Ultrasonic sensor UC2000-30GM-IUR2-T-V15

Technical data

General specifications

Sensing range 80 ... 2000 mm

Adjustment range 120 ... 2000 mm

Dead band 0 ... 80 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 175 kHz

Model Number

UC2000-30GM-IUR2-T-V15

Single head system

Features

• Parameterization interface for the

application-specific adjustment of

the sensor setting via the service

program ULTRA 3000

• Analog current and voltage output

• Synchronization options

• Adjustable acoustic power and

sensitivity

• Temperature compensation

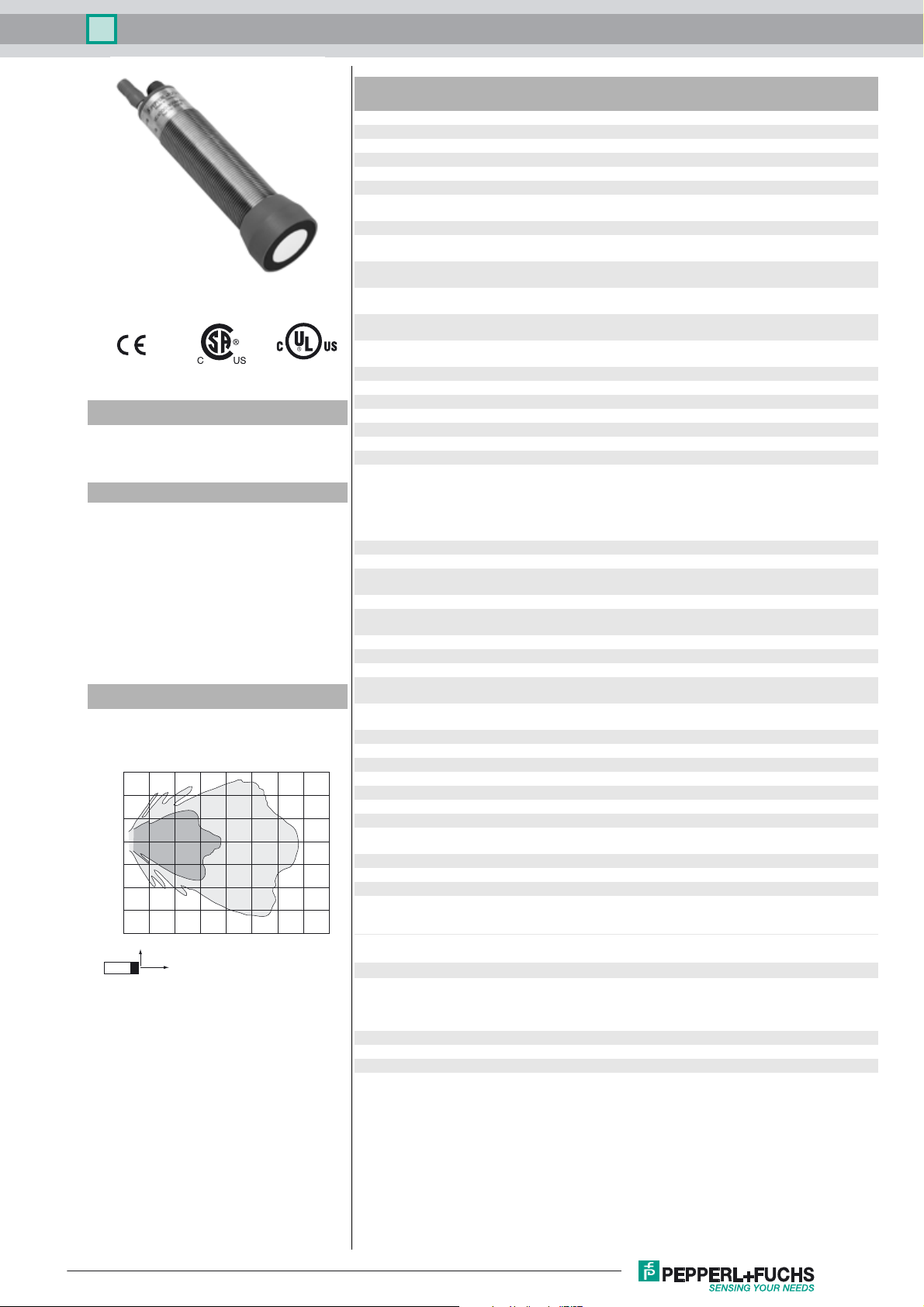

Diagrams

Characteristic response curve

Distance Y [m]

0.6

0.4

0.2

0.0

-0.2

-0.4

-0.6

-0.8

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Curve 1: flat surface 100 mm x 100 mm

Curve 2: round bar, Ø 25 mm

2

Y

X

1

Distance X [m]

Response delay 65 ms minimum

Indicators/operating means

LED green solid: Power-on

LED yellow 1 solid: object in evaluation range

LED yellow 2 solid: object in detection range

LED red solid: temperature/program plug not connected

Temperature/TEACH-IN connector Temperature compensation , Evaluation range programming

Electrical specifications

Operating voltage U

Power consumption P

Time delay before availability t

Interface

Interface type RS 232, 9600 Bit/s , no parity, 8 data bits, 1 stop bit

Input/Output

Synchronization bi-directional

Synchronization frequency

Common mode operation ≤ 30 Hz

Multiplex operation ≤ 30 Hz / n , n = number of sensors , n ≤ 5

Output

Output type 1 current output 4 ... 20 mA

Resolution evaluation range [mm]/4000, but ≥ 0.35 mm

Deviation of the characteristic curve ≤ 0.2 % of full-scale value

Repeat accuracy ≤ 0.1 % of full-scale value

Load impedance current output: ≤ 500 Ohm

Temperature influence ≤ 2 % from full-scale value (with temperature compensation)

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Connection type Connector plug M12 x 1 , 5-pin

Degree of protection IP65

Material

Housing stainless steel (1.4305 / AISI 303)

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Mass 210 g

Factory settings

Output evaluation limit A1: 200 mm

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated ≤36 V

B

0

v

195 ms factory setting

flashing: Standby mode or program function object detected

flashing: program function

flashing: program function

flashing: fault or program function object not detected

, output function setting

10 ... 30 V DC , ripple 10 %

≤ 900 mW

≤ 500 ms

0 level -U

1 level: +4 V...+U

input impedance: > 12 KOhm

synchronization pulse: ≥ 100 µs, synchronization interpulse

period: ≥ 2 ms

1 voltage output 0 ... 10 V

voltage output: ≥ 1000 Ohm

≤ 0.2 %/K (without temperature compensation)

PBT plastic parts

evaluation limit A2: 2000 mm

rising ramp

IEC 60947-5-2:2007 + A1:2012

EN 60947-5-7:2003

IEC 60947-5-7:2003

...+1 V

B

SS

B

Release date: 2018-01-08 10:27 Date of issue: 2018-01-09 129684_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Ultrasonic sensor UC2000-30GM-IUR2-T-V15

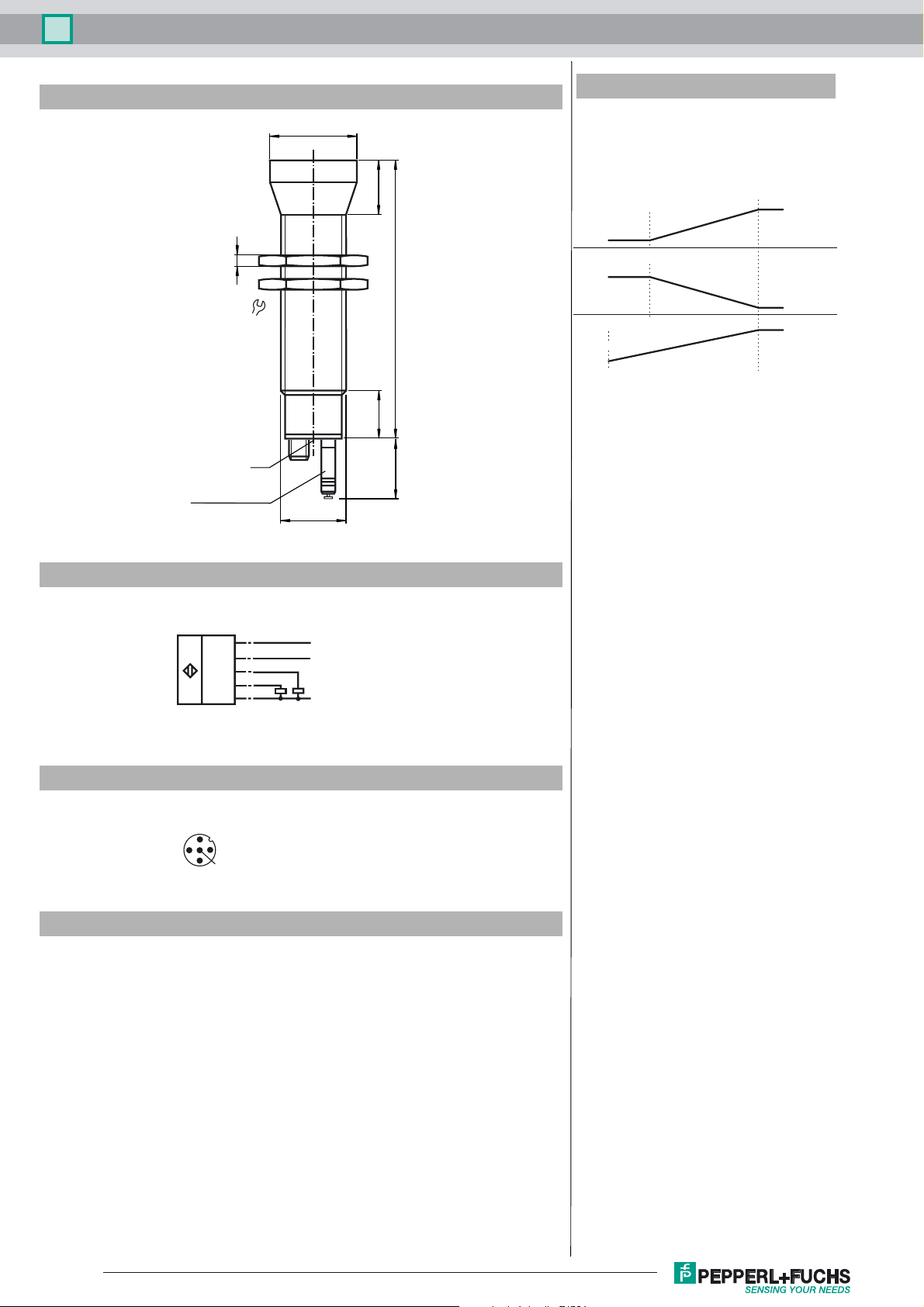

Dimensions

5

36

LED

Temperature probe

Coded plug

ø40

M30x1.5

Additional Information

Analogue output function

Analog function

Near distance

25

of evaluation

Rising slope

4 mA/0 V

Falling slope

20 mA/10 V

128

Zero line mode

4 mA/0 V

A1= 0 mm A2

22

27.5

Far distance

of evaluation

20 mA/10 V

4 mA/0 V

20 mA/10 V

Electrical Connection

Standard symbol/Connection:

(version IU)

1

(BN)

(GY)

U

Core colors in accordance with EN 60947-5-2.

5

2

(WH)

(BK)

4

(BU)

3

Pinout

Connector V15

2

1

3

5

4

Accessories

BF 30

Mounting flange, 30 mm

BF 30-F

Mounting flange with dead stop, 30 mm

UC-30GM-PROG

+ U

B

Sync.

0-10 V

4-20 mA

- U

B

ULTRA3000

Software for ultrasonic sensors, comfort line

UC-30GM-R2

DA5-IU-2K-V

Process control and indication equipment

V15-G-2M-PVC

Female cordset, M12, 5-pin, PVC cable

Description of Sensor Functions

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Release date: 2018-01-08 10:27 Date of issue: 2018-01-09 129684_eng.xml

Ultrasonic sensor UC2000-30GM-IUR2-T-V15

Programming procedure

The sensor features 2 programmable analog outputs with programmable evaluation range. Programming the evaluation

range and the operating mode is done either via the sensor's RS232 interface and ULTRA3000 software (see the

ULTRA3000 software description) or by means of the programming plug at the sensor's back end which is described

here.

Programming of Evaluation Range

1. Disconnect supply voltage

2. Remove the programming plug to activate program mode.

3. Reconnect supply voltage (Reset)

4. Place the target at the desired position for A1

5. Momentarily insert the programming plug in position A1 and then remove. This will program the position A1.

6. Place the target at the desired position for A2

7. Momentarily insert the programming plug in position A2 and then remove. This will program the position A2.

Notes:

Coded plug

• Removing the programming plug saves the new position into the device memory.

• The programming status is indicated by the LED. A flashing green LED indicates that the target is detected; a flashing red LED indicates that

no target is detected.

Programming the Operation Mode

If the program mode is still activated, continue at number 4. If not, activate program mode by performing the sequence numbers 1 to 3.

1. Disconnect supply voltage

2. Remove the programming plug to activate program mode.

3. Reconnect supply voltage (Reset)

4. Insert the programming plug in position E2/E3. By removing and reinserting the plug, the user can toggle through the three different modes

of operation. The selected mode is indicated by the LEDs as shown below:

• Rising slope mode, LED A2 flashes

• Falling slope mode, LED A1 flashes

• Zero line mode, LEDs A1 and A2 flash

5. Once the desired mode is selected, insert the programming plug in position T. This completes the programming procedure and saves the

switch points and mode of operation.

6. The sensor now operates in normal mode.

Note:

The programming plug also functions as the temperature compensation. If the programming plug has not been inserted in the T position within 5

minutes, the sensor will return to normal operating mode with the latest saved values, without temperature compensation.

A2

A1

T

E2/E3

Factory settings

See technical data.

Display

The sensor provides LEDs to indicate various conditions.

#

During Normal Operation

- Temperature compensated

- with removed programming plug

Interference (e.g. compressed air)

During Sensor Programming

Evaluation limit A1:

Object detected

No object detected

Evaluation limit A2:

Object detected

No object detected

Operation mode:

Rising slope mode

Falling slope mode

Zero line mode

Standby

LED

yellow

E2 E3

Evaluation limit 1

Dual-LED

green/red

A1 A2

"Power on"/Disturbance

Green LED Red LED Yellow LED A1 Yellow LED A2

On

Off

Off

Flashing

Off

Flashing

Off

On

On

On

Flashing Off remains in previous state remains in previous state

LED

yellow

Evaluation limit 2

Off

On

Flashing

Off

Flashing

Off

Flashing

Off

Off

Off

Object in evaluation range

Object in evaluation range

remains in previous state

Flashing

Flashing

Off

Off

Off

Flashing

Flashing

Object in sensing range

Object in sensing range

remains in previous state

Off

Off

Flashing

Flashing

Flashing

Off

Flashing

Synchronization

This sensor features a synchronization input for suppressing ultrasonic mutual interference ("cross talk"). If this input is not connected, the sensor

will operate using internally generated clock pulses. It can be synchronized by applying an external square wave. The pulse duration must be ≥

100 µs. Each falling edge of the synchronization pulse triggers transmission of a single ultrasonic pulse. If the synchronization signal remains low

for ≥ 1 second, the sensor will revert to normal operating mode. Normal operating mode can also be activated by opening the signal connection

to the synchronization input (see note below).

If the synchronization input goes to a high level for > 1 second, the sensor will switch to standby mode, indicated by the green LED. In this mode,

the outputs will remain in the last valid output state.

Release date: 2018-01-08 10:27 Date of issue: 2018-01-09 129684_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Ultrasonic sensor UC2000-30GM-IUR2-T-V15

Note:

If the option for synchronization is not used, the synchronization input has to be connected to ground (0 V) or the sensor must be operated via a

V1 cordset (4-pin).

The synchronization function cannot be activated during programming mode and vice versa.

The following synchronization modes are possible:

1. Several sensors (max. number see technical data) can be synchronized together by interconnecting their respective synchronization inputs.

In this case, each sensor alternately transmits ultrasonic pulses in a self multiplexing mode. No two sensors will transmit pulses at the same

time (see note below).

2. Multiple sensors can be controlled by the same external synchronization signal. In this mode the sensors are triggered in parallel and are synchronized by a common external synchronization pulse.

3. A separate synchronization pulse can be sent to each individual sensor. In this mode the sensors operate in external multiplex mode (see note

below).

4. A high level (+U

Note:

Sensor response times will increase proportionally to the number of sensors that are in the synchronization string. This is a result of the multiplexing of the ultrasonic transmit and receive signal and the resulting increase in the measurement cycle time.

) on the synchronization input switches the sensor to standby mode.

B

Note on communication with the UC-30GM-R2 interface cable

The UC-30GM-R2 interface cable allows for communication with the ultrasonic sensor using

ULTRA3000 software. The cable creates a connection between a PC RS-232 interface and the

programming plug socket on the sensor. When connecting to the sensor, make certain the plug

is lined up correctly; otherwise no communication will be possible. The key of the cable’s plug

must be aligned to the groove of the socket on the sensor (not with the arrow symbol on the sensor).

Programmable parameters with the ULTRA3000 software

Temperature/program

connector

(PC connection via interface cable UC-30GM-R2)

1: TXD

2: RXD

3: not used

4: GND

Groove

4

3

1

2

V15-plug connector

(M12x1)

LED-window

• Evaluation limits A1 and A2

•Operation mode

• Sonic speed

• Temperature offset (The inherent temperature-rise of the sensor can be considered in the temperature compensation)

• Expansion of the unusable area (for suppression of unusable area echoes)

• Reduction of the detection range (for suppression of remote range echoes)

• Time of measuring cycle

• Acoustic power (interference of the burst duration)

• Sensitivity

• Behavior of the sensor in case of echo loss

• Behavior of the sensor in case of a fault

• Average formation via an allowed number of measuring cycles

• Selection of the parameter set, RS 232 or manually

Note:

When connected to a PC and running the ULTRA3000 software, the sensor can act as a long term data logger as well.

Installation conditions

If the sensor is installed in an environment where the temperature can fall below 0 °C, one of these mounting flanges must be used for mounting:

BF30, BF30-F, or BF 5-30.

If the sensor is mounted in a through hole using the included steel nuts, it must be mounted at the middle of the threaded housing. If it must be

mounted at the front end of the threaded housing, plastic nuts with centering ring (optional accessories) must be used.

Release date: 2018-01-08 10:27 Date of issue: 2018-01-09 129684_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

4

Loading...

Loading...