Page 1

FACTORY AUTOMATION

MANUAL

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

AS-Interface Motor Control Module

Page 2

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

Page 3

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

1 Introduction................................................................................. 4

1.1 Content of this Document ................................................................... 4

1.2 Target Group, Personnel...................................................................... 4

1.3 Symbols Used ...................................................................................... 4

2 Product Description ................................................................... 6

2.1 Use and Application............................................................................. 6

2.2 Housing................................................................................................. 7

2.3 Displays and Operating Elements ...................................................... 7

2.4 Interfaces and Connections................................................................ 9

3 Installation................................................................................. 11

3.1 Storage and Transport ....................................................................... 11

3.2 Unpacking........................................................................................... 11

3.3 Connecting the AS-Interface and Auxiliary Power Flat Cable ....... 11

3.4 Connecting Motors and Sensors...................................................... 14

4 Commissioning......................................................................... 15

4.1 AS-Interface Communication............................................................ 15

4.2 Configuring the Start/Stop Ramps ................................................... 17

5 Troubleshooting........................................................................ 20

3

Page 4

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

■

Product identification

■

Delivery, transport, and storage

■

Mounting and installation

■

Commissioning and operation

■

Maintenance and repair

■

Troubleshooting

■

Dism ounting

■

Disposal

Note!

For full information on the product, refer to the fur ther documentation on the Internet at

www.pepperl-fuchs.com.

The documentation comprises the following parts:

■

This document

■

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

■

EU-type examination certificate

■

EU declaration of conformity

■

Attestation of conformity

■

Certificates

■

Control drawings

■

Instruction manual

■

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, m aintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

2018-09

4

Page 5

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandator y

that you observe these warning messages for your personal safety and in order to avoid

property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or resu lt in

their complete failure.

Informative Symbols

Note!

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

2018-09

5

Page 6

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Product Description

2 Product Description

2.1 Use and Application

The VAA-4E4A-G20-ZEJ/M2L-P7-GEB motor control module is an AS-Interface connection

module for controlling 1 or 2 DC roller motors. The module is optimized for ITOH Denki

PM...XE/XP motors, but can also be used for compatible DC motors.

To record statuses in the field environment, the module also has 4 inputs for 3-wire sensors

with positive-switching outputs (PNP) or for mechanical contacts. The input characteristic of

the inputs corresponds to type 1 in accordance with EN 61131-2.

The motors are supplied with power via an external auxiliary voltage. Sensors a re supplied

from the AS-Interface. The auxiliary voltage is supplied to the motor control module via a 2nd

flat cable in addition to the AS-Interface flat cable.

■

The permissible auxiliary power is 18 V...30 V.

■

The sensor power supply may be loaded, in total, with 100 mA.

■

For each motor, a maximu m current load of 5 A is permitted briefly (<2 s).

Figure 2.1 VAA- 4E4A-G20-ZE J/M2 L-P7-GEB motor control module

Essential function and application characteristics of the motor control module are:

■

Compact housing for direct mounting in support profiles or cable ducts

■

Connection of the motors/sensors via cable outputs with M8 connectors

■

Piercing technology with gold-plated contact pins for contacting the AS-Interface flat cable

■

Function displays for the bus, external auxiliary voltage, status information, inputs, and

outputs

■

Communication m onitoring

■

Configurable start/stop ram ps for motor control

■

Supply of the connected motors from the external auxiliary voltage

■

Supply of the connected sensors from the AS-Interface

2018-09

6

Page 7

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

53.3

13.5

27.2

152

3.5

18.6

100

136.5

138.5

15

27.5

YELLOW ASI

BLACK AUX

PWR

FAULT

AUX

FUSE1

FUSE2

DIR

MOT1

MOT2

IN1

IN2

IN3

IN4

IN1/3

MOT1

IN2/4

MOT2

Product Description

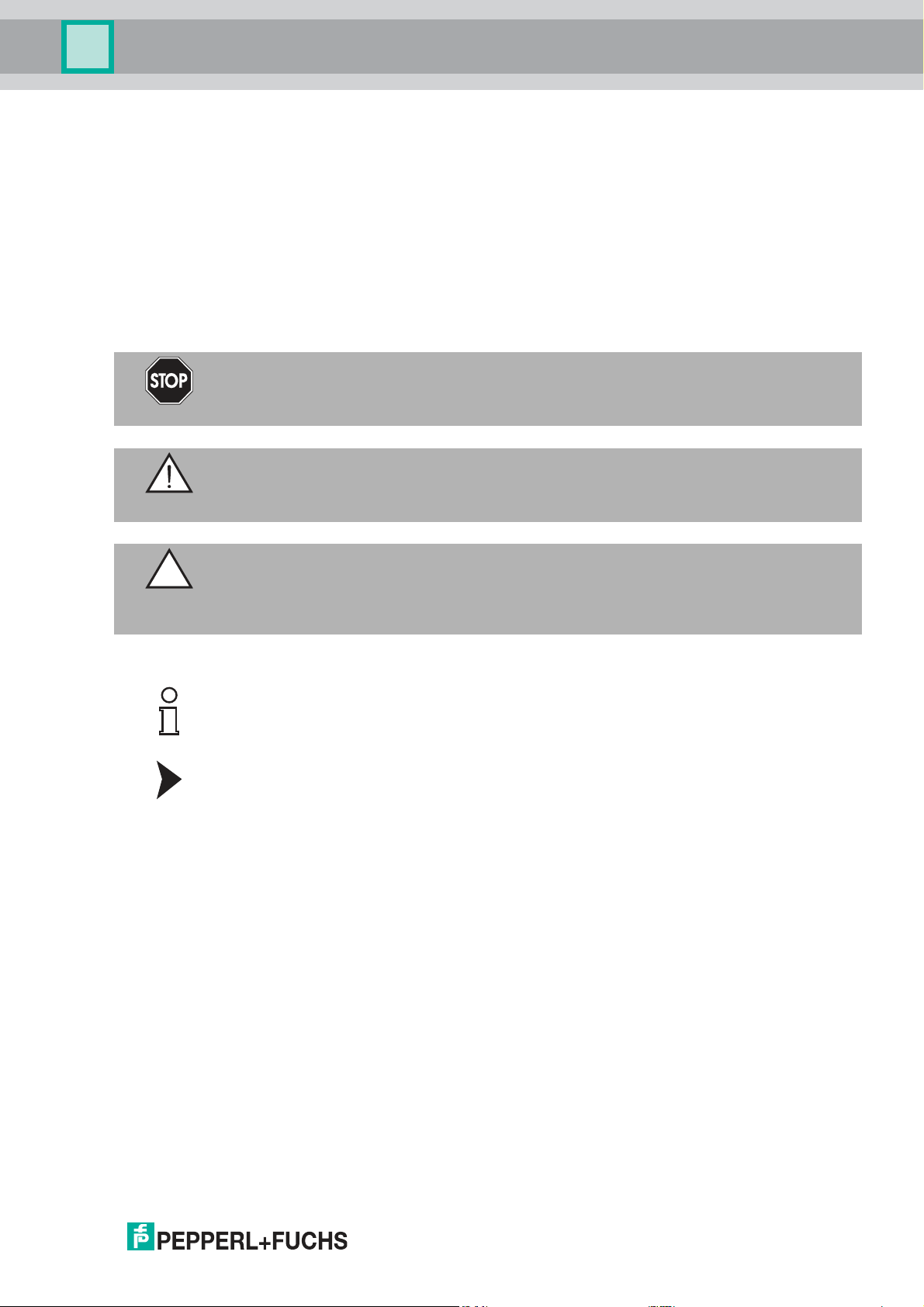

2.2 Housing

The housing is made entirely of plastic, with the exception of the hinge pins for the hinged cable

guide.

The main components are:

■

A mounting base with electronics coated in hot-melt adhesive

■

A folding guide cage as a cable guide for the AS-Interface flat cable.

Figure 2.2 Housing dimensions

2.3 Displays and Operating Elements

Figure 2.3 Status indic ations on the motor control module.

The operating status of the motor control module is displayed via 12 LEDs.

Status Indications for AS-Interface and Power Supply

The PWR LED and the FAULT LED show the AS-Interface operating status. Various error

statuses are displayed as a collective error message "Peripheral fault."

Display of the AS-Interface Operating Statuses

PWR LED, Green FAULT LED, Red Status

On Off AS-Interface power supply is OK

Flashing On Address = 0

On On AS-Interface communication error

2018-09

7

Page 8

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Product Description

PWR LED, Green FAULT LED, Red Status

Flashing Flashing Peripheral fault, collective error message for:

Off Off AS-Interface voltage missing

The AUX LED shows the status of the AUX external auxiliary voltage supply.

Display of the AUX External Auxiliary Voltage Supply

AUX LED

Red/green Status

Green on AUX external auxiliar y voltage is OK

Red on AUX external auxiliary voltage is inverted

Off AUX external auxiliary voltage is m issing

■

AUX external auxiliary power is missing or is

inverted

■

Overload of the sensor supply (IN+, IN-)

■

Overload of the speed signal SPEED

Status Indications for Motor Fuses

The FUSE1 LED for motor 1 and the FUSE2 LED for motor 2 show the status of the power

supplied to the motors.

Motor Fuse Indicator

LED FUSE1

LED FUSE2

Green Status

On Power supply for motor is O K

Off Power supply for motor is missing:

■

Fuse is faulty or

■

AUX external auxiliary voltage is not connected

Note!

Motor Fuses Are Safety Fuses

Fuses w ith a 5 A rated current act as protection against short circuits. Each motor is

safeguarded with a fuse. The fuses are not interchangeable. If a fuse is faulty, the module must

be replaced.

Status Indications for Motors MOT1, MOT2

The MOT1, MOT2, and DIR LEDs display information about the operating states of the

respective motor.

Motor Activity Indicators

LED MOT1

LED MOT2

Yellow Status

On Motor is in operation

Off Motor is off

2018-09

8

Page 9

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Product Description

Motor Direction of Rotation Indicator

LED DIR

Yellow Status

On Direction of rotation to the right (ITOH Denki)

Off Direction of rotation to the left (ITOH Denki)

Status Indicators for Sensors IN1, IN2, IN3, IN4

The LED IN1 for input 1, LED IN2 for input 2, LED IN3 for input 3, and LED IN4 for input 4

indicate the switch states of the inputs.

Display of the Inputs

LED IN1

LED IN2

LED IN3

LED IN4

Yellow Status

On Input is set (high)

Off Input is not set (low)

2.4 Interfaces and Connections

Flat Cable Specification

The AS-Interface motor control module is compatible with the AS-Interface standard cable in

accordance with IEC 62026-2.

The following AS-Interface cable types with "UL Recognized" approval are available:

AS-Interface Cable Types with UL Approval

Pepperl+Fuchs

Designation Color

VAZ-FK-R-YE Yellow TPE/TPE 2x 1.5 mm 2103

VAZ-FK-R-BK Black TPE/TPE 2x 1.5 mm 2103

VAZ-FK-PUR-YE Yellow PUR(TMPU)/TPM 2x 1.5 mm 20549

VAZ-FK-PUR-BK Black PUR(TMPU)/TPM 2x 1.5 mm 20549

Input/Output Connections

The sensors and motors are connected to the motor control module via cables with round M8

connectors:

Sheathing/wire

insulation material Cross section UL "Cable Style" Approval

■

Sensors: socket, 4-pin

■

Motors: socket, 5-pin

The cable length is 0.5 m.

2018-09

9

Page 10

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

3 1

4 2

3 1

4 2

5

Product Description

Motor Supply from Auxiliary Power

The motors are supplied with power directly from the AUX external auxiliary power and this

cannot be switched. The voltage is always present at contacts 1 and 3 of the 5-pin M8

connector.

Connector Assignment

Connection for Connector

Sensor Input: in accordance w ith IEC/EN 61076-2-104

Motor Motor: in accordance with IEC/EN 61076-2-104

Connector type/assignment

M8, 4-pin, socket, screw-locking, coding A

Suitable counterpart connector:

M8, 4-pin, plug, screw-locking, coding A

IN1/IN3

1: IN+ sensor supply

2: IN3: Input

3: IN- sensor supply

4: IN1: Input

IN2/IN4

IN+ sensor supply

IN4: Input

IN- sensor supply

IN2: Input

M8, 5-pin, socket, screw-locking, coding B

Suitable counterpart connector:

M8, 5-pin, plug, screw-locking, coding B

1: MOT+ motor supply

2: DIR direction of rotation

3: MOT- (=AUX-) motor supply

4: RUN motor start

5: SPEED velocity signal

2018-09

10

Page 11

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Installation

3 Installation

3.1 Storage and Transport

For storage and transport purposes, package the unit using shockproof packaging material

and protect it against moisture. The best method of protection is to package the unit using the

original packaging. Furthermore, ensure that the ambient conditions are within allowable range.

3.2 Unpacking

Check the product for damage while unpacking. In the event of damage to the product, inform

the post office or parcel ser vice and notify the supplier.

Retain the original packaging in case the device must be stored or shipped again at a later

date.

Should you have any questions, please contact Pepperl+Fuchs.

3.3 Connecting the AS-Interface and Auxiliary Power Flat Cable

The motor control module is connected to the AS-Interface network and the AUX auxiliary

power via the AS-Interface flat cable. The yellow flat cable is for communication and the black

flat cable is for the AUX auxiliary power. The permissible auxiliary power is 18 V ... 30 V.

Contact between the motor control module and flat cables is established v ia two metal

mandrels and using insulation piercing technology. The flat cables are routed through a hinged

cable guide. When closed, the cable guide is locked using a locking bracket and can be

opened again without the needs for tools.

The profiled flat cables have a narrow upper side (with a visibly offset profile edge) and a wide

under side (profile edge not visible). The cable guide allows the flat cables to be inserted on

both sides, for flexible connection of flat cables already laid in cable ducts. However, you must

make sure that the profile edge always points to the motor control module. Mechanical reverse

polarity protection prevents complete closure of the cable guide if the flat cable is inserted

incorrectly.

Caution!

If one is inserted incorrectly, the motor control module will not work.

If the flat cable is inserted in the cable guide in the wrong direction, the voltage is inverted. The

motor control module will not work. H owever, internal electrical reverse polarity protection

protects it against breakage.

Connecting Flat Cables on the Narrow Side

The profile edge is visible from above.

1. Open the cable guide. To do this, push the locking bracket (1) slightly to one side.

2. Insert the black AUX flat cable with the profile edge (4) to the motor control module into the

lower guide (see the module tag "Black AUX").

3. Insert the yellow AS-Interface flat cable with the profile edge (3) to the motor control module

into the upper guide (see the module tag "YELLOW").

4. Make sure that the profile edges of both flat cables are under the respective reverse polarity

protection (2, 5).

5. Close the cable guide. It must engage securely in the locking bracket (1).

The metal mandrels contact the strands in the flat cables.

2018-09

11

Page 12

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

YELLOW

BLACK AUX

1

2

3

5

4

Installation

Figure 3.1 Connecting Flat Cables on the Narrow Side

Connecting Flat Cables on the Wide Side

The profile edge is not visible from above. For orientation purposes in the figure below, the

edge is shown as a hidden edge drawn with a dotted line.

1. Open the cable guide. To do this, push the locking bracket (1) slightly to one side.

2. Insert the black AUX flat cable with the profile edge (3) to the motor control module into the

lower guide (see the module tag "Black AUX").

3. Insert the yellow AS-Interface flat cable with the profile edge (2) to the motor control module

into the upper guide (see the module tag "YELLOW").

4. Close the cable guide. It must engage securely in the locking bracket (1).

The profile edges (2, 3) of both flat cables are above the two reverse polarity protections.

The metal mandrels contact the strands in the flat cables.

12

2018-09

Page 13

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

YELLOW

BLACK AUX

1

23

1

2

Installation

Figure 3.2 Connecting flat ca bles on the wide side (p rofile edge as dotted line)

Flat Cable Inserted Incorrectly

The figure below shows an incorrectly inserted flat cable. The profile edge (2) does not point to

the motor control module; the flat cable is therefore inserted with reverse polarity. The flat cable

is located on the reverse polarity protection (1) with a curvature, which means that the cable

guide cannot be closed completely (mechanical reverse polarity protection).

2018-09

Figure 3.3 Flat cable inserted incorrectly (profile edge as dotted line)

13

Page 14

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

PWR

AUX+

AUX-

AS-Interface +

AS-Interface -

FAULT

AUX

1

4

3

2

IN

1

2

4

5

3

FUSE

IN1/3

IN+

IN1

ININ3

IN2/4

IN+

IN2

ININ4

MOT1 & MOT2

MOT+

DIR

RUN

SPEED

MOT-

3 1

4 2

M

3 1

4 2

5

DIR

MOT

Installation

3.4 Connecting Motors and Sensors

Figure 3.4 Connection wiring diagram for motors and sensors

14

2018-09

Page 15

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Commissioning

4 Commissioning

4.1 AS-Interface Communication

Assigning the AS-Interface Data Bits

4 data bits are available for communication between the motor control module and the m aster

and 4 data bits are available for controlling the motors.

The following designations apply below:

■

DI0...DI3 for AS-Interface input data (motor control module to master)

■

DO0...DO 3 for AS-Interface output data (master to motor control module)

DI0...DI3 motor control module to master

AS-Interface data bit Input DI

DI0 Switch state input IN1

DI1 Switch state input IN2

DI2 Switch state input IN3

DI3 Switch state input IN4

DO0...DO3 Master to Motor Control Module

AS-Interface data bit Output DO

DO0 Start/stop motor 1

DO1 Start/stop motor 2

DO2 Direction of rotation of motor 1 and motor 2

DO3 Slow rotation speed of motor 1 and motor 2

AS-Interface Communication Monitoring

The motor control module has a watchdog function. If there has been no communication with

the master for more than 40 ms, the motor control module sets the output data DO0...DO3 to

logical 0.

Starting/Stopping the Motors (DO0, DO1)

You can start or stop the motors separately via bits DO 0 and DO1. To start the motors, you

must set the corresponding data bit to logical 1. Via the shared SPEED control signal, the

motor control module uses an analog voltage value to actuate the respective motor that has

been switched on. The SPEED control signal is released for the relevant output only when data

bit DO0 or DO 1 is set. The analog voltage value corresponds to the set speed.

Data Bits DO0, DO1

Data bit State Function Motor start signal RUN LED MOT1/2

DO0 1 Start motor 1 1: ≥ (U

0 Stop motor 1 MOT1: off

DO1 1 Start motor 2 MOT2: on

0 Stop motor 2 MOT2: off

0: high impedance

- 2.5 V) in no-load operation

AUX

MOT1: on

2018-09

15

Page 16

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Commissioning

Switching the Motor Direction of Rotation (DO2)

You can switch the direction of rotation of the motors using the DIR control signal. The direction

of rotation signal applies to both motors. To control the direction of location, you must

param eterize data bit DO2 accordingly.

For ITOH Denki, logical 0 corresponds to a direction of rotation to the left. The motor control

module sw itches the DIR control signal to high impedance.

For ITOH Denki, logical 1 corresponds to a direction of rotation to the right. The m otor control

module sw itches the DIR control signal to AUX level.

Data Bit DO2

Data bit State Function DIR direction of rotation signal LED DIR

DO2 0 Direction of rotation left High impedance, approx. 0 V Off

1 Direction of rotation right ≥ (U

operation

Switching the Motor Speed (DO3)

- 2.5 V) in no-load

AUX

On

You can switch both motors to a slow speed via data bit DO3. The slow speed is determined

based on the set speed.

Data Bit DO3

Data bit State Function

DO3 0 Fast speed

1 Slow speed

Adjusting the Motor Speed (P0 ... P2)

You can adjust the speed via parameter bits P0...P2. This always applies to both motors

simultaneously. To do this, you must pa rameterize 1 of 8 predefined speed values. The speed

values correspond to analog voltage values.

If the master does not change the parameter bits when the AS-Interface network is switched

on, the 8th speed value (9.7 V) is set by default on the motor control module.

Geschwindigkeitswert (9,7 V) voreingestellt.

Using data bit DO3, you can switch the speed of both motors between fast and slow.

The motor control module issues the set control voltage to the motors via the SPEED control

signal as soon as the motors are switched on via data bits DO0 and DO1 (logical 1). The

control voltage is readjusted by the motor control module and is therefore independent of the

load within certain limits. If the control limits are exceeded due to an excessive load, the motor

control module issues a peripheral fault.

Parameter Bits P0 ... P2

DO0 (MOT1)

P2 P1 P0

x x x 0 < 1 V < 1 V

0 0 0 1 2.7 V 0.7 V

0 0 1 1 3.7 V 0.7 V

0 1 0 1 4.7 V 1.7 V

0 1 1 1 5.7 V 1.7 V

1 0 0 1 6.7 V 2.7 V

1 0 1 1 7.7 V 2.7 V

or DO 1 (MOT2)

Speed signal U

Fast (D3=0) Slow (D3=1)

S

16

2018-09

Page 17

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Commissioning

DO0 (MOT1)

P2 P1 P0

1 1 0 1 8.7 V 3.7 V

1 1 1 1 9.7 V 4.7 V

or DO1 (MOT2)

Speed signal U

Fast (D3=0) Slow (D3=1)

S

Default setting

Reversing the Direction of Rotation of MOT2 (P3)

You can reverse the direction of rotation of MOT2 via parameter bit P3.

Parameter Bit P3

Parameter bit State Function

P3 0 counter-rotating; direction of rotation of MOT2 inverted

1 synchronized, direction of rotation of MOT1 = direction of rotation of MOT2

(Default setting)

Status of Sensor Inputs (DI0 ... DI3)

The motor control module transfers the switch states of inputs IN1 to IN4 to the master via data

bits DI0 (IN 1) to DI3 (IN4).

There is a filter upstream of the inputs that suppresses pulses ≤ 2 ms.

Data Bits DI0 ... DI3

Data bit State Input switching status LEDs IN1 ... IN 4

DI0 0 Unattenuated, IIN ≤ 0.5 mA IN1: off

1 Attenuated, IIN ≥ 2.0 mA IN1: on

DI1 0 Unattenuated, IIN ≤ 0.5 mA IN2: off

1 Attenuated, IIN ≥ 2.0 mA IN2: on

DI2 0 Unattenuated, IIN ≤ 0.5 mA IN3: off

1 Attenuated, IIN ≥ 2.0 mA IN3: on

DI3 0 Unattenuated, IIN ≤ 0.5 mA IN4: off

1 Attenuated, IIN ≥ 2.0 mA IN4: on

4.2 Configuring the Start/Stop Ramps

Overview

To control the acceleration and to stop the motors, you can set 1 of 8 defined start/stop ramps

for the speed signal SPEED. These ramps always apply to both m otors simultaneously. The

ramp duration corresponds to the time from stopped to reaching the maximum speed or from

the maximum speed to stopped. The inclines of the ramps are constant for each of the 8 ramps

and independent of the set speed. The reference value for all ramps is the speed signal

SPEED = 9.7 V. For a lower parameterized speed, the ramp duration is proportionally shorter.

2018-09

17

Page 18

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Commissioning

Predefined Start/Stop Ramps

Ramp no. Ramp duration

0 no ramp

1 50 ms

2 100 ms

3 200 ms

4 300 ms

5 500 ms (default setting)

6 1000 ms

7 1500 ms

The ramp is not effective if the direction of rotation signal is switched when the motor is active.

In this case, the direction of rotation is reversed immediately.

Note!

Default Setting on Delivery

On outbound delivery, ramp no. 5 (500 ms) is the default.

Configuring Start/Stop Ramps

To adjust a start/stop ram p, you must change the motor control module to configuration mode.

The motor control module stores a new ramp configuration in the internal non-volatile memory.

This ramp is activated automatically after each switch-on. You can reconfigure a ram p as often

as required.

A prerequisite for configuration is that the flat cables for the AS-Interface and AUX are

connected. Communication must already be taking place between the master and motor

control module.

Note!

Configuration Mode Display via LEDs

If the motor control module is in configuration mode, the MOT1 and MOT2 LEDs flash

simultaneously at a frequency of approx. 2 Hz .

The configuration sequence consists of 9 steps. As part of this, defined data is transferred via

data bits DO0 ... DO3 and parameter bits P0... P3 between the m aster and the motor control

module. The master must keep the data and param eter bits constant for at least 10 ms for each

step. Longer intervals are possible as long as a period of 10 s is not exceeded for steps 1...6.

Configuring a new start/stop ramp involves the following phases:

■

In steps 1 ... 6, the master sends param eter values to the motor control module to activate

configuration mode (max. 10 s). For each step, DO0 ... DO3 must have the data value "4."

■

As soon as the motor control module is in configuration m ode, the 2 MOT1 and MOT2

LEDs start to flash.

18

■

In step 7, the master sends the selected ramp no. via DO0 ... DO3 to the motor control

module.

■

In step 8, the master sends the parameter value "4" via P0 ... P3 to the motor control

module. The motor control module stores the ram p number in the non-volatile memory.

■

In step 9, the master exits configuration mode. It sends the data value "4" via DO0 ... DO3

and the data value "7" via P0 ... P3. The motor control module switches to normal mode.

The MOT1 and MOT2 LEDs stop flashing.

2018-09

Page 19

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Commissioning

Note!

Sequence for Com mand Transmission

For each step, you generally send the data value via DO0 ... D03 first, and then the parameter

value P0 ... P3. The following table depicts the contexts of the communication between the

master and the motor control module. The value "x" represents any of the values in the table.

Sequence for Configuring a Start/Stop Ramp

Send the following data values and parameter values to the motor control module:

1. For each of steps 1...6, send the data value "4" via DO0 ... DO3 as well as, via P0 ... P3, the

corresponding value from the parameter sequence 3,1,6,3,1,6.

2. If configuration mode is active, as step 7, send the required ramp no. via DO0 ... DO3 and

via P0 ... P3 the parameter value "6."

3. As step 8, send the ramp no. again via DO0 ... DO3 and via P0 ... P3 the parameter value

"4."

4. As step 9 send data value "0" via DO0 ... DO3 and via P0 ... P3 the parameter value "7."

The motor control module has stored the new start/stop ramp and switched back to

normal mode.

Contexts of Module Communication

Step DO0...DO3 P0...P3 Comment

≠ 4 x Motor control module in normal mode

1 4 3 Start activation sequence for configuration mode

2 4 1

3 4 6

4 4 3

5 4 1

6 4 6 End activation sequence for configuration mode.

7 Ramp no. 6 Transfer of the ramp number to the motor control module

8 Ramp no. 4 The ramp is stored

9 0 7 Motor control module switches back to normal mode

Troubleshooting during Configuration

The following table describes the behavior of the motor control module if a fault occurs during

the 9-step configuration process.

Fault Scenarios

Step Possible fault Motor control module reaction

1 ... 6

7 or 8 Incorrect data or parameter values

2018-09

■

Incorrect data or parameter values or

■

steps 1 to 6 take longer than 10 s

Motor control module remains in normal mode

■

The motor control module changes to

normal operation only when the master

sends "0" via DO0 ... DO3 and "7" via P0 ...

P3.

■

If "0" or "7" has already been set by the

master in one of these steps, the motor

control module switches directly to normal

operation. The stored ramp is not

changed.

19

Page 20

VAA-4E4A-G20-ZEJ/M2L-P7-GEB

Troubleshooting

5 Troubleshooting

Fault Information and Remedy

Error LED indicator Possible cause Remedy

No data

communication

with AS-Interface

master

Motors will not

start

Sensors or

inputs IN1 ... IN4

not working

PWR off AS-Interface voltage is missing or is

inverted

PWR flashes and

FAULT on

PWR on and

FAULT on

AUX off AUX external power supply is

AUX red on AUX external power supply is

AUX green on

and

FUSE1 (motor 1)

off and/or FUSE2

(motor 2) off

PWR and FAULT

flash alternately

PWR and FAULT

flash alternately

Module address is 0 Program module address

AS-Interface Master is not switched

on (offline) or

There is duplicate addressing

missing

inverted

Motor fuse is faulty due to

overloading of the motor supply

Peripheral fault "Overload speed

signal SPEED:"

Motor, motor cable, or motor control

module is faulty

Peripheral fault: overload on sensor

supply

Check AS-Interface wiring

Switch on the AS-Interface master

or

Check the addresses of all modules

on the AS-Interface segment

Check AUX voltage and AUX flat

cable

Correct the polarity of the AUX flat

cable in the cable guide

Replace the m otor control module

(cannot be repaired) and remove

the cause of the overload before

starting the motor again

Replace motor or motor control

module

Check the sensors and eliminate

the overload

20

2018-09

Page 21

FACTORY AUTOMATION –

SENSING YOUR NEEDS

Worldwide Headquarters

Pepperl+Fuchs GmbH

68307 Mannheim · Germany

Tel. +49 621 776-0

E-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc.

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555

E-mail: sales@us.pepperl-fuchs.com

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd.

Company Registration No. 199003130E

Singapore 139942

Tel. +65 67799091

E-mail: sales@sg.pepperl-fuchs.com

www.pepperl-fuchs.com

Subject to modifications

Copyright PEPPERL+FUCHS • Printed in Germany

/ DOCT-6161

09/2018

Loading...

Loading...