Page 1

UC***-18GS series

Configuring

Ultrasonic Sensors

with IO-Link Interface

Manual

Page 2

With regard to the supply of products, the current issue of the following document is applicable: The

General Terms of Delivery for Products and Services of the Electrical Industry, published by the Central

Association of the Electrical Industry (Zentralverband Elektrotechnik und Elektroindustrie (ZVEI) e.V.)

in its most recent version as well as the supplementar y clause: "Expanded reservation of proprietorship"

Worldwide

Pepperl+Fuchs Group

Lilienthalstr. 200

68307 Mannheim

Germany

Phone: +49 621 776 - 0

E-mail: info@de.pepperl-fuchs.com

North American Headquarters

Pepperl+Fuchs Inc.

1600 Enterprise Parkway

Twinsburg, Ohio 44087

USA

Phone: +1 330 425-3555

E-mail: sales@us.pepperl-fuchs.com

Asia Headquarters

Pepperl+Fuchs Pte. Ltd.

P+F Building

18 Ayer Rajah Crescent

Singapore 139942

Phone: +65 6779-9091

E-mail: sales@sg.pepperl-fuchs.com

https://www.pepperl-fuchs.com

Page 3

UC***-18GS series

Contents

1 Introduction................................................................................................................ 6

1.1 Content of this Document ............................................................................. 6

1.2 Target Group, Personnel ............................................................................... 6

1.3 Symbols Used ................................................................................................ 6

1.4 Intended Use .................................................................................................. 7

1.5 General Safety Notes..................................................................................... 7

1.6 Declaration of Conformity............................................................................. 8

2 Product Description .................................................................................................. 9

2.1 Use and Application ...................................................................................... 9

2.2 Indicators and Operating Elements ........................................................... 11

2.3 Accessories.................................................................................................. 12

2.3.1 Accessories for Mounting and Connection ...................................... 12

2.3.2 Parameterization Aids...................................................................... 12

3 Installation................................................................................................................ 14

3.1 Safety Information ....................................................................................... 14

3.2 Preparation ................................................................................................... 14

3.3 Mounting....................................................................................................... 14

3.4 Connection ................................................................................................... 15

4 Commissioning without IO-Link............................................................................. 16

5 Sensor Programming via the Programming Button.............................................17

5.1 Programming Switch Points / Limits.......................................................... 17

5.2 Programming Sensor Operating Modes for Switching Output ............... 19

5.3 Programming the Sensor Operating Modes for Analog Output.............. 20

6 Commissioning Using PACTware and DTM........................................................... 22

6.1 Commissioning via IO-Link......................................................................... 22

6.2 Commissioning Using IrDa Infrared Interface .......................................... 24

7 Configuration and Analysis with DTM via IO-Link................................................ 27

7.1 Overview ....................................................................................................... 27

7.2 Sensor Information Menu Option...............................................................27

7.3 Output Configuration Menu Option ........................................................... 28

7.4 Sensor Configuration Menu Option ........................................................... 29

2020-11

3

Page 4

UC***-18GS series

Contents

7.5 Analysis & Echo Suppression Menu Option .............................................31

7.6 Observation Menu Option........................................................................... 38

7.7 Service Menu Option ................................................................................... 42

7.8 Information Menu Option ............................................................................43

8 Description of Sensor Parameters.........................................................................44

8.1 Sensor Information ...................................................................................... 44

8.2 Output – Switching Output..........................................................................44

8.2.1 Output Mode .................................................................................... 44

8.2.2 Output Logic.....................................................................................47

8.2.3 Switch Point 1...................................................................................47

8.2.4 Switch Point 2...................................................................................47

8.2.5 Retroreflective Mode Offset..............................................................48

8.2.6 Switching Hysteresis........................................................................48

8.2.7 Switch-On Delay ..............................................................................49

8.2.8 Switch-Off Delay ..............................................................................49

8.3 Output Configuration – Analog Output......................................................50

8.3.1 Output Mode .................................................................................... 50

8.3.2 Output Type...................................................................................... 50

8.3.3 Near Limit.........................................................................................50

8.3.4 Far Limit ........................................................................................... 51

8.3.5 Lower Output Value ..........................................................................51

8.3.6 Upper Output Value.......................................................................... 51

8.4 Sensor Configuration – Evaluation ............................................................52

8.4.1 Sound Beam Width .......................................................................... 52

8.4.2 Echo Evaluation ...............................................................................53

8.4.3 Evaluation Method............................................................................ 53

8.4.4 Averages & Skip Count..................................................................... 54

8.4.5 Weighting of Former Measurement .................................................. 54

8.4.6 Allowed Deviation to the Former Measurement ................................55

8.4.7 Skip Time ......................................................................................... 55

8.4.8 Temperature Compensation ............................................................. 55

8.4.9 Operating Temperature.....................................................................56

8.4.10 Foreground Suppression.................................................................. 57

8.4.11 Background Suppression................................................................. 57

8.4.12 Sensor Cycle Time ........................................................................... 57

8.4.13 Ultrasonic Pulse Length ................................................................... 58

2020-11

4

Page 5

UC***-18GS series

Contents

8.5 Sensor Configuration – Synchronization .................................................. 58

8.6 Sensor Configuration – Echo Loss and Error Handling ..........................59

8.6.1 No Echo........................................................................................... 59

8.6.2 Output Behavior if an Error Occurs .................................................. 60

8.6.3 Error Replacement Value – Current/Voltage..................................... 60

8.7 Sensor Configuration – Local Controls ..................................................... 61

8.7.1 Local Controls.................................................................................. 61

8.7.2 Local Controls Status....................................................................... 61

8.8 Service .......................................................................................................... 61

8.8.1 Locator Indication ............................................................................ 61

8.8.2 "Reset to Factory Defaults" Button................................................... 62

9 Synchronizing Multiple Sensors ............................................................................ 63

10 Maintenance and Repair ......................................................................................... 64

10.1 Maintenance Work ....................................................................................... 64

10.2 Cleaning........................................................................................................ 64

10.3 Resetting to the Factory Default................................................................. 64

11 Troubleshooting....................................................................................................... 65

11.1 What to Do in Case of an Error................................................................... 65

2020-11

5

Page 6

UC***-18GS series

Introduction

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

• Product identification

• Delivery, transport, and storage

• Mounting and installation

• Commissioning and operation

• Maintenance and repair

• Troubleshooting

• Dism ounting

• Disposal

Note

For full information on the product, refer to the further documentation on the Internet at

www.pepperl-fuchs.com.

The documentation comprises the following parts:

• This document

• Datasheet

In addition, the documentation may comprise the following parts, if applicable:

• EU-type examination certificate

• EU declaration of conformity

• Attestation of conformity

• Certificates

• Control drawings

• Instruction manual

• Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation, commissioning, operation, maintenance, and dismounting of the product. The personnel must have

read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

2020-11

6

Page 7

UC***-18GS series

Introduction

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is mandatory

that you observe these warning messages for your personal safety and in order to avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as follows:

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Informative Symbols

Note

This symbol brings important information to your attention.

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

1.4 Intended Use

The UC***-18GS series ultrasonic sensors use ultrasonic pulses to detect objects. The sensor

emits ultrasound, which is reflected by the object and received again by the sensor. The measured sound propagation time is used to determine the distance to the object (pulse-echo principle). Objects in the following forms can be detected: solid, granular, powder, or liquid. The

color and surface structure of the objects are irrelevant. Gases cannot be detected.

Note

UC***-18GS series ultrasonic sensors are not safety components within the meaning of the EC

Machinery Directive 2006/42/EC. They must not be used for the purposes of avoiding risk to

individuals or parts of the body.

Always operate the device as described in these instructions to ensure that the device and connected systems function correctly. The protection of operating personnel and the plant is guaranteed only if the device is operated in accordance with its intended use.

The operator is responsible for complying with all local safety regulations.

Only use recommended original accessories.

2020-11

7

Page 8

UC***-18GS series

ISO9001

Introduction

1.5 General Safety Notes

Responsibility for planning, assembly, commissioning, operation, maintenance, and dismounting lies with the plant operator.

Installation and commissioning of all devices may be performed only by trained and qualified

personnel.

The device is only approved for appropriate and intended use. Ignoring these instructions will

void any warranty and absolve the manufacturer from any liability.

If serious faults occur, stop using the device. Secure the device against inadvertent operation.

In the event of repairs, return the device to your local Pepperl+Fuchs representative or sales

office.

Note

Disposal

Electronic waste is hazardous. When disposing of the equipment, observe the current statutory

requirements in the respective country of use, as well as local regulations.

1.6 Declaration of Conformity

This product was developed and manufactured in line with the applicable European sta ndards

and directives.

Note

A declaration of conformity can be requested from the manufacturer.

The product manufacturer, Pepperl+Fuchs Group, 68307 Mannheim, Germany, has a certified

quality assurance system that conforms to ISO 9001.

2020-11

8

Page 9

UC***-18GS series

Product Description

2 Product Description

2.1 Use and Application

The UC***-18GS series ultrasonic sensors use ultrasonic pulses to detect objects. The sensor

emits ultrasound, which is reflected by the object and received again by the sensor. The measured sound propagation time is used to determine the distance to the object (pulse-echo principle). Objects in the following forms can be detected: solid, granular, powder, or liquid. The

color and surface structure of the objects are irrelevant. Gases cannot be detected.

Typically, ultrasonic sensors are used in a wide range of applications including:

• Sag control on packaging and metal processing machines

• To measure diameter of roll material (e.g., film, paper, metal sheet)

• To detect fill levels in tanks and silos

• To avoid collisions with self-propelled or controlled machines

• Height control of booms for sprayers

• To detect containers on refuse collection vehicles

• To detect objects or to measure fill levels on conveyor belts

• To detect pallets on forklifts

• To monitor range on barrier systems

• To detect PCBs when feeding them to SMD placement machines

The standard cylindrical 18GS housing design can be program med and adapted to various

applications. You can program boundaries, output modes, output types, and sound beam width

via the programming buttons on the sensor or via the convenient IO-Link or IrDa interfaces.

Convenient programming via the IO-Link or IrDa interfaces makes setting many other parameters such as filter options, echo suppression, synchronization settings, etc. possible. You therefore have various channels and adjustment options available for programming that can be used

individually depending on your application.

Programming of the ultrasonic sensors via IO-Link is possible offline using IODD or DTM and

an FTD frame program. You can program it online via a PLC via IO-Link master and IODD. Programming via the IrDA interface is possible using a DTM and an FTD frame program.

The IO-Link versions with switching output enable IO-Link communication in accordance with

the IO-Link standard. The 18GS versions with analog output can be parameterized via their IOLink interface.

The advantages of the UC***-18GS ultrasonic sensors are:

• Proven cylindrical housing design

• Advanced setting options via programming button on the device

• IO-Link 1.1 interface for service and process data, and for parameterization

• Excellent immunity to background noise such as compressed air

• Can be self-synchronized to avoid mutual interference of several adjacently mounted

ultrasonic sensors

• Programmable echo suppression

What Is IO-Link?

IO-Link enables seamless communication and digital data transfer from the control panel level

down to the sensor level. The intelligent sensors can be used to their full potential with IO-Link,

paving the way for Industry 4.0 in automation technology. The internationally standardized

interface provides value at all stages, from plant design and installation through to operation

and servicing. This value is achieved by sustained cost reductions and efficiency improvements.

2020-11

9

Page 10

UC***-18GS series

Product Description

Standardized device description files ("IODDs") and parameterization via software tools ensure

convenient configuration and integration of IO-Link sensors. Intelligent and transparent parameter management increases application flexibility and keeps downtimes to a minimum.

Parameters can be customized quickly and easily, even for complex production and batch

changes. Transparency right through to the sensor gives users access to a comprehensive

range of parameterization options and device diagnostics functions, allowing them to perform

predictive serv icing.

The technology offers particular benefits

• In service (troubleshooting, ser vicing, and device exchange)

• During commissioning (cloning, identification, configuration, and localization)

• And during operation (job changeover, continuous parameter monitoring, and online diag-

Device Description File (IODD)

The sensor parameters are different for each device. A standardized description of these

param eters can be found in the IO Device Description (IODD). The IODD can be imported into

various engineering tools from different system providers, providing they suppor t IODD. The

sensor can be configured or diagnosed using the appropriate tool.

IODDs can be integrated in a control environment to allow IO-Link devices to be used for IOLink operation. Both programming and exchanging process data can be performed with a PLC.

The IODD can be imported into a range of engineering tools from various system providers for

programming and diagnostics, provided these tools support IODD

DTM (Device Type Manager)

If a sensor is not used long-term in an IO-Link environment, but nevertheless needs to be configured, this can be done easily via a PC with installed FDT frame application (e.g., PACTware)

and with the DTM (Device Type Manager, a kind of "device driver") available for the sensor.

Unlike configuration via the IODD, this method provides extended functions and ensures

improved graphic visualization and convenient operation. Functions such as UC*** -18GS

series "echo suppression" can only be configured via the relevant DTM.

Offline Parameterization

For offline parameterization, IO-Link devices are already configured before mounting. To do

this, use the Pepperl+Fuchs IO-Link USB master.

We recommend using the "PACTware" software as an FDT frame application and user interface. So that it can be used in PACTware, the IODD mu st first be translated via the "IODD interpreter DTM" software. "IODD Interpreter DTM" is used to transform the IODD into a tabular user

inter face for parameterization.

The software components required in each case are summarized in the most current version of

the "IO-Link Offline Parameterization Tool" software package. The software package and the

documentation on its installation and use can be found online at www.pepperl-fuchs.com.

If you use the "IO-Link Offline Parameterization Tool" software package, have active internet

access, and have connected your device via the Pepperl+Fuchs IO-Link USB master, the

PACTware will automatically find the right IODD online.

The device description file (IODD) required for integration in an IO-Link system and for parameterization and diagnosis is available online. Visit www.pepperl-fuchs.com and navigate to the

relevant product page for the UC***-18GS sensor.

Online Parameterization

When commissioning machines and plants, you must integrate master and IO-Link devices into

the appropriate control environment. Depending on the components used, different software is

required.

You can configure and parameterize the devices using an IO-Link configuration tool. During

operation, you can check the parameters for the IO-Link devices, read, and monitor the status

and diagnostic data. IO-Link data is integrated into an application program using function

blocks.

nostics)

2020-11

10

Page 11

UC***-18GS series

1

2

3

4

Product Description

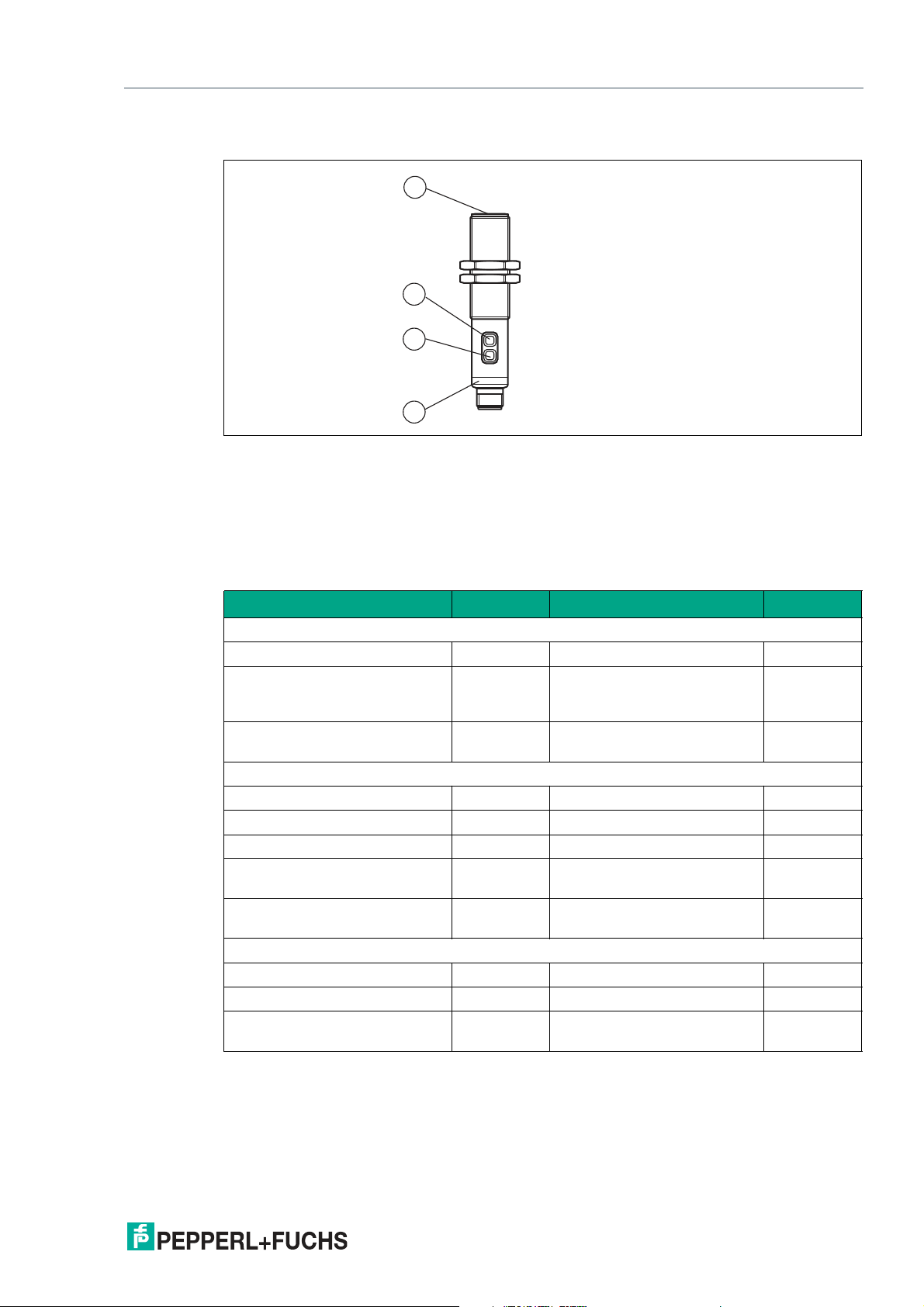

2.2 Indicators and Operating Elements

Figure 2.1

1. Yellow/green/red LED

2. Programming button T1

3. Programming button T2

4. Sonically-active area

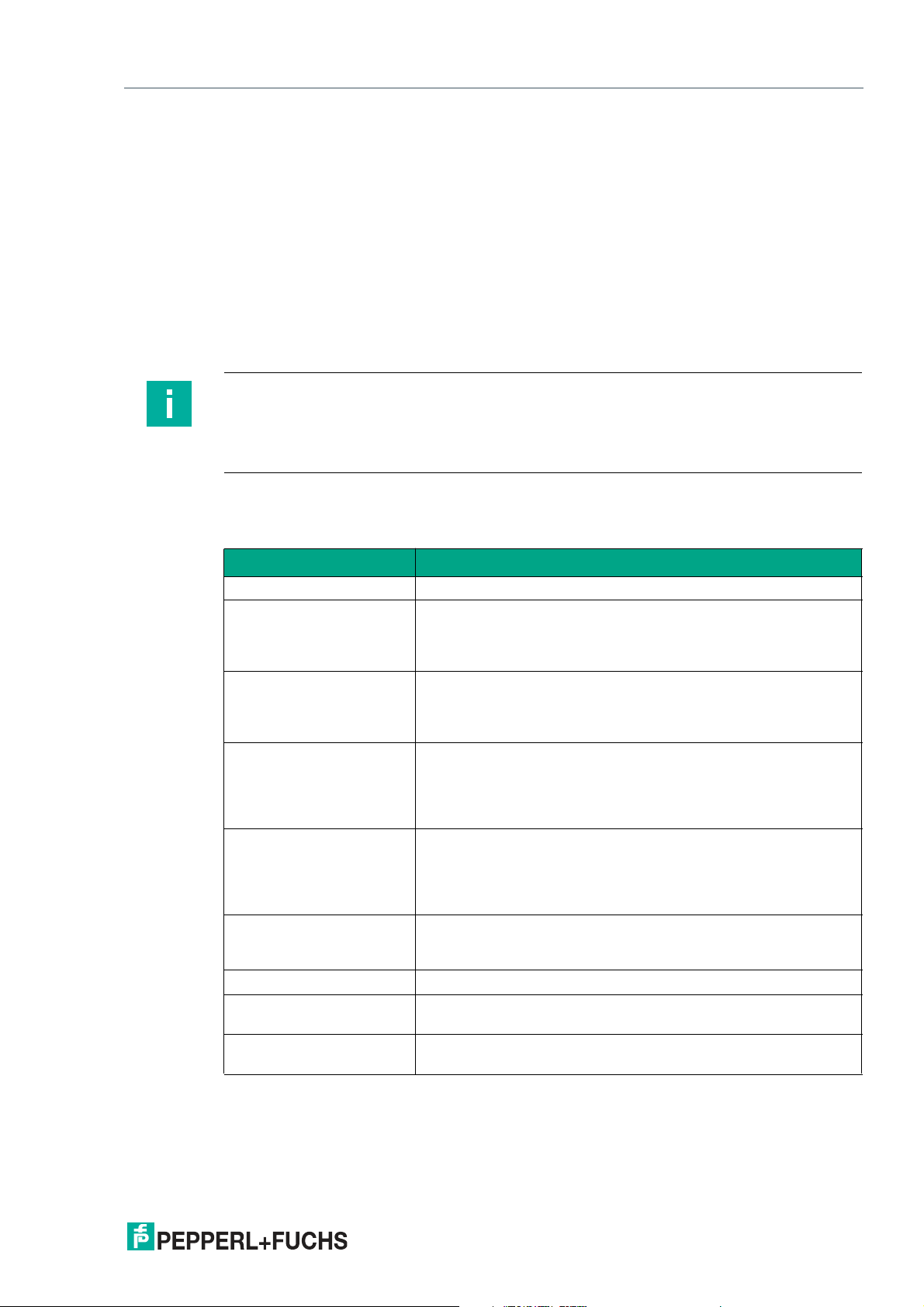

LED display for sensors with switching output

Green LED Yellow LED Red LED

In normal operation

Error-free operation On Switch state Off

Fault (e.g., compressed air) Off Retains previous state (factory

default setting, can be

changed via IO-Link)

Standby (high level for > 1 s at

Flashing Retains previous state Off

synchronization input)

When programming the switch points

Object detected Off Flashing slowly Off

No object detected Off Flashing quickly Off

Unreliable object detection Off Off Flashing

Confirmation of successful pro-

Flashes 3x Off Off

gramming

Warning in the event of invalid

Off Off Flashes 3x

program ming

When programming operating modes

Programming the Output Mode Flashing Off Off

Programming the Output Logic Off Flashing Off

Programming the Sound Beam

Off Off Flashing

Width

Table 2.1

On

2020-11

11

Page 12

UC***-18GS series

Product Description

LED display for sensors with analog output

In normal operation

Error-free operation On Output state Off

Fault (e.g., compressed air) Off Retains previous state (factory

Standby (high level for > 1 s at

synchronization input)

When program ming the limits

Object detected Off Flashing slowly Off

No object detected Off Flashing quickly Off

Unreliable object detection Off Off Flashing

Confirmation of successful programming

Warning in the event of invalid

programming

When program ming operating modes

Programming the ou tput mode Flashing Off Off

Programming the ou tput type Off Flashing Off

Programming the sound beam

width

Table 2.2

Green LED Yellow LED Red LED

On

default setting, can be

changed via IO-Link)

Flashing Retains previous state Off

Flashes 3x Off Off

Off Off Flashes 3x

Off Off Flashing

12

2020-11

Page 13

UC***-18GS series

Product Description

2.3 Accessories

Various accessories are available.

2.3.1 Accessories for Mounting and Connection

Several components are available for mounting and connecting UC***-18GS series sensors.

You will find details online at www.pepperl-fuchs.com on the product page for the relevant

sensor or on the relevant datasheet.

The following types of accessories are available for order:

• Mounting aid AB-18

• Connection cable and cordset

Note

For mounting, connection, and commissioning, the following product information is available

online at www.pepperl-fuchs.com on the product page for the relevant sensor: datasheet,

commissioning instructions, m anual. The relevant DTM also contains comprehensive contextrelated help texts.

2.3.2 Parameterization Aids

The following parameterization aids are available:

Designation Description

PACTware FDT frame application for operating IODDs and DTMs

Pepperl + Fuchs PACTware

Connection Wizard

IODD for UC***-18GS* IODD (IO Device Description) – device description for operating

DTM for UC***-18GS* DTM (Device Type Manager) – device description and graphic

IO-Link Offline Parameterization Tool

IO-Link-Master02-USB

UC-PROG-IR-USB Interface cable to parameterize sensors with IrDA interface

V1-G-2M-PVC-V1-G 4-pin cordset, M12 to M12, to connect a UC***-18GS series sen-

IO-Link-Master-USB DTM Device type manager – software for operating the IO-Link-Mas-

Table 2.3

Wizard for simple project and connection set-up of the ultrasonic

sensor in PACTware.

Visit www.pepperl-fuchs.com and access the product page for

the relevant UC***-18GS series sensor.

the sensor, integration in the system environment

Visit www.pepperl-fuchs.com and access the product page for

the relevant UC***-18GS series sensor

user interface for operating the sensor, integration into the system

environment

Visit www.pepperl-fuchs.com and access the product page for

the relevant UC***-18GS series sensor

FDT frame application for operating IODDs and DTMs. This tool

contains PACTware, IODD Interpreter DTM, and IO-Link USB

Master DTM.

Visit www.pepperl-fuchs.com and access the product page for

the relevant UC***-18GS series sensor.

IO-Link USB adapter box to communicate with the IO-Link device

via a PC, M12 connection for sensor

sor to the IO-Link-Master02 USB

ter02 USB via FDT.

2020-11

13

Page 14

UC***-18GS series

LED

4

24

48

80

90

M12 x 1

18 x 1

Installation

3 Installation

3.1 Safety Information

Caution!

Risk of short circuit

Carrying out work while the system is energized m ay result in damage to the device.

• Always disconnect the supply voltage before carrying out work on the device.

• Only connect the device to the su pply voltage once all work has been completed.

3.2 Preparation

Unpacking the Device

1.

Check the packaging and contents for damage.

In the event of damage, inform the shipping company and notify the supplier.

2.

Check the package contents against your order and the shipping documents to ensure that all

items are present and correct.

Should you have any questions, direct them to Pepperl+Fuchs.

3.

Retain the original packaging in case the device is to be stored or shipped again at a later date.

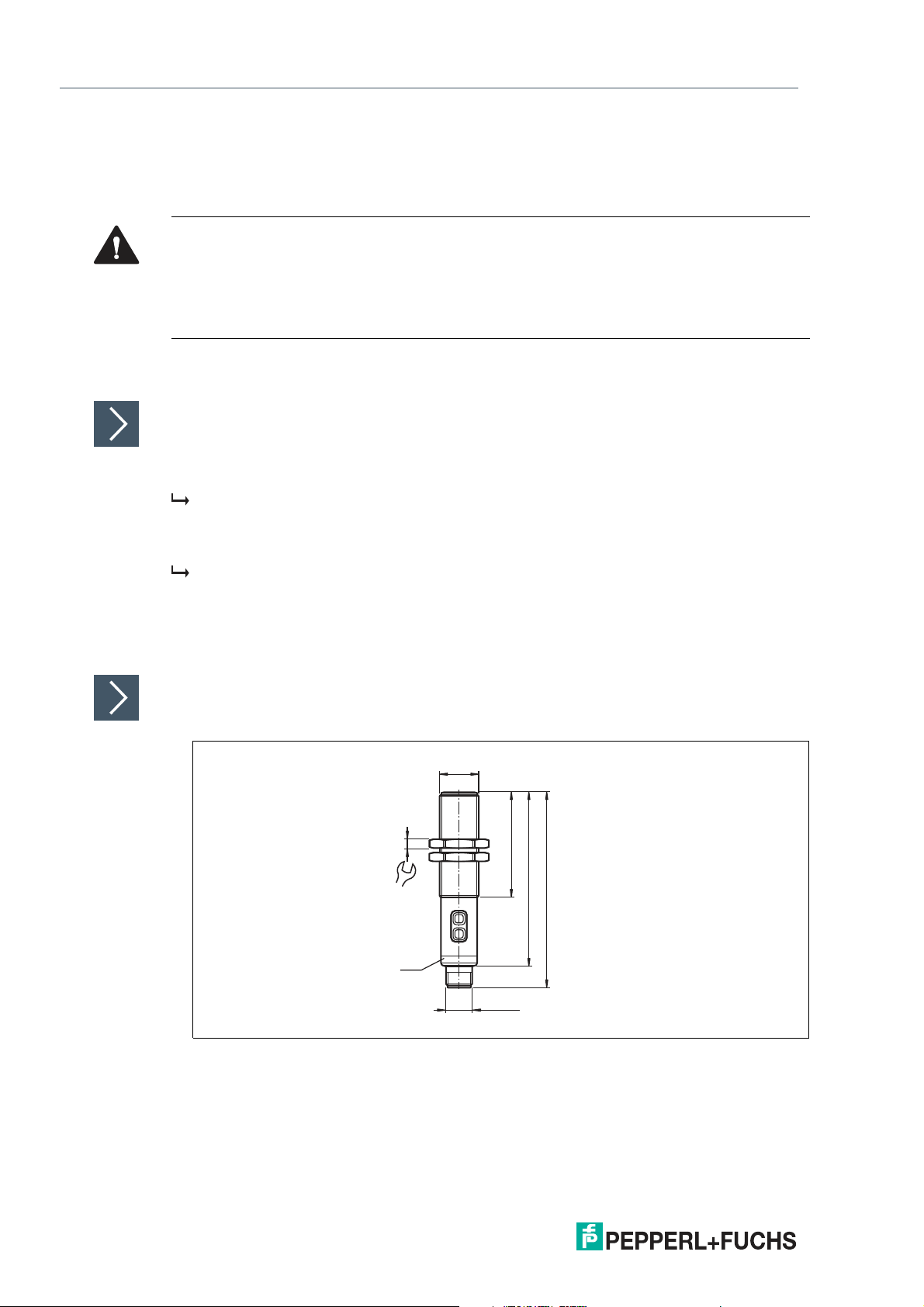

3.3 Mounting

Mounting UC***-18GS Sensors

Use M18 nuts (included as standard) to secure the sensor and tighten to a maximum torque of

30 Nm.

14

Figure 3.1

2020-11

Page 15

UC***-18GS series

1

5

2

3

4

L+

L-

Q2

SYNC

C/Q

1

5

2

3

4

L+

I/U

SYNC

C/Q

L-

Installation

3.4 Connection

Note

A three-pin adapter or triple-strand connection cable must be used when connecting the

sensor to an IO-Link Class B master port.

If the synchronization option is unused, connect the synchronization input to ground (0 V)

during operation without IO-Link.

Connection Images

Figure 3.2 UC****-18GS-2EP-IO-V15

Figure 3.3 UC****-18GS-IUEP-IO-V15

Applying Supply Voltage for a Sensor with Connector Plug

To supply voltage to the sensor, proceed as follows:

1.

Insert the prepared connection cable into the connector plug provided for this purpose on the

underside of the housing.

2.

Screw the u nion nut onto the connector plug as far as it will go. This ensures that the power

cable cannot be pulled out inadvertently.

3.

Connect the supply voltage to the cables provided for this purpose and switch it on.

The sensor is ready for operation.

Control via IO-Link

To prepare the sensor for control via IO-Link, proceed as follows:

Connect the sensor to an IO-Link master. For a sensor with connector plug, screw the union nut

onto the connector plug as far as it will go. Use a four-strand sensor cable for the connection.

The sensor is now prepared for IO-Link communication.

2020-11

15

Page 16

UC***-18GS series

Commissioning without IO-Link

4 Commissioning without IO-Link

Switch on the supply voltage. The operating indicator on the sensor lights up green.

The sensor will now function using the preset parameters.

Note

It is only possible to change configuration by programming with the programming button or by

configuring via IO-Link!

16

2020-11

Page 17

UC***-18GS series

Sensor Programming via the Programming Button

5 Sensor Programming via the Programming Button

Basic information about programming

In terms of factor y settings, the sensor can only be programmed during the first 5 minutes after

switching on. This time is extended during the actual programming process. The option of programming the sensor is revoked if no programming activities take place for 5 minutes. After this,

programming is no longer possible until the sensor is switched off and on again.

When configuring sensors via the IO-Link, you can use the DTM to adjust the programming

button’s locking logic. This is done in the "Sensor configuration" menu option, "Local controls"

tab.

When actively communicating via the IO-Link interface of the sensor, it is not possible to use

the program ming button to program.

The programming activities can be canceled at any time without changing the sensor settings.

To do so, press and hold the programming button for 10 seconds.

Programming via the programming button can take place in the stand-alone mode of a sensor

or also in the synchronized sensor group of several sensors (only for automatic common mode

and multiplex mode). When program ming in the synchronized sensor group, there may be a

delay to starting the programming routine, depending on when the sensor in question is next in

line. For the duration of the programming process, the other sensors in the sensor group go into

standby mode (green LED is flashing). Then synchronization mode continues to operate as

normal.

5.1 Programming Switch Points / Limits

Note

Depending on the sensor type, you can program the switch points (SP1, SP2) for sensors with

switching output and program the limits (SP1, SP2) for sensors with analog output using

programming buttons T1 and T2.

Depending on the output, the following programming buttons are used for programming:

• Switching output 1 via programming button T1

• Switching output 2 via programming button T2 (only with UC*-18GS-2EP* sensors)

• Analog output via programming button T2 (only with UC*-18GS-IUEP* sensors)

The programming sequence for SP1 and SP2 are identical in both cases and are therefore

described consecutively below. You must carry out the two programming steps separately for

each switching output / analog output. To ease understanding, the programming button is only

called T below.

2020-11

17

Page 18

UC***-18GS series

Sensor Programming via the Programming Button

Figure 5.1

Programming Switch Point 1 / Near Limit (SP1)

If the object is detected correctly during the programming process, the yellow LED flashes

slowly. If no object is detected, the yellow LED flashes at a higher frequency. A flashing red LED

during or when com pleting the programming process indicates unreliable object detection. In

this case, correct the alignment of the object during the program ming process until the yellow

LED flashes. Only then will the settings be transferred to the sensor memory.

1.

Position the object at the site of the required switch point / the required near limit.

2.

Press and hold the T programming button for two seconds (yellow LED flashes)

3.

Briefly press the T programming button (green LED flashes 3 times as confirmation). The

sensor returns to normal operation.

Programming Switch Point 2 / Far Limit (SP2)

1.

Position the object at the site of the required switch point / required far limit.

2.

Press and hold the T programming button for two seconds (yellow LED flashes)

3.

Press and hold the T programming button for two seconds (green LED flashes 3 times as

confirmation). The sensor returns to normal operation.

18

2020-11

Page 19

UC***-18GS series

T

5s

1x

2x

3x

4x

T

T

2s

1x

2x

T

T

2s

1x

2x

3x

T

2s

T

Ausgangsmodus

LED grün

Ausgangsverhalten

LED gelb

Schallkeulenbreite

LED rot

Normalbetrieb

kurz kurz kurz

Sensor Programming via the Programming Button

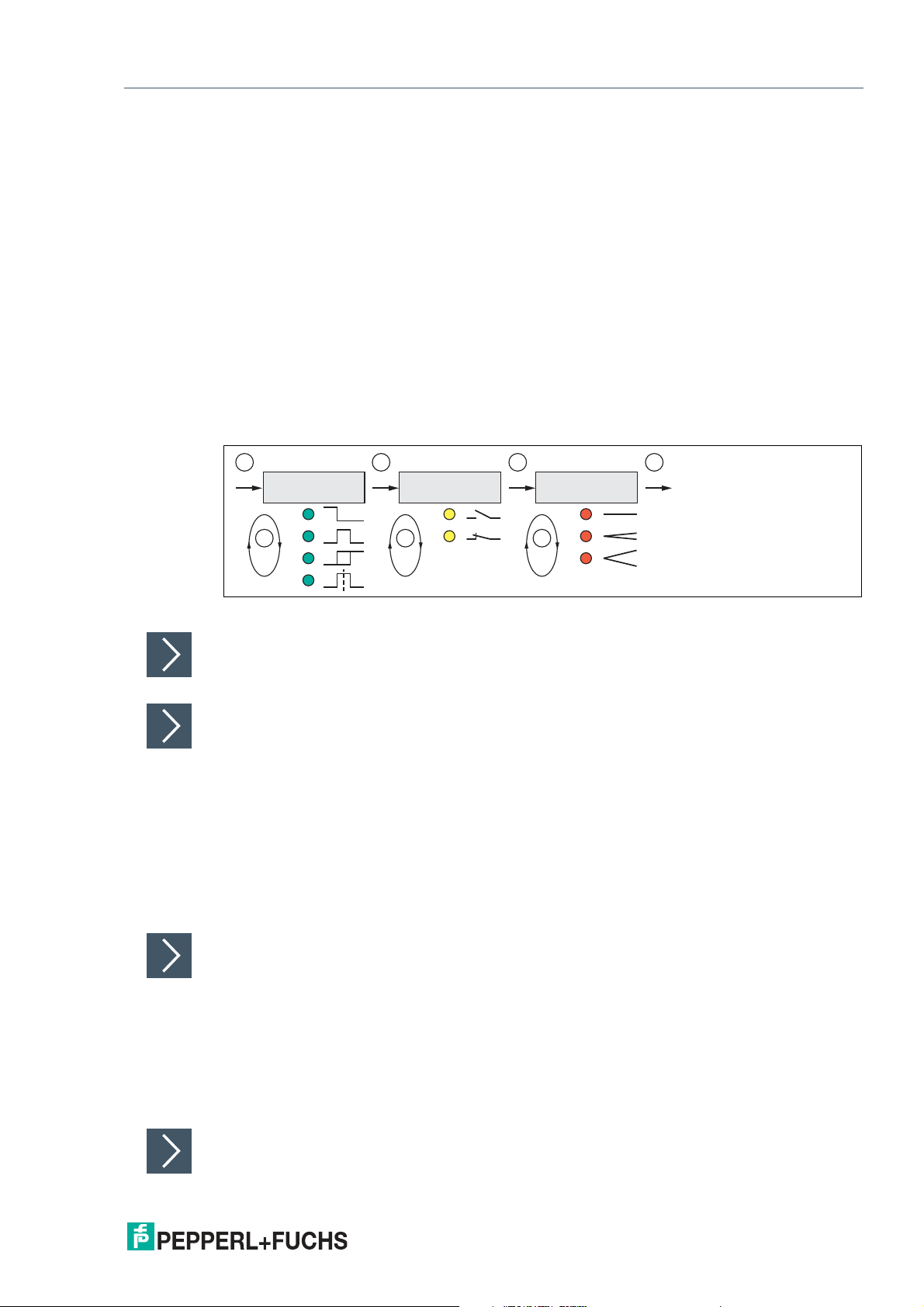

5.2 Programming Sensor Operating Modes for Switching Output

The sensor features a 3-stage process for programming the sensor operating modes. In this

programming routine you can program as follows:

• A) Output mode

• B) Output logic

• C) Sound beam width

The programming sequence for switching output 1 and switching output 2 are identical and are

therefore described consecutively below. You must perform the programming steps separately

for each switching output. However, the width of the sound beam is generally set only once for

the sensor. You can set the sound beam width while programming switching output 1. To ease

understanding, the programming button is only called T below.

These stages of the process are programmed in succession. To switch from one programming

step to the next, press and hold the programm ing button for two seconds.

The following graphic illustrates the programming routine:

Figure 5.2

Activating the Programming Routine

To activate the program ming routine, press the programming button for five seconds until the

green LED begins to flash.

Programming the Output Mode

The green LED is now flashing. The number of flashing pulses indicates the currently programmed output mode:

1x: switch point mode

2x: window mode

3x: hysteresis mode

4x: retroreflective mode

1.

Briefly press the programming button to navigate through the output modes in succession.

Select the required output mode.

2.

Press the programming button for two seconds to switch to the next output logic programming

step.

Programming the Output Logic

The yellow LED is now flashing. The number of flashing pulses indicates the currently programmed output logic:

1x: normally-open

2x: normally-closed

1.

Briefly press the programming button to navigate through the output logic in succession. Use

this m ethod to choose the output logic.

2.

Press the programming button for two seconds to switch to the next programming step, the

programming of the sound beam width.

Programming the Sound Beam Width

2020-11

19

Page 20

UC***-18GS series

T

5s

1x

2x

T

T

2s

1x

2x

T

T

2s

1x

2x

3x

T

2s

T

Output mode

LED green

Output type

LED yellow

Beam width

LED red

Normal

operation

short short short

Current

Voltage

Sensor Programming via the Programming Button

The red LED is now flashing. The number of flashing pulses indicates the currently programmed sound beam width:

1x: narrow

2x: medium

3x: wide

The sound beam width is generally set only once for the sensor.

1.

Briefly press the programming button to navigate through the sound beam widths in

succession. Use this method to choose the required sound beam width.

2.

Press and hold the programming button for two seconds to save all per formed settings and to

return to normal operation.

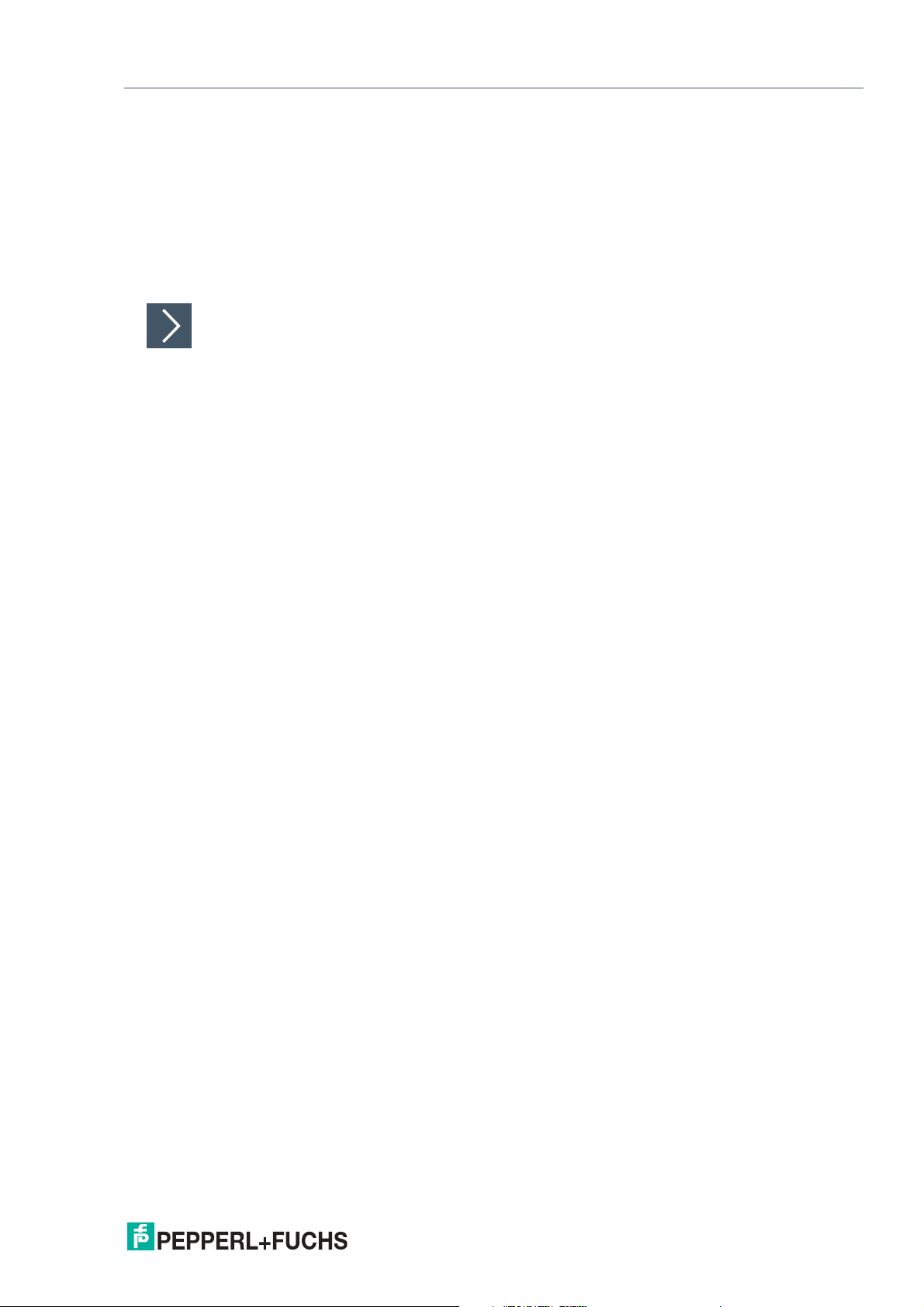

5.3 Programming the Sensor Operating Modes for Analog Output

The sensor features a 3-stage process for programming the sensor operating modes. In this

programming routine you can program as follows:

• A) Output mode

• B) O utput type

• C) Sound beam width

These stages of the process are programmed in succession. To switch from one programm ing

step to the next, press and hold the T2 programming button for two seconds.

To ease understanding, the programming button is only called T below.

The following graphic illustrates the programming routine:

Figure 5.3

Note

To exit the IO-Link parameter mode in normal operation (analog signal at the output), briefly

disconnect the sensor from the voltage supply.

Activating the Programming Routine

To activate the programming routine, press the programming button for five seconds until the

green LED begins to flash.

Programming the Output Mode

The green LED is now flashing. The number of flashing pulses indicates the currently programmed output mode:

1x: rising ramp

2x: falling ramp

1.

Briefly press the programming button to navigate through the output modes in succession.

Select the required output mode.

2.

Press the programming button for two seconds to change to the next programming step, the

selection of the output type.

Programming the Output Logic

20

2020-11

Page 21

UC***-18GS series

Sensor Programming via the Programming Button

The yellow LED is now flashing. The number of flashing pulses indicates the currently programmed output type:

1x: current output

2x: voltage output

1.

Briefly press the programming button to navigate through the output types in succession.

Select the required output type.

2.

Press the programming button for two seconds to switch to the next programming step, the

programming of the sound beam width.

Programming the Sound Beam Width

The red LED is now flashing. The number of flashing pulses indicates the currently programmed sound beam width:

1x: small

2x: medium

3x: wide

1.

Briefly press the programming button to navigate through the sound beam widths in

succession. Use this method to choose the required sound beam width.

2.

Press and hold the programming button for two seconds to save all performed settings and to

return to normal operation.

2020-11

21

Page 22

UC***-18GS series

Commissioning Using PACTware and DTM

6 Commissioning Using PACTware and DTM

There is a DTM available to download to help you fully configure the sensor easily via IO-Link.

Visit www.pepperl-fuchs.com and access the product page for the relevant UC***-18GS

series sensor. Configuration via IO-Link and via the IrDa infrared interface is possible with this

DTM.

This manual sets out how to configure using the "PACTware" FDT frame application in which

the DTM (Device Type Manager) is loaded. In principle you can use other appropriate FDT

frame applications. It is also possible to use the appropriate IODD for configuration instead of

using the DTM.

6.1 Commissioning via IO-Link

Note

An M12 cordset is necessary to connect the sensor to the IO-Link master. You can find suitable

cordsets by visiting www.pepperl-fuchs.com and clicking on the product page for the relevant

sensor.

Prerequisites for Commissioning

Proceed as follows to communicate with the sensor via IO-Link using the "PACTware DC" software and the associated DTM (Device Type Manager):

1.

Make sure that PACTware DC and the necessary DTMs (Device Type Managers), and the

IODD device description for the sensor, IO-Link master, and any required communication

DTMs for upstream components (e.g., IO-Link master) are installed.

2.

Connect the sensor via an M12 cordset to an IO-Link USB master.

3.

Connect the IO-Link USB master to a USB connection on your PC via a USB cable.

Setting Up Sensor Communication Using PACTware DC

1.

Launch PACTware DC by double-clicking the PACTware DC icon.

22

Figure 6.1

2020-11

Page 23

UC***-18GS series

Commissioning Using PACTware and DTM

2.

Click Search new device.

The IO-Link USB master will be identified by the PACTware DC if it is connected to the PC.

Figure 6.2

3.

In the Project, click IO-Link USB Master...

The PACTware DC automatically establishes the connection to the sensor if the ultrasonic

sensor is connected to the IO-Link USB m aster.

Figure 6.3

4.

Select Read data from device.

The PACTware DC starts continuous data retrieval from the sensor.

2020-11

23

Page 24

UC***-18GS series

12

Commissioning Using PACTware and DTM

Setting Up Sensor Communication Using PACTware via the

"Pepperl+Fuchs PACTware Connection Wizard"

You need to install "Pepperl + Fuchs PACTware Connection Wizard" on your PC and connect

the sensor to the PC via the IO-Link USB master.

As an alternative to establishing a connection via PACTware DC, you can simply start and

establish a connection with the sensor using the "Pepperl + Fuchs PACTware Connection Wizard." This wizard assumes all necessary steps in opening a PACTware project.

Double-click the "Pepperl+Fuchs PACTware Connection Wizard" icon.

Loads PACTware and the associated DTM and the connection to the sensor is automatically

established.

6.2 Commissioning Using IrDa Infrared Interface

Note

To connect the sensor via the IrDa infrared interface, the UC-PROG-IR-USB interface cable is

required. You can find this interface cable at ww w.pepperl-fuchs.com and by navigating to the

product page for the relevant sensor.

Refer to the datasheet for the UC-PROG-IR-USB interface cable and read the description

regarding correct orientation of the sensor to the interface cable.

The "Pepperl+Fuchs PACTware Connection Wizard" is available to help you launch and connect the sensor easily. The wizard takes you through all the necessary steps for opening a

PACTware project. Alternatively, you can launch PACTware directly and add or launch devices

such as the UC-PROG-IR-USB interface cable, the sensor, the DTM, and connection set-up on

a step-by-step basis.

Prerequisites for Commissioning

Proceed as follows to communicate with the sensor via the infrared interface IrDA using

"PACTware DC" software and the associated DTM (Device Type Manager):

1.

Make sure that PACTware DC and the necessary DTMs (Device Type Managers), and/or the

IODD device description for the sensor, the IO-Link master, and any required communication

DTMs for upstream components (e.g., the UC-PROB-IR-USB interface cable) are installed.

Figure 6.4

2.

Attach the UC-PROG-IR-USB interface cable (1) to the back of the sensor such that the

marking arrow (1) points to the mark on the sensor infrared interface (2).

24

3.

Connect the sensor to a voltage supply via an M12 cordset.

4.

Connect the UC-PROG-IR-USB interface cable to a USB connection on your PC.

2020-11

Page 25

UC***-18GS series

Commissioning Using PACTware and DTM

Setting Up Sensor Communication Using PACTware DC

1.

Launch PACTware DC by double-clicking the PACTware DC icon.

Figure 6.5

2.

Click Search new device.

If the UC-PROG-IR-USB interface cable is connected to the PC, it will be detected by the

PACTware DC.

3.

In the Project, click IO-Link USB Master...

When the ultrasonic sensor has established the connection with the infrared interface of the

UC-PROG-IR-USB interface cable, the PACTware DC automatically establishes the connection to the sensor.

Figure 6.6

2020-11

25

Page 26

UC***-18GS series

Commissioning Using PACTware and DTM

Figure 6.7

4.

Select Read data from device.

The PACTware DC starts continuous data retrieval from the sensor.

Setting Up Sensor Communication Using PACTware via the

"Pepperl+Fuchs PACTware Connection Wizard"

You need to install "Pepperl + Fuchs PACTware Connection Wizard" on your PC and connect

the sensor to the PC via the UC-PROG-IR-USB interface cable.

As an alternative to establishing a connection via PACTWare DC, you can simply start and

establish a connection with the sensor using the "Pepperl + Fuchs PACTware Connection Wizard." This wizard assumes all necessary steps in opening a PACTware project.

Double-click the "Pepperl+Fuchs PACTware Connection Wizard" icon.

Loads PACTware and the associated DTM and the connection to the sensor is automatically

established.

26

2020-11

Page 27

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

7 Configuration and Analysis with DTM via IO-Link

7.1 Overview

The sensor parameters are different for each device. These parameters are clearly set out in

the DTM (Device Type Manager), with guidance being provided in the form of graphics for

some of the parameters. The DTM can be imported into various engineering tools from different system providers, providing they support DTM. The sensor can then be configured or diagnosed using the appropriate tool (e.g., PACTware). The DTM menus are outlined below on the

basis of the "PACTware" FDT fram e application being used.

The DTM (Device Type Manager) set out below provides you with various ways of easily and

fully configuring the sensor via IO-Link and analyzing sensor logic.

In addition to configuring the sensor, you can use the Analysis & Echo suppression and

Observation menus to display and record sensor logic in operation to adapt it in the best way

possible to your application.

Note

The following DTM screenshots in the PACTware framework program apply to all versions of

UC***-18GS-...-IO-.. product versions and are described using examples. Individual sensors of

the product family vary in terms of the number of switching outputs or in terms of whether they

are fitted with or without analog output, for example. Consequently the DTMs of the respective

product versions may differ from the following screenshots.

Context-Related Help Texts via F1

Figure 7.1

In the DTM, you can access context-related help texts by clicking on the "?" icon in the displayed menu or by clicking on the required parameter and then pressing the F1 button. A display will then open showing information about the setting options of the relevant menu and its

parameters.

2020-11

27

Page 28

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

7.2 Sensor Information Menu Option

Preprogram med manufacturer and device information is displayed in the Sensor inform ation

Figure 7.2

• menu option, and the number of operating hours. These are read-only fields.

• You can input application-specific tags to identify and mark your sensor in the system

environment. Text inform ation (string) can be input in the "User tag" and "Application-specific tag" fields.

7.3 Output Configuration Menu Option

Figure 7.3

In the Output configuration menu option, it is possible to set the sensor's output logic and

switching characteristics.

28

2020-11

Page 29

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

7.4 Sensor Configuration Menu Option

Overview of the Sensor Configuration Menu Option

Figure 7.4

The Sensor configuration menu option consists of 4 tabs

• Evaluation (with reduced and advanced view)

• Synchronization

• Echo loss + Error handling

• Local controls

Evaluation Tab (Advanced View)

Figure 7.5

In the Evaluation tab, you can set the functions which impact evaluation logic with sensor measurement. You can choose between a reduced view for basic settings and an advanced view

for evaluation expert settings.

2020-11

29

Page 30

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

Synchronization Tab

Figure 7.6

In the Synchronization tab, you can set the required synchronization mode if you want to suppress cross-talk when operating several UC***-F77-...-IO-.. sensors. Details of the individual

synchronization modes can be found in the chapter "Synchronizing Multiple Sensors."

Echo Loss + Error Handling Tab

Figure 7.7

In the Echo loss + Error handling tab, you can adjust the evaluation of a loss of echo and the

error output behavior of the sensor output.

Local Controls Tab

30

Figure 7.8

In the Local controls tab, you can lock or activate the programming button, or use a time lock

and display the status of the programming button (pressed / not pressed).

2020-11

Page 31

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

7.5 Analysis & Echo Suppression Menu Option

Figure 7.9

In some applications, machine parts or support bars within a tank obstruct the sensing area,

preventing proper distance or level measurement. Using the Analysis & Echo Suppression

menu option, you can visualize and analyze all echoes received by the ultrasonic sensor from

one or a series of measurements, as well as suppress the disruptive objects in the sensing

area.

The general procedure is as follows:

1.

You must first establish a connection to a sensor built into the application environment.

2.

Ideally carry out multiple echo samples.

The corresponding data will then be shown in the display together with the switching thresh-

old of the sensor (blue line).

3.

Start automatic echo suppression. If necessary, you can correct the suppression areas.

Alternatively, you can also manually set the suppression areas.

4.

Finally, verify the detected settings by taking fresh echo samples.

The detected settings can be stored to/loaded from a file.

2020-11

31

Page 32

UC***-18GS series

1 2

3

6

4

8

13

7

9

11

5

10

12

Configuration and Analysis with DTM via IO-Link

Menu Description

Figure 7.10

No. Name Description

1 Echo sampling In the "Echo sampling" area, you can choose whether to record a

2 Display in graphic You can u se the "Display in graphic" area to set whether all of the

3 Start The "Start" button is used to start and stop echo sampling. After

4 Display area The sampled echoes are displayed in the form of thin columns

5 Save to file You can save the echo sample, including set suppression areas,

single value, 50 values or continuous data.

Using the continuous display also provides you with an alignment

aid. You can use the displayed amplitude of the evaluated echo to

check whether the sensor is optimally aligned to the object. You

will know this has worked when slightly varying the alignment no

longer increases the displayed echo amplitude.

gathered recorded echoes are shown or only the last recorded

echo image. The former is recom mended if you want to set suppression areas in an application; the latter in order to verify

detected suppression areas.

echo sampling has started, the button changes to "Stop."

• In the case of "individual" echo sampling, echo sampling stops

after one measurem ent.

• In the case of "50 values" echo sampling, echo sampling auto-

matically stops after 50 measurements. You can stop it at any

time by pressing the button.

• In the case of "continuous" echo sampling, echoes will con-

tinue to be sampled until you press the button again.

during and after completion of echo sampling.

The counter in the upper left corner indicates the number of echo

samples the current graphic is based on.

as a .CSV file, .XML file or .TXT file by pressing the "Save to file"

button. In addition to this data, sensor settings (parameter values)

will also be saved. This means it is possible to evaluate recorded

data later "offline."

32

2020-11

Page 33

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

No. Name Description

6 Load file You can load previously-saved echo samples to the DTM by

pressing the "Load file" button, allowing you to assess or evaluate

the samples.

Note: You can only load a saved file if disconnected from the sensor.

7 Sensor switching

threshold (blue line)

8 Details of the

selected echo

9 Clear echo sample You can use the "Clear echo sam ple" button to clear the display

10 Rescale diagram You can use the "Rescale diagram" (magnifying glass) button to

11 Manually adjusting

the suppression

areas

12 Start automatic echo

suppression

13 Echo suppression

activated/not activated

Table 7.1

In addition to the recorded echoes, the switching threshold of the

sensor will also be displayed as a "blue line." Echoes for which

amplitude exceeds this threshold can be evaluated by the sensor.

Echoes below the switching threshold are in effect suppressed

and are discounted by the sensor during evaluation.

Clicking on one of the echo columns shown in the graphic displays detailed information about the selected echo below the

graphic.

Note: More information on this can be found in the following section "Details about sampled echoes."

area and restore to the original state.

enlarge the view along the x-axis 5-fold in 100 % increments.

If magnification is set to more than 100 %, the displayed area of

the x-axis can be shifted (by scrolling) to be able to obtain a magnified view of sections of the entire sam ple area.

To do so, right-click on the x-axis, keep it pressed and move left or

right with the mouse.

The area allows you to manually set individual suppression areas.

10 areas can be individually customized as well as deleted individually or all at once. Each suppression area is determined by

three parameters: "Start point," "Amplitude," and "Length."

• The mm value entered for "Start point" specifies where the

• The % value for "Amplitude" specifies the height of the sup-

• The mm value entered for "Length" specifies the length of the

Individual areas can be cleared by either pressing the relevant

button with the red "X" or by going directly to the graphic and clicking on the framed area and pressing the "Del" button on the keyboard. It is necessary to clear a single area, for exam ple, if the

echo from the target object is also contained in the echo sample

and was also suppressed by automatically setting the suppression areas.

All areas can be cleared by pressing the "Clear all areas" button.

Automatic echo suppression is a quick and simple, one-click

option to suppress all previously sampled echoes.

You must first take a sample of the echoes in the sensor’s installed

state and then press the "Start automatic echo suppression" button. The recorded echoes are then suppressed by setting the individual suppression areas based on algorithms.

The "Echo suppression activated/not activated" param eter

switches echo suppression in the sensor on or off and shows or

hides the echo suppression display in the m enu.

suppression area starts on the X-axis of the graph.

pression area in keeping with the scale of the Y-axis.

suppression area measured from the respective start point.

2020-11

33

Page 34

UC***-18GS series

2 3

5

1

6

4

Configuration and Analysis with DTM via IO-Link

Details about sampled echoes

Using an echo sample with manual echo suppression as an example, the following sets out the

graphic elements of information in the display area.

Figure 7.11

No. Name Description

1 Suppression area A rectangle indicates the specified suppression area.

2 Black part of the col-

umn

3 Gray part of the col-

umn

If multiple echo samples are shown in the graphic, the black part

of each column shows the amplitude which each of the recorded

echoes reached from this distance.

The gray part of the column, above the black part, shows the variance in the strength of amplitude of all echoes from this distance.

34

2020-11

Page 35

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

No. Name Description

4 Details of the

selected echo

5 Red column The evaluated echo of the last recorded echo samples is dis-

6 Sensor switching

threshold (blue line)

Table 7.2

Clicking on a colum n from the echo sample displays the following

detailed information in the "Details of the selected echo" area:

• Echo number: The echo number is a consecutive number

• Frequency of occurrence: The value of the frequency of occur-

• Amplitude: The strength of the amplitudes of the selected

• Distance: The distance indicates the distance corresponding

• Suppressed: When indicating suppression (yes/no), the dis-

• Reserve to threshold: The threshold reserve value indicates

played in the graphic as a red column.

This specific representation makes it possible to subsequently

verify the effectiveness of set suppression areas because the

evaluated echo can be easily distinguished from the rest.

In the graphic, a "blue line" indicates the switching threshold of the

sensor alongside the recorded echoes. Echoes for which amplitude exceeds this threshold can be evaluated by the sensor.

Echoes below the switching threshold are in effect suppressed

and will be discounted.

which numbers the echoes shown in the graphic from left to

right.

rence indicates how often the selected echo occurs in the currently displayed number of echo samples.

echo is displayed as a % value

to the displayed echo value, measured from the sensor surface in mm.

Note: The displayed distance value always refers to the runtime measured by the sensor after the relevant echo was

taken. This does not m ean that an object has to be physically

present in each of these distances. For example, if an object is

located close to the sensor, so-called multiple echoes may

occur. This involves reflecting the sound pulse of a measurement back and forth several times between the sensor and the

object. The sensor sees each fresh echo reflected from the

object as its own echo and provides it accordingly. These multiple echoes can be identified in the graphic as echoes in the

x-times actual object distance.

plays shows whether the selected echo exceeds or falls below

the switching threshold. If the echo amplitude exceeds the

switching threshold, the echo is "not suppressed," but can be

evaluated by the sensor. If the echo amplitude is lower than

the switching threshold, the echo is "suppressed."

how reliably an echo is detected or suppressed. This va lue is

shaded by traffic light colors so that evaluation can be carried

out easily.

2020-11

35

Page 36

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

Application Information for Echo Suppression

In order to be able to suppress echoes, you first have to set the "Echo suppression" parameter

to "enabled," provided that the parameter is not already set accordingly in the connected sensor. The "Start automatic echo suppression" button as well as the parameter values of the available suppression areas 1–10 are then displayed in the DTM.

Ideally, echo suppression areas should be based on a variety of echo samples (at least 50)

because the echo amplitude can vary from measurement to m easurement depending on the

ambient conditions.

Obtaining sampled echoes from the original sensor mounting location in the plant is mandator y

before starting targeted echo suppression.

Automatic Echo Suppression

If the echo from the target object is also contained in the echo samples, this will be suppressed

through automatic echo suppression. This m ay occur, for example, when echo samples are

taken in a partially-filled tank because then the echo from the surface of the liquid is also

included in the echo sam ples.

The same applies in the case where samples are carried out in an empty tank because the

echo from the base of the tank in most cases should still be identified as "Tank empty," even

after echo suppression.

In these cases, a manual correction must be carried out to the corresponding suppression area

to eliminate the relevant echo from the suppression (see section on "Manual echo suppression").

A lot of "Echo blocks" in the echo samples may lead to the 10 available suppression areas not

being sufficient for algorithm-based automatic suppression to really suppress all recorded

echoes. In this case, it is necessary to carry out m anual adjustments to the individual suppression areas (see section on "Manual echo suppression").

Manual Echo Suppression

Each of the 10 suppression areas is specified via the "Start point," "Amplitude," and "Length"

param eters (see section on "Menu description"). Each area can be modified or deleted individually or all at once.

To reliably suppress echoes under varying ambient conditions (for example fluctuations of air

temperature or air humidity), we recommend selecting a suppression area which is larger than

the echo or echo block to be suppressed. Specifically, this means that the amplitude value of

the suppression area should be set at least 10 % higher than the largest echo amplitude to be

suppressed. However, the amplitude value should not be set so high that the echo to detect

(e.g., a fill level) is no longer recognized. For indoor applications, the lateral boundaries of the

suppression area should be set to +/- 5 % and for outdoor applications to +/- 10% of the relevant echo distances, which should be suppressed with the area.

36

2020-11

Page 37

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

Example

In terms of the following echo sample, the echo labeled with the red arrow should be suppressed. The echo labeled with the green arrow echo comes from the object that is to be

detected (e.g., the level surface).

Figure 7.12

The echo to be suppressed has an amplitude of 59 % at a distance of 84 mm. To suppress the

echo correctly and with reserve, for an indoor application the parameters for the suppression

area should be set as follows (in brackets are the corresponding values for an outdoor environment):

• Start point: 80 m m (75 mm)

• Amplitude: 69 % (69 %)

• Length: 8 mm (18 mm)

2020-11

37

Page 38

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

The graphic with set suppression area for an interior application is as follows:

Figure 7.13

Note

The boundaries of suppression areas can also be adjusted directly within the graphic by leftclicking and dragging with the mouse.

Note

The amplitude difference between unwanted echoes and echoes from the desired target is

critical to proper echo suppression performance.

With echoes from target objects which reflect well, unwanted echoes in the peripheral areas

can be suppressed very successfully without impairing function because the echo amplitudes

of the unwanted echoes are not too high in this case.

On the other hand, unwanted echoes in the center of the sound beam usually create an echo

which is situated in approximately the same amplitude range as the echo of the object to be

detected. For this reason it is not usually possible to suppress unwanted echoes with normal

reflective properties in the center of the sound beam.

38

2020-11

Page 39

UC***-18GS series

1

2

Configuration and Analysis with DTM via IO-Link

7.6 Observation Menu Option

Figure 7.14

You can use the Observation menu option to track and record data from the ultrasonic sensor

over time, and the corresponding behavior of the switching and analog outputs. You can

choose from the "Visual observation" (1) or "Event-driven data logging" (2) application focuses.

Visual Observation

The visual observation functions (1) allow you during commissioning for example to observe

whether data and switching characteristics of the sensor behave as intended.

When you first access the Observation menu option in the DTM, automatic recording of data

will start in the graphic. From this point in time, recording will run continuously in the background. The data display works according to the "follow-mode-principle." It will always track

the current measured value in accordance with the rescale settings in the x-axis and make sure

it is visible in the display. You can save the data displayed in this trend graphic in a file in various

file formats for evaluation at a later stage.

Placing the check mark in front of the available measured variables or output statuses selects

which data will appear in the graphic.

Event-Driven Data Logging

Event-driven data logging functions (2) allow you, for cause analysis for example, to monitor

sensor logic in such a way that an event occurring sporadically is recorded in a file. You can

specify the recording conditions from predefined trigger criteria such as changing the status of

the switching output or a change to the value of the distance measurement. The DTM function

then observes the sensor and writes the measured variables and output statuses to a file if an

event occurs.

Note

If the DTM is closed w hilst data is being recorded, recording automatically stops. Values

recorded up to this point in time are and will remain in the corresponding file.

2020-11

39

Page 40

UC***-18GS series

1

8

7

5

2

6

3 4

9

10

11

12

Configuration and Analysis with DTM via IO-Link

Menu Description

Figure 7.15

No. Name Description

1 Follow m ode on / off If follow m ode is "On," data is displayed in accordance with the

current rescale setting of the x-axis. The measured value is visible

in the display. If follow mode is "Off," the data stops being continuously displayed. When follow mode is re-started, data recorded in

the background is added in the meantime.

2 Save trend data Only for visual observation

You can save data recorded via follow mode in one of three available file form ats (.csv, .xm l. or .txt) by pressing the "Save trend

3 Load data You can load the saved trend data (visual observation) or logging

4 Delete Pressing the "Delete" button allows you to delete all data in the

5 Distance By clicking on the check box, you can enable or disable display of

data" button. In addition to this data, sensor settings (parameter

values) will also be saved. This means it is possible to evaluate

recorded data later "offline."

data (event-driven data logging) to the DTM again by pressing the

"Load data" button to assess or evaluate the data.

Files with recorded data combined with the parameter settings

can be very useful for discussing issues with our experts.

Note: You can only load a saved file if disconnected from the sensor.

display area (10).

All data recorded up to this point is discarded and the display is

cleared. Recording au tom atically restarts from scratch.

the distance values in the display area in the form of a blue line.

40

2020-11

Page 41

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

No. Name Description

6 Output By clicking on the check box, you can enable or disable display of

the output status (0/1) in the display area in the form of a green

line.

The analog output value is displayed in the diagram for an analog

output.

7 Interval You can use the "Interval" selection function to specify the time

interval at which data is recorded in the graphic. There are several

fixed inter vals available between 100 ms and 1 hour.

8 Start logging Only for event-driven data logging

You can use the "Start recording" button to start and end eventdriven recording of data in a file (data logging).

9 Settings for data log-

ging

10 Display area In the display area, the "Distance" and "Output" check boxes can

11 Output logic (green

line)

12 Distance value line

(blue line)

Table 7.3

Only for event-driven data logging

You can use the "Settings for data logging" button to specify

events for data recording and the name of the log file via a menu.

be used to display selected measured variables and output statuses in the form of line diagrams.

The green line indicates the logical status of the output (right yaxis) for the switch point set in the Output configuration menu

option.

The analog output value is displayed (likewise right y-axis) for a

sensor with analog output.

The blue line shows the distance value measured from the sensor

(left y-axis).

Scaling the X-Axis and Navigating to Significant Data

Use the left mouse button and Shift key to zoom the display area in the x direction; doing so

zooms in on selected data.

While holding down the Shift key, move the mouse cursor into the display area until the mouse

cursor changes to a magnifying glass icon (+). Hold down the left mouse button and define the

required magnification area with the selection window. You can repeat this process multiple

times.

The x-axis is then displayed in the corresponding zoom ratio. A scroll bar appears for the xaxis and y-axis, allowing you to scroll through the adjacent areas.

You can undo the zoom by holding down the Alt key and clicking the left mouse button in the

display area.

To zoom in / out:

• Zoom in >> press left mouse button and Shift key

• Zoom out >> press left mouse button and Alt key

2020-11

41

Page 42

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

Data Logging Setting

Pressing the "Settings for data logging" button opens the menu displayed below.

Figure 7.16

You can use the "Name of log file" field to set the file path and file names for logging data.

You can select "Data logging mode" to set the events that trigger automatic data logging. You

need to press the OK button at the end to save the setting.

Measured data can be recorded either on a continuous or event-driven basis. For event-driven

recording, the number of measured values to be recorded before and after the event is independently defined via two parameters.

The following recording modes are ava ilable:

• Continuous

Data is continuously recorded and saved in the file. Data is sequentially recorded, but is

not necessarily consistent. Individual data may not be recorded depending on the sensor's repeat measurement rate, data transmission rate, computer's capacity, and operating system tasks.

• Fixed time interval

Data is recorded at fixed time intervals. The time interval can be selected in fixed increments between 500 ms and 2 hours.

• Change of switching output state

Data is recorded in the event of a change of status of a sensor switching output. A further

parameter is used to define with what type of status change data should be recorded. You

can choose status changes to "Closed," "Open," or "In both directions." If the sensor has

more than one switching output, but only one should be used as a trigger for recording

data, the other parameters need to be set to "Ignore."

42

• Value changes exceed defined tolerances

Data recording is triggered by changes to data which exceed the specified tolerance limits. The reference value is the distance value determined during the previous m easurement. The permissible tolerances can be specified either as an absolute value, i.e., in

mm, or as a percentage, relative to the previous measurement. If this tolerance limit is

exceeded from one measurement to the next, data recording is triggered.

2020-11

Page 43

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

• Value outside the set limits

Data is recorded if specified, absolute limit values are exceeded. The distance value in

mm and the value at the sensor analog output (if physically present on the sensor) are

available as reference values. In addition, the "Trigger" parameter can be used to determine whether data recording should take place once per limit being exceeded or for the

full duration.

1.

Use the "Name of log file" field to set the file path and file name for logging data. To do so, click

on the "..." button.

2.

Use the "Data logging mode" option to set the events which should trigger automatic recording

of data. You need to press the "OK" button at the end to save the setting.

2020-11

43

Page 44

UC***-18GS series

Configuration and Analysis with DTM via IO-Link

7.7 Service Menu Option

Figure 7.17

You can use the Service menu option to set the following service functions.

• Reset to factory defaults: activating the switch resets the sensor to settings as deliv-

ered. All previous parameter changes are lost as a result of this.

• Locator indication: setting the "localization display" to "enabled" makes the LEDs flash

simultaneously. This function can be used to locate a sensor in a plant or machine more

easily. This function is disabled by default, which means that the LEDs indicate status and

diagnostic information.

7.8 Information Menu Option

Figure 7.18

The Inform ation menu option consists of 3 tabs

• Sensor details: information about hardware and software version

• IO-Link details: information about the device ID, vendor ID and information about the IO-