Ultrasonic sensor UB1500-F42-UK-V95

Technical data

General specifications

Sensing range 70 ... 1500 mm

Adjustment range 90 ... 1500 mm

Dead band 0 ... 70 mm

Standard target plate 100 mm x 100 mm

Transducer frequency approx. 175 kHz

Response delay approx. 150 ms

Indicators/operating means

LED green solid green: Power on

Model Number

UB1500-F42-UK-V95

Single head system

Features

• Relay output for high power

• Extremely small unusable area

•TEACH-IN

• Interference suppression

(adjustable divergence of sound

cone in close range)

• Temperature compensation

• NO/NC selectable

Diagrams

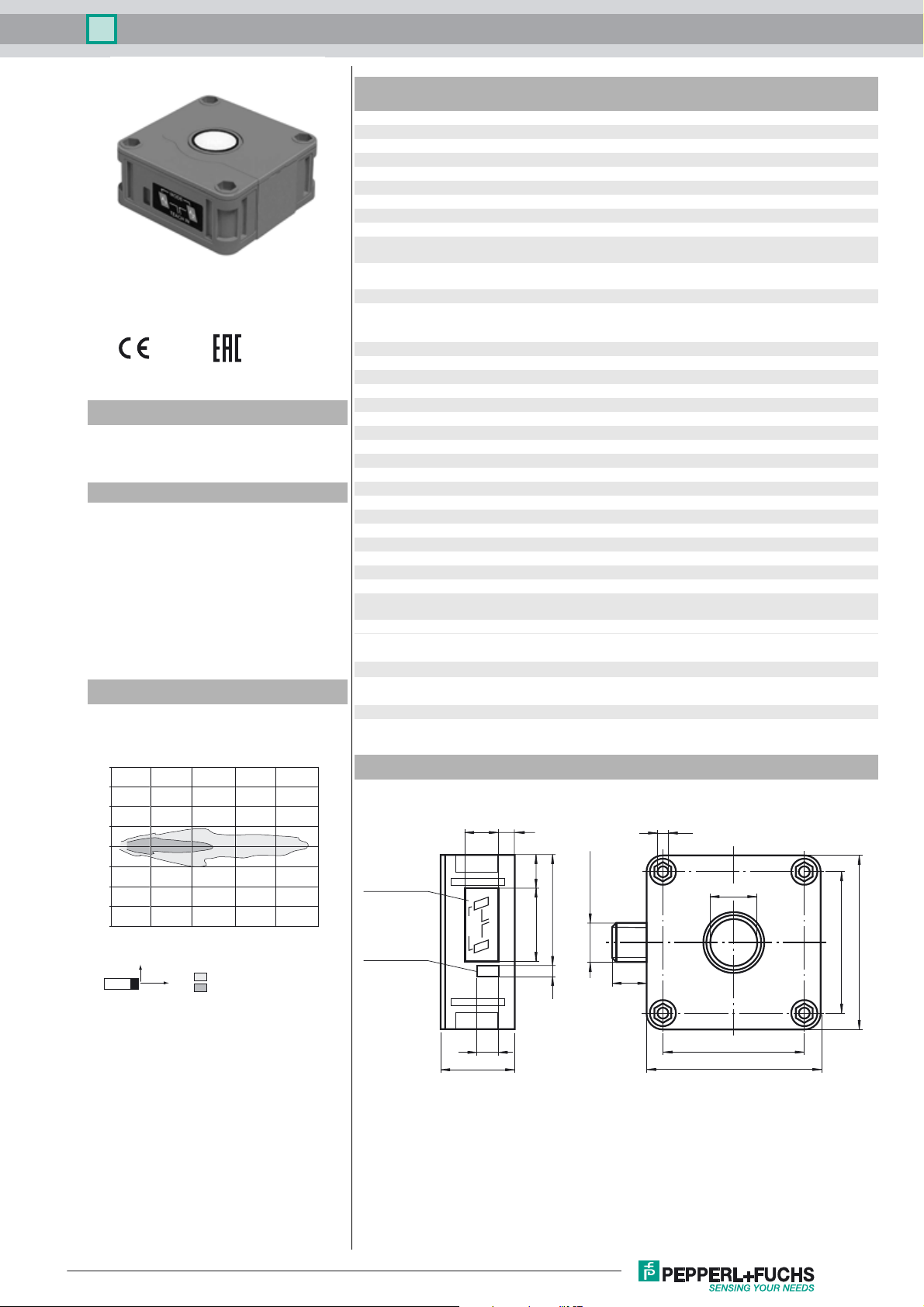

Characteristic response curve

Distance Y [mm]

1000

flat surface 100 mm x 100 mm

750

500

250

0

-250

-500

-750

round bar, Ø 25 mm

-1000

0 500 1000 1500 2000 2500

Y

flat surface 100 mm x 100 mm

X

round bar, Ø 25 mm

Distance X [mm]

LED yellow solid: switching state switch output

LED red normal operation: "fault"

Electrical specifications

Fusing ≤ 3 A Slow-blow fuse in accordance with IEC 60127-2

Operating voltage U

No-load supply current I

Time delay before availability t

Output

B

0

v

Output type 1 relay output

Rated operating current I

Repeat accuracy ≤ 0.5 % of switching point

e

Switching frequency f ≤ 3 Hz

Range hysteresis H 1 % of the set operating distance

Temperature influence ± 1 % of full-scale value

Ambient conditions

Ambient temperature -25 ... 70 °C (-13 ... 158 °F)

Storage temperature -40 ... 85 °C (-40 ... 185 °F)

Mechanical specifications

Degree of protection IP65

Connection 5-pin V95 connector (7/8"-16 UN 2A)

Material

Housing PBT

Transducer epoxy resin/hollow glass sphere mixture; foam polyurethane,

Mass 260 g

Compliance with standards and

directives

Standard conformity

Standards EN 60947-5-2:2007+A1:2012

Approvals and certificates

EAC conformity TR CU 004/2011

Dimensions

7.5

15

TEACH IN

15.5

34

Membrane keys

LED window

MODE

2

A

1

A

flashing: program function

program function: no object detected

Sheet 5 required. Recommendation: after a short circuit,

check that the device is functioning correctly.

22 ... 253 V AC/DC

≤ 60 mA

≤ 800 ms

3 A

cover PBT

IEC 60947-5-2:2007 + A1:2012

TR CU 020/2011

5.2

22

7/8"-16 UN 2A

52.5

5

16

80

65

Release date: 2017-08-24 08:53 Date of issue: 2017-08-24 111683_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

10

34

65

80

1

Ultrasonic sensor UB1500-F42-UK-V95

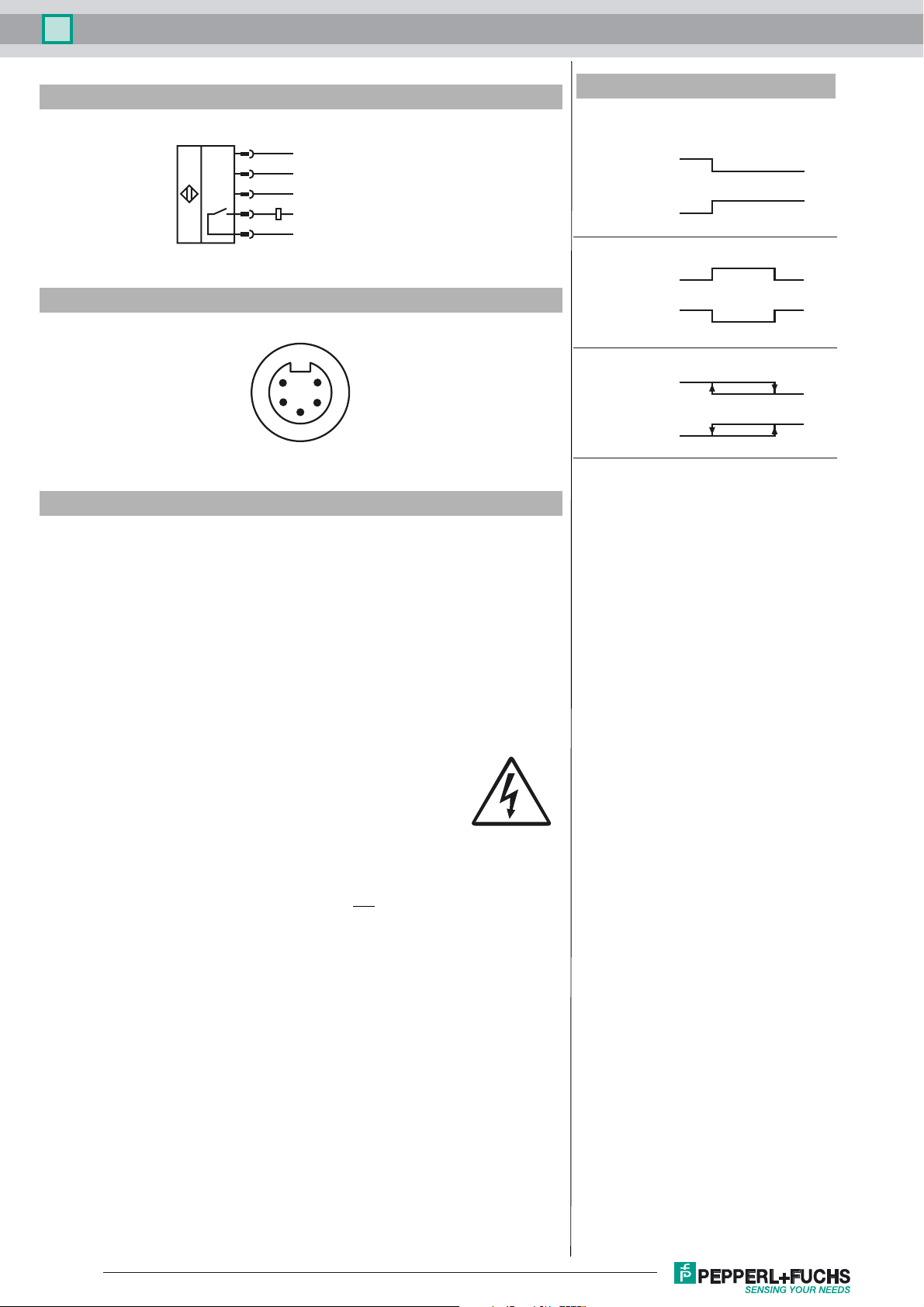

Electrical Connection

1

5

3

4

2

22 V ... 253 V ~/=

22 V ... 253 V ~/=

n.c.

≤

250 V ~/120 V =

≤

3 A

I

Pinout

1

2

3

5

4

Accessories

V95-G-Y

Female connector, 7/8" - 16 UN, 5-pin, field attachable

V95-W-5M-PVC

Female cordset, 7/8", 5-pin, PVC cable

V95-W

Female cordset, field attachable

V95-W-2M-PVC

Female cordset, 7/8", 5-pin, PVC cable

MH 04-3505

Mounting aid for FP and F42 sensors

MHW 11

Mounting brackets for sensors

Additional Information

Possible operating modes

1. Switch point operation

normally open

A1 -> ∞

normally closed

A2 -> ∞

2. Window operation

normally open

A1 < A2

normally closed

A2 < A1

3. Hysteresis operation

normally open

A1 < A2

normally closed

A2 < A1

4. Object presence detection mode

A1 -> ∞, A2 -> ∞: Sensor detects object presence within

sensing range

Note A1 -> ∞, A2 -> ∞ means: cover sensor with hand

or remove all objects from sensing range

A2

A1

A1 A2

A2 A1

A1 A2

A2 A1

Safety notes:

The supply circuit is separated from the relay circuit by basic insulation.

Safety class II is only guaranteed when using cable connectors listed in the accessories. The connector cable may only be separated

from the unit when the power is off.

CAUTION:

The UB...-F42(S)-UK-V95 ultrasonic sensor is not

suitable for use in environ-

ments subject to explosion hazards.

Conformity: EN 60947-5-2

Housing insulation: Safety class II

Degree of contamination: 3

Overvoltage category: III

Parameterisation:

You can use 2 keys to parameterise the sensor. In order to start the switch point 1

learning mode, press the A1 key; in order to start the switch point 2 learning mode,

press the A1 key.

If you keep both keys pressed as you switch on the power supply, the sensor will

switch over to the sensitivity adjustment mode of operation.

In case the parameterisation procedure is not completed within 5 minutes, the sensor

will discontinue the process and retain all previous settings.

Release date: 2017-08-24 08:53 Date of issue: 2017-08-24 111683_eng.xml

Refer to “General Notes Relating to Pepperl+Fuchs Product Information”.

2

Loading...

Loading...