Page 1

SmartRunner Matcher*

Light section sensor for highprecision profile comparison

FACTORY AUTOMATION

MANUAL

Page 2

With regard to the supply of products, the current issue of the following document is ap-

plicable: The General Terms of Delivery for Products and Services of the Electrical Indus-

try, published by the Central Association of the Electrical Industry (Zentralverband

Elektrotechnik und Elektroindustrie (ZVEI) e.V.) in its most recent version as well as the

supplementary clause: "Expanded reservation of proprietorship"

SmartRunner Matcher*

Page 3

SmartRunner Matcher*

3

1 Introduction................................................................................. 5

1.1 Content of this Document ................................................................... 5

1.2 Target Group, Personnel...................................................................... 5

1.3 Symbols Used ...................................................................................... 5

2 Product Specifications............................................................... 7

2.1 Use and Application............................................................................. 7

2.2 Hazards of Laser Radiation................................................................. 9

2.3 Dimensions......................................................................................... 10

2.4 Displays and Controls ....................................................................... 10

2.5 Interfaces ............................................................................................ 12

2.6 Accessories ........................................................................................ 13

3 Installation................................................................................. 14

3.1 Storage and Disposal ........................................................................ 14

3.2 Preparation ......................................................................................... 14

3.3 Mounting the Sensor ......................................................................... 14

3.4 Electrical Connection ........................................................................ 16

3.5 Detection range.................................................................................. 19

4 Commissioning......................................................................... 20

4.1 Connecting the Sensor...................................................................... 20

5 Vision Configurator Software .................................................. 21

5.1 Connecting to Vision Configurator .................................................. 21

5.2 Application Window Structure .......................................................... 23

Page 4

4

SmartRunner Matcher*

5.3 Menu Bar .............................................................................................24

5.3.1 File Menu ......................................................................................... 24

5.3.2 View Menu ....................................................................................... 24

5.3.3 Sensor Menu....................................................................................25

5.3.4 Image Menu ..................................................................................... 25

5.3.5 Administration Menu ........................................................................26

5.3.6 Help Menu........................................................................................ 26

5.4 Toolbar.................................................................................................27

5.5 Sensor Data.........................................................................................28

5.6 Image Display .....................................................................................28

5.7 Configuration window........................................................................33

5.7.1 Sensor Information........................................................................... 33

5.7.2 Common Tab.................................................................................... 34

5.7.3 Matcher Tab .....................................................................................36

6 Operation................................................................................... 41

6.1 Configuration Mode............................................................................41

6.2 Code Card Mode.................................................................................47

6.2.1 Setting Device Parameters via Control Code.................................... 48

6.3 Presentation Mode .............................................................................49

6.4 Runtime Mode.....................................................................................50

6.4.1 Communication via the RS-485 Interface ......................................... 50

7 Maintenance and Repair.......................................................... 54

7.1 Maintenance........................................................................................ 54

7.2 Repair ..................................................................................................54

8 Troubleshooting........................................................................ 55

8.1 What to Do in Case of a Fault ............................................................55

9 License Note ............................................................................. 57

Page 5

SmartRunner Matcher*

Introduction

2018-01

5

1 Introduction

1.1 Content of this Document

This document contains information required to use the product in the relevant phases of the

product life cycle. This may include information on the following:

Product identification

Delivery, transport, and storage

Mounting and installation

Commissioning and operation

Maintenance and repair

Troubleshooting

Dismounting

Disposal

The documentation comprises the following parts:

This document

Datasheet

In addition, the documentation may comprise the following parts, if applicable:

EU-type examination certificate

EU declaration of conformity

Attestation of conformity

Certificates

Control drawings

Instruction manual

Other documents

1.2 Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation, maintenance, and

dismounting lies with the plant operator.

Only appropriately trained and qualified personnel may carry out mounting, installation,

commissioning, operation, maintenance, and dismounting of the product. The personnel must

have read and understood the instruction manual and the further documentation.

Prior to using the product make yourself familiar with it. Read the document carefully.

1.3 Symbols Used

This document contains symbols for the identification of warning messages and of informative

messages.

Note!

Visit www.pepperl-fuchs.com to access further documentation for full information about the

product.

Page 6

2018-01

6

SmartRunner Matcher*

Introduction

Warning Messages

You will find warning messages, whenever dangers may arise from your actions. It is

mandatory that you observe these warning messages for your personal safety and in order to

avoid property damage.

Depending on the risk level, the warning messages are displayed in descending order as

follows:

Informative Symbols

Action

This symbol indicates a paragraph with instructions. You are prompted to perform an action or

a sequence of actions.

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

Warning!

This symbol indicates a possible fault or danger.

Non-observance may cause personal injury or serious property damage.

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt the device and any connected systems and plants, or result in

their complete failure.

Note!

This symbol brings important information to your attention.

Page 7

SmartRunner Matcher*

Product Specifications

2018-01

7

2 Product Specifications

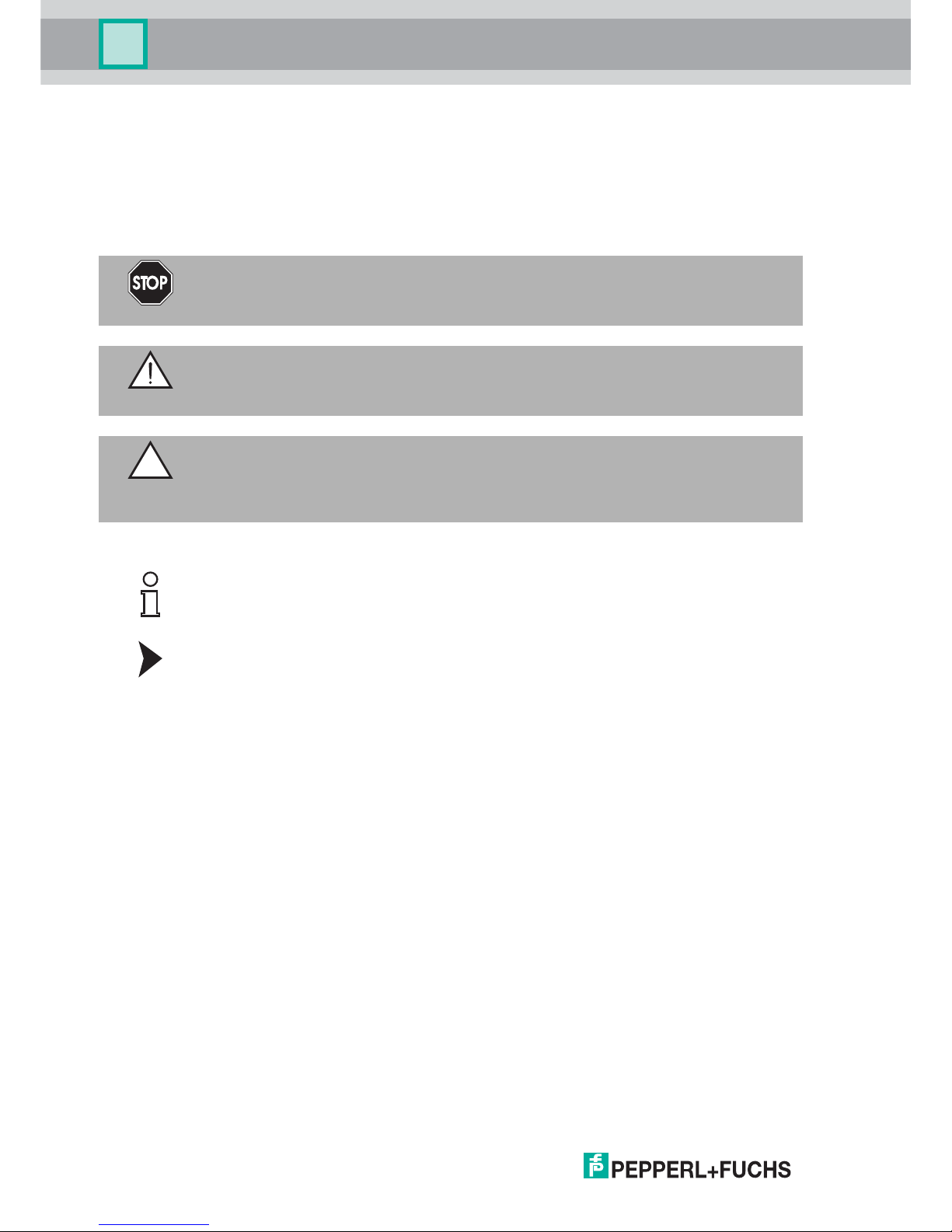

2.1 Use and Application

This manual applies to the light section sensors VLM350-F280-2E2-1000, VLM350-F280-R41001 and VLM350-F280-R4-1101 (hereafter referred to as

sensor). The sensor compares

cu

rrent height profiles with a previously taught-in height profile. The sensor is based on

SmartRunner technology and combines the light section method for detecting height profiles

with a 2-D vision sensor.

An emitter optic is used to project a laser line onto an object as part of the light section method.

This is detected by a camera at a specific angle. A height and width profile is created using the

triangulation principle. This laser technology provides reliable measurements on different

surfaces.

The sensor is commissioned and operated using the Vision Configurator software. In addition,

preset parameters can be transferred to the sensor via Data Matrix control codes. In this way

you have the opportunity to quickly adapt the settings to the conditions of the measuring

environment and the measuring object without using a laptop in case of replacement.

Structure of the sensor

Figure 2.1 Overview of components and measurement result

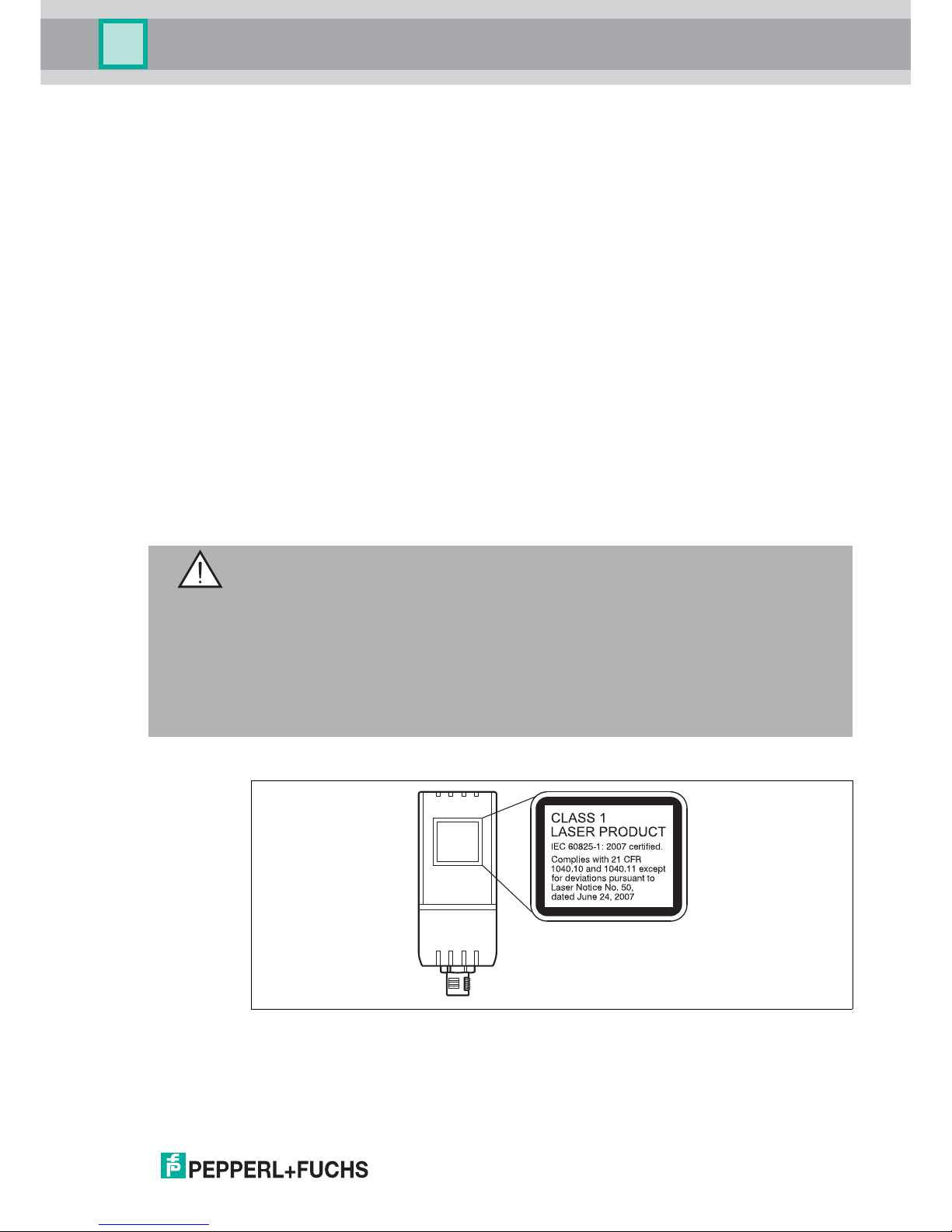

The SmartRunner has an optimized hardware and software platform. It is available in different

versions for specific applications. The device is certified according to laser protection class 1.

Features of the sensor

The sensor, optimized and pre-configured for comparing height profiles, offers protection from

damage and from the production of rejects. An object is identified by comparing with stored

reference profiles, which detects whether the object is in the correct position. This means

gripping processes, such as in robotics, are always accurate.

1 Flat profile

2 Raised profile

3 Emitter optic (vision sensor including LED lighting)

4 Camera

5 Height profile on the image sensor (measuring result)

1

1

2

2

3

4

5

Page 8

2018-01

8

SmartRunner Matcher*

Product Specifications

The integrated control interface of the sensor has been optimized by the factory to report

deviations from a previously programed contour. Via the profile comparison, the sensor

detects the recorded contour of an object, its correct location, and spacing. In case of a fault,

collisions and damage are safely eliminated and lengthy machine downtimes are therefore

avoided.

For this, the sensor is taught in to a specific height profile and a trigger executes a

reconciliation between the currently-recorded contour and the reference contour. A "good"

signal is produced if these are identical. If the two profiles differ, a "Bad" signal is produced.

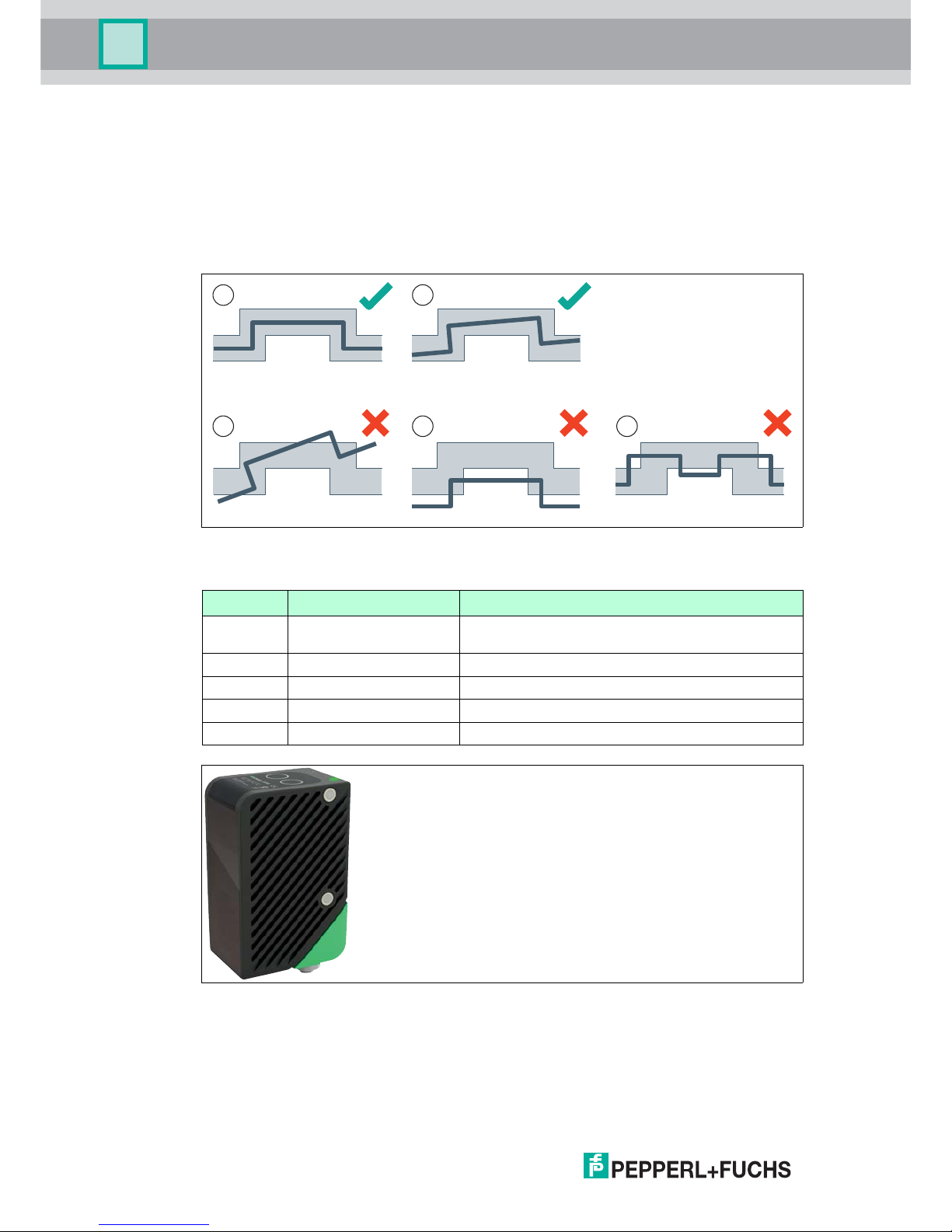

Figure 2.2 Capturing object contour, position, and distance

Figure 2.3 Sensor

Position Designation Function

1 Good-signal-scenario 1 Taught-in reference contour with adjustable

tolerance range

2 Good-signal-scenario 2 Slight torsion within the tolerance range

3 Bad-signal-scenario 3 Excessive torsion outside the tolerance range

4 Bad-signal-scenario 4 Too great a distance between sensor and object

5 Bad-signal-scenario 5 Incorrect or faulty object detected

2

1

3 54

Page 9

SmartRunner Matcher*

Product Specifications

2018-01

9

Parameterization and Operating Modes

The laser-line triangulation sensor can be configured or parameterized via 3 different methods.

Reading in code cards via the sensor camera

Processing configuration telegrams via the bus interface

Using the Vision Configurator software

The sensor has different operating modes, which can be activated for configuration,

presentation, or normal operation.

Runtime mode: measurement mode, sensor works as configured

Configuration mode: mode for configuring the sensor via data telegrams and via the

Vision Configurator configuration program

Code card mode: mode for configuring the sensor via Data Matrix control codes without

the assistance of a PC

Presentation mode: mode for presentation or testing without the assistance of a PC

2.2 Hazards of Laser Radiation

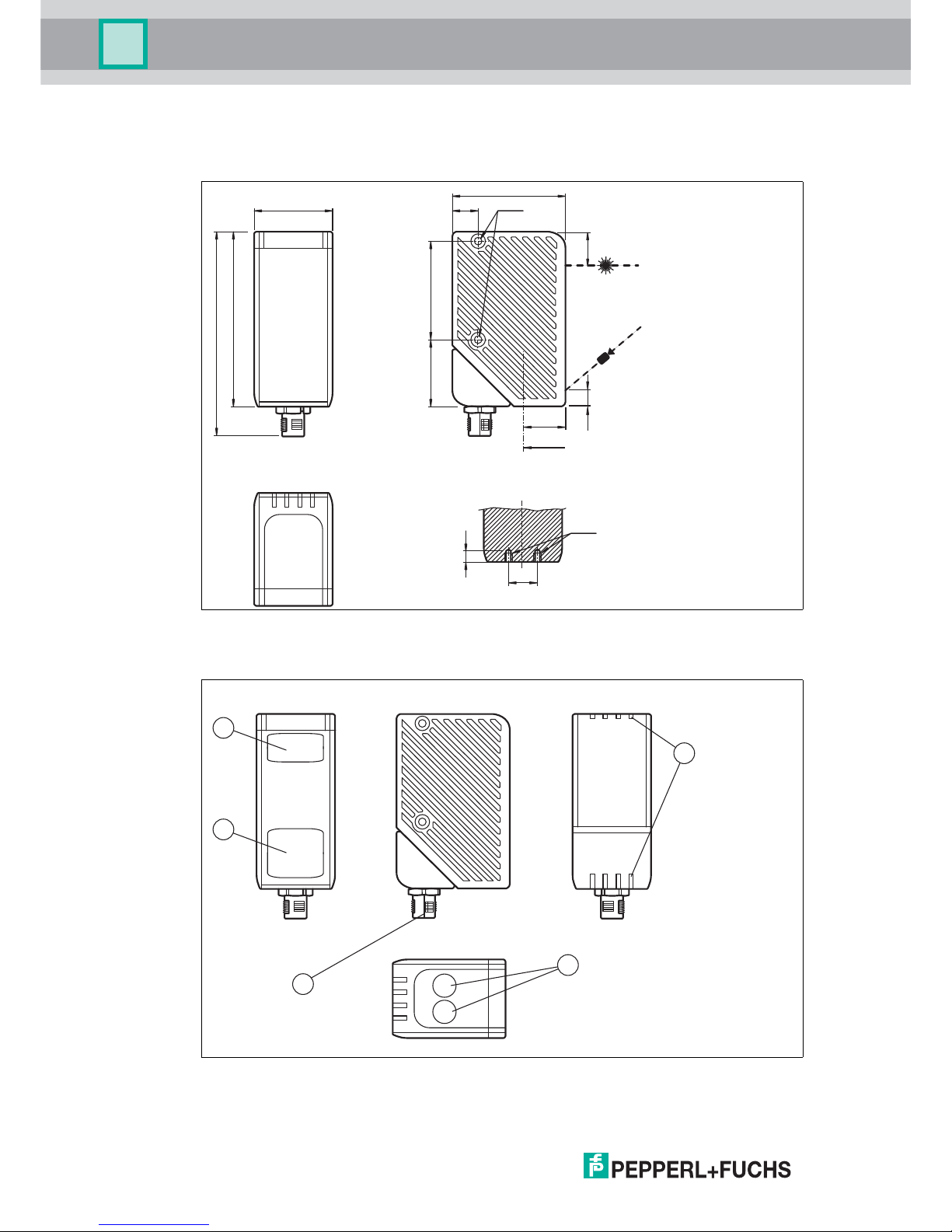

This section describes the contents and location of the warning label.

The sensor used corresponds to the safety standard IEC 60825-1:2007 for a laser class 1

product. In addition, the US regulation 21 CFR 1040.10 and 1040.11 is fulfilled except for

Laser Notice No. 50 dated June 24, 2007.

The warning label is fixed to the back of the housing as shown in the following figure.

Figure 2.4 Laser radiation warning message

Warning!

Class 1 laser light

The laser light can be an irritant, especially in a dark environment. Do not point lasers at

people!

Never look into the laser beam port if the sensor is operating.

Maintenance and repairs must be carried out by authorized service personnel only!

Install the device so that the warning is clearly visible and legible.

Do not remove the sensor's protective cover.

Page 10

2018-01

10

SmartRunner Matcher*

Product Specifications

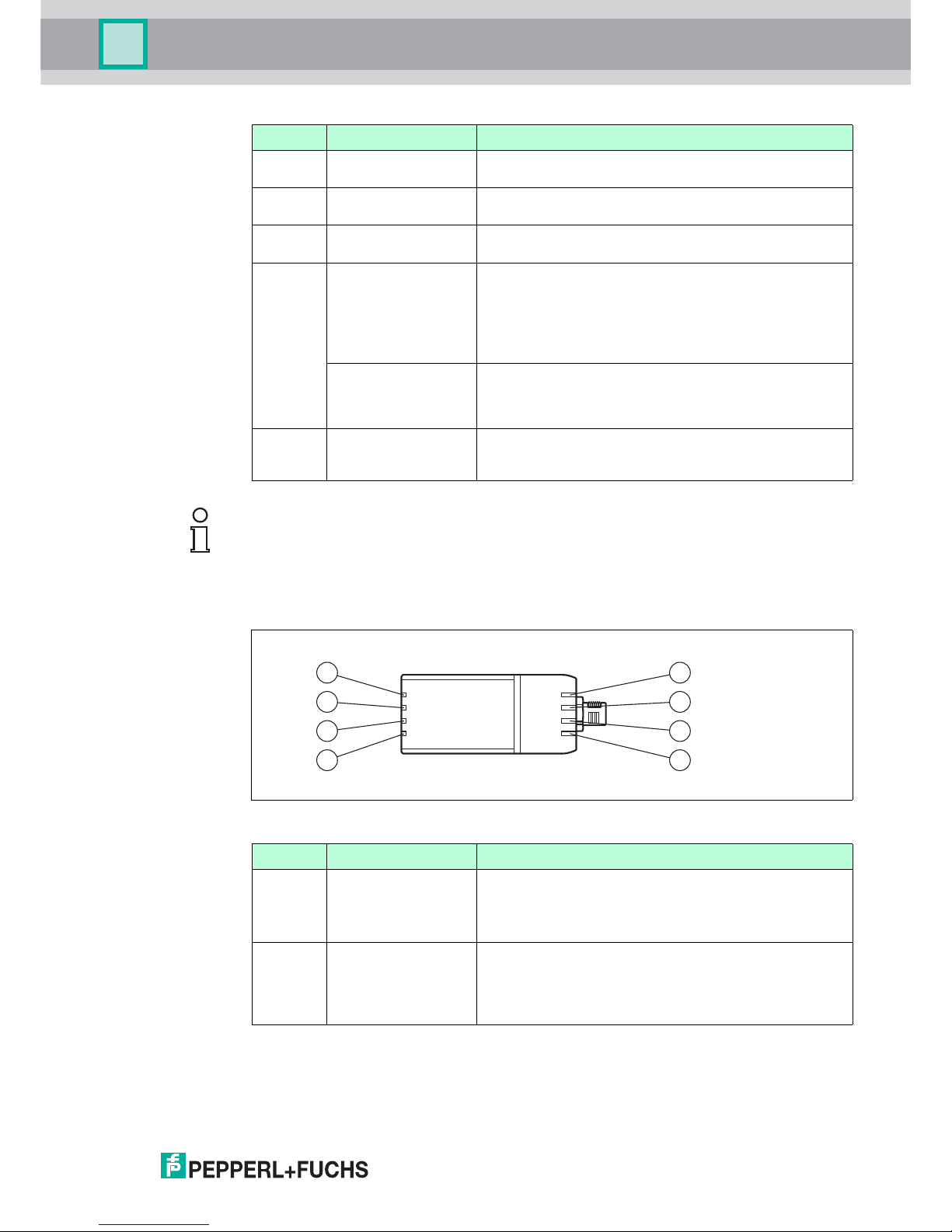

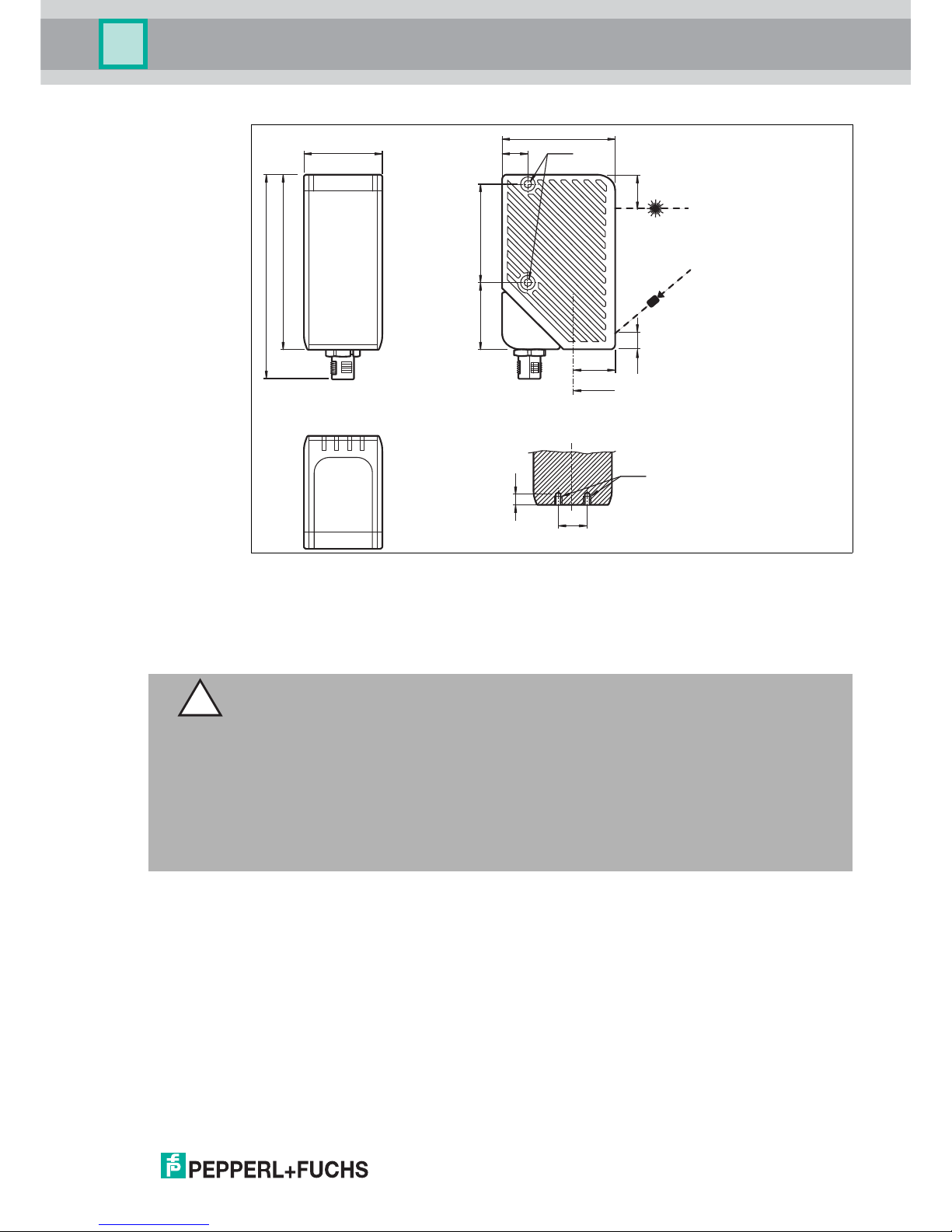

2.3 Dimensions

The devices in the SmartRunner series have the following identical housing dimensions.

Figure 2.5 Dimensions of the SmartRunner series

2.4 Displays and Controls

Figure 2.6 Overview of displays and controls

38 12 M4

55

85

99.1

32 48

5

8 15.35

M4

20

A

A

14

1

3

4

2

12

5

Page 11

SmartRunner Matcher*

Product Specifications

2018-01

11

Description of the LEDs

Figure 2.7 LEDs overview

Position Designation Function

1 Emitter optic

protective cover

Is used to protect against damage and contamination

2 Reception optic

protective cover

Is used to protect against damage and contamination

3 LEDs The functional description for the LEDs can be found in

the table below.

4 Function keys in

Presentation mode

Function key 1: triggers an evaluation

Function key 2: when pressed and held for 2 seconds,

activates the teach-in process. When pressed and

held for longer than 2 seconds, activates Code Card

mode

Function keys in

Runtime mode

Function key 1: no function

Function key 2: when pressed and held for longer than

2 seconds, activates Code Card mode

5 Electrical Connection The sensor is connected electrically via a MAIN 8-pin M12

connector plug on the bottom of the housing. See chapter

3.4.

Note!

The function keys are only activated during a parameterizable time span after the sensor is

switched on, after which they are locked. The default value for this time span is 5 minutes.

The function keys have different functions depending on the selected operating state.

Position Designation Function

1 Ready (green/red) Lights up red if there is a sensor fault

Lights up green when the sensor is ready for operation

Flashes green if the sensor is in Configuration mode

2 Match 3/4

(green/yellow)

Lights up green if the scanned profile matches the

taught-in profile 3 (MATCH 3)

Lights up yellow if the scanned profile matches the

taught-in profile 4 (MATCH 4)

2

1

5

6

7

8

4

3

Page 12

2018-01

12

SmartRunner Matcher*

Product Specifications

2.5 Interfaces

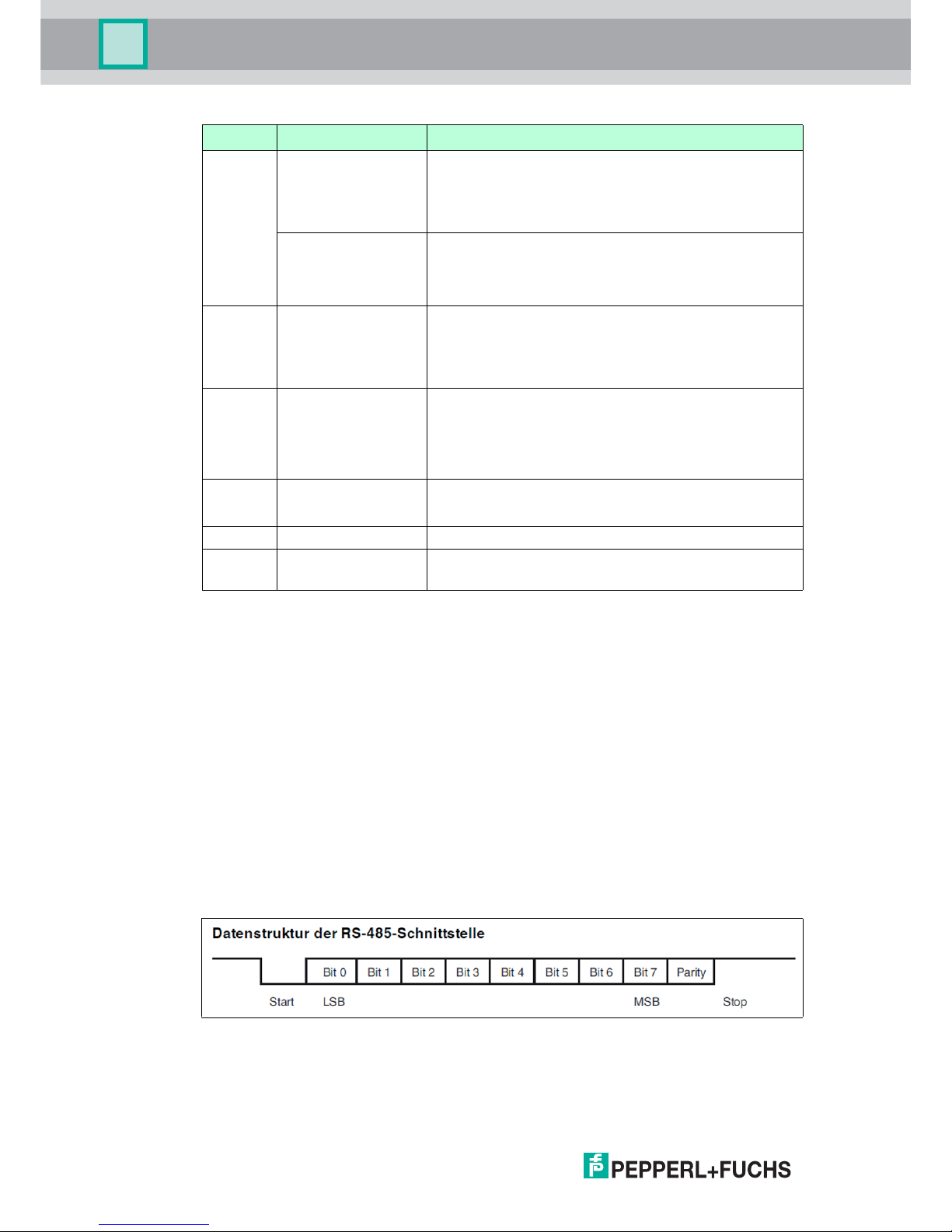

The RS-485 Interface

The reader is equipped with an RS-485 interface for communication purposes, i.e.,

parameterizing the reader functions or reading out current process data during operation. This

interface is operated in 8-E-1 operating mode and fitted with a terminator that can be activated

or deactivated by parameterizing the sensor head.

The RS-485 interface supports the following transfer rates:

38400 bit/s

57600 bit/s

76800 bit/s

115200 bit/s (default value)

230400 bit/s

Data structure of the RS-485 interface

3 Result (green/red) Lights up green if a scanned profile matches a taught-

in profile

Lights up red if a scanned profile does not match a

taught-in profile

Applies in Code Card

mode

Lights up green when a correct code has been read

Lights up red when an incorrect code has been read

Off if no code has been read

4 Match 1/2

(green/yellow)

Lights up green if the scanned profile matches the

taught-in profile 1 (MATCH 1)

Lights up yellow if the scanned profile matches the

taught-in profile 2 (MATCH 2), optional

5 Diagnosis (red) Lights up red if a bus error has occurred

Lights up red if a system error has occurred on the

interface controller

Flashes red if the sensor is in Update mode

6 POWER (green) Lights up as soon as voltage is present

Flashes in Configuration mode

7 Teach in (yellow) Lights up yellow during the teach in process

8 TRIGGER (yellow) Lights up yellow if the hardware trigger signal is

activated

Position Designation Function

Page 13

SmartRunner Matcher*

Product Specifications

2018-01

13

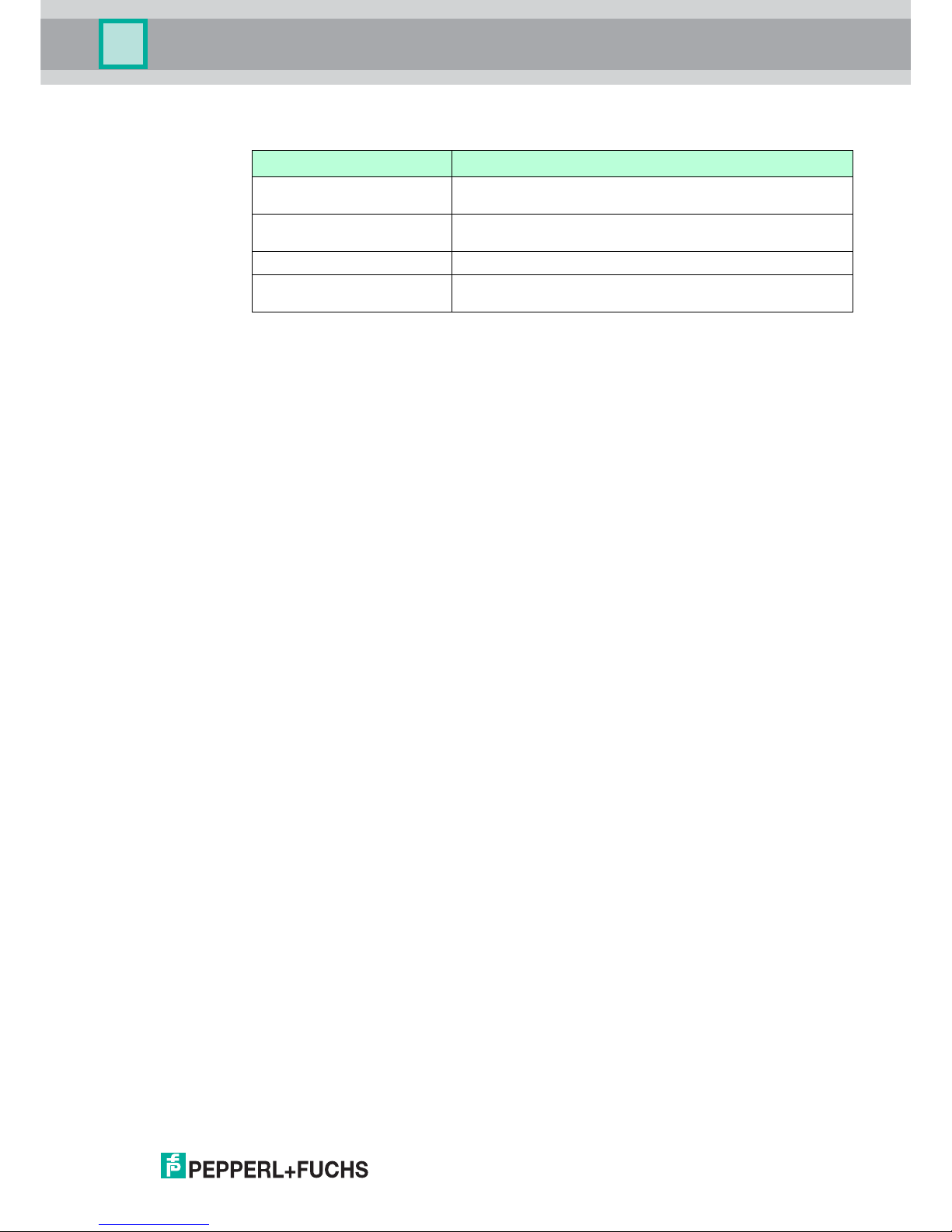

2.6 Accessories

Other accessories can be found online at www.pepperl-fuchs.com.

Order designation Description

V19-G-5M-PUR-ABG Single-ended female cordset, M12, 8-pin, shielded, PUR

cable

VLX-MB1 Mounting aid, adaptable 360° adjustment of mounting head

and mounting foot

VLX-MB2 Mounting aid, fixing bracket

PCV-USB-RS485 Converter

Set

USB to RS 485 interface converter

Page 14

2018-01

14

SmartRunner Matcher*

Installation

3Installation

3.1 Storage and Disposal

Keep the original packaging. Always store and transport the device in the original packaging.

Store the device in a clean and dry environment. The permitted ambient conditions must be

considered, see datasheet.

Disposing of device, packaging, and possibly contained batteries must be in compliance with

the applicable laws and guidelines of the respective country.

3.2 Preparation

Unpacking the unit

1. Check that all package contents are present and undamaged.

If anything is damaged, inform the shipper and contact the supplier.

2. Check that all items are present and correct based on your order and the shipping

documents.

If you have any questions, please contact Pepperl+Fuchs.

3. Keep the original packing material in case you need to store or ship the unit at a later time.

3.3 Mounting the Sensor

The operating distance differs depending on the sensor. The correct operating distance can be

found in the datasheet for the sensor to be installed.

The following illustration shows all the relevant housing dimensions in mm:

Note!

Mounting an optical device

Do not aim the sensor at the sun.

Protect the sensor from direct long-term exposure to sun.

Prevent condensation from forming by not exposing the sensor to any major fluctuations

in temperature.

Do not expose the sensor to the effects of any aggressive chemicals.

Keep the lenses and reflector of the device clean. Clean with a soft cloth, using standard

commercial glass cleaner if necessary.

We recommend to clean the optical surface and to check screw fittings and electrical

connections at regular intervals.

Page 15

SmartRunner Matcher*

Installation

2018-01

15

Figure 3.1 Space requirements

The surface must be level to prevent the housing from becoming misaligned when the fittings

are tightened. We advise securing the screws with spring disks to prevent the sensor

becoming misaligned. Following installation of the sensor, ensure that there is still sufficient

space to connect the connection cable to the sensor

Mounting the Housing

The device has 2 M4 threads on the base and on both sides of the housing to allow easy

installation of the sensor in your plant. This means there are 3 different ways to mount the

sensor in your plant.

One-sided lateral mounting with M4 screws: You can mount the housing on its right-hand

or left-hand side using the 2 M4 threaded sleeves. The maximum screw-in depth of the

M4 screws is 8 mm.

Continuous lateral mounting with M3 screws: M4 threaded sleeves are designed in such

a manner that M3 screws pass all the way through the housing. Use 2 sufficiently long M3

screws with 2 lock nuts to mount the device in the plant

38 12 M4

55

85

99.1

32 48

5

8 15.35

M4

20

A

A

14

Caution!

Damage to the equipment caused by improper installation!

Device components can be damaged if the permissible screw-in depths and the maximum

permissible tightening torque is exceeded.

Note that the threads on the bottom of the housing are not thru–holes.

Observe the maximum permissible screw-in depth to avoid damaging the device or mounting

incorrectly.

Never exceed the maximum permissible tightening speed of the fixing screws. The maximum

tightening torque of the mounting screws must not exceed 2 Nm.

Page 16

2018-01

16

SmartRunner Matcher*

Installation

Mounting on the underside of the device with M4 screws: You can use the 2 threaded

sleeves to mount the housing on the underside of the device. The maximum screw-in

depth of the M4 screws is 5 mm.

Positioning the Sensor

When positioning the sensor, ensure that the camera's field of vision is not obscured by the

objects being scanned.

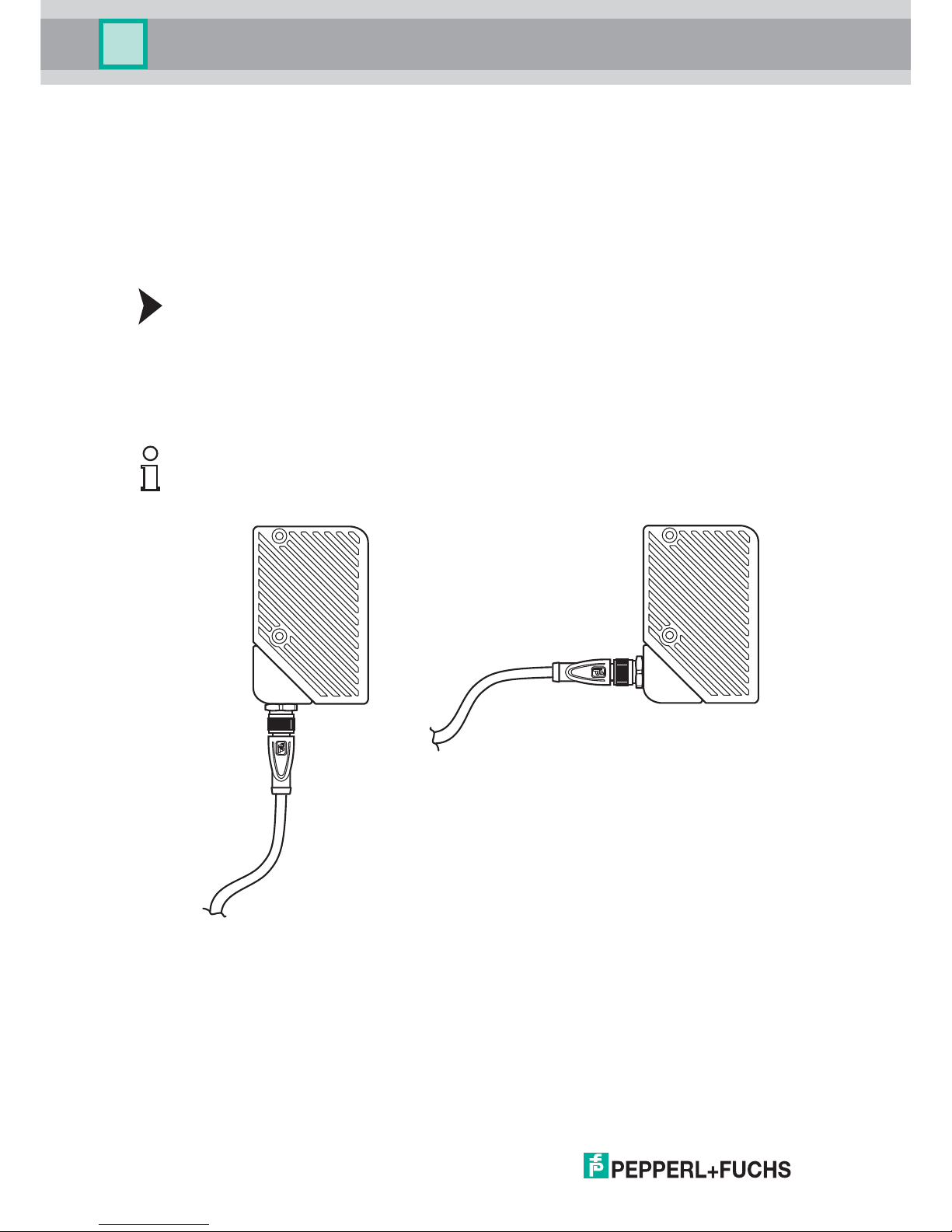

3.4 Electrical Connection

Connecting the Supply Voltage

The sensor is connected electrically via a MAIN 8-pin M12 connector plug on the bottom of the

housing. The power supply and data transfer take place via this connection. To connect the

sensor, proceed as follows:

1. Plug the 8-pin M12 socket into the plug on the bottom of the housing.

2. Screw the lock nut onto the connector as far as it will go. This ensures that the power cable

cannot be pulled out inadvertently.

Tip

The corner of the housing where the MAIN 8-pin M12 connector plug is located can be rotated.

Depending on the mounting position, you can rotate the connector plug in a different direction

to ensure simple cabling.

Figure 3.2 M12 connector plug

Page 17

SmartRunner Matcher*

Installation

2018-01

17

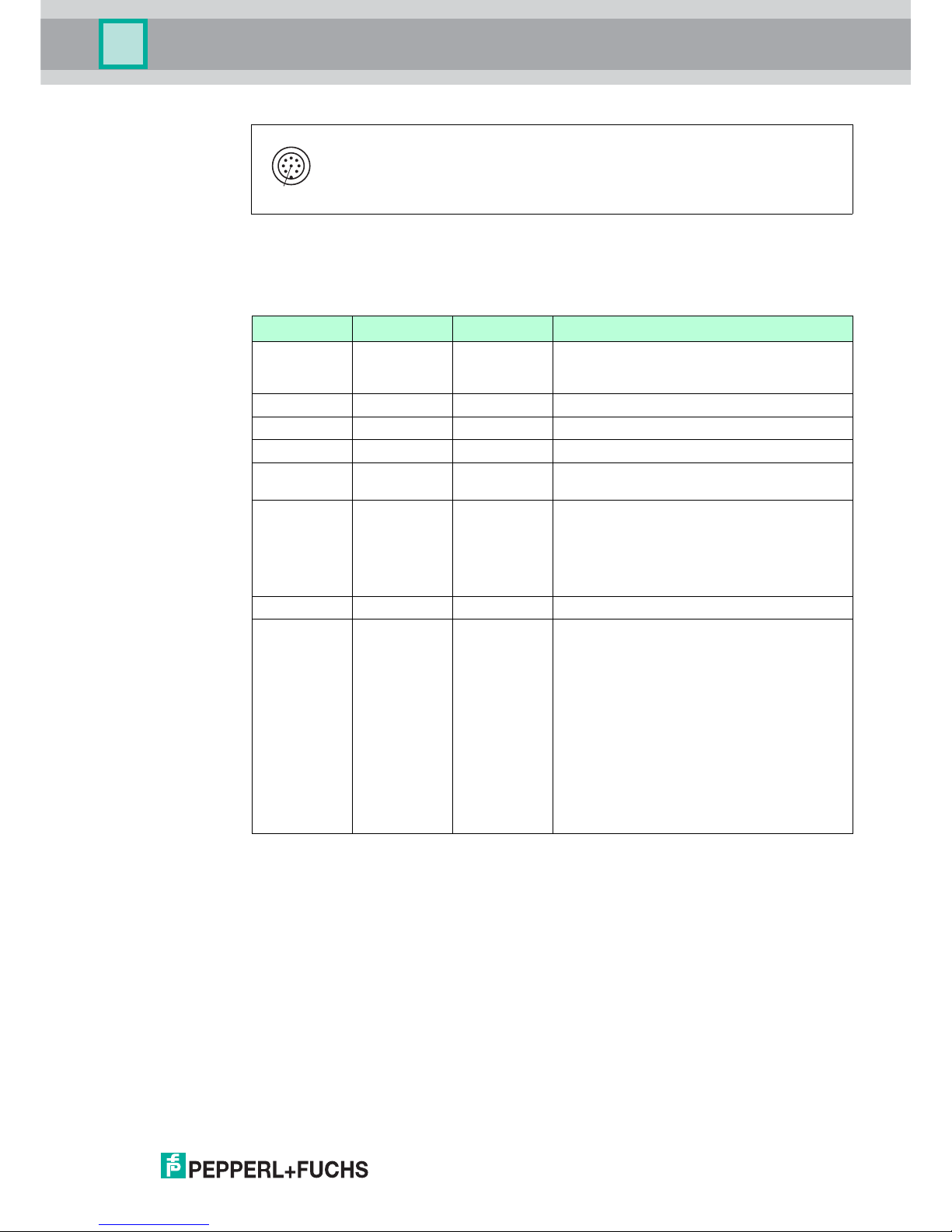

Figure 3.3 Connection layout

Pepperl+Fuchs single-ended female cordsets are manufactured in accordance with EN609475-2. When using a V19-G-5M-PUR-ABG single-ended female cordset with an open cable end,

connector pins are assigned as follows:

Pin Wire color Signal Description

1 white IN trigger Trigger input. Triggers an evaluation, if the

sensor is in continuous evaluation mode

(independent)

2 brown +UB + 24 V power supply

3 green Data+ RS-485 RS-485 interface: Data +

4 yellow Data- RS-485 RS-485 interface: Data -

5 gray Teach Control signal for teaching in the background

line

6 pink Good Output 1 is set if the height profile detected

matches the taught-in profile in terms of form

and position.

Once the teach-in process has been

performed, this output signals that teach-in

was successful

7 blue GND Ground for the + 24 V power supply

8 red Bad Output 2 is set if:

No object has been detected

or

The form detected does not match the

taught-in form

or

The position detected is outside the

tolerance.

Once the teach-in process has been

performed, this output signals that teach-in

has not been successful

1

4

6

7

8

5

3

2

Page 18

2018-01

18

SmartRunner Matcher*

Installation

Connection using the RS-485 Interface

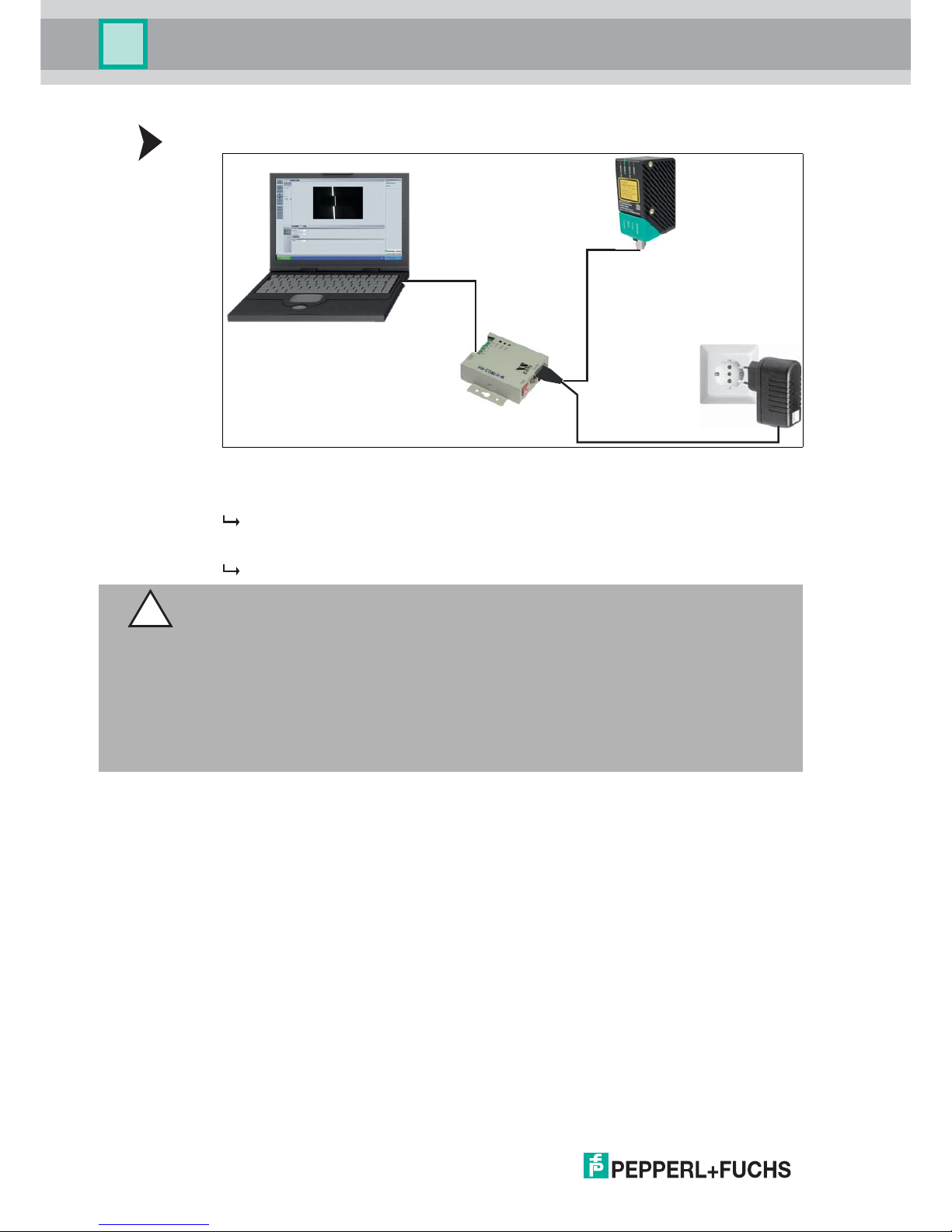

Figure 3.4 PCV-USB-RS-485 Converter Set

1. Plug a plug-in power supply into a socket and connect it to the interface converter.

The indicator LEDs on the sensor light up.

2. Establish a USB connection between the PC system and interface converter.

The PWR LED on the interface converter lights up red.

Shielding Cables

The shielding of connection lines is required to suppress electromagnetic interference.

Establishing a low resistance or low impedance connection with the protective conductor or

equipotential bonding circuit is a particularly important factor in ensuring that these

interference currents do not become a source of interference themselves. Only use connection

lines with braid. Avoid connection lines with foil shield because this would increase the line

capacities. The shielding is integrated at both ends, i.e., in the switch cabinet, on the control

panel, and on the reader. The grounding terminal available as an accessory allows easy

integration in the equipotential bonding circuit.

In exceptional cases, the shielding of a connection at one end may be more favorable if:

An equipotential bonding cable is not laid or cannot be laid.

A film shield is used.

The following points relating to shielding must also be noted:

Use metal cable clips that cover large areas of the shield.

After installing the cable shield in the control cabinet, place it directly on the equipotential

bonding rail.

USB

110 V / 230 V

24 V DC

RS 485

Caution!

Damage to the device

Connecting an alternating current or excessive supply voltage can damage the device or

cause the device to malfunction.

Electrical connections with reversed polarity can damage the device or cause the device to

malfunction.

Connect the device to direct current (DC). Ensure that the supply voltage rating is within the

specified device range. Ensure that the connecting wires on the female cordset are connected

correctly.

Page 19

SmartRunner Matcher*

Installation

2018-01

19

Direct the protective grounding connections to a common point in a star configuration.

The cross-section of the cables used for grounding should be as large as possible.

Additional Ground Connection

3.5 Detection range

Figure 3.5 Detection range

Note the detection range of the SmartRunner Matcher when planning your plant. You will find

more information on the detection range in the following table.

Order designation Description

PCV-SC12 Clip for mounting an additional ground

connection.

PCV-SC12A

1 Field of view

Detection range X Distance Z to the sensor

min 40 mm 60 mm

max 160 mm 350 mm

max

X

min

X

max

min

Z

Z

1

Note!

The smallest possible resolution in the X and Z direction increases on a linear basis to the

distance Z to the sensor.

Page 20

2018-01

20

SmartRunner Matcher*

Commissioning

4 Commissioning

4.1 Connecting the Sensor

The sensor is configured using the Vision Configurator software. You have the opportunity to

carry out settings on the sensor directly using the Vision Configurator software.

Aligning the Sensor

Use the image display and diagram display in the Vision Configurator software to optimally

align the sensor.

1. Power the reader via the 24 VDC socket on the device.

2. Use the automatic exposure time control to set an appropriate exposure value.

If exposure time control was successful, the result LED will light up green.

3. Align the sensor so that a complete line that is as narrow as possible can be seen in the

image display.

The optimal reading distance between the sensor and the measurement object is set.

Page 21

SmartRunner Matcher*

Vision Configurator Software

2018-01

21

5 Vision Configurator Software

The sensor is commissioned and operated using the Vision Configurator software.

The Vision Configurator software makes it easy to operate the sensor with its user-friendly

interface. Standard functions include making connections to the sensor, specifying the

operating parameters, saving data sets, and displaying data and error diagnostics.

User Rights and Password

Establishing a Network Connection

To establish a network connection with the sensor, proceed as follows:

1. Supply the sensor with power.

2. Start the Vision Configurator software.

3. Enter your user name and password.

5.1 Connecting to Vision Configurator

Connect Vision Configurator

Connect the SmartRunner to a PC.

Note!

The following user roles are predefined with different authorizations in the Vision Configurator.

User rights Description Password

Default View all information

Sensor configuration

Create users at same or lower level

A password is not required

User View all information

Sensor configuration

Create users at same or lower level

User

Admin View all information

Sensor configuration

Request the admin

password from

Pepperl+Fuchs

Table 5.1 The users have different access and administration rights depending on the respective

user role.

Note!

Additional steps for user-defined installation and installation of additional components are

described in the Vision Configurator manual. The Vision Configurator manual can be found

online at www.pepperl-fuchs.com.

Note!

Use a suitable RS-485/USB connecting cable and an adapter cable to do this:

Function Order designation

USB interface converter to RS-485 including

cable unit with power supply

PCV-USB-RS485-Converter Set

Cable unit with power supply for USB/RS-485

interface converter

PCV-KBL-V19-STR-RS485

Page 22

2018-01

22

SmartRunner Matcher*

Vision Configurator Software

Figure 5.1 Home screen

Wizard - Operation assistant for Vision Configurator

The Wizard complements the Vision Configurator configuration software. Double-click on the

Wizard button to launch the operation assistant. You will be guided step-by-step through the

individual settings.

Proceed as follows to launch the Vision Configurator.

Starting Vision Configurator

1. Select the 2-D/3-D button on the "Sensor Family" tab.

2. Select SMARTRUNNER in the "parameter range" with connection type RS485.

3. Select the required COM port.

4. In the Baud rate window ensure that the value 115,200 is set. Otherwise select the value.

5. In the Head address window, ensure that the address is set to Address 0. Otherwise

select the address.

6. Use the OK button to confirm your settings.

The application window will open.

Page 23

SmartRunner Matcher*

Vision Configurator Software

2018-01

23

5.2 Application Window Structure

The application screen opens after you log in.

The software is designed to be similar to most Windows applications.

Note!

The individual functions depend on the type of sensor connected and the current authorization

level, so they are not always all visible.

1 Title bar Shows the IP address, the software name, and the

version number

Contains the Minimize/Maximize/Close buttons

2 Menu bar Displays all the menus in the program

Provides an overview and helps with navigation

3 Sensor data screen Displays data for the connected sensor

4 Sensor output screen Shows the log display

5 Status bar Displays status information about the application

6 Configuration window Contains the sensor-specific parameters that you

can set

7 Toolbar Contains icon buttons as an extension to the menu

8 Check boxes Show images: Enables or disables the image

display

Show results: Enables or disables the results area

9 Results area Displays results from the sensor

A varying number of tabs can be displayed

depending on which sensor is connected

This field can be enabled or disabled via Show

results

1

2

3

4

5

6

7

8

10

11

9

Page 24

2018-01

24

SmartRunner Matcher*

Vision Configurator Software

5.3 Menu Bar

The menu bar contains a list of menu items. The functionality depends on the type of sensor

that is connected and the permissions of the user logged in.

Figure 5.2 Menu Bar

5.3.1 File Menu

Figure 5.3 File Menu

5.3.2 View Menu

Figure 5.4 View Menu

10 Image display Displays the images captured or stored in the error

memory

This field can be enabled or disabled via Show

images

11 Tab Displays information about the current image and the

pixel under the mouse pointer. The following items are

displayed:

Image size

Zoom level

Mouse position in image coordinates

Current grayscale value

Image number

Change device Disconnects the device and returns to the Login dialog.

Open job Loads a sensor configuration stored on the PC.

Save job Saves the current sensor configuration on the PC.

Quit Terminates the program.

Table 5.2 File Menu

Page 25

SmartRunner Matcher*

Vision Configurator Software

2018-01

25

5.3.3 Sensor Menu

Figure 5.5 Sensor Menu

5.3.4 Image Menu

Figure 5.6 Image Menu

Show standard buttons Toggles the display of the buttons in the bar on the left on and off.

Show sensor data Hides the display of the sensor data in the top right of the screen.

Table 5.3 View Menu

Load settings Loads the saved settings from the sensor

Save settings Saves the settings to the sensor

Make firmware update Performs firmware updates. This command should be used by

experienced users only.

Show device version Displays the device version

Sync with sensor Synchronization with the sensor

Table 5.4 Sensor Menu

Note!

Firmware Update

Once you have upgraded the firmware and Update complete is displayed, restart the sensor.

Open image folder Opens the folder in which images are currently saved.

Save image Saves the image currently displayed on the PC.

Copy image to clipboard Loads an image file to the clipboard.

Show graphic Turns display data sent from the sensor on and off in the image.

Table 5.5 Image Menu

Page 26

2018-01

26

SmartRunner Matcher*

Vision Configurator Software

5.3.5 Administration Menu

Figure 5.7 Administration Menu

5.3.6 Help Menu

Figure 5.8 Help menu

User administration Opens a window that displays all of the currently created users at

the same authorization level or lower. New users with the same

authorization level or lower can also be created and deleted here.

In addition, a user password can be reset to the default password

for the relevant user level.

Change password Changes the current user's password.

Change user The Login screen opens and a different user and/or sensor can

be selected.

Send XML file... Saves the XML data on a computer.

Load XML file... Loads XML data from a computer.

Table 5.6 Administration Menu

Info Displays information about Vision Configurator.

Table 5.7 Help menu

Page 27

SmartRunner Matcher*

Vision Configurator Software

2018-01

27

5.4 Toolbar

The toolbar can be used to select various functions.

Selecting the Connect button establishes a connection between

the PC and the sensor.

The connection between the PC and the sensor is disconnected.

Opens a saved setting.

Saves the settings made.

Settings are read out from the sensor.

All settings made are saved on the sensor.

Reset to default settings.

Perform manual trigger.

Perform LEDs trigger

Caution: If autotrigger is activated, a line image will be issued

using the "Trigger LED."

Current sensor image is loaded.

The line image is loaded.

Profile is taught in using the next trigger.

LED

Page 28

2018-01

28

SmartRunner Matcher*

Vision Configurator Software

5.5 Sensor Data

This section shows the connected device type and firmware version.

Figure 5.9 Device data

5.6 Image Display

You can evaluate the data recorded in the image display. By analyzing the recorded profile

form, it is possible to use the measurement result to make a qualitative assessment. This

enables intrusive reflections to be identified and eliminated. There is a relationship between

the exposure time and image blur. A correct exposure is dependent on the brightness of the

profile and the incident amount of light. An exposure time that is too short leads to

underexposed (too dark) images, an exposure time that is too long to overexposed images.

There are various options available to you to display and correct recorded data to avoid errors

during recording.

Image View

You can open the currently recorded image under the Image View tab. To do this, you must

click on the Teach > Trigger laser > Get image buttons in the toolbar.

Figure 5.10 Image View

The following context menu appears when you click the right mouse button over the recorded

image:

Figure 5.11 Image View context menu screen

x.x.x.xxxxx

Page 29

SmartRunner Matcher*

Vision Configurator Software

2018-01

29

Image View - Toolbar

The toolbar is located on the left side under the Image View tab. There are some useful

functions in the toolbar which are used to further process recorded images. The following

functions are available to you.

Figure 5.12 Toolbar

Designation Function

Load image file... Loads a sensor image. You can select the sensor image.

Open image folder Opens the storage location

Copy image to clipboard Copies image to the clipboard

Save image Saves the displayed sensor image

Position Designation Function

1 Magnifier + Maximize image

2 Magnifier - Minimize image

3 Fit to window Fit image size to the window

4 Original size Set size of original image

5 Size details Image size information field

6 Zoom factor Zoom factor information field. Zoom factor of

100 % is the original image size

7 Position details Shows the position of the mouse cursor

8 Gray scale value details Gray scale value details for the pixel indicated

by the mouse cursor

9 Image counter Displays the current image number

10 Save image Saves image following transfer

11 Select path Select path on the storage medium

1 2

3

4

5

8

7

6

9

10

11

Page 30

2018-01

30

SmartRunner Matcher*

Vision Configurator Software

Diagram View

You can open the result data graphic under the Diagram View tab. To do this, you must click

on the Teach > Trigger laser > Get lines buttons in the toolbar. The graphic can be retrieved

using the Get lines button. In doing so, the Get lines button does not trigger new image

captures or evaluation. To do so, Trigger laser must be clicked beforehand.

Figure 5.13 Diagram View

The following context menu appears when you click the right mouse button over the graphic:

Figure 5.14 Diagram View image display context menu

Designation Function

Copy Copies diagram into working memory

Save Image As... Saves diagram to hard disk

Page Setup... Page setup for print function

Print... Print diagram

Show Point Values Shows the values of the discrete line points in world coordinates

[mm] as tooltip.

Un-zoom Undo the last zoom action

Undo All Zoom/Pan Undo all the zoom and pan actions

Set Scale to Default Scales the measure using the line data

Page 31

SmartRunner Matcher*

Vision Configurator Software

2018-01

31

Diagram View - Toolbar

The toolbar is located below the diagram view. There are some useful functions in the toolbar

which are used to further process the diagrams. The following functions are available to you.

Position Designation Function

1 Gray scale value Gray scale value of the pixel

2 Position details Shows the position of the mouse cursor in the

world coordinate system [mm]

3 Show ROIs The evaluation range is displayed if the field is

selected.

The evaluation range is hidden if the field is

deactivated.

4 Auto reset view Automatically jump back to the evaluation

range

5 Reset view Resets to the original view

1 2

3 4 5

Page 32

2018-01

32

SmartRunner Matcher*

Vision Configurator Software

Result View

With the SmartRunner, a Quality Good quality threshold can be entered to distinguish

between good and bad parts. A good part is taught in to set the quality threshold and the

Quality Good value is displayed under the Result View tab. To do this, the Autotrigger must

be activated. The results are output using the Start request button. Measuring is stopped by

clicking on the Stop request button.

Figure 5.15 Result View

Designation Function

Result The sensor automatically gives the Good or Bad output result.

Counter Counter

Quality Good Measure of the ratio of the number of pixels in the envelope curve

from the taught-in profile to the reference profile.

Quality Variation A gage for the average deviation of the taught-in profile in the range

from 0 % - 100 %, evaluated using the envelope curve.

This means that a value of 100 % is produced if the taught-in profile

and the reference profile are equal at all points.

A value of 0 % is produced if the reference profile for all points is

located on the envelope curve or above.

Quality Outliers Gage for assessing the quality of the curve. The value worsens if parts

of the curve are detected as being outside the envelope curve.

This means that a value of 100 % is produced if there is no part of the

profile outside the envelope curve.

X position Position of the object in the X direction.

Z position Position of the object in the Z direction.

Page 33

SmartRunner Matcher*

Vision Configurator Software

2018-01

33

5.7 Configuration window

Various parameters are specified in the configuration window. The individual parameters

depend on the current authorization level and are, therefore, not always all visible. Some

features are available in different variants only. Depending on the parameters set, some fields

will be grayed out.

5.7.1 Sensor Information

Sensor Information Tab

Name: "Pepperl+Fuchs GmbH"

Homepage: "http://www.pepperl-fuchs.com/"

Product name: "Smartrunner"

Firmware version: Current firmware version of the main processor.

The version designation as a whole is made up as follows: Major Version.Minor Version.

Tag Number– Revision Number

Figure 5.16 Sensor Information Tab

Note!

Some of the values under the Result View tab are password-protected. The access

permissions are connected by a password level for each user role. The user rights are defined

as follows:

User/Default: Result, Counter, Quality Good, X Position, Z Position

Admin: Result, Counter, Quality Good, Quality Variation, Quality Outliers, X Position, Z

Position

Page 34

2018-01

34

SmartRunner Matcher*

Vision Configurator Software

5.7.2 Common Tab

There are 4 menu items available under the Common tab. The purpose of this section is to

present the menu items in detail.

Illumination menu item

You can adjust the sensor's exposure under the Illumination menu item.

Figure 5.17 Illumination menu item

Trigger menu item

You can enable or disable the autotrigger under the Trigger menu item.

Figure 5.18 Trigger menu item

Designation Function

Exposure time Setting the manual exposure time. The "Use manual exposure time"

function must be activated to manually adjust the exposure time. By

increasing the value, the exposure time and thus the image brightness

increase. Values below 1000 µs are suitable in most cases

Use manual exposure

time

When enabled, the manually set exposure time is used. If this box is

not checked, the exposure time during the teach-in process is

controlled automatically

Auto exposure time The current exposure time is output in this field

Refresh auto

exposure time

The "Auto exposure time" field is updated by pressing the button

Designation Function

Autotrigger The autotrigger must be activated in "Presentation mode."

The autotrigger must be activated to adjust the "quality threshold."

Page 35

SmartRunner Matcher*

Vision Configurator Software

2018-01

35

Mode menu item

You can enable or disable "Presentation mode" and "function keys 1 and 2" under the Mode

menu item. "Presentation mode" and "function keys 1 and 2" are activated if checked and

deactivated if unchecked.

Figure 5.19 Mode menu item

Communication menu item

You can adjust the connection parameters between the sensor and computer under the

Communication menu item.

Figure 5.20 Communication menu item

Designation Function

Presentation mode Mode of operation for presentation or testing without the assistance of

a PC

Designation Function

RS-485 head address Address in the RS-485 bus. The address is sent with every RS485

command (see chapter 2.5) and is used for identification purposes if

multiple sensors are installed in the bus.

Baud rate Data transfer speed setting. The default value of the sensor is 115200

bps. When you change the baud rate, the baud rate of the Vision

Configurator is automatically changed so that communication remains

possible.

Bus termination Activates the integrated terminating resistor to terminate the RS-485

bus on the sensor

Page 36

2018-01

36

SmartRunner Matcher*

Vision Configurator Software

5.7.3 Matcher Tab

4 menu items are available under the Matcher tab. The purpose of this section is to present

the menu items in detail.

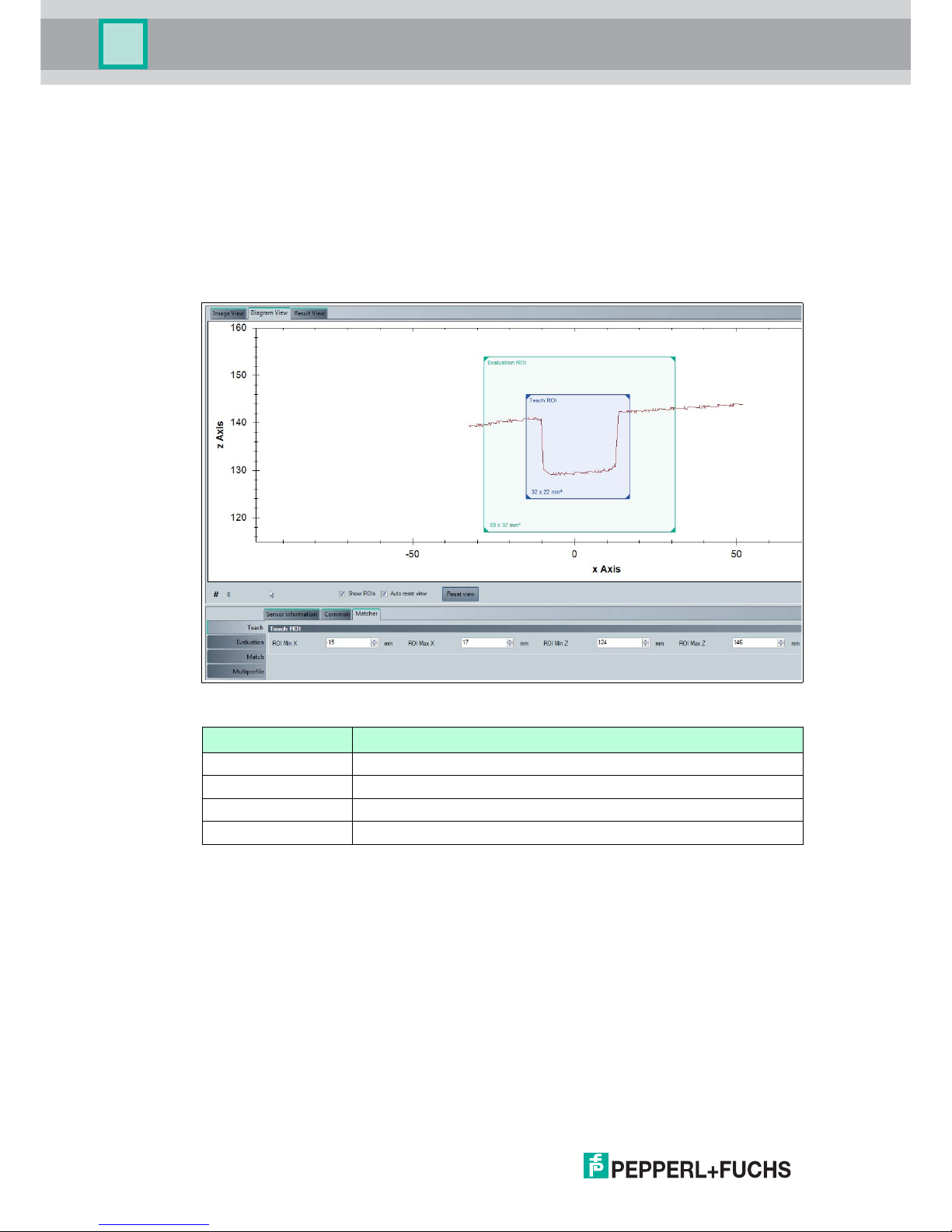

Teach menu item

You can adjust the teach-in range of the sensor under the Teach menu item. The teach-in

range allows you to restrict the range of the reference height profile. The required "Teach ROI"

teach-in range is adjusted using the line profile under the "Diagram View" tab. The coordinates

of the x and z axis are shown in the display field below the graphic.

Figure 5.21 Teach menu item

Designation Function

ROI Min X the smallest value on the x axis

ROI Max X the largest value on the x axis

ROI Min Z the smallest value on the z axis

ROI Max Z the largest value on the z axis

Page 37

SmartRunner Matcher*

Vision Configurator Software

2018-01

37

Evaluation Menu Item

You can adjust the sensor's evaluation range under the Evaluation menu item. The evaluation

range is the range in which the sensor seeks out the taught-in height profile. The required

"Evaluation ROI" evaluation range is adjusted using the line profile under the "Diagram View"

tab. The coordinates of the x and z axis are shown in the display field below the graphic.

Figure 5.22 Evaluation Menu Item

Designation Function

ROI Min X the smallest value on the x axis

ROI Max X the largest value on the x axis

ROI Min Z the smallest value on the z axis

ROI Max Z the largest value on the z axis

Note!

Setting the Frame Size

Moving the teach-in range and evaluation range

This gives you the option to move the teach-in range and evaluation range. To do this, click

with the left mouse button in the teach-in range or evaluation range. The frame of the selected

area is shown as a dashed line. Hold down the mouse button and the window moves as you

move the mouse. Release the mouse button at the position where you want to place the

window. The coordinates in the display field are updated automatically.

Minimizing/maximizing the teach-in range and evaluation range

This gives you the option to broaden or narrow the teach-in range and evaluation range or to

decrease or increase the height. Move the mouse to any edge of the frame until the mouse

cursor changes. This turns into an arrow with 2 ends. When the mouse cursor has changed,

click and hold with the left mouse button and move the mouse until the window is the desired

width and/or height. The size can be changed on all 4 edges, and at the corners, too. The

mouse cursor changes to a diagonal double arrow at the corners and changes the height and

width in the same ratio. The coordinates in the display field are updated automatically.

Page 38

2018-01

38

SmartRunner Matcher*

Vision Configurator Software

Match Menu Item

You can adjust the x and z tolerance range for the sensor under the Match menu item. The

tolerance range determines by how much the height profile may move within the evaluation

range and still be recognized.

Figure 5.23 Match Menu Item

Designation Function

Object contrast Contrast threshold used to detect the laser line on the object.

Tolerance object "Tolerance object" is used to input the width of the envelope curve

around the taught-in object in 0.1 mm increments. The envelope curve

is the basis for the quality parameters. The width of the envelope

curve should be selected so that all good part profiles are located

within the envelope curve despite height profile deviations.

Tolerance X Maximum permitted displacement of the object within the evaluation

range in the X direction.

Tolerance Z Maximum permitted displacement of the object within the evaluation

range in the Z direction.

Quality Good Quality threshold that distinguishes good parts from bad parts.

Quality Variation Quality threshold that distinguishes good parts from bad parts.

Quality Outliers Quality threshold that distinguishes good parts from bad parts.

Note!

More information about the Quality parameters can be found in the chapter on image display

under Result View (see chapter 5.6).

Page 39

SmartRunner Matcher*

Vision Configurator Software

2018-01

39

Multiprofile menu item

The following description only applies to the "VLM350-F280-R4-1001 and VLM350-F280-R41101". You can save different profiles under the Multiprofile menu item. The stored profiles

can be retrieved at any time. You have the option to create up to 32 different profiles. This

means you are in a position to respond quickly and flexibly in the case of frequent adjustments

to production in particular.

Figure 5.24 Multiprofile menu item

The information window consists of 5 columns and 3 buttons. These are explained in more

detail in the following table:

Information window

Designation Function

Active The activated profile is marked by a green arrow. A profile is activated

using the Active selected parameter set button. For this purpose,

the desired profile is selected by clicking with the right mouse cursor

and activated using the Active selected parameter set button.

State The status light changes from yellow to green as soon as a new profile

is created and confirmed using the Rename/Save selected

parameter set button.

Number Profile number

Name The profile name is modified using the Rename/Save selected

parameter set button. Enter the required profile name in the

Parameter set name input field and confirm with OK.

Information Information about the profile can be entered in the information field.

The information is entered using the Rename/Save selected

parameter set button. Enter the required information in the

Parameter set information input field and confirm with OK .

Page 40

2018-01

40

SmartRunner Matcher*

Vision Configurator Software

Save Parameter Settings

The following description only applies to the "VLM350-F280-R4-1001 and VLM350-F280-R41101". The Save job function is used to save parameter data to a read/write tag. This makes it

possible to save settings for different profiles on a read/write tag. You have the option to load

the saved parameters at any time on your sensor. 3 different file types are available to save the

parameters on a read/write tag.

The file types have the following properties:

Figure 5.25 Save Parameter Settings

Position Designation Function

1 Pepperl+Fuchs Config Files

(*.SMARTRUNNER_pfc)

Saves all parameter settings including

communication parameters for 1 profile

2 Pepperl+Fuchs Parameter Set

(*.SMARTRUNNER_pfs)

Saves all parameter settings without

communication parameters for 1 profile

3 Pepperl+Fuchs Complete

Parameter Set

(*.SMARTRUNNER_pfa)

Saves all parameter settings without

communication parameters for 32 profiles

1

3

2

Note!

A parameter file stored on the read/write tag can only be opened using the Vision

Configurator software.

Note!

Please note that the transferred parameter files overwrite the current parameters on the Vision

Configurator software. This can lead to data being lost.

Page 41

SmartRunner Matcher*

Operation

2018-01

41

6Operation

The light section sensor is factory pre-configured to a specific application. As a result, it does

not deliver raw data that needs to be evaluated first, but switching signals that are simple to

process. The sensor only needs to be mounted, connected, and parameterized using teach-in.

The sensor has 4 different operating modes, which can be activated for settings, presentation,

or normal operation.

The following provides more detailed information about the operating modes.

6.1 Configuration Mode

Configuration protocol in configuration mode

To adjust the sensor, it must be in configuration mode.

The command to put the sensor in this mode is 0xA8 0x57. After successfully changing mode,

the sensor responds with an Acknowledge (0x81 0xAC 0x00 0x2D). After an error when

converting the configuration, the sensor responds with a No Acknowledge (0x81 0x53 0xXX

0xYY, where XX = error code and YY = checksum). To check whether the sensor is in

configuration mode, the command Is_In_Config_Mode (0x00 0xFE 0xFE) can be sent. If the

sensor is in configuration mode, it responds with an Acknowledge. Otherwise there is no

response.

Error codes with "No Acknowledge":

0x00 = everything OK

0x01 = checksum incorrect

0x04 = parameter has a different length than that transferred

0x05 = internal error

0x06 = parameter index is unknown

0x07 = read/write access, although not allowed

0x09 = parameter value range is violated

0x0B = other error

0x0E = configuration command too long/short

In this mode, messages are sent according to the extended protocol:

Byte/bit 7 6 5 4 3 2 1 0

1 R/W Length6 Length5 Length4 Length3 Length2 Length1 Length0

2 Index7 Index6 Index5 Index4 Index3 Index2 Index1 Index0

3 Data 1.7 Data 1.6 Data 1.5 Data 1.4 Data 1.3 Data 1.2 Data 1.1 Data 1.0

... ... ... ... ... ... ... ... ...

n Data (n-

2).7

Data (n-

2).6

Data (n-

2).5

Data (n-

2).4

Data (n-

2).3

Data (n-

2).2

Data (n-

2).1

Data (n-

2).0

n+1 xor

B1.7...B(

n).7

xor

B1.6...B(

n).6

xor

B1.5...B(

n).5

xor

B1.4...B(

n).4

xor

B1.3...B(

n).3

xor

B1.2...B(

n).2

xor

B1.1...B(

n).1

xor

B1.0...B(

n).0

Table 6.1 R/W:

0: write

1: read/command

Length: row data length (Data1 ... Data(n-2) )

Page 42

2018-01

42

SmartRunner Matcher*

Operation

Description of Messages

Index Parameter name

Data

Length/bytes

Read/write Description

0xA8 GotoParamMode 0 W Puts the sensor in Configuration

mode

0x01 VendorName Variable R String containing "Pepperl+Fuchs"

0x02 VendorHomepage Variable R String containing the Pepperl+Fuchs

homepage

0x03 ProductName Variable R String containing the product name

0x07 SoftwareVersionDSPVariable R String containing the version

information

0xFE InParamMode 0 R Queries whether the sensor is in

parameterization mode

0xFF LeaveParamMode 0 W Request to exit parameterization

mode

0x20 Interface_Address 1 R/W Set the bus address, value range 0 –

3

0x23 Interface Baudrate 4 R/W Baud rate int32 little-endian in baud

(9600 - 230400)

0x25 Termination

enable

1 R/W Enable/disable termination of the RS-

485 bus

0x68 Laser exposure

time

4 R/W Sets the exposure time in µs

increments

0x10 Flash time 4 R/W Sets the exposure time (LED lighting)

in µs

0xFD Presentation

mode

4 R/W Presentation mode on [0] or off [1]

0x6D Go to teach mode 0 W Puts the sensor in teach-in mode

0xC8 ROI Evaluation 16 R/W "Region of interest" evaluation, 4

bytes in each case: X

min

, X

max

, Z

min

,

Z

max

in mm

0xC9 ROI Teach 16 R/W "Region of interest" for teach-in, 4

bytes in each case: X

min

, X

max

, Z

min

,

Z

max

in mm

0xAD Quality Good 4 R/W Threshold for the part of the contour

that must be within the variation, in %

[0 – 100]

0xAE Quality Variation 4 R/W Threshold for the average deviation

from the taught-in curve, in % [0 –

100]

0xAF Quality Outliers 4 R/W Gage for assessing the quality of the

curve, in % [0 – 100]. The value

worsens if parts of the curve are

detected as being outside the

envelope

0x51 Autotrigger 4 R/W Activates the autotrigger function.

With auto trigger, the sensor triggers

itself cyclically

00 = off

01 = on

0x9F Object contrast 4 R/W Threshold used for detecting the

laser line, in % [0 – 100]

Page 43

SmartRunner Matcher*

Operation

2018-01

43

Save settings

01 F3 10 E2

Saves the current settings in the flash memory

Reset

01 F3 02 F0

Returns to default settings.

Load settings

01 F3 00 F2

The current order and the settings are reloaded.

Switch to Profile

1

02 F3 03 XX XOR

XX = profile number (1…32)

Example: profile number [2]: 02 F3 03 02 F0

Trigger Laser

01 64 01 XOR

Triggers an image capture with evaluation

Trigger LED

01 64 02 XOR

Triggers the LEDs

0xCD Tolerance object 1 R/W Envelope around the taught-in profile

in 0.1 mm increments. The envelope

is the basis for the quality parameters

0x29 Tolerance X 4 R/W Maximum permissible deviation of

the object in the X direction relative to

the taught-in position in mm

0x38 Tolerance Z 4 R/W Maximum permissible deviation of

the object in the Z direction relative to

the taught-in position in mm

0x54 Set/Get Profile

name

1

0 – 32 R/W Write/read a name for the current

profile.

0x55

Get Profile index

1

0 R Returns the index of the currently

active profile.

0x56 Set/Get Profile

information

1

255 R/W Set/retrieve profile information.

1.Only with VLM350-F280-R4-1001 and VLM350-F280-R4-1101

Index Parameter name

Data

Length/bytes

Read/write Description

Page 44

2018-01

44

SmartRunner Matcher*

Operation

Note!

All values are transferred in little-endian format. In this case, the smallest value byte is stored at

the starting address or the smallest value component named first.

Read commands always have a length of 0 bytes.

Example!

In this example, the ROI evaluation is set as follows: set the ROI to ±50 mm in the X direction

and to +100 mm to +200 mm in the Z direction.

0x 10 C8 CE FF FF FF 32 00 00 00 64 00 00 00 C8 00 00 00 77

0x10 = data length

0xC8 = index

0xCEFFFFFF = X

min

-50 mm (little-endian, two's complement)

0x32000000 = X

min

+50 mm (little-endian, two's complement)

0x64000000 = Z

min

+100 mm (little-endian, two's complement)

0xC8000000 = Z

min

+200 mm (little-endian, two's complement)

Response telegram:

[TX] -80 C8 48

[RX] -90 C8 CE FF FF FF 32 00 00 00 64 00 00 00 C8 00 00 00 F7

Example!

In this example, the sensor is transferred to Parameter mode to change some settings.

Afterwards it switches to Runtime mode, a profile is taught in, and a comparison is made

between this profile and another profile (object_1 differs greatly from object_2).

[TX] - A8 57 = GotoParamMode

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 00 FE FE = InParamMode

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 80 AD 2D = Read Quality Good

[RX] - 84 AD 50 00 00 00 7F = Quality Good=80 (0x50)

[TX] - 04 AD 55 00 00 00 FF = Write Quality Good=55 (0x55)

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 04 51 00 00 00 00 55 = Write Autotrigger = Off

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 01 F3 10 E2 = Save settings

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 00 FF FF = LeaveParamMode

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 94 6B = Teach (Object_1)

[TX] - D8 27 = Trigger

[TX] - 90 6F = Teach Result

[RX] - 00 00 00 64 00 00 00 64 = Result=Good

[TX] - D8 27 = Trigger (Object_1)

Page 45

SmartRunner Matcher*

Operation

2018-01

45

[TX] - 84 7B = Result Data

[RX] - 00 01 4C 64 64 64 00 00 00 00 29 = Result Data=Good

[TX] - D8 27 = Trigger (Object_2)

[TX] - 84 7B = Result Data

[RX] - 02 00 4D 50 4A 51 00 01 00 00 05 = Result Data=Bad

Multiprofile:

[TX] - A8 57 = GotoParamMode

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 02 F3 03 02 F0 = Switch to Profile 2

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 03 54 42 61 72 06 = Set Profile Name to "Bar"

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 13 56 54 68 69 73 20 69 73 20 74 68

65 20 42 61 72 20 6A 6F 62 36

= Set Profile information to "This is

the Bar job"

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 80 55 D5 = Read Profile index

[RX] - 81 55 02 D6 = Job index = 2 (0x02)

[TX] - 04 51 00 00 00 00 55 = Write Autotrigger=Off

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 01 F3 10 E2 = Save settings

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 00 6D 6D = Go to teach mode (Object_2)

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 01 64 01 64 = Write Trigger

[RX] - 81 AC 00 2D = Acknowledge

[TX] - 00 FF FF = LeaveParamMode

[RX] - 81 AC 00 2D = Acknowledge

[TX] - D8 27 = Trigger (Object_2)

[TX] - 84 7B = Result Data

[RX] - 00 02 11 64 64 64 00 00 00 00 77 = Result Data=Good

[TX] - D8 27 = Trigger (Object_2 shifted in X

direction)

[TX] - 84 7B = Result Data

[RX] - 00 02 12 64 63 64 00 06 00 00 75 = Result Data=Good

[TX] - D0 01 01 2F = choose Profile 1

[TX] - D8 27 = Trigger (Object_1)

[TX] - 84 7B = Result Data

[RX] - 00 01 13 64 64 64 00 00 00 00 5D = Result Data=Good

Page 46

2018-01

46

SmartRunner Matcher*

Operation

Description of Quality Parameters

Quality Variation =

Quality Good =

Quality Outliers =

1 Variation

2 Learned curve

3 Current curve

Legend

X

T

Number of values in the taught-in profile curve

Z

T

(x) Distance value of the taught-in profile at position x

Z

s

(x) Distance value of the current profile at position x

v Set variation

X

N

Number of values detected during evaluation, although not present during teach-in

X

B

Number of values that lie outside of the envelope

X

L

Number of values that were present during teach-in, but can no longer be found during

evaluation

2 3

1

Page 47

SmartRunner Matcher*

Operation

2018-01

47

6.2 Code Card Mode

The built-in camera function including LED lighting allows for parameterization using Data

Matrix control codes. The control codes are generated using the "Vision Configurator"

operating software. All sensor parameters can be specified in a Data Matrix control code. For

this purpose, the Data Matrix control code is placed in front of the camera. The control code is

registered immediately and decoded. The sensor automatically activates the parameters

contained within. So a large number of sensors can be put into operation easily and quickly.

Generating a control code

1. In the menu bar, select Administration > Create reader programming code.

2. In the Device type section, select sensor type SMARTRUNNER.

3. Select the required parameters in the Select function section.

The control code is displayed in different sizes in the Control Code section.

4. To print the control code, click Print or Print preview.

To save the control code, click Save image.

Figure 6.1 Generating a control code

Tip

It is also possible to generate control codes when no sensor is connected to Vision

Configurator. In this case, you can, for example, generate a control code to assign a particular

IP address to a sensor and then establish a connection with a PC.

Page 48

2018-01

48

SmartRunner Matcher*

Operation

6.2.1 Setting Device Parameters via Control Code

Use Vision Configurator to generate control codes.

Enabling Code Card Mode

Hold down the 2 button on the back of the sensor for more than 2 seconds. Then release the

button.

The Ready LED flashes rapidly and the sensor's camera system begins to flash.

Setting Parameters

1. To assign a parameter, position the relevant control code in the sensor's field of view.

If a valid code is detected, the Result LED lights up green briefly

If an invalid code is detected, the Result LED lights up red briefly

2. The modified parameter is now saved in the sensor's volatile memory. The "Save settings"

control code saves the parameter in the non-volatile memory if necessary.

Disabling Code Card Mode

Press the 2 button on the back of the sensor.

The Ready LED stops flashing and the camera system stops flashing.

Note!

Parameterization mode can be activated only within 10 minutes of the sensor being switched

on.

Page 49

SmartRunner Matcher*

Operation

2018-01

49

6.3 Presentation Mode

You can demonstrate or test the sensor in Presentation mode without the assistance of a PC.

Furthermore, the control buttons are activated/deactivated.

Setting Presentation Mode

1. Connect the sensor to a power supply.

2. Align the sensor to the measurement object.

3. Teach in the measurement object by tapping button 2 on the sensor.

Figure 6.2 Result LED

The result LED lights up red.

4. Press button 1.

The trigger is activated. The result LED lights up green. The measurement object is

taught in.

The result LED lights up red if the profile contour deviates.

Note!

If the autotrigger is activated in the Vision Configurator operating software, you just need to

press button 2 to teach in the measurement object. If the autotrigger is deactivated, the trigger

must be activated by pressing button 1 once the measurement object has been taught in.

Page 50

2018-01

50

SmartRunner Matcher*

Operation

6.4 Runtime Mode

The Runtime mode is the main mode in which the measuring process operates as configured

in the operating software.

6.4.1 Communication via the RS-485 Interface

The control panel and reader communicate via the RS-485 interface during operation. Make

sure that the basic communication settings have been made on the reader, such as setting the

reader address and baud rate.

A distinction is made between request telegrams that the control panel sends to the reader and

response telegrams that the reader sends to the control panel. Each byte of a request or

response telegram consists of 9 bits (8 data bits + 1 parity bit).

Parity Bit

A bit assigned to a binary string used to detect errors. It is added in such a way that the sum

modulo 2 of all bits that are regarded as binary digits in the string, including the parity bit, is

either 0 or 1 depending on the requirement; additional bit that is added to each string or each

byte for control purposes so that the sum of all bits containing binary 1 in the characters or

bytes including control bit results in an odd or even value.

Request Telegram

A request telegram always consists of 2 bytes. The 2nd byte corresponds to the 1st byte;

however, the 8 data bits of the 1st byte are inverted.

Structure of a Request Telegram

Meaning of bits:

R/W: 0 = response, 1 = request

Meaning of Bits

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 1 R/W Req. bit 4Req. bit 3Req. bit 2Req. bit 1Req. bit 0A1 A0

Byte 2 ~R/W ~Req. bit 4~Req. bit 3~Req. bit 2~Req. bit 1~Req. bit 0~A1 ~A0

7 6 5 4 3 2 1 0 <- Bit

FunctionR/W R.4 R.3 R.2 R.1 R.0 A.1 A.0 Value

0 x x x x x x x Answer

1 x x x x x x x Request

1 x x x x x 0 0 Read head address 0

1 x x x x x 0 1 Read head address 1

1 x x x x x 1 0 Read head address 2

1 x x x x x 1 1 Reader address 3

1 0 0 0 0 0 x x 0x80 Status (is alive)

1 0 0 0 0 1 x x 0x84 Result data

1 0 0 1 0 0 x x 0x90 Teach result

1 0 1 0 1 0 x x 0xA8 Enable Configuration Mode

1 0 0 1 0 1 x x 0x94 Enable Teach Mode

1 1 0 1 1 0 x x 0xD8 Generate a software trigger

1 1 0 1 0 0 x x 0xD0

Choose Profile

1

Page 51

SmartRunner Matcher*

Operation

2018-01

51

Response Telegram

Status (is alive)

The status always returns 0x55 if the sensor is ready for operation.

Result Protocol

Result Data provides the measurement status and result as a response.

Legend

1.Only with VLM350-F280-R4-1001 and VLM350-F280-R4-1101

7 6 5 4 3 2 1 0

Byte R/W R.4 R.3 R.2 R.1 R.0 A.1 A.0

1 0 1 0 1 0 1 0 1

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 1 Status

0 - Addr 1 Addr 0 Event WRN No

Match

ERR

Byte 2 Result

0 R6 R5 R4 R3 R2 R1 R0

Byte 3 Counter

0 C06 C05 C04 C03 C02 C01 C00

Byte 4 Quality

0 Q06 Q05 Q04 Q03 Q02 Q01 Q00

Byte 5 Quality

0 Q16 Q15 Q14 Q13 Q12 Q11 Q10

Byte 6 Quality

0 Q26 Q25 Q24 Q23 Q22 Q21 Q20

Byte 7 PosX

0 PosX13 PosX12 PosX11 PosX10 PosX09 PosX08 PosX07

Byte 8 PosX

0 PosX06 PosX05 PosX04 PosX03 PosX02 PosX01 PosX00

Byte 9 PosZ

0 PosZ13 PosZ12 PosZ11 PosZ10 PosZ09 PosZ08 PosZ07

Byte 10 PosZ

0 PosZ06 PosZ05 PosZ04 PosZ03 PosZ02 PosZ01 PosZ00

Byte 9 Checksum

0 xor xor xor xor xor xor xor

Status Addr Device address

Event Event occurred (future)

Currently read as 0

WRN Unused

No Match Profile does not match the

saved profile

ERR System error or evaluation

error

Result R0 ... R6 Profile number 1 ... 32

0x00 = no object found

Page 52

2018-01

52

SmartRunner Matcher*

Operation

Teach Result Protocol

Teach Result Data returns the status and result of the teach-in process as a response.

Legend

Quality Q00 ... Q26 Quality of the current profile (0

= no profile found, 100 =

perfect match)

Quality: Quality Good

Quality2: Quality Variation

Quality3: Quality Outliers

Counter Increments for each

evaluation, is restarted at

0x3F

Position Data

1

PosX16 ... PosX00 X-deviation of current profile

to saved profile

PosZ16 ... PosZ00 Z-deviation of current profile

to saved profile

1.Only with VLM350-F280-R4-1001 and VLM350-F280-R4-1101

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 1 - Status 0 - Addr 1 Addr 0 Event WRN 0 ERR

Byte 2 - Result 0 0 0 0 0 0 0 0

Byte 3 - Counter 0 C06 C05 C04 C03 C02 C01 C00

Byte 4 - Quality A 0 QA6 QA5 QA4 QA3 QA2 QA1 QA0

Byte 5 - Quality B 0 QB6 QB5 QB4 QB3 QB2 QB1 QB0

Byte 6 - Quality C 0 QC6 QC5 QC4 QC3 QC2 QC1 QC0

Byte 7 - Quality D 0 QD6 QD5 QD4 QD3 QD2 QD1 QD0

Byte 8 Checksum

0 xor xor xor xor xor xor xor

Status Addr Device address

Event Event has occurred - for future

use, currently read as 0

WRN Unused

ERR System error or evaluation

error

Result R0 For extended protocol

Always 0

Counter C00 ... C06 Increments with each teach-in

Quality A The quality of the current

teach-in

0 = teach-in not possible

100 = perfect teach-in

Quality B-D Unused

Page 53

SmartRunner Matcher*

Operation

2018-01

53

Software Trigger

After sending the sequence for the software trigger, the sensor triggers an image capture. No

response telegram is generated to the command.

Teach-In

After transmitting the command to start the teach-in (0x94), the sensor begins the teach-in

routine. A trigger must subsequently be transmitted.

Choose profile

1

Legend

1.Only with VLM350-F280-R4-1001 and VLM350-F280-R4-1101

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 1 Request

1 1 0 1 0 0 Address1Address

0

Byte 2 Data

length

0 0 0 0 0 0 0 1

Byte 3 Data

0 6 P5 P4 P3 P2 P1 P0

Byte 4 Checksum

~xor ~xor ~xor ~xor ~xor ~xor ~xor ~xor

Request Bit 7 ... 2 Command ID

Address Address of the current device

Data Bit 7 0

Bit 6 0

P5 ... P0 1 ... 32: Profile number

0... : not defined

> 32: not defined

Page 54

2018-01

54

SmartRunner Matcher*

Maintenance and Repair

7 Maintenance and Repair

7.1 Maintenance

The device is maintenance-free. To get the best possible performance out of your device, keep

the optical unit on the device clean, and clean it when necessary.

Observe the following instructions when cleaning:

Do not touch the optical unit with your fingers.

Do not immerse the device in water. Do not spray the device with water or other fluids.

Do not use a scouring agent to clean the surface of the device.

Use a cotton or paper cloth moistened with water or isopropyl alcohol (not soaked).

Remove any residual alcohol using a cotton or paper cloth moistened with distilled water

(not soaked).

Wipe the device surfaces dry using a lint-free cloth.

7.2 Repair

The device must not be repaired, changed, or manipulated. In case of failure, always replace

the device with an original device.

Danger!

Risk of death due to electrical current!

Contact with live parts causes immediate risk of death.