Ultrasonic sensor UC500-D1-3K-V7

Technical data

General specifications

Sensing range 60 ... 550 mm

Dead band 0 ... 60 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 380 kHz

Model Number

UC500-D1-3K-V7

Single head system

Features

• Specially for level monitoring in

vessels

• Large operating voltage range

10 V DC ... 253 V DC

20 V AC ... 253 V AC

•3 relay outputs

• Parameter assignment via DIPswitches

• Temperature compensation

• Cable socket included with

delivery

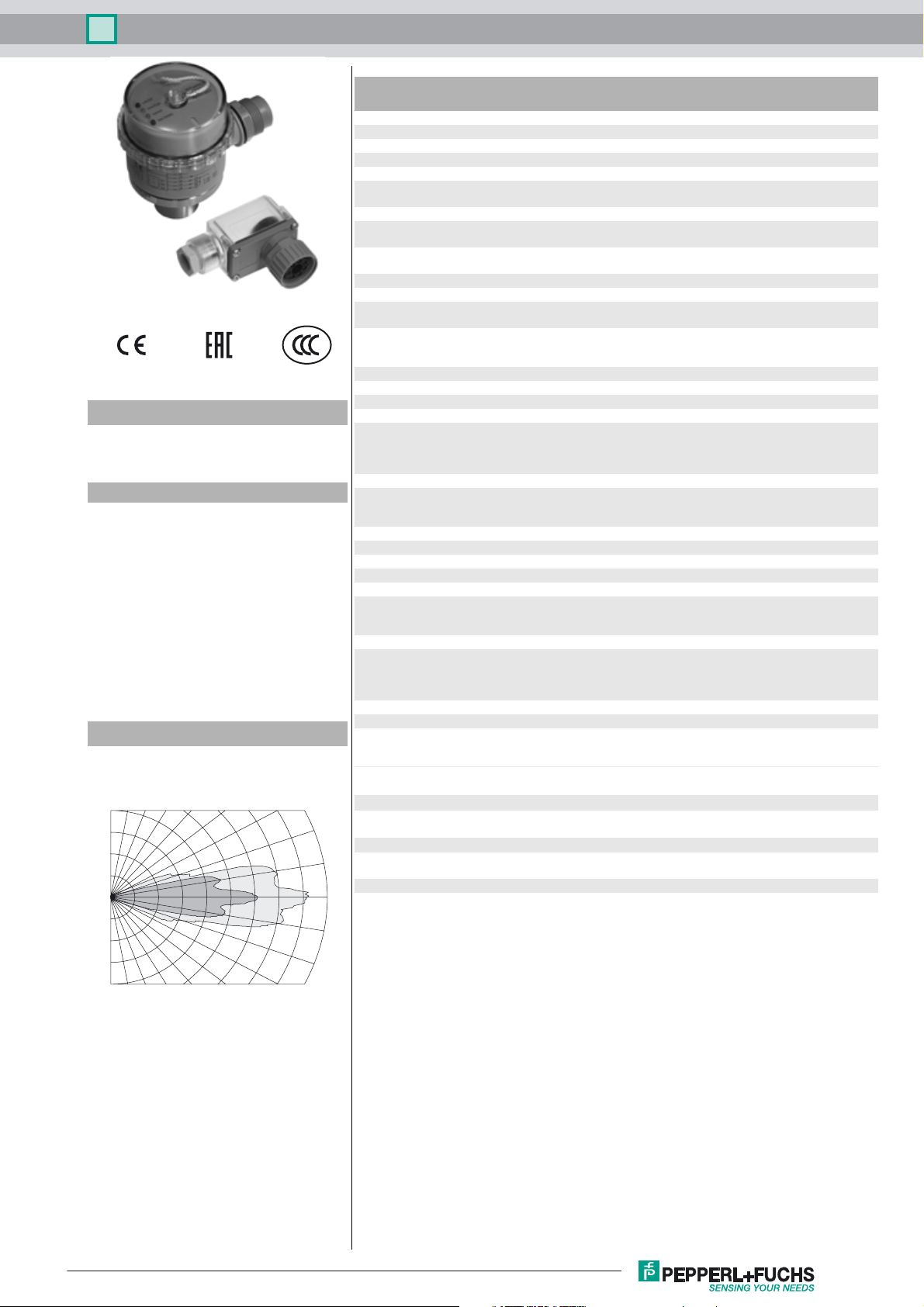

Diagrams

Characteristic response curves

90 80 70 60 50 40 30

0.0

0.1

0.2

0.3

0.4

Distance [m]

0.5 0.6 0.7 0.8 0.9

2

Angle [degrees]

1

-20

Response delay > 10 s, relay

Indicators/operating means

LED red LED 1: overfill indication

LED green/yellow LED 2: overfill warning and normal operation

DIP switch setting of the switch points/operating modes

Electrical specifications

Operating voltage U

S

No-load supply current I

Output

Output type 3 relay outputs, normally open/closed, selectable

Range hysteresis H 20 mm

Contact loading 253 V AC/150V DC, 3 A (ohm. load)

Life span electrical: 105 switching cycles with ohmic load

Temperature influence < 4 %

Fusing ≤ 3 A Slow-blow fuse per output in accordance with

Ambient conditions

Ambient temperature -20 ... 60 °C (-4 ... 140 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Degree of protection IP65

Connection Female connector, V7 (7-pin), 90°

Material

Housing cover: PC

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Mass 700 g

Note In case of loss or damage, the cable socket mu st be replaced

Compliance with standards and

directives

Standard conformity

20

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

EAC conformity TR CU 004/2011

10

CCC approval Certified by China Compulsory Certification (CCC)

-0

-10

B

0

< 1 s, LEDs

LED 4: underfill indication

LED 3: normal operation and underfill warning

10 ... 253 V DC

20 ... 253 V AC , 47 ... 63 Hz

< 30 mA with UB = 30 V DC

< 110 mA at U

< 25 mA at U

(3 A/253 V AC or 3 A/30 V DC)

minimum contact load: 100 µA/100 mV DC

mechanical: 20 x 10

IEC 60127-2 Sheet 5 required. Recommendation: after a

short circuit, check that the device is functioning correctly.

Wire cross section: ≤1.5 mm

= 10 V DC

B

= 220 V AC

B

6

switching cycles

2

cable diameter Ø7 ... 9 mm

housing: PBT

threaded flange: stainless steel

installation connector/cable socket: PETP

by an identical cable socket (type V7-W) from

Pepperl+Fuchs!

IEC 60947-5-2:2007 + A1:2012

TR CU 020/2011

Curve 1: flat surface 100 mm x 100 mm

Curve 2: round bar, Ø 25 mm

Release date: 2017-08-24 08:53 Date of issue: 2017-08-24 212371_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Ultrasonic sensor UC500-D1-3K-V7

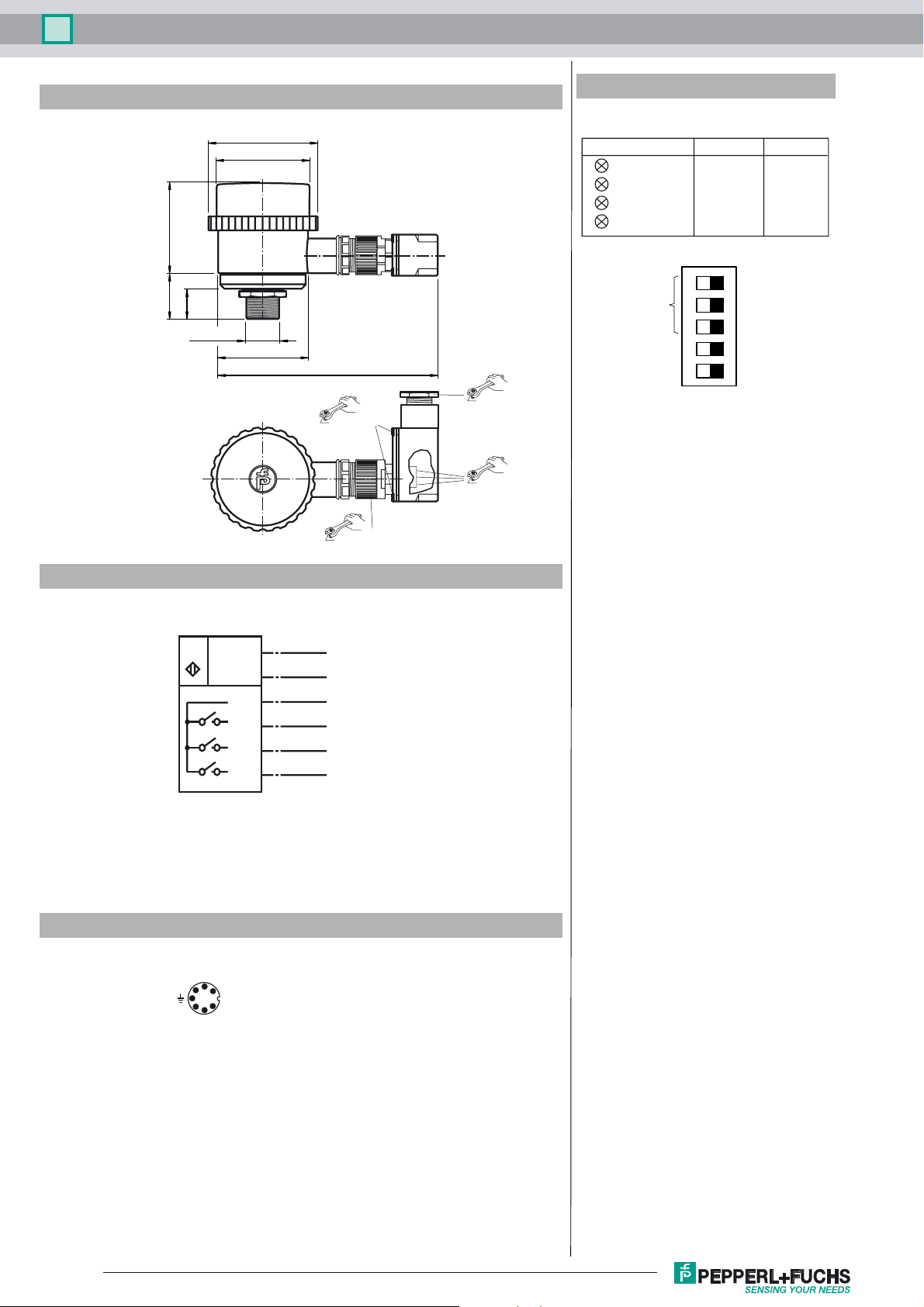

Dimensions

6838

28

M30 x 1.5

ø 75

ø 65

ø 64.5

144

0.4 ... 0.5 Nm

0.4 ... 0.5 Nm

2.5 ... 3.75 Nm

0.4 ... 0.5 Nm

Additional Information

Indicators/operating means

12345

S4 = OFF

full

high

normal

empty

ON

LED

1 (red)

2 (green/yellow)

3 (green/yellow)

4 (red)

switch output

adjustment

overspill warning

normal operation

S4 = ON

full

normal

low

empty

run-dry warning

TEACH-IN mode

Electrical Connection

Standard symbol/Connection:

U

Pinout

Connector V7

1

2

1

2

U

B

U

B

3

4

A1

5

A2

6

A3

6

5

4

3

Release date: 2017-08-24 08:53 Date of issue: 2017-08-24 212371_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Ultrasonic sensor UC500-D1-3K-V7

Safety notes:

The supply circuit is separated from the relay circuit by basic insulation.

The cover may only be opened by specially trained personnel. Pollution degree 2 is permissible when

the cover is open. Ensure that the sealing ring of the cover is in good condition.

Protection class II is only guaranteed when using the recommended cable socket. The cable box may

only be separated from the unit when the power is off.

The connector pin 7 of the connector is not connected to the sensor. An eventually present earth connection in the cable socket therefore will not be looped into the sensor.

CAUTION:

The UC500-D1-K3-V7 ultrasonic sensor is not

Conformity: EN 60947-5-2

Housing insulation: Protection class II

Pollution degree: 4 (process face)

3 (housing- and connector side)

Overvoltage category: III

TEACH-IN of switching points:

One switching point can be taught for each of the 3 switch outputs. Set DIP switch 5 to ON to put the sensor in TEACH-IN mode.

The sensor indicates TEACH-IN mode with two lit red LEDs. The green-yellow LEDs are off.

Next, position a suitable target object at the desired switching point in front of the sensor and switch the DIP switch associated

with the relevant switch output (switches 1-3). The sensor will now be flashing yellow or green in addition to the lit red LEDs.

Flashing green indicates that the target object was detected; flashing yellow signals that it was not detected. The measured

switching point will be transferred to RAM when the associated DIP switch is switched back while the LED is flashing green.

Only the red LEDs should now be lit. This signals the user that the DIP switches 1-3 have been restored to their original positions. The other switching points are set in the same manner. The TEACH-IN procedure is completed by setting DIP switch 5

back to the OFF position. The measured switching points will then be transferred to the nonvolatile EEPROM.

Under normal circumstances, switching point A1 should be less than A2, and A2 less than A3. If this is not observed, the sensor

will automatically exchange the switching points after the TEACH-IN procedure is complete so that A1 < A2 < A3. This ensures

that the LEDs respond correctly and that the shortest switching point is assigned to relay 1, the middle distance to relay 2 and

the longest distance to relay 3.

If DIP switch 4 is switched during TEACH-IN, the default value for the switching point will be set rather than a target object. The

default values for the switching points are 60 mm for A1, 220 mm for A2 and 270 mm for A3.

suitable for use in environments subject to explosion hazards.

Display

DIP1-3 one or more DIP switches changed

DIP4 normal state

State object detected object not

during TEACH-IN:

TEACH-IN of object distance

TEACH-IN active

changed

default parameter

default active

in normal state

TEACH-IN complete

normal

changed

state

detected

LED 1, red lit lit lit lit lit

LED 2, green/yellow flashes green off lit green off lit green

LED 3, green/yellow off flashes yellow lit yellow off lit yellow

LED 4, red lit lit lit lit lit

The relays switch to the "safe state" (all relays open, regardless of close/open function) during TEACH-IN.

Setting the switching behaviour:

In normal mode (DIP switch 5 OFF), the DIP switches 1 to 3 can be used to set the switching behaviour of the switch outputs 1

to 3. If the associated DIP switch is ON, the associated switch output has a close function; if the switch is set to OFF the output

has an open function. Close function means that the relay trips when the object distance is less than the associated switching

point; in the case of open function, the relay trips when the object distance is greater than the switching point.

The relays switch to the "safe state" (all relays open, regardless of close/open function) in the event of a failure

Setting the display modes:

Two display modes can be selected with DIP switch 4:

Release date: 2017-08-24 08:53 Date of issue: 2017-08-24 212371_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Ultrasonic sensor UC500-D1-3K-V7

Display mode 1: DIP switch 4 ON, underfill warning:

Object distance x x < A1 A1 < x < A2 A2 < x < A3 x > A3

LED 1, red (full) flashes off off off

LED 2, green/yellow (normal) off lit green off off

LED 3, green/yellow (low) off off flashes yellow off

LED 4, red (empty) off off off flashes

In this mode LED 1 (red) serves as the overfilling indicator, LED 2 (green) indicates the normal state, LED 3 (yellow) serves as

the preliminary warning that the container is nearly empty and LED 4 (red) signalises the "container empty" state.

Display mode 2: DIP switch 4 OFF, overfill warning

Object distance x x < A1 A1 < x < A2 A2 < x < A3 x > A3

LED 1, red (full) flashes off off off

LED 2, green/yellow (high) off flashes yellow off off

LED 3, green/yellow (normal) off off lit green off

LED 4, red (empty) off off off flashes

In this mode LED 1 (red) serves as the overfilling indicator, LED 2 (yellow) serves as the preliminary warning that the container

is nearly full, LED 3 (green) indicates the normal state, and LED 4 (red) signalises the "container empty" state.

The relays switch to the "safe state" (all relays open, regardless of close/open function) in the event of a failure.

Release date: 2017-08-24 08:53 Date of issue: 2017-08-24 212371_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...