Page 1

FACTORY AUTOMATION

ManualManual

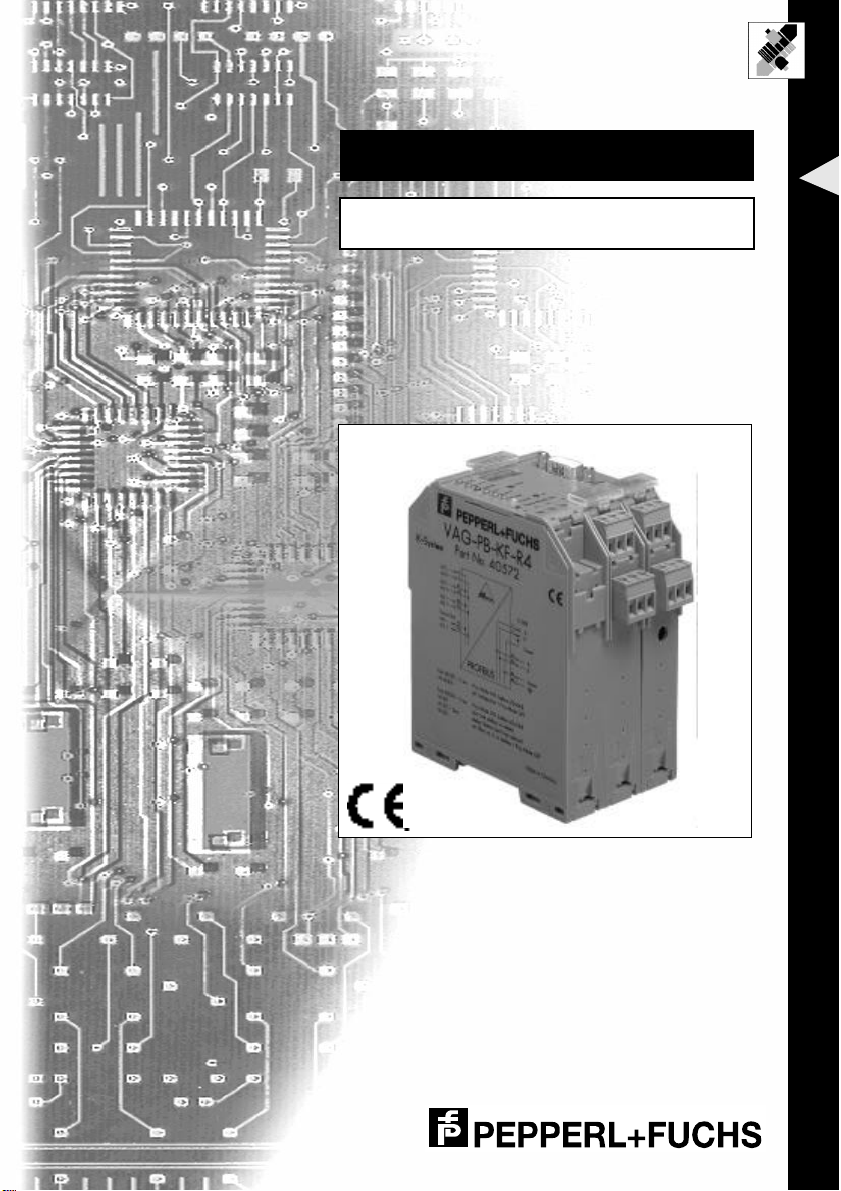

VAG-PB-KF-R4

AS-Interface/PROFIBUS Gateway AS-Interface/PROFIBUS Gateway

IP20IP20

Page 2

With regard to the supply of products, the current issue of the following document is applicable:

The General Terms of Delivery for Products and Services of the Electrical Industry, as published by

the Central Association of the 'Elektrotechnik und Elektroindustrie (ZVEI) e.V.',

including the supplementary clause "Extended reservation of title"

We at Pepperl+Fuchs recognise a duty to make a contribution to the future.

For this reason, this printed matter is produced on paper bleached without the use of chlorine.

Page 3

AS-i/PROFIBUS Gateway

Table of Contents

Table of Contents

1 Declaration of Conformity .......................................................................5

2 The Used Symbols ...................................................................................7

3 Safety ........................................................................................................9

3.1 Intended Use ........................................................................................................... 9

3.2 General Safety Information .................................................................................... 9

4 General Information ...............................................................................11

5 Connections, Displays and Controls ...................................................13

5.1 Device Schematics .............................................................................................. 13

5.2 Displays and Controls .......................................................................................... 14

5.3 Mounting and Connections ................................................................................. 15

5.3.1 Mounting ................................................................................................................. 15

5.3.2 Connection via the Power Rail ................................................................................ 15

5.3.3 Device Terminal Connections ................................................................................. 16

5.3.4 Gateway Power Supply .......................................................................................... 16

5.4 The PROFIBUS Interface ...................................................................................... 16

6 Operating the AS-i/PROFIBUS Gateway ..............................................19

6.1 Master Start-Up ..................................................................................................... 19

6.2 Configuration Mode .............................................................................................. 19

6.3 Protected Operating Mode ................................................................................... 20

6.3.1 Switching to Protected Operating Mode ................................................................. 20

6.3.2 Configuration Errors in Protected Operating Mode ................................................. 20

6.4 Assigning an AS-i Address in Configuration Mode .......................................... 21

6.4.1 Assigning a Slave Address ..................................................................................... 21

6.4.2 Erasing the Slave Address ..................................................................................... 21

6.5 Programming the Address in Case of Configuration Errors ............................ 22

6.5.1 Automatic Address Assignment .............................................................................. 22

6.5.2 Manual Address Assignment .................................................................................. 22

6.6 Setting of the Profibus Station Address and the Protocol Type ...................... 23

6.6.1 Profibus Station Address ........................................................................................ 23

6.7 Error Messages ..................................................................................................... 23

7 Advanced Diagnostics for AS-i Masters ..............................................25

7.1 List of Corrupted AS-i Slaves (LCS) ................................................................... 25

7.2 Error Counter: Counter of corrupted data telegrams ........................................ 25

7.3 Off-line Phase on Configuration Errors .............................................................. 25

8 Profibus-DP ............................................................................................27

8.1 Easy Mode ............................................................................................................. 28

8.1.1 Mapping of the AS-i data in the Profibus-DP-Telegram ..........................................28

8.1.2 Configuration of the AS-i Network .......................................................................... 28

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

3

Page 4

AS-Interface

Table of Contents

8.1.3 Projecting of the Profibus-DP Master ......................................................................28

8.1.4 Parameterization of the Profibus-DP Slave ............................................................28

8.1.5 Configuration of the Profibus-DP Slave ..................................................................29

8.2 Advanced Mode ....................................................................................................29

8.2.1 Mapping of the AS-i Data in the Profibus-DP Telegram .........................................30

8.2.2 Configuration of the AS-i Network ...........................................................................31

8.2.3 Configuration of the Profibus-DP Master ................................................................31

8.3 Professional Mode ................................................................................................34

8.3.1 Mapping of the AS-i Data in the Profibus-DP Telegram .........................................37

8.3.2 Configuration of the AS-i Network ...........................................................................38

8.3.3 Configuration of the Profibus-DP Master ................................................................38

8.4 Profibus Diagnosis telegram ...............................................................................41

8.4.1 Diagnosis telegram in easy mode and advanced mode .........................................41

8.4.2 Diagnosis telegram in professional mode ...............................................................43

9 Accessories for Putting AS-i into Operation and Test Tools ............ 45

9.1 Windows Software AS-i Control Tools ...............................................................45

9.2 Profibus-DP-Mastersimulator ..............................................................................48

10 Displays of the Figure Display ............................................................. 49

11 Appendix: AS-i Slave Lists and Data Telegrams ................................ 51

11.1 AS-i Slave Lists .....................................................................................................51

11.2 Execution Control Flags .......................................................................................51

11.3 Structure of the Profibus-DP Data Telegram ......................................................52

11.3.1 Structure of the AS-i data window ...........................................................................52

11.3.2 Data Window for Transmission of AS-i Parameters in Advanced Mode .................53

11.3.3 Transmission Window for AS-i Control Code in Advanced Mode ...........................53

12 Appendix: The First Commissioning of AS-i ...................................... 57

13 Appendix: Putting Profibus into Operation with a Siemens S5 ........ 59

13.1 Putting into Operation in Easy Mode ..................................................................59

13.2 Putting into Operation in Professional Mode .....................................................62

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

4

issue date 12.10.199 9

Page 5

AS-i/PROFIBUS Gateway

Declaration of Conformity

1 Declaration of Conformity

The AS-i/PROFIBUS Gateway VAG-PB-G4F-R4 have been developed and produced

in accordance with the applicable European standards and directives.

The corresponding of conformity can be requested from the manufacturer.

The manufacturer of the product, Pepperl & Fuchs Group in D- 68307 Mannheim,

possesses a certified quality assurance system in accordance with ISO 9001.

ISO

9001

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

5

Page 6

AS-Interface

Declaration of Conformity

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

6

issue date 12.10.199 9

Page 7

2 The Used Symbols

This symbol warns the user of possible danger. Failure to heed this

warning can lead to personal injury or death and/or damage to equipment.

This symbol warns the user of a possible failure. Failure to heed this

warning can lead to total failure of the equipment or any other connected equipment.

This symbol gives the user important hints.

AS-i/PROFIBUS Gateway

The Used Symbols

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

7

Page 8

AS-Interface

The Used Symbols

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

8

issue date 12.10.199 9

Page 9

3 Safety

3.1 Intended Use

The protection of operating personnel and the system against possible

danger is not guaranteed if the control interface unit is not operated in

accordance with its intended use.

The device may only be operated by appropriately qualified personnel

in accordance with this operating manual.

3.2 General Safety Information

Safety and correct functioning of the device cannot be guaranteed if any

operation other than that described in this operation manual is performed.

The connecting of the equipment and any maintenance work to be carried out with voltage applied to the equipment must only be performed

by appropriately qualified electrotechnical personnel.

In the case that a failure cannot be repaired, the device must be taken

out of operation and kept from inadvertently put back into operation.

Repair work is to be carried out by the manufacturer only. Additions or

modifications to the equipment are not allowed and void the warranty.

The operator is responsible for the observance of local safety standards.

AS-i/PROFIBUS Gateway

Safety

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

9

Page 10

AS-Interface

Safety

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

10

issue date 12.10.199 9

Page 11

AS-i/PROFIBUS Gateway

General Information

4 General Information

This operating instruction is for use with the following devices of the Pepperl+Fuchs

GmbH:

• VAG-PB-KF-R4

The AS-i/PROFIBUS-Gateways serve to connect the Actuator-Sensor-Interface to

the PROFIBUS-DP. A gateway represents the master for the AS-Interface and the

slave for the PROFIBUS.

The AS-i/PROFIBUS-Gateway is constructed as a PROFIBUS DP slave only. It supports all PROFIBUS transmission rates up to 12 MBaud.

All AS-Interface functions can be called via the Profibus. There are three operation

modes for the data exchange with Profibus-DP: the easy mode, the advanced mode

and the professional mode. In the easy mode, the gateway uses a fixed I/O-configuration for the Profibus and the gateway can be put into operation very easily without

further parameterization on the Profibus master. In the advanced mode, the size of

the I/O window can be matched to the actual structure of the AS-i network. The AS-i

master is configured by the Profibus master. During operation, AS-i parameters can

be transmitted to the AS-i slaves. Also the mini-PLC AS-i Control is accessible. All

AS-i Control functions are available (program download, upload, start, stop, read and

write user memory). The professional mode is the advancement of the advanced

mode. With its management channel it is additionally possible to execute further AS-i

commands via Profibus. Furthermore you can operate the advanced AS-i diagnosis

via Profibus.

The scope of delivery includes several GSD-files to ensure the easy putting into operation in each operating mode. In contains also the Siemens type files version 4.0

(German) and 5.x.

All devices contain the integrated mini-PLC AS-i Control for the fast distributed preprocessing of AS-i data. Furthermore advanced AS-i diagnosis functions are implemented to locate sporadically occurring configuration errors and to judge the quality

of the AS-i communication.

All devices are delivered together with the AS-i Control Tools, a Windows software for

the easy putting into operation of the AS-Interface and the programming of AS-i Control. The software communicates via the serial interface of the PC without additional

expensive hardware. Merely a Profibus converter is needed to connect the RS232 interface of the PC with the Profibus interface of the AS-i/PROFIBUS Gateway.

If no PC is available the putting into operation, troubleshooting and setting up of the

AS-i parameters can be accomplished with the use of two push-buttons, the display

and the LEDs directly on the device.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

11

Page 12

AS-Interface

General Information

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

12

issue date 12.10.199 9

Page 13

AS-i/PROFIBUS Gateway

Connections, Displays and Controls

5 Connections, Displays and Controls

5.1 Device Schematics

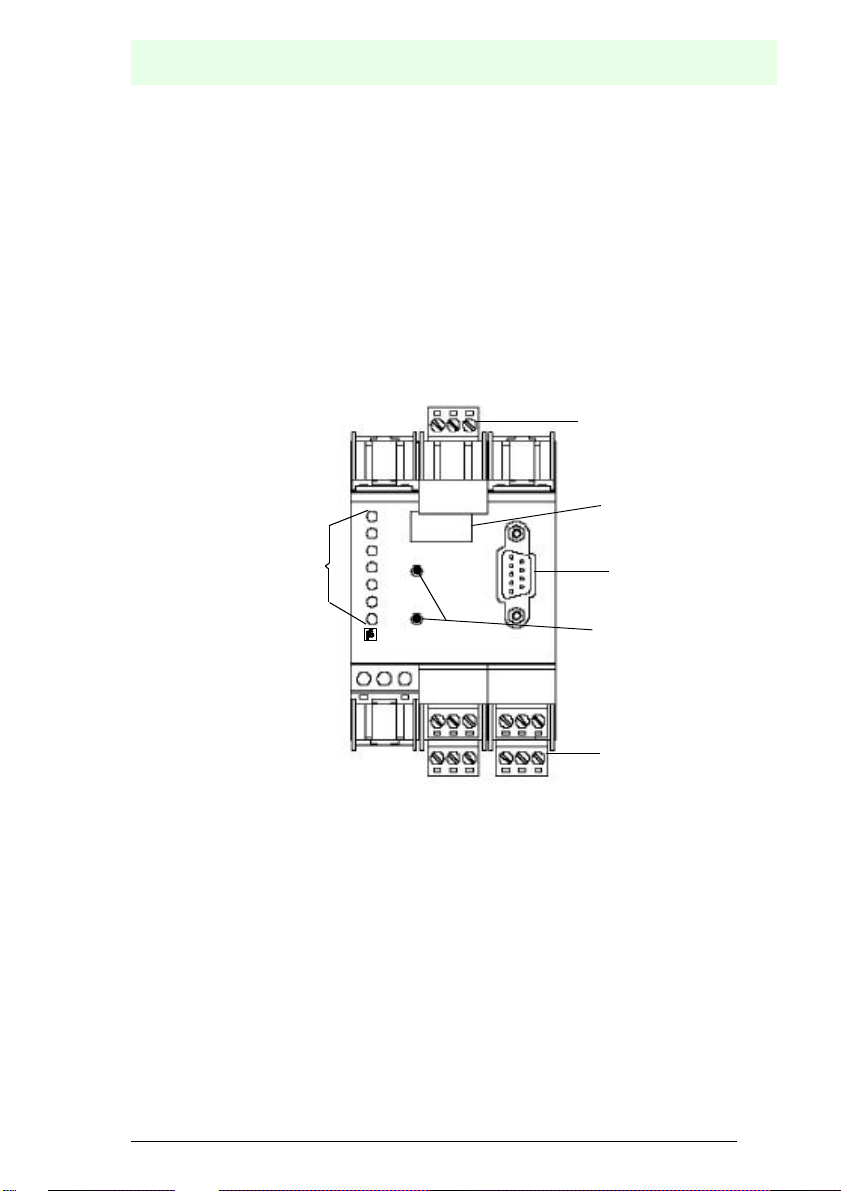

The following are found on the front of the AS-i/Profibus gateway (see diagram below):

1. Connection terminals for the AS-i circuit, also used for the power supply

2. A nine pin SUB-D connector as a Profibus-interface (see chapter 4.5),

3. 7 LEDs

4. A four position, seven section display for indicating the gateway's operating status

5. 2 buttons for projecting the gateway.

1

1 2 3

POWER

PB active

CONFIG ERR

3

U ASI

ASI active

PRG ENABLE

PRJ MODE

VAG-PB-KF-R4

192820

21

30 31 32

29

22 23 24 25

7

8

RS485

26

33 34 35 36

9

4

2

27

5

1

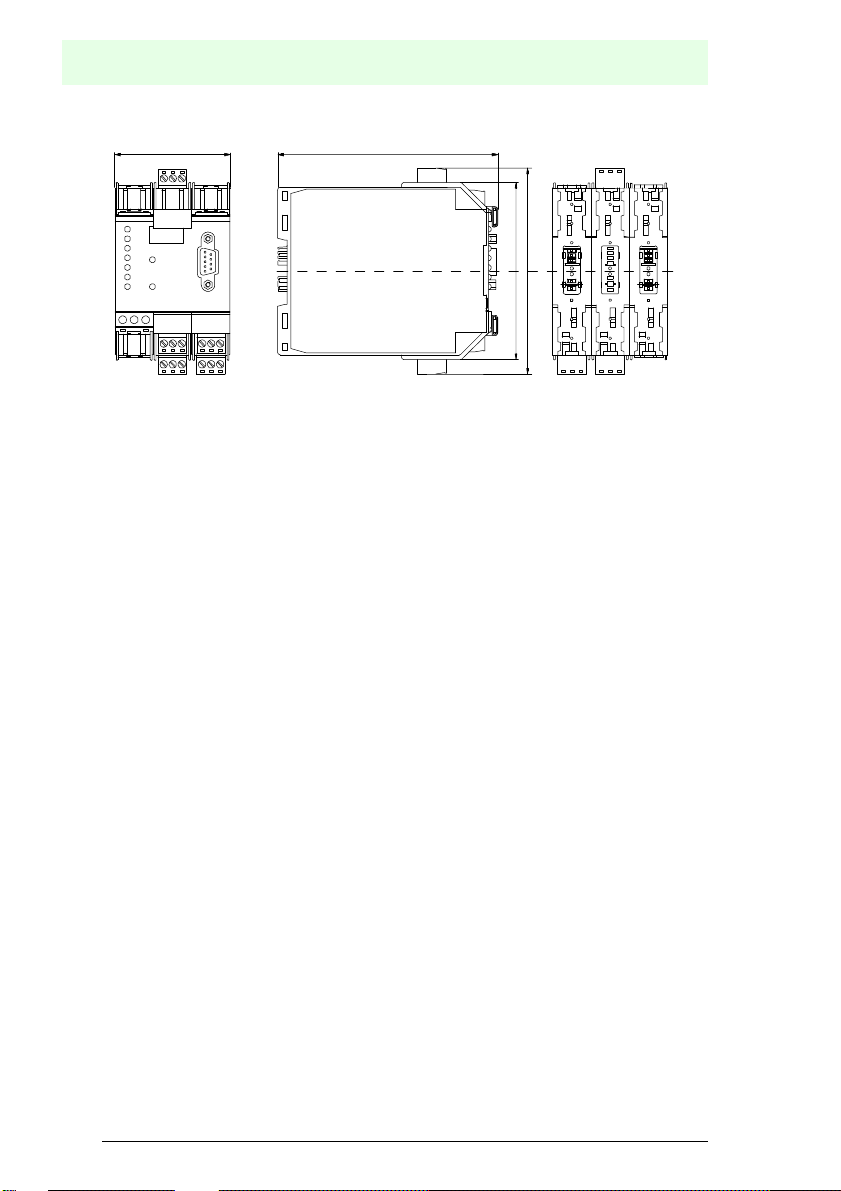

The following diagram provides the dimensions of the AS-i/PROFIBUS-gateway.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

13

Page 14

AS-Interface

Connections, Displays and Controls

60

115

107

92,5

5.2 Displays and Controls

The seven LEDs on the front of the gateway signal the following:

power The gateway is sufficiently supplied with power.

PB active LED on: The PROFIBUS communications are active.

LED off:PROFIBUS communications are inactive.

config err A configuration error is imminent or no PROFIBUS communications

are taking place (when the "PB active" LED is not illuminated). This

means that with configuration errors, at least one projected slave is

missing or the actual configuration data does not correspond with the

reference configuration data for a projected and recognized slave.

U AS-i The AS-i line is sufficiently supplied with power.

(AS-i Flag "APO").

AS-i active Standard operation is active (AS-i Flag "Normalbetrieb").

prg enable Automatic address programming is possible

(AS-i Flag "Auto_prog_available").

Precisely one slave is missing in the protected operating mode. This

slave can be replaced with a slave of similar design and an address

of 0. The gateway automatically programs the new slave to the faulty

address and thereby resolves the configuration error.

prj mode The gateway is in the projection mode

(AS-i Flag "projecting_active").

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

14

issue date 12.10.199 9

Page 15

AS-i/PROFIBUS Gateway

Connections, Displays and Controls

The two buttons have the following functions:

mode Used to switch between the projection mode and the protected oper-

ating mode and to store the actual AS-i configuration as the reference

configuration.

set Selection and storage of an AS-i slave address.

5.3 Mounting and Connections

5.3.1 Mounting

The KF… design of the gateway can be mounted on a 35 mm DIN rail in accordance

with EN 50022 and facilitates electrical connection through the "Power Rail". It is also

possible to use the more conventional and expensive method of cable connections to

terminals with this design.

The gateway is snapped directly onto the DIN rail. When using the power rail, an electrical connection is automatically made (to the AS-i Bus) by snapping the gateway

onto the rail leads..

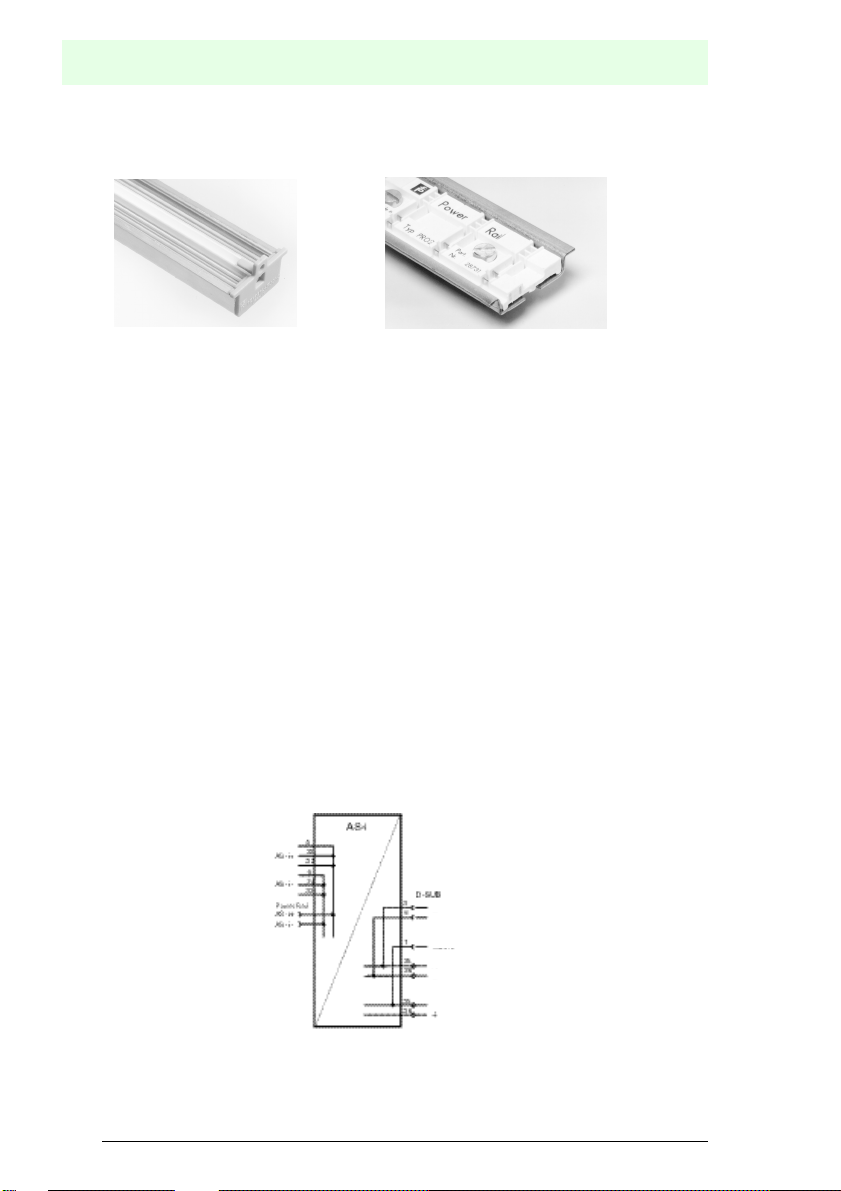

5.3.2 Connection via the Power Rail

The PR05 power rail is an insert for the DIN rail in accordance with EN 50 022. The

UPR 05 is delivered with the appropriate DIN rail.

The 5 pin version of the power rail must be used during the establishment of AS-interface circuits. Two of the five power rails make up the AS-i bus.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

15

Page 16

AS-Interface

Connections, Displays and Controls

Lead breakage as well as a short circuit caused by the power rail is prevented due to

the power rail's solid construction..

UPR 05

PR 05

5.3.3 Device Terminal Connections

In addition to or in combination with power rail connections, the KF… designs can be

conventionally connected by means of removable device terminals. The terminal arrangement is shown below.

The device terminals consist of screw type cable piercing terminals which allow for

the connection of 14 AWG cables (2.5 mm²). The connectors are 3 pin connectors;

they can be keyed to prevent connection errors.

Removable terminals simplify the assembly of the switch encloser and allow for the

replacement of components without taking the system off line.

5.3.4 Gateway Power Supply

The gateway is supplied through the AS-i circuit. A connection to the AS-i cable is established by means of the power rail and/or with the device terminals. The terminal

layout is displayed in the diagram above.

It is important to note when using the power unit that these AS-Interfaces are compatible and have the necessary decoupling coils.

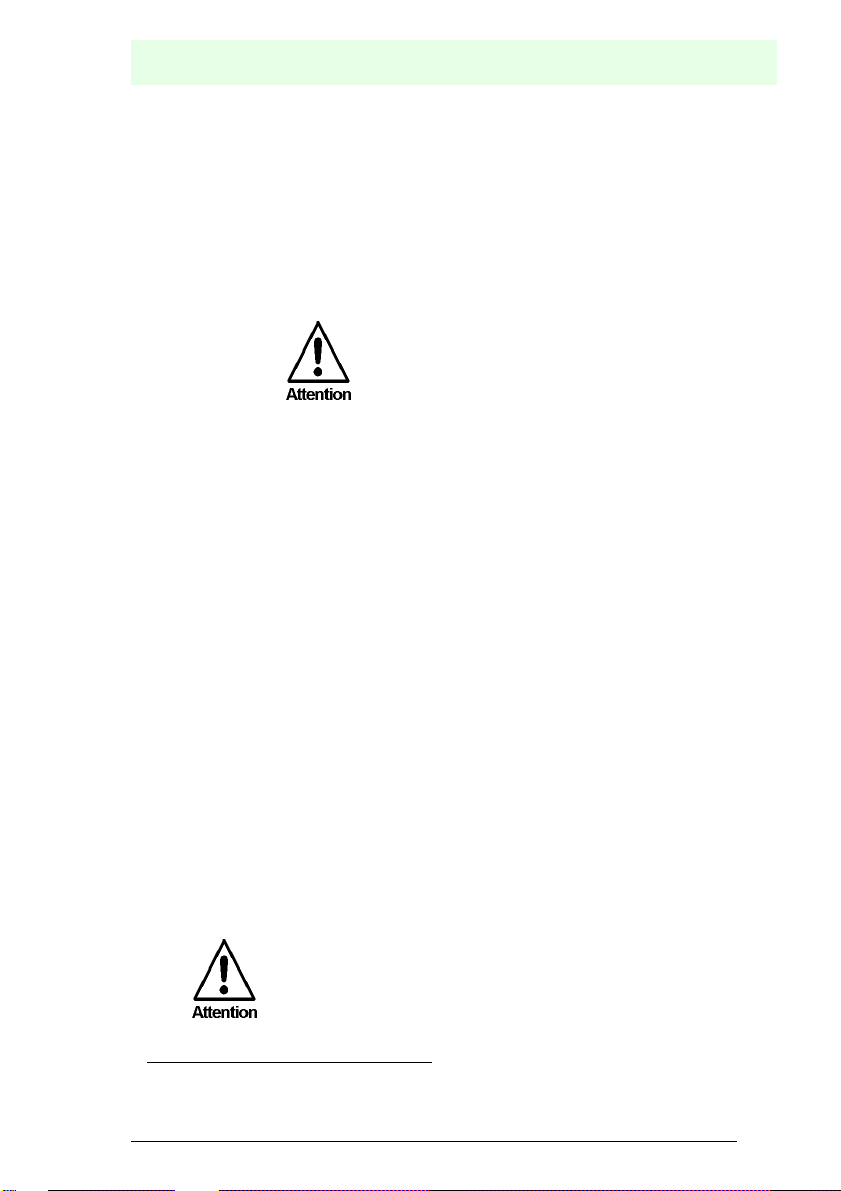

5.4 The PROFIBUS Interface

The serial interface is a 9 pin SUB-D connector. It is located on the right side of the

device front. The other possibility is to use the device terminals. The wiring is shown

in the picture below:

RxD/TxD-P

RxD/TxD-N

Shield

PROFIBUS

RxD/TxD-P

interface

RxD/TxD-N

Shield

The AS-i/Profibus-Gateway with an RS485 interface transmitts and receives through

pins 3 and 8 of the SUB-D connector or terminals 25 and 26 of the device terminals.

The RxD-TxD-P signal (B cable per PROFIBUS specifications) is assigned to pin 3

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

16

issue date 12.10.199 9

Page 17

AS-i/PROFIBUS Gateway

Connections, Displays and Controls

and to terminal 25. The RxD/TxD-N signal (A cable per PROFIBUS specifications) is

assigned to pin 8 and to terminal 26.

In order to prevent equalizing currents, the interface cable's shielding is connected

with the gateways grounding clamp through a capacitor. Otherwise, it should be galvanically grounded.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

17

Page 18

AS-Interface

Connections, Displays and Controls

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

18

issue date 12.10.199 9

Page 19

AS-i/PROFIBUS Gateway

Operating the AS-i/PROFIBUS Gateway

6 Operating the AS-i/PROFIBUS Gateway

6.1 Master Start-Up

After powering on, all segments of the figure display and all LEDs light up for approximately one second (self-test). Afterwards, the LEDs display the condition of their respective flags. The LCD displays the condition of the master:

40 Off-line Phase

The AS-i Master initializes—there is no data communication on the AS-i.

If the AS-i circuit is insufficiently powered (“U ASI” does

not light up) or there is no communication relationship

between the Profibus master and the AS-i/PROFIBUS

Gateway, the master remains in the off-line phase.

In configuration mode or when an AS-i Control program is started automatically the device can leave the Off-line phase.

In protected mode, if the Profibus communication is interrupted, the AS-i

Master switches to the off-line phase after the watchdog time of the Profibus has expired unless an AS-i Control program is running and was

started automatically.

41 Detection Phase

Start of the start-up phase, where the system looks for slaves located on

the AS-i. The master remains in the detection phase until it finds at least

one slave.

42 Activation Phase

Condition at the end of the start-up operation where the parameters are

transmitted to all connected and recognized slaves. This enables access

to the AS-i slaves’ data connections.

431Start of Normal Operation

In normal operation the AS-i master can exchange data with all active

slaves. It transmits management messages and looks for and activates

newly connected slaves. During normal operation, the system keeps the

maximum cycle time of 5 milliseconds.

6.2 Configuration Mode

The configuration mode serves to configure the AS-i circuit.

In the configuration mode, all recognized slaves are activated even

when the desired and actual configurations do not match.

1. Activation phase and the start of normal operation maybe so short that the numbers can not be seen in the display.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

19

Page 20

AS-Interface

Operating the AS-i/PROFIBUS Gateway

Pressing the “mode” button for at least five seconds switches the master to configuration mode. While in configuration mode, the yellow “prj mode” LED lights up.

The system then displays one after the other all detected slaves at a speed of two per

second. If the display is empty, no slaves were detached on the AS-i circuit.

In configuration mode, all recognized slaves are activated except of slave zero. The

AS-i Master is in normal operation. There is data exchange between the AS-i Master

and all AS-i slaves detected by the master regardless of whether the detected AS-i

slaves were projected before.

When delivered the AS-i/PROFIBUS Gateway is in configuration mode.

6.3 Protected Operating Mode

In contrast with the configuration mode in the protected mode there is

only data exchange between the AS-i Master and the projected AS-i

slaves.

6.3.1 Switching to Protected Operating Mode

You leave the configuration mode by pressing the “mode” button.

Pressing the button shortly:

Exits the configuration mode without projecting the current AS-i configuration.

Pressing the button for more than five seconds:

Exits the configuration mode and projects the actual AS-i configuration. Simultaneously the actual AS-i configuration is stored as nominal configuration

in the EEPROM.

If the system detects an AS-i slave with address zero on the AS-i, it can

not leave the configuration mode.

In the protected operating mode, only AS-i slaves that are projected and whose actual

configurations match the nominal configurations will be activated.

6.3.2 Configuration Errors in Protected Operating Mode

As long as there is no configuration error, the numeric display is turned off while in

protected operating mode. Otherwise, the that address a faulty assignment is displayed. A faulty assignment occurs when a slave has been recognized or projected

but cannot be activated.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

20

issue date 12.10.199 9

Page 21

AS-i/PROFIBUS Gateway

Operating the AS-i/PROFIBUS Gateway

If there are more than one faulty assignments the one that was first detected is displayed. Pressing the “set” button shortly displays the next higher faulty address.

Shortly appearing configuration errors are stored in the device (advanced AS-i diagnosis). The last error that occurred can be displayed by pressing the set button. If a

short AS-i power failure is responsible for the configuration error the display shows a

“39“.

6.4 Assigning an AS-i Address in Configuration Mode

AS-i can be put into operation in a very comfortable manner by using the Windows

software AS-i Control Tools (see chapter 9.1)(addressing directly or with the AS-i address assistant).

Furthermore you can use a hand held addressing device.

If you don’t have neither a PC nor a hand held addressing device, address assigning

of the AS-i slaves is also possible with the AS-i/PROFIBUS Gateway using the push

buttons. How it works is described as follows.

6.4.1 Assigning a Slave Address

(assigning an available address to a slave with address zero)

In configuration mode, the addresses of all detected slaves are displayed one after

the other. To display the next higher available operating address, press the “set” button shortly. Each time you press the “set” button, the next available address is displayed.

Chose the displayed address as your target address by pressing the button for more

than five seconds. The address display blinks. The master is ready for programming;

pressing the “set” button again addresses the connected slave with address zero to

the target (blinking address.

Any errors will be displayed by their error codes according to chapter 10. Otherwise,

the detected slaves are displayed again as described in chapter 6.2.

6.4.2 Erasing the Slave Address

AS-iIn configuration mode, the addresses of all recognized slaves are displayed one

after the other. By pressing and releasing the “set” button, the master displays the

next available address. If you press the button for more than five seconds while the

address of a detected slave is displayed, this slave is will get the address zero and

the display shows “00”.

When you release the button, the display continues to display the detected slaves.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

21

Page 22

AS-Interface

Operating the AS-i/PROFIBUS Gateway

6.5 Programming the Address in Case of Configuration Errors

6.5.1 Automatic Address Assignment

One of AS-i’s great advantages is the automatic address assignment. If

a slave fails, it can be replaced by one of the same type with address

zero. The master will detect the replacement and automatically

addresses the new slave with the address of the faulty one.

For automatic programming to work, some requirements must be met:

1.The AS-i master must be in the protected operating mode.

2.The “Auto_Address_Assign” release flag must be set.

3.Only one of the projected slaves may not be detected.

If these requirements are met, the AS-i master’s “prg enable” LED lights up and a

slave with address zero will be automatically assigned to the operating address of the

missing slave.

If the two slaves have different configuration data, i.e. are not of the

same type as far as AS-i is concerned, the automatic address assignment will not be carried out.

6.5.2 Manual Address Assignment

If several slaves fail, they cannot be replaced automatically by the AS-i

master. You must set their addresses manually. If this should not be

done via the Profibus interface (using the AS-i Control Tools) or with a

hand held addressing device, you can set them with the push buttons

and the figure display of the device.

In protected operating mode, wrong assignments are displayed as errors (see chapter

6.3). By pressing the “set” button, you can display all faulty assignments one after the

other. By pressing the “set” button for more than five seconds, you can select the currently displayed address as a potential target address, and the display starts to blink.

If the faulty slave was previously replaced by a slave with address zero, the new slave

can now be programmed for the blinking address by pressing the “set” key again. As

a requirement, the new slave’s configuration data must match the configuration data

for the blinking address.

After the address has been successfully set, the next faulty assignment is displayed

and the address assignment can begin from the start. Otherwise, the system displays

an error code (chapter 10). When all faulty assignment are eliminated the display is

empty.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

22

issue date 12.10.199 9

Page 23

AS-i/PROFIBUS Gateway

Operating the AS-i/PROFIBUS Gateway

6.6 Setting of the Profibus Station Address and the Protocol Type

6.6.1 Profibus Station Address

The addressing of the AS-i/PROFIBUS Gateway as a Profibus slave

can be done locally at the gateway or via Profibus according to the

Profibus norm.

Station addresses from 1 to 99 can be set, when delivered station address 3 is set.

For the relocation, both the "set" button and the "mode" button have to be pushed si-

multaneously for at least 5 seconds until the current bus address is shown on the LCD

display. With every pushing of the "set" button, the station address can now be increased by 1.

Once the desired Profibus station address is shown on the display, it will be stored

non-volatile in the EEPROM by pushing the “mode“ button.

6.7 Error Messages

The system displays error codes for error messages that do not point to

faulty assignments on the AS-icircuit. The code numbers are larger than

50 and are therefore outside the slave address range. These codes are

described in the appendix, chapter 10.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

23

Page 24

AS-Interface

Operating the AS-i/PROFIBUS Gateway

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

24

issue date 12.10.199 9

Page 25

AS-i/PROFIBUS Gateway

Advanced Diagnostics for AS-i Masters

7 Advanced Diagnostics for AS-i Masters

The advanced AS-i diagnostics serves to locate occasionally occurring errors and to

judge the quality of data transmission on AS-i without additional diagnostics tools.

The AS-i Control Tools, Bihl+Wiedemann’s software for the comfortable commissioning of the AS-Interface and the programming of AS-i Control, will include the operation

of the Advanced Diagnostics from version 3.0 on.

7.1 List of Corrupted AS-i Slaves (LCS)

To locate occasionally occurring short-time configuration errors the AS-i Masters with

advanced diagnostics manage beside the list of projected slaves (LPS), the list of detected slaves (LDS) and the list of activated slaves (LAS) a forth list, the list of cor-

rupted slaves (LCS). This list contains entries of all AS-i slaves which were

responsible for at least one configuration error since powering up the AS-i master or

reading the list. Short-time AS-i power failures are represented in the LCS at the position of AS-i slave with address 0.

With every read access the LCS will be deleted.

The last short-time configuration error can also be displayed on the AS-i

Master:

Pressing the “set“ button of the AS-i Master shows the AS-i slave which

was responsible for the last short-time configuration error. Was there a

short-time AS-i power failure the display shows “39“ after pressing the

“set“ button.

7.2 Error Counter: Counter of corrupted data telegrams

The AS-i Master with advanced diagnostics has an error counter for each AS-i slave,

which is increased every time there is a corrupted AS-i telegram. This makes it possible to judge the quality of the AS-i network, even if only a few corrupted telegrams

occurred and the AS-i slave did not cause any configuration errors.

The counter values can be read via the host interface and will be

deleted with every read access. The counter value is limited to 254. 255

means counter overflow.

The error counter is included in the command Master | AS-i Diagnostics of AS-i Control Tools version 3.0.

7.3 Off-line Phase on Configuration Errors

The AS-i Masters with advanced diagnostics offer the possibility to put themselves

into the Off-line Phase when a configuration error on the AS-Interface occurs. In this

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

25

Page 26

AS-Interface

Advanced Diagnostics for AS-i Masters

way the security of the application can be ensured. The reaction to a configuration error is very fast and the host can be relieved from this task. If there are any problems

on the AS-i network, the AS-interface can be switched to a secure state.

There are two different ways to parameterize the AS-i Master for this feature:

• Every configuration error during normal operation in protected mode releases the

Off-line Phase.

• For each slave address can be chosen whether a configuration error on this ad-

dress will release the Off-line Phase or not. This information is stored in the List of

Off-line Slaves (LOS).

The user himself can decide how the system reacts to a configuration error on the

AS-interface. The AS-i Master can release the Off-line Phase in critical situations,

i.e. only with certain slave addresses, while in less critical situations (if one of the

other AS-i slaves have a configuration error) only the error message configuration

error is sent to the host, but AS-i is still running.

The parameterization of Off-line Phase on Configuration Error is also supported by

the AS-i Control Tools version 3.0.

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

26

issue date 12.10.199 9

Page 27

AS-i/PROFIBUS Gateway

Profibus-DP

8 Profibus-DP

In this chapter, you learn everything necessary to run the AS-i/PROFIBUS Gateway

in a Profibus-DP network.

For data exchange on Profibus-DP there are three operation modes: the easy mode,

the advanced mode and the professional mode (advanced mode with management

channel).

Hint: If you try to put an AS-i/PROFIBUS Gateway in operation the first

time it is advisable to use the easy mode because it is much easier than

the advanced modes.

The following table shows the differences between the three modes:

following Functions are available

Transmission of AS-i input and

outut data

AS-i circuit can be configured

locally on the gateway

Putting into Operation without additional parameterization of the Profibus master

Working with a standard I/O-configuration on Profibus-DP

Detection of AS-i errors via DPdiagnosis

Transmission of AS-i parameters to

the gateway while the system is

running (e.g. switching of the measurement range of sensors)

Configuring and parameterizing the

AS-i circuit by the DP-master

Reading and Writing AS-i Control

programs via Profibus-DP

AS-i Transmission of user flags for

the AS-i Control program via Profibus DP

Adjust the size of the I/O windows

to the actual extension of the AS-i

circuit

Transmission of additional AS-i

commands and advanced diagnosis

in easy mode in advanced

mode

X X X

X - X

X - -

X - -

X X X

- X X

- X X

- X -

- X X

- X X

- X X

in professional

mode

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

27

Page 28

AS-Interface

Profibus-DP

8.1 Easy Mode

8.1.1 Mapping of the AS-i data in the Profibus-DP-Telegram

The inputs and outputs of the AS-i network are mapped identically in the DP master's

input or output memory area respectively. In the easy mode the DP-telegram contains

16 bytes in- and output data with a single master.

AS-i circuit 1:

Byte 0 Byte 1 ... Byte 15

Slave 1, AS-i flags Slave 3, Slave 2 ... Slave 31, Slave 30

The AS-i flags and every AS-i slave take up four bits. The meaning and allocation of

these bits is explained in the appendix, chapter 11.3.1.

If the AS-i flags shall not be used, you have to make sure that by all

means these four bits are set to zero.

8.1.2 Configuration of the AS-i Network

The AS-i network can be put into operation without the Profibus-DP master. A connection to the Profibus-DP master is not necessary.

A comfortable way to configure the AS-i circuit on the AS-i/PROFIBUS Gateway is to

use the Windows software AS-i Control Tools.

However it is also possible to configure the AS-i network locally on the gateway by

using the push buttons “set“ and “mode“ (see chapter 6.4)

8.1.3 Projecting of the Profibus-DP Master

To project the Profibus-DP network you have to copy a GSD-file (enclosed on diskette) to the working directory of your Profibus configuration software (some programs have a directory named GSD, where the GSD-files have to be copied to,

please see the manual of the used software). Depending on the software you may

have to dispatch a command like „read GSD-files“.

The GSD-files can be found on the enclosed diskette „AS-i/PROFIBUS-Gateway IBM

PC Software“ in the directory GSD.

For the easy mode the following GSD-files are available:

bwes1742.gsd

device: AS-i/PROFIBUS-DP Gateway,

model name in the GSD-file: „AS-i/DP“

If the Profibus configuration software needs the older type files instead of the GSDfiles, please read the file \gsd\readme.txt on the enclosed diskette.

8.1.4 Parameterization of the Profibus-DP Slave

The parameters the gateway needs are completely appropriated by the GSD-file,

there is no need to state user-parameters. If nevertheless user-parameters are transmitted, the device will switch to easy mode, if the first byte (element selection) is

00

.

hex

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

28

issue date 12.10.199 9

Page 29

AS-i/PROFIBUS Gateway

Profibus-DP

8.1.5 Configuration of the Profibus-DP Slave

In the easy mode the gateway uses a fixed I/O-configuration. If you use the GSD-file

select the module “Standardmodus“.

If you configure the master without the GSD-file, select the identification byte

3F

(=63

hex

For double masters you need this identification byte for each AS-i circuit.

8.2 Advanced Mode

The extended functionality of the advanced mode affords a more extensive configuration of Profibus-DP. The I/O window can be adjusted optimally to the additional

transmitted data (AS-i parameters, user memory, AS-i Control Code). The length of

the I/O-window depends on the following factors:

• number of the AS-i slaves (number of input and output bytes)

• shall AS-i parameters be transmitted?

• shall AS-i Control code be transmitted?

• shall user memory be transmitted?

Size of the Window for the AS-i Input and Output Data

The size of the window for the AS-i input and output data is automatically adjusted to

the AS-i configuration that is transmitted in the Profibus parameter telegram (user-parameter).

However, you must pay attention to this when configuring the Profibus-DP slave (see

chapter 8.2.3).

Transmission of AS-i Parameters

For the transmission of AS-i parameters the DP-input and output data fields are enlarged by two bytes each. The AS-i slave address and the AS-i parameters are entered to these bytes. In the output data field, the DP master deposits the AS-i

parameters to be written; in the input data field, the gateway deposits the data read

during the AS-i parameterization.

The AS-i slaves are parameterized sequentially, i. e. only one slave can be parameterized in one Profibus cycle. The gateway signals errors of the parameterization by

setting the leftmost bit in the slave address.

Transmission of AS-i Control code

).

dec

For AS-i/PROFIBUS Gateways with 2 AS-i Masters and/or the advanced AS-i diagnostics1 we recommend to use the professional

mode instead of the older advanced mode.

1. these are all devices that were delivered since September 1998; these devices have the following feature string:

„*B..Dc..***.....“ oder „*B..Dc2.***.....“, * is a placeholder for various characters

(this string can be read with AS-i Control Tools with the command Master | Identity)

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

29

Page 30

AS-Interface

Profibus-DP

For the programming of AS-i Control, the I/O field is further enlarged by 5-17 additional bytes. They contain an identification byte (read/write/start/stop), the base address

and 2-14 bytes user data. It is not possible to read and write at the same time.

Transmission of user memory

User memory can be transmitted in the I/O field by adding bytes for the memory locations to be written (O-field) or to be read (I-field). The amount of user memory to be

written or read can be different.

8.2.1 Mapping of the AS-i Data in the Profibus-DP Telegram

The data in the DP telegram is always mapped in the same fixed order:

• AS-i I/O data

• AS-i parameters

• AS-i Control code

• user memory

If some elements are missing (e.g. no transfer of the AS-i Control code), subsequent

elements are added directly.

The individual parts of the DP-telegram are coded as follows:

N bytes

AS-i I/O data

2 bytes

AS-i parameter

5-17 bytes

AS-i Control

M bytes

user memory

code

user memory 0..

user memory M-1

high address, control byte

low-address, L bytes data

AS-i slave address, AS-i parameter

byte 0. .. byte N-1

slave 1 AS-i flags ... slave (K-1) slave (K-2)

with K = number of AS-i slaves + 1

(instead of slave 0 the AS-i flags are transmitted)

N = K/2

M = number of user memory bytes up to 128 bytes

L = number of bytes of AS-i Control code

(calculated out of value in element selection of the user-parameter telegram)

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

30

issue date 12.10.199 9

Page 31

AS-i/PROFIBUS Gateway

Profibus-DP

The AS-i flags and every AS-i slave take up four bits. The meaning and allocation of

these bits is explained in the appendix, chapter 11.3.2.

If the AS-i flags shall not be used, you have to make sure that by all

means these four bits are set to zero.

Bit allocation AS-i parameters: see appendix, chapter 11.3.2.

Constants for the control byte in the DP-telegram's AS-i Control part: see appendix,

see chapter 11.3.3.

8.2.2 Configuration of the AS-i Network

During the building up of the connection to a Profibus-DP master, the AS-i network is

configured via the Profibus. The AS-i configuration does not have to be stored locally

(via the push buttons mode and set or the AS-i Control Tools). Merely the AS-i slaves

have to get the designated addresses.

The AS-i/PROFIBUS Gateway compares the nominated AS-i configuration received

from the DP-master with the actual configuration of the AS-i network. If they match,

the gateway does data exchange on AS-i. (This does not affect the data exchange on

Profibus).

The AS-i configuration data of the AS-i slaves (ID-code and I/O-configuration) should

be known before configuring the DP-master. You find them in the AS-i slave's documentation.

The configuration via Profibus-DP offers the following advantage: The

AS-i configuration data of the AS-i network is stored in the DP-master.

This way, an immediate start-up without any need for manual intervention is possible when exchanging the gateway (one exception is the

Profibus station address).

8.2.3 Configuration of the Profibus-DP Master

To project the Profibus-DP network you have to copy a GSD-file (enclosed on diskette) to the working directory of your Profibus configuration software (some programs have a directory named GSD, where the GSD-files have to be copied to,

please see the manual of the used software). Depending on the software you may

have to dispatch a command like „read GSD-files“.

The GSD-files can be found on the enclosed diskette „AS-i/PROFIBUS-Gateway IBM

PC Software“ in the directory \GSD.

For the advanced mode the following GSD-files are available:

bwas1742.gsd

device: AS-i/PROFIBUS-DP Gateway,

model name in the GSD-file: „AS-i/DP-A“

If the Profibus configuration software needs the older type files instead of the GSDfiles, please read the file \gsd\readme.txt on the enclosed diskette.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

31

Page 32

AS-Interface

Profibus-DP

Parameterization of the Profibus-DP-Slave

The parameters needed by the gateway are coded in the user-parameters. They contain one byte element selection, the AS-i configuration data and AS-i parameters for

all the AS-i slaves and the statements about user memory bytes to be read and to be

written.

Element

selection

AS-i configuration data and

AS-i (startup-) parameters

user memory

statement

The fields are constructed as follows:

• Element selection (1 byte)

Bit field for the selection of the data to be transmitted:

Bit 0 = 1 Transmission of AS-i parameters

= 0 No transmission of AS-i parameters

Bit 1 = 1 Transmission of user memory

= 0 No transmission of user memory

Bit 2 = 1 Transmission of 2 bytes of AS-i Control code additionally

Bit 3 = 1 Transmission of 4 bytes of AS-i Control code additionally

Bit 4 = 1 Transmission of 8 bytes of AS-i Control code additionally

Bit 5 = 0 (reserved, 0 cogently necessary)

Bit 6 = 1 Transmission of AS-i input data

= 0 AS-i input data field is left out

Bit 7 = 1 Transmission of AS-i output data

= 0 AS-i output data field is left out

If the ID-Byte is set to 00hex, the device will switch to the easy mode.

• AS-i configuration data and AS-i (startup) parameters (62 bytes)

For each AS-i slave 2 bytes are used. AS-i slave 0 is disregarded.

In the first byte, the AS-i configuration data is specified. The AS-i ID-code is coded in the byte's high nibble and the I/O-configuration in its low nibble.

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

ID-code IO-configuration

In the second byte's low nibble, the AS-i (startup) parameters are transmitted.

The upper half of this byte is unused.

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 0 0 0 P3 P2 P1 P0

unused (=0) AS-i parameter

The default parameter for an AS-i slave is F

0F

is stated.

hex

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

32

, so that normally as second byte

hex

issue date 12.10.199 9

Page 33

AS-i/PROFIBUS Gateway

Profibus-DP

If a slave address is to remain unused, either FF

hex

, FF

hex

or 256

dec

, 256

to be entered.

The highest slave address used determines the size of the

window for input and output data in the DP-data telegram.

The configuration of the DP-slave has to be adjusted accordingly (see below).

• user memory statement (4 bytes)

The user memory statement always has to be stated.

Byte 0:Start address of the user memory window in the input data telegram

(read user memory)

Byte 1:Length of the user memory window in the input data telegram

Byte 2:Start address of the user memory window in the output data telegram

(write user memory)

Byte 3:Length of the user memory window in the output data telegram

If user memory bytes shall only to be read or written, the appurtenant length byte

has to be set to 0.

If no user memory bytes shall be transmitted it is recommended to set the user

memory statement to FF

hex

FF

hex

FF

hex

FF

hex

.

The maximum length of the user memory window is 128 bytes.

Example: Parameter telegram for the advanced mode:

3 AS-i slaves and transmission of user memory, all slaves AS-i ID 0

Slave 1: 4 inputs

Slave 2: 4 outputs

Slave 3: 2 inputs, 2 outputs

from user memory byte 0 read 4 bytes of user memory

no writing of user memory

dec

has

El. slave 1 slave 2 slave 3 slave 4 slave 31 user mem. st.

conf

ID,IO

par conf

ID,IO

par conf

ID,IO

par conf

ID,IO

par conf

ID,IO

par

C2 00 0F 08 0F 03 0F FF FF ... FF FF 00 04 00 00

(all data stated in hexadecimal code)

Configuration of the Profibus-DP slave

In contrast to the easy mode, the size of the I/O window can be matched to the extension of the AS-i network. Its size in bytes amounts:

(highest AS-i slave address + 1) / 2

Any non-integer value has to be rounded up to a full byte. Extra bytes have to be added for possible AS-i (startup) parameters, user memory or AS-i Control code.

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

33

Page 34

AS-Interface

Profibus-DP

Only "standard identification bytes" with a maximum size of 16 bytes or words may be

used as identification bytes. If the data windows to be transmitted shall be bigger than

16 bytes or words, they have to be out together out of several "standard identification

bytes".

If the requested data field length is smaller than the one calculated out of the parameter telegram, the gateway will not take up any communication relationship with the

DP-master.

The maximum data field length for input respectively output data is 149 bytes with a

device with one AS-i Master and 160 bytes with a device with two AS-i Masters.

8.3 Professional Mode

All AS-i/PROFIBUS Gateways with 2 AS-i Masters and/or the advanced AS-i diagnostics1 have a third operation mode, which we call the professional mode. We recommend the use of the professional mode instead of the older advanced mode.

The AS-i/PROFIBUS Gateways with 2 AS-i Masters only allow the use of the easy

mode or the professional mode. The AS-i/PROFIBUS Gateways (FMS/DP) only run

in the easy mode or the advanced mode.

The extended functionality of the advanced mode affords a more extensive configuration of Profibus-DP. The I/O-window has to be enlarged for the additional data

(management commands and user memory). The length of the I/O-window depends

on the following factors:

• number of the AS-i slaves (number of input and output bytes)

• size of the management channel (0, 3 or 5 Bytes)

• number of the user memory bytes

Size of the Window for the AS-i Input and Output Data

The size of the window for the AS-i input and output data has to be adjusted to the

AS-i configuration (see chapter 8.3.3).

Transmission of Management Commands (0, 3 or 5 bytes)

With the management commands you can transmit acyclically additional AS-i data

like e.g. AS-i parameters or reading the LDS or also writing the AS-i Control flags e.g.

to start an AS-i Control program.

The management channel uses either 3 or 5 bytes. If the commands write LPS, read

LPS, read LAS, read LDS, read LCS, read communication errors, write LOS or read

LOS shall be used, the management channel has to have a length of 5 bytes because

these commands use 4 bytes of data.

The management channel is built up as follows:

byte 0 byte 1 - 2 respectively 1 - 4

Profibus output data command byte output data

Profibus input data mirrored command byte input data

1. these are all devices that were delivered since September 1998; these devices have the following feature string:

„*B..Dc..***.....“ oder „*B..Dc2.***.....“, * is a placeholder for various characters

(this string can be read with AS-i Control Tools with the command Master | Identity)

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

34

issue date 12.10.199 9

Page 35

AS-i/PROFIBUS Gateway

Profibus-DP

If the same command byte shall be sent several times one after the other, the bit 7

(valence 27) has to be toggled each repetition.

The bit 6 (valence 26) of the command byte states the number of the AS-i Masters to

address to. If this bit is 0, AS-i Master 1 is addressed, otherwise AS-i Master 2. With

single masters this bit has to be 0, with double masters the AS-i circuit to address can

be selected. (e.g. command read AS-i Control Flags of AS-i circuit 2: 4D

After execution of the command the command byte is mirrored. Illegal commands

(AS-i circuit number 2 with single masters, illegal command byte or a data field which

is too short) always return as mirrored command byte 00

was set.

Commands that may fail return an error code (00

hex

hex

: OK, FF

or 80

hex

: error) in data byte[0]

hex

(status).

The possible commands are listed as follows:

)

hex

, if the toggle bit

AS-i function command

Idle

(no function)

write projected

parameter

read projected

parameter

output 00

input 00

output 01

input 01

output 02

input 02

write parameter output 03

input 03

read actual

paramter

write (project)

actual parameter

write projected

coniguration

read projected

coniguration

write projected

coniguration

read actual configuation

output 04

input 04

output 05

input 05

output 06

input 06

output 07

input 07

output 08

input 08

output 09

input 09

address AS-i slave output 0A

input 0A

byte

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

data

byte[0]

data

byte[1]

data

byte[2]

data

byte[3]

- - - -

- - - -

slave address parameter - -

status - - -

slave address - - -

status parameter - -

slave address parameter - -

status parameter - -

slave address - - -

status parameter - -

- - - -

status - - -

slave address conf.-daten - -

status - - -

slave address - - -

status conf.-daten - -

- - - -

status - - -

slave address - - -

status conf.-daten - -

old address new address - -

status - - -

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

35

Page 36

AS-Interface

Profibus-DP

AS-i function command

AS-i command call output 0B

input 0B

write AS-i Control

flags

read AS-i Control

flags

output 0C

input 0C

output 0D

input 0D

write LPS output 0E

input 0E

read LPS output 0F

input 0F

read LAS output 10

input 10

read LDS output 11

input 11

read LCS output 12

input 12

read communication error

output 13

input 13

write LOS output 14

input 14

read LOS output 15

input 15

remarks to the table:

• possible values for status:

The status byte, which is returned from certain commands, can have the follow-

ing values:

FF error occurred at execution of the host command

00 no error occurred

If errors occur while changing slave addresses, the status byte contains one of

the following error codes:

01 no failure.

02 the slave, whose address should be changed does not exist.

03 There is a slave with address zero.

byte

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

hex

data

byte[0]

data

byte[1]

data

byte[2]

data

byte[3]

slave address data - -

status answer - -

flags - - flags - - -

- - - -

flags - - -

LPS LPS LPS LPS

status - - -

- - - -

LPS LPS LPS LPS

- - - -

LAS LAS LAS LAS

- - - LDS LDS LDS LDS

LCS LCS LCS LCS

- - -

index (0-7) - - -

error error error error

LOS LOS LOS LOS

- - - -

- - - -

LOS LOS LOS LOS

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

36

issue date 12.10.199 9

Page 37

AS-i/PROFIBUS Gateway

Profibus-DP

04 The address to which the slave shall be addressed

is reserved by another slave

05 The slave could not be addressed to address 0.

06 The new operation address could not be assigned.

07 The new operation address could not be stored

in the EEPROM of the slave.

• AS-i command call :

The function of the execution control Execute_Command() is executed. The in-

formation part of the master request has to be stated in “data“. (see AS-i specification).

The AS-i Master stores the slave answer in the byte “answer“.

• LPS, LAS, LDS, LCS, LOS:

Structure of the AS-i slave lists see appendix, chapter 11.1.

• read communication errors:

For each slave there is one byte for the number of communication errors that

occurred since the last read access. With every read access only 4 bytes are

read simultaneously. Therefore you have to state the index for the data you

want to read:

index = slave address / 4 (integer)

data byte number = slave address - (4 * index)

Transmission of user memory

The user memory is transmitted in an own Profibus slot. The amount of user memory

to be written or read can be different.

8.3.1 Mapping of the AS-i Data in the Profibus-DP Telegram

The data in the DP telegram is always mapped in the same fixed order:

• AS-i I/O data

• AS-i parameters

• AS-i Control code

• user memory

If some elements are missing (e.g. no transfer of the AS-i Control code), subsequent

elements are added directly.

The AS-i data is represented in the DP-telegram as follows:

byte 0 byte 1 ... byte N-1

slave 1, AS-i flags slave 2, slave 3 ... slave(K-1), slave(K-2)

with K = number of AS-i slaves + 1

(instead of slave 0 the AS-i flags are transmitted)

N = K/2

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

37

Page 38

AS-Interface

Profibus-DP

The AS-i flags and every AS-i slave take up four bits. The meaning and allocation of

these bits is explained in the appendix, chapter 11.3.1.

If the AS-i flags shall not be used, you have to make sure that by all

means these four bits are set to zero.

8.3.2 Configuration of the AS-i Network

During the building up of the connection to a Profibus-DP master, the AS-i network is

configured via the Profibus, unless the AS-i configuration and the AS-i (startup) parameters are not stated in the Profibus parameter telegram. The AS-i configuration

only has to be stored locally (via the push buttons mode and set or the AS-i Control

Tools), if the configuration of AS-i was not stated in the Profibus parameter telegram.

Merely the AS-i slaves have to get the designated addresses.

The AS-i/PROFIBUS Gateway compares the nominated AS-i configuration received

from the DP-master with the actual configuration of the AS-i network. If they match,

the gateway does data exchange on AS-i. (This does not affect the data exchange on

Profibus).

The AS-i configuration data of the AS-i slaves (ID-code and I/O-configuration) should

be known before configuring the DP-master. You find them in the AS-i slave's documentation.

The configuration via Profibus-DP offers the following advantage: The

AS-i configuration data of the AS-i network is stored in the DP-master.

This way, an immediate start-up without any need for manual intervention is possible when exchanging the gateway (one exception is the

Profibus station address).

If the AS-i configuration and the AS-i (startup) parameters were not stated in the Profibus parameter telegram AS-i has to be projected (and the configuration stored) with

the push buttons at the device or with the windows software AS-i Control Tools.

8.3.3 Configuration of the Profibus-DP Master

To project the Profibus-DP network you have to copy a GSD-file (enclosed on diskette) to the working directory of your Profibus configuration software (some programs have a directory named GSD, where the GSD-files have to be copied to,

please see the manual of the used software). Depending on the software you may

have to dispatch a command like “read GSD-files“.

The GSD-files can be found on the enclosed diskette „AS-i/PROFIBUS-Gateway IBM

PC Software“ in the directory \GSD.

For the professional mode the following GSD-files are available:

bwps1742.gsd

device: AS-i/PROFIBUS-DP Gateway

model name in the GSD-file: „AS-i/DP-Profi“

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

38

issue date 12.10.199 9

Page 39

AS-i/PROFIBUS Gateway

Profibus-DP

Parameterization of the Profibus-DP-Slave

The parameters needed by the gateway are coded in the user-parameters. They contain one byte to select the professional mode, the AS-i configuration data and AS-i parameters for all the AS-i slaves and the statements about user memory bytes to be

read and to be written.

20

user memory

hex

statement

(4bytes)

The fields user memory statement and AS-i configuration data and AS-i (startup-) parameters are optional. However the order of the fields is stipulated. Therefore the following four combinations are possible:

1.

20

hex

2.

20

user memory

hex

statement

(4bytes)

3.

AS-i configuration data

and AS-i (startup-)

parameters of

AS-icircuit1 (62 bytes)

AS-i configuration data

and AS-i (startup-)

parameters of

AS-icircuit2 (62bytes)

20

user memory

hex

statement

(4bytes)

AS-i configuration data

and AS-i (startup-)

parameters of

AS-icircuit1 (62 bytes)

4.

20

user memory

hex

statement

(4bytes)

AS-i configuration data

and AS-i (startup-)

parameters of

AS-icircuit1 (62 bytes)

AS-i configuration data

and AS-i (startup-)

parameters of

AS-icircuit2 (62bytes)

In the cases 1 and 2 no AS-i configuration data and AS-i (startup-) parameters are

stated in the user parameter telegram. In these cases the AS-i configurations stored

in the EEPROM of the AS-i/PROFIBUS Gateway are used. So AS-i can be projected

using the AS-i Control Tools or the push buttons on the device before Profibus is put

into operation.

The fields of the Profibus parameter telegram are constructed as follows:

• user memory statement (4 bytes)

Byte 0: Start address of the user memory window in the input data telegram

(read user memory)

Byte 1: Length of the user memory window in the input data telegram

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

39

Page 40

AS-Interface

Profibus-DP

Byte 2: Start address of the user memory window in the output data telegram

(write user memory)

Byte 3: Length of the user memory window in the output data telegram

If user memory bytes shall only to be read or written, the appurtenant length

byte has to be set to 0.

If no user memory bytes shall be transmitted it is recommended to set the user

memory statement to FF

The maximum length of the user memory window is 128 bytes.

• AS-i configuration data and AS-i (startup) parameters (62 bytes)

For each AS-i slave 2 bytes are used. AS-i slave 0 is disregarded.

In the first byte, the AS-i configuration data is specified. The AS-i ID-code is

coded in the byte's high nibble and the I/O-configuration in its low nibble.

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

ID-code IO-configuration

In the second byte's low nibble, the AS-i (startup) parameters are transmitted.

The upper half of this byte is unused.

Furthermore during the operation of the system AS-i parameters can be transmitted via Profibus in the management channel as described above (command

write parameter).

hex

FF

hex

FF

hex

FF

hex

.

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 0 0 0 P3 P2 P1 P0

unused (=0) AS-i parameter

The default parameter for an AS-i slave is F

0Fhex is stated.

If a slave address is to remain unused, either FF

has to be entered.

, so that normally as second byte

hex

, FF

hex

or 256

hex

The configuration of the DP-slave (I/O data fields) has to be adjusted according

to the highest AS-i slave address.

Example: Parameter telegram for the professional mode:

3 AS-i slaves and transmission of user memory, all slaves AS-i ID 0

Slave 1: 4 inputs

Slave 2: 4 outputs

Slave 3: 2 inputs, 2 outputs

from user memory byte 0 read 4 bytes of user memory

no writing of user memory

user mem. st. slave 1 slave 2 slave 3 slave 4 slave 31

conf

par conf

ID,IO

20 00 04 00 00 00 0F 08 0F 03 0F FF FF

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

40

ID,IO

par conf

ID,IO

par conf

ID,IO

par conf

...

, 256

hex

ID,IO

FF FF

hex

par

issue date 12.10.199 9

Page 41

AS-i/PROFIBUS Gateway

Profibus-DP

(all data stated in hexadecimal code)

Profibus Configuration of the Profibus-DP slave

The Profibus configuration of the AS-i/PROFIBUS Gateways built up out of the following Profibus slots:

process data/AS-i flags of AS-i Master 1

standard identification byte (1..16 bytes) or empty slot

management channel

standard identification byte 0xB2 (3 bytes) or 0xB4 (5 bytes) or empty slot

user memory (AS-i Control)

standard identification byte or extended identification byte (altogether up

to 128 bytes) or empty slot

Empty slots at the end of the configuration telegram can be left out.

In contrast to the easy mode, the size of the I/O window can be matched to the exten-

sion of the AS-i network. Its size in bytes amounts:

(highest AS-i slave address + 1) / 2

Any non-integer value has to be rounded up to a full byte.

If the requested data field length for the user memory is smaller than the calculated

length from the parameter telegram, the gateway will not take up any communication

relationship with the DP-master.

The maximum data field length for input respectively output data is 149 bytes with a

device with one AS-i Master.

8.4 Profibus Diagnosis telegram

Besides the on-the-spot-diagnosis via the figure display and the seven LEDs, there is

also the possibility of a diagnosis via the Profibus-DP. The Profibus diagnosis telegram meets the Profibus norm.

The Profibus diagnosis telegram depends on the operation mode.

8.4.1 Diagnosis telegram in easy mode and advanced mode

The diagnosis telegram contains 9 bytes in the easy mode or the advanced mode.

The structure is represented in the following table.

byte content

0 station status 1

1 station status 1

2 station status 1

3 station number DP-master

4-5 manufacturer code

6 header and length of the device-based diagnosis

7 AS-i slave address

8 type of configuration error

issue date 12.10.199 9

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group · Tel.: Germany (621) 776-0 · USA (330) 4253555 · Singapore 7799091 · Internet http://www.pepperl-fuchs.com

41

Page 42

AS-Interface

Profibus-DP

Whereas the bytes 0 to 5 of the diagnosis telegram are stipulated by the Profibus-DP