Splice sensor UDBK-18GM35-3E2

Technical data

General specifications

Transducer frequency 180 kHz

Indicators/operating means

LED green indication: single sheet detected

LED yellow indication: no sheet detected

LED red indication: double sheet or contact spot detected

Electrical specifications

Model Number

UDBK-18GM35-3E2

Features

• Ultrasonic system for detection of

single and pasted double sheet

• Weights of paper from 30 g up to

cartons weighing over 1200 g can

be detected

• It is also possible to detect thin

metal and plastic films.

• Various materials and thicknesses

are programmed in using a

TEACH-IN signal

• Automatic compensation of the

operating point with slowly

changing ambient condition

• Signal output via short-circuit

proof PNP switch outputs

• Very high processing speeds are

possible.

Diagrams

Operating voltage U

No-load supply current I

Input

Input type 1 pulse input for Teach-In

Pulse length ≥ 100 ms

Impedance ≥ 10 kOhm

Voltage 12 ... 30 V

Output

Output type 3 switch outputs PNP, NO

Rated operating current I

Voltage drop U

Switch-on delay t

Switch-off delay t

Ambient conditions

Ambient temperature 0 ... 60 °C (32 ... 140 °F)

Storage temperature -40 ... 70 °C (-40 ... 158 °F)

Mechanical specifications

Connection type emitter: V1-W connector with 2.5 m cable

Degree of protection IP65

Material

Housing Makrolon/nickel-plated brass

Mass 370 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated ≤36 V

B

0

e

d

on

off

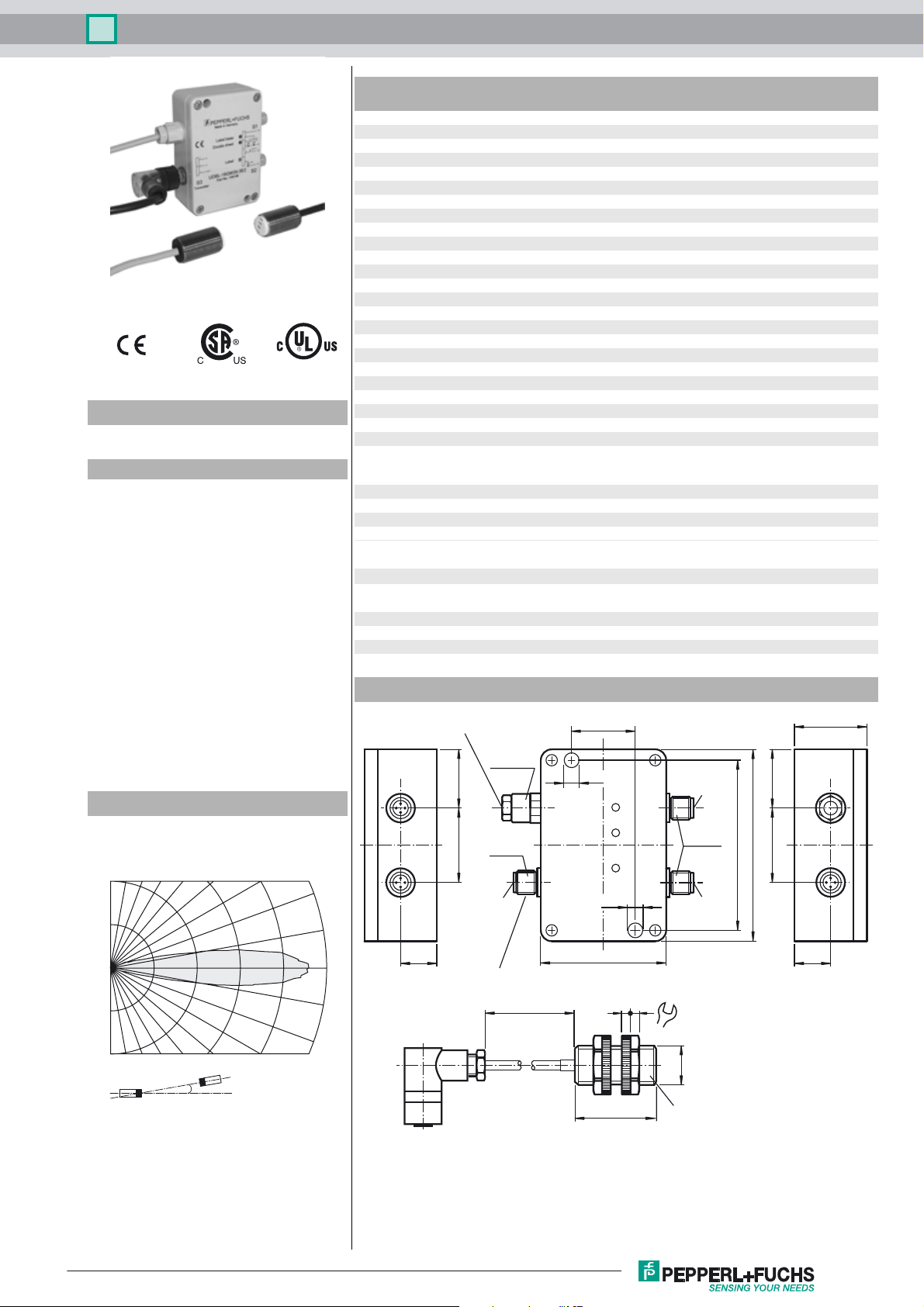

Dimensions

Connector Receiver

M12 x 1.5

3038

20 ... 30 V DC , ripple 10 %

< 80 mA

3 x 200 mA

≤ 2 V

≤ 1 ms

≤ 100 ms

receiver: 2.5 m fixed cable (not disconnectable)

S1,S2: 2 connectors V1-W, M12x1 (included with delivery)

IEC 60947-5-2:2007 + A1:2012

36

6.8

S1

SS

3038

37

Characteristic response curves

90 80 70 60 50 40 30

0.0

0.2

0.4

Distance [m]

Release date: 2016-04-25 09:35 Date of issue: 2016-04-25 106195_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

0.6 0.8 1.0

α

Angle [degrees]

20

10

0

-10

-20

18.5

M12 x 1

S3

Connector Emitter

2.5 m

M12 x 1

6.8

64

44

S2

98

86

18.5

24

M18 x 1

35

Ultrasonic-Transducer (Emitter)

1

Splice sensor UDBK-18GM35-3E2

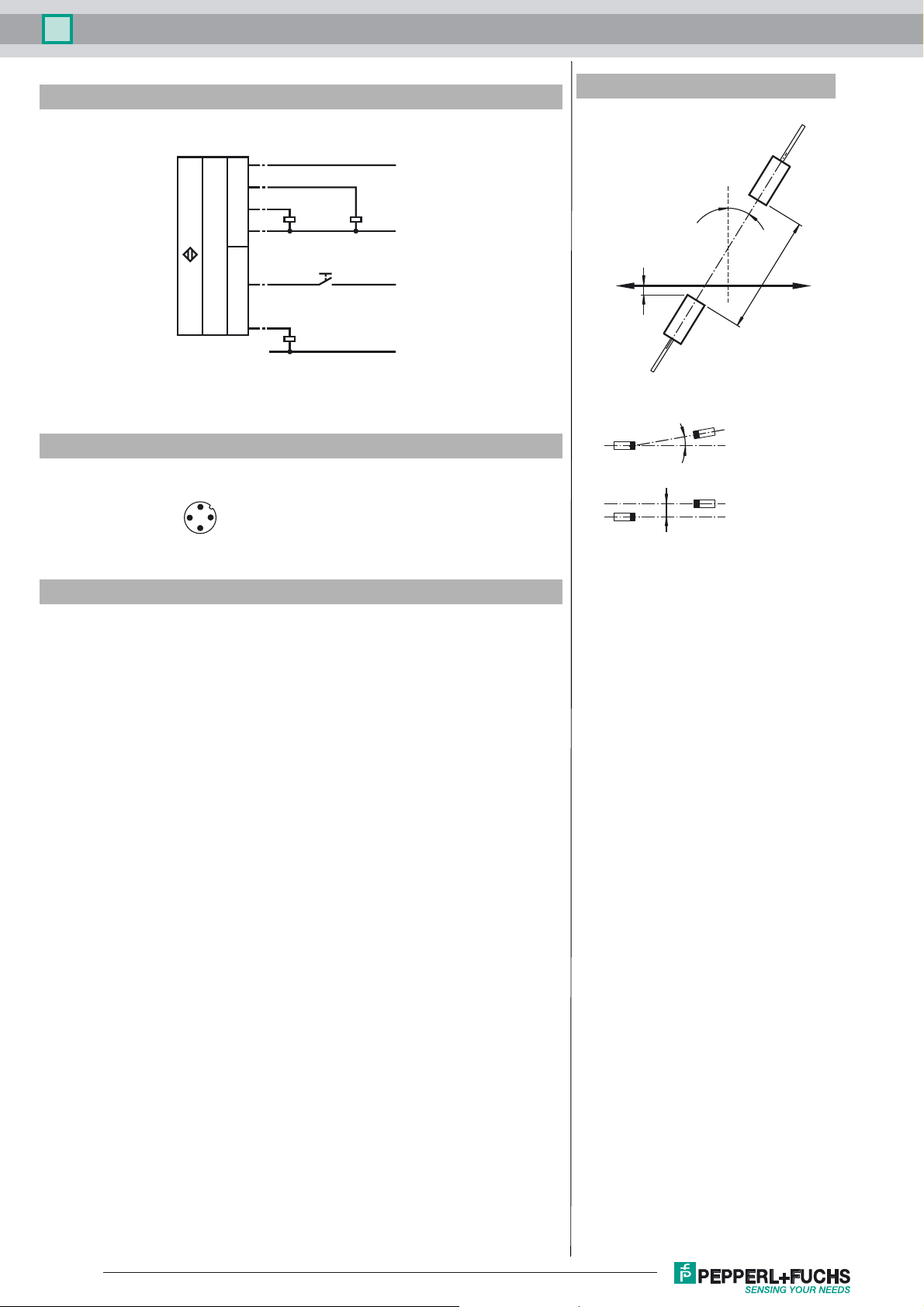

Electrical Connection

Standard symbol/Connection:

Double-sheet-control

U

Pinout

Connector V1

3

Additional Information

Mounting/Adjustment

Receiver

S1

S2

1

2

4

3

2

4

Double sheets

or splices

TEACH-IN key

No sheet

Single

sheet

+U

B

Relative position

-U

B

+U

B

-U

B

Paper position:

about 5 ... 15 mm above

the emitter

Angular alignment

α < +/- 2˚

Sensor offset

2

1

4

s < +/- 2 mm

20 ... 45˚

Emitter

(black cable)

α

s

(yellow cable)

d = 20 ... 80 mm

Accessories

MH-UDB01

Mounting bracket for double sheet monitor

Description of the sensor functions

Ultrasonic double-sheet monitoring to detect splice points is used in all situations in which

an automatic distinction must be made between splice points and double sheets in order

to protect machines or avoid waste production. Double-sheet monitoring for splice point

detection is based on the ultrasonic through-beam principle. The following can be detected:

- No sheet

- Individual sheet

- Splice point or double sheet

A microprocessor system evaluates the signals. The appropriate switch outputs are set

as a result of the evaluation. Changes in ambient conditions such as temperature and

humidity are automatically compensated. The evaluation electronics are installed in a

cuboid plastic housing separate from the sensor heads.

Measuring system

A complete system consists of an ultrasonic emitter, an ultrasonic receiver and an evaluation unit. These units have been optimally tuned to one another at the factory and may

not be used separately.

Alignment

When adjusting the emitter and receiver, take care to align them as precisely as possible.

Distance of the sensor heads: d = 20 mm ... 80 mm

Angular tolerance: α < +/- 2°

Maximum offset: s < +/- 2 mm

To ensure their correct function, the sensor heads must be aligned at an angle of

20° ... 45° from vertical onto the paper surface. The paper is guided over the emitter at a

distance of 5 mm ... 15 mm. The emitter is installed below in order to prevent dust deposits. Install the sensor heads using the included plastic nuts. The sound cone must be

completely covered by the paper. This means that the sensor heads must be installed

above the sheet of paper and at least 10 mm away from the side edge of the paper.

Feed speed of the sheet (approximate value)

v

= 0.035 m/s

min

v

[m/s] = overlapping of sheets [mm] / 1 ms (approx. value, overlapping > 20 mm)

max

Teach-In

2

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Release date: 2016-04-25 09:35 Date of issue: 2016-04-25 106195_eng.xml

Splice sensor UDBK-18GM35-3E2

1. After the operating voltage has been applied, a single sheet can be fed in as the first sheet. It will automatically be programmed as a reference value

by the system.

2. If a single sheet of paper is located between the ultrasonic emitter and receiver when the operating voltage is turned on, it will automatically be programmed as

a reference value by the system.

Automatic learning for thinner types of sheets

If you are inserting a thinner type of sheet, you can dispense with the use of the Teach-In signal to program the system. In order to do

this, a single sheet of paper must be between the emitter and receiver for at least 2 s.

Automatic learning for thicker types of sheets

If you are inserting a thicker type of sheet but still not one that will result in double-sheet output, you can dispense with learning by

means of the Teach-In signal. In order to do this, a single sheet of paper must be between the emitter and receiver for at least 2 s.

Teach-In for new type of sheet

If you are inserting a new type of sheet that will result in double-sheet output, the system must be reprogrammed. To do this, a single

sheet must be placed between the emitter and receiver. After the Teach-In signal has been applied, the corresponding reference value

will be accepted.

Caution!

The paper sheets may not touch the sensor heads during operation. Depending on physical conditions, reflections on the

edge of a single sheet may result in double-sheet output. This is not an error, and can be masked out in the higher-level control system.

Sensor systems for ultrasonic double-sheet monitoring can also be delivered with a customised time response for optimal adaptation

to specific applications.

Notes:

When installing, care has to be taken that the ultrasonic signal cannot pass around the material that is to be detected, due to multiple

reflections. This can happen if large surfaces are present at right angles to the direction of sound propagation. This can be the case if

unsuitable mounting brackets are used, or if assemblies with large surface are part of the machine. In the latter case such machine

parts should be covered by sound absorbing material or a different location for the installation should be chosen.

In cases where more than one system is needed per machine, acoustic isolation should be provided to avoid cross-talk. This can be

provided, for example, by appropriately positioning isolation panels.

Release date: 2016-04-25 09:35 Date of issue: 2016-04-25 106195_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...