Page 1

Instruction Manual

AS-Interface Safety at Work

VAA-2E2A-KE1-S/E2

Version 1.0

FACTORY AUTOMATION

Page 2

With regard to the supply of products, the current issue of the following document is applicable: The General

published by the Ce ntral Association of the "Elektrotechnik und Elektroindustrie (ZVEI) e.V.

in their most recent version as well as the supplementary clause: "Extended reservation of title".

For this reason, this printed matter is produced on paper bleached without the use of chlorine.

Terms of Delivery for Products and Services of the Electrical Industry,

We at Pepperl+Fuchs recognise a duty to make a contribution to the future,

Page 3

VAA-2E2A-KE1-S/E2

S

Table of contents

1 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Symbols used in this document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.1 Non-secure outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.2 Requirements for the safety monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.3 Requirements for wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1.4 Switches or sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Transfer time of the safety-relevant information . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 PFD-calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Working principles of the module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Safety related inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Non-secure outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Connections and displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Interface properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 AS-Interface, auxiliary energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2.2 Safety category . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2.3 Cross fault monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.1 Requirements for configuring the safety monitor . . . . . . . . . . . . . . . . . . . . . . 13

7.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.3 Addressing modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.4 Function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.5 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8 Operation of AS-Interface safety modules . . . . . . . . . . . . . . . . . . . . . . 14

9 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

A Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

A.1 Category 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

A.2 Category 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

A.3 Category 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

B Summery of the requirements for categories . . . . . . . . . . . . . . . . . . . 20

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

1

Page 4

VAA-2E2A-KE1-S/E2

S

Declaration of conformity

1 Declaration of conformity

The AS-Interface safety module VAA-2E2A-KE1-S/E2 with 2 safety-related inputs for

mechanical switches and 2 non-safety related outputs was developed and manufactured in observance of applicable European standards and regulations.

A corresponding declaration of conformity can be requested from the

manufacturer.

The manufacturer of the product, Pepperl+Fuchs GmbH in D-68307 Mannheim, has

a certified quality assurance program in accordance with ISO 9001.

ISO

9001

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

2

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 5

S

2 Symbols used in this document

This symbol warns of danger .

In the event the warning is ignored, the consequences may range from

personal injury to death of persons or from damage to destruction of

equipment.

This symbol warns of a possible fault.

Failure to observe may result in damage to the device or systems and

installations connected to it up to and including compete lack of proper

functionality.

This symbol brings important information to your attention.

VAA-2E2A-KE1-S/E2

Symbols used in this document

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

3

Page 6

VAA-2E2A-KE1-S/E2

S

Safety

3 Safety

3.1 Intended use

The AS-Interface safety module described here, when used properly in combination

with an AS-Interface safety monitor programmed appropriately, allows for operation

of sensor-controlled devices for protection of persons up to Category 4 according to

EN 954-1 or up to SIL 3 according to EN/IEC 61508.

Protection of operating personnel and the system is not ensured if the

module is not used in accordance with its intended purpose.

3.1.1 Non-secure outputs

The outputs must not be used for safety-related functions.

3.1.2 Requirements for the safety monitor

The module must only be used in a proper manner as a safety-related slave on an

AS-Interface line with the corresponding AS-i safety monitor. The AS-Interface safety

monitor must meet the requirements of the system specification "Specification of safe

AS-Interface transfer" Version 2.01 dated May12, 2000.

All components must be evaluated for functionality according to this safety standard

for the evaluation of a safety-related function.

The correct execution of the desired safety function also depends on the wiring and

programming of the safety monitor. This also applies to the desired safety response

after a code malfuntion or failure. See also the documentation for the safety monitor.

The safety function (including all safety-related sensors) must be tested before it is

placed in service the first time.

3.1.3 Requirements for wiring

The requirements of EN/IEC 60204-1 (or similar standard) must always be observed.

The requirements for external wiring and the selection of sensors that are connected

are based on both the functionality to be provided as well as the required category

(EN 954-1/ISO 13849-1 or EN/IEC 61508). The category can be determined by

means of a risk analysis (for example as described by EN1050) or can be derived

from a C standard. The category or SIL of the safety monitor must at least correspond

to the category or SIL required by the application.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

4

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 7

VAA-2E2A-KE1-S/E2

S

3.1.4 Switches or mechanical contacts

The switches must either be of the forced-opening variety or must have a defined failure behaviour. Combinations of switches that ensure comparable safety (error behaviour analysis) can be used.

3.2 General safety instructions

Any type of operation other than what is described in the instructions

places the safety and functionality of the module and connected systems in question.

The module can only be operated by trained professionals in accordance with the

available instruction manual (see section 8).

Connecting modules and performing maintenance tasks while the devices are connected to a power source must only be performed by trained electrical specialists.

If malfunctions cannot be eliminated, the module must be taken out of operation and

protected from being inadvertently placed back in operation.

Repairs must only be performed directly by the manufacturer.

Making changes to or tampering with the device is not permitted and will render the

warranty void.

When operating the device, care must be taken to ensure that the requirements for

installation of a housing in IP20 are also maintained.

The plant management is responsible for heeding local safety regulations.

Safety

3.3 Transfer time of the safety-relevant information

The transfer time depends essentially on the monitor. The corresponding documentation and the switch-off times of the actuators must be observed.

3.4 PFD-calculation

To calculate the PFD (probability of failure on demand) of a safety-related function, all

PFD values of all components used in this function must be taken into consideration.

The AS-Interface safety slave does not make any significant contribution to the PFD

or PDH (probability of dangerous failure per hour) of the overall system.

For the PFD or PFH-values of other components, especially of the safety monitor,

please refer to the relevant documentation.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

5

Page 8

VAA-2E2A-KE1-S/E2

S

Working principles of the module

4 Working principles of the module

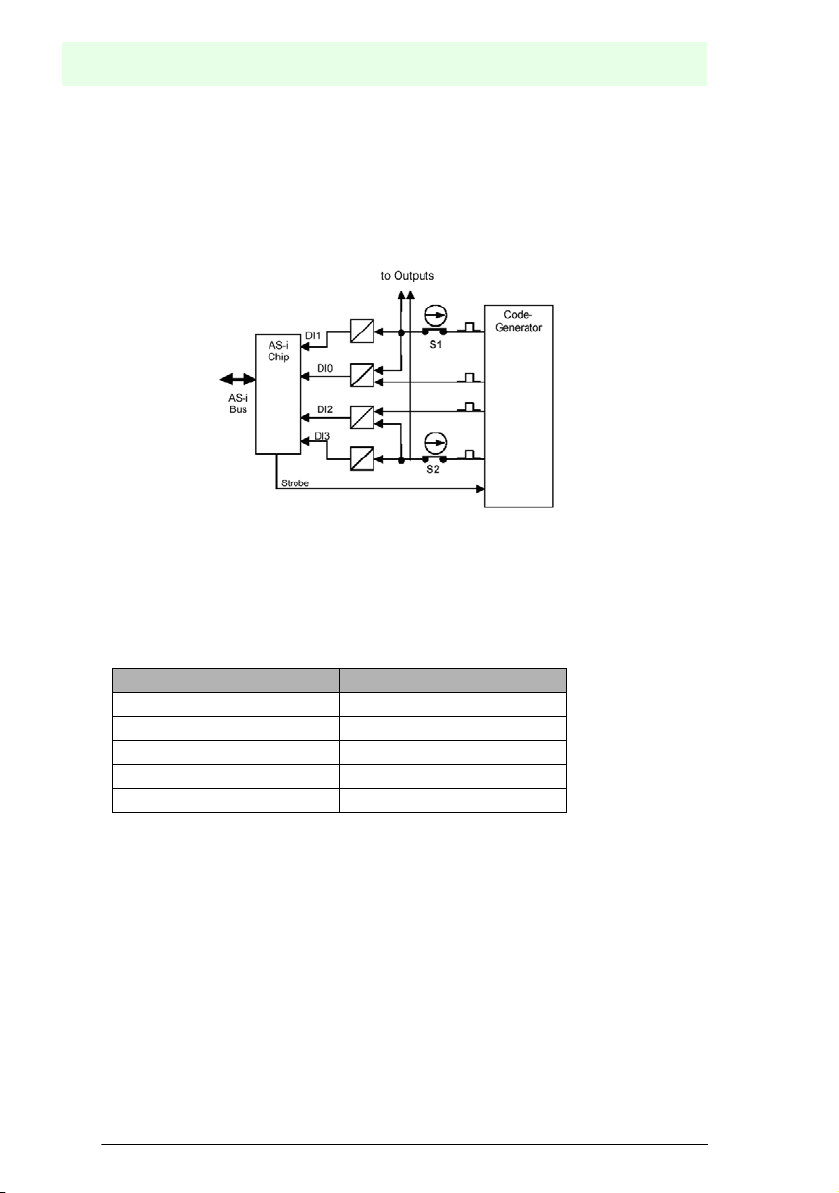

4.1 Safety related inputs

The module generates a code sequence internally. This code sequence is monitored

by a safety monitor (an additional bus station) for the correct sequence.

.

Figure 4.1: Code generation

The transfer of the code sequence is affected by the status of the externally connected mechanical switch.

Information on the activation of the connected mechanical switches (e. g. for emergency stop button activated, code transfer interrupted) is transferred as follows:

Activated input channel Code

DI3 DI2 DI1 DI0

1XX00

200XX

1 and 2 0 0 0 0

none X X X X

Code words 0000, XX00 and 00XX cause the safety monitor to bring the system to a

secure state (for example with the emergency stop button) without reporting a malfunction. If a bit of a code word deviates from the nominal code word, the safety monitor switches the system into the secure state and signals a malfunction of the slave.

The two input channels of the safety module are independent of each other. Parameters can be set in the safety monitor for monitoring the synchronicity of the two inputs

for two-channel applications. For more information, see also the application examples

in Appendix A.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

6

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 9

VAA-2E2A-KE1-S/E2

S

Working principles of the module

.

Figure 4.2: Example: An emergency off button with two separate circuits is assigned to both module inputs.

4.2 Non-secure outputs

The outputs are designed according to the AS-Interface standard. These are switched

to positive potential (PNP technology).

The state of the outputs is set according to the operating mode, which in turn is adjusted by parameter on the AS-Interface master, either switched by the master or derived from the states of the inputs. For a more detailed description, see section 6.3.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

7

Page 10

VAA-2E2A-KE1-S/E2

S

Connections and displays

5 Connections and displays

.

S+1 S-1 S+2 S-2

1

S

FAULT

PWR

ADDR

OUT

01

AS-i AS-i

5.1 Connections

Safety related inputs Outputs and others

Designation Description Designation Description

S1+ Mechanical switch 1+ O1 Output 1+

S1+- Mechanical switch 1- O-1 Output 1-

S2+ Mechanical switch 2+ O2 Output 2+

S2- Mechanical switch 2- O-2 Output 2-

S

AUX

122

01

02

02

AUX AUX

++

ASi+ AS-Interface +

ASi- AS-Interface -

AUX+ Auxiliary power U

AUX- Auxiliary power U

AUX

AUX

+

-

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

8

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 11

VAA-2E2A-KE1-S/E2

S

Connections and displays

5.2 Displays

Designation Description Designation Description

S1 Yellow LED,

switching state of input

circuit 1

S2 Yellow LED,

switching state of input

circuit 2

PWR Green LED,

AS-Interface power

FAULT Red LED,

AS-Interface communication error

AUX Green LED,

auxiliary power

OUT1 Yellow LED,

switching state of

output 1, U

through with active LED

OUT2 Yellow LED,

switching state of

output 2, U

through with active LED

+ switched

AUX

+ switched

AUX

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

9

Page 12

VAA-2E2A-KE1-S/E2

S

Interface properties

6 Interface properties

6.1 AS-Interface, auxiliary energy

In case of the KE1-series all interfaces are connected via removable terminals. Thus

also AS-Interface and auxiliary energy. The cable has to meet the minimum requirements for AS-Interface (e.g. AS-Interface flat band cable, VAZ-FK-S-YE for AS-Interface and VAZ-FK-S-BK for auxiliary energy).

6.2 Inputs

6.2.1 General

In this case the switches are also connected to removable terminals. One or more mechanical switches, switched in series, can be connected per channel.

.

Figure 6.1: 2 mechanical switches (or one two-channel switch)

.

Figure 6.2: 1 mechanical switch

If only one single-channel switch is used, input 1 must be used for this purpose. If input 2 is to remain unswitched, it must be jumpered.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

10

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 13

VAA-2E2A-KE1-S/E2

S

Interface properties

6.2.2 Safety category

The module contains two input channels independent of each other and redundantly

structured that individually meet the requirements of Category 4 according to

EN 954-1.

6.2.3 Cross fault monitoring

The inputs are monitored for cross fault with each other. Cross fault monitoring is capable of detecting low-resistance cross faults between the two inputs caused by a metallic connection.

6.3 Outputs

The outputs are designed according to the AS-Interface standard. These are switched

to positive potential (PNP technology).

The outputs can be operated in two modes:

1. The outputs are controlled directly by the corresponding data bits of the AS-Interface master.

2. The output signals of the AS-Interface master are linked with the secure inputs. The

outputs are turned on if the master turns them on or if the inputs are in a secure

state.

This operating mode is used to control signal lights that must display the state of

the inputs without the master being involved.

.

Figure 6.3: Output modes

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

11

Page 14

VAA-2E2A-KE1-S/E2

S

Interface properties

Modes and logic table of the outputs

The modes are selected by the Master with parameter bit P0:

P0

S1 / S2 1)DO0 / DO1

1

X / X 0 / 0 0 / 0

X / X 1 / 1 1 / 1

2)

OUT1 / OUT2 Mode

Outputs independent of

inputs

Open switch at the input

0 / 0 X / X 1 / 1

0

1 / 1 0 / 0 0 / 0 When the switches are

1 / 1 1 / 1 1 / 1

1)

0 corresponds to an open switch (secure state). 1 means closed switch.

X means any state that has no effect on the outputs.

2)

1 means outputs are turned on, 0 means outputs are voltage-free.

sets the corresponding

output

closed on the input, the

master controls the output

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

12

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 15

VAA-2E2A-KE1-S/E2

S

Commissioning

7 Commissioning

7.1 Requirements for configuring the safety monitor

On measures related to the safety monitor that are required for organisation, please

refer to the safety monitor documentation.

7.2 Installation

For installation of the module a suitable top hat DIN rail in accordance with DIN 50022

is recommended.

7.3 Addressing modules

Addressing of the module is performed by means of a manual addressing device or

with an AS-Interface master. If a manual addressing device is used, it should be connected and addressed to the addressing socket of the module (identified with ADDR)

using the addressing cable included with delivery. Addresses from 1 to 31 can be assigned. The state as supplied is address 0.

7.4 Function test

Function tests must be performed as part of the installation. Because of the cross fault

monitoring of the secure inputs, there is no need for a test for short circuits in the wiring. The function test covers all faults present at the time of installation.

7.5 Operating modes

No operating modes can be switched for the inputs. The parameters in the AS-Interface can affect the behaviour of the outputs. For a more detailed description of connecting peripheral devices, consult section 5.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

13

Page 16

VAA-2E2A-KE1-S/E2

S

Certificates

8 Operation of AS-Interface safety modules

The safety function of the module is determined by how the monitor is programmed.

Please observe the corresponding documentation. Depending on the safety category,

regular function tests may not be required.

9 Certificates

Approvals according to EN 954-1/ISO 13849-1 and EN/IEC 61508.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

14

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 17

VAA-2E2A-KE1-S/E2

S

Application examples

A Application examples

The examples listed here correspond to our understanding of the categories according to EN 954-1 and should not be seen as binding.

A.1 Category 2

The safety function(s) must be tested at appropriate intervals of time by the machine

control system. Loss of the safety function will be detected by the test. The test intervals must be adjusted to match the application.

Connecting two independent mechanical position switches of Category 2:

.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

15

Page 18

VAA-2E2A-KE1-S/E2

S

Application examples

A.2 Category 3

Occurrence of a fault must not result in a loss of the safety function.

Connecting two dependent mechanical position switches per channel (2 safety functions)

Example 1

.

Example 2

If the possibility of a dangerous failure (short circuit) of the switch cannot be excluded,

these switches must be doubled and switched in series.

.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

16

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 19

VAA-2E2A-KE1-S/E2

S

Application examples

Example 3

If the possibility of a short circuit in the wiring cannot be excluded with the switches,

both channels are required to achieve a Category 3 safety function.

.

.

Parameters can be set for the following function modules to achieve safety category

3 in this application while the AS-Interface safety module is in operation on a safety

monitor (for example VAS-1A-K12 or VAS-2A-K12):

Example 1 and 2:

Dual channel independent

Example 3:

Dual channel dependent

Dual channel force-guided

The function module 'two-channel independent' must not be used

in example 3.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

17

Page 20

VAA-2E2A-KE1-S/E2

S

Application examples

A.3 Category 4

Occurrence of a fault and an accumulation of faults must result in a loss of the safety

function.

Example 1

Connecting a dual-channel mechanical position switch.

The safety function must be tested to detect a dangerous accumulation of faults. The

test intervals must be adjusted to match the application.

.

Example 2

If it is not possible to exclude a dangerous failure (short circuit) for the switches, two

dependent mechanical switches must be used for each channel. The safety function

must be tested to detect a dangerous accumulation of faults. The test intervals must

be adjusted to match the application.

.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

18

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 21

VAA-2E2A-KE1-S/E2

S

Application examples

Parameters can be set for the following function modules to achieve safety category

4 in this application while the AS-Interface safety module is in operation on a safety

monitor (for example VAS-1A-K12 or VAS-2A-K12):

Dual channel force-guided

Dual channel dependent

The function module 'two-channel independent' must not be used.

The cable length between the VAA-2E2A-KE1-S/E2 and the sensor is

limited to 30 m.

Date of Issue 2003-11-28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

19

Page 22

VAA-2E2A-KE1-S/E2

S

Summery of the requirements for categories

B Summery of the requirements for categories

to EN 954-1/ISO 13849-1

Summary of requirements System behaviour 1)Important prin-

ciple for

achieving

Category

The safety-related parts of the machine control

B

system and/or their components must be

designed, constructed, selected, put together

and combined to meet the requirements of the

corresponding standards in such a manner as to

be able to withstand anticipated effects.

The requirements of B must be met.

1

Use of components and principles with proven

safety-related effectiveness

The requirements of B and the use of compo-

2

nents and principles with proven safety-related

effectiveness must be satisfied.The safety function(s) must be tested at appropriate intervals of

time by the machine control system.

NOTE:

What is suitable depends on the application and

the type of machine.

The requirements of B and the use of compo-

3

nents and principles with proven safety-related

effectiveness must be satisfied.

The control systems must be designed in such a

manner that:

• an individual fault in the control system does

not result in a loss of the safety function an d

• the individual fault is dete cted whenever it is

practical to do so in a reasonable manner.

The requirements of B and the use of compo-

4

nents and principles with proven safety-related

effectiveness must be satisfied.

The control systems must be designed in such a

manner that:

• an individual fault in the control system does

not result in a loss of the safety function an d

• the individual fault is dete cted during or before

the next requirement for the safety function. If

this is not possible, then it must not be possible

for an accumulation of faults to result in loss of

the safety function.

1)

The risk evaluation indicates whether the complete or partial loss of safety function(s) resulting from

the occurrence of faults is acceptable.

If a fault occurs, it may

result in a loss of the safety

function.

As described for Category

B, but with higher safetyrelated reliability of the

safety function

• The occurrence of a fault

may result in a loss of the

safety function between

testing intervals.

• Loss of the safety function

will be detected by the

test.

• If the individual fault

occurs, the safety function

still remains intact.

• Some but not all fau lts are

detected.

• An accumulation of

unknown faults may result

in a loss of the safety

function.

If errors occur, the safety

function still remains intact.

The fault is detected with

sufficient time to prevent a

loss of the safety function.

safety

By selection of

components

by the structure

Date of ISsue 2003-11- 28

ubject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

20

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Page 23

With regard to the supply of products, the current issue of the following document is applicable: The General Terms of

published by the Central Association of the "Elektrotechnik und Elektroindustrie (ZVEI) e.V.

in their most recent version as well as the supplementary clause: "Extended reservation of title".

For this reason, this printed matter is produced on paper bleached without the use of chlorine.

Delivery for Products and Services of the Electrical Industry,

We at Pepperl+Fuchs recognise a duty to make a contribution to the future,

Page 24

d

o

l

f

r

o

w

e

h

t

r

o

f

s

l

a

n

g

i

S

a

u

t

o

m

a

t

i

o

n

www.pepperl-fuchs.com

Worldwide Headquarters

Pepperl+Fuchs GmbH · Königsberger Allee 87

68307 Mannheim · Germany

Tel. +49 621 776-0 · Fax +49 621 776-1000

e-mail: info@de.pepperl-fuchs.com

USA Headquarters

Pepperl+Fuchs Inc. · 1600 Enterprise Parkway

Twinsburg, Ohio 44087 · USA

Tel. +1 330 4253555 · Fax +1 330 4254607

e-mail: sales@us.pepperl-fuchs.com

Subject to reasonable modifications due to technical advances Copyright PEPPERL+FUCHS Printed in Germany

Asia Pacific Headquarters

Pepperl+Fuchs Pte Ltd. · P+F Building

18 Ayer Rajah Crescent · Singapore 139942

Tel. +65 67799091 · Fax +65 68731637

e-mail: sales@sg.pepperl-fuchs.com

SIGNALS FOR THE WORLD OF AUTOMATION

130863 11/03 01

Loading...

Loading...