Ultrasonic sensor UC500-30GM-IUEP-IO-V15

Technical data

General specifications

Sensing range 30 ... 500 mm

Adjustment range 50 ... 500 mm

Dead band 0 ... 30 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 380 kHz

Model Number

UC500-30GM-IUEP-IO-V15

Single head system

Features

• IO-link interface for service and

process data

• Programmable via DTM with

PACTWARE

• Switch output and analog output

• Selectable sound lobe width

• Synchronization options

• Temperature compensation

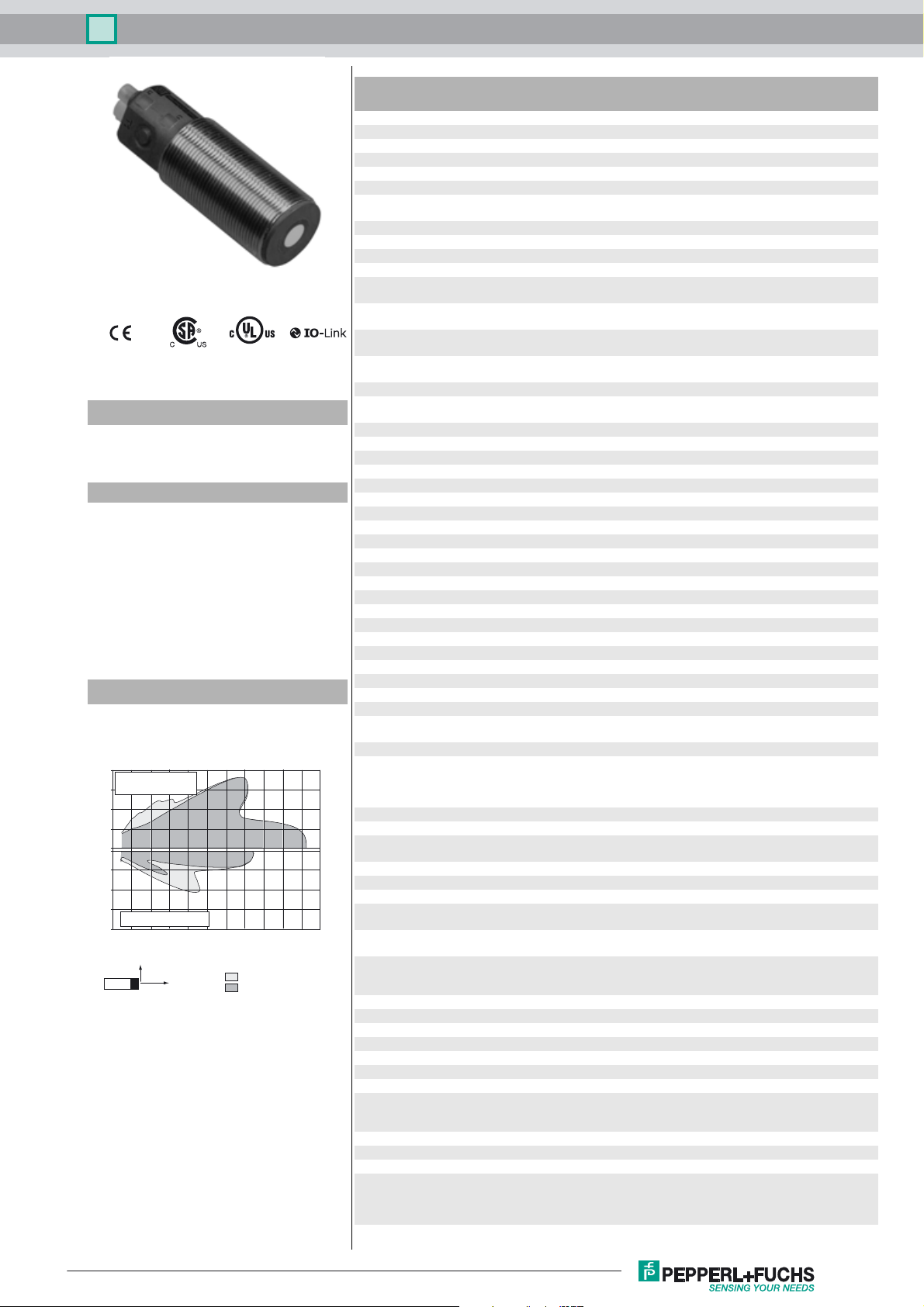

Diagrams

Characteristic response curve

Distance Y [mm]

200

flat surface

150

100 mm x 100 mm

100

50

0

-50

-100

-150

round bar, Ø 25 mm

-200

0 100 200 300 400 500 600 700 800 900 1000 1100

Y

X

Distance X [mm]

wide sound lobe

narrow sound lobe

Response delay minimum : 25 ms

Memory

Non-volatile memory EEPROM

Write cycles 100000

Indicators/operating means

LED green solid: Power on

LED yellow 1 solid: Object in evaluation range

LED yellow 2 solid: Object in evaluation range

LED red solid red: Error

Electrical specifications

Operating voltage U

No-load supply current I

Power consumption P

Time delay before availability t

Interface

B

0

0

v

Interface type IO-Link

Protocol IO-Link V1.0

Transfer rate Acyclical: typical 240 Bit/s

Cycle time min. 13.2 ms

Mode COM 2 (38.4 kBaud)

Process data witdh 16 bit

SIO mode support yes

Input/Output

Input/output type 1 synchronization connection, bidirectional

0 Level 0 ... 1 V

1 Level 4 V ... U

Input impedance > 12 kΩ

Output rated operating current < 12 mA

Pulse length 0.5 ... 300 ms (level 1)

Pulse interval ≥ 14 ms (level 0)

Synchronization frequency

Common mode operation ≤ 70 Hz

Multiplex operation ≤ 90 Hz / n , n = number of sensors , n ≤ 10

Output

Output type 1 push-pull (4 in 1) output, short-circuit protected, reverse

Rated operating current I

Voltage drop U

Resolution current output: evaluation range [mm]/3200 but ≥0.05 mm

d

e

Deviation of the characteristic curve ≤ 0.2 % of full-scale value

Repeat accuracy ≤ 0.1 % of full-scale value

Switching frequency f ≤ 11 Hz

Range hysteresis H 1 % of the adjusted operating range (default settings),

Load impedance current output: ≤ 300 Ohm

Temperature influence ≤ 1.5 % from full-scale value (with temperature

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector plug M12 x 1 , 5-pin

Degree of protection IP67

Material

Housing Stainless steel 1.4305 / AISI 303

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Mass 66 g

Factory settings

Output 1 near switch point: 50 mm

factory setting: 45 ms

flashing: Standby mode or IO link communication

flashing: Learning function, object detected

flashing: Learning function, object detected

red, flashing: program function, object not detected

10 ... 30 V DC , ripple 10 %SS

15 ... 30 V voltage output

≤ 60 mA

≤ 1 W

≤ 100 ms

B

(factory setting: n = 5 )

polarity protected

Current output 4 mA ... 20 mA or

voltage output 0 V ... 10 V configurable

200 mA , short-circuit/overload protected

≤ 2.5 V

voltage output: evaluation range [mm]/4000 but ≥0.05 mm

programmable

voltage output: ≥ 1000 Ohm

compensation)

≤ 0.2 %/K (without temperature compensation)

TPU

Polyamides

far switch point: 500 mm

Output mode: Window mode

output behavior: NO contact

Release date: 2017-10-24 12:02 Date of issue: 2017-10-27 191238_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Ultrasonic sensor UC500-30GM-IUEP-IO-V15

Output 2 near limit: 100 mm

Beam width wide

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated ≤36 V

far limit: 250 mm

Output mode: rising ramp

output behavior: Current output 4 mA ... 20 mA

IEC 60947-5-2:2007 + A1:2012

EN 60947-5-7:2003

IEC 60947-5-7:2003

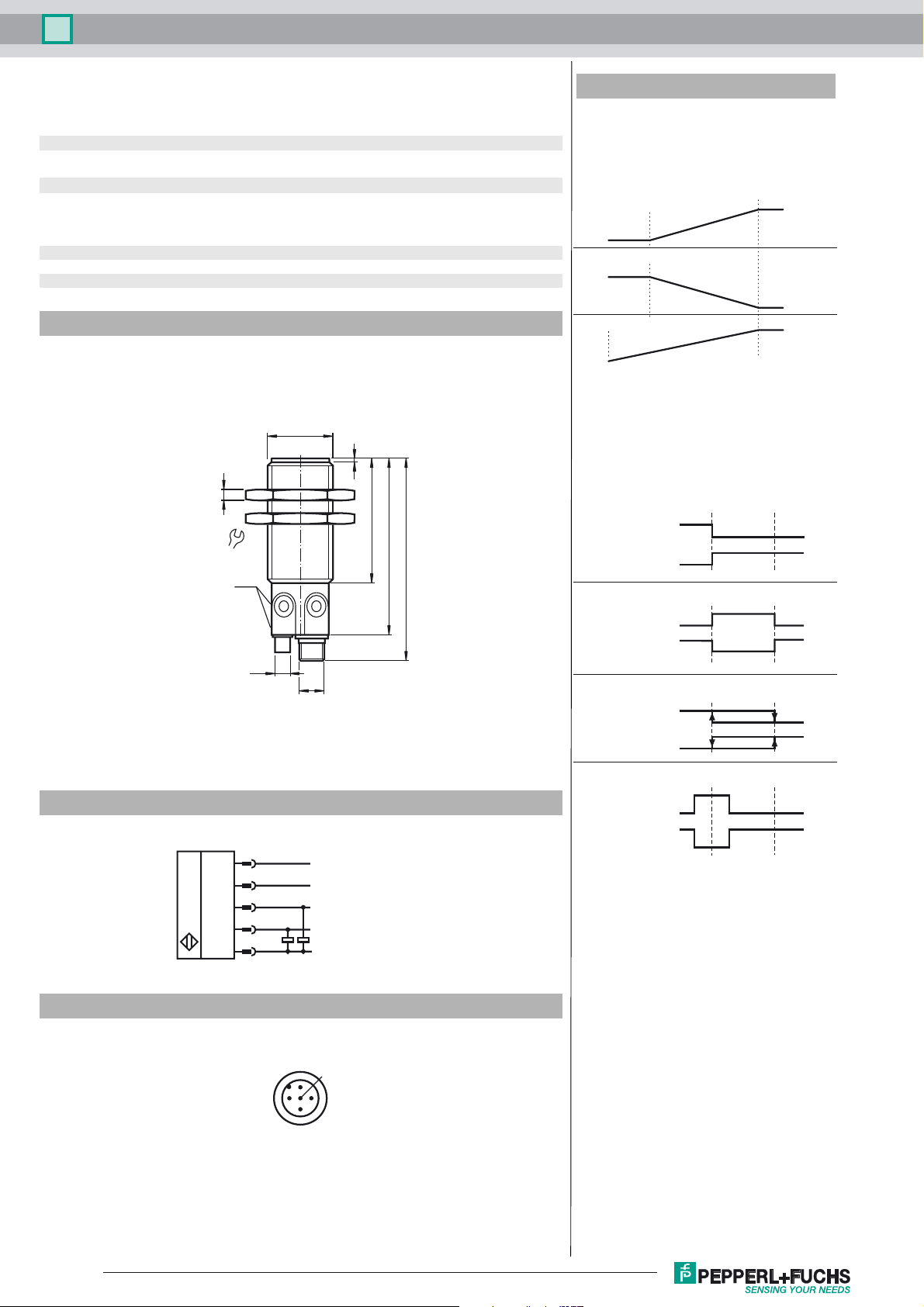

Dimensions

M30 x 1.5

2

5

56

36

LED

81

93

Additional Information

Analog output operating modes

Analog functions

Near trip value Distant trip value

Rising ramp

Falling ramp

Zero point line

0

Switching output operating modes

1. Switching point mode

NO contact

NC contact

2. Window mode

Near

switching

point

Far

switching

point

Electrical Connection

Pinout

T1 T2

ø7

M12

1

5

4

2

3

2

L+

Sync.

C/Q

Analog output

L-

1

5

4

NO contact

NC contact

3. Hysteresis mode

NO contact

NC contact

4. Retroreflective sensor mode

NO contact

NC contact

3

Release date: 2017-10-24 12:02 Date of issue: 2017-10-27 191238_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Ultrasonic sensor UC500-30GM-IUEP-IO-V15

Wire colors in accordance with EN 60947-5-2

1 BN

2 WH

3 BU

4 BK

5 GY

Accessories

IO-Link-Master02-USB

IO-Link master, supply via USB port or separate power supply, LED indicators, M12

plug for sensor connection

BF 30

Mounting flange, 30 mm

BF 30-F

Mounting flange with dead stop, 30 mm

BF 5-30

Universal mounting bracket for cylindrical sensors with a diameter of 5 ... 30 mm

V15-W-2M-PVC

Female cordset, M12, 5-pin, PVC cable

UVW90-M30

Ultrasonic -deflector

UVW90-K30

Ultrasonic -deflector

DA5-IU-2K-V

Process control and indication equipment

(brown)

(white)

(blue)

(black)

(gray)

Description of Sensor Functions

Programming

The sensor is equipped with two outputs. Two switching points or trip values as well as the output mode, can be programmed for each output.

The shape of the sensor sound cone can also be programmed. These parameters can be configured using two different methods:

- Using the sensor push buttons

- Using the IO-link interface of the sensor. This method requires an IO-link master (e.g. IO-link master01 USB) and the associated software.

The download link is available on the product page for the sensor with the IO link at www.pepperl-fuchs.de

Configuration using the push buttons is described below. To configure the parameters using the sensor IO-link interface, please read the software

description. The processes for configuring the switching points and the sensor operating modes run completely independently and do not influence one another.

Note:

- The sensor can only be programmed during the first 5 minutes after switching on. This time is extended during the actual programming process. The option of programming the sensor is revoked if no programming activities take place for 5 minutes. After this, programming is no

longer possible until the sensor is switched off and on again.

- The programming activities can be canceled at any time without changing the sensor settings. To do so, press and hold the push button for

10 seconds.

Programming the switching point/trip value of the analog characteristic

Note:

Each push button is assigned to a physical output. The switching output (C/Q) is programmed via push button T1. The analog output is programmed via push button T2.

A flashing red LED during the programming process indicates unreliable object detection. Should this occur, correct the alignment of the object

until the yellow LED L1 or L2 flashes. Only then will the settings be transferred to the sensor memory.

Programming the switching points/trip values using the push button

Programming the near switching point/trip value of the analog characteristic

1. Position the object at the site of the required near switching point or trip value.

2. Press and hold the push button for 2 seconds (yellow LED flashes)

3. Briefly press the push button (green LED flashes 3 times as confirmation). The sensor returns to normal mode.

Programming the far switching point/trip value of the analog characteristic

1. Position the object at the site of the required far switching point or trip value.

2. Press and hold the push button for 2 seconds (yellow LED flashes)

3. Press and hold the push button for 2 seconds (green LED flashes 3 times as confirmation). The sensor returns to normal mode.

Programming the operating modes

The sensor features a 3-stage process for programming the sensor operating modes. You can program the following with this process:

1. Output mode

2. Output behavior of the switching output/analog output

3. The shape of the sound cone

These two stages of the process are programmed in succession. To switch from one programming function to the next, press and hold the push

button for 2 seconds.

Release date: 2017-10-24 12:02 Date of issue: 2017-10-27 191238_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Ultrasonic sensor UC500-30GM-IUEP-IO-V15

Accessing the programming routine

The operating mode can be programmed separately for each of the two switching outputs. The operating mode of the switching output (C/Q) is

programmed via push button T1. The operating mode of the analog output is programmed via push button T2.

To access the programming routine for the sensor operating mode, press the push button for 5 seconds.

Programming the output mode

The green LED is now flashing. The number of flashes indicates the output function currently programmed:

Switching output Analog output

1x: Switching point mode 1x: rising slope

2x: Window mode 2x: falling slope

3x: Hysteresis mode 3x: zero point line

4x: Retroreflective sensor mode

1. Briefly press the push button to navigate through the output configurations in succession. Use this method to choose the required output

mode.

2. Press and hold the push button for 2 seconds to save the selection and switch to the programming routine for the output behavior.

Programming the output behavior

The yellow LED is now flashing. The number of flashes indicates the output behavior currently programmed:

Switching output Analog output

1x: NO contact 1x: Current output (4–20 mA)

2x: NC contact 2x: Voltage output (0–10 V)

1. Briefly press the push button to navigate through the output behaviors in succession. Use this method to choose the required output function.

2. Press and hold the push button for 2 seconds to save the selection and switch to the programming routine for the sound cone.

Programming the shape of the sound cone

The red LED is now flashing. The number of flashes indicates the sound cone shape currently programmed:

1x: narrow

2x: medium

3x: wide

1. Briefly press the push button to navigate through the different sound cone shapes in succession. Use this method to choose the required

sound cone shape.

2. Press and hold the push button for 2 seconds to return to normal mode.

Note

The last sound cone shape programmed applies for both

3x: Deactivated: high impedance

outputs in equal measure.

Resetting the sensor to the factory settings

The sensor can be reset to the original factory settings.

1. Disconnect the sensor from the power supply

2. Press and hold one of the push buttons

3. Connect the power supply (yellow and red LEDs flash simultaneously for 5 seconds, followed by the yellow and green LEDs flashing simultaneously)

4. Release the push button

The sensor will now function with the original factory settings.

Factory settings

See technical data.

Indicators

The sensor has four LEDs for indicating the status and two buttons for setting parameters.

In normal mode

Error-free operation

Fault (e.g. compressed air)

When programming the switching

points or trip values

Object detected

No object detected

Confirmation, programming successful

Warning, programming invalid

When programming the operating

mode

Programming the output mode

Programming the output behavior

Programming the sound cone

LED,

green

On

Off

Off

Off

Flashes 3x

Off

Flashes

Off

Off

LED L1, yellow LED L2, yellow LED, red

The output status

retains the last

status

Flashes

Off

Off

Off

Off

Flashes

Off

The output status

retains the last

status

Flashes

Off

Off

Off

Off

Flashes

Off

Off

On

Off

Flashes

Off

Flashes 3x

Off

Off

Flashes

Release date: 2017-10-24 12:02 Date of issue: 2017-10-27 191238_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

T1 T2

L1

L2

L1

LED yellow LED yellow

L2

LED

green/red

4

Ultrasonic sensor UC500-30GM-IUEP-IO-V15

Synchronization

The sensor is fitted with a synchronization input that suppresses mutual interference from external ultrasonic signals. If this input is not connected,

the sensor operates with internally generated cycle pulses. The sensor can be synchronized by creating external rectangular pulses and by setting the appropriate parameters via the IO-link interface. Each falling pulse edge sends an individual ultrasonic pulse. If the signal at the synchronization input is low for >

is disconnected from external signals (see note below).

If a high signal is applied to the synchronization input for > 1 second, the sensor switches to standby. This is indicated by the green LED. In this

operating mode, the last recorded output statuses are retained. Please observe the software description in the event of external synchronization.

Note:

If the option of synchronizing is not used, the synchronization input must be connected to ground (L-) or the sensor must be operated with a V1connection cable (4-pin).

The option of synchronization is not available during the programming process. During synchronization, the sensor can switch to programming

via the IO-link interface. This interrupts the synchronization process and the sensor is no longer synchronized.

The following synchronization modes are available:

1. Multiple sensors (see Technical data for the maximum number) can be synchronized by connecting the synchronization inputs on the sensors. In this case, the sensors synchronize themselves in succession in multiplex mode. Only one sensor sends signals at any one time.

(See note below)

2. Multiple sensors (see Technical data for the maximum number) can be synchronized by connecting the synchronization inputs on the sensors. The sensor interface can be used to parameterize the sensors so that one functions as a master and the others function as slaves.

(See interface description) In this case, the sensors in master/slave mode work simultaneously, i.e. in synchronization where the master sensor plays the role of an intelligent external impulse generator.

3. Multiple sensors can be controlled collectively by an external signal. In this case, the sensors are triggered in parallel and operate synchronously, i.e. at the same time. All sensors must be parameterized via the sensor interface so that they are set to external. See the software

description.

4. Several sensors are controlled with a time delay by an external signal. In this case, only one sensor is externally synchronized at any one

time (see note below). All sensors must be parameterized via the sensor interface so that they are set to external. See the software description.

5. A high signal (L+) or a low signal (L-) at the synchronization input switches the sensor to standby in the case of external parameterization.

Note:

The response time of the sensors increases in proportion to the number of sensors in the synchronization chain. In multiplex mode, the measuring

cycles of the individual sensors run in succession in a chronological sequence.

Note:

The synchronization connection of the sensors supplies an output current in the case of a low signal, and generates an input impedance in the

case of a high signal. Please note that the synchronizing device must have the following driver properties:

Driver current according to L+ >

Driver current according to L- >

1 second, the sensor reverts to the normal, unsynchronized operating mode. This also occurs if the synchronization input

n * high level signal/input impedance (n = number of sensors to be synchronized)

n * output current (n = number of sensors to be synchronized).

Release date: 2017-10-24 12:02 Date of issue: 2017-10-27 191238_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

5

Loading...

Loading...