Ultrasonic sensor UC10000-F260-IE8R2

Technical data

General specifications

Sensing range 800 ... 10000 mm

Adjustment range 800 ... 10000 mm

Dead band 0 ... 800 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 60 kHz

Nominal ratings

Model Number

UC10000-F260-IE8R2

Single head system

Features

• Large sensing range

• Adjustable Bracket

• Programmable by means of Interface (see accessories) and SONPROG

• Analog output 4 ... 20 mA

•2 switch outputs

• Synchronization options

• Temperature compensation

Description

This ultrasonic sensor is a contactless distance sensor

based on the echo run time principle. It is suitable for

the detection of solid, liquid or powder sound-reflecting

objects. The unique sensor design allows easy movement of the direction of sound radiation in all spatial directions by up to 10° without additional an additional

assembly device.

Diagrams

Characteristic response curve

Distance Y [mm]

1800

1600

1400

1200

1000

800

600

400

200

0

-200

-400

-600

-800

-1000

-1200

-1400

-1600

-1800

0 2000 4000 6000 8000 10000 12000 14000 16000

Y

2

X

1

Distance X [mm]

Time delay before availability t

Limit data

v

Permissible cable length max. 300 m

Indicators/operating means

LED yellow solid: switching state switch output

Electrical specifications

Rated operating voltage U

Operating voltage U

e

B

Ripple ≤ 10 %

No-load supply current I

Input/Output

0

Input/output type 1 synchronization connection, bidirectional

0 Level ≤ 3 V

1 Level 15 ... 30 V

Input impedance typ. 0.9 kΩ

Number of sensors max. 10

Switching output

Output type 2 switch outputs PNP, NO

Repeat accuracy R ± 15 mm

Operating current I

Voltage drop ≤ 3 V

L

Switch-on delay 800 ms

Analog output

Output type 1 current output 4 ... 20 mA rising ramp

Default setting 800 ... 10000 mm

Linearity error ≤ 1.5 %

Load resistor ≤ 300 Ω

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Shock resistance 30 g , 11 ms period

Vibration resistance 10 ... 55 Hz , Amplitude ± 1 mm

Mechanical specifications

Connection type screw terminals , PG 13.5 cable gland

Degree of protection IP65

Material

Housing UP 1225 SF/R8

Transducer epoxy resin/hollow glass sphere mixture; polyurethane foam

Installation position any position

Mass 1800 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007 + A1:2012

Approvals and certificates

UL approval cULus Listed, General Purpose

CSA approval cCSAus Listed, General Purpose

CCC approval CCC approval / marking not required for products rated

280 ms

flashing: misadjustment

24 V DC

15 ... 30 V (including ripple)

In supply voltage interval 15 ... 20 V sensitivity reduced to

20% ... 0%

≤ 75 mA

300 mA , short-circuit/overload protected

IEC 60947-5-2:2007 + A1:2012

EN 60947-5-7:2003

IEC 60947-5-7:2003

≤36 V

Curve 1: flat surface 100 mm x 100 mm

Curve 2: round bar, Ø 25 mm

Release date: 2016-02-16 08:15 Date of issue: 2016-02-16 250790_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

1

Ultrasonic sensor UC10000-F260-IE8R2

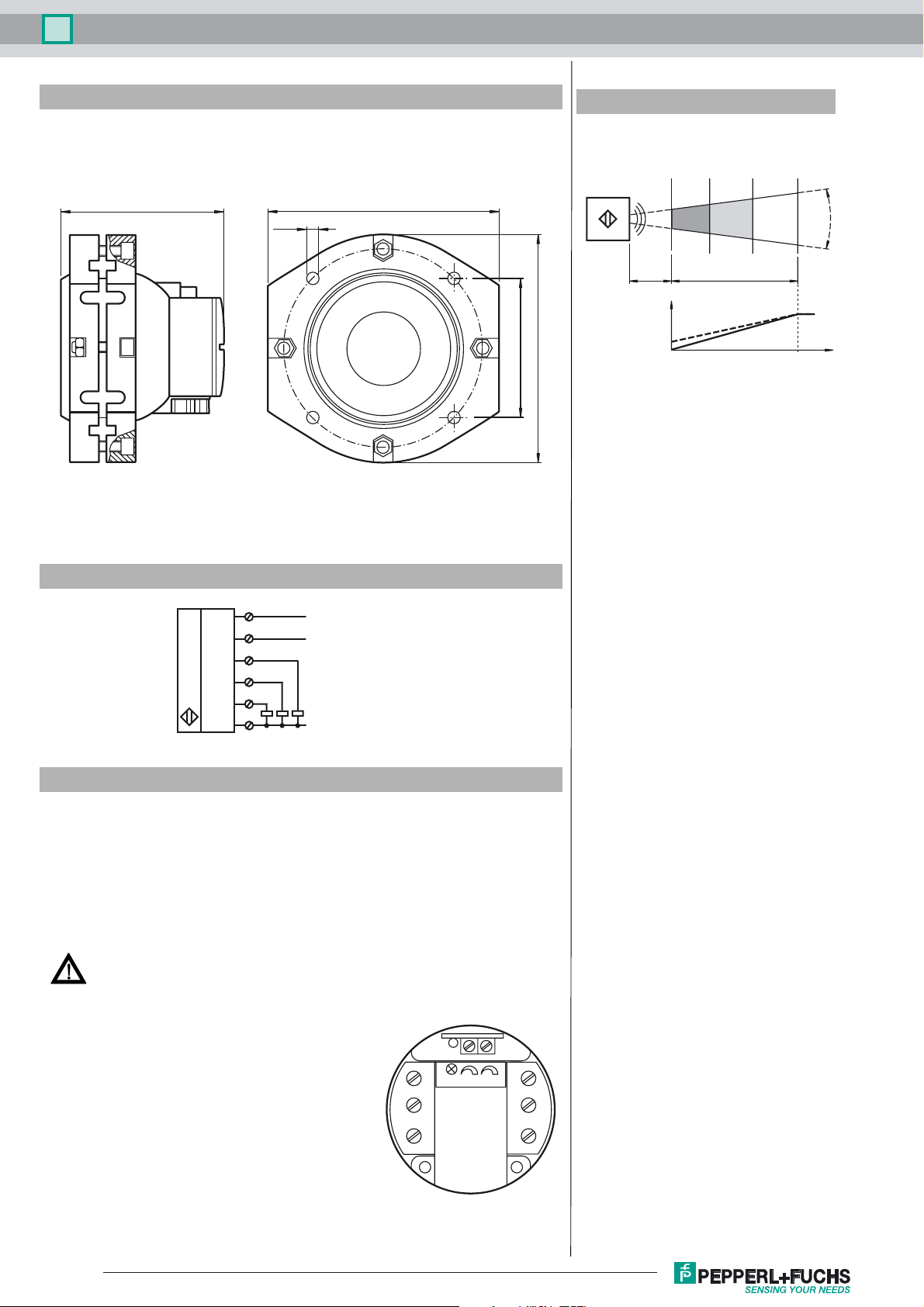

Dimensions

112

ø 8.5

160

97.6

160

Additional Information

Area definitions

S

AE

min

Blind

area

Analog output

4 mA

0 mA/0 V

Sensing range

S

max

ca. 5°

20 mA

10 V

Electrical Connection

L+

XI

I

A/UA

S

SX

GND

+U

B

Input

Analog output

Switch output 1

Switch output 2

-U

B

Accessories

DA5-IU-C

Digital display unit

3RX4000-PF

PC interface

V15S-G-2M-PVC

Cable connector, M12, 5-pin, PVC cable

V1-M20-80

Receptacles, M12/M20; plastic version

Danger!

This product must not be used in applications in which the safety of persons depends on the device

function.

This product is not a safety component in accordance with the EU Machinery Directive.

Assembly and connection

When installing the sensor, make sure that the space filled by the sound

cone is free from interfering objects. Objects in the blind zone cause

cause false signals. Implement suitable measures to ensure that objects

cannot enter the blind zone.

The electrical connection is made via screw terminals. The connections

are protected against reverse polarity, short circuits and overloads.

Shielded cables are recommended if there is electrical interference.

Setting

The detection range limits S

Within these limits, the switch points A and E are set using a potentiom-

min

and S

are fixed (see Technical data).

max

eter. Switch point A must be smaller than switch point E. If this is not the

case, the LED flashes and correct switching is not possible.

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

LED P1(A)

GND L+

A

/U

A

I

P2(E)

XI

NO/NC

SX S

NO/NC

Release date: 2016-02-16 08:15 Date of issue: 2016-02-16 250790_eng.xml

Ultrasonic sensor UC10000-F260-IE8R2

Parameterisation via SONPROG

The following parameters can be changed via the SONPROG parameterisation software:

• Measuring range limits S

• Switch-on and switch-off points E and A

• Blind zone

• Averaging

• Analogue limits

• Analogue characteristic, rising/falling

Operation

Within the detection range, which is restricted by the detection range limits S

maximum inclination of 3° to the direction of sound propagation. With rough, uneven surfaces the angular deviation can be bigger. The actual value depends signficantly on

the object finish and should be obtained experimentally if necessary.

Behaviour of the switch outputs:

• If the object is at a distance > E, both switch outputs are in standby mode.

• If the object is between E and A, switch output S is activated and switch output SX is in standby mode.

• If the object is at a distance < A, switch output SX is activated and switch output S is in standby mode.

Behaviour of the analogue output:

The object distance between the detection range limits (S

its minimum value at distance S

output retains its maximum value.

Display:

The sensor has an LED. It lights up continuously when the output terminal S is carrying a voltage. It flashes when switch points A and E are set incorrectly (see Setting).

Function input XI

The sensor is placed in standby mode by connecting a low level at the function input XI (blocked release). The sensors then performs no measurements. The switch outputs

retain the most recent status. As soon as function input XI is disconnected from the low level or a high level is connected (release), the sensor resumes its normal function

after the release period has expired.

The function input XI can be used during operation for the synchronisation of multiple sensors in the event of mutual interefence. The following synchronisation modes are

possible:

• Triggering of each individual sensor with a separate control signal, e.g. by a PLC (external synchronisation).

• Connection of the function inputs XI of all sensors and joint triggering with an external control signal, e.g. by a PLC (external synchronisation, common-mode operation).

• Connection of the function inputs XI of all sensors and without triggering with an external signal (internal synchronisation, multiplex mode).

Maintenance

The ultrasonic sensor is maintenance-free. However, the converter surface must not be wet, damaged, painted or covered with material deposits..

and S

min

max

, S

and its maximum value at distance S

min

min

and S

min

) are displayed in the form of an analogue output signal at the analogue output. The analogue output delivers

max

. The characteristic between the two measuring range limits is linear. Outside of S

max

, the object distance is detected. Objects with an even, smooth surface can have a

max

the analogue

max

Connecting the PC interface 3RX4000-PF to use SONPROG

This sensor can be parameterised using SONPROG for an optimum adaptation to the application. Therefore the sensor provides communication

with the 3RX4000-PF PC interface. To connect to the 3RX4000-PF PC interface a 4- or 5-pin M12 male cable connector is reqired. We recommend e. g. an adapter V1-M20-80 or a cable connector V15S-G-2M-PVC.

Please connect the wires to the sensors terminals as shown, below.

braun BN

blau BU

grau GY

(optional)

The terminals I

P2(E)

XI

SX S

LED P1(A)

GND L+

A

/U

A

I

(analog output) and SX (2nd switching output) are not needed for programming.

A/UA

weiß WH

schwarz BK

NO/NC

NO/NC

Release date: 2016-02-16 08:15 Date of issue: 2016-02-16 250790_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

3

Loading...

Loading...