is active.

Signals at

EIA levels

RTS

TX

Transmitted data Transmitted data

CTS

Host bus

Figure 31 - RTS/CTS handshaking

Software handshaking: (XON/XOFF)

During transmission, if the Host sends the XOFF character (13 Hex), the decoder

interrupts the transmission with a maximum delay of one character and only resumes

when the XON character (11 Hex) is received.

Transmitted dataTransmitted data

TX

RX

XONXOFF

Host bus

Host read

Figure 32 - XON/XOFF handshaking

34

Date of issue 12/2005 Part No. 193603

Page 39

VB8-305

Preferences

4.1.2 ACK/NACK from Host Protocol

This parameter sets a transmission protocol in which the Host responds to the reader

after every code transmitted. The Host sends an ACK character (06 HEX) in the case

of good reception or the NACK character (15 HEX) requesting re-transmission, in the

case of bad reception.

data

VB8

cable

ACK or NACK

Figure 33 - ACK/NACK enabled

Host

4.1.3 FIFO

This parameter determines whether data (barcodes) are buffered on a First In First

Out basis allowing faster data collection in certain cases for example when using

slow baud rates and/or hardware handshaking.

If the FIFO buffering is enabled, codes are collected and sent out on the serial line in

the order of acquisition. About 800 characters can be collected (buffer full), after

which the reader signals an error and discards any further codes until the

transmission is restored.

If the FIFO buffering is disabled, each code must be transmitted before another one

can be read.

4.1.4 RX Timeout

When the RS232 interface is selected, the Host can be used to configure the device

by sending it command strings (see chapter 3).

This parameter can be used to automatically end data reception from the Host after

the specified period of time.

If no character is received from the Host, after the timeout expires, any incomplete

string (any string not terminated by <CR>) is flushed from the device buffer.

Date of issue 12/2005 Part No. 193603

35

Page 40

VB8-305

Preferences

4.2 PEN PARAMETERS

4.2.1 Minimum Output Pulse

This parameter sets the duration of the output pulse corresponding to the narrowest

element in the barcode. In this way the code resolution is controlled by the signal

sent to the decoder, independently of the physical resolution of the code read.

µ

The shortest pulse (200

therefore a shorter transfer speed to the decoder (for decoders able to work on high

resolution codes). Likewise, longer pulses correspond to low resolution code

emulation and therefore a longer transfer time to the decoder.

s) corresponds to a high resolution code emulation and

4.2.2 Overflow

This parameter generates a white space before the first bar and after the last bar of

the code. The selections are as follows:

narrow = space 10 times the minimum output pulse.

medium = space 20 times the minimum output pulse.

wide = space 30 times the minimum output pulse.

36

Date of issue 12/2005 Part No. 193603

Page 41

VB8-305

Preferences

4.2.3 Output and Idle Levels

The following state diagrams describe the different output and idle level combinations

for Pen Emulation:

OUTPUT: Normal

IDLE: Normal

OUTPUT: Normal

IDLE: Inverted

idle

idle

space

barcode output

space

barcode output

bar

bar

black

white

black

white

OUTPUT: Inverted

IDLE: Normal

OUTPUT: Inverted

IDLE: Inverted

idle

idle

space

space

barcode output

barcode output

bar

bar

white

black

white

black

Figure 34 - Output and Idle Levels

4.2.4 Inter-Block Delay

For the PEN Emulation interface, data are sent to the Host in fixed size blocks of 20

characters each. The inter-block delay parameter allows setting a delay between

each block sent to the Host.

Date of issue 12/2005 Part No. 193603

37

Page 42

VB8-305

Preferences

4.3 DATA FORMAT

4.3.1 Header/Terminator Selection

The header/terminator selection is not effected by the reading of the restore default

code. In fact, header and terminator default values depend on the interface selection:

RS232: no header, terminator CR-LF

WEDGE: no header, terminator ENTER

These default values are always

interface selection code, see chapter 3.

For the WEDGE interface, the following extended keyboard values can also be

configured:

EXTENDED KEYBOARD TO HEX CONVERSION TABLE

HEX KEY KEY KEY KEY

83

84

85

86

87

88

89

8A

8B

8C

8D

8E

8F

90

91

92

93

94

95

96

97

98

99

9A

9B

For all readers using Wedge interface, all values from

IBM AT

IBM 3153

APPLE ADB

ENTER ENTER FIELD EXIT RETURN

TAB TAB TAB TAB

F1 F1 F1 F1

F2 F2 F2 F2

F3 F3 F3 F3

F4 F4 F4 F4

F5 F5 F5 F5

F6 F6 F6 F6

F7 F7 F7 F7

F8 F8 F8 F8

F9 F9 F9 F9

F10 F10 F10 F10

F11 ESC F11 F11

F12 BACKSPACE F12 F12

HOME HOME ENTER F13

END END RESET F14

PG UP PG UP INSERT F15

PG DOWN PG DOWN DELETE F16

↑

↓

←

→

ESC ESC ESC

CTRL (Right) CTRL (Right) CTRL (Right)

Euro Space Space Space

restored through the reading of RS232 or WEDGE

IBM XT IBM 31xx, 32xx,

34xx, 37xx

↑

↓

←

→

FIELD - UP

FIELD + DOWN

ENTER (Paddle) LEFT

PRINT RIGHT

9C

to FE send the Space character.

Wyse

Digital

Date of issue 12/2005 Part No. 193603

38

Page 43

VB8-305

Preferences

SET CUSTOM EXTENDED HEADER/TERMINATOR KEYS

The extended Header/Terminator keys for Wedge Interface

customized by defining them through a simple keyboard setting procedure.

For example, the Numeric Keypad keys can be set for use as Headers or

Terminators by substituting the default extended keys using this procedure.

The type of computer or terminal must be selected before activating the keyboard

setting command.

Press and release a key to set it.

Some characters may require more than one key pressed simultaneously during

normal use (refer to the manual of your PC or terminal for keyboard use). The exact

sequence must be indicated to the reader in this case pressing and releasing the

different keys.

Example:

If one has to press the "Shift" and "4" keys simultaneously on the keyboard to

transmit the character "$" to the video, to set the "$", press and release "Shift" then

press and release "4".

Each pressed and released key must generate an acoustic signal on the reader,

otherwise repress the key. Never press more than one key at the same time, even if

this corresponds to the normal use of your keyboard.

Press "Backspace" to correct a wrong key entry. In this case the reader emits 2

beeps.

Note: "CAPS LOCK" and "NUM LOCK" must be off before starting the keyboard

setting procedure. "SHIFT" must be repressed for each character and cannot

be substituted by "CAPS LOCK".

users can be

Date of issue 12/2005 Part No. 193603

39

Page 44

VB8-305

Preferences

Set Custom Extended Header/Terminator Keys

Enter the code above.

•

If the first 4 KEYS (Shift, Alt, Ctrl, and Backspace) are not available on

your keyboard, you can only substitute them with keys not used, or

substitute them with each other.

•

Keys 5 to 28 must be defined

Press the desired keys in the following order:

The reader signals the end of the procedure with 2 beeps indicating the keys

have been registered.

CUSTOM EXTENDED KEYBOARD SETTING TABLE

$+FB1$-

Order HEX KEY

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

-

-

-

83

84

85

86

87

88

89

8A

8B

8C

8D

8E

8F

90

91

92

93

94

95

96

97

98

99

9A

Custom

Shift

Alt

Ctrl

Backspace

40

Date of issue 12/2005 Part No. 193603

Page 45

VB8-305

Preferences

4.4 POWER SAVE

4.4.1 Sleep State

µ

This mode allows the

consumption. This command is only valid when On-Line is selected.

Before entering Sleep mode, the following are verified:

•

no commands coming from Host

•

no data being transmitted to Host

•

Enter Sleep Timeout ended

To exit Sleep mode press the trigger.

Enabling the Sleep state implements Standby mode for CCD devices.

P in the reader to enter a “Sleep” state for minimum power

4.4.2 Enter Sleep Timeout

For readers that have the Sleep state enabled, this timeout determines when the

reader will enter this state.

4.4.3 Standby

If this command is enabled, part of the CCD circuitry shuts down (Standby), in order

to optimize low power consumption when not reading. When the trigger is pressed

this circuitry powers up. This mode causes a minor delay of about 100 ms before the

reader is ready.

4.5 READING PARAMETERS

4.5.1 Operating Modes

This group of parameters allows setting different reading modes:

•

ON-LINE: the VB8 reader is connected to an external Presence Sensor

using EXT TRIG+ and EXT TRIG- inputs. During the active phase of the

presence sensor, the VB8 tries to acquire and correctly decode the code. If the

operation is successful, the barcode characters are transmitted on the serial

interface in the format defined by the current configuration. Otherwise a No

Read message is sent: it is fixed as the CAN symbol;

Date of issue 12/2005 Part No. 193603

41

Page 46

VB8-305

Preferences

•

AUTOMATIC: the VB8 reader does not require connections with external

presence sensors in this operating mode. In this mode the illuminator is always

ON and VB8 is continuously scanning. The reading phase is enabled when a

barcode enters the reading zone of the camera and is terminated after a fixed

number of scans without a code. The next reading phase will begin when a code

enters the reading zone again.

The number of scans without a code is an optimized value for the CCD camera

in order to improve code identification in the reading zone. Code transmission

occurs as in the other operating modes but in case of No Read condition there is

no transmission on the serial port.

•

SERIAL ON-LINE: the reading phase starts when the Serial Start Character is

received on the serial interface and ends when the code is read or a Serial Stop

Character is received. If decoding is correct, the data is transmitted on the serial

port as defined by the configuration. Otherwise a No Read message is sent: it is

fixed as the CAN symbol. The Start and Stop characters are also fixed:

Serial START: STX

Serial STOP: ETX

•

TEST MODE: test mode allows verifying the reader position and the associated

reading features. The code is continuously read when in this mode. After

400 ms, the values relative to an internal counter and the decoded code are

displayed and transmitted on the serial interface.

The counter reports a statistical calculation which consists of a good reading

percentage of the total acquisitions.

The following message could be displayed:

Counter value Code

090% 12345ABC

If the CCD reader cannot decode a label, the following message will be

displayed:

0%.

Only one barcode label must be read for each reading cycle.

Since Test Mode is basically a diagnostic mode, it can only be

enabled at run time and not saved to a non-volatile memory.

For the same reason, this operating mode must be disabled

NOTE

only via RS232 interface by selecting another Operating Mode

command, if you want to restore the previous state of the

reader.

42

Date of issue 12/2005 Part No. 193603

Page 47

VB8-305

Preferences

4.5.2 Reads per Cycle

In general, a reading cycle corresponds to the Phase ON / Phase OFF times of a

device.

The resulting effects of this parameter on code reading depend on other related

configuration conditions. Here are the definitions of Phase ON and Phase OFF times.

When one read per cycle is selected, the device decodes only one code during the

Phase ON period and immediately turns to the Phase OFF

another code when the next Phase ON time occurs.

In multiple reads per cycle, the Phase ON period is extended so that the device

can continue decoding codes until an OFF event occurs.

. It is only possible to read

4.6 DECODING PARAMETERS

These parameters are intended to enhance the decoding capability

of the reader for particular applications. Used incorrectly, they can

degrade the reading performance or increase the possibility of a

CAUTION

decoding error.

4.6.1 Ink-Spread

The ink-spread parameter allows the decoding of codes which are not perfectly

printed because the page texture tends to absorb the ink.

4.6.2 Overflow Control

The overflow control parameter can be disabled when decoding codes printed on

small surfaces, which don’t allow the use of an overflow space.

This command does not effect code families 2/5, Code 128 and Code 93.

This command is forced (enabled) when PDF417 codes are enabled.

4.6.3 Interdigit Control

The interdigit control parameter verifies the interdigit spacing for code families

Code 39 and Codabar.

Date of issue 12/2005 Part No. 193603

43

Page 48

VB8-305

Technical Features

5 TECHNICAL FEATURES

ELECTRICAL FEATURES

Supply voltage

Model1: 10 - 30VDC / Model2: 5 VDC ± 5%

Power consumption 1.5 W

Interfaces RS232, Wedge, PEN Emulation

LED Indicators

Power ON / Power OFF / Good Read / Miss

OPTICAL FEATURES

Sensor CCD solid state

Max read rate 270 read/sec

Reading field See diagrams on page 45

Max. resolution 0.076 mm (3 mils)

ENVIRONMENTAL FEATURES

Working temperature 0° to +40 °C / 32° to 104 °F

Storage temperature -20° to +70 °C / 4° to 158 °F

READING FEATURES

Readable codes:

Pharmaceutical codes

Codablock-F Std

Codablock-F EAN

MECHANICAL FEATURES

Dimensions (LxWxH) 60.5 x 63 x 27 mm / 2.38 x 2.48 x 1.06 in

Read

EAN/UPC

Code 39

2/5 family

Codabar

Code 128

EAN 128

ISBT 128

Code 93

Telepen

MSI

Plessey

Delta IBM

Codablock-A

Code 11

Code 16K

Code 49

Date of issue 12/2005 Part No. 193603

44

Page 49

VB8-305

Technical Features

READING DIAGRAMS

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320

160

140

120

100

80

0.20 mm

60

40

20

0

-20

-40

-60

-80

-100

-120

0.13 mm

-140

(5 mils)

-160

Reading Diagram VB8-xxx (code 39)

0.20 mm

(8 mils)

0.30 mm

(12 mils)

0.50 mm

(20 mils)

Date of issue 12/2005 Part No. 193603

45

Page 50

VB8-305

Technical Features

mm

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 32 0

160

140

120

100

80

0.20 mm

60

40

20

0

-20

-40

-60

-80

-100

-120

0.13 mm

-140

(5 mils)

-160

0.20 mm

(8 mils)

0.30 mm

(12 mils)

Reading Diagram VB8-xxx (code 39)

0.50 mm

(20 mils)

46

Date of issue 12/2005 Part No. 193603

Page 51

VB8-305

Code Identifier Table

A CODE IDENTIFIER TABLE

CODE IDENTIFIER TABLE

CODE AIM STANDARD Custom

2/5 interleaved ] I y N

2/5 industrial ] X y P

2/5 normal 5 bars ] S y O

2/5 matrix 3 bars ] X y Q

EAN 8 ] E 4 A

EAN 13 ] E 0 B

UPC A ] X y C

UPC E ] X y D

EAN 8 with 2 ADD ON ] E 5 J

EAN 8 with 5 ADD ON ] E 6 K

EAN 13 with 2 ADD ON ] E 1 L

EAN 13 with 5 ADD ON ] E 2 M

UPC A with 2 ADD ON ] X y F

UPC A with 5 ADD ON ] X y G

UPC E with 2 ADD ON ] X y H

UPC E with 5 ADD ON ] X y I

Code 39 ] A y V

Code 39 Full ASCII ] A y W

CODABAR ] F y R

ABC CODABAR ] X y S

Code 128 ] C y T

EAN 128 ] C y k

ISBT 128 ] C4 f

Code 93 ] G y U

CIP/39 ] X y Y

CIP/HR ] X y e

Code 32 ] X y X

Codablock-A ] O 6 n

Codablock-F Std ] O 4 l

Codablock-F EAN ] O 5 m

MSI ] M y Z

Plessey Standard ] P 0 a

Plessey Anker ] P 1 o

Telepen ] X 0 d

Part No. 193603

Delta IBM ] X 0 c

Code 11 ] H y b

Code 16K ] K 0 p

Code 49 ] T y q

PDF417 ] L 0 r

Date of issue 12/2005

P+F STANDARD

47

Page 52

VB8-305

Hex/Numeric Table

B HEX/NUMERIC TABLE

CHARACTER TO HEX CONVERSION TABLE

char hex char hex char hex

NUL

SOH

STX

ETX

EOT

ENQ

ACK

BEL

BS

HT

LF

VT

FF

CR

SO

SI

DLE

DC1

DC2

DC3

DC4

NAK

SYN

ETB

CAN

EM

SUB

ESC

FS

GS

RS

US

SPACE

!

"

#

$

%

&

'

(

)

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

22

23

24

25

26

27

28

29

*

+

,

.

/

0

1

2

3

4

5

6

7

8

9

:

;

<

=

>

?

@

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

3D

3E

3F

40

41

42

43

44

45

46

47

48

49

4A

4B

4C

4D

4E

4F

50

51

52

53

54

U

V

W

X

Y

Z

[

\

]

^

_

`

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

s

t

u

v

w

x

y

z

{

|

}

~

DEL

55

56

57

58

59

5A

5B

5C

5D

5E

5F

60

61

62

63

64

65

66

67

68

69

6A

6B

6C

6D

6E

6F

70

71

72

73

74

75

76

77

78

79

7A

7B

7C

7D

7E

7F

Part No. 193603

Date of issue 12/2005

48

Page 53

VB8-305

Part No. 193603

Date of issue 12/2005

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry, published by

the Central Association of the "Elektrotechnik und Elektroindustrie (ZVEI) e.V.

in their most recent version as well as the supplementary clause: "Extended reservation of title".

Page 54

FACTORY AUTOMATION – SENSING YOUR NEEDS

For half a century, Pepperl+Fuchs have been continually providing new stimuli for the world of automation. The company

is also setting standards in quality and innovative technology. We develop, produce and distribute electronic sensors and

interface modules on a global scale. By means of our world-wide presence and our high flexibility in production and customer service we are able to individually offer complete solutions – right where you need us. We know what we are talking

about – Pepperl+Fuchs have established a good reputation in supplying the world’s biggest offer of industrial sensor

technology for a large scale of applications. Our signals move the world.

Twinsburg

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-Mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-Mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd. · P+F Building

Singapore 139942

Tel. +65 6779-9091

E-Mail: sales@sg.pepperl-fuchs.com

Mannheim

Singapur

www.pepperl-fuchs.com

Subject to reasonable modifications due to technical advances

Copyright PEPPERL+FUCHS • Printed in Germany

TDOCT-0965AENG

Part No. 193603

12/2005

Loading...

Loading...