Ultrasonic sensor UC500-F65-E8R2-V15

Technical data

General specifications

Sensing range 60 ... 500 mm

Adjustment range 60 ... 500 mm

Dead band 0 ... 60 mm

Standard target plate 10 mm x 10 mm

Transducer frequency approx. 300 kHz

Nominal ratings

Model Number

UC500-F65-E8R2-V15

Features

• Level indication

•2 switch outputs

• Program input

• Programmable by means of Interface (see accessories) and SONPROG

• Synchronization options

• Temperature compensation

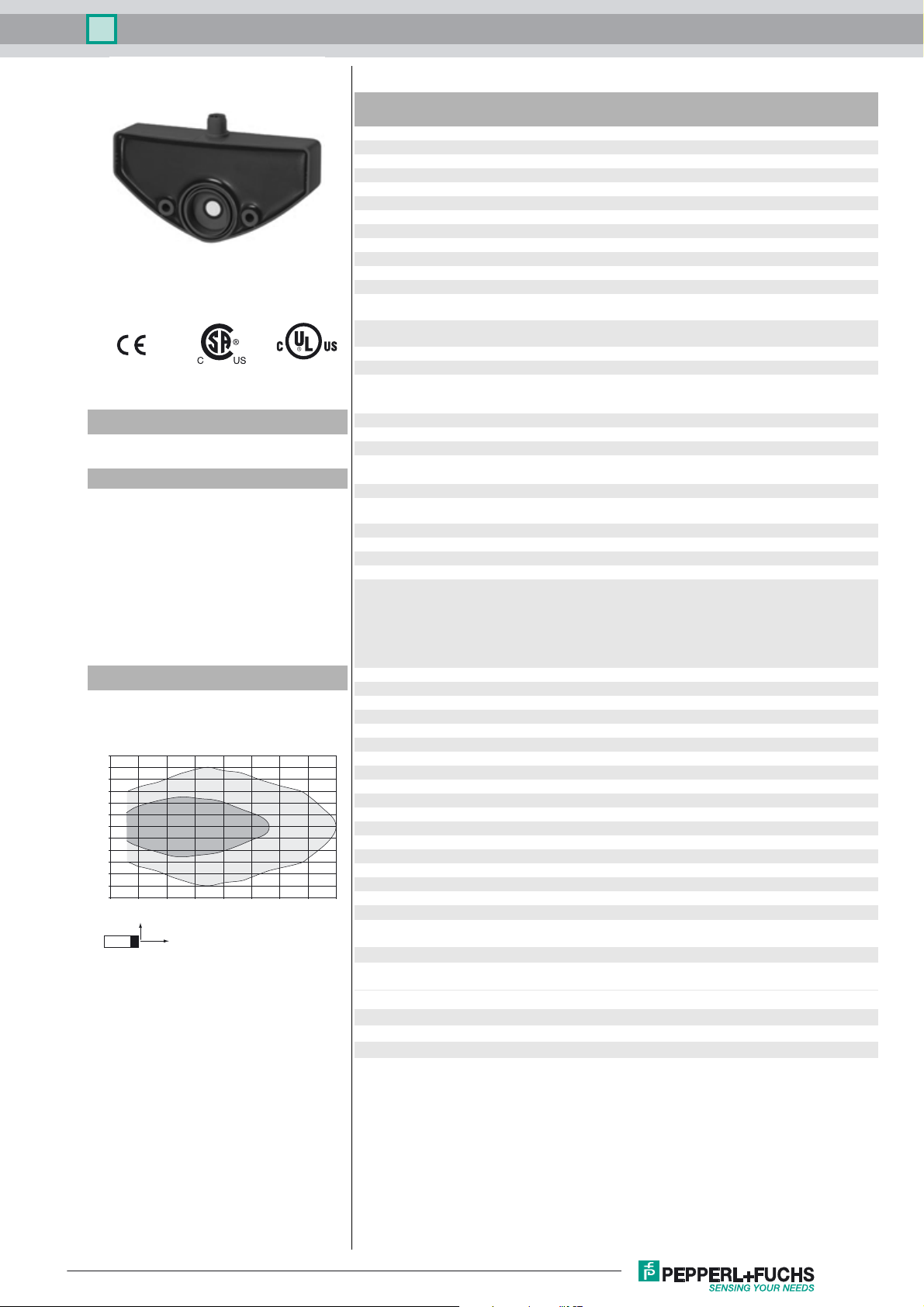

Diagrams

Characteristic response curve

Distance Y [mm]

150

125

100

75

50

25

0

-25

-50

-75

-100

-125

-150

0 100 200 300 400 500 600 700 800

Y

Curve 1: flat surface 100 mm x 100 mm

Curve 2: round bar, Ø 25 mm

2

X

1

Distance X [mm]

Time delay before availability t

Limit data

v

Permissible cable length max. 300 m

Indicators/operating means

LED green Power on

LED yellow 1 solid: switching state switch output 1

LED yellow 2 solid: switching state switch output 2

Electrical specifications

Rated operating voltage U

Operating voltage U

e

B

Ripple ≤ 10 %

No-load supply current I

Input

0

Input type 1 program input

Input voltage ≤ Operating voltage

Level low level : 0 ... 3 V (Teach-In active)

Pulse length ≥ 150 ms

Output

Output type 2 switch outputs PNP, NO

Rated operating current I

Default setting Switching distance "full", S

Voltage drop U

Switch-on delay t

d

Repeat accuracy ± 0.45 mm

Off-state current I

Temperature influence ≤ ± 1.5 %

e

on

r

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Shock resistance 30 g , 11 ms period

Vibration resistance 10 ... 55 Hz , Amplitude ± 1 mm

Mechanical specifications

Connection type Connector M12 x 1 , 5-pin

Degree of protection IP65

Material

Housing PBT

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Installation position any position

Mass 500 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

250 ms

flashing: misadjustment

flashing: misadjustment

24 V DC

12 ... 30 V (including ripple)

In supply voltage interval 12 ... 20 V sensitivity reduced to

20% ... 0%

≤ 60 mA

Teach-In of S

min

high level : ≥ 15 V (Teach-In inactive)

150 mA , short-circuit/overload protected

: 80 mm

Smax

max

: 20

Smin

min

Smax

: 110

: 450 mm

: 20 mm

: 100 mm

Smin

Switching distance "empty", S

Switching hysteresis "full", H

Switching hysteresis "empty", H

average value "full", M

average value "empty", M

≤ 3 V

80 ms

0.01 mA

IEC 60947-5-2:2007 + A1:2012

Release date: 2016-02-16 08:26 Date of issue: 2016-02-16 235136_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated

≤36 V

1

Ultrasonic sensor UC500-F65-E8R2-V15

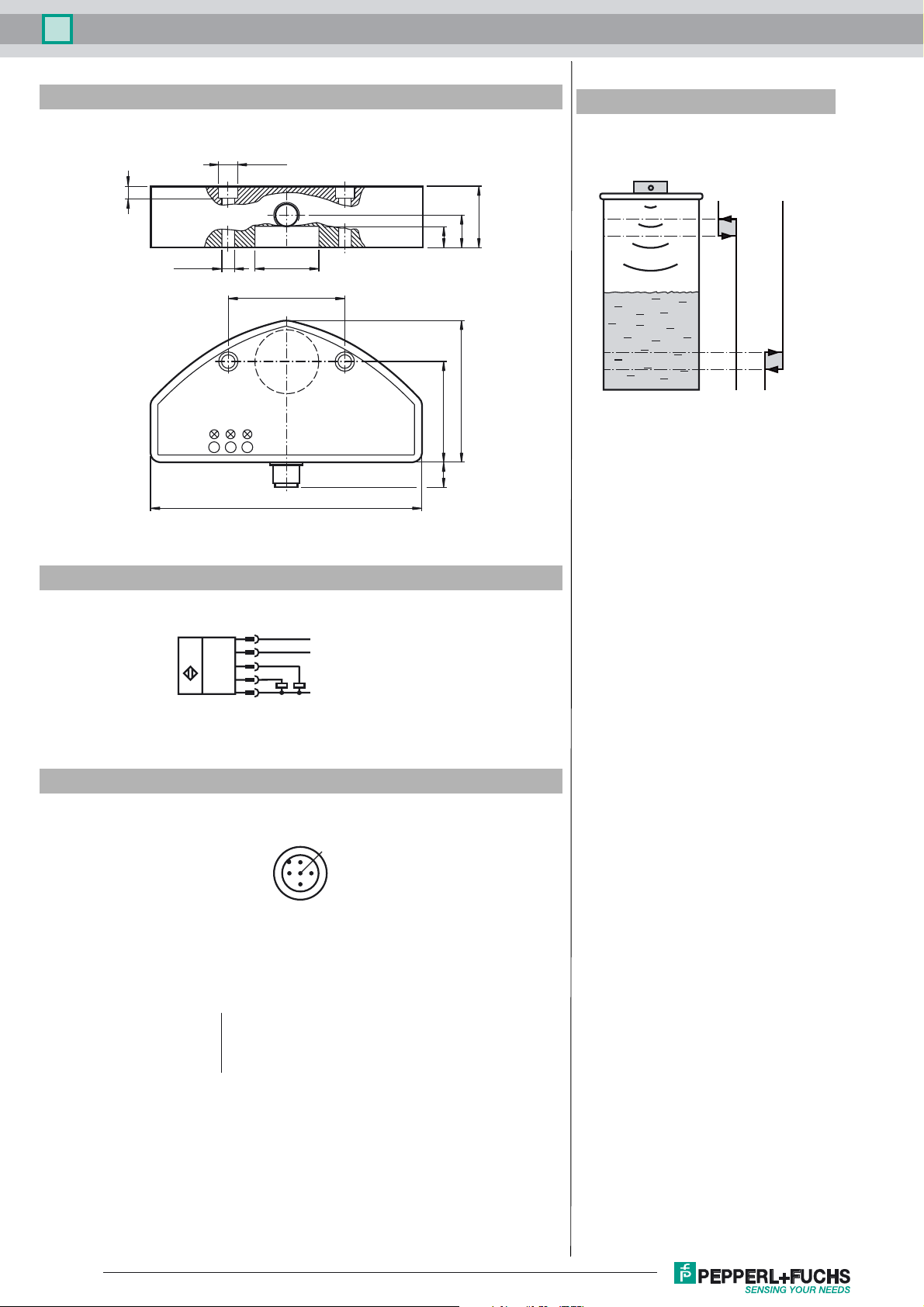

Dimensions

Additional Information

Function of the switching outputs

2 x ø8.8

Sensor

Sensor

6

)

Q2 (S

30

17

10

2 x ø5.5

ø30

54

64.4

1

4612

125

max

)

min

Q1 (S

H

S

max

H

S

min

0

1

0

Electrical Connection

Pinout

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

5 GY

1

2

4

5

3

2

+ U

B

XI

Q1 (S

)

min

Q2 (S

)

max

- U

B

1

5

4

3

(brown)

(white)

(blue)

(black)

(gray)

Release date: 2016-02-16 08:26 Date of issue: 2016-02-16 235136_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Ultrasonic sensor UC500-F65-E8R2-V15

Accessories

V15-G-2M-PUR

Female cordset, M12, 5-pin, PUR cable

V15-G-2M-PVC

Female cordset, M12, 5-pin, PVC cable

V15-W-2M-PVC

Female cordset, M12, 5-pin, PVC cable

3RX4000-PF

PC interface

Applications

The design and functionality makes this sensor best suitable for level detection applications in small containers or tanks. The device provides 2 switching outputs Q1 (S

and Q2 (S

be programmed with SONPROG or with an automatic setup (Teach-In).

). Special distances can be assigned to each of them - e. g. the minimum and maximum levels in a tank can be evaluated and displayed. The parameters can

max

Mounting and Connection

All parts are accommodated in a fully enclosed housing. The ultrasonic transducer is set back in the housing, so it is protected. Because of the built-in sealing the sensor can

be used as a closure with integrated level detection. The opening of the tank must have a diameter of 26 mm. The sensor is fixed by means of two M5 screws. The sensor

has a 5 pin M12 x 1 connector. The BERO has built-in polarity reversal as well as short-circuit and overload protection. Where there is electrical interference, shielded cables

are recommended.

Setup

The two ranges, the associated hysteresis and the average value are preset at the factory (see technical data). The parameters can be programmed with SONPROG or with

an automatic setup (teach-in). Teach-in can be done by means of the keys of the interface (accessories) or the function input XI.

Automatic Setup (Teach-in)

With this function the minimum level S

can be set. The following steps must be performed in the correct order:

min

1. Fill the tank up to the required minimum level or place an object at the required distance.

2. Apply "low" signal (0 to 3 V) to the function input XI - e.g. connect XI via a key to 0 V, or connect it via a PLC to "LOW"). The LED "S

disabled; it‘s learning the distance. The signal duration must be at least 150 ms.

3. Remove signal from XI - e.g. disconnect it from the function input XI, connect it to +U

Important! As long as the function input XI is connected to "low", the sensor is disabled.

or connect it via a PLC to "HIGH").

B

" flashes, then. The sensor is

min

SONPROG

With SONPROG the following parameters can be programmed:

• Start or end of both switching ranges S

• Hysteresis (HS

max

, HS

min

)

min

and S

max

• Blind zone

• Sensing range

• Average value

• Switching output S

Customer specific programming is available on request.

NC / NO

min

Operation

The level of liquid inside a tank is detected within the sensing range. If the level reaches one of the two switching levels (S

, HS

active. Both switching levels are equipped with a switching hysteresis (HS

min

). The switching status of each output is indicated by the corresponding yellow LED. If the

max

, S

), then the corresponding output will be set

min

max

filling level is in between the 2 switching levels, both of the outputs are in off state.

Objects inside the blind zone will cause error signals. Therefore the user has to mount the sensor that way that the level cannot be inside the blind zone.

min

)

Release date: 2016-02-16 08:26 Date of issue: 2016-02-16 235136_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...