Ultrasonic sensor UMB800-18H40-U-2M-FA

Technical data

General specifications

Sensing range 70 ... 800 mm

Adjustment range 90 ... 800 mm

Dead band 0 ... 70 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 170 kHz

Response delay approx. 100 ms

Electrical specifications

Model Number

UMB800-18H40-U-2M-FA

Single head system

Features

• Front of transducer and housing

manufactured entirely from

stainless steel

• Hygienic design, easy to clean

• Degree of protection IP68 / IP69K

• Short version: 55 mm

• Mounting bracket MH-18H-01-FA

included in delivery

•Program input

• Temperature compensation

Description

Functional description

The enclosure and transducer of this ultrasonic sensor

form a hermetically sealed unit. Due to its special

design, this sensor is EHEDG compliant, and together

with an appropriate fixture are especially suitable for

applications where there are increased hygiene

requirements, such as in the manufacture and handling

of food.

For reliable operation, due to the special design of this

sensor, solely the enclosed mounting accessories must

be used, even in applications without special hygiene

requirements.

Operating voltage U

No-load supply current I

Input

Input type 1 program input

Output

Output type 1 analog output 0 ... 10 V , short-circuit/overload protected

Resolution 0.4 mm at max. sensing range

Deviation of the characteristic curve ± 1 % of full-scale value

Repeat accuracy ± 0.5 % of full-scale value

Load impedance > 1 kOhm

Temperature influence ± 1.5 % of full-scale value

Ambient conditions

Ambient temperature -25 ... 85 °C (-13 ... 185 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type cable PUR , 2 m , Polyether based

Core cross-section 4 x 0.19 mm

Degree of protection IP68 / IP69K

Material

Housing stainless steel 1.4404 / AISI 316L

Transducer Stainless steel 1.4435 / AISI 316L

Seal Cable seal : TPU , Elastollan 1185 A10 (FDA)

Mass 90 g

Factory settings

Output evaluation limit A1: 90 mm

General information

Supplementary information FDA: All materials used for the sensor comply with CFR, title

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

CCC approval CCC approval / marking not required for products rated ≤36 V

EHEDG Type EL Class I AUX

ECOLAB yes

B

0

Dimensions

15 ... 30 V DC

≤ 15 mA

operating distance 1: -U

... +U

B

input impedance: > 4,7 kΩ program pulse: ≥ 1 s

2

evaluation limit A2: 800 mm

Output mode: rising ramp

21, §177.2600 (FDA)

IEC 60947-5-2:2007 + A1:2012

EN 60947-5-7:2003

IEC 60947-5-7:2003

... +1 V, operating d istance 2: +6 V

B

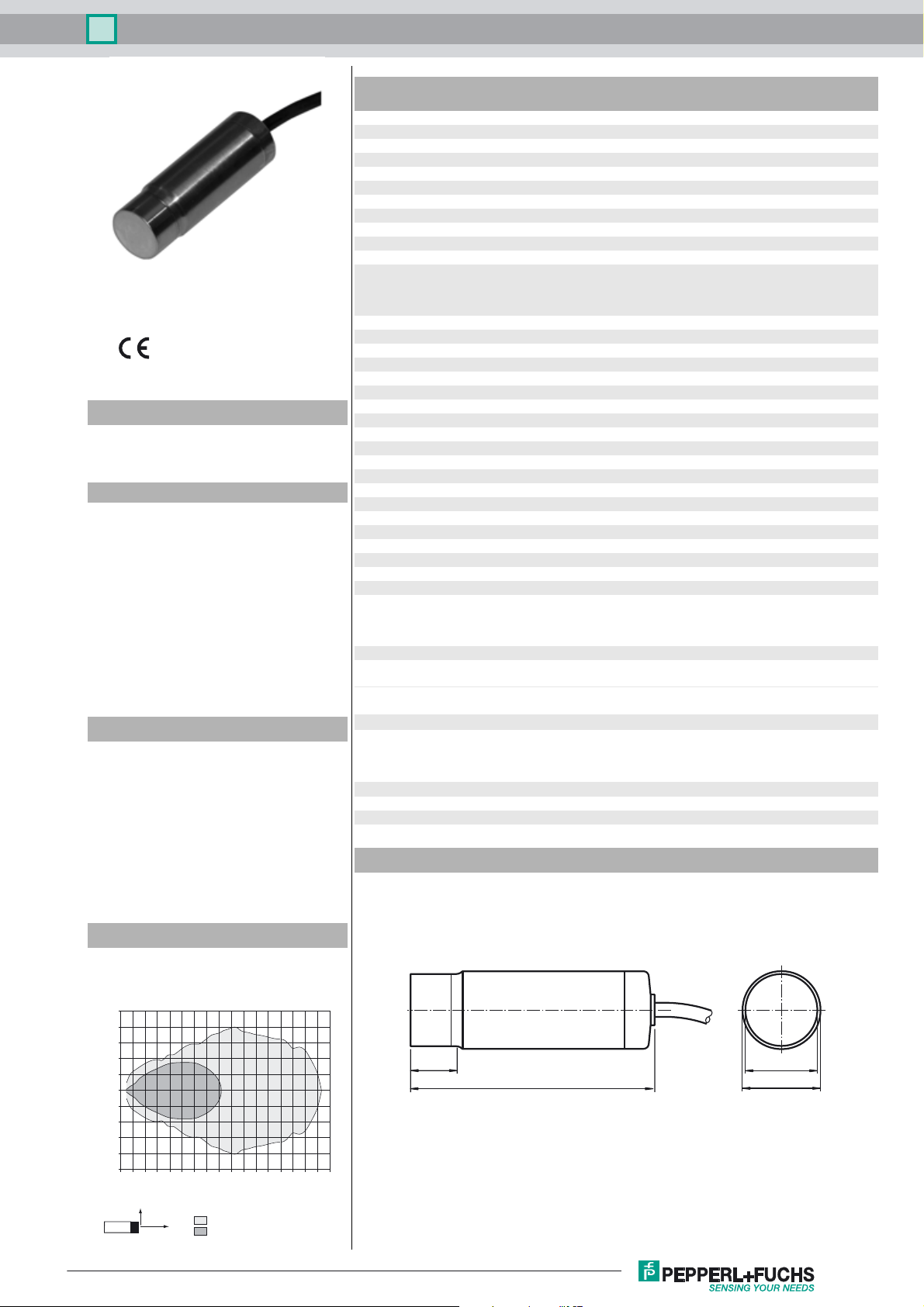

Diagrams

Characteristic response curve

Distance Y [mm]

250

200

150

100

50

0

-50

-100

-150

-200

-250

0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Y

Release date: 2016-03-01 11:55 Date of issue: 2017-03-21 274817_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

flat surface 100 mm x 100 mm

X

round bar, Ø 25 mm

Distance X [m]

11

56

16.7

18h11

1

Ultrasonic sensor UMB800-18H40-U-2M-FA

Electrical Connection

BN

U

WH

BK

BU

+ U

B

Teach input

Analogue output

- U

B

Accessories

MH-18H-01-FA

Mounting aid, 18 mm in accordance with EHEDG

Installation

Cleaning the Sensor in Areas with Hygiene Requirements

The sensor may only be used with the mounting aid included in the scope of delivery

as the fixture. Please note the information in the enclosed package insert for the

mounting aid with regard to the correct position of the seals and the correct process

for tightening the screw connections.

If the sensor as a whole is located in an area subject to hygiene requirements, the

sensor must be accessible from all sides for cleaning purposes. If the sensor is fitted

with only the front in an area subject to hygiene requirements, the front must be accessible from all sides accordingly.

The sensor and corresponding fixture are certified by ECOLAB. The components

were subjected to the cleaning agents listed in the certificate and are resistant to these agents. Use of other cleaning agents and chemicals is also possible. However, to

ensure the sensor and fixture offer resistance to these substances, corresponding

tests must be performed by the user.

For cleaning purposes, as a general rule you can completely cover the sensor including the fixture with foam and clean using a water jet. Cleaning at elevated temperatures of up to 85 °C is possible. It is not permitted to use high-pressure cleaning

equipment for cleaning purposes in areas subject to hygiene requirements.

Due to the unique design of this sensor, only the mounting accessories included with the sensor must be used in order to ensure reliable operation, even in applications without specific hygiene requirements.

Additional Information

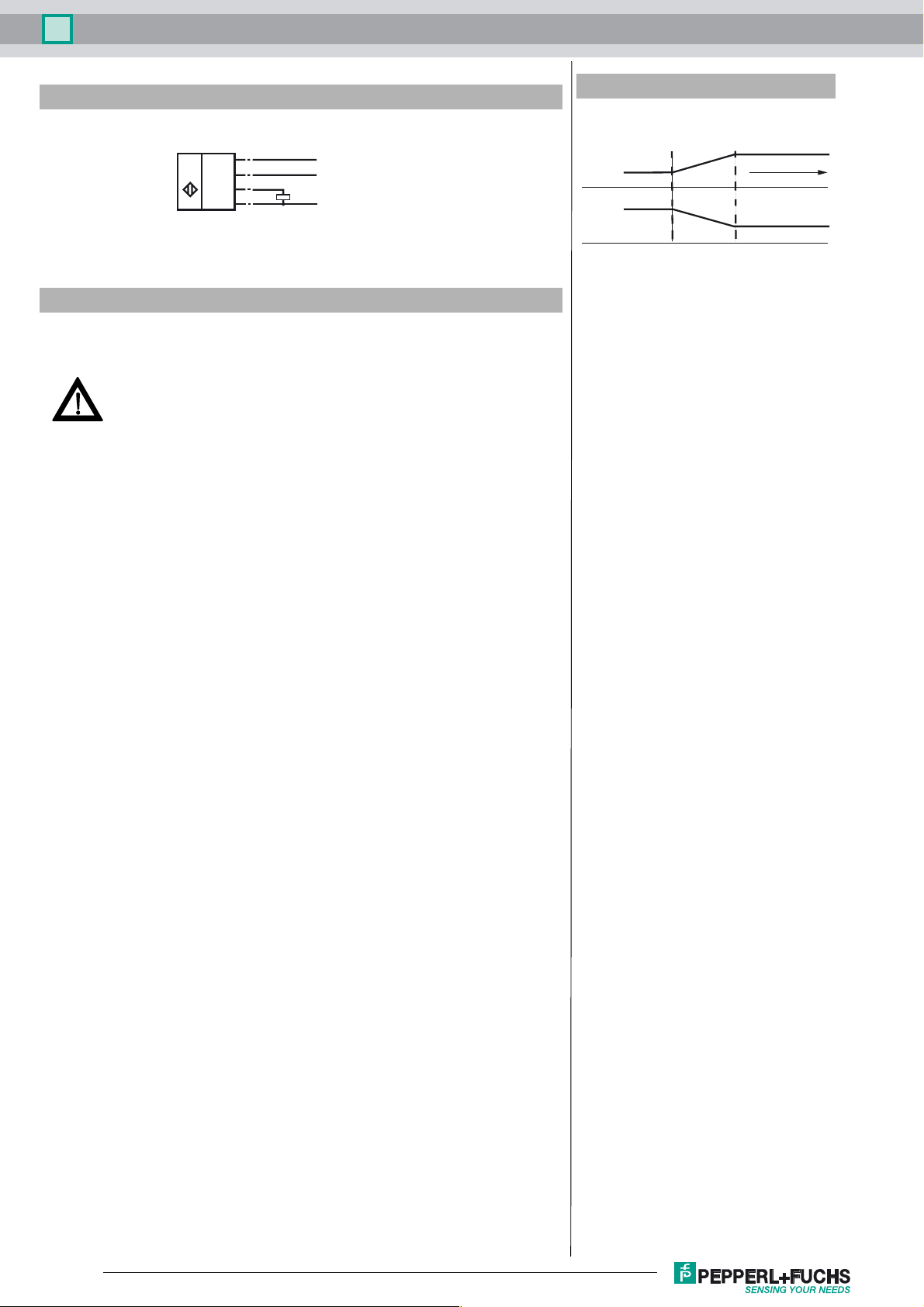

Programming the analog output mode

Rising ramp

A1 < A2:

Falling ramp

A2 < A1:

A1 -> ∞, A2 -> ∞: Detection of object presence

Object detected: 10 V

No object detected: 0 V

A1

A2

object range

A2

A1

Adjusting the evaluation limits

The ultrasonic sensor features an analogue output with two teachable evaluation limits. These are set by applying the supply voltage -U

or +UB to the TEACH-IN input.

B

The supply voltage must be applied to the TEACH-IN input for at least 1 s. The lower

evaluation limit A1 is taught with -U

, A2 with +UB.

B

Two different output modes can be set:

1. Analogue value increases with rising distance to object (rising ramp)

2. Analogue value falls with rising distance to object (falling ramp)

TEACH-IN rising ramp (A2 > A1)

- Position object at lower evaluation limit

- TEACH-IN lower limit A1 with - U

B

- Position object at upper evaluation limit

- TEACH-IN upper limit A2 with + U

B

TEACH-IN falling ramp (A1 > A2):

- Position object at lower evaluation limit

- TEACH-IN lower limit A2 with + U

B

- Position object at upper evaluation limit

- TEACH-IN upper limit A1 with - U

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

B

2

Release date: 2016-03-01 11:55 Date of issue: 2017-03-21 274817_eng.xml

Loading...

Loading...