Page 1

FACTORY AUTOMATION

MANUAL

VAZ-2E2A-G20-ZPA1

ZPA Motor Control Module

from Firmware Version V.28

Page 2

VAZ-2E2A-G20-ZPA1

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

VAZ-2E2A-G20-ZPA1

1 Introduction................................................................................. 5

1.1 Content of this Document ................................................................... 5

1.2 Target Group, Personnel...................................................................... 5

1.3 Symbols Used ...................................................................................... 5

1.4 Intended Use ........................................................................................ 6

1.5 General Safety Instructions ................................................................. 6

1.6 Declaration of Conformity ................................................................... 7

2 Product Description ................................................................... 8

2.1 Use and Application............................................................................. 8

2.2 Operating Modes of the ZPA Motor Control Module....................... 11

2.2.1 Overview.......................................................................................... 11

2.2.2 Standard ZPA................................................................................... 11

2.2.3 Enhanced ZPA................................................................................. 12

2.2.4 Transportation .................................................................................. 13

2.2.5 Long Zone - Single Zone.................................................................. 14

2.2.6 Direct Control................................................................................... 15

2.2.7 Direction Control .............................................................................. 15

2.2.8 Slave................................................................................................ 16

2.3 Indicators and Operating Elements ................................................. 17

2.3.1 LED Indicators ................................................................................. 17

2.3.2 Rotary Switches for Configuration.................................................... 20

2.4 Interfaces and Connections.............................................................. 22

3 Installation................................................................................. 24

3.1 Safety Information.............................................................................. 24

3.2 Preparation ......................................................................................... 24

3.3 Mounting ............................................................................................. 24

3.4 Power Supply Connection................................................................. 25

3.5 Special Requirements when Connecting to a PLC......................... 28

3.6 Connecting Motors, Sensors, and Zone Coupling.......................... 29

3

Page 4

VAZ-2E2A-G20-ZPA1

4 Operating Behavior .................................................................. 34

4.1 Switch-On Behavior............................................................................34

4.2 Switch-On Delay .................................................................................34

4.3 Search Time ........................................................................................34

4.4 Leaving Time.......................................................................................34

4.5 Entry Time...........................................................................................34

4.6 Transportation Time ...........................................................................35

4.7 Motor Run-On Time ............................................................................35

4.8 Release Delay .....................................................................................35

4.9 Idle Mode Delay ..................................................................................35

5 Manual Intervention in the Conveying Process..................... 36

5.1 Manual Feeding of Conveyed Product .............................................36

5.2 Manual Removal of Conveyed Product ............................................36

5.3 Manual Stop/Release..........................................................................36

5.4 Manually Correcting Accumulations ................................................37

6 Troubleshooting........................................................................ 38

6.1 What to Do in the Event of a Fault.....................................................38

4

Page 5

VAZ-2E2A-G20-ZPA1

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dismounting

■

Disposal

Note!

For full information on the product, refer to the further documentation on the Internet at

www.pepperl-fuchs.com.

The documentation comprises the following parts:

■

This document

■

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

■

EU-type examination certificate

■

EU declaration of conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Instruction manual

■

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

2018-06

5

Page 6

VAZ-2E2A-G20-ZPA1

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and a ny connected systems and plants, or result in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph w ith instructions. You are prompted to perform an action or

a sequence of actions.

1.4 Intended Use

The VAZ-2E2A-G20 ZPA1 motor control module is a field device for controlling one or two

consecutive zones of an accumulation conveyor line. The m otor control module has two

electronic outputs for controlling a DC roller motor each as well as two sensor inputs for

detecting conveyed product, e.g., via light barriers.

Read through this manual carefully. Before mounting, connecting, and operating the ZPA motor

control module, be sure to familiarize yourself with the device.

Operate the ZPA motor control module only as described in this manual to ensure that the

device and the systems connected to the device work correctly.

2018-06

6

Page 7

VAZ-2E2A-G20-ZPA1

ISO9001

Introduction

1.5 General Safety Instructions

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Installation and commissioning of all devices may only be performed by trained and qualified

personnel.

User modification and or repair are dangerous and will void the warranty and exclude the

manufacturer from any liability. If serious faults occur, stop using the device. Secure the device

against inadvertent operation. In the event of repairs, return the device to your local

Pepperl+Fuchs representative or sales office.

Note!

Disposal

Electronic waste is hazardous waste. When disposing of the equipment, obser ve the current

statutory requirements in the respective country of use, as well as local regulations.

1.6 Declaration of Conformity

This product was developed and manufactured under observance of the applicable European

standards and guidelines.

Note!

A Declaration of Conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs GmbH, D-68307 Mannheim, has a certified quality

assurance system that conforms to ISO 9001.

2018-06

7

Page 8

VAZ-2E2A-G20-ZPA1

ZoneUpstream

zone

Downstream

zone

Roller motor Zone sensor

Conveying direction

Product Description

2 Product Description

2.1 Use and Application

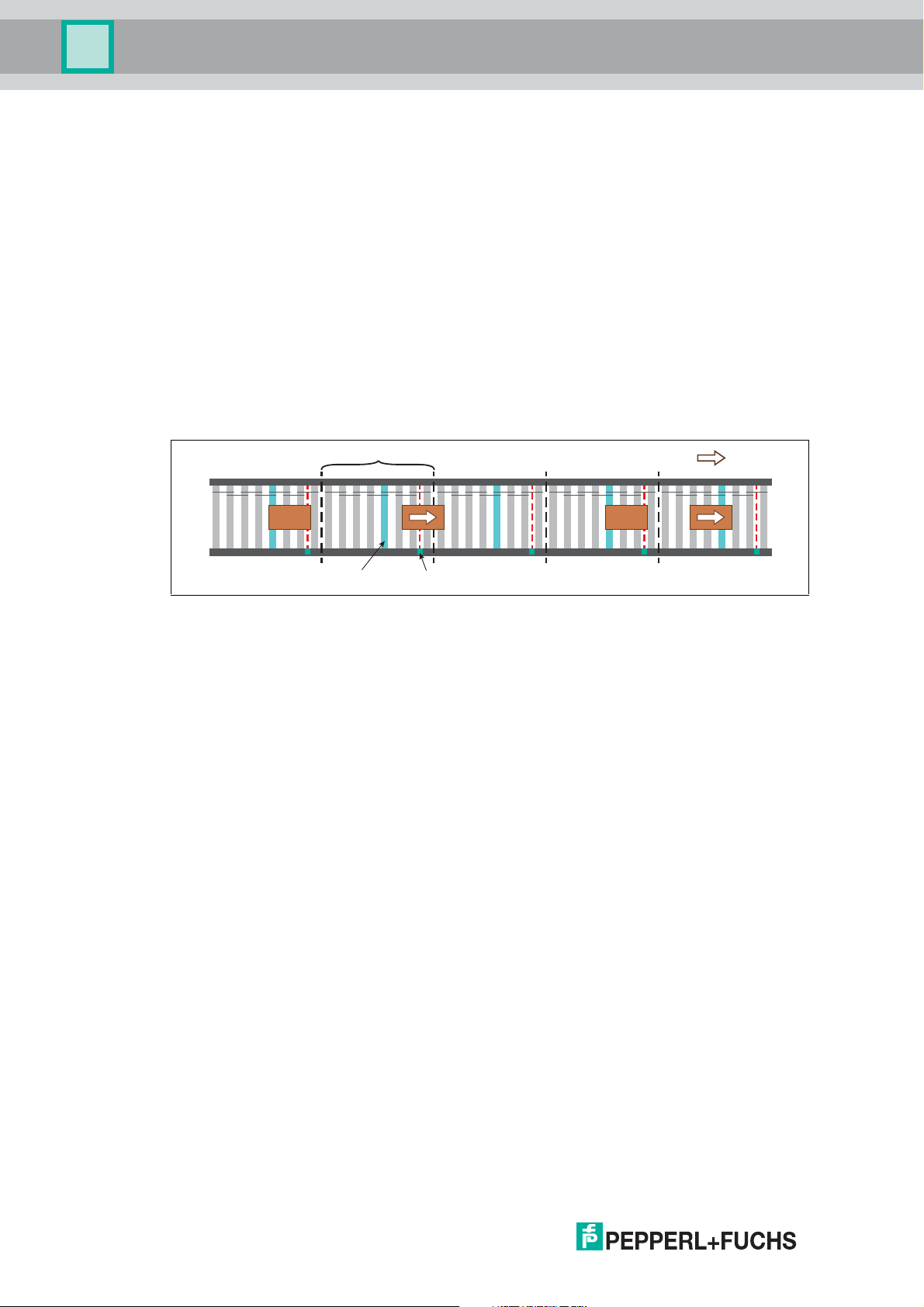

Zero Pressure Accumulation (ZPA)

During zero pressure accumulation, conveyed product is moved along a conveyor line in a

controlled manner and collisions between the conveyed product is prevented. For this purpose,

a conveyor line is divided into several sections or zones.

Each zone has its own drive, which can be activated independently of the neighboring zones.

At the end of each zone, a zone sensor is installed that detects the conveyed product.

The accumulation conveyor logic ensures that there is only ever one conveyed product present

in a zone. Conveyed products can therefore only be conveyed to the downstream zone once

there is no more conveyed product in that zone. As long as the downstream zone is occupied,

the conveyed product is stopped when it reaches the zone sensor and thus accumulates

irrespective of subsequent conveyed product.

Figure 2.1 Conveying scenario for the example Standard ZPA operation mode

Benefits and Features of the ZPA Motor Control Module

The ZPA motor control module is easy to install and can be configured for a wide range of

application situations. The main benefits and features of this m odule are:

■

Compact housing for direct mounting in support profiles and cable ducts.

■

Connection of the power supply using piercing technology via black AS-Interface flat

cable.

■

All other connections are implemented as connectors.

■

Decentralized control: The field module contains the logic for zero pressure accumulation.

A central control unit for the accumulation conveyor line is not required.

■

Support for master-slave operation

■

Control of two successive zones of an accumulation conveyor line using one module.

■

Simple adjustment of the operating mode, the conveyor direction, the motor speed, and

start/stop ramps via rotary switches.

■

Display of status and diagnostic information via LEDs.

■

Optimized for operation with DC roller motors type Interroll EC310.

■

Support for conveyed product that is longer than one zone.

■

Detection of accumulations leads to shutdown of the DC roller motors.

8

2018-06

Page 9

VAZ-2E2A-G20-ZPA1

X1 X2

IN1

MOT1

IN2

MOT2

PWR

X1 IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN

OUT

OUT

X2 X2X1X1

IN

OUT

IN

OUT

OUT

IN

OUT

IN

IN

OUT

IN

OUT

MOT1 MOT2 IN2 MOT2 IN2MOT1 IN1

IN

ZoneUpstream

zone

Downstream

zone

Roller motor Roller motor Zone sensor Roller motor Zone sensor

Conveying direction

Roller motor Zone sensor

Release

Sensor

Zone coupling

Sensor Sensor

Release Release

ZPA motor control module

Zone coupling Zone coupling

2 zones

ZPA motor control module

1 zone

Release

Sensor

Zone Zone ZoneZone

Product Description

Figure 2.2

Function of the ZPA Motor Control Module

The ZPA motor control module is an intelligent field module that already contains the logic for

zero pressure accumu lation. It assumes the control of one or two consecutive zones powered

by DC roller motors. The m otors (MOT1, MOT2) and zone sensors (IN1, IN2) are connected

directly with the ZPA motor control module for this purpose.

The ZPA motor control module has two separate zone controls. Both zone controls are logically

coupled w ithin the module. The access-side zone control can be deactivated within the

module, so that the outgoing-side zone control controls both DC roller motors as the master.

Only the sensor input (IN1 and IN2) of the master is evaluated in this case.

A coupling with the neighboring zones is created via two interfaces for the zone coupling (X1,

X2). This makes it possible to connect several ZPA motor control modules in series to create an

accumulation conveyor line of any length.

The ZPA motor control module is powered via the black AS-Interface flat cable, which is

connected using piercing technology without the need for tools. The ZPA motor control module

is configured directly on the device using the three rotary switches (S1, S2, S3). In addition to

various operating modes, the motor speed, the conveyor direction, and start and stop ramps

can be configured.

2018-06

Figure 2.3

1-zone Operation/2-zone Operation

If the ZPA motor control module is to only control a single zone, the second zone logic must be

manually deactivated in some operating modes. For this purpose, the rear zone in the conveyor

direction is bypassed internally. The DC roller motor of this zone then runs synchronous to that

of the zone in front (see previous figure). It can therefore support the other DC roller motor by

driving the same zone and thereby doubling the drive power of that zone.

9

Page 10

VAZ-2E2A-G20-ZPA1

IN

OUT

OUT

X2 X2X1X1

IN

OUT

IN

OUT

OUT

IN

OUT

IN

IN

OUT

IN

OUT

MOT1 MOT2 IN2 MOT2 IN2MOT1 IN1

IN

ZoneUpstream

zone

Downstream

zone

Roller motor Roller motor Zone sensor Roller motor Zone sensor

Conveying direction

Roller motor Zone sensor

Release

Sensor

Zone coupling

Sensor Sensor

Release Release

ZPA motor control module

Zone coupling Zone coupling

2 zones

ZPA motor control module

1 zone

Release

Sensor

Zone Zone ZoneZone

Product Description

Zone coupling

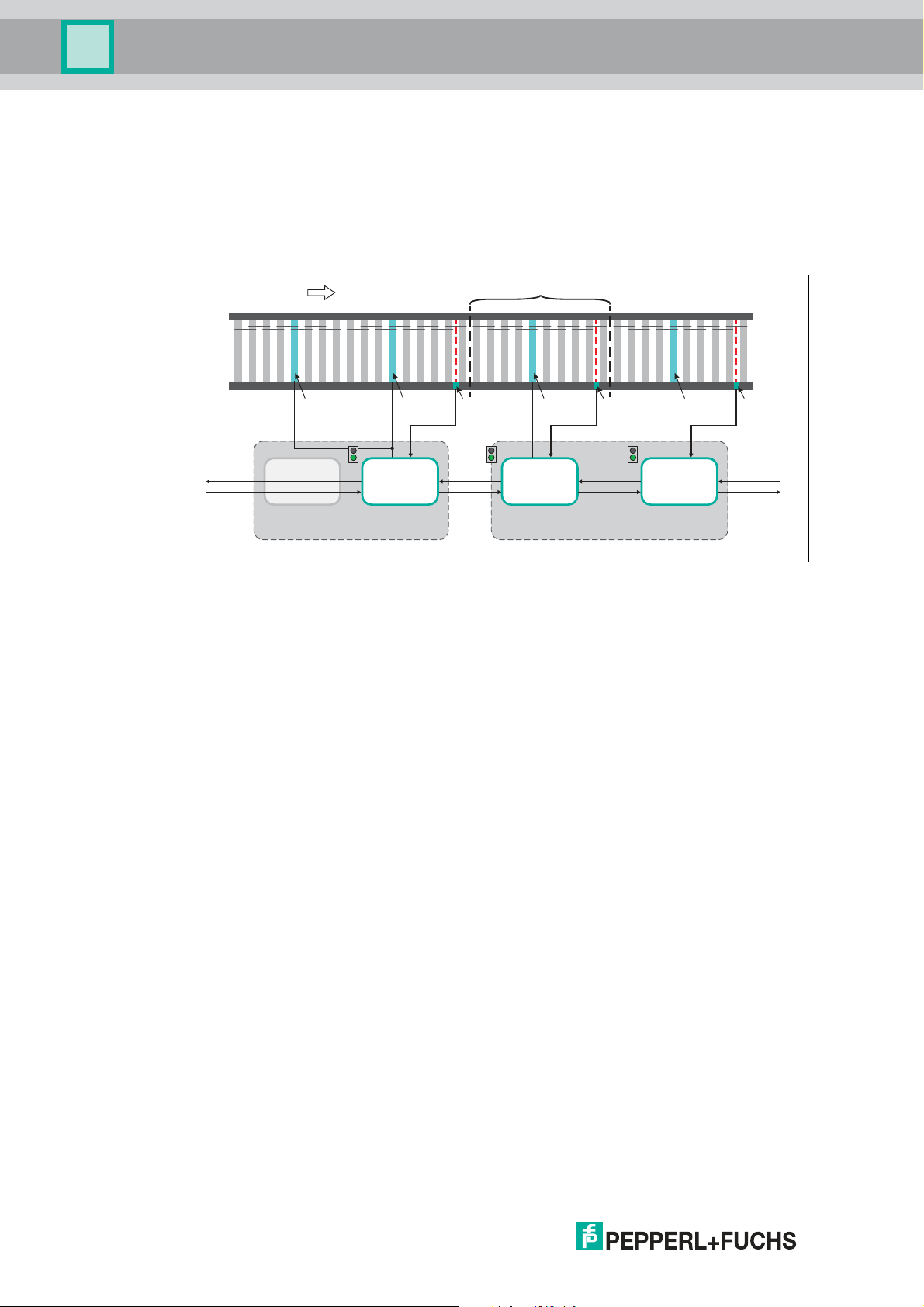

The two interfaces for zone coupling (X1, X2) are used for receiving and transmitting

information to and from neighboring zones. Additional ZPA motor control modules or other

suitable communication partners can be connected via the zone coupling. The electrical

signals are compatible with the standard 24 V IOs of a PLC. Conveyed product can therefore

also be fed in and discharged at both ends of the accumu lation conveyor line by a separate

controller.

Figure 2.4

The interfaces for the zone coupling each consist of one signal input and one signal output.

The meaning of the zone coupling signals depends on the selected conveyor direction and

follows a simple principle:

Signal in the conveyor direction (zone sensor): A zone is communicating to the

downstream zone whether conveyed product is located at its end. It therefore always

corresponds to the signal of the zone sensor (e.g., light barrier).

Signal against the conveyor direction (release signal): A zone is communicating to the

upstream zone whether conveyed product may enter. It thus represents the release signal. The

release signal is determined by the accumulation conveyor logic and also set if no conveyed

product has yet reached the zone sensor of the upstream zone.

The logic in the ZPA motor control modules expects the release signal to last until the conveyed

product has left the zone sensor. If the release signal is withdrawn before the conveyed product

has left the zone, the m otor is stopped until the release signal is set again.

This results in the following signal sequences:

The dashed lines show the situation in which the downstream zone withdraws the release

signal for a short period of time. In this case, the DC roller motor is stopped immediately without

any run-on time.

1. Conveyed product reaches the zone sensor before the release signal is set.

10

2018-06

Page 11

VAZ-2E2A-G20-ZPA1

IN (Photo eye)

X OUT

X IN (Release)

MOT

Motor after run

Conveyor good

has left zone

Release from

downstream zone

Conveyor good

is stopped

to downstream zone

from downstream zone

Motor after run

Conveyor good

has left zone

Release from

downstream zone

Conveyor good reaches zone sensor

IN (Photo eye)

X OUT

X IN (Release)

MOT

to downstream zone

from downstream zone

Product Description

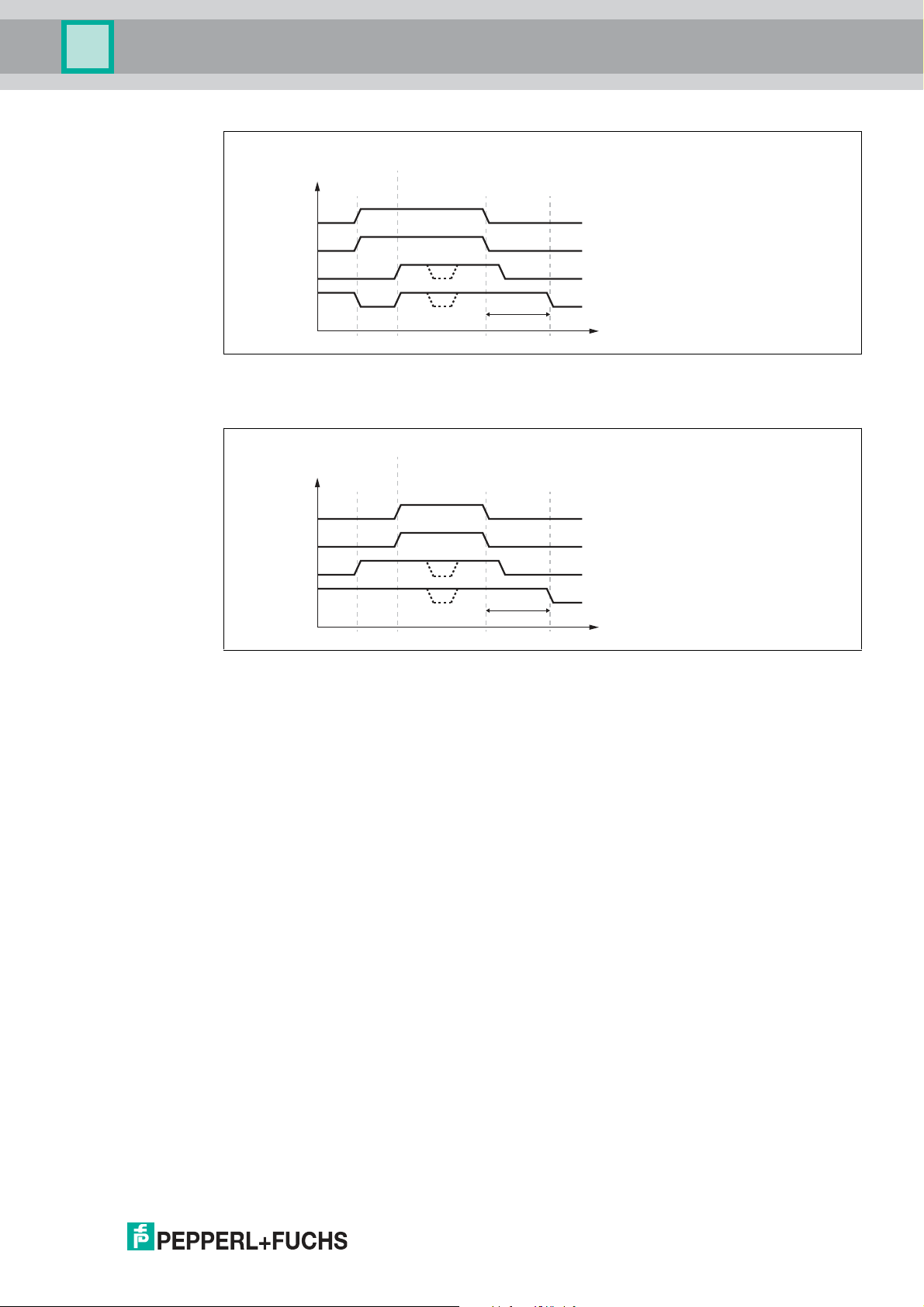

Figure 2.5

2. Release signal is set before the conveyed product reaches the zone sensor.

Figure 2.6

Since the ZPA motor control module can control two consecutive zones simultaneously, the

zone coupling of these two zones is performed internally. The zone coupling to the upstream

and downstream zones is routed via connections X1 and X2.

2.2 Operating Modes of the ZPA Motor Control Module

2.2.1 Overview

The ZPA motor control module has multiple operating modes that realize different

accumulation conveyor logics. All operate zone coupling as per the preceding description and

are therefore fully compatible with each other. The only exception to this rule are the two

operating modes "direct control" and "direction control." These operating modes do not

execute logic and a re used for direct control of the connected DC roller motors via the zone

coupling interfaces.

For the operation of only one zone, the mode for 1-zone operation must be selected in the case

of some operating modes. Different time conditions detect accumulations on the conveyor line

and shut down the DC roller motors if one or more conveyed products are stuck. All operating

modes support the handling of conveyed product that is longer than the actual zone.

2018-06

11

Page 12

VAZ-2E2A-G20-ZPA1

5 64

B

2 31

A

8 97

C

Roller motor

Zone sensor Zone sensor

Roller motor

Zone sensor Zone sensor

Roller motor

Zone sensor Zone sensor

Product Description

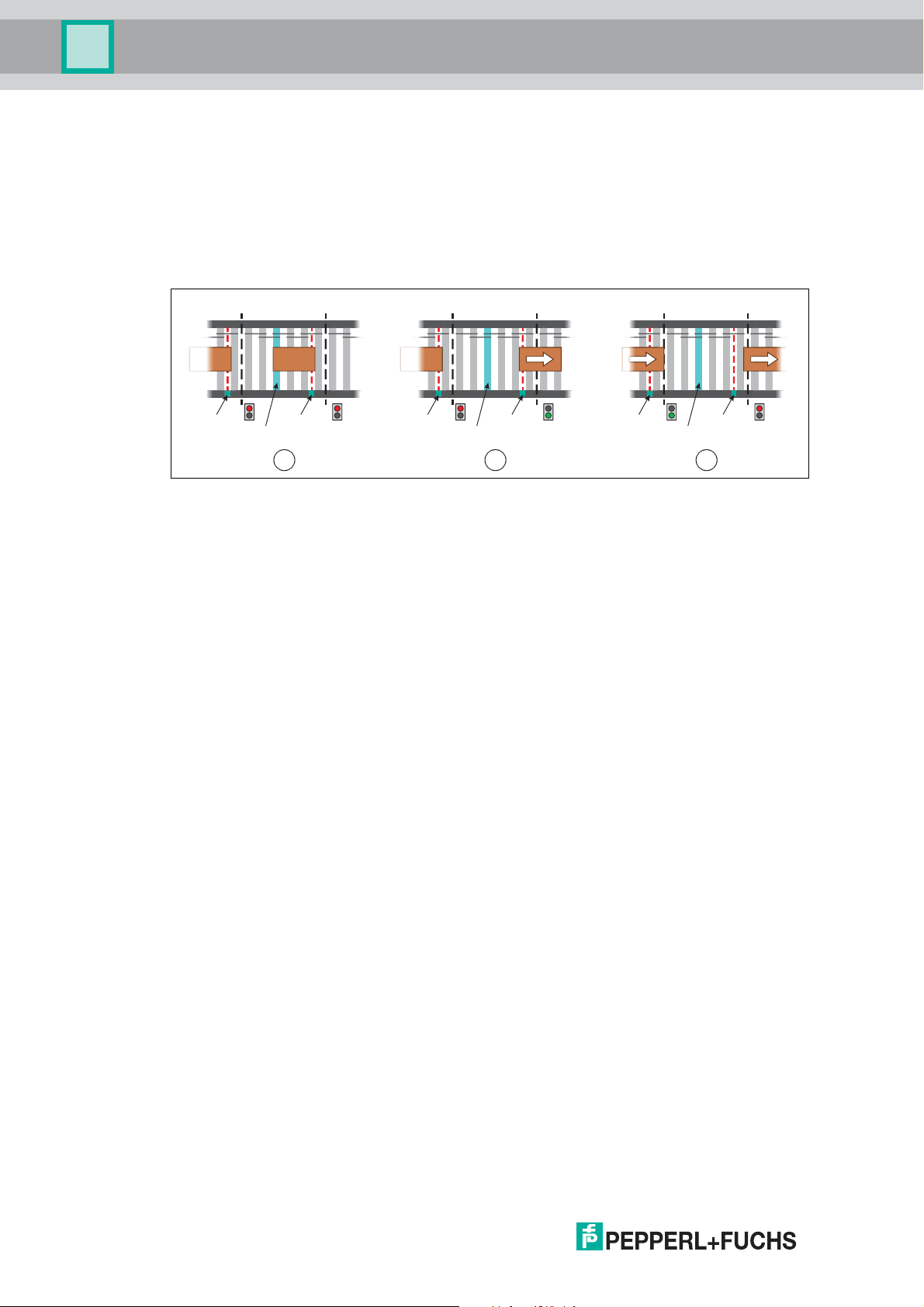

2.2.2 Standard ZPA

Conveyed product must have completely left the zone before the next conveyed product may

enter. As soon as the outgoing conveyed product is no longer detected by the zone sensor, the

release signal is set. This operating mode thereby realizes zero pressure accumulation with

single accumulation and single release. It ensures a strict separation of the conveyed product

while maintaining the maximum safety distance.

The following example describes the sequence in the operating mode "Standard ZPA":

Figure 2.7

■

Step A: Zone (2) has accumulated its conveyed product because downstream zone (3)

has not set its release signal (red light). Because zone (2) is occupied, it also does not

issue a release to upstream zone (1).

■

Step B: Downstream zone (6) has set the release signal (green light) and the conveyed

product is conveyed to the next zone (6). Because the conveyed product has not yet left

the zone sensor (5), zone (5) does not issue a release to upstream zone (4).

■

Step C: The conveyed product has left the zone sensor. Therefore, zone (8) sets the

release signal for upstream zone (7) to allow the next conveyed product to be transported.

Downstream zone (9) has now completely accepted the conveyed product and prohibits

further produ ct from entering by withdrawing the release.

The following time conditions are used in the operating mode "Standard ZPA" (see Chapter

"Operating Behavior"):

■

Leaving time

■

Entry time

■

Transportation time

■

Motor run-on time

■

Switch-on delay

■

Search time

Please note that this operating mode distinguishes between 1-zone operation and 2-zone

operation and separate settings exist for both operating modes.

12

2018-06

Page 13

VAZ-2E2A-G20-ZPA1

5 64

B

2 31

A

8 97

C

Roller motor

Zone sensor Zone sensor

Roller motor

Zone sensor Zone sensor

Roller motor

Zone sensor Zone sensor

Product Description

2.2.3 Enhanced ZPA

This operating mode implements zero pressure accumulation with block accumulation or block

release. A zone will let the following conveyed product enter once the conveyed product

located in that zone receives the release signal to leave the zone. This reduces the safety

distance between the conveyed product and increases the throughput. If the foremost zone of

such an accum ulation conveyor line receives a release signal, the signal will be forwarded

directly to the zones behind it. All accumulated conveyed product will be simultaneously

transported to the next zone. However, in case of block release, it is always ensured that only

one further conveyed product is conveyed into the zone. This conveyed product must then

advance all the way to the zone sensor before the next conveyed product may be conveyed.

The following example describes the sequence in the operating mode "Enhanced ZPA."

Figure 2.8

■

Step A: Zone (2) has accumulated its conveyed product because downstream zone (3)

has not set its release signal (red light). Because zone (2) is occupied, it also does not

issue a release to upstream zone (1).

■

Step B: Downstream zone (6) has set the release signal (green light) and the conveyed

product is conveyed to the next zone (6). At the same time, the release signal is forwarded

to upstream zone (4) and the following conveyed product is conveyed to zone (5). The

conveyed product starts up at the same time.

■

Step C: The previous conveyed product has departed zone (8), so downstream zone (9)

withdraws its release. The following conveyed product has also already left upstream

zone (7). Zone (8) moves the conveyed product to its zone sensor while it prevents other

conveyed product from entering by resetting the release.

The following time conditions are used in the operating mode "Enhanced ZPA" (see Chapter

"Operating Behavior"):

■

Leaving time

■

Entry time

■

Transportation time

■

Motor run-on time

■

Switch-on delay

■

Search time

2018-06

■

Release delay

Please note that this operating mode distinguishes between 1-zone operation and 2-zone

operation and separate settings exist for both operating modes.

13

Page 14

VAZ-2E2A-G20-ZPA1

5 64

B

2 31

A

8 97

C

Roller motorRoller motor Roller motor

Product Description

2.2.4 Transportation

In this operating mode, a zone forwards the release signal directly to the zones behind it. At the

same time, the release signal also switches on the zone motor. The release is not set

independently. Therefore, only a block release is carried out, which does not cause the

conveyed product to be separated.

Connecting a zone sensor is optional in this operating mode. If a zone sensor is connected, the

logic can detect accumulations and shut down the zone DC roller motor, if necessary. If the

downstream zone is operating in a different mode, the zone sensor must be connected so that

its status can be forwarded via the zone coupling.

The following example describes the sequence in the operating mode "Transportation":

Figure 2.9

■

Step A: Downstream zone (3) has not set its release signal (red light). Zone (2) therefore

also does not set its release signal, meaning that the DC roller motor does not rotate.

■

Step B: Downstream zone (6) has set the release signal (green light). Zone (5)

immediately forwards the release signal to its upstream zone (4) and switches on its DC

roller motor. The conveyed product starts up at the same time.

■

Step C: Downstream zone (9) has reset its release signal. Zone (8) immediately resets its

release signal and shuts down the DC roller motor.

The following time condition is used in the operating mode "Transportation" (see Chapter

"Operating Behavior"):

■

Leaving time (only if a zone sensor is connected)

This operating m ode can be used without restriction in 1-zone and 2-zone operation. For this

reason, there is no option for a separate switchover.

14

2018-06

Page 15

VAZ-2E2A-G20-ZPA1

5 64

B

2 31

A

8 97

C

Roller motor

Zone sensor Zone sensor

Roller motor

Zone sensor Zone sensor

Roller motor

Zone sensor Zone sensor

Product Description

2.2.5 Long Zone - Single Zone

This operating mode is designed specifically for the operation of a zone in a range of Standard

zones or Enhanced ZPA zones that is significantly longer than the surrounding zones. A longer

zone like this would negatively affect the throughput of the entire conveyor line because the

distance between the conveyed product is primarily determined by the zone length. This is why

conveyed product is not separated in this case, which m ight cause the distance between the

conveyed product to increase.

If there is a release signal, it is forwarded directly to the zones behind that zone and the DC

roller motor of the zone is switched on (block release). If there is no conveyed product in front of

the zone sensor, the zone will independently set the release signal to allow more conveyed

product to enter. If no conveyed product has been detected for a certain period of time, the

zone will shut down its DC roller motor. It will start its DC roller motor again if the status of the

upstream zone sensor changes and conveyed product is conveyed into the zone.

The following example describes the sequence in the operating mode "Long Zone":

Figure 2.10

■

Step A: Downstream zone (3) has set its release signal (green light). Zone (2) immediately

forwards it to its upstream zone (1) and conveys its conveyed produ ct to the next zone (3).

■

Step B: Downstream zone (6) has reset its release signal (red light). Because no product

has arrived in front of the zone sensor in zone (5) yet, it will retain its release and move the

conveyed product to its final position. The subsequent conveyed product (4) can enter

freely.

■

Step C: The conveyed product has reached the zone sensor (8). Because the

downstream zone (9) is still not issuing a release signal, zone (7) stops the conveyed

product and resets its release signal to also stop the subsequent conveyed product.

The following time conditions are used in the operating mode "Long Zone" (see Chapter

"Operating Behavior"):

■

Leaving time

■

Switch-on delay

■

Idle mode delay

This operating mode always works in 1-zone operation, meaning that the DC roller motor of the

rear zone is synchronized with that of the front zone and the rear zone sensor has no function.

2018-06

15

Page 16

VAZ-2E2A-G20-ZPA1

Product Description

2.2.6 Direct Control

In this operating mode, the DC roller motors connected to the ZPA motor control module can be

controlled using external signals. In this way, the ZPA control module can, for example, be

connected directly to a PLC that follows its own logic for controlling the DC roller motors. The

control signals are transferred via the inputs of the respective zone coupling inter faces. The

outputs of the two zone coupling interfaces indicate the status of the zone sensors.

Connection Signal Meaning

X1 IN Control signal for DC roller m otor at MOT1

X1 OUT Signal for zone sensor at IN1

X2 IN Control signal for DC roller m otor at MOT2

X2 OUT Signal of zone sensor at IN2

Table 2.1

■

Low: Motor is at a standstill

■

High: Motor is running

■

Low: No conveyed product detected

■

High: Conveyed product detected

■

Low: Motor is at a standstill

■

High: Motor is running

■

Low: No conveyed product detected

■

High: Conveyed product detected

2.2.7 Direction Control

This operating m ode supplements the "Direct Control" operating mode with the option of

reversing the direction of rotation of the connected DC roller motors via an external signal. One

input controls both DC motor rollers while the other input reverses their configured direction of

rotation.

The "Direction Control" operating m ode will be supported from firmware version V.26.

Connection Signal Meaning

X1 IN Control signal for DC roller m otors at MOT1 and MOT2

X1 OUT Signal for zone sensor at IN1

X2 IN Direction reversal for DC roller m otors at MOT1 and

X2 OUT Signal of zone sensor at IN2

Table 2.2

■

Low: Motor is at a standstill

■

High: Motor is running

■

Low: No conveyed product detected

■

High: Conveyed product detected

MOT2

■

Low: Motors rotate in the direction configured via S2

■

High: Motors rotate in the opposite direction to that

configured via S2

■

Low: No conveyed product detected

■

High: Conveyed product detected

16

2018-06

Page 17

VAZ-2E2A-G20-ZPA1

X2 X1X1

OUT

IN

OUT

IN

MOT MOT MOT1 IN1

X2

IN

OUT

IN

OUT

MOT2 IN2

MasterSlave 1 ... n

OUT

MOT

2

Roller motor Roller motor Roller motor

Master-slave zone

Conveyor direction

Release

Sensor

Zone coupling Zone coupling

Zone

Roller motor Zone sensor

Zone

Product Description

2.2.8 Slave

In this operating mode, the ZPA motor control module functions as a slave to a downstream

master zone. Both slave motors are synchronized to the master zone motors. The master zone

is extended by the slave. The signals from the rear zone coupling of the master are transmitted

by the slave through to the upstream zone. The zone sensors of the slaves have no function in

this operating mode and do not need to be connected.

As the master, all of the ZPA motor control module operating modes can be used, except for

"Direct Control" and "Direction Control." No special settings are required at the master. As soon

as the upstream ZPA motor control module has been configured as a slave, the switchover to

master operation occurs automatically.

Any number of slaves can be run on a master zone. Each slave corresponds to a ZPA motor

control module. The zone length, which is controlled by the master, is extended by the

connected slaves. The following time conditions for the master and the connected slaves are

added up. Up to four slaves can be taken into account.

1. Search time

2. Transportation time

3. Idle mode delay

2018-06

Figure 2.11

Please note that the zone couplings between master and slave work in master-slave operation.

There, there are no PLC-compatible zone coupling signals. If the zone coupling of a slave has

not been connected to a compatible master, the corresponding LED flashes "X1 IN" or "X2 IN"

and the ZPA motor control module has no function.

The "Slave" operating mode is supported from firmware version V.28 (master and slave).

17

Page 18

VAZ-2E2A-G20-ZPA1

X1 X2

IN1

MOT1

IN2

MOT2

PWR

X1 IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

Product Description

2.3 Indicators and Operating Elements

2.3.1 LED Indicators

Overview

The LEDs on the ZPA motor control module display the following information:

■

Firmware version (only immediately after switching on),

■

Setting of the rotary switch (only immediately after switching on),

■

Status of the power supply,

■

Switching states of the connected zone sensors,

■

Operating/fault state of the connected DC roller motors,

■

States of the zone coupling signals.

While the ZPA motor control module is starting up, the LEDs indicate the firmware version and

the setting of the rotary switches using flash codes (binary code; least significant byte is on the

right).

The meaning of the individual zone coupling signals depends on the conveyor direction and

how the ZPA motor control module is connected. (See Chapter "Use and Application", Section

"Zone Coupling").

Figure 2.12

LED Behavior after Switch-On

In case of an invalid configuration or an invalid operating mode, the four left LEDs X1 ...X2 OUT

will flash simultaneously.

While the ZPA motor control module is starting up, the LEDs indicate the firmware version and

the setting of the rotary switches S1 ... S3 in four steps using flash codes. The LEDs provide

the information in binary form. The least significant byte is on the right.

The two left LEDs X1 IN and X1 OUT indicate the respective step from 0 ... 3. The steps

designate the type of information.

The remaining LEDs indicate the corresponding values for the steps, such as the setting of a

rotary switch.

Each step is displayed for 1 s. After 4 s, all the steps have been displayed.

Step Information displayed

0 Firmware version

1 S1 setting: Motor speed

2 S2 setting: Start/stop ramp and direction of rotation

3 S3 setting: Operating mode

18

2018-06

Page 19

VAZ-2E2A-G20-ZPA1

Product Description

Note!

Motor Fuses Are Safety Fuses

For protection against short circuits, each DC roller motor is secured with its own safety fuse

with a 5 A rated current. The fuses are not interchangeable. If a fuse is faulty, the module must

be replaced.

LEDs for PWR, MOT1, MOT2, ERR1, ERR2, IN1, IN2

LED Color Description

PWR Green

MOT1 Yellow Operating status of DC roller motor 1:

MOT2 Yellow Operating status of DC roller motor 2:

■

On = Power supply is OK

■

Off = Power supply is not OK

■

On = Motor is active

■

Off = Motor is at a standstill or running down as per set start/stop

ramp

■

On = Motor is active

■

Off = Motor is at a standstill or running down as per set start/stop

ramp

ERR1 Yellow Fault status of DC roller motor 1:

■

On = Motor fault or no motor connected

■

Flashing = Motor fuse 1 of the motor control module is faulty

■

Off = No motor fault

ERR2 Yellow Fault status of DC roller motor 2:

■

On = Motor fault or no motor connected

■

Flashing = Motor fuse 2 of the motor control module is faulty

■

Off = No motor fault

IN1 Switch state of zone sensor 1:

■

On = Zone sensor has detected conveyed product (high level)

■

Off = Zone sensor has not detected any conveyed product (low

level)

IN2 Switch state of zone sensor 2:

■

On = Zone sensor has detected conveyed product (high level)

■

Off = Zone sensor has not detected any conveyed product (low

level)

Table 2.3

Status LEDs for zone coupling: Conveyor direction from left to right

LED Color Description

X1 IN Yellow Input from interface 1: Status of zone sensor of upstream zone

■

On = Zone sensor has detected conveyed product (high level)

■

Off = Zone sensor has not detected any conveyed product (low

level)

X1 OUT Yellow Output from interface 1: Release signal for upstream zone

■

On = Release signal for upstream zone has been set (high level)

■

Off = Release signal for upstream zone has not been set (low

level)

2018-06

19

Page 20

VAZ-2E2A-G20-ZPA1

Product Description

LED Color Description

X2 IN Yellow Input from interface 2: Release signal from downstream zone

X2 OUT Yellow Output from interface 2: Status of zone sensor at IN2

Table 2.4

Status LEDs for zone coupling: Conveyor direction from right to left

LED Color Description

X1 IN Yellow Input from interface 1: Release signal from downstream zone

■

On = Release signal from downstream zone has been set (high

level)

■

Off = Release signal from downstream zone has not been set (low

level)

■

On = Zone sensor has detected conveyed product (high level)

■

Off = Zone sensor has not detected any conveyed product (low

level)

■

On = Release signal from downstream zone has been set (high

level)

■

Off = Release signal from downstream zone has not been set (low

level)

X1 OUT Yellow Output from interface 1: Status of zone sensor at IN1

■

On = Zone sensor has detected conveyed product (high level)

■

Off = Zone sensor has not detected any conveyed product (low

level)

X2 IN Yellow Input from interface 2: Status of zone sensor of upstream zone

■

On = Zone sensor has detected conveyed product (high level)

■

Off = Zone sensor has not detected any conveyed product (low

level)

X2 OUT Yellow Output from interface 2: Release signal for upstream zone

■

On = Release signal for upstream zone has been set (high level)

■

Off = Release signal for upstream zone has not been set (low

level)

Table 2.5

20

2018-06

Page 21

VAZ-2E2A-G20-ZPA1

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

S3 S2 S1

Product Description

2.3.2 Rotary Switches for Configuration

On the back of the device, there are three rotary switches for configuring

■

Motor speed via S1

■

Start/stop ramp and direction of rotation via S2

■

Operating mode via S3

Figure 2.13

Note!

Configuration Requires the Power Supply to Be Switched Off/On

The settings of the rotary switches are applied when the ZPA motor control module is switched

on. When a change is m ade to the configuration, you will need to shut down the power supply

to the ZPA motor control module and then switch it on again.

S1: Motor speed

Switch setting

Speed signal U

s

0 3.96 V

1 4.78 V

2 5.61 V

3 6.44 V

4 8.50 V

5 9.63 V

6 10.00 V

7 7.26 V

8 Reserved

9 Reserved

Table 2.6

S2: Start/stop ramp and direction of rotation

You can use rotary switch S2 to set the direction of rotation of the connected DC roller motors

(conveyor direction) and configure a start/stop ramp for the acceleration at the same time.

Five start/stop ramps can be configured for each direction of rotation. The slope of the

acceleration is constant and independent of the set maximum speed.

The ramp duration defines the time from stationary to maximum speed (US = 10 V), or from

maximum speed to stationary. When the set motor speed is lower, the ram p duration is shorter

as well.

The following diagram shows the start behavior of the start/stop ramp using the example of the

setting "1000 ms."

2018-06

21

Page 22

VAZ-2E2A-G20-ZPA1

100

75

50

25

200 400 600 800 1000

Speed [%]

Time [ms]

Speed 100%

Speed 60%

acceleration

time setting

Product Description

Figure 2.14

The direction of rotation setting defines not only the direction of rotation of the connected DC

roller motors but also which of the two zones is the "downstream zone" and which is the

"upstream zone." In this way, the conveyor direction is also defined.

For clockwise direction of rotation, the left zone (IN1, MOT1) is the "upstream zone."

For counterclockwise direction of rotation, the right zone (IN2, MOT2) is the "upstream zone."

■

Switch position 0 ... 5: Clockwise direction of rotation (conveyor direction from left to right),

UD = High

22

■

Switch position 6 ... 9: Counterclockwise direction of rotation (conveyor direction from

right to left), UD = Low

Switch setting Ramp duration Direction of rotation

0 0 ms clockwise

1 500 ms clockwise

2 1000 ms clockwise

3 1500 ms clockwise

4 3000 ms clockwise

5 0 ms counterclockwise

6 500 ms counterclockwise

7 1000 ms counterclockwise

8 1500 ms counterclockwise

9 3000 ms counterclockwise

S3: Operating mode

Depending on the application, you can select one of eight different operating modes for 1-zone

control or 2-zone control. For 1-zone control (Single Zone), the inactive zone synchronizes its

motor output with the active zone.

Switch setting Operation Mode 1-/2-zone operation

0 Standard ZPA 2-zone operation

1 Enhanced ZPA 2-zone operation

2 Standard ZPA—Single

Zone

3 Enhanced ZPA—Single

Zone

4 Transportation 1-zone operation and 2-zone operation

5 Long Zone—Single Zone 1-zone operation

6 Direct Control 1-zone operation and 2-zone operation

7 Direction Control 1-zone operation

1-zone operation

1-zone operation

2018-06

Page 23

VAZ-2E2A-G20-ZPA1

BLACK

PWR

+

-

3 1

4 2

3 1

4 2

5

Product Description

Switch setting Operation Mode 1-/2-zone operation

8 Slave 1-zone operation

9 Reserved -

Table 2.7

2.4 Interfaces and Connections

Connections: Inputs/Outputs

The sensors and motors are connected to the ZPA motor control module via cables with round

M8 connectors:

■

Sensors: socket, 4-pin

■

Motors: socket, 5-pin

The signals for zone coupling are connected to the ZPA motor control module via cables with

round M12 connectors.

The exact meaning of the inputs and outputs of the signals for zone coupling depends on the

connection of the ZPA motor control m odule (see Chapter "Use and Application," Section

"Zone Coupling").

Power Supply

The power supply of the ZPA motor control module is provided using piercing technology with

an AS-Interface flat cable via the PWR contacts of the ZPA motor control module.

Connector Assignment

Connection Connector Connector type/assignment

PWR Power supply: black AS-Interface flat cable

(2 x 1.5 m m2)

Two pins for piercing technology

-: Negative power supply pole

+: Positive power supply pole

IN1, IN2: sensor Input: LF004-GS1-A in accordance with

MOT1, MOT2: motor Motor: NF005-SS1-B in accordance with

IEC/EN 61076-2-104

M8, 4-pin, socket, cap nut, coding A

Matching female connector: LM004-Gx1-A

or similar

1: IN+ sensor supply

2: Not used

3: IN- sensor supply GND

4: IN sensor signal

IEC/EN 61076-2-104

M8, 5-pin, socket, snap-locking, coding B

Matching female connector: NM005-Sx1-B

or similar

1: MOT+ motor supply

2: DIR direction of rotation

3: MOT- motor supply GND

4: ERROR input for motor fault

5: SPEED speed signal (default value)

2018-06

23

Page 24

VAZ-2E2A-G20-ZPA1

1

5

3

2

4

1

3

4

2

Product Description

Connection Connector Connector type/assignment

X1: Zone coupling,

interface 1

X1 Zone coupling M12 round plug connector

in accordance with IEC/EN 61076-1-101

M12, 4-pin, socket, screw-locking, coding A

1: X1 IN input signal

2: X1 IN- input GND

3: X1 OUT output signal

4: X1 OUT- output GND

5: Not assigned

X2: Zone coupling,

interface 2

X2 Zone coupling M12 round plug connector

in accordance with IEC/EN 61076-1-101

M12, 4-pin, plug, screw-locking, coding A

1: X2 OUT output signal

2: X2 OUT- output GND

3: X2 IN output signal

4: X2 IN- input GND

24

2018-06

Page 25

VAZ-2E2A-G20-ZPA1

X1 X2

IN1

MOT1

IN2

MOT2

PWR

X1 IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

S3 S2 S1

Installation

3 Installation

3.1 Safety Information

Caution!

Risk of short circuit

Carrying out work while the system is energized may result in damage to the device.

■

Always disconnect the supply voltage before carrying out work on the device.

■

Only connect the device to the supply voltage once all work has been completed.

3.2 Preparation

Unpacking the unit

1. Check that all package contents are present and undamaged.

If anything is damaged, inform the shipper and contact the supplier.

2. Check that all items are present and correct based on your order and the shipping

documents.

If you have any questions, please contact Pepperl+Fuchs.

3. Keep the original packing material in case you need to store or ship the unit at a later time.

3.3 Mounting

Note!

Note the Mounting Direction of the ZPA Motor Control Module

The ZPA motor control module is designed to be mounted between two conveyor zones. The

mounting direction is such that the LEDs always point downward and the hinged cable guide

upward. This ensures the correct assignment of the connected zones (right zone -> right-side

connection, left zone -> left-side connection).

Figure 3.1

Set the rotary switches S1...S3 as per their desired application. (see Chapter "Product

Description", Subsection "Indicators and Operating Elements").

24

2018-06

Page 26

VAZ-2E2A-G20-ZPA1

Installation

3.4 Power Supply Connection

The power supply is connected to the ZPA motor control module via a black AS-Interface flat

cable. The permissible supply voltage is 18 V ... 30 V.

The electric connection between the ZPA motor control module and flat cables is established

via two metal pins using piercing technology. The flat cable is routed through a hinged cable

guide. When closed, the cable guide is locked using a locking bracket and can be opened

again without the need for tools.

The profiled flat cable has a narrow upper side (with a visibly offset profile edge) and a wide

under side (profile edge not visible). The cable guide allows the flat cable to be inserted on

both sides, for flexible connection of flat cables already laid in cable ducts. However, you must

make sure that the profile edge always points to the motor control module. Mechanical reverse

polarity protection prevents complete closure of the cable guide if the flat cable is inserted

incorrectly.

Caution!

If a flat cable is inserted incorrectly, the ZPA motor control module will not work.

If the flat cable is inserted in the cable guide in the wrong direction, the voltage is inverted. The

ZPA motor control module will not work. However, internal electrical reverse polarity protection

protects it against breakage.

Connecting Flat Cables on the Narrow Side

The profile edge is visible from above.

1. O pen the cable guide. To do this, push the locking bra cket (1) slightly to one side.

2. Insert the black flat cable with the profile edge (2) to the ZPA motor control module into the

upper duct (see module tag "PWR").

3. Make sure that the profile edge of the flat cable is under the respective reverse polarity

protection (3).

4. C lose the cable guide. It must engage securely in the locking bracket (1).

The metal pins contact the cores of the flat cable.

2018-06

25

Page 27

VAZ-2E2A-G20-ZPA1

PWR

1

2

3

Installation

Figure 3.2 Connecting flat cables on the narrow side

Connecting Flat Cables on the Wide Side

The profile edge is not visible from above. For orientation purposes in the figure below, the

edge is shown as a hidden edge drawn with a dotted line.

1. Open the cable guide. To do this, push the locking bracket (1) slightly to one side.

2. Insert the black flat cable with the profile edge (2) to the ZPA motor control module into the

upper duct (see module tag "PWR").

The profile edge (2) of the flat cable is above the reverse polarity protection.

3. Close the cable guide. It must engage securely in the locking bracket (1).

The metal pins contact the cores of the flat cable.

26

2018-06

Page 28

VAZ-2E2A-G20-ZPA1

PWR

1

2

Installation

Figure 3.3 Connecting flat cables on the wide side (profile edge as dotted lin e)

Flat Cable Inserted Incorrectly

The figure below shows an incorrectly inserted flat cable. The profile edge (2) does not point to

the motor control module; the flat cable is therefore inserted with reverse polarity. The flat cable

is located on the reverse polarity protection (1) with a curvature, which means that the cable

guide cannot be closed completely (mechanical reverse polarity protection).

2018-06

27

Page 29

VAZ-2E2A-G20-ZPA1

1

2

X1 X2

IN1

MOT1

IN2

MOT2

PWR

X1 IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

Installation

Figure 3.4 Flat cable inserted incorrectly (profile edge as dotted lin e)

3.5 Special Requirements when Connecting to a PLC

The electrical signals from the zone coupling interfaces are compatible with the standard 24 V

IOs of a P LC.

■

The inputs (X1 IN, X2 IN) are galvanically isolated. Therefore, there are no special

requirements for the connection of other potentials.

■

The outputs (X1 OUT, X2 OUT) are powered directly by the power supply of the ZPA

motor control module. Therefore, there is a risk of ground loops when connecting to other

potentials

Caution!

Malfunctions with ground loops

Because the outputs of the ZPA motor control module are not galvanically isolated,

equalization currents could flow through their ground lines. Therefore, connect the zone

coupling outputs (X1 OUT, X2 OUT) only to galvanically isolated, current-consuming inputs of a

PLC input/output card.

A common ground of the PLC input/output card may be connected to other ZPA motor control

modules, but not to their power supply.

If the specified rules are not followed, malfunctions may occur in the interconnected

components.

3.6 Connecting Motors, Sensors, and Zone Coupling

Figure 3.5

28

2018-06

Page 30

VAZ-2E2A-G20-ZPA1

(n.c.)

PWR +

IN1 & IN2

MOT1 & MOT2

3 1

4 2

M

3 1

4 2

5

ERR1,2

PWR

PWR -

IN1,2

1

4

3

2

1

2

4

5

3

MOT1,2

IN +

IN

IN -

MOT +

DIR

ERROR

SPEED

MOT -

X1OUT

X1IN

1

2

3

4

X1IN

X1IN X1OUT

X1OUT -

3

4

1

2

X2IN

X2IN X2OUT

X2OUT -

ZPA1

PLC

ZPA1

PLC

3

1

4 2

3

1

2 4

X2OUT

X2IN

X1

X2

Installation

Note!

The connection of DC roller motors and zone sensors to the ZPA motor control module

depends on the circumstances of the zones to be controlled. There are a variety of connection

scenarios depending on whether you want to control one or two zones or when changing the

mounting side on the conveyor line. These scenarios are described in the following sections.

Figure 3.6 Connection wiring diag ram for motors, sensors, and zone coupling

Note!

Note the Mounting Direction of the ZPA Motor Control Module

The ZPA motor control module is designed to be mounted between two conveyor zones. The

mounting direction is such that the LEDs always point downward and the hinged cable guide

upward. This ensures the correct assignment of the connected zones (right zone -> right-side

connection, left zone -> left-side connection). The mounting side on the conveyor line may

need to be changed due to curves or structural restrictions. In this case, special adapter cables

are required that cross the signal lines. (See Accessories section of datasheet). When

changing the m ounting side, the direction of rotation at S2 m ust also be changed.

Standard Connection of the ZPA Motor Control Module (2-Zone

Operation)

The ZPA motor control module is designed to control two consecutive zones.

The ZPA motor control module is mounted between the two zones. The connection lines of the

DC roller motors and zone sensors are connected to the respective side of the ZPA motor

control module near the zone.

The zone coupling signals are connected to the ZPA motor control modules or other

communication partners of the zone upstream and downstream of the two control zones (Zone

1, Zone 2).

2018-06

29

Page 31

VAZ-2E2A-G20-ZPA1

Switch S2 = 0..4 (CW)

Zone 1 Zone 2Upstream zone

Downstream zone

X2

MOT1 MOT2

IN1

IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

Switch S2 = 5..9 (CCW)

Zone 1 Zone 2 Upstream zoneDownstream zone

X2

MOT1 MOT2

IN1

IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

Installation

Conveyor Direction from Left to Right (Clockwise Rotation)

Interface zone coupling Description Behavior

X1 IN Output signal from the zone

X2 OUT Output signal of the zone

X1 OUT Release signal for upstream

X2 IN Release signal from

sensor of the upstream zone

sensor at IN2

zone

downstream zone

■

Low level: No conveyed

product detected

■

High level: Conveyed

product detected

■

Low level: No release

■

High level: Release

Figure 3.7 Conveying direction from left to right (clockwise)

Conveyor Direction from Right to Left (Counterclockwise Rotation)

Interface zone coupling I/O Description Behavior

X2 IN Zone sensor of upstream zone

X1 OUT Output signal of the zone

sensor at IN1

■

Low level: No conveyed

product detected

■

High level: Conveyed

product detected

X1 IN Release signal from

downstream zone

■

Low level: No release

■

High level: Release

X2 OUT Release signal for upstream

zone

30

Figure 3.8 Conveying direction from right to left (counterclockwise)

2018-06

Page 32

VAZ-2E2A-G20-ZPA1

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

Switch S2 = 0..4 (CW)

ZoneUpstream zone Downstream zone

Single-zone operation

Dual-zone operation

Single-zone operation

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

Installation

Connect the connection lines of the motors, zone sensors, and the zone coupling signals

according to the connection wiring diagram and the conveyor direction.

Caution!

Malfunctions due to incorrect assignment of connections

When connecting the ZPA motor control module, you should never form connection loops as

shown in the following figure. The incorrect assignment of connections will create false logical

connections between the zones. This can lead to malfunctions of the ZPA motor control

module.

Figure 3.9 Incorrect connection

Standard Connection of the ZPA Motor Control Module (1-Zone

Operation)

In 1-zone operation, the ZPA motor control module controls only one zone. Its zone sensor is

always connected to the input "IN..." at the front in the conveyor direction. Both motor

connections are switched synchronously in 1-zone operation. The second motor connection

can be connected to another motor that drives the same zone and thus doubles the drive

power of this zone.

Figure 3.10 Conveying direction from left to right (clockwise)

2018-06

31

Page 33

VAZ-2E2A-G20-ZPA1

Switch S2 = 5..9 (CCW)

Zone

Upstream

zone

Downstream

zone

Dual-zone operation

Single-zone operation

Single-zone operation

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

IN

IN-

OUT

OUT-

IN

IN-

OUT

OUT-

X1 X1

1

2

3

4

1

2

3

4

IN

IN-

OUT

OUT-

IN

IN-

OUT

OUT-

1

2

3

4

1

2

3

4

X2 X2

Installation

Figure 3.11 Conveying direction from right to left (counterclockwise)

Connect the connection lines of the motors, zone sensors, and the zone coupling signals

according to the connection wiring diagram and the conveyor direction.

Connecting the ZPA Motor Control Module when Changing the Mounting

Side on the Conveyor Line

Note!

The mounting side on the conveyor line may need to be changed due to curves or structural

restrictions. The mounting direction of the ZPA motor control modules remains the same even

when changing sides. At the zone coupling, two identical interfaces X1 and X2 meet. To

connect them, you will need a crossover adapter cable. These adapter cables are available as

accessories. For more details, please refer to the "Accessories" section in the datasheet.

Figure 3.12 Crossover adapter cables

X1 Adapter cable M12 plug to M12 plug

X2 Adapter cable M12 socket to M12 socket

32

2018-06

Page 34

VAZ-2E2A-G20-ZPA1

Female to female

crossover cable

Rotary switch S2 = 0..4 (CW)

Rotary switch S2 = 5..9 (CCW)

Zone 1

Upstream zone

Downstream

zone

Zone 2

X2

MOT1 MOT2

IN1 IN2

X1

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT2

IN2

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN2

MOT2

X2

PWR

X1IN

X1 OUT

X2 IN

X2 OUT

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN1

MOT1

IN2

MOT2

X1 X2

X2

MOT1MOT2

IN1IN2

X1

MOT1

MOT2

ERR1

ERR2

IN1

IN2

IN2

MOT2

X2

MOT2

IN2

X2

Installation

Figure 3.13 Conveyor direction from left to right (clockwise)

Connect the connection lines of the motors, zone sensors, and the zone coupling signals

according to the connection wiring diagram.

2018-06

33

Page 35

VAZ-2E2A-G20-ZPA1

Operating Behavior

4 Operating Behavior

4.1 Switch-On Behavior

In the operating modes "Standard ZPA," "Enhanced ZPA," and "Long Zone," the ZPA motor

control module waits for the duration of the switch-on delay after the power supply is switched

on before it is ready for operation. The only exception is the output of the status of the zone

sensor at the relevant interface for zone coupling (X1 or X2). This signal is present 1 s after

switch-on.

After the switch-on delay, the ZPA motor control modules of the individual zones start searching

for conveyed product that might be lying undetected between the zone sensors. The search

ends as soon as conveyed product is detected at the zone sensor or once the search time has

passed. The switch-on delay randomly delays the start of the search for a ZPA motor control

module. This is done to prevent current peaks caused by the simultaneous activation of the DC

roller motors at all ZPA motor control modules whose zone sensor did not detect any conveyed

product.

While the ZPA motor control module is starting up, the LEDs indicate the firmware version and

the setting of the rotary switches using flash codes. Details can be found in the Chapter

"Indicators and Operating Elements."

4.2 Switch-On Delay

The switch-on delay is the time that a zone waits after startup before resuming normal

operation. The time is randomly selected in the range 2 ... 5 s by the ZPA motor control module.

4.3 Search Time

Search time = 4 s

If there is no conveyed product in front of the zone sensor after startup or if conveyed product

was unexpectedly removed from the zone sensor during normal operation, the search time will

begin.

During this time, the zone will search for conveyed product that might lie undetected between

its sensor and the upstream zone sensor. For this purpose, it switches the motor on and waits

for conveyed product to reach the zone sensor. Once the search time has passed, the zone will

assum e that it is empty and continue with norm al operation.

In the operating mode "Standard ZPA," the release signal is set during the search time only if

conveyed product is located in front of the zone sensor of the upstream zone. Becau se the

zone is not able to detect whether the conveyed product is still completely in the upstream zone

or partially extends into the zone itself, it sets the release.

In the operating m ode "Enhanced ZPA," the release signal is always set during the search time

to ensure a rapid startup of the conveyor line. If conveyed product is detected at the zone

sensor during the search time, the zone will continue normal operation. After the conveyed

product has been conveyed out, the zone begins to search again to make su re that no

conveyed product remains undetected between the zone sensors.

4.4 Leaving time

Leaving time = 8 s

The leaving time is the time it takes for conveyed product located in front of the zone sensor to

move away from this sensor after the motor has been switched on.

If the conveyed product requires longer than the leaving time, the zone will assume that there is

an accum ulation. It shuts down its motor and resets the release signal. The zone will resume

normal operation once the blocked conveyed product is m anually removed from the zone

sensor. Immediately after that, the search time begins again.

34

2018-06

Page 36

VAZ-2E2A-G20-ZPA1

Operating Behavior

4.5 Entry Time

Entry time = 8 s

The entry time is the time required by conveyed product to leave the upstream zone and

therefore its zone sensor after the release signal is set.

If the conveyed product requires longer than the entry time, the zone will shut down its motor

and wait for the conveyed product to disappear from the upstream zone or appear in front of its

zone sensor.

4.6 Transportation Time

Transportation time = 8 s

The transportation time is the time it takes for conveyed product to reach the next zone sensor

after leaving the upstream zone sensor.

If the conveyed product takes longer than the transportation time for this step, the zone will

assum e that it is empty and continue with normal operation.

4.7 Motor Run-On Time

Motor run-on time = 2 s

Once conveyed product has left the zone sensor of a zone, the motor run-on time begins. It

ensures that the motor will continue to run so that the conveyed product can completely leave

the zone. Furthermore, it reduces the constant switching on and off of the motors if conveyed

products are following each other closely. Subsequent conveyed product can be received

during that time without shutting down the motor.

4.8 Release Delay

Release delay = 0.1 s

In the operating mode "Enhanced ZPA," the direct forwarding of release signals is delayed by

this period of time if conveyed product has been stopped before the zone sensor and

subsequent conveyed product has not yet partially entered the zone.

The release delay is used to avoid power spikes that would result from the simultaneous startup

of accumulated conveyed product.

4.9 Idle Mode Delay

Idle m ode delay = 10 s

The idle m ode delay is the time that a zone will wait on incoming conveyed product in the

operating mode "long zone" with the motor running. After this time, the motors will shut down

but the release signal remains set. The time will begin again if the status of the upstream zone

sensor changes.

2018-06

35

Page 37

VAZ-2E2A-G20-ZPA1

IN

IN-

OUT

OUT-

X1 X2

1

2

3

4

1

2

34IN

IN-

OUT

OUT-

1

2

3

4

1

2

3

4

Manual Intervention in the Conveying Process

5 Manual Intervention in the Conveying Process

5.1 Manual Feeding of Conveyed Product

It is always possible to manually feed conveyed product. When doing so, it is assumed that the

conveyed product is placed in front of a zone sensor.

5.2 Manual Removal of Conveyed Product

It is possible to manually remove conveyed product from the accum ulation conveyor line at any

time.

The zone logic distinguishes between the following cases:

Manual Removal with DC Roller Motor Running

During the removal of conveyed product, the zone whose sensor the product would have

reached next waits for the duration of the transportation time (see Chapter "Operating

Behavior") for the conveyed product to arrive. After this time, the zone will assume that it is

empty and continue with normal operation.

Manual Removal with DC Roller Motor Not Running

The conveyed product is located in front of a zone sensor. The zone detects the manual

removal at the zone sensor. The zone switches on its DC roller motor and starts searching for

conveyed product to ensure that the product was not simply pushed back and is now located

undetected between the zone sensors.

After the search time (see Chapter "Operating Behavior") has passed, the zone will return to

normal operation.

5.3 Manual Stop/Release

The zone coupling between the individual ZPA motor control modules can easily be used to

stop and resume conveyance. For this purpose, a suitable two-pin switch is inserted into the

zone coupling between two ZPA motor control modules, which separates the two input lines

and output lines from each other. An open switch ensures that the two zones connected via the

zone coupling can no longer receive control signals from each other and therefore can no

longer exchange conveyed product.

Manual Stop

As soon as the switch is opened, the release signal no longer reaches the upstream zone,

meaning that this upstream zone does not allow any more conveyed product to be conveyed to

the next zone. Furthermore, the sensor signal no longer reaches the downstream zone, which

in turn no longer attempts to receive the conveyed product.

Figure 5.1

36

2018-06

Page 38

VAZ-2E2A-G20-ZPA1

IN

IN-

OUT

OUT-

X1 X2

1

2

3

4

1

2

34IN

IN-

OUT

OUT-

1

2

3

4

1

2

3

4

Manual Intervention in the Conveying Process

Manual Release

When the switch is closed, the release signal of the downstream zone reaches the upstream

zone once again (as long as activated by the downstream zone). The upstream zone can pass

on any conveyed product present to the downstream zone. At the same time, the sensor signal

also reaches the downstream zone, so that it receives information about the incoming

conveyed product and activates its DC roller motor accordingly.

Figure 5.2

5.4 Manually Correcting Accumulations

When the conveyor line is in operation, one or more conveyed products may become blocked,

resulting in an undesired accumulation.

If conveyed product takes too long to leave the zone sensor (see leaving time/entry time), the

zone logic detects an accumulation and automatically shuts down the DC roller motor. To

resume normal operation, the cause of the accumulation must be eliminated and the blocked

conveyed product in front of the zone sensor must be removed. Ideally, simply slide the

conveyed product away from the detection range of the sensor in the conveyor direction.

The zone logic will detect that the accum ulation has been resolved and will continue with

normal operation.

2018-06

37

Page 39

VAZ-2E2A-G20-ZPA1

Troubleshooting

6 Troubleshooting

6.1 What to Do in the Event of a Fault

In case of a fault, use the checklist to determine whether a fault with the ZPA motor control

module can be remedied.

If none of the information specified in the checklist solves the problem, in the event of queries

contact Pepperl+Fuchs via your sales office. Have the type designation and firmware version of

the product ready.

In the following checklist, "x" represents the channel for the LED descriptions and can be either

"1" or "2".

Checklist

Fault Possible cause Remedy

No LED is lit. The power supply is not

connected or is connected

with reverse polarity.

ZPA motor control module is

not working, the four yellow

LEDs (X1 IN ... X2 OUT) are

flashing.

DC roller motor is not running,

even though the relevant LED

"MOTx" is lit and the

associated LED "ERRx" is not

lit.

DC roller motor is not running,

even though the relevant LED

"MOTx" is lit. The associated

LED "ERRx" lights up

permanently.

DC roller motor is not running,

even though the relevant LED

"MOTx" is lit. The associated

LED "ERRx" is flashing.

The conveyed product is not

detected in a zone. The

relevant LED "INx" of the zone

is not lit.

The conveyed product does

not exit the zone. The zone is

not receiving a release signal

from the downstream zone.

The associated LED "X1

IN"/"X2 IN" is not lit.

An invalid (reserved)

operating mode has been

selected.

An invalid speed setting has

been selected.

The DC roller motor reports a

fault, for example due to

blocking or the DC roller motor

is not connected correctly.

The internal safety fuse of the

module for the DC roller motor

is faulty, for example due to