Label sensor ULB-18GM50-255-2E1

Technical data

General specifications

Sensing range 20 ... 60 mm , optimal distance: 45 mm

Transducer frequency 255 kHz

Indicators/operating means

LED green Display: readiness

LED yellow indication: label detected

LED red Display: error

Electrical specifications

Model Number

ULB-18GM50-255-2E1

Features

• Ultrasonic system for detection of

labels and carrier materials.

• Short version

• Insensitive to printing, colors, and

shining surfaces

• Automatic compensation of the

operating point with slowly

changing ambient condition

• Very high processing speeds are

possible.

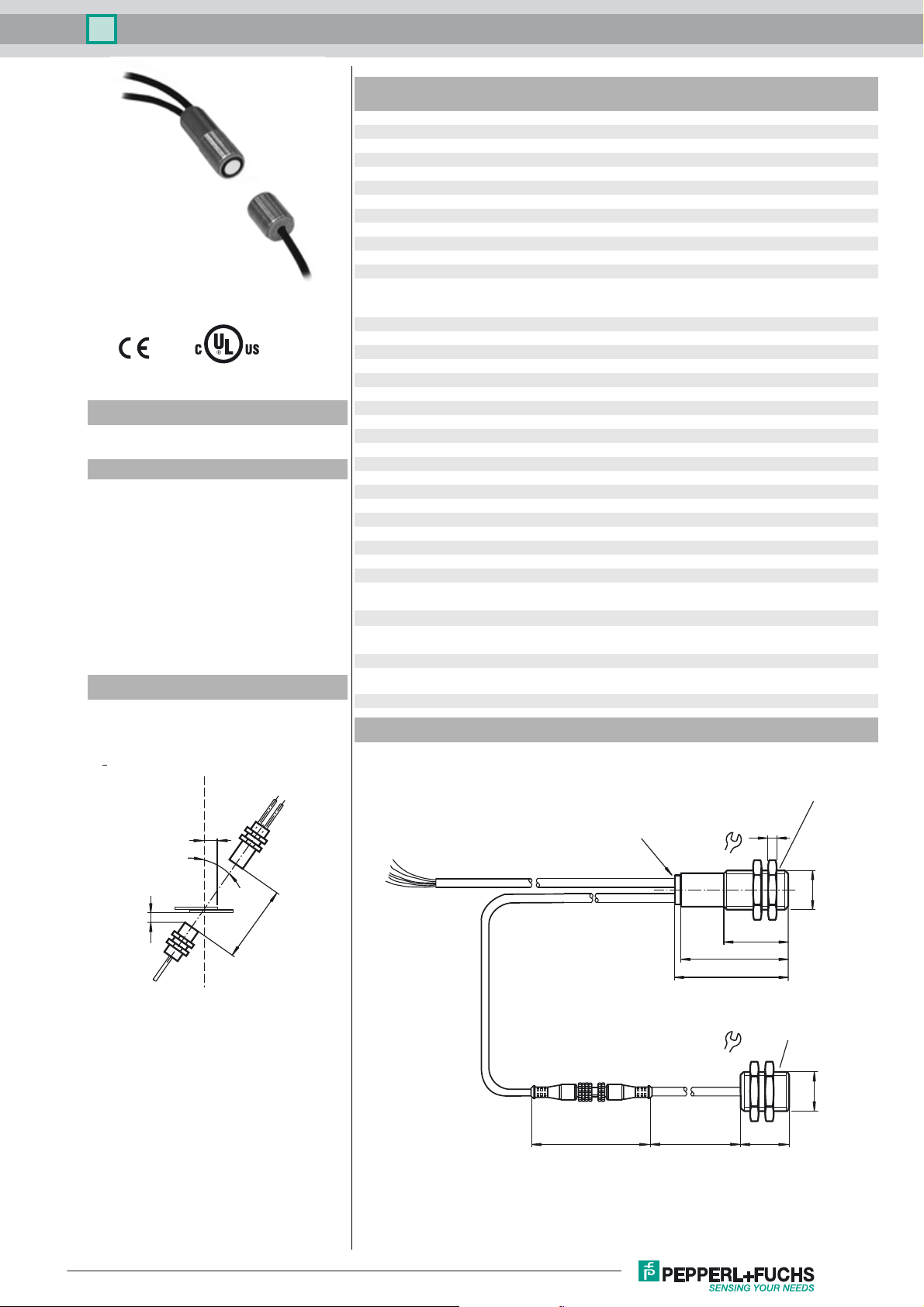

Diagrams

Mounting/Adjustment

Suggestions:

a = 5 mm ... 15 mm

b > 10 mm

d = 40 mm ... 45 mm

β = 20˚ ... 40˚

Operating voltage U

No-load supply current I

Time delay before availability t

Input

Input type Teach-In input

Pulse length ≥ 500 ms

Impedance ≥ 10 kΩ

Output

Output type 2 switch outputs NPN, NC

Rated operating current I

Voltage drop U

Switch-on delay t

Switch-off delay t

Ambient conditions

Ambient temperature 0 ... 60 °C (32 ... 140 °F)

Storage temperature -40 ... 70 °C (-40 ... 158 °F)

Mechanical specifications

Connection type cable PVC , 2 m

Core cross-section 0.14 mm

Degree of protection IP67

Material

Housing nickel plated brass; plastic components: PBT

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Mass 150 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

UL approval C-UL listed: 57M3, IND CONT. EQ., "Powered by Class 2

CCC approval CCC approval / marking not required for products rated ≤36 V

B

0

v

e

d

on

off

Dimensions

18 ... 30 V DC , ripple 10 %

< 60 mA

< 500 ms

0-level: -U

1-level: +U

2 x 100 mA , short-circuit/overload protected

≤ 3 V

≤ 600 µs

≤ 600 µs

IEC 60947-5-2:2007 + A1:2012

Power Source"

... -UB + 1V

B

- 1 V ... +U

B

2

SS

B

Evaluation unit with

receiver unit

b

β

a

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193010_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

d

wires 70 mm with

wire end ferrules

l = 2 m

l = 0.5 m

ø 15

70

LEDs

500

4

24

M18 x 1

30

50

53

Emitter unit

24

M18 x 1

22

1

Label sensor ULB-18GM50-255-2E1

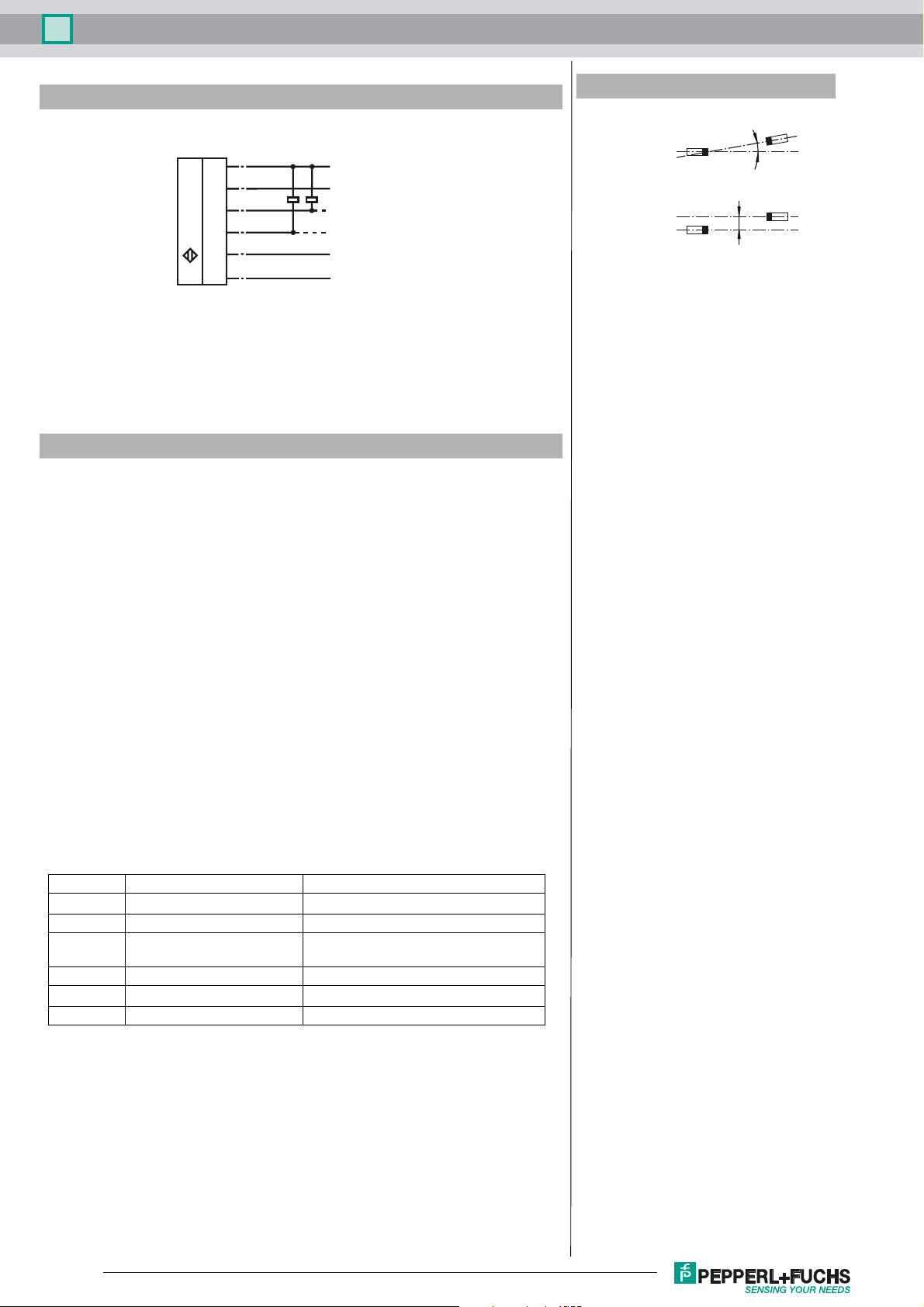

Electrical Connection

Standard symbol/Connection:

Label monitor

(BN)

(PK)

(WH)

(BK)

U

(GY)

(BU)

+U

B

TEACH IN

Output label

Output base material / air

n.c.

-U

B

Accessories

MH-UDB01

Mounting bracket for double sheet monitor

Operation in applications with increased ESD requirements

Using the included metal screw caps, the sensor can be used in applications with increased

ESD requirements up to 30 kV (ESD = electrostatic discharge). The metal coupling nuts are

screwed on the front of the transmitter and receiver. The installation of the transmitter and receiver must ensure a large area electrical connection to the machine earth.

Additional Information

Angular misalignment

< +/- 1°

α

Sensor offset

s < +/- 1 mm

α

s

Description of sensor functions

The ultrasonic double sheet monitor for label detection can be used in all applications,

where an automatic detection of labels is required, to automatise labelling of goods. Even

transparent or metalised labels can be detected without problem. The double-sheet monitor is based on the ultrasonic through-beam principle. The following can be detected:

- No base material, i.e. air,

- Labels

A microprocessor system evaluates the signals. The appropriate switch outputs are set

as a result of the evaluation. Changes in ambient conditions such as temperature and

humidity are compensated for automatically. The interface electronics is integrated into

a compact M18 metal housing together with a sensor head.

Electrical connection

The sensor is equipped with 6 connecting wires. The functionality of the connections is

described in the following table. The teach input (PK) is used to teach the sensor.

Colour Switching on Comments

BN +U

B

WH Switch output for labels Pulse width corresponds to the event

BK Switch output for base mate-

Pulse width corresponds to the event

rial / air

GY not connected

PK -U

/ n.c. / +U

B

B

Normal operation / TEACH-IN

BU -UB

Normal mode

The sensor is working in normal mode if the function input (PK) is applied to -UB or not

connected.

Displays:

LED yellow: Detection of labels

LED green: Power on

LED red: Error

Switch outputs:

The switch outputs are only active in normal operation!

White: WH Label output

Black: BK Base material / air output

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193010_eng.xml

Label sensor ULB-18GM50-255-2E1

TEACH-IN mode

Connecting the teach input (PK) with +UB for at least 500 ms causes the sensor to change into TEACH-IN mode. The TEACH-IN procedure takes place by the transition from label to base material. We suggest to accomplish the TEACH-IN procedure with activated

material feeding and multiple label/base material transitions.

During the TEACH-IN procedure flashes the yellow LED; the green LED is off.

After returning to the normal operation mode (teach input (PK) detached from

cedure was successful or not.

TEACH-IN procedure successful: green LED flashes 3 times

TEACH-IN procedure not successful: red LED flashes 3 times

Notes:

A complete device consists of an ultrasonic emitter and an evaluation unit with an ultrasonic emitter. The sensor heads are optimally

adjusted to each other when they leave the factory. Therefore, they must not be used separately or exchanged with other devices of

the same type. The plug connector on the emitter/receiver connection cable is only intended to be used for easier mounting, not to

replace units.

If two or more double sheet controls are used in the immediate vicinity of each other, there may be mutual interference between them,

which can result in improper functionality of the devices. Mutual interference can be prevented by introducing suitable countermeasures

when planning systems. Suitable measures can be:

- Mounting of sound absorbers (foam material)

- mounting of sound separators (sheet metal)

- insallation of the sensors with different directions of sound transmission.

+U

) the sensor indicates whether the TEACH-IN pro-

B

Release date: 2017-09-25 08:45 Date of issue: 2017-09-25 193010_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...